Page 1

INSTRUCTIONS FOR:

POWER BELT SANDER

MODEL NO: SM100

Thank you for purchasing a Sealey product. Manufactured to a high standard this product will, if used according to these instructions and

properly maintained, give you years of trouble free performance.

IMPORTANT: PLEASE READ THESE INSTRUCTIONS CAREFULLY. NOTE THE SAFE OPERATIONAL REQUIREMENTS, WARNINGS, AND

CAUTIONS. USE THIS PRODUCT CORRECTLY, AND WITH CARE FOR THE PURPOSE FOR WHICH IT IS INTENDED. FAILURE TO DO SO MAY

CAUSE DAMAGE AND/OR PERSONAL INJURY AND WILL INVALIDATE THE WARRANTY.

1. SAFETY INSTRUCTIONS

1.1 ELECTRICAL SAFETY

WARNING! It is the responsibility of the owner and the operator to read, understand and comply with the following:

You must check all electrical products, before use, to ensure that they are safe. You must inspect power cables, plugs, sockets and

any other connectors for wear or damage. You must ensure that the risk of electric shock is minimised by the installation of

appropriate safety devices. A Residual Current Circuit Breaker (RCCB) should be incorporated in the main distribution board. We also

recommend that a Residual Current Device (RCD) is used. It is particularly important to use an RCD with portable products that are

plugged into a supply which is not protected by an RCCB. If in any doubt consult a qualified electrician. You may obtain a Residual

Current Device by contacting your Sealey dealer.

You must also read and understand the following instructions concerning electrical safety.

1.1.1 The Electricity at Work Act 1989 requires that all portable electrical appliances, if used on business premises, are tested by a qualified

electrician, using a Portable Appliance Tester (PAT), at least once a year.

1.1.2 The Health & Safety at Work Act 1974 makes owners of electrical appliances responsible for the safe condition of those appliances

and the safety of the appliance operators. If in any doubt about electrical safety, contact a qualified electrician.

1.1.3 Ensure that the insulation on all cables and on the appliance is safe before connecting it to the power supply. See 1.1.1 and 1.1.2

and use a Portable Appliance Tester.

1.1.4 Ensure that cables are always protected against short circuit and overload.

1.1.5 Regularly inspect power supply cables and plugs for wear or damage and check all

connections to ensure that none is loose.

1.1.6 Important: Ensure that the voltage marked on the appliance matches the power supply

to be used and that the plug is fitted with the correct fuse - see fuse rating at right.

1.1.7 DO NOT pull or carry the appliance by the power cable.

1.1.8 DO NOT pull the plug from the socket by the cable.

1.1.9 DO NOT use worn or damaged cables, plugs or connectors. Immediately have any faulty

item repaired or replaced by a qualified electrician. When a BS 1363/A UK 3 pin plug is

Blue

Neutral

Wire

damaged, cut the cable just above the plug and dispose of the plug safely.

Fit a new plug according to the following instructions (UK only).

a) Connect the GREEN/YELLOW earth wire to the earth terminal ‘E’.

b) Connect the BROWN live wire to the live terminal ‘L’.

c) Connect the BLUE neutral wire to the neutral terminal ‘N’.

d) After wiring, check that there are no bare wires, that all wires have been correctly connected, that the cable outer insulation extends

beyond the cable restraint and that the restraint is tight. Double insulated products, which are always marked with this symbol , are

fitted with live (brown) and neutral (blue) wires only. To rewire, connect the wires as indicated above - DO NOT connect either wire to

the earth terminal.

1.1.10 Products which require more than 13 amps are supplied without a plug. In this case you must contact a qualified electrician to ensure

that a suitably rated supply is available. We recommend that you discuss the installation of an industrial round pin plug and socket

with your electrician.

1.1.11 If an extension reel is used it should be fully unwound before connection. A reel with an RCD fitted is preferred since any appliance

plugged into it will be protected. The cable core section is important and should be at least 1.5mm², but to be absolutely sure that the

capacity of the reel is suitable for this product and for others which may be used in the other output sockets, we recommend the use

of 2.5mm² section cable.

