Page 1

INSTRUCTIONS FOR:

12” HORIZONTAL BANDSAW

MODEL No:

Thank you for purchasing a Sealey product. Manufactured to a high standard this product will, if used according to these instructions and properly

maintained, give you years of trouble free performance.

IMPORTANT: PLEASE READ THESE INSTRUCTIONS CAREFULLY. NOTE THE SAFE OPERATIONAL REQUIREMENTS, WARNINGS & CAUTIONS.

USE THE PRODUCT CORRECTLY AND WITH CARE FOR THE PURPOSE FOR WHICH IT IS INTENDED. FAILURE TO DO SO MAY CAUSE DAMAGE

AND/OR PERSONAL INJURY AND WILL INVALIDATE THE WARRANTY. PLEASE KEEP INSTRUCTIONS SAFE FOR FUTURE USE.

SM353CE.V2

1. SAFETY INSTRUCTIONS

1.1. ELECTRICAL SAFETY. WARNING! It is the user’s responsibility to read, understand and comply with the following:

You must check all electrical equipment and appliances to ensure they are safe before using. You must inspect power supply leads, plugs and

all electrical connections for wear or damage. You must ensure the risk of electric shock is minimised by the installation of appropriate safety

devices. An RCCB (Residual Current Circuit Breaker) should be incorporated in the main distribution board. We also recommend that an RCD

(Residual Current Device) is used with all electrical products. It is particularly important to use an RCD with portable products that are plugged

into an electrical supply not protected by an RCCB. If in doubt consult a qualified electrician. You may obtain a Residual Current Device by

contacting your Sealey dealer. You must also read and understand the following instructions concerning electrical safety.

1.1.1. The Electricity At Work Act 1989 requires all portable electrical appliances, if used on business premises, to be tested by

a qualified electrician, using a Portable Appliance Tester (PAT), at least once a year.

1.1.2. The Health & Safety at Work Act 1974 makes owners of electrical appliances responsible for the safe condition of those appliances,

and the safety of appliance operators. If in any doubt about electrical safety, contact a qualified electrician.

1.1.3. Ensure the insulation on all cables and the product itself is safe before connecting to the mains power

supply. See 1.1.1. & 1.1.2. above and use a Portable Appliance Tester (PAT).

1.1.4. Ensure that cables are always protected against short circuit and overload.

1.1.5. Regularly inspect power supply leads and plugs for wear or damage and connections to

ensure that none are loose.

1.1.6. Important: Ensure the voltage marked on the product is the same as the electrical power

supply to be used, and check that plugs are fitted with the correct capacity fuse.

A 13Amp plug may require a fuse smaller than 13Amps for certain products - see fuse rating

at right.

1.1.7. DO NOT pull or carry the powered appliance by its power supply lead.

1.1.8. DO NOT pull power plugs from sockets by the power cable.

1.1.9. DO NOT use worn or damage leads, plugs or connections. Immediately replace or have

repaired by a qualified electrician. Where a U.K. 3 pin plug with ASTA/BS approval is fitted, in

case of damage, cut off and fit a new plug according to the following instructions (discard old

plug safely).

