Page 1

INSTRUCTIONS FOR:

WELDING HELMET SOLAR POWERED SHADE 9-13

MODEL Nos: PWH699G, PWH699R, PWH699B

Thank you for purchasing a Sealey Power Product. Manufactured to a high standard this product will,

if used according to these instructions and properly maintained, give you years of trouble free performance.

IMPORTANT: PLEASE READ THESE INSTRUCTIONS CAREFULLY. NOTE THE SAFE OPERATIONAL

REQUIREMENTS, WARNINGS AND CAUTIONS. USE THIS PRODUCT CORRECTLY AND WITH CARE FOR THE

PURPOSE FOR WHICH IT IS INTENDED. FAILURE TO DO SO MAY CAUSE DAMAGE OR PERSONAL INJURY

AND WILL INVALIDATE THE WARRANTY. PLEASE KEEP INSTRUCTIONS SAFE FOR FUTURE USE.

1. SAFETY INSTRUCTIONS

WARNING! THIS HELMET IS NOT SUITABLE FOR USE WITH LASER OR GAS WELDING/CUTTING.

3 Ensure all workshop safety rules, regulations and conditions are complied with when using welding equipment. The helmet

will not offer protection against misuse of workshop tools, equipment, or accessories.

3 Maintain the helmet in good condition and protect cartridge from liquid and dirt contact. Regularly replace the protective lens

and replace any damaged or worn parts. Use genuine parts only. Unauthorised parts may be dangerous and will invalidate

the warranty.

3 Whilst the front cover lense is impact resistant it can break in extraordinary circumstances. Always wear CE approved

safety glasses when using this helmet to provide additional protection against flying particles, splash, spray and

spatter.

3 Ensure the front cover lens is securely in place before use.

3 Fit the helmet and adjust the head band so the helmet will sit as low and near to your face as possible,

3 Use helmet only in temperatures ranging from -10°C to 55°C (14°F to 131°F).

3 Store helmet only in temperatures ranging from -20°C to 70°C (-4°F to 158°F).

3 Remove ill fitting clothing, remove ties, watches, rings and other loose jewellery.

3 Maintain correct balance and footing.

3 Ensure the floor is clear from obstructions, not slippery and wear non-slip shoes.

3 Keep children and unauthorised persons away from the working area.

WARNING! The helmet will only protect the eyes and face from radiation and sparks. It will not protect against explosive

devices or corrosive liquids.

7 DO NOT use helmet for any other purpose, other than face protection when grinding.

7 DO NOT use helmet unless you have been instructed in its use by a qualified person.

7 DO NOT open or tamper with the shade cartridge.

7 DO NOT get the helmet wet or use in damp or wet locations.

7 DO NOT leave work place with helmet in lowered position, as bright light source may darken cartridge unexpectedly.

7 DO NOT place the helmet on a hot surface.

7 DO NOT use helmet without front cover lens fitted. To do so will invalidate your warranty.

3 Clean helmet (see section 5.4) and store the helmet in a safe, dry, childproof location.

WARNING! The materials of the helmet may, when coming into contact with the wearers skin, cause an allergic reaction to

susceptible individuals.

WARNING! Before welding always inspect the cartridge filter to ensure that it is not damaged. To test the filter prior to

welding, direct the front of the cartridge filter to a bright light source which will cause the lens to darken. Then using your

hand rapidly cover and uncover the sensor. The filter should lighten momentarily then return to a dark state.

WARNING! DO NOT use the helmet if damaged or you suspect it may be faulty. (Contact your Sealey dealer).

DANGER! DO NOT USE if, at any time, the face plate in the cartridge FAILS to darken

when exposed to a welding spark. Remove cartridge and return to your Sealey dealer for

inspection. Continued use of the product knowing that the auto darkening feature is

NOT FUNCTIONING may DAMAGE YOUR EYES and CAUSE BLINDNESS.

2. INTRODUCTION

High quality lenses with large viewing area

manufactured and tested to BSEN379. Variable

shade from 9-13. Fully automatic switching from light

to dark on striking arc. Fitted with solar power panel no batteries required. PWH699 features infinitely

adjustable sensitivity and delay switches. PWH699

Range has a special grinding feature enabling the

user to grind without having to remove the mask, still

offering a full face protection. All models feature

deluxe contoured helmets approved to BSEN175

which give full neck protection and protects lens from

scratching when helmet is laid down. Comfortable

headband and non-slip quick release ratchet

mechanism. Suitable for MIG and arc welding.