1.2 GENERAL SAFETY

Disconnect the sander from the mains power before changing accessories, servicing or performing any maintenance.

Maintain sander and belts in good condition. Check moving parts and alignment. If necessary use an authorised service agent.

Replace or repair damaged parts. Use genuine parts only. Unapproved parts may be dangerous and will invalidate the warranty.

WARNING! Always work with the sander safety guard in place.

Wear approved safety goggles, ear defenders, appropriate dust mask if sander generates dust and safety gloves.

Remove ill fitting clothing. Remove ties, watches, rings, and other loose jewellery, and contain long hair.

Use sander in a suitable work area, keep area clean, tidy and free from unrelated materials, and ensure adequate lighting.

Maintain correct balance and footing. DO NOT over-reach and ensure the floor is not slippery. Wear non-slip shoes.

Check grinding disc to ensure they are not split, cracked or damaged in anyway. See chapter 4. If in doubt to not use the disc.

Grinding discs must be securely attached before use, but not over tightened.

Secure unstable workpiece with a clamp, vice or other adequate holding device, and ensure the sander is gripped with both hands.

Keep non essential persons away from the working area, use screens if necessary.

DO NOT operate the sander if any parts are missing or the sander is damaged.

DO NOT use the sander for a task it was not designed to perform.

DO NOT operate sander where there are flammable liquids or gasses.

WARNING! DO NOT grind any materials containing asbestos.

DO NOT get the sander wet or use in damp or wet locations.

DO NOT switch the sander on whilst the belt is in contact with the workpiece.

DO NOT touch the workpiece immediately after grinding as it will be very hot.

DO NOT hold unsecured work in your hand, and DO NOT touch the sanding belt whilst operating, or whilst plugged into the mains power.

DO NOT leave the sander running unattended.

DO NOT operate the sander when you are tired or under the influence of alcohol, drugs or intoxicating medication.

When not in use switch sander off, remove plug from power supply and store in safe, dry, childproof area.

Original Language Version

Yellow & Green

Earth Wire

Brown

Live

Wire

Cable

Restraint

FUSE RATI NG 13 AMP

SM100 Issue: 2 - 23/11/09

Page 2

2. DESCRIPTION & SPECIFICATIONS

The SM100 has a heavy cast base with adjustable sanding table. Fitted with magnetic no-volt release switch to prevent accidental starting

should the belt jam. Equipped with a quiet and powerful 230V 1Hp motor, the SM100 is suitable for metal and fabrication workshops.

An optional floor stand is available.

Motor .......................... 0.75kW 1Hp

Power .......................... 230V - 1ph

Sanding belt ..................... 100 x 1220mm

Belt speed ...................... 19m/sec (50Hz)

Driving wheel .................... Ø 126 x 105mm

Flat grinding surface............... 320 x 105mm

Dimensions (LxWxH) .............. 650x380x260mm

Weight ......................... 27.5kg

“A” weighted sound ............... 82.0 dB

“B” weighted sound ............... 81.6 dB

Spare belts available as follows:

SM100/B080G 80 grit sanding belt

SM100/B100G 100 grit sanding belt

Optional stand part number SM100/ST specifications:

