Sealey LS1050V User Manual

5.5 TON LOG SPLITTER 1050MM CAPACITY

IMPORTANT: PLEASE READ THESE INSTRUCTIONS CAREFULLY. NOTE THE SAFE OPERATIONAL REQUIREMENTS, WARNINGS & CAUTIONS. USE

THE PRODUCT CORRECTLY AND WITH CARE FOR THE PURPOSE FOR WHICH IT IS INTENDED. FAILURE TO DO SO MAY CAUSE DAMAGE AND/OR

PERSONAL INJURY AND WILL INVALIDATE THE WARRANTY. KEEP THESE INSTRUCTIONS SAFE FOR FUTURE USE.

MODEL NO: LS1050V

Thank you for purchasing a Sealey product. Manufactured to a high standard, this product will, if used according to these

instructions, and properly maintained, give you years of trouble free performance.

Refer to

instructions

Wear eye

protection

Wear protective

gloves

Wear safety

footwear

Warning

crushing of

hands

Warning

1. SAFETY

1.1. ELECTRICAL SAFETY

WARNING! It is the user’s responsibility to check the following:

Check all electrical equipment and appliances to ensure that they are safe before using. Inspect power supply leads, plugs and

all electrical connections for wear and damage. Sealey recommend that an RCD (Residual Current Device) is used with all electrical

products. You may obtain an RCD by contacting your local Sealey dealer.

If the product is used in the course of business duties, it must be maintained in a safe condition and routinely PAT (Portable

Appliance Test) tested.

Electrical safety information, it is important that the following information is read and understood.

1.1.1. Ensure that the insulation on all cables and on the appliance is safe before connecting it to the power supply.

1.1.2. Regularly inspect power supply cables and plugs for wear or damage and check all connections to ensure that they are secure.

1.1.3. Important: Ensure that the voltage rating on the appliance suits the power supply to be used and that the plug is tted with the

correct fuse - see fuse rating in these instructions.

8 DO NOT pull or carry the appliance by the power cable.

8 DO NOT pull the plug from the socket by the cable.

8 DO NOT use worn or damaged cables, plugs or connectors. Ensure that any faulty item is repaired or is

replaced immediately by a qualied electrician.

1.1.4. This product is tted with a BS1363/A 13 Amp 3 pin plug.

If the cable or plug is damaged during use, switch the electricity supply and remove from use.

Ensure that repairs are carried out by a qualied electrician.

Replace a damaged plug with a BS1363/A 13 Amp 3 pin plug. If in doubt contact a qualied electrician.

