Sealey PW5000 Instructions Manual

INSTRUCTIONS FOR

PROFESSIONAL PRESSURE WASHER 150BAR

WITH TSS AND NOZZLE SET 230V

MODEL NO: PW5000

Thank you for purchasing a Sealey product. Manufactured to a high standard, this product will, if used according to these instructions,

and properly maintained, give you years of trouble free performance.

IMPORTANT: PLEASE READ THESE INSTRUCTIONS CAREFULLY. NOTE THE SAFE OPERATIONAL REQUIREMENTS, WARNINGS & CAUTIONS. USE

THE PRODUCT CORRECTLY AND WITH CARE FOR THE PURPOSE FOR WHICH IT IS INTENDED. FAILURE TO DO SO MAY CAUSE DAMAGE AND/OR

PERSONAL INJURY AND WILL INVALIDATE THE WARRANTY. KEEP THESE INSTRUCTIONS SAFE FOR FUTURE USE.

1. SAFETY

1.1. ELECTRICAL SAFETY

WARNING! It is the user’s responsibility to check the following:

Check all electrical equipment and appliances to ensure that they are safe before using. Inspect power supply leads, plugs and all

electrical connections for wear and damage. Sealey recommend that an RCD (Residual Current Device) is used with all electrical

products. You may obtain an RCD by contacting your local Sealey stockist.

If the pressure washer is used in the course of business duties, it must be maintained in a safe condition and routinely PAT (Portable

Appliance Test) tested.

Electrical safety information, it is important that the following information is read and understood.

1.1.1. Ensure that the insulation on all cables and on the appliance is safe before connecting it to the power supply.

1.1.2. Regularly inspect power supply cables and plugs for wear or damage and check all connections to ensure that they are secure.

Important: Ensure that the voltage rating on the appliance suits the power supply to be used and that the plug is tted with the correct

fuse - see fuse rating in these instructions.

8 DO NOT pull or carry the appliance by the power cable.

8 DO NOT pull the plug from the socket by the cable.

8 DO NOT use worn or damaged cables, plugs or connectors. Ensure that any faulty item is repaired

or replaced immediately by a qualied electrician.

1.1.3. This product is tted with a BS1363/A 13 Amp 3 pin plug.

If the cable or plug is damaged during use, switch the electricity supply and remove from use.

Ensure that repairs are carried out by a qualied electrician.

Replace a damaged plug with a BS1363/A 13 Amp 3 pin plug. If in doubt contact a qualied electrician.

a) Connect the GREEN/YELLOW earth wire to the earth terminal ‘E’.

b) Connect the BROWN live wire to the live terminal ‘L’.

c) Connect the BLUE neutral wire to the neutral terminal ‘N’.

Ensure that the cable outer sheath extends inside the cable restraint and that the restraint is tight.

Sealey recommend that repairs are carried out by a qualied electrician.

1.2. GENERAL SAFETY

WARNING! Water and electricity are dangerous partners. Be extremely cautious and ALWAYS be aware that this device uses an

electric motor. Always plug into a RCD (See electrical safety above). Unplug from mains before changing accessories or servicing.

WARNING! DO NOT use the washer if any part of the unit, gun, nozzle, detergent tank, hose or cables is damaged. Replace or repair

using genuine parts only. Unauthorised parts may be dangerous and will invalidate your warranty. Always check connections

are correctly secured and not cracked or damaged in any way before using the machine.

8 WARNING! Use washer on a flat, level surface, in an upright position. Failure to do so will invalidate your warranty.

NEVER lay the washer down during use.

9 Ensure you comply with all local water supply regulations. Power washers may only be connected to mains water supply if a check valve

is installed in the supply hose, or at the tap outlet.

9 The supply hose must be reinforced, and have an internal diameter of 1/2” (13mm). The water supply must be at least equal to the

cleaner capacity. The water temperature must NOT exceed 122°F (60°C). The water supply pressure must NOT exceed 6 bar (90psi).

99 99 Always be aware of the hazards that may occur during use. Study all applications and limitations of the washer before use.

99 99 Use where air can freely circulate around the washer to avoid the machine overheating.

9 Keep the washer in good condition. Use an authorised service agent to service the unit.

99 99 Wear adequate protective clothing, goggles and anti-slip rubber soled footwear.

9 Position the washer as near to the water supply as possible.

9 99 WARNING! Ensure all persons and animals keep at a minimum distance of 15mtr from the washer when in use.

9 99 WARNING! The pressure washer must only be used with clean water. Unfiltered water or corrosive chemicals must not be used as

these will damage the cleaner.