Machine height (with stand) ......... 1070mm

Cabinet stand size (LxWxH)......... 380x395x810mm

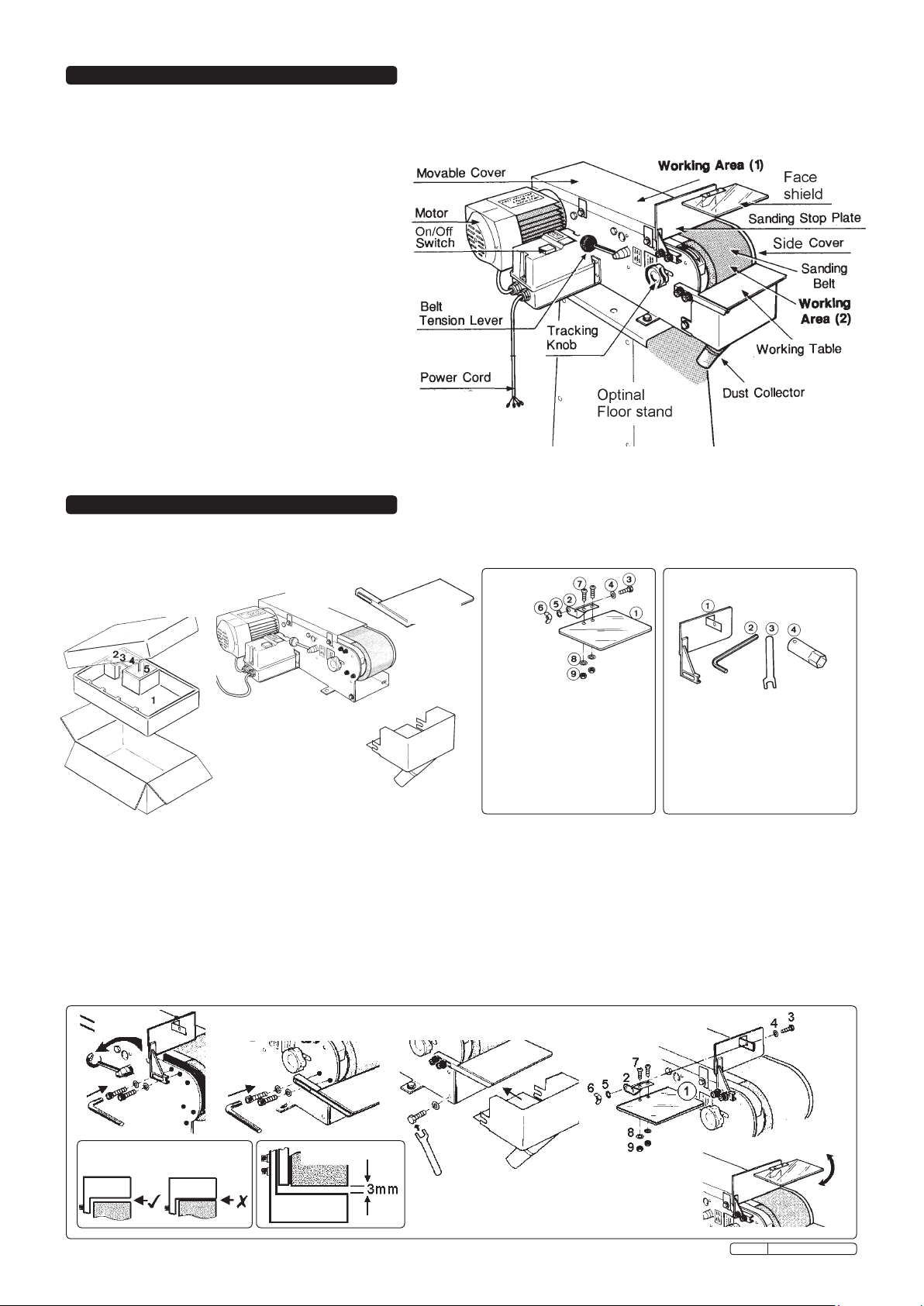

3. PACKAGE CONTENT & ASSEMBLY

3.1. Package content

Unpack carton as illustrated below and identify each part according to item description. Should there be any damaged or missing parts contact

your supplier immediately.

Carton

with item identification

Item 1

Main body

Item 2

Work table

Face

Shield

Item 4 Sanding stop plate & toolsItem 3

No Description Qty

Item 5

Dust cover

1 Face shield 1

2 Support plate 1

3 Hex bolt 1/4” x 1/2”L 1

4 Washer M6 x18x2 1

5 Spring washer 1/4” 1

6 Wing Nut 1/4” 1

7 Screw 3/16 x 7/16”L 2

8 Washer 3/16”x12x0.8 2

9 Hex nut 3/16” 2

No Description Qty

1 Sanding stop plate 1

2 6mm Hex wrench 1

3 12mm open spanner 1

4 socket wrench 1

3.2 ASSEMBLY

WARNING! Ensure sander has not been connected to mains power supply. Refer to diagrams to assist assembly.

