Page 1

IMPORTANT: PLEASE READ THESE INSTRUCTIONS CAREFULLY. NOTE THE SAFE OPERATIONAL REQUIREMENTS, WARNINGS & CAUTIONS. USE

THE PRODUCT CORRECTLY AND WITH CARE FOR THE PURPOSE FOR WHICH IT IS INTENDED. FAILURE TO DO SO MAY CAUSE DAMAGE AND/OR

PERSONAL INJURY AND WILL INVALIDATE THE WARRANTY. KEEP THESE INSTRUCTIONS SAFE FOR FUTURE USE.

InStRUCtIOnS FOR:

TElEScOpIc SpRING cOMpRESSOR

WIShbONE SuSpENSION

MODEL nO: RE2280.V2

Thank you for purchasing a Sealey product. Manufactured to a high standard, this product will, if used according to these instructions,

and properly maintained, give you years of trouble free performance.

1250KG

Refer to

instruction

manual

Wear eye

protection

1. SAFETY

▲ DANGER! Stop compressing the spring before the coil windings touch.

WARNING! Ensure Health & Safety, local authority, and general workshop practice regulations are adhered to when using this

equipment.

WARNING! Wear approved safety eye protection (standard spectacles are not adequate).

WARNING! Measure the outer diameter of the spring to be compressed and select the correct set of jaws to fit the spring.

8 DO NOT operate spring compressor if parts are damaged or missing as this may cause failure and/or personal injury.

8 DO NOT force the spring compressor to achieve a task it is not designed to perform.

8 DO NOT allow untrained persons to use the spring compressor.

9 Familiarise yourself with the applications, limitations and potential hazards of the spring compressor.

9 Maintain the spring compressor in good condition.

9 Replace or repair damaged parts. Use genuine parts only. Unauthorised parts may be dangerous and will invalidate the warranty.

9 Keep the work area clean, uncluttered and ensure there is adequate lighting.

9 Keep hands and body clear of the spring when operating the spring compressor.

9 Maintain correct balance and footing. Ensure the floor is not slippery and wear non-slip shoes.

9 Remove ill fitting clothes. Remove ties, watches, rings, other loose jewellery. Contain and/or tie back long hair.

9 Wear appropriate protective clothing.

9 When not in use clean and store the spring compressor in a safe, dry, childproof location.

2. INTRODucTION

Designed for use on wishbone suspension using access points in the rear suspension arm. Features two pairs of carefully shaped yokes that

prevent the coil spring from bowing. Saves time over traditional methods of demounting springs.

3. SpEcIFIcATION

Model no: ............................................................RE2280.V2

Maximum Spring Load: .................................................1250kg

Size/Suitability: ...........................................(Ø80mm - 135mm)

Jaw Opening: .........................................................115-300mm

Drive: .......................................................................19mm Hex

Fig.1

© Jack Sealey Limited

Original Language Version

RE2280.V2| Issue:1 09/01/17

Page 2

4. OpERATION

WARNING! Measure the outer diameter of the spring to be compressed and select the correct set of jaws.

IMpORTANT! DO NOT start by using the coil spring compressor fully extended, but adjusted to a length of approx. 200mm. this will

ensure adequate travel to fully expand and compress the spring regardless of the initial spring tension.

4.1. Ensure that the coil spring to be compressed is free from dirt and grease where the jaws will be in contact with it.

4.2. Jack up the vehicle to remove the coil spring. Ensure that the vehicle is safely and properly supported.

4.3. Insert the jaw (FIG.2-A) into the lower spring windings.

4.4. Insert jaw (FIG.2-B) into the upper spring windings. Ensure that the spring windings sit between the inner and outer rims of the jaw.

4.5. Insert the main body of the spring compressor into the inside of the spring from below with the hexagonal drive nut facing downwards.

Guide compressor through the lower jaw and up into the upper jaw, when the compressor has passed through the upper jaw turn the

body through approx 50° so it locates in the locking grooves on the jaw FIG.3.

4.6. Using a 19mm hex socket, begin to turn the hexagonal drive nut until the jaws are firmly in contact with the spring.

4.7. Before proceeding ensure that the spring is correctly placed within both jaws and jaws are correctly aligned on the compressor body.

4.8. now continue compress the spring.

WARNING! An air wrench must not be used. Use of air wrench will invalidate warranty.

WARNING! Spring compression MuST cEASE bEFORE the windings touch. DO NOT allow the compressor to reach the limit of its

travel in either direction.

4.9. Remove the spring and compressor assembly from the vehicle as soon as you have attained sufficient compression.

4.10. With the spring adequately supported drive the compressor in the opposite direction and remove the compressor and jaws from the

spring.

4.11. to re-mount the spring back in the wishbone assembly, reverse the compress procedure.