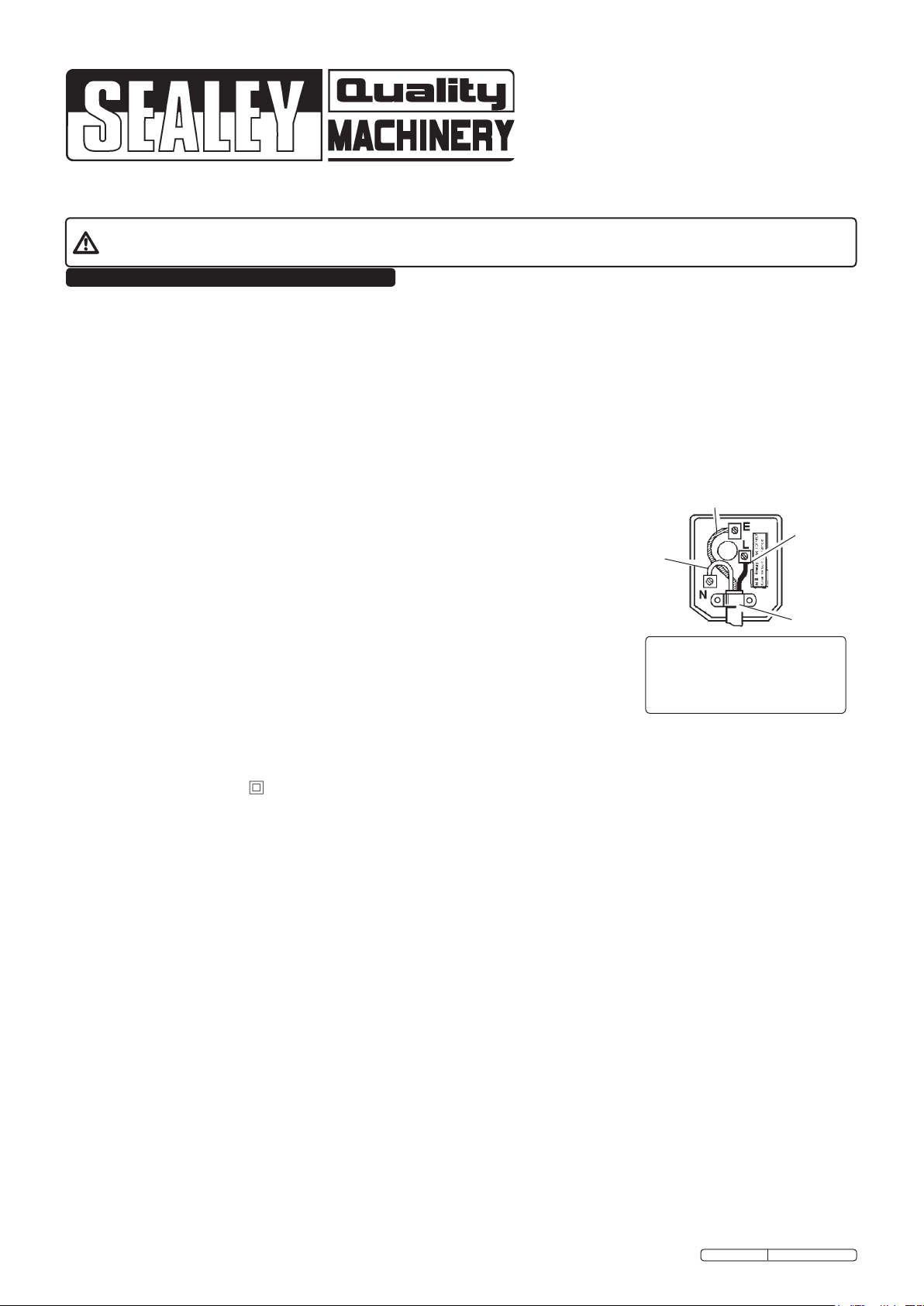

(UK only - see diagram at right). Ensure the unit is correctly earthed via a three-pin plug.

a) Connect the GREEN/YELLOW earth wire to the earth terminal ‘E’.

b) Connect the BROWN live wire to the live terminal ‘L’.

c) Connect the BLUE neutral wire to the neutral terminal ‘N’.

d) After wiring, check there are no bare wires, that all wires have been correctly connected, that the cable outer insulation

extends past the cable restraint and that the cable restraint is tight.

Double insulated products are often fitted with live (BROWN) and neutral (BLUE) wires only. Double insulated products are always

marked with this symbol . To re-wire, connect the brown & blue wires as indicated above. DO NOT connect the brown or blue

wires to the earth terminal.

1.1.10. NOTE: If this product requires more than a 13Amp electrical supply, then NO plug is fitted. You must therefore contact a qualified

electrician to ensure a 30Amp fused supply is available. We recommend you discuss the installation of a industrial round pin plug and

socket with your electrician.

1.1.11. Cable extension reels. When a cable extension reel is used it should be fully unwound before connection. A cable reel with an RCD

fitted is recommended since any product which is plugged into the cable reel will be protected. The section of the cores in the cable

is important and should be at least 1.5mm² , but to be absolutely sure that the capacity of the cable reel is suitable for this product and

for others that may be used in the other output sockets, the use of 2.5mm² section is recommended.