3.2.1 TENSION AND SANDING STOP PLATE

The belt tension has been pre-set by the manufacturer. For shipping purposes the manufacturer has slackened the tension by turning

the tension lever to the “Loosen” position. To re-tension the belt push the lever down toward the “tighten” position (fig 1). Install the

sanding stop plate and ensure that it does not touch the sanding belt see fig 1 & 1a.

3.2.2 WORKING TABLE

Locate working table in correct position (fig 2) Ensure the distance between the working table and the sanding belt is at 3mm (fig 2a).

3.2.3 DUST COLLECTOR

Fit the dust collector unit with washer and bolt on each side (fig 3).

3.2.4 SAFETY FACE SHIELD

Install the face shield and make adjustments to gain the maximum protection (fig 4 & 5).

fig 1

fig 2

fig 3

fig 4

fig 1a

fig 2a

Original Language Version

fig 5

SM100 Issue: 2 - 23/11/09

Page 3

4. SANDING BELT ADJUSTMENT

4.1 TRACKING ADJUSTMENT

WARNING! Ensure mains power lead is unplugged from the mains supply,

4.1.1 Connect the other end of the mains power lead to the sanding machine (fig 6)

4.1.2 Identify the tracking knob (fig 7) each turn of the knob will only render a slight

adjustment to the belt tracking.

4.1.3 Rotate the tracking knob clockwise to move the belt to the left and anti-clockwise to move

belt to the right.

4.1.4 Rotate the belt by hand whilst turning the tracking knob to effect movement.

4.1.5 To ensure the belt is aligned, connect the machine to the mains power supply, turn the machine

“On”, and then “Off”, whilst adjusting the tracking knob to effect further fine adjustments.

Note: “I” = On. “0” = Off.

4.2 BELT TENSION

WARNING! Ensure the sander is switch off and unplugged from the mains power supply.

The belt tension has been pre-set by the manufacturer but will require adjustment after a period

of use or when a new belt is fitted.

4.2.1 Locate cover plate to the right of the tension lever. Loosen screw and open the cover plate (fig 8).

4.2.2 Turn the tension lever to “Loosen”.

4.2.3 Loosen locking nut (fig 9).

4.2.4 To decrease tension turn adjusting rod upward (fig 10).

To increase the tension turn the adjusting rod downward.

Note: One 360° turn on the adjusting rod will move the belt roller in or out by approximately 2.5mm.

We recommend small adjustments are made by turning the adjusting rod only to the degree that access

will allow the spanner to move, and then test the belt tension before making further adjustments.

4.2.5 When complete tighten the locking nut, close and lock the cover plate in place. Turn the belt tension lever

back to the “Tighten” position, and re-check that the belt tracking is correct.

fig 6

fig 7

fig 8

5. OPERATING PRINCIPLE

fig 9

fig 10

5.1 GENERAL

5.1.1 Ensure you have read and understood chapter 1 safety instructions.

5.1.2 Double check that the gap between the worktable and the belt is set at no more than

3mm.

5.1.3 Always start the belt first and bring your workpiece to the moving belt.

DO NOT start the belt whilst the workpiece is resting against the abrasive surface.

5.1.4 Check that there are no foreign bodies in the workpiece which could damage

the sanding belt or cause a hazard. i.e. nails, screws etc.

5.1.5 We recommend you practice with off-cuts of wood to familiarise yourself with

the machines capabilities.

WARNING! do not allow your fingers to touch the surface of the moving belt.

5.2 ROLLER-SANDING

To sand work piece on the roller end of machine, position face guard for maximum

protection and hold the workpiece firmly by hand whilst using the working

table for support (fig 11).