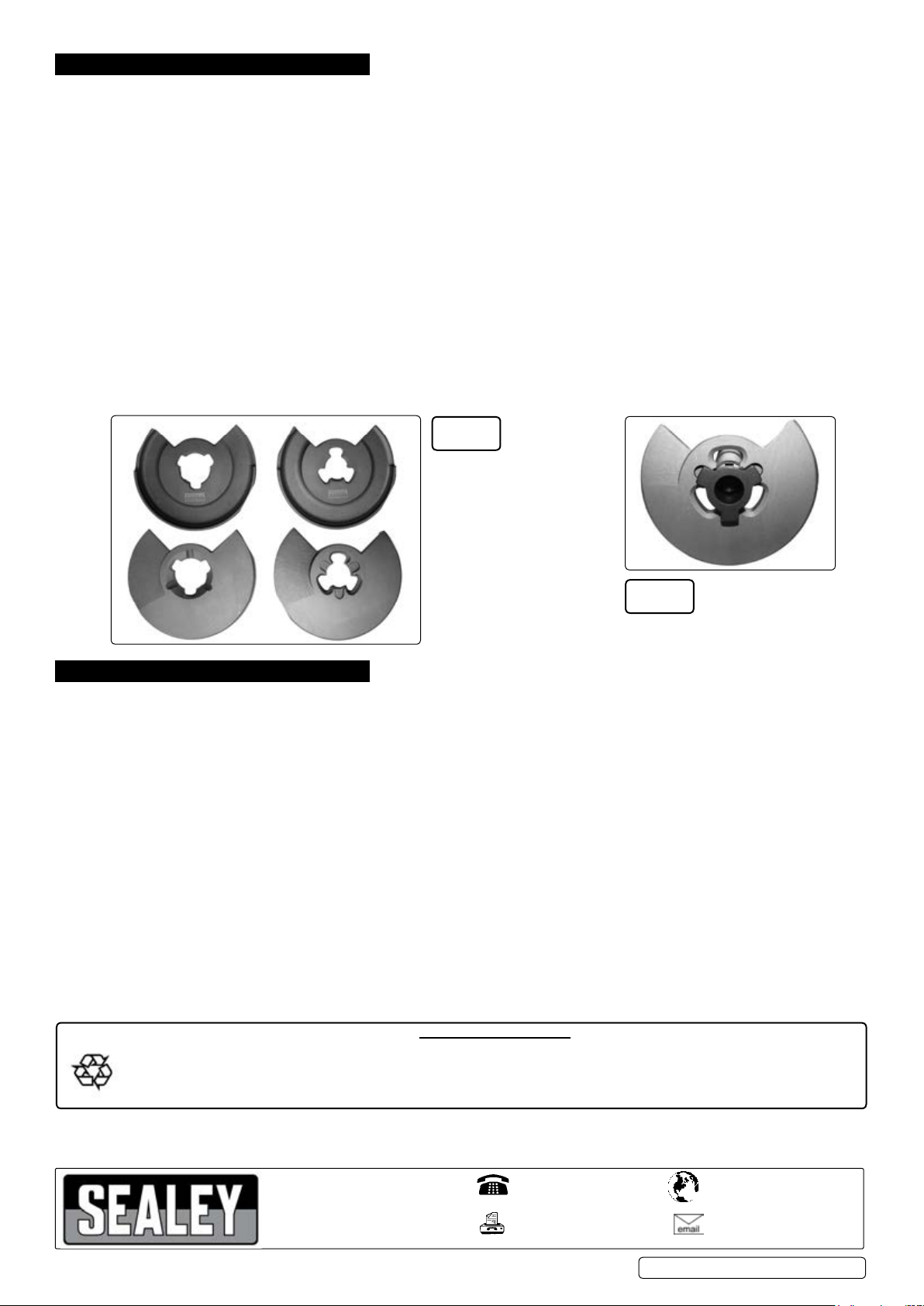

Fig.2

A

b

Fig.3

5. MAINTENANcE

5.1. Before each use check the compressor to ensure it is not damaged or worn.

5.2. If suspect, do not use the unit, but contact your Sealey stockist who will be able to advise you regarding repair kits and spare parts.

5.3. Grease the compressor spindle as necessary, at least every six months using graphite grease.

5.4. Keep the compressor clean, and when not in use store in a safe, dry, childproof location.

NOTE: It is our policy to continually improve products and as such we reserve the right to alter data, specications and component parts without prior notice.

IMpORTANT: no liability is accepted for incorrect use of this product.

WARRANTY: Guarantee is 12 months from purchase date, proof of which will be required for any claim.

© Jack Sealey Limited

Recycle unwanted materials instead of disposing of them as waste. All tools, accessories and packaging should be

sorted, taken to a recycling centre and disposed of in a manner which is compatible with the environment.

When the product becomes completely unserviceable and requires disposal, drain off any fluids (if applicable)

into approved containers and dispose of the product and the fluids according to local regulations.

Sole UK Distributor, Sealey Group.

Kempson Way, Suffolk Business Park,

Bury St. Edmunds, Suffolk.

IP32 7AR

Original Language Version

Environmental protection

01284 757500

01284 703534

www.sealey.co.uk

Web

sales@sealey.co.uk

RE2280.V2| Issue:1 09/01/17

Loading...

Loading...