1.2. GENERAL SAFETY

Familiarise yourself with the application and limitations of the saw, as well as the specific potential hazards.

WARNING! Ensure all Health and Safety, local authority, and general workshop practice regulations are strictly adhered to.

WARNING! Keep all guards and holding screws in place, tight and in good working order. Check regularly for damaged parts.

WARNING! Disconnect bandsaw from the mains power supply before changing accessories, making repairs or adjustments.

WARNING! Wear approved safety eye protection, ear defenders, gloves and, if dust is generated, respiratory protection.

WARNING! Evaluate your working area before using the bandsaw and always give your work your undivided attention.

WARNING! Replace warning labels if they become obscured or removed.

WARNING! Always provide adequate support for long and heavy material.

WARNING! Never operate the bandsaw unless all blade guards are installed and in proper working order.

WARNING! Never operate the bandsaw with the blade in the raised position.

WARNING! DO NOT turn bandsaw on until workpiece is secured in vice and the blade has been positioned just above the

workpiece.

WARNING! DO NOT over tighten blade as it will stretch and warp.

WARNING! Take care lifting the bandsaw arm as it is heavy, and could, if not correctly lifted, affect the whole balance of the machine.

Locate the bandsaw in a suitable area, keep area clean and uncluttered and ensure there is adequate lighting.

Maintain the machine and keep in good condition (use an authorised service agent).

Blue

Neutral

wire

Yellow & Green

Earth wire

Brown

Live

wire

Cable

restraint

FUSE RATING

THE PLUG FITTED TO PRODUCT

MUST BE EQUIPPED WITH A

13 AMP FUSE

Original Language Version

SM353CE.V2 Issue: 3 - 15/12/11

Page 2

Ensure the machine is situated on a solid surface, adequate for supporting the weight of the machine and the workpiece.

Check the alignment of moving parts regularly, for safest performance keep the machine clean at all times.

Turn off the machine before raising the blade

Avoid unintentional starting.

Regularly remove, clean and inspect the blade brush.

Remove any adjusting keys and wrenches from the bandsaw before turning it on.

Replace or repair damaged parts. Use recommended parts only. Unauthorised parts may be dangerous and will invalidate the

warranty.

Keep hands and body clear of the work table when operating the bandsaw.

Maintain correct balance and footing, ensure the floor is not slippery and wear non-slip rubber soled footwear.

Remove ill fitting clothing, ties and loose jewellery, and tie back long hair.

Ensure there are no flammable or combustible materials near the work area.

DO NOT leave the machine running unattended.

DO NOT operate the machine if any parts are damaged or missing as this may cause failure and/or personal injury.

DO NOT use the bandsaw for a task it is not designed to perform.

DO NOT use bandsaw near to flammable liquids, solids or gases, such as paint solvents and including waste wiping or cleaning rags.

DO NOT use damaged or deformed bandsaw blades.

DO NOT remove the safety guard whilst in use.

DO NOT hold the workpiece by hand.

DO NOT touch the workpiece immediately after cutting, it may be very hot.

DO NOT operate the machine when you are tired or under the influence of alcohol, drugs or intoxicating medication.

DO NOT allow children or untrained persons to operate the machine. Keep them away from the work area.

When not in use unplug from the mains supply and make every effort to ensure that the machine is childproof.

2. INTRODUCTION & SPECIFICATION

The SM353CE.V2 has a large cutting capacity making it ideal for Industrial and Agricultural engineering applications. A 24V system for

coolant pump and motor controls gives added safety to the operator.

The bandsaw is not suitable for cutting wood and, if used for this purpose, the insurer will not provide coverage.

The saw arm is fitted with hydraulic damping to prevent it being dropped onto the workpiece and to ensure a smooth cutting performance.

The heavy-duty single phase electric motor has an over-current sensor to cut the power in the event of blade jamming.

The saw is manufactured to comply with Supply of Machinery (Safety) Regulations 1992 (S.I.3073) and is fully CE approved.