5.3 SURFACE SANDING

For sanding a large flat workpiece, remove the belt cover. Hold workpiece on the flat

surface of the abrasive belt to complete task (fig12).

Use the stop plate to rest work against.

5.4 DUST COLLECTOR

The SM100 is equipped with a dust collector provided with a 35mm Ø outlet

for connection to your own dust extraction system (fig 13).

WARNING! Dust produced by this operation may be hazardous in which case

we recommend the use a face or dust mask.

6. MAINTENANCE

WARNING! Ensure the sander is switched off and unplugged from the mains power

supply.

6.1 OVERLOAD SWITCH

Should the sander motor be overloaded an overload switch will activate cutting the

power to the machine. If this happens allow the motor to cool. The overload switch

is located on the main contactor underneath the switch cover.

6.2 BELT REPLACEMENT

6.2.1 Turn the belt tension lever to “Loosen”.

6.2.2 Remove the two screws in (fig 14), open the belt cover and remove the used belt.

6.2.3 Place the new belt over the end rollers (fig 15).

6.2.4 Re set the belt tension lever by turning it to the “tighten” position.

6.2.5 Rotate the belt by hand whilst checking and adjusting the tracking.

6.2.6 Check and adjust the belt tension accordingly.

fig 14

fig 15

fig 11

fig 12

fig 13

Original Language Version

SM100 Issue: 2 - 23/11/09

Page 4

WARNING! Ensure the sander is switched off and unplugged from the mains power

supply.

6.3 PRIME WHEEL REPLACEMENT

fig 16

6.3.1 Turn the belt tension lever to “Loosen”.

6.3.2 Remove belt cover and remove the belt (fig 16).

6.3.3 Remove motor rear guard (fig 17).

6.3.4 Stop the motor shaft from turning by inserting a screw driver in spindle hole (fig 17).

6.3.5 Place socket wrench (chapter 3 item 4.4) over wheel nut, secure motor spindle whilst

loosening nut (fig 18).

6.3.6 Remove retaining nut and draw the prime roller off centre spindle (fig 19) and

replace with a new wheel reversing the above process to make ready for use.

fig 17 fig 18 fig 19

7. OPTIONAL FLOOR STAND

List of contents

No Description Qty

1 Stand leg (front & rear) 2

2 Stand leg (left & right) 2

3 Stand Top 1

4 Square neck bolt

5/16”-18NCx5/8” 4

5 Hex bolt

5/16” -NCX3/4” 4

6 Washer

5/16”x23/32Dx1/16” 12

7 Spring washer 5/16” 8

8 Hex nut 5/16” -18NC 8

Assembly

1

2

3

NOTE: It is our policy to continually improve products and as such we reserve the right to alter data, specifications and component parts without prior notice.

IMPORTANT: No liability is accepted for incorrect use of this product.

WARRANTY: Guarantee is 12 months from purchase date, proof of which will be required for any claim.

INFORMATION: For a copy of our latest catalogue and promotions call us on 01284 757525 and leave your full name and address, including postcode.

4

Sole UK Distributor, Sealey Group,

Kempson Way, Suffolk Business Park,

Bury St. Edmunds, Suffolk,

IP32 7AR

Original Language Version

01284 757500

01284 703534

www.sealey.co.uk

Web

sales@sealey.co.uk

email

SM100 Issue: 2 - 23/11/09

Page 5

PARTS LIST FOR:

POWER BELT SANDER

MODEL NO: SM100

Issue: ............ 2

Issue Date: ...020305

01284 757500

Sole UK Distributor, Sealey Group, Bury St. Edmunds, Suffolk.