9 Ensure the nozzle is aimed correctly at the work surface before switching the machine on.

9 Before activating the trigger, grip the gun firmly to counteract the recoil from the high pressure water jet.

9 99 WARNING! Avoid sudden bursts of water as these will cause water pressure to drop and put extreme pressure on hoses and

connectors.

9 If, during operation, power failure occurs turn the electricity and water off for safety reasons.

PW5000 | Issue:2(L) 11/04/17

Original Language Version

© Jack Sealey Limited

Refer to

instruction

manual

Wear eye

protection

Wear ear

protection

Wear safety

footwear

Wear protective

clothing

Recommended fuse rating

13 Amp

9 99 WARNING! The high pressure jet will cause loose particles to be propelled at high speed, which may cause serious injury.

9 99 WARNING! DO NOT operate the machine without a water supply. Dry running can seriously damage the unit.

9 99 WARNING! DO NOT leave the washer switched on for more than 15 minutes without operating the trigger.

98 99 DO NOT obstruct ventilation grilles during operation.

98 99 DO NOT use the washer with flammable or toxic liquids or any other product. Use only recommended detergent. Unapproved

detergents may corrode the machine cover and accessories.

98 99 DO NOT jam the trigger in the operating position.

98 99 DO NOT adjust any internal control valves, as they have been factory set.

98 99 DO NOT connect other appliances to the machine inlet or outlet.

98 99 DO NOT use hoses and fittings other than those designed for use with this machine.

8 DO NOT move the unit by pulling the hoses or electrical cables. Use the handle and transport by means of the wheels.

8 DO NOT touch plug with wet hands. To avoid the risk of electrocution keep all connections dry and off the ground.

8 DO NOT direct jet against yourself, other persons, animals, electrical equipment or the machine itself.

8 DO NOT use washer if you are tired or under the influence of alcohol, drugs or intoxicating medication.

8 DO NOT allow children or untrained persons to operate the washer.

9 99 WARNING! Discharge residual pressure before disconnecting the washer hose. Pressure left in unit may cause injury.

9 After use, disconnect washer from electrical mains and water supply and store in a safe, dry, childproof area.

99 99 Protect from freezing conditions during winter.

NOTE: Pressure washer shall not be used by children. Children should be supervised to ensure that they do not play with the machine.

The machine can be used by people with reduced physical, sensory or mental capabilities or lack of experience and knowledge if they

have been given supervision or instruction concerning the use of the machine in a safe way and understand the hazards involved.

