Page 1

INSTRUCTIONS FOR

PRESSURE WASHER 220BAR 600LTR/HR

SELF PRIMING 6.5HP PETROL

MODEL NO: PWM2500SP

Thank you for purchasing a Sealey product. Manufactured to a high standard, this product will, if used according to these instructions,

and properly maintained, give you years of trouble free performance.

IMPORTANT: PLEASE READ THESE INSTRUCTIONS CAREFULLY. NOTE THE SAFE OPERATIONAL REQUIREMENTS, WARNINGS & CAUTIONS. USE

THE PRODUCT CORRECTLY AND WITH CARE FOR THE PURPOSE FOR WHICH IT IS INTENDED. FAILURE TO DO SO MAY CAUSE DAMAGE AND/OR

PERSONAL INJURY AND WILL INVALIDATE THE WARRANTY. KEEP THESE INSTRUCTIONS SAFE FOR FUTURE USE.

1. SAFETY

1.1. GENERAL SAFETY

WARNING! RISK OF FLUID INJECTION. This washer operates at fluid pressures and velocities high enough to penetrate

human and animal flesh. If there is an occurrence of fluid injection seek medical help immediately

WARNING! Stop the engine and disconnect the mains water supply before changing accessories or performing any maintenance.

WARNING! Do not operate the washer if damaged. Replace or repair using recommended parts only. Unauthorised parts may be

dangerous and will invalidate your warranty. Use authorised Service agent only.

9 Keep the washer in good condition. Regular maintenance will give the best and safest performance.

9 Ensure you comply with the water supply company regulations before connecting to the mains. If you are connecting to the mains drinking

9 water supply ensure you have a back flow preventer valve installed.

9 The water supply hose must be reinforced and have an internal diameter of 13mm (1/2”). The minimum water supply rate must be at least

9 equal to the cleaner capacity. The water temperature must not exceed 50°C and the pressure must not exceed 10bar.

WARNING! DO NOT operate the washer without the water supply connected. To do so will damage the machine.

9 Position the washer as near as possible to the mains water supply.

9 Only use recommended washing detergents. Failure to do so may cause corrosion to equipment and hoses.

WARNING! Use the washer on a at, level surface, in a horizontal position. Failure to do so will invalidate your warranty.

9 Wear safety goggles and adequate protective clothing and anti-slip rubber soled footwear.

WARNING! The high pressure jet must be used with caution. Ensure you aim the lance correctly at the work surface. Failure to do so may

scatter loose particles at the same force as the water pressure, resulting in possible damage or personal injury.

9 Keep all persons and animals at a safe distance from the hose working area. It is difficult to give an exact safe distance as it will depend

upon your circumstances. We recommend at least 15 metres (16 yards). Also ensure other persons are aware before you start to depress

the washer trigger.

9 Hold the gun firmly for it will tend to “kick” backwards when you first pull the trigger.

8 DO NOT allow children or untrained persons to operate the washer.

8 DO NOT connect other appliances to the washer inlet or outlet. Only use the supplied or recommended outlet nozzle.

8 DO NOT use the washer if the water supply hose is damaged. Also check that the hose is laid out straight and safely.

8 DO NOT jam the operating trigger in the operating position, and DO NOT pull the trigger without holding and aiming the gun correctly.

WARNING! DO NOT attempt to alter the pressure regulating valve as this may cause serious damage.

8 DO NOT move the washer by pulling on the high pressure hose or the mains water supply hose. Use the machine handle.

8 DO NOT direct jet against yourself, other persons or animals, electrical equipment or the machine itself.

WARNING! DO NOT leave the engine running for more that 2 minutes without operating the trigger, as temperature/pressure increase

may damage the sealing system.

8 DO NOT use the washer if you are tired or under the influence of alcohol, drugs or intoxicating medication.

9 Ensure that the hose pressure is discharged before disconnecting the mains water hose.

9 When not in use, disconnect from the water supply. Clean and dry the washer and store in a safe, dry, childproof area.

8 DO NOT allow the machine to become frozen.

1.2. ENGINE SAFETY

WARNING! Check the engine oil level before each startup. Only use an approved oil and never operate the engine with insufcient

oil.

