Page 1

INSTRUCTIONS FOR

IMPORTANT: PLEASE READ THESE INSTRUCTIONS CAREFULLY. NOTE THE SAFE OPERATIONAL REQUIREMENTS, WARNINGS & CAUTIONS. USE

THE PRODUCT CORRECTLY AND WITH CARE FOR THE PURPOSE FOR WHICH IT IS INTENDED. FAILURE TO DO SO MAY CAUSE DAMAGE AND/OR

PERSONAL INJURY AND WILL INVALIDATE THE WARRANTY. KEEP THESE INSTRUCTIONS SAFE FOR FUTURE USE.

COIL SPRING COMPRESSOR RESTRAINT

SYSTEM

MODEL NO: RE23RS

Thank you for purchasing a Sealey product. Manufactured to a high standard, this product will, if used according to these

instructions, and properly maintained, give you years of trouble free performance.

Refer to

instructions

Wear full face

protection

Wear protective

gloves

Wear safety

footwear

Wear protective

clothing

1. SAFETY

1.1. GENERAL SAFETY.

WARNING! Ensure Health & Safety, local authority, and general workshop practice regulations are adhered to when using this equipment.

WARNING! Wear approved safety hands, face and eye protection (full face visor is essential).

WARNING! TRAPPING DANGER – Keep hands and fingers away from the spring and compressing jaws in use.

9 Keep the work area clean, uncluttered and ensure there is adequate lighting.

9 Maintain correct balance and footing. Ensure the floor is not slippery and wear non-slip shoes.

9 Remove ill-fitting clothes. Remove ties, watches, rings, other loose jewellery. Contain and/or tie back long hair.

9 Wear appropriate protective clothing (leather gauntlets and leather apron for example).

9 Familiarise yourself with the applications, limitations and potential hazards of the compression spring restraint.

8 DO NOT allow untrained persons to use the compression spring restraint.

1.2. PRE OPERATIONAL SAFETY.

9 Strut and Spring Compression station should be securely bolted to the workshop floor before use.

8 DO NOT operate spring compressor if parts are damaged or missing as this may cause failure and/or personal injury.

9 Before commencing compression of spring, ensure coils of the spring are seated securely in the jaws of the compressor and

cannot slide out during compression.

9 Always fit the restraining chain around strut and spring (ensure the restraining chain is not trapped in the coils of the spring as compressed).

9 Always fit the coil spring compressor restraint system.

1.3. OPERATIONAL SAFETY.

9 When applying compression to the spring, always stand to one side of the unit.

▲ DANGER! Stop compressing the spring as soon as the top cap of shock absorber is no longer under load . Never allow coils to touch

each other.

9 Before attempting to remove top cap nut, always use a tool to test if the compression has been relieved. DO NOT use your

hands/fingers to test for strut to spring forces.

9 We recommend the use of purpose made strut tools to remove the top-nut from the shock piston.

9 Once compressed, and the strut removed, we recommend releasing the tension on the spring. DO NOT leave the spring under compression in

the machine unattended and DO NOT leave in compression for prolonged periods, i.e. overnight.

9 Before releasing the compression ensure that the top strut-nut is securely fastened to the maker’s tolerance.

9 Release the compression slowly keeping your hands and fingers away from the spring assembly.

9 Be sure that the tension on the spring is fully controlled by the strut assembly before removing it from the jaws of the compressor.

1.4. POST OPERATIONAL SAFETY.

9 When not in use, clean and store the spring compressor including restraint in a safe, dry, childproof location.

9 Maintain the spring compressor and restraint in good condition. Replace or repair damaged parts. Use genuine parts only. Unauthorised

parts may be dangerous and will invalidate the warranty.

2. INTRODUCTION

Safety restraint system designed for use with Model No’s RE231, RE2311 and RE232 Coil Spring Compressors. Quickly installed and fast and

simple to operate in use.

RE231/RE2311/RE232 Not included.

