HYDRAULIC LOG SPLITTER 8TONNE 575MM

I

MPORTANT:

PLEASE READ THESE INSTRUCTIONS CAREFULLY. NOTE THE SAFE OPERATIONAL REQUIREMENTS, WARNINGS & CAUTIONS. USE

THE PRODUCT CORRECTLY AND WITH CARE FOR THE PURPOSE FOR WHICH IT IS INTENDED. FAILURE TO DO SO MAY CAUSE DAMAGE AND/OR

PERSONAL INJURY AND WILL INVALIDATE THE WARRANTY. KEEP THESE INSTRUCTIONS SAFE FOR FUTURE USE.

CAPACITY VERTICAL TYPE

MODEL NO: LS575VH.V2

Thank you for purchasing a Sealey product. Manufactured to a high standard, this product will, if used according to these

instructions, and properly maintained, give you years of trouble free performance.

Refer to

instructions

Wear eye

protection

Wear protective

gloves

Wear safety

footwear

1. SAFETY

1.1. GENERAL SAFETY

IMPORTANT! Ensure you read, understand and apply the safety instructions before use.

9 Ensure the log splitter is in sound condition and good working order. Take action for immediate repair or replacement of damaged parts.

9 Locate the log splitter in a suitable work area, keep the area clean and tidy, free from unrelated materials and ensure there is adequate

lighting.

8 DO NOT make any modifications to the log splitter.

8 DO NOT use the log splitter for a task it is not designed to perform. NEVER attempt to split a log shorter than minimum specification.

WARNING! DO NOT force the log splitter to work beyond its specified capacity.

9 Ensure that there are no nails, screws or other foreign objects in logs to be split.

WARNING! The warnings, cautions and instructions referred to in this manual cannot cover all possible conditions and situations that

may occur. It must be understood that common sense and caution are factors which cannot be built intothis product, but must be applied

by the operator.

9 When not in use, store the log splitter, with the hydraulic unit fully lowered, in a safe, dry, childproof location.

1.2. SAFETY OF OTHERS

▲ DANGER! The log splitter must always be operated by one person only. Other people must keep a safe distance from the log splitter

especially when it is in operation.

8 DO NOT allow another person to help you with a jammed log.

9 Keep children and unauthorised persons away from the work area.

9 Store the log splitter in a safe area away from children and other people not qualified to use the log splitter.

1.3. OPERATOR SAFETY

9 Remove ill fitting clothing. Remove ties, watches, rings and other loose jewellery, and contain long hair.

9 Always wear safety goggles. Everyday spectacles are not sufficient protection.

9 Maintain correct balance and footing, DO NOT over-reach. Ensure the floor is not slippery and wear non-slip, protective footwear.

9 Ensure unit is on level ground preferably concrete.

IMPORTANT! The ends of logs should be cut square and also if possible logs should be cut to a uniform length within the

specifications.

8 DO NOT allow untrained persons to operate the log splitter.

8 DO NOT operate the log splitter with the guards or guides removed.

8 DO NOT operate the log splitter when you are tired or under the influence of alcohol, drugs

or intoxicating medication.

8 DO NOT leave unattended while loaded with a log. Always lower hydraulic pump at it’s

lowest position to minimise corrosion.

9 Keep hands away from moving parts of the log splitter.

9 Keep hands away from splits and cracks which open in logs. They may close suddenly

which could cause serious personal injury. For this reason DO NOT attempt to remove

jammed logs by hand. A jammed log is a log which is only partially split and continues to grip

the splitting wedge. Lower the hydraulic pump and release the log by hitting with a heavy

hammer.

1.4. WORKSHOP/ENVIRONMENTAL SAFETY

9 Locate the log splitter on dry, level and solid ground in a suitable work area with adequate

lighting.

9 Keep the area clean and tidy and free from unrelated materials. DO NOT leave tools, logs or

other items lying around where they could become a tripping hazard.