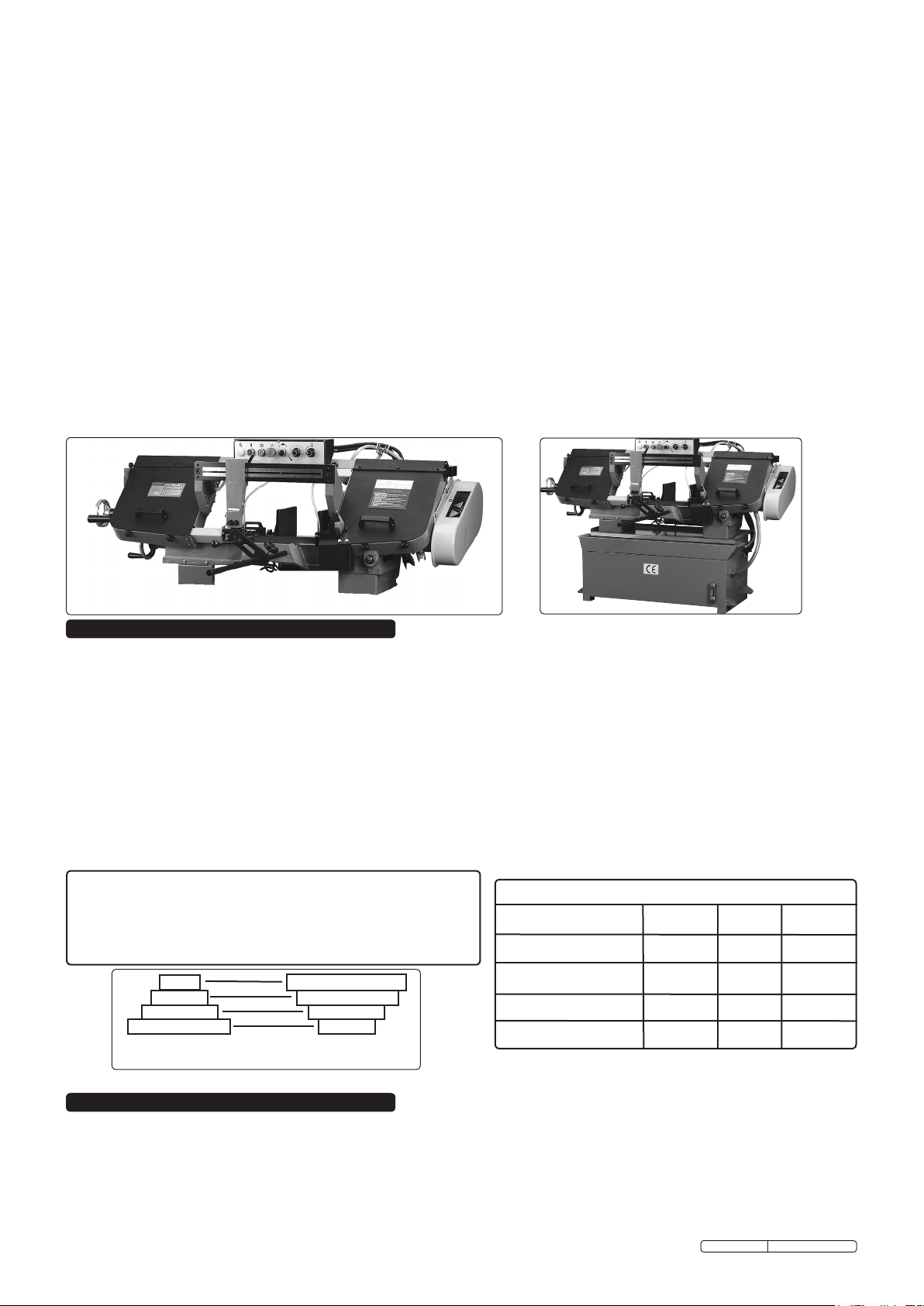

2.1. SPECIFICATION.

Capacity 90° round .............................................................Ø230mm

Capacity 90° square/rectangular H x W ......................230 x 370mm

Capacity 45° round .............................................................Ø185mm

Capacity 45° square/rectangular H x W ......................230 x 185mm

Blade Size .....................................................25.0 x 0.89 x 3035mm

Cutting Chart for Flat and Round Bar

Recommended blade teeth per inch (tpi) for nominal cut length

Cut length <13mm 6-16mm 8-22mm 17-40mm >38mm

Tpi 24 18 14 8 4

A

B

C

D

Motor Pulley

E

F

G

H

Saw Pulley

Blade Speeds ................................................. 25, 40, 51, 71mtr/min

Motor Power ...........................................................................1120W

Power Supply .................................................................... 230V/1ph

Weight .....................................................................................285kg

Recommended Pulley Selection for Various Metals

Material

Tool, stainless or alloy steel.