Original Language Version

PWH699 Issue No.1 05/11/09

Page 2

3. SPECIFICATION

PWH699G ................................................Colour Grey

PWH699R .................................................Colour Red

PWH699B ................................................Colour Blue

Shade Active: ........................................9 - 13 Variable

Shade Inactive: ........................................................... 4

Viewing Area: .............................................98 x 47mm

UV/IR Protection: ........ Up to Shade DIN16 at all times

Light/Dark: ........................................................ 0.04ms

Temperature Range: ............................. -10°C to +55°C

Power: ........................................................ Solar Cells

Grinding ..................................................................YES

4. INSTRUCTIONS FOR USE

WARNING! Before using the helmet for welding ensure you

have read and understood the safety instructions in Section 1.

4.1 The helmet comes ready assembled but before it can be

used it must be adjusted to fit the user properly.

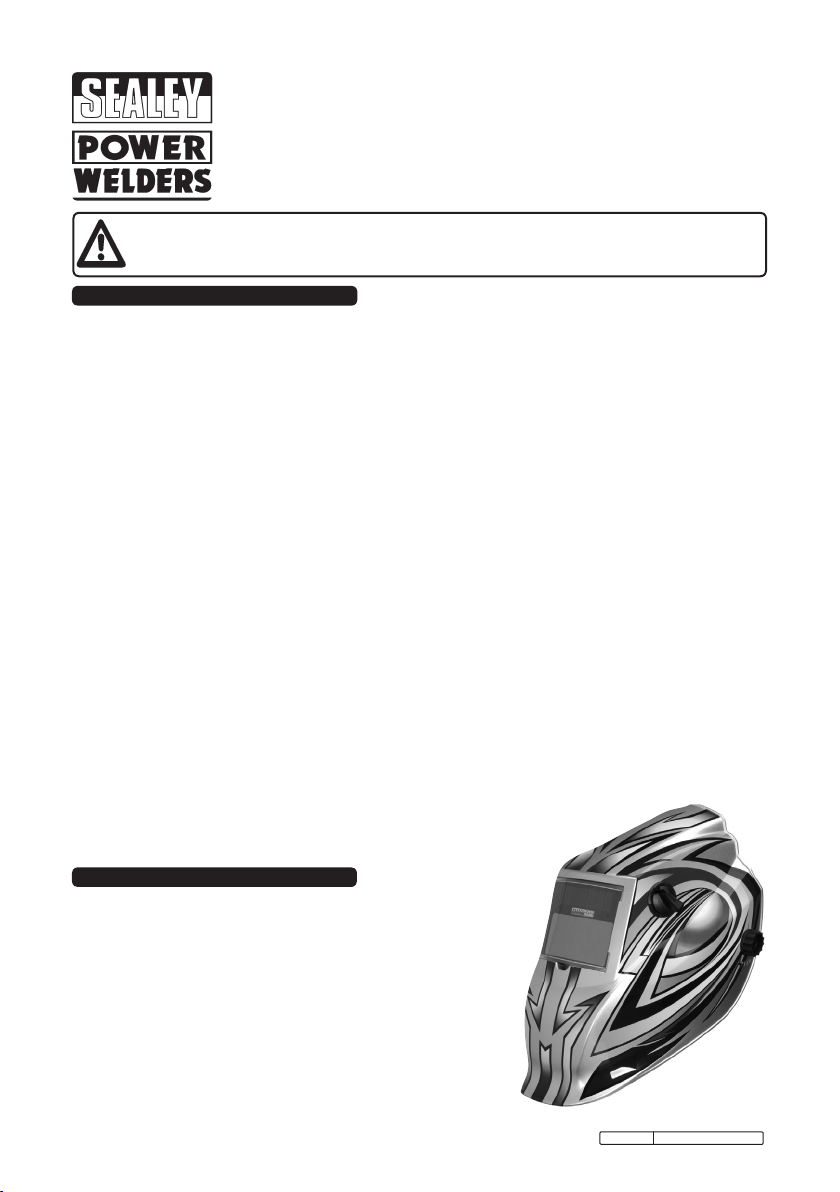

4.2 ADJUSTING THE FIT OF THE HELMET.

The overall circumference of the headband can be made

larger or smaller by pushing in and rotating the knob on the

back of the headband (See adjustment ‘A’ in fig.1). This

can be done whilst wearing the helmet and allows just the

right tension to be set to keep the helmet firmly on the

head without it being too tight.

4.3 If the headband is riding too high or too low on your head

adjust the strap which passes over the top of your head. To

do this release the end of the band by pushing the locking

pip out of the hole in the band. Slide the two portions of the

band to a greater or lesser width as required and push the

locking pip through the nearest hole (See adjustment ‘B’ in

fig.1).

4.4 Test the fit of the headband by lifting up and closing down

the helmet a few times whilst wearing it. If the headband

moves whilst tilting re-adjust it until it is stable.