8 DO NOT operate the log splitter in wet or damp areas or expose it to rain.

8 DO NOT operate the log splitter in areas where fumes from paint, solvents, or flammable

liquids pose a potential hazard.

1.5. SAFETY AND MAINTENANCE

9 Keep the log splitter clean for best and safest performance.

9 Maintain the log splitter in a good condition (use an authorised service agent).

9 Use a qualified person to lubricate and maintain the log splitter.

8 DO NOT top up hydraulic unit using brake fluid. Use hydraulic jack oil only.

8 DO NOT operate the log splitter if damaged.

9 Replace or repair damaged parts. Use genuine parts only. Unauthorised parts may be dangerous and will invalidate the warranty.

© Jack Sealey Limited

Original Language Version

LS575VH.V2 | Issue 3 (H,F,1,4,5,6) 4/2/2019

2. INTRODUCTION

Safe and easy way to split logs, offering continuous sizing and up to 8tonne of pressure. Seven tier wedge system allows workpiece to be as

near to wedge as possible, therefore minimising splitting time. Operated by foot pump requiring a maximum of 15 strokes to capacity (without

load) for easy and fast splitting.

3. SPECIFICATION

Model No: ..................................... LS575VH.V2

Maximum Load Pressure: .............................. 8tonne

Maximum Log Diameter: ...............................160mm

Overall Size (W x D x H): ...................285 x 540 x 1040mm

Tier Log Lengths: ............300, 350, 400, 450, 500, 550, 575mm

Vertical Ram Travel: ..................................158mm

Nett Weight: ...........................................30kg

4. ASSEMBLY

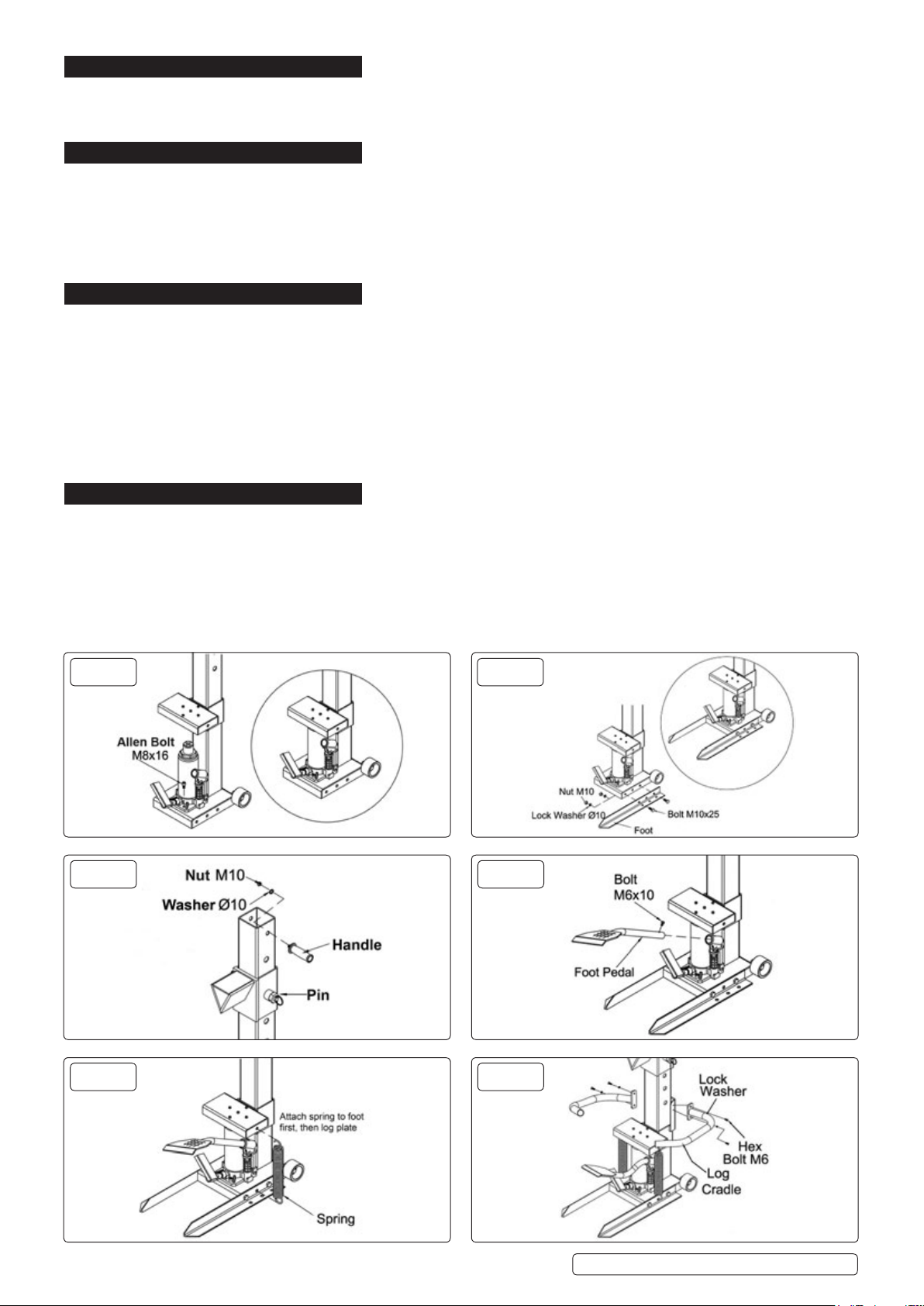

4.1. Attach the hydraulic pump to the base by using two M8 allen bolts (fig.1).

4.2. Slide the log support over the main post and down onto the hydraulic pump unit, if it isn’t already assembled (fig.1).

4.3. Attach the two feet to the bottom of the main post, Secure each foot using two M10 bolts, two lock washers Ø10 and two M10 nuts.

Bolt through the two outer holes (fig.2).

4.4. Slide the wedge assembly over the main post, if not already assembled, locate the pins into one of the sets of locating holes (fig.3).