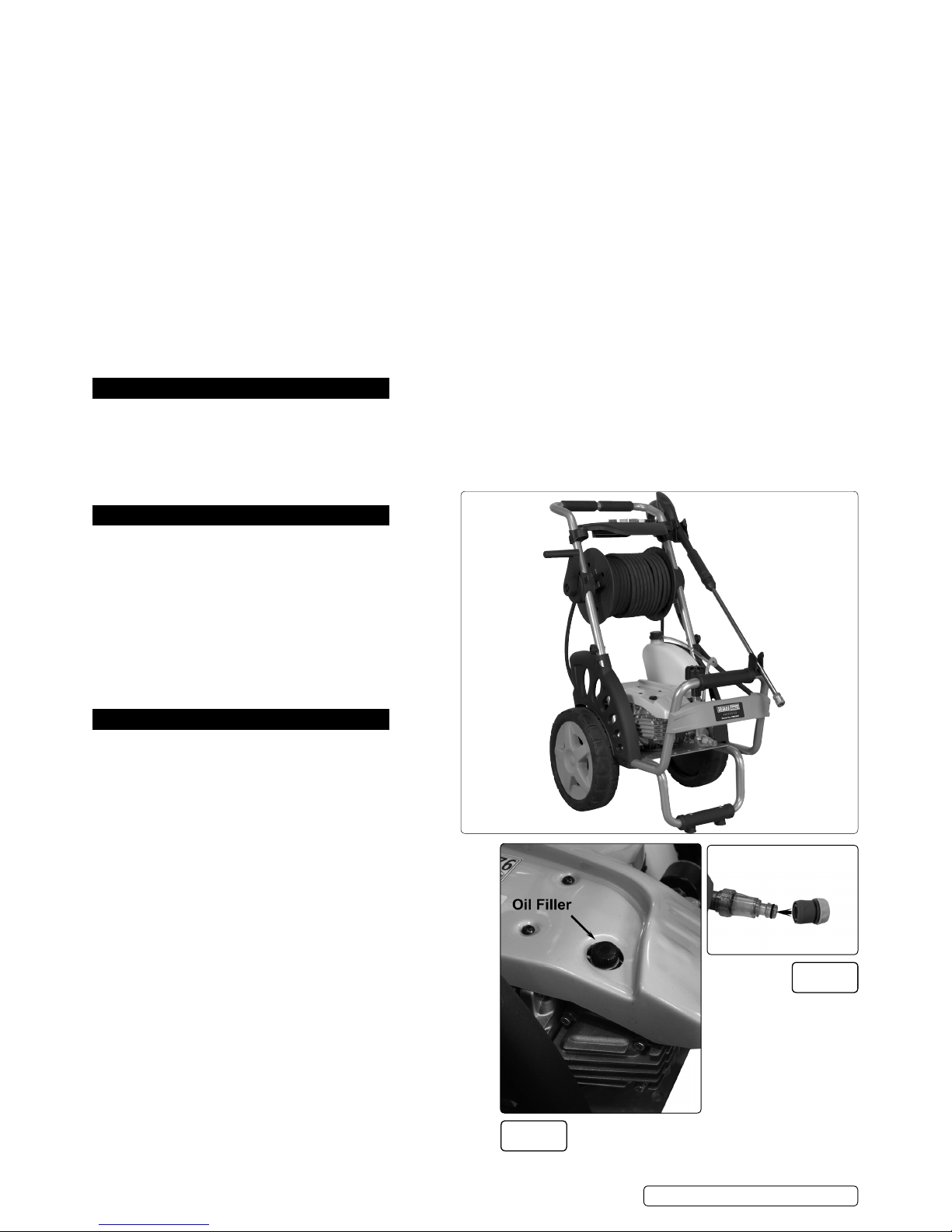

2. i INTRODUCTION

Professional unit, designed and manufactured in Italy. Ideal for a wide variety of applications including commercial and agricultural use. Fitted

with a powerful 2500W induction motor and brass pump head and ttings with ceramic pistons. Capable of pumping up to 8.3 litres of water per

minute with a maximum pressure of 150bar. The PW5000 features Automatic Total Stop System (TSS) technology which switches the motor

on and off when the lance trigger is operated, prolonging motor life. Fitted with 10mtr hose reel, built-in pressure gauge, adjustable pressure

controls and 3ltr detergent tank. Supplied with 5 interchangeable nozzle attachments. Manufactured with a lightweight, durable aluminium frame

and large heavy-duty wheels.

3. SPECIFICATION

Model No: ................................................................ PW5000

Maximum Pressure: ..................................... 150bar(2200psi)

Water ow: ................................................................498ltr/hr

Motor power: ...............................................................2500W

Supply: ....................................................................230V-13A

Total stop system: ............................................................ Yes

Hose length: .................................................................. 10mtr

Weight: ........................................................................ 33.2kg

Wash nozzles: .. pencil jet, fan jet, 15°, 25°, 40°, low pressure

Noise power: ..................................................................92dB

Noise pressure: .........................................................83.96dB

4. ASSEMBLY

4.1. Attach handle/reel assembly to the machine base by

sliding the handle tubes over tubular stubs protruding

from base and securing by means of M6 x 40 bolts

(x2) and securing knobs.

4.2. Attach winding handle to the reel by 4mm hex bolt.

WARNING! Ensure that the transit plug tted to the

oil ller is replaced by the vented dipstick supplied.

(See g.1)

4.3. Connecting the water supply.

4.3.1. Use a reinforced hose pipe with an internal diameter of 1/2” and

connect to the mains water supply. Before attaching the hose to

the pressure washer flush the hose through with some clean water

to remove any foreign matter from within the hose.

4.3.2. Connect female quick connection hose fitting to the clear inlet filter

on the front of the machine (fig.2).

4.3.3. Push male leader hose connection (fig.3.1.) into the pump outlet

connector (fig.3.2) and secure by tightening the collar (fig.3.3). Push

the nozzle into the gun as shown in fig.4 (1 and 2) and screw the

threaded male lance connector into the gun, again ensuring that

the connection is tight.

4.4. Connecting to mains electrical supply.

9 99 WARNING! Ensure the On/Off switch (fig.5) is in the ‘Off’ position.

Using an RCD plugged into a 13A mains socket, DO NOT turn the

power on. DO NOT touch the plug with wet hands

Fig.1

Fig.2

PW5000 | Issue:2(L) 11/04/17

Original Language Version

© Jack Sealey Limited

Loading...

Loading...