01284 703534

www.sealey.co.uk

Web

email

sales@sealey.co.uk

SM100 - 2 - 280205

Page 6

No. Stock Code Description

1 SM100/001 Hex Bolt

2 SM100/002 Screw

3 SM100/003 Spring washer

4 SM100/004 Dust Proof Cover

5 SM100/005 Base

6 SM100/006 Hex. Bolt

7 SM100/007 Bush

8 SM100/008 Dust Proof Plate

9 SM100/009 Belt Support

10 SM100/010 Arrow Mark

11 SM100/011 Cam

12 SM100/012 Hex Nut- Looseproof

13 SM100/013 Press Block

14 SM100/014 Adjusting Rod

15 SM100/015 Hex. Nut

16 SM100/016 Sliding Block

17 SM100/017 Pin

18 SM100/018 Adjusting Block

19 SM100/019 Spring

20 SM100/020 Spring Stop Plate

21 SM100/021 Upper Support

22 SM100/021 Cap Screw

23 SM100/023 Block Stop Plate

24 SM100/024 Lower Support

25 SM100/025 Movable Cover

26 SM100/026 Aluminium Roller

27 SM100/027 Hex. Nut

28 SM100/027 Rubber Roller

29 SM100/029 Snap Ring

30 SM100/030 Ball Bearing

31 SM100/031 Bush

32 SM100/032 Shaft

33 SM100/033 Snap Ring

34 SM100/034 Sanding Belt

35 SM100/035 Washer

36 SM100/036 Hex. Shaft

37 SM100/037 Protection Cover

38 SM100/038 Hex. Bolt

39 SM100/039 Ball Knob

40 SM100/040 Screw Shaft

41 SM100/041 Cam Shaft

42 SM100/042 Loosen-Tighten Plate

43 SM100/043 Adjusting Plate

44 SM100/044 Cover Screw

45 SM100/045 Wave Washer

46 SM100/046 Cover Plate

47 SM100/047 Cover

48 SM100/048 Tracking Knob

49 SM100/049 Spring

50 SM100/050 Washer

PARTS LIST FOR:

POWER BELT SANDER

MODEL NO: SM100

No. Stock Code Description

51 SM100/051 Cap Screw

52 SM100/052 Washer

53 SM100/053 Working Table

54 SM100/054 Sanding Stop Plate

55 SM100/055 Wing Nut

56 SM100/056 Support Plate

57 SM100/057 Screw

58 SM100/058 Washer

59 SM100/059 Hex. Bolt

60 SM100/060 Dust Collector

61 SM100/061 Eye Shield

62 SM100/062 Washer

63 SM100/063 Hex. Nut

64 SM100/064 Screw

65 SM100/065 Rear Protector

66 SM100/066 Fan

67 SM100/067 Rear Support

68 SM100/068 Ball Bearing

69 SM100/069 Rotor

70 SM100/070 Stator Housing

71 SM100/071 Ball Bearing

72 SM100/072 Front Support

73 SM100/073 Screw

74 SM100/074 Screw

75 SM100/075 Switch Box Cover

76 SM100/076 Switch Box

77 SM100/077 Screw

78 SM100/078 Supporting Plate

79 SM100/079 Screw

80 SM100/080 Strain Relief

81 SM100/081 Power Cord

82 SM100/082 Wiring Box Cover

83 SM100/083 Packing

84 SM100/084 Screw

85 SM100/085 Capacitor Sleeve

86 SM100/086 Running Capacitor

87 SM100/087 Capacitor Cover

88 SM100/088 Plug

89 SM100/089 Plug Socket

90 SM100/090 Packing

91 SM100/091 Wire Connector

92 SM100/092 Wiring Box

93 SM100/093 Screw

94 SM100/094 Int. Washer

95 SM100/095 Packing

96 SM100/096 Screw

97 SM100/097 Copper Set

98 SM100/098 Ext. Washer

99 SM100/099 Strain Relief

100 SM100/100 Screw

SM100

Wiring

diagram

01284 757500

Sole UK Distributor, Sealey Group, Bury St. Edmunds, Suffolk.

01284 703534

www.sealey.co.uk

Web

email

sales@sealey.co.uk

SM100 - 2 - 280205

Loading...

Loading...