4.5. Attach the two handles to the top of the log splitter, one handle per side. Secure each handle using a lock washer Ø10 and a M10 nut

(fig.3).

4.6. Attach foot pedal by inserting into the hydraulic pump socket. Tighten bolt to secure the foot pedal in place (fig.4).

4.7. Attach the two springs into the centre holes of the feet first. Then attach the other ends of the springs to the log support. (fig.5).

4.8. Attach the two log cradle arms to the splitter using four M6 bolts and four lock washers (fig.6).

5. OPERATION

5.1. TRANSPORTATION

5.1.1. Carefully tip the log splitter backwards onto it’s wheels, using the handles to transport it short distances.

5.2. WORK SITE PREPARATION

5.2.1. Plan the work site beforehand to ensure a safe working environment and to save effort by positioning the logs so they can easily be

reached. Ensure that the log splitter is positioned on firm and level ground. Locate site so that the split wood can be stacked or loaded

directly into a suitable vehicle or trailer.

5.2.2. When cutting up wood for splitting, bear in mind the capacity of the splitter, which is between 300mm and 575mm, decide which length

is most appropriate and cut the wood slightly shorter than the set length.

g.1 g.2

g.3 g.4

g.5 g.6

© Jack Sealey Limited

Original Language Version

LS575VH.V2 | Issue 3 (H,F,1,4,5,6) 4/2/2019

WARNING! Ensure you read, understand and apply the safety instructions in Section 1

before use.

WARNING! This system has been designed to prevent the operator from handling the log

during the splitting process. For safety reasons the operator must not ask a second person

to place or handle the log. The system is designed to be operated by one person only.

WARNING! Always split a log along its grain. Never attempt to split a log laid across the

machine as this could be dangerous for the operator and could seriously damage the splitter .

WARNING! Never attempt to split a log if it is sitting at an angle.

▲ DANGER! Never attempt to split a log sitting on another log, split only single pieces at a time.

5.3. Pump the foot pedal of the hydraulic pump to raise the splitter log support to a suitable

working height.