WARNING! DO NOT touch spark plug or plug lead whilst the engine is running; severe, potentially fatal, electric shock may

result.

9 For safety instructions relative to the maintenance and use of the petrol engine refer to the engine instruction manual.

9 Ensure that only the correct fuel type and grade is used.

8 DO NOT check ignition system by removing the spark plug or spark plug lead. Use specific tester or contact service agent.

8 DO NOT operate the washer in an enclosed area as the motor exhaust fumes are a health hazard.

8 DO NOT use the washer with flammable, toxic or corrosive liquids.

8 DO NOT leave the washer unattended whilst operating and DO NOT remove the fuel cap whilst the engine is running.

8 DO NOT refuel the engine whilst it is running. Stop the engine and allow it to cool for two minutes before attempting to refuel.

8 DO NOT refuel in a closed or poorly ventilated environment as there is a danger of explosion or fire. Refuel out doors.

8 DO NOT smoke or place the washer near any naked flames whilst re-fuelling.

8 DO NOT operate washer if there is a fuel leak. Move the unit and avoid using until the leak has been fixed and the machine is dry.

Refer to

instructions

Wear ear

protection

Wear eye

protection

PWM2500SP | Issue:3 13/07/17

Original Language Version

© Jack Sealey Limited

WARNING The pump and engine are

shipped without oil.

Therefore both the pump and engine must

be lled with the correct type and quantity

of oil.

See section 3 for Oil specications

Page 2

8 DO NOT start the engine if there are any flammable materials near the exhaust system or in the path of the exhaust gases.

8 DO NOT block the engine ventilation grilles.

9 Ensure engine fuel is stored in an approved container.

9 For long term storage ensure the fuel is drained and that the washer is adequately protected against frost.

8 DO NOT operate the engine with either the silencer or air filter removed.

8 DO NOT touch the engine during or after use. To avoid burns allow it to cool before handling.

WARNING! The warnings referred to in this guide cannot cover all possible conditions and situations that may occur. It must be

understood that common sense and caution are factors which cannot be built into this product, but must be applied by the operator.

NOTE: This appliance is not intended for use by persons (including children) with reduced physical, sensory or mental capabilities or lack

of experience and knowledge, unless they have been given supervision or instruction concerning the use of the appliance by a person

responsible for their safety. Children should be supervised to ensure that they do not play with the appliance.