3. SPECIFICATION

Assembled weight: ..............................................................4kg

Envelope: ..................................................... 645mm x 365mm

Restraint rod diameter: ......................................................8mm

Pillar adaptor size: .............................................60mm x 60mm

Pinch knob: ...........................................................................M8

© Jack Sealey Limited

Original Language Version

RE23RS | Issue 2 12/05/17

Page 2

Item no Description Qty

1 Pillar adaptor bar 1

2 Pivot spindle 1

3 Plain washer 12 dia 2

4 Hexagon stiff nut M12 2

5 Side restraint hoop right hand 1

6 Side restraint hoop left hand 1

7 Inner restraint hoop 1

8 Intermediate restraint hoop 1

9 Intermediate restraint hoop 1

10 Outer restraint hoop 1

11 Pinch knob M8 X 16 1

4. ASSEMBLY

NOTE! Lugs on underside

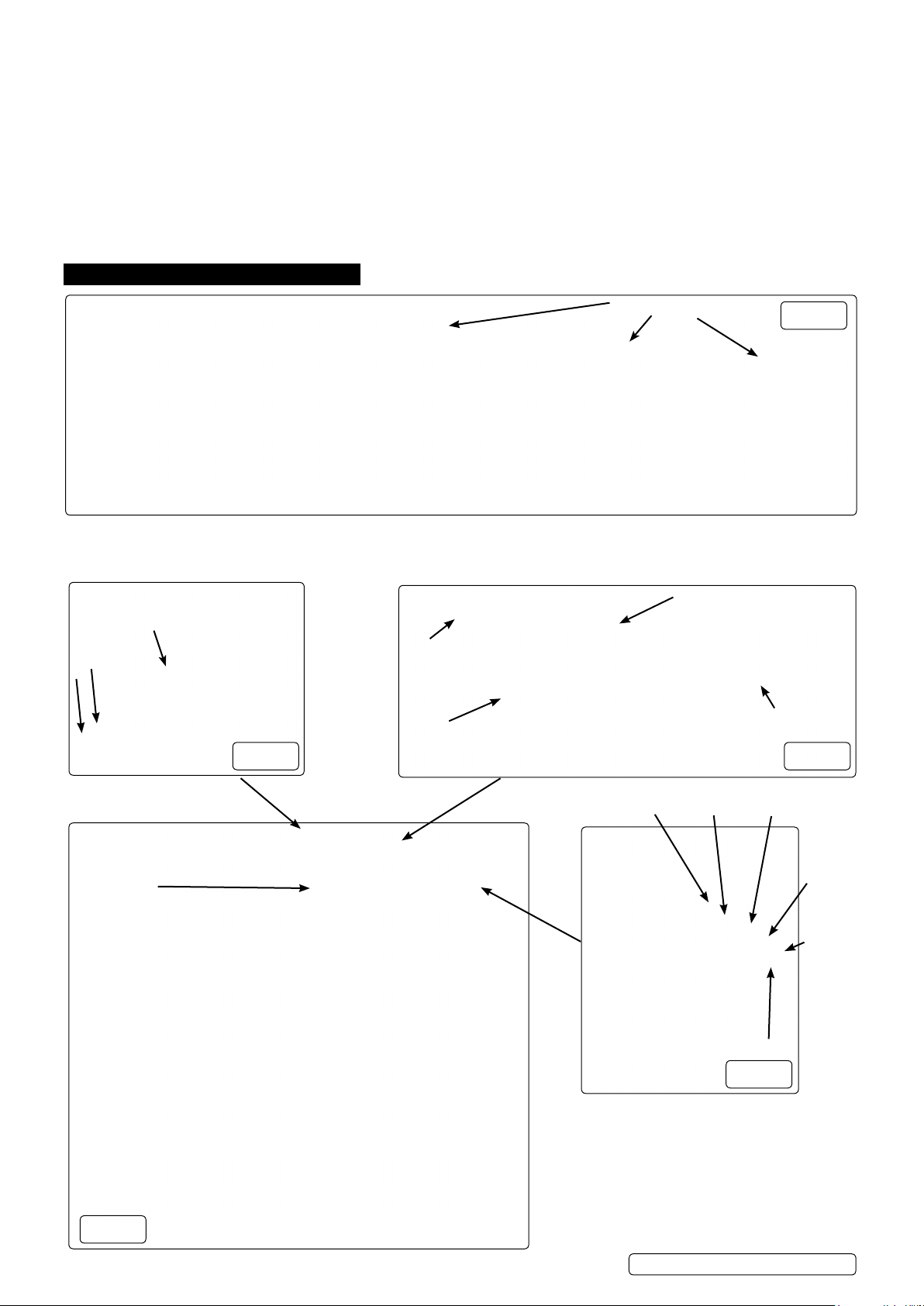

g.1

10

9

Display on bench for quick indentication.

