Sealey SA11/S Instructions Manual

INSTRUCTIONS FOR:

LONG STROKE AIR HAMMER

Model:

Thank you for purchasing a Sealey product. Manufactured to a high standard this product will, if used according to these instructions

and properly maintained, give you years of trouble free performance.

IMPORTANT: PLEASE READ THESE INSTRUCTIONS CAREFULLY. NOTE THE SAFE OPERATIONAL REQUIREMENTS, WARNINGS & CAUTIONS.

USE THE PRODUCT CORRECTL

DAMAGE AND/OR PERSONAL INJURY AND WILL INVALIDATE THE WARRANTY. PLEASE KEEP INSTRUCTIONS SAFE FOR FUTURE USE.

Y AND WITH CARE FOR THE PURPOSE FOR WHICH IT IS INTENDED. FAILURE TO DO SO MAY CAUSE

SA11/S

1. SAFETY INSTRUCTIONS

p WARNING! Ensure Health & Safety, local authority and general workshop practice regulations are adhered to when using this equipment.

p WARNING! Disconnect the hammer from the air supply before changing accessories, servicing or performing any maintenance.

3 Keep the hammer clean and maintain it in good condition (use an authorised service agent).

3 Replace or repair damaged parts. Use genuine parts only. Unauthorised parts may be dangerous and will invalidate the warranty.

3 Keep the work area clean and uncluttered. Ensure that there is adequate lighting.

3 Ensure chisels are correctly rated for the job. DO NOT use damaged or suspect chisels.

p WARNING! Wear approved safety eye or face protection, ear defenders and, if dust is generated, respiratory protection.

3 Keep hands and body clear of the work when operating the hammer.

3 Maintain correct balance and footing. Ensure that the floor is not slippery and wear non-slip shoes.

3 Remove ill fitting clothing. Remove ties, watches, rings and other loose jewellery and contain

and/or tie back long hair.

3 Keep children and unauthorised persons away from the work area.

3 Check moving parts alignment on a regular basis.

3 Secure unstable workpiece with a clamp, vice or other adequate holding device.

3 Avoid unintentional starting.

p WARNING! Ensure that the correct air pressure is maintained and not exceeded.

3 Keep air hose away from heat, oil and sharp edges. Check air hose for wear before each use

and ensure that all connections are secure.

7 DO NOT use the hammer for a task it is not designed to perform.

7 DO NOT operate the hammer if any parts are damaged or missing as this may cause failure and/or personal injury.

p WARNING! DO NOT chisel into any materials containing asbestos.

7 DO NOT switch the hammer on whilst the chisel is in contact with the workpiece.

7 DO NOT carry the by the hose, or yank the hose from the air supply.

7 DO NOT hold the workpiece by hand. Use clamps or a vice (not included) to secure the workpiece. Available from your Sealey dealer.

7 DO NOT allow untrained persons to operate the hammer.

7 DO NOT operate the hammer when you are tired or under the influence of alcohol, drugs or intoxicating medication.

7 DO NOT use hammer where there is flammable liquid, solid or gas such as paint solvent, including waste wiping or cleaning rags etc.

7 DO NOT leave the hammer operating unattended.

7 DO NOT carry the hammer with your finger on the trigger.

7 DO NOT direct air from the air hose at yourself or others.

3 When work is complete ensure that the air supply is turned of

3 When not in use disconnect from the air supply and store in a safe, dry, childproof area.

f.