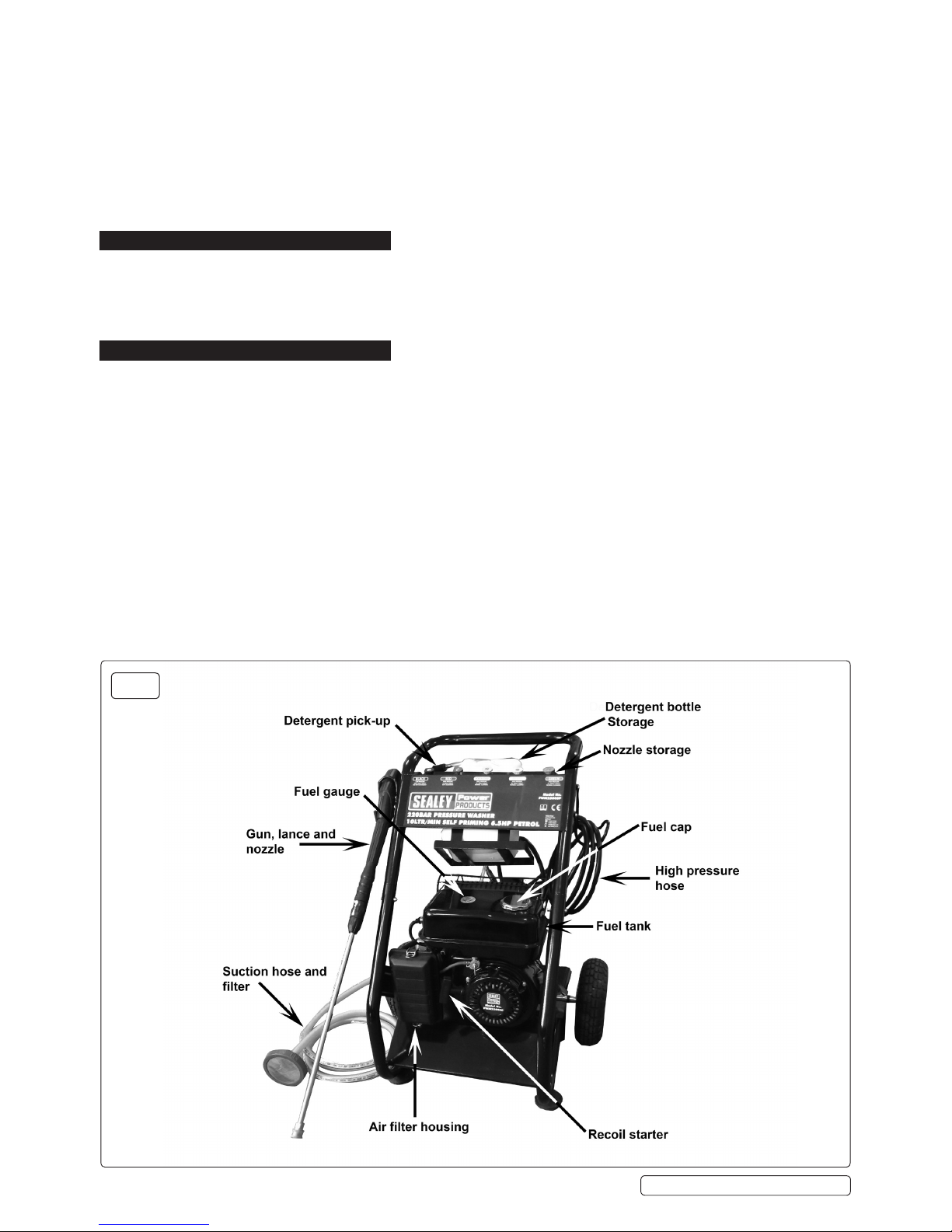

2. INTRODUCTION

Petrol powered pressure washer with recoil starting. Ideal for commercial applications: with 5mtr pressure hose, 1mtr gun and lance and adjustable

nozzle. Self priming pump makes this unit fully portable and can be used where no mains pressure is available. Can draw clean water from water

butts and tanks etc. Low-pressure liquid detergent injection system with provision for detergent bottle stowage. Safety latch on trigger and automatic

low-oil engine shutdown reduce risks of misuse and equipment damage. Unit stands on four legs, two with sucker feet to prevent creep, and tilts back

onto two pneumatic tyred wheels for moving. Supplied with tools and full Instructions.

3. SPECIFICATION

MODEL NO: ........................................................ PWM2500SP

Manifold Pressure: ...........................................175bar/2538psi

Maximum Pressure: .........................................220bar/3190psi

Flow Rate: ................................................................... 600ltr/hr

Hose Length: ..................................................................... 5mtr

Nozzle: ................................... 0°, 15°, 25°, 40° fan & detegent

Maximum Inlet Temperature: .............................................50°C

Engine Type:...........................4 Stroke, Single Cylinder, Petrol

Engine Capacity: ............................................................. 196cc

Engine Power ..................................................................6.5hp

Starting: ...........................................................................Recoil

Fuel Tank: .............................................................................4ltr

Fuel Consumption: ............................................... 2.1 - 2.6ltr/hr

Weight: ..............................................................................42kg

Noise Level: ............................................................... 109dB(A)

Pump Oil ................................................................SAE15W-40

Engine Oil ..............................................................SAE10W-30