Bearing bronze.

Medium to high carbon steel.

Hard brass or bronze. Cast iron.

Low to medium carbon steel.

Soft brass.

Aluminium. Copper. Brass.

Motor Pulley

Small (A)

Medium (B)

Medium (C)

Large (D)

Saw Pulley Blade Speed

Large (E) 25m/min

Large (F) 40m/min

Medium (G) 51m/min

Small (H) 71m/min

3. ASSEMBLY

3.1. UNPACKING.

3.1.1. Unpack the bandsaw and inspect all parts. If any parts are damaged contact your distributor.

3.1.2. Unbolt from the transport skid and place on a firm, level surface.

3.1.3. Clean all rust protected surfaces with kerosene, diesel oil, or a mild solvent. Do not use cellulose based solvents as these will damage painted

surfaces.

3.2. ASSEMBLY.

3.2.1. Attach the pulley cover with the screws and washers provided. Close when attached and secure with thumb screw.

Original Language Version

SM353CE.V2 Issue: 3 - 15/12/11

Page 3

4. OPERATING INSTRUCTIONS

WARNING! Before operating the bandsaw ensure that you read, understand and apply the safety instructions in Section 1.

4.1. OPERATION.

NOTE: Before operating the machine certain checks and adjustments will need to be carried out. It is very important that

these instructions are followed carefully in order that the machine is set up safely and correctly.

4.1.1. Check that the blade is suitable for the material to be cut.

4.1.2. Check the blade for correct tension and check the blade guide bearings.

4.1.3. Select the appropriate speed for the material being cut.

4.1.4. Raise the blade arm and lock in position by closing hydraulic valve.

4.1.5. Secure the material to be cut in the vice.

4.1.6. Open hydraulic valve, lower blade arm until blade is just above workpiece, close valve and then position both blade guides as close to

the work as possible.

4.1.7. Check the coolant level.

4.1.8. Plug in the saw, turn on isolating switch, switch on the coolant pump and then the saw.

DO NOT start saw with blade touching workpiece.

4.1.9. Open hydraulic valve to allow blade to come down onto workpiece. Adjust feed rate as required with control knob. Coolant flow may

be adjusted by control valve.

Note: If the emergency stop switch has been pressed it must be rotated to reset before the saw can be used again.

5. ADJUSTMENTS

WARNING! Before following any of the steps below ensure the bandsaw is switched off, isolated from the mains power

supply and at a complete standstill. Failure to comply with this instruction can result in serious injury.

5.1. BLADE AND SPEED SELECTION.

5.1.1. Refer to Section 2 for the recommended setup for cutting various materials.

5.1.2. A good rule for blade selection is that three teeth should always be in contact with the workpiece, therefore, the thinner the work

piece, the more teeth the blade should have.

5.2. TO ADJUST BLADE SPEED.

5.2.1. Disconnect the machine from the power supply.

5.2.2. Loosen the wing nut on the pulley guard then lift up and swing the guard to the front of the machine.

5.2.3. Release tension on the belt by turning the tension lock knob counter-clockwise and letting the motor swing forward.

5.2.4. Shift the belt to the desired grooves on the pulleys. Adjust the belt tension by pulling the motor plate back until correct tension is

obtained then tighten the tension lock knob.

5.2.5. Close the cover guard.

5.3. TO CHANGE BLADE AND ADJUST TENSION.

Caution: Blade teeth are sharp, handle with care.

NOTE: Proper blade tension is very important to the safe and efficient running of the bandsaw. The correct tension for the

SM353CE.V2 is between 700 to 900 kg as measured with a blade tension gauge.