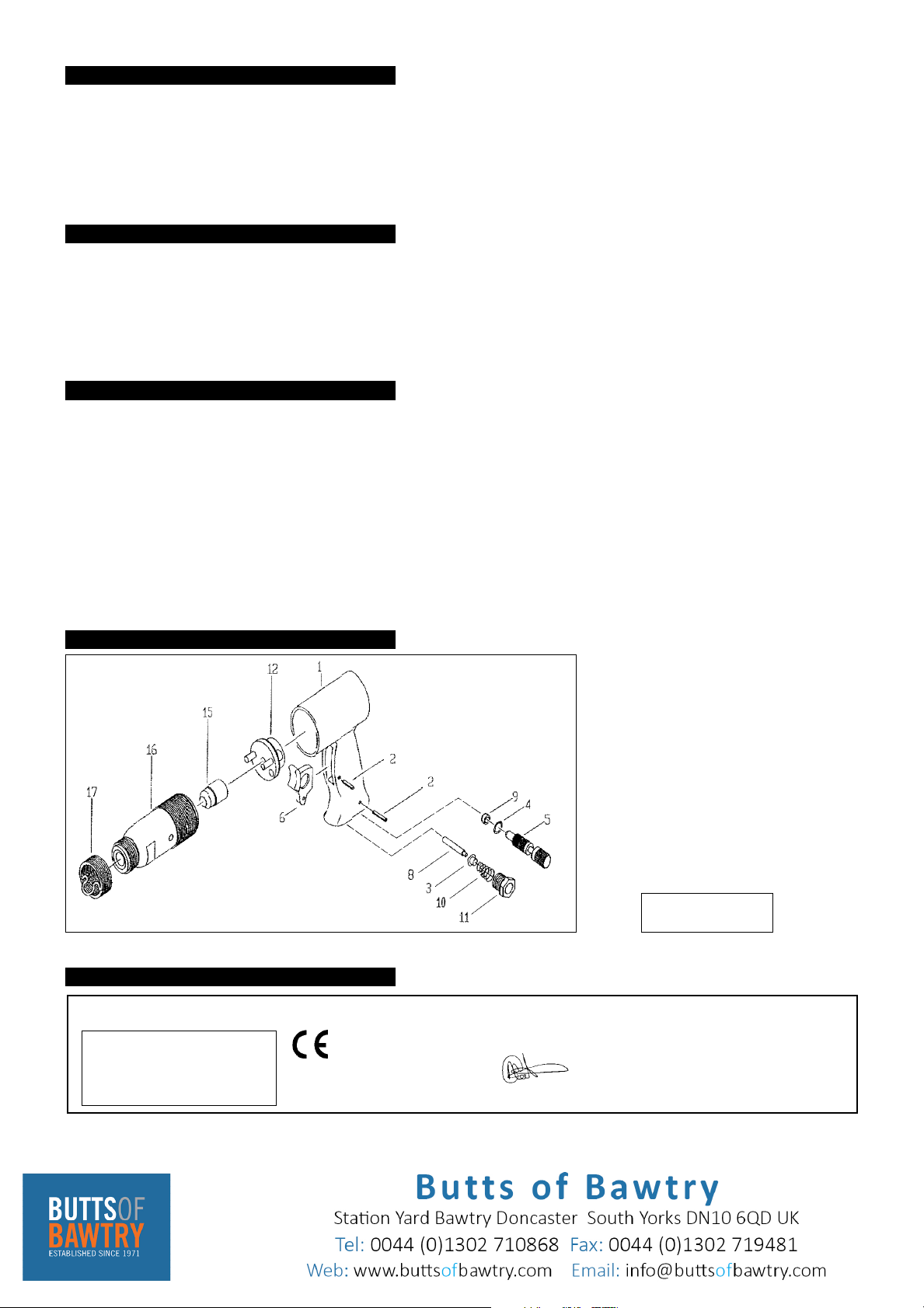

AIR SUPPLY

2.

The recommended hook-up is shown in fig. 1.

2.1. Ensure the trigger is in the "off" position before connecting to the air supply.

ou will require an air pressure of 90psi and an available air flow of 4cfm to operate the unit.

Y

2.2.

2.3. p WARNING! Ensure the air supply does not exceed 120psi while operating the hammer. Too high an air pressure and/or unclean air

will shorten the product life due to excessive wear and may be dangerous, causing damage and/or personal injury.