5.4. Place a log securely on the log support.

5.5. When logs of approximately the same length are to be split, the wedge can be set to avoid

having to pump the ram to operate through it’s full stroke every time. Pull both of the

wedge release pins out of the locating holes in the post (fig.7), and adjust the wedge as

near to the log as possible and replace the wedge release pins ensuring that they have

both located into a hole - Make sure the wedge release pins are firmly seated in the post

holes before continuing - the wedge may have to be raised slightly to do this.

5.6. Ensure the log is stable and keeping hands out of the way of the wedge, pump the foot

pedal (fig.7) to raise the log up tight against the wedge, continue with even strokes of the

foot pedal until the log is split.

5.7. Remove or stack the logs as you work and regularly clear the area of any accumulated

wood chips and other debris to keep the work area safe.

5.8. To lower the splitter log support, release the pressure from the hydraulic pump by pushing on the release lever (fig.7), the springs will

force the log support to lower.

5.9. Wipe down the log splitter to remove tree sap or dirt after each use and tidy the work area ready for the next work session.

5.10. When the splitter is not in use, thoroughly clean it and store it in a dry location with the hydraulic pump at it’s lowest position to minimise

corrosion.

g.7

6. MAINTENANCE

6.1. HYDRAULIC PUMP

6.1.1. To add oil to the hydraulic pump:

6.1.1.1. Remove the two springs from the log support and undo the two allen bolts, remove the hydraulic unit from the base unit.

6.1.1.2. Position the hydraulic unit vertically and remove the round rubber oil plug on the back of the unit’s housing. Using a piece of wire or

similar, dip into the oil to check it’s level. It should be immediately below the plug hole (¾ full). Add hydraulic jack oil if required (see

6.1.1.4. for specification).

6.1.1.3. Replace the rubber oil plug and re-assemble the log splitter.

6.1.1.4. After one year the hydraulic oil should be replaced in order to extend the life of the unit. Use hydraulic jack oil only.

IMPORTANT: Only fully qualified personnel should attempt hydraulic maintenance or repair.

NOTE: Use Sealey quality hydraulic jack oil, Model No.s HJO500MLS / HJO5LS to top up or replace the hydraulic fluid.

6.1.1.5. When draining the oil make sure that no dirt is allowed to enter the hydraulic unit.

6.1.2. Periodically check the hydraulic unit’s piston and ram for signs of corrosion. Clean exposed areas with a clean oiled cloth.

6.2. HYDRAULIC PUMP WILL NOT LIFT

6.2.1. The oil level may be low. Check oil level as described in section 6.1.1.2. and top up if necessary.

6.2.2. The pump may have air trapped in the system. To eliminate trapped air, open the release valve by pushing on the release lever and

pumpthefootpedalofthepumpatthesametime,throughitsfullstroke,veorsixtimes.Closethereleasevalve.

6.2.3. Hydraulic pump’s piston ‘O’ ring seal may have become worn. If this is suspected take the jack to an approved agent for servicing.

ENVIRONMENT PROTECTION

Recycle unwanted materials instead of disposing of them as waste. All tools, accessories and packaging should be sorted, taken to

a recycling centre and disposed of in a manner which is compatible with the environment. When the product becomes completely

unserviceable and requires disposal, drain any fluids (if applicable) into approved containers and dispose of the product and fluids

according to local regulations.

Note: It is our policy to continually improve products and as such we reserve the right to alter data, specifications and component parts without prior notice.

Important: No Liability is accepted for incorrect use of this product.

Warranty: Guarantee is 12 months from purchase date, proof of which is required for any claim.

Sealey Group, Kempson Way, Suffolk Business Park, Bury St Edmunds, Suffolk. IP32 7AR

01284 757500 01284 703534 sales@sealey.co.uk www.sealey.co.uk

© Jack Sealey Limited

Original Language Version

LS575VH.V2 | Issue 3 (H,F,1,4,5,6) 4/2/2019

Loading...

Loading...