PWM2500SP | Issue:3 13/07/17

Original Language Version

© Jack Sealey Limited

fig.1

Page 3

4. ASSEMBLY / PREOPERATION

4.1. ASSEMBLY (See fig.1.)

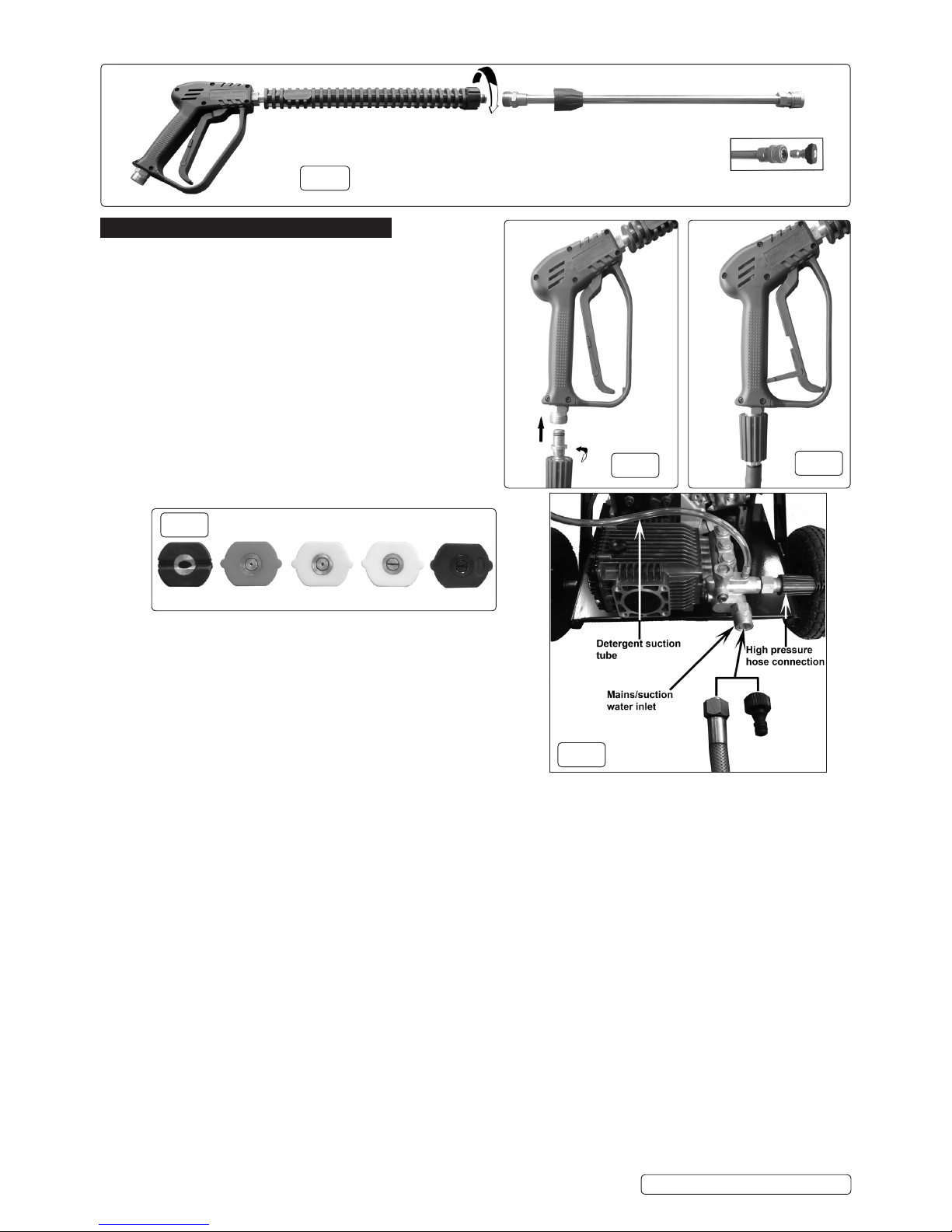

4.1.1. Screw together the two halves of the lance as shown in fig.2.

4.1.2. Select an appropriate nozzle from the nozzle stowage area. Pull

back the spring loaded sleeve at the end of the lance and insert the

nozzle. Let go of the sleeve and check that the nozzle is firmly gripped

in the fitting. The nozzle selection is colour coded and offers the following

options.

BLACK Low pressure wide angle spray for use with detergent.

RED High pressure, 0° degree spray, Very Aggressive. Use

with extreme caution to prevent damage to the surface

being cleaned or injury to persons or animals.

YELLOW High pressure, 15° Spray angle, normal cleaning, provides

a wide coverage and powerful water stream.