2.4. Drain the air tank daily. Water in the air line will damage the hammer.

2.5. Clean the air inlet filter screen weekly.

2.6. Line pressure should be increased to compensate for unusually long air hoses (over 8 metres). The minimum hose diameter should

be 10mm I.D. and fittings must have the same inside dimensions.

2.7. Keep hose away from heat, oil and sharp edges.

Check hoses for wear, and make certain that

all connections are secure.

fig. 1

SA11/S - 1 - 091101

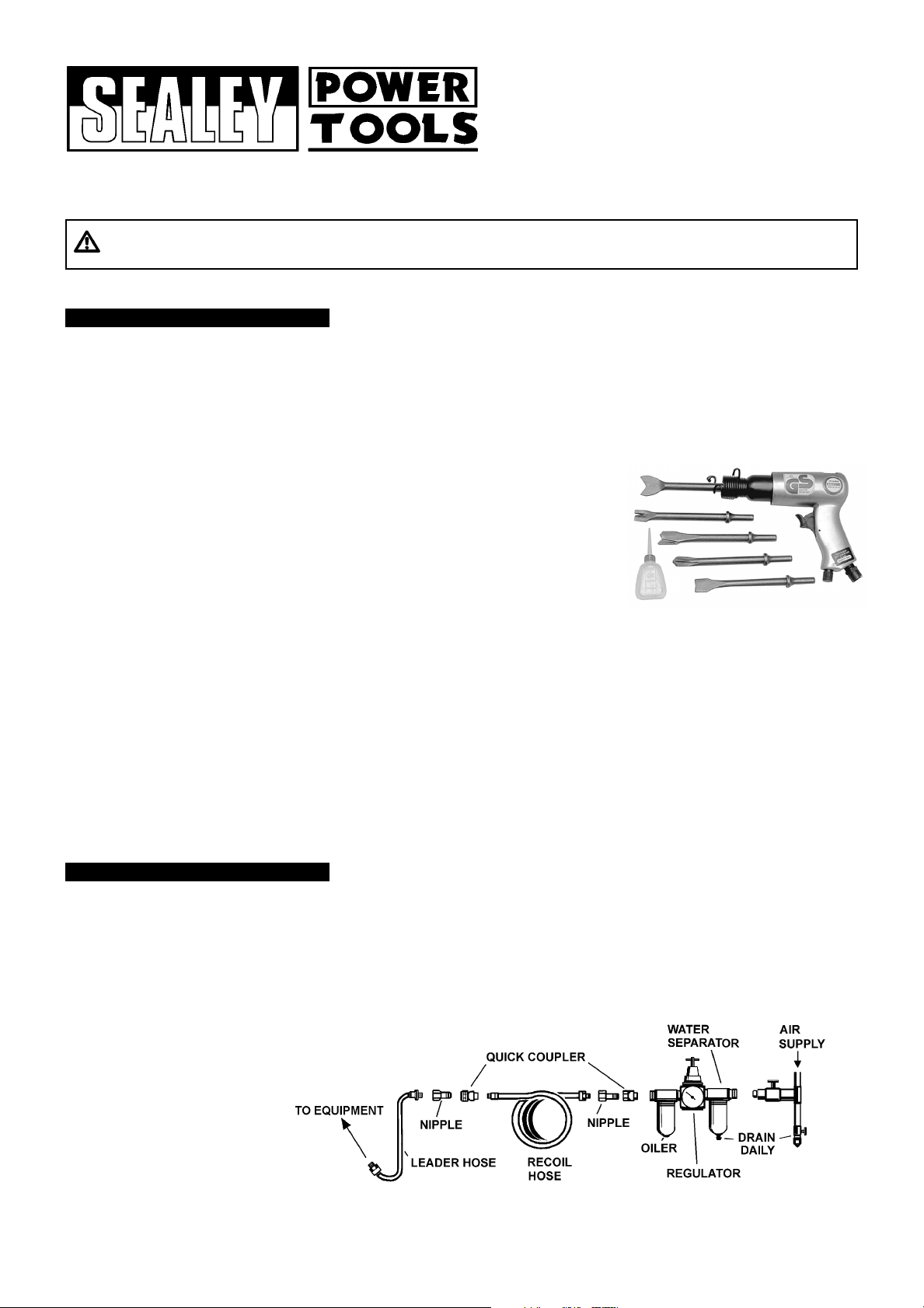

3. INTRODUCTION & SPECIFICATION

GS/TUV approved quality long stroke air hammer supplied in carry case. Kit also includes spare retainer spring, long blade panel cutter, special