NOTE: The teeth must be pointing in the correct direction (indicated on the label found on the saw arm).

5.3.1. Raise saw frame to the vertical position and close the feed control valve by turning clockwise as far as it will go (Do not overtighten).

5.3.2. Open both wheel covers and clean the swarf out of the machine.

5.3.3. Release blade tension by turning the blade tension handwheel counter-clockwise.

5.3.4. Slide the left blade guide arm to the right as far as it will go.

5.3.5. Remove the blade from both wheels and out of each blade guide.

5.3.6. Install the new blade, (teeth pointing down) on the blade wheels and through the upper blade guide, working all the way up between

the blade guide bearings with the back of the blade against the back-up bearing.

5.3.7. Put light tension on the blade and work onto both wheels. (Ensure the back of the blade is against the wheel flanges of both wheels).

5.3.8. Adjust blade to the final tension. Proper tension is achieved when the pointer is on the left mark of the blade tension scale behind

the idle wheel.

5.3.9. Connect the machine to the power supply and turn it on and off two to three times to ensure the blade is seated and tracking properly.

When finished close the wheel covers.

5.4. HYDRAULIC FEED ADJUSTMENT.

5.4.1. Adjust the hydraulic feed by turning the knob situated on the hydraulic cylinder.

Anti-clockwise will increase the feed rate, clockwise will decrease it.

5.4.2. To stop the flow of hydraulic fluid, turn off the hydraulic valve.

5.5. TO ADJUST THE BLADE GUIDES.

5.5.1. Loosen the adjusting knob on each blade guide and slide guide assemblies as close as possible to each side of the workpiece and re tighten.

5.6. TO ADJUST THE BLADE GUIDE BEARINGS.

5.6.1. Raise the saw arm to a vertical position and close the hydraulic valve.

5.6.2. Loosen the hex. cap screw on the guide assembly and adjust the rear bearing to 0.025 mm from the blade.

5.6.3. Loosen lock nut and turn the front bearing eccentric so that bearing is snug with the blade. The blade should still

move up and down freely if grasped. Repeat the procedure for the other guide assembly.

Original Language Version

SM353CE.V2 Issue: 3 - 15/12/11

Page 4

5.7. ADJUSTING THE VICE.

NOTE: Do not adjust the vice or load/unload any material while the saw is running. The vice can be adjusted

to hold the workpiece at angles between 0° and 45°.

5.7.1. To position the moveable vice jaw, turn the vice handwheel counter-clockwise half a turn and move the vice jaw to the desired position

and tighten using hand wheel.

5.7.2. Vice can be adjusted to cut any angle from 0° to 45° by loosening the two bolts on each vice jaw. Position the jaw to the desired angle

and tighten the bolts

5.7.3. When cutting at an angle, it is necessary to move the right vice jaw to the left until the workpiece and the right hand vice jaw are clear

of the right hand guide arm.

5.8. TO ADJUST BLADE TRACKING.

NOTE: Blade tracking is factory set and should not require adjustment. However, if it does become necessary, proceed as follows:

5.8.1. Run saw for a short time and then switch off.

5.8.2. Raise saw arm, open blade cover and check blade-to-wheel relationship (tracking). Rear edge of blade should be very close to, but

not hard against, the wheel flanges.

5.8.3. If inspection indicates that adjustment is required tighten or loosen the screw (fig.1.A) until it tracks properly.

5.8.4. Having made a small adjustment close the blade cover and run the saw for a short time.

5.8.5. Switch saw off, open blade cover and check tracking. Repeat adjustment procedure if necessary.

Fig.1

6. MAINTENANCE

WARNING! Before carrying out any maintenance ensure that the bandsaw is switched off, isolated from the mains supply

and that the blade is at a complete standstill. Failure to comply with this instruction can cause serious injury.

6.1. LUBRICATION.

6.1.1. Ball bearings on the blade guide assemblies and blade wheels are permanently sealed requiring no lubrication.

6.1.2. Keep all surfaces clean and free of rust, swarf and coolant build-up.

6.1.3. Lightly lubricate vice screw with grease.

6.2. CHANGING GEARBOX OIL.

6.2.1. Change gearbox oil after the first 50 days of operation and thereafter every six months.

6.2.2. Remove the drain plug, drain oil and replace the plug.

6.2.3. Fill the gearbox with approximately 850ml of SA20/50W weight gear oil.

6.3. GENERAL MAINTENANCE.

WARNING! Do not use compressed air to clean the bandsaw as metal filings may blow into the blade guide bearings and

other critical areas. There is also a danger of flying particles being released into the surrounding area.