4.5 ADJUSTING DISTANCE BETWEEN HELMET & FACE.

To adjust the distance between the helmet and your face in

the down position loosen the tilt knobs (D) on either side of

the helmet and slide it nearer to or further from your face.

(See adjustment ‘C’ in fig.1) It is important that your eyes

are each the same distance from the lens otherwise the

darkening effect may appear uneven. Re-tighten the tilt

knobs when adjustment is complete.

4.6 SELECTING DELAY TIME/RESPONSE TIME

The delay time in which it takes the lens to change from

dark to light or vice versa can be varied from 0.1sec to 1

sec, this adjustment is carried out by turning the delay time

knob on the inside of the lens (see fig.3).

4.7 SENSITIVITY

4.7.1 For normal ambient light conditons set the sensitivity knob

to the high setting (fig.3).

4.7.2 For conditions where there is an excess of light, which may

affect the performance of the lens, turn the knob to the low

setting.

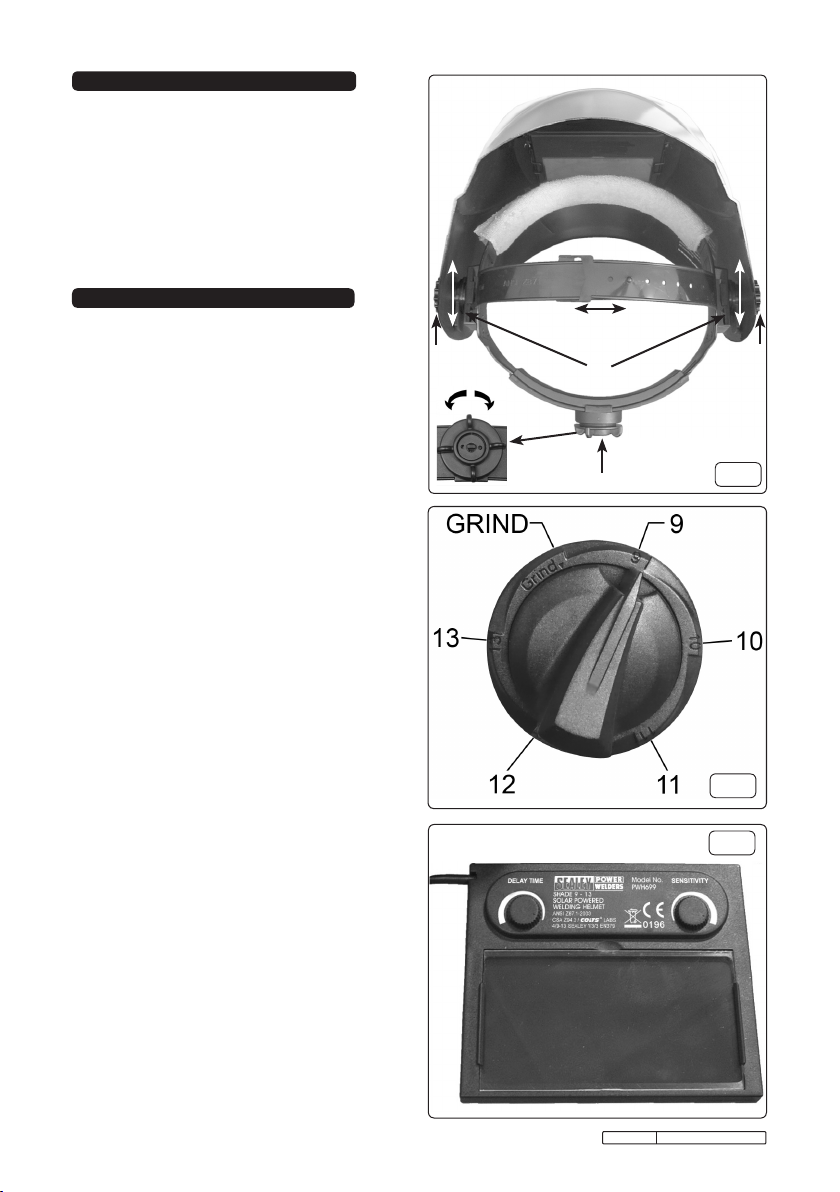

4.8 SELECTING SHADE LEVEL

Refer to the shade guide in Section 7 and adjust the knob

on the side of the helmet to the correct setting (fig.2).

4.9 SELECTING THE GRIND OPTION

When the shade knob is turned to the “grind” position the

shade function is turned off allowing a clear view to grind a

weld with the helmet providing face protection. Ensure that

the shade function is turned back on before welding again.