WHITE High pressure, 40° Spray angle, normal cleaning and rinsing,

provides a less powerful stream of water and is suitable for

most general cleaning jobs.

GREEN High Pressure, 25° Spray angle, normal cleaning.

4.1.3. To attach the high pressure hose to the water inlet on the gun, push it

into the inlet on the gun until it is fully seated and tighten as shown in

figs.4 & 5.

4.1.4. Attach the other end of the high pressure hose to the pump outlet as

shown in fig.6. Push the end of the hose into the pump outlet until it is

fully seated and then tighten to secure.

Connect either a mains water supply hose or the suction hose to the

pump inlet as shown in fig.6. USE COLD WATER ONLY.

Note: The water supply hose must be reinforced and have an internal

diameter of 13mm (1/2”). The minimum water supply rate must be at least

equal to the washer ow rate.

The suction pipe may require priming if drawing water from a level lower than the pump.

4.2. DETERGENT DELIVERY

4.2.1. Attach the BLACK low pressure nozzle to the end of the lance. Remove the cap from a bottle of detergent and place the bottle in the

detergent holder.

4.2.2. On the top of the pump outlet is a brass suction injection fitting. Push the detergent input pipe onto the fitting (fig.6) and place the

filter on the other end into the container of detergent ensuring that it goes all the way to the bottom. When used with the low pressure

black nozzle detergent will be drawn from the container by suctionic action and will mix automatically with thewater from the pump. Use

Sealey General Purpose Detergent, AK130 (25ltr) or AK131 (5ltr). Traffic Film Remover is also available, AK132 (25ltr) or AK133 (5ltr).

4.3. ENGINE LUBRICATION.

THE PRESSURE WASHER ENGINE IS SHIPPED FROM THE FACTORY WITHOUT OIL. DO NOT ATTEMPT TO START THE ENGINE

BEFORE THE SUMP HAS BEEN FILLED WITH THE CORRECT AMOUNT OF OIL. Refer to the section 8.2.

4.4. FUEL.

4.4.1. Fill the tank with fresh unleaded petrol fuel. Keep fuel level below the fuel filter which sits in the neck of the tank.

4.5. PUMP

4.6. The pump is supplied empty of oil. Fill with 400ml of 15W-40 oil before using the unit. The combined oil filler cap and dipstick is on top of

the pump.

4.7. POSITIONING OF UNIT

4.8. Ideally the unit should be used on level ground. Where this is not possible the unit should not be inclined more than 20° in any one

direction.

4.9. RUNNING IN THE ENGINE

4.9.1. For the first 20 hours of operation the unit should not be placed under heavy load. After the first 20 hours change the oil.

SAFETY FEATURES

fig.2

fig.4

fig.5

fig.6

BLACK RED YELLOW WHITE GREEN

fig.3

PWM2500SP | Issue:3 13/07/17

Original Language Version

© Jack Sealey Limited

Page 4

5. SAFETY FEATURESa

5.1. THERMAL RELIEF VALVE

5.1.1. A thermal relief valve is fitted to protect the machine from overheating if the gun remains closed for an extended period of time or if the

nozzle becomes blocked. To prolong the life of the washer every effort should be made to avoid overheating. It is recommended that if the

unit is not going to be used for two minutes or more it should be switched off.

5.2. TRIGGER LOCK

5.2.1. To prevent accidental starting of the pressure washer the trigger can be locked as shown in fig.4 by hinging out the lever built into the

back of the trigger and pressing it until it locks into position. To release the locking lever flex the trigger handle forwards and flip the lever

out and fold it back into the trigger. The trigger should be locked whenever the washer is not in use.

5.3. LOW OIL SHUTDOWN

5.3.1. The engine on this washer is equipped with a low oil shutdown feature which stops the engine if the oil drops below a specified level.

Should the engine cut out, first check that it is standing on a level surface. If the oil level is still low top it up as described in Section 8.2.

6. OPERATIONo

WARNING! THE PRESSURE WASHER ENGINE IS SHIPPED FROM THE FACTORY WITHOUT OIL.

WARNING! RISK OF FLUID INJECTION. This washer operates at fluid pressures and velocities high enough to penetrate

human and animal flesh. If there is an occurrence of fluid injection seek medical help immediately.