6.3.1. Use a small paint brush or parts cleaning brush to remove metal particles. If inaccessible (and ferrous) use a magnetic pick-up tool.

6.3.2. Regularly wipe the saw down with a clean dry cloth and protect all unpainted surfaces with light machine oil.

6.3.3. Keep blade guides clean and free of metal filings.

6.3.4. Check the guide bearings frequently to make sure they are properly adjusted and turning freely.

6.4. BLADE CLEANING BRUSH.

6.4.1. Replace the brush as soon as it becomes worn or damaged or blade life will be significantly shortened.

Original Language Version

SM353CE.V2 Issue: 3 - 15/12/11

Page 5

7. TROUBLESHOOTING

PROBLEM CAUSE SOLUTION

Excessive blade breakage and/

or teeth ripping from the blade.

Workpiece is loose in the vice.

Incorrect speed or feed.

Blade is too course.

Workpiece is too course.

Incorrect blade tension.

Blade is in contact with workpiece when

saw is started.

Blade is rubbing on the wheel flange.

Blade guides are misaligned.

Blade is too thick.

Clamp the workpiece securely.

Adjust the speed or feed to suit the workpiece.

Replace with a finer blade.

Use the saw at slower speed and use a finer blade.

Adjust blade tension.

Place blade in contact with the workpiece only after the

saw has started.

Adjust tracking.

Adjust blade guides.

Use correct blade.

Premature blade dulling.

Unusual wear on side or back

of blade.

Motor overheating.

Bad, crooked or rough cuts.

Blade twisting.

Blade is too course.

Incorrect speed - too fast.

Inadequate feed

Hard spots or scale on the workpiece.

Blade is twisting.

Insufficient blade tension.

Blade is sliding.

Blade guides are worn.

Blade guides are misaligned.

Blade guide brackets are loose.

Blade tension too high.

Drive belt tension too high.

Blade too coarse or too fine.

Gears need lubrication.

Blade is binding in the cut.

Feed pressure too great.

Blade guides are misaligned.

Inadequate blade tension.

Blade is dull.

Incorrect speed.

Blade guides too far from workpiece.

Blade guide assembly is loose.

Blade is too coarse.

Blade is binding in the cut.

Blade tension is too high.

Replace with a finer blade.

Reduce blade speed.

Adjust hydraulic feed control and/or bow weight.

Reduce blade speed, increase feed pressure.

Replace blade and adjust to the correct tension.

Increase blade tension.

Increase blade tension and reduce blade speed.

Replace blade guides.

Adjust guide pivots.

Tighten blade guide brackets.

Reduce blade tension.

Reduce drive belt tension.

Use a blade more suitable for the workpiece.

Lubricate the gears.

Decrease feed and blade speed.

Adjust hydraulic feed control and/or bow weight.

Adjust blade guides.

Increase blade tension.

Replace the blade.

Adjust the speed.

Adjust guides.

Tighten the guide assembly.

Use a finer blade.

Adjust hydraulic feed control to decrease feed pressure.

Decrease blade tension.

NOTE: It is our policy to continually improve products and as such we reserve the right to alter data, specifications and component parts without prior notice.

IMPORTANT: No liability is accepted for incorrect use of this product.

WARRANTY: Guarantee is 12 months from purchase date, proof of which will be required for any claim.

INFORMATION: For a copy of our latest catalogue and promotions call us on 01284 757525 and leave your full name and address, including postcode.

Sole UK Distributor, Sealey Group,

Kempson Way, Suffolk Business Park,

Bury St. Edmunds, Suffolk,

IP32 7AR

Original Language Version

01284 757500

01284 703534

www.sealey.co.uk

Web

sales@sealey.co.uk

email

SM353CE.V2 Issue: 3 - 15/12/11

Loading...

Loading...