Original Language Version

B

D

C

A

D

fig.1

fig.2

fig.3

PWH699 Issue No.1 05/11/09

Page 3

5. MAINTENANCE

5.1 REPLACING PROTECTIVE LENS COVERS.

The shade cartridge is fitted with two protective lens covers

to protect the inside and outside from weld splatter. Place

your finger or thumb into the recess on the long edge of the

cover lens frame and flex the frame upwards until it releases

from one edge. (See fig.4-C). Remove the protective film

from the new lens. Hook the lens under the side retaining lip

shown at ‘A’ in fig.4. Press on the other side of the frame to

snap it under the edge shown at ‘B’ in fig.4. Use the same

procedure for the inner protective lens cover.

5.2 CHANGING THE SHADE CARTRIDGE.

Pull off the shade adjustment knob from the side of the

helmet and remove the nut holding the potentiometer. The

cartridge is retained by a wire loop clip as shown in fig.5.

Release the front edge of the clip (fig.6-D) from its retaining

lugs (fig.6-E) and hinge it upwards and out of the way. Lift

the shade cartridge out of its frame.

5.3 FITTING NEW CARTRIDGE.

Take the new shade cartridge and place the cartridge into its

retaining frame inside the helmet. Hinge down the wire loop

clip and ensure that the front edge of the loop is properly

retained under the retaining lugs as shown in fig.5. Insert the

potentiometer through the side of the helmet and secure

with the nut. Refit the knob ensuring that the arrow points to

the min and max settings when turned.

5.4 CLEANING.

Clean helmet by wiping with a soft cloth. Clean cartridge

surfaces regularly. Do not use strong cleaning solutions.

Clean sensors and solar cells with methylated spirit using a

clean cloth and wipe dry with a lint-free cloth.

A

B

C

fig.4

fig.5

6. PROBLEM SOLVING

Problem Cause Solution

Irregular darkening or

dimming.

Shade cartridge does

not darken or ickers.

Poor vision.

Slow response. Operating temperature too low.

Welding helmet slips. Headband adjustments incorrect. Refer to section 4.

The headband may have been unevenly set on the two

sides of the helmet (unequal distances from the eyes to

the shade cartridge).

Readjust the distance of the

shade cartridge.

The sensors are soiled or obstructed. Clean.

Front cover lens oiled or damaged. Clean or replace.

Welding current too low. Adjust weld amps.

Operative lenses and/or shade cartridge soiled. Check, clean or replace.

Insufcient background lighting. Adjust light.

Do not use at temperatures

below -10oC (14oF).

Original Language Version

PWH699 Issue No.1 05/11/09

fig.6

Page 4

7. SHADE GUIDE & MARKINGS

SHADE GUIDE

ARC CURRENT (AMPS)

Welding

Process

SMAW 9 10 11 12 13 14

MIG (Heavy) 10 11 12 13 14

MIG (Light) 10 11 12 13 14 15

TIG/GTAW 9 10 11 12 13 14

MAG/CO2 10 11 12 13 14 15

SAW 10 11 12 13 14 15

PAC 11 12 13

PAW 8 9 10 11 12 13 14 15

SMAW - Shielded Metal Arc Welding

MIG (Heavy)- MIG on Heavy Metals PAW- Plasma Arc Welding PAC- Plasma Arc Cutting

SAW- Shielded Semi-Automatic Arc Welding MAG/CO2- Metal Active Gas

0.5 2.5 10 20 40 80 125 175 225 275 350 450

1 5 15 30 60 100 150 200 250 300 400 500

TIG/GTAW- Gas Tungsten Arc Welding MIG (Light)- MIG on Light Alloys

Meaning of the markings on the filter:

4 9 - 13 SEALEY 1 / 3 / 3 / 379

Light state scale no.

Lightest dark state scale no.

Darkest state scale no.

Manufacturers identification.

Optical class.

Diffusion of light class.

Variation in luminence transmittance class.

Number of the applied standard.

Meaning of the markings on the helmet: EN 175 = Number of the applied standard

CE = CE Mark

Parts support is available for this product. To obtain a parts listing and/or diagram, please log on to

www.sealey.co.uk, email sales@sealey.co.uk or phone 01284 757500.

NOTE: It is our policy to continually improve products and as such we reserve the right to alter data, specifications and component parts without prior notice.

IMPORTANT: No liability is accepted for incorrect use of this product.

WARRANTY: Guarantee is 12 months from purchase date, proof of which will be required for any claim.

INFORMATION: For a copy of our latest catalogue and promotions call us on 01284 757525 and leave your full name and address, including postcode.

Sole UK Distributor, Sealey Group,

Kempson Way, Suffolk Business Park,

Bury St. Edmunds, Suffolk,

IP32 7AR

Original Language Version

01284 757500

01284 703534

www.sealey.co.uk

Web

sales@sealey.co.uk

email

PWH699 Issue No.1 05/11/09

Loading...

Loading...