panel cutter, panel cutter, muffler tail pipe remover, cold chisel, air hose connector and air tool lubricating oil.

SPECIFICATION

Chisel Shank . . . .0.401 Parker Taper

Speed . . . . . . . . . . . . . . . . . .3500bpm

Stroke . . . . . . . . . . . . . . . . . . . .20mm

Operating Pressure . . . . . . . . . . .90psi

Air Consumption . . . . . . . . . . . . .4cfm

Air Inlet . . . . . . . . . . . . . . . . . .1/4BSP

Weight . . . . . . . . . . . . . . . . . . . .1.5kg

Vibration . . . . . . . . . . . . . . . . . .18m/s

Noise Level . . . . . . . . . . . . .99.9dB(A)

4. OPERATING INSTRUCTIONS

Note: Numbers in brackets refer to item numbers in the parts list.

The air hammer is designed primarily for use on vehicle bodywork. We do not recommend any other use. Ensure you read, understand and

follow the safety instructions in Section 1.

4.1. Attach the retaining spring (17) by screwing it onto the Cylinder (16).

4.2. Insert the chisel using the hooked end of the spring to hold the chisel in place.

4.3. Attached the tool to the air supply (see Section 2).

4.4. To operate the hammer, squeeze the trigger (6). The air regulator (5) may be used as a means of throttle control.

5. MAINTENANCE

p WARNING! Disconnect the hammer from the air supply before changing chisels, servicing or performing any maintenance.

5.1. Keep the hammer oiled for optimum performance.

Lubricate with a good grade of air tool oil such as Sealey ATO/500 or ATO/1000. If there is no oiler in the air system then a teaspoon of

oil can be poured into the air inlet of the hammer, or into the hose at the nearest connection to the air supply. Then run the hammer for

a short time.

Note: The following external factors may cause loss of power and effect hammer performance:

The air supply

Reduced compressor output, excessive drain on the air line, moisture or restrictions in air pipes or the use of hose connectors

having too small a bore. Correct as necessary.

The hammer

Grit or gum deposits in the tool. Correct by cleaning the air strainer and flushing out the tool with gum solvent oil or an equal mixture of

SAE No.10 oil and kerosene.

If, despite taking action as above, the tool function is still impaired, contact your local Sealey service agent.

2

6. PARTS LIST

Item Part No. Description

1 SA11R/01 Housing

2 SA11R/02 Pin

3 SA11R/03 Ball Seat

4 SA11R/04 0-ring

5 SA11R/05 Air Regulator

6 SA11R/06 Trigger

8 SA11R/08 Valve Stem

9 SA11R/09 Bushing

10 SA11R/10 Spring

11 SA11R/11 Air Inlet

12 SA11R/12 Valve Case

15 SA11R/15 Piston

16 SA11R/16 Cylinder

17 SA11R/17 Spring

Issue No: 1

Date Issued: 091101

7. DECLARATION OF CONFORMITY

Declaration of Conformity We, the sole importer into the UK, declare that the product listed here is in conformity with the following standards and directives.

LONG STROKE AIR HAMMER

Model SA11/S

98/37/EC Machinery Directive

93/68/EEC CE Marking Directive

The construction file for this product is held by the Manufacturer and may be inspected, by a national authority, upon

request to Jack Sealey Ltd.

12th November 2001Signed by Mark Sweetman

For Jack Sealey Ltd. Sole importer into the UK of Sealey Power Tools.

Loading...

Loading...