WARNING! Ensure you read, understand and apply Section 1 safety instructions.

WARNING! Dry running can seriously damage the unit.

WARNING! DO NOT leave motor running for more than 2 minutes without operating the trigger, as temperature/pressure

increase may damage sealing system.

6.1. MANUAL STARTING PROCEDURE

6.1.1. Check engine and pump oil level before each use.

6.1.2. Check that the mains water feed hose is laid straight, and

then fully open the water tap. Check to ensure there are no

leaks from hoses or connections.

6.1.3. Release gun trigger safety catch and depress trigger to allow

any air left in the system to escape, hold until there is a steady

flow of water coming out and release the trigger.

6.1.4. Rotate the engine switch clockwise to the ON position. See fig.8.

6.1.5. Fig.7 shows the fuel tap in the OFF position. Push the fuel tap up

to the right to the open position.

6.1.6. If the engine is cold move the choke lever to the left to close

the choke.

6.1.7. Move the throttle lever slightly to the left, fig.7 shows the

throttle in the full throttle position.

6.1.8. Turn the engine switch to the ON position.

Take hold of the recoil starter handle (see fig.1) and pull it

slowly until you feel resistance, then let it return slowly.

6.1.9. Now pull the starting handle hard and fast all the way out. Use

two hands if necessary.

6.1.10. If the engine doesn’t start repeat the process from 6.1.9.

6.1.11. Once started adjust throttle valve to the required setting and

return the choke to the open position when the engine is warm.

6.2. CLEANING

6.2.1. Only apply detergent using the BLACK low pressure nozzle.

6.2.2. Depress the trigger to apply the detergent to the dry surface

which is to be cleaned.

6.2.3. Vertical surfaces should be cleaned from the bottom upwards.

6.2.4. When detergent application is complete remove the syphon tube

from the detergent container and place it in a container of clean

water. Run the washer at low pressure to purge the gun of

detergent.

6.2.5. Leave the detergent to act for 1-2 minutes, but DO NOT allow

the surface to dry.

The detergent should be rinsed off using either the YELLOW

or WHITE high pressure nozzles depending on the spray angle

required. Do not use the RED nozzle as the aggressive

spray action may erode the surface being cleaned. Always

lock the gun trigger before changing nozzles.

5.2.6. Hold the gun firmly with both hands and commence washing

with high pressure clean water. When rinsing work from the

top to the bottom to avoid streaks.

Note: Care should be taken when selecting the nozzle for the job in hand. The distance from the nozzle to the surface being cleaned

will depend on the condition of that surface. Always start further away and slowly move closer until the level of cleaning required is

achieved.

6.3. SHUT DOWN PROCEDURE

6.3.1. When cleaning has nished and the unit is no longer required allow the engine to run unloaded for 2 minutes before shutting down.

6.3.2. Stop the engine by pushing the throttle lever fully to the right. (See g.7) and turn the engine switch to the OFF position.

6.3.3. Turn off the fuel tap. (See g.7)

6.3.4. Turn off the mains water supply.

fig.7

fig.8

Engine ON / OFF Switch

PWM2500SP | Issue:3 13/07/17

Original Language Version

© Jack Sealey Limited

Page 5

6.3.5. Discharge residual pressure from the washer by pressing the trigger until no more water comes out of the nozzle.

6.3.6. Engage the gun trigger safety catch.

6.3.7. In an emergency turn the engine switch to the OFF position.

CAUTION!

a) Avoid sudden bursts of water as this will cause the water pressure to drop and put extreme pressure on the hoses and

connections.

b) If another person is using water from the same supply as the washer, the water pressure will drop and the washer

will not operate correctly. Switch the engine off immediately and wait until the pressure is restored.

5.4 USING SUCTION HOSE

6.3.8. Connect the suction hose to the pump inlet (g.6).

6.3.9. Put the inlet lter into water supply.

6.3.10. Start the engine and operate as normal.

6.3.11. The lter must stay submerged completely.

6.3.12. The pump will only self-prime to maximum height between pump and surface of supply (suction head) of 1mtr. Above this height, the

pump will not achieve suction.