4.1. Empty contents of packaging and display on a bench top to identify and check for missing or damaged parts. In the unlikely event

of missing or damaged parts, consult your Sealey Dealer immediately.

8

7

1

6

3

2

4

6

5

11

g.2

g.3

5

7

8

9

10

3

g.5

g.4

© Jack Sealey Limited

Assembled complete in a

vice tted with soft jaws.

(suggested method)

Original Language Version

RE23RS | Issue 2 12/05/17

Page 3

4.2. Sequence of assembly

4.2.1. Align (items 5, 1 and 6) as shown in g.3, then pass the pivot spindle (item 2) through all three items with equal projection. Correct

orientation is critical. Note (item 5) has a longer boss than (item 6) which makes it easier to identify, both are assembled with the lug

projecting inboard. Orientation of (Item 1) is clearly shown by the position of the tapped hole for the pinch knob (item 11).

4.2.2. Spring (item 7) over ends of pivot spindle paying particular attention to the position of the lug on the boss shown in g.5. DO NOT over

bend the loop when tting over spindle, this note also applies when tting (items 8, 9 and 10).

4.2.3. Spring (item 8) over ends of pivot spindle paying particular attention to the position of the lug on the boss shown in g.5.

4.2.4. Spring (item 9) over ends of pivot spindle paying particular attention to the position of the lug on the boss shown in g.5.

4.2.5. Spring (item 10) over ends of pivot spindle paying particular attention to the position of the lug on the boss shown in g.5.

4.2.6. Place washer (item 3) at each end of spindle and wind on hexagon stiff nuts (item 4) with equal engagement, without clamping the

assembly. All loops to pivot freely under their own weight, limited only by the lugs.

4.2.7. Fit pinch knob (item 11) until ush with inside face of bracket (without protrusion).

4.3. Fitting to Sealey RE231, RE2311 and RE232 Coil Spring Compressors

4.3.1. Read these instructions in conjunction with RE231, RE2311 or RE232 spring compressor instructions. As explained in section 1;

always fit the restraining chain around strut and spring fig.3 (single restraint). Strut and spring compression station should be securely bolted to

the workshop floor before use.

4.3.2. Offer complete assembly as shown in fig.4 on to the vertical column of the spring compressor.

4.3.3. With the pinch knob, clamp the assembly at the desired height such that incremental holes in the column align with holes in the restraint bracket

lugs. DO NOT over-tighten deforming pillar or bracket. This height position is determined by the position of the spring being compressed.

4.3.4. Finally insert a M12 X 75 bolt through the restraint bracket lugs and column; retain with a M12 hexagon nut.

SINGLE RESTRAINT

ADDITIONAL

RESTRAINT

g.6 g.7

5. OPERATION

5.1. All the loops of the restraint system, except item 5, can be readily swept up and away from the work area. These loops go beyond the vertical to

a self supported leaning position. Item 5 swept path is limited by a mechanical stop.

6. MAINTENANCE

6.1. The robust nature of the restraint system means that it only requires cleaning after use with a lightly oiled cloth.

6.2. Check freedom of loop sweep, which should result from the cleaning/lubricating process in 6.1.

6.3. Replace immediately any part that is or appears to be damaged.

Environmental Protection

Recycle unwanted materials instead of disposing of them as waste. All tools, accessories and packaging should be

sorted, taken to a recycling centre and disposed of in a manner which is compatible with the environment.

When the product becomes completely unserviceable and requires disposal, drain off any fluids (if applicable)

into approved containers and dispose of the product and the fluids according to local regulations.

NOTE: It is our policy to continually improve products and as such we reserve the right to alter data, specications and component parts without prior notice.

IMPORTANT: No liability is accepted for incorrect use of this product.

WARRANTY: Guarantee is 12 months from purchase date, proof of which will be required for any claim.

© Jack Sealey Limited

Sole UK Distributor, Sealey Group.

Kempson Way, Suffolk Business Park,

Bury St. Edmunds, Suffolk.

IP32 7AR

Original Language Version

01284 757500

01284 703534

www.sealey.co.uk

sales@sealey.co.uk

RE23RS | Issue 2 12/05/17

Loading...

Loading...