6.3.13. In case of difculty in priming the pump, turn engine off and remove the high pressure hose. With suction lter immersed, restart the

engine and run until water emerges from the pump outet; stop the engine, reconnect the high pressure hose and restart.

7. MAINTENANCE - WASHER

Maintenance should only be performed with the engine turned off and the unit disconnected from the mains water supply.

7.1. CLEANING THE NOZZLES

7.1.1. Pull back the brass sleeve on the end of the lance and pull out the nozzle. Clean the nozzle with wire provided (fig 9). If this does not

improve the flow from the nozzle it should be replaced.

7.2. Check and clean the water inlet filter every 50 operating hours. The filter is moulded into a rubber washer. Unscrew the brass connector

from the black fitting on the water inlet on the pump. Push the black fitting backwards which will eject the filter/washer and then clean the

filter washer. If the filter is damaged in any way it should be replaced.

7.3. Check and clean the detergent filter at the end of the detergent input tube on a regular basis.

7.4. WINTER STORAGE

7.4.1. Fill the pump with an antifreeze mixture before storing in a frost free, safe, dry area for the winter. Introduce the antifreeze by the

following method.

7.4.2. Shut off the water supply and disconnect the supply hose. Relieve pressure within the pump by squeezing the gun trigger. Remove the

high pressure hose and let all water drain from it. Hold gun/lance with nozzle downwards and pull trigger until all water has drained out.

7.4.3. Connect a short length of garden hose to the water inlet and using a funnel pour an antifreeze mixture into it.

7.4.4. Pull the recoil starter several times to circulate the antifreeze through the pump. Continue to add antifreeze and pull the recoil until

antifreeze is expelled from the pump.

8. MAINTENANCE - ENGINE

8.1. Change engine oil after the first 8 hours of operation. Thereafter, change oil monthly or every 50 hours of operation.

Change oil more often if engine is operated under heavy load, or in high ambient air temperatures. During normal operation, partially

burned fuel, small particles of metal from the cylinder walls, pistons, bearings and combustion deposits will gradually contaminate the

oil. If the oil is not changed regularly, these foreign particles can cause increased friction and a grinding action which shortens the life of

the engine. Fresh oil also assists in cooling. Old oil gradually becomes thick and loses its cooling ability as well as its lubricating qualities.

8.2. CHECKING THE OIL LEVEL

8.2.1. Ensure the unit is on a level surface.

8.2.2. Unscrew the dipstick and wipe it clean of oil. Note that the

maximum oil level should be just below the opening of the filler

neck.

8.2.3. Check the oil level by seating the dipstick into the hole without

screwing it in. See fig.8 above. If there is no oil on the dipstick

when it is removed the level is too low and should be topped

up immediately with an SAE10W-30 oil.

8.2.4. Top up oil if necessary and recheck level.

8.2.5. Screw dipstick fully home to seal oil fill hole.

Note: The engine is fitted with a low oil sensor which will

automatically shut the engine down in a low oil situation. The

sensor may also operate if the unit is not on a level surface.

8.3. ENGINE STORAGE

8.3.1. If the unit is not to be used for more than one month the following procedure should be followed.

8.3.2. Top-up engine oil to maximum.

8.3.3. Drain petrol from the fuel tank, fuel line, fuel tap and carburettor.

8.3.4. Pour one teaspoon of engine oil through the spark plug hole, pull the recoil starter several times and replace the spark plug. Then

pull the starter slowly until an increase in pressure is felt indicating that the piston has commenced its compression stroke and leave it in this

position. This closes both the intake and exhaust valves and prevents the inside of the cylinder from rusting.

7.3.4. Cover the unit and store it in a clean dry place that is well ventilated and away from open flame or sparks.

fig.9

fig.10

PWM2500SP | Issue:3 13/07/17

Original Language Version

© Jack Sealey Limited

Page 6

8.4. AIR CLEANER.

8.4.1. The air cleaner is situated below the fuel tank (see fig.2). To access the air cleaner elements, unclip the over-centre clips at the top and

bottom and remove the black cover to reveal the foam pads as shown in fig.11.

8.4.2. Remove the foam pads from the air cleaner housing.

8.4.3. Wash the foam pads with a household detergent or a high flash-point solvent and squeeze dry.

8.4.4. Refit the two foam pads (coarse pad outermost) into the location and bed down.

8.4.5. Replace air filter casing lid and secure with both over-centre clips.

WARNING! Petrol is extremely ammable and potentially explosive. Do not perform maintenance on petrol associated components

where there is any source of ignition present such as cigarettes, sparks, naked ame or hot surfaces.

8.5. MAINTENANCE

Before each use.

Check engine oil level.

Inspect the unit for evidence of oil and fuel leaks.

After the first month or 20 hours only.

Change the engine oil.

Every 50 hours.

Change the engine oil.

Every 6 months or 100 hours.

Change the engine oil.

Inspect and clean air filter.

Clean the deposit cup.

Clean spark plug and check gap.

Every 300 hours.

Replace air cleaner element.

Check valve clearances.

Check idling speed.

Clean spark plug and check gap.

Clean fuel tank fuel filter

fig.11

fig.12

PWM2500SP | Issue:3 13/07/17

Original Language Version

© Jack Sealey Limited

Page 7

PROBLEM POSSIBLE CAUSES REMEDY

Engine will not start Low oil sensor has shut down engine Top up oil level

Engine Switch not in the ON position Turn switch ON

Pressure build up in pump Operate trigger

Engine is overloaded Nozzle partially blocked Clean nozzle

Excessive pressure build up Return to Sealey stockist to have reux valve adjusted

Engine running, but pump not

building maximum pressure or

has irregular pressure

Mains water turned off or insufcient supply Turn on mains water or increase supply

Unit has been stored in freezing temperatures Thaw out completely including hose, gun and wand

Water inlet lter clogged Clean out lter

Kink in water supply hose Straighten out hose

Lance nozzle worn or damaged Replace nozzle

Air in pump Refer to section 5.1 - 5.1.3 and bleed air out of system

No intake of detergent Injection tube not properly attached to unit Push tube rmly on to suction nozzle

Tube cracked or split Replace tubing

High pressure nozzle tted Fit low pressure nozzle (BLACK)

Suction nozzle blocked Clean nozzle

Trigger will not move Trigger lock engaged Release trigger lock

Noisy operation Worn bearings Return to Sealey stockist for bearing replacement

Tappet clearances excessive Return to Sealey stockist for servicing.

Cavitation in pump Check inlet hose for correct size or leaks

Rough / pulsating operation

with pressure drop

Inlet restriction Check inlet hose for correct size, blockages or leaks

Cavitation in pump Check inlet hose for correct size or leaks

Engine running hot Wrong grade of oil Use recommended oil

Oil too high / low Adjust oil level to recommended level

PWM2500SP | Issue:3 13/07/17

Original Language Version

© Jack Sealey Limited

Sealey Group, Kempson Way, Suffolk Business Park, Bury St Edmunds, Suffolk. IP32 7AR

01284 757500 01284 703534 sales@sealey.co.uk www.sealey.co.uk

ENVIRONMENT PROTECTION

Recycle unwanted materials instead of disposing of them as waste. All tools, accessories and packaging should be sorted, taken to

a recycling centre and disposed of in a manner which is compatible with the environment. When the product becomes completely

unserviceable and requires disposal, drain any fluids (if applicable) into approved containers and dispose of the product and fluids

according to local regulations.

WEEE REGULATIONS

Dispose of this product at the end of its working life in compliance with the EU Directive on Waste Electrical and Electronic Equipment

(WEEE). When the product is no longer required, it must be disposed of in an environmentally protective way. Contact your local solid

waste authority for recycling information.

Note: It is our policy to continually improve products and as such we reserve the right to alter data, specifications and component parts without prior

notice.

Important: No Liability is accepted for incorrect use of this product.

Warranty: Guarantee is 12 months from purchase date, proof of which is required for any claim.

Parts support is available for this product. To obtain a parts listing and/or diagram, please log on to

www.sealey.co.uk, email sales@sealey.co.uk or telephone 01284 757500

9. TROUBLESHOOTINGr

Loading...

Loading...