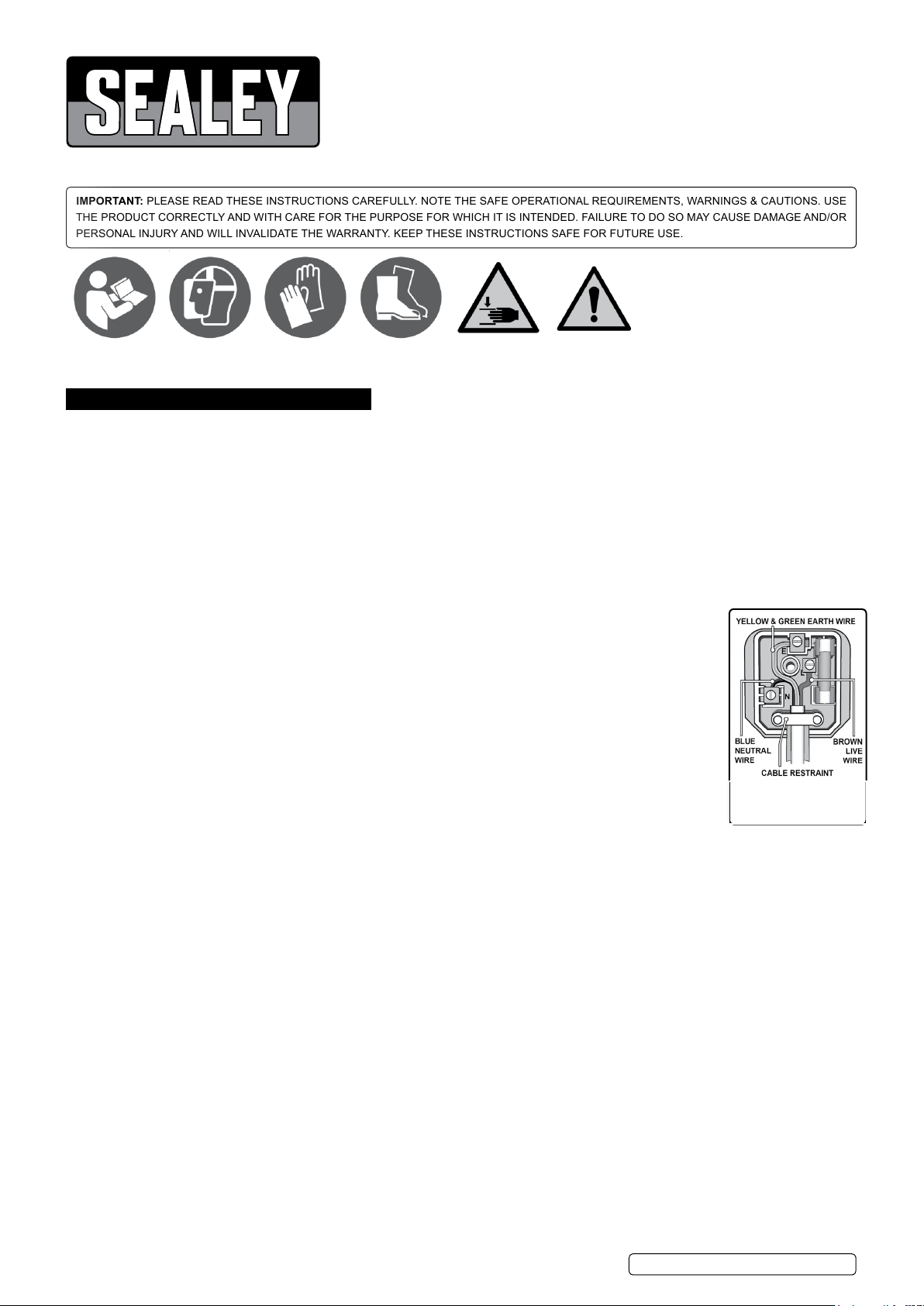

a) Connect the GREEN/YELLOW earth wire to the earth terminal ‘E’.

b) Connect the BROWN live wire to the live terminal ‘L’.

c) Connect the BLUE neutral wire to the neutral terminal ‘N’.

Ensure that the cable outer sheath extends inside the cable restraint and that the restraint is tight.

Sealey recommend that repairs are carried out by a qualied electrician.

1.2. SAFETY AND MAINTENANCE.

9 Keep the log splitter clean for best and safest performance.

9 Maintain the log splitter in good condition (use an authorised service agent).

9 Use a qualified person to lubricate and maintain the log splitter.

8 DO NOT use brake fluid to top up hydraulic unit.

8 DO NOT operate the log splitter if damaged.

9 Replace or repair damaged parts. Use genuine parts only. Unauthorised parts may be dangerous and will invalidate the warranty.

1.3. WORKSHOP/ENVIRONMENTAL SAFETY.

9 Locate the log splitter on dry, level and solid ground in a suitable work area with adequate lighting.

9 Keep the area clean and tidy and free from unrelated materials. DO NOT leave tools, logs or other items lying around where they could

become a tripping hazard.

8 DO NOT operate the log splitter in wet or damp areas or expose it to rain.

8 DO NOT operate the log splitter in areas where fumes from paint, solvents, or flammable liquids pose a potential hazard.

1.4. OPERATOR SAFETY.

9 Remove ill fitting clothing. Remove ties, watches, rings and other loose jewellery, and contain long hair.

9 Wear protective, electrically non conductive gloves .

9 Always wear safety goggles. Everyday spectacles are not sufficient protection.

9 Maintain correct balance and footing, DO NOT over-reach. Ensure the floor is not slippery and wear non-slip, protective footwear.

8 DO NOT allow untrained persons to operate the log splitter.

8 DO NOT operate the log splitter with the guards or guides removed.

8 DO NOT operate the log splitter when you are tired or under the influence of alcohol, drugs or intoxicating medication.

8 DO NOT attempt to load a log until the log pusher has returned to the stop position.

9 Stay alert and always pay attention to the movement of the log pusher.

9 The log splitter must always be operated by one person only.

9 Keep hands away from the moving parts of the log splitter.

9 Keep hands away from splits and cracks which open in logs. They may close suddenly and crush or cut off parts of your hands.

© Jack Sealey Limited

Original Language Version

LS1050V Issue 3 (HF) 25/06/18

Recommended fuse rating

13 Amp

For this reason do not attempt to remove jammed logs by hand. A jammed log is a log which is only partially split and continues to grip

the splitting wedge.

1.5. SAFETY OF OTHERS.

8 DO NOT allow another person to help you with a jammed log.

9 Keep children and unauthorised persons away from the work area.

9 The log splitter must always be operated by one person only. Other people must keep a safe distance from the log splitter especially

when it is in operation.

9 Store the log splitter in a safe area away from children and other people not qualified to use the log splitter.

1.6. GENERAL SAFETY.

8 DO NOT make any modifications to the log splitter.

8 DO NOT exceed the stated log capacity of the log splitter.

8 DO NOT use the log splitter for a task it is not designed to perform.

8 DO NOT leave the log splitter until the splitting wedge has returned to the start position.

8 DO NOT force the log splitter to work beyond its specified capacity.

9 Ensure that there are no nails, screws or other foreign objects in logs to be split.

9 The end of logs should be cut square.

WARNING! The warnings, cautions and instructions referred to in this manual cannot cover all possible conditions and situations that

may occur. It must be understood that common sense and caution are factors which cannot be built into this product, but must be

applied by the operator.

2. INTRODUCTION

Safe and easy way to split logs, oering continuous sizing and up to 5.5tonne of pressure. Three tier table system and adjustable wedge

allows work-piece to be as near to wedge as possible minimising splitting time. Fitted with a two hand safety operation, twin pull-in and pushdown levers.

3. SPECIFICATION

Model No: ...................................... LS1050V

Tier Log Lengths ..........................540, 790, 1050mm

Maximum Log Diameter ..............................320mm

Vertical Ram Travel .................................500mm

Maximum Load Pressure .............................5.5ton

Motor Power: ......................................3000W

Overall (W x L x H): ......................565 x 840 x 1520mm

Weight: .............................................97kg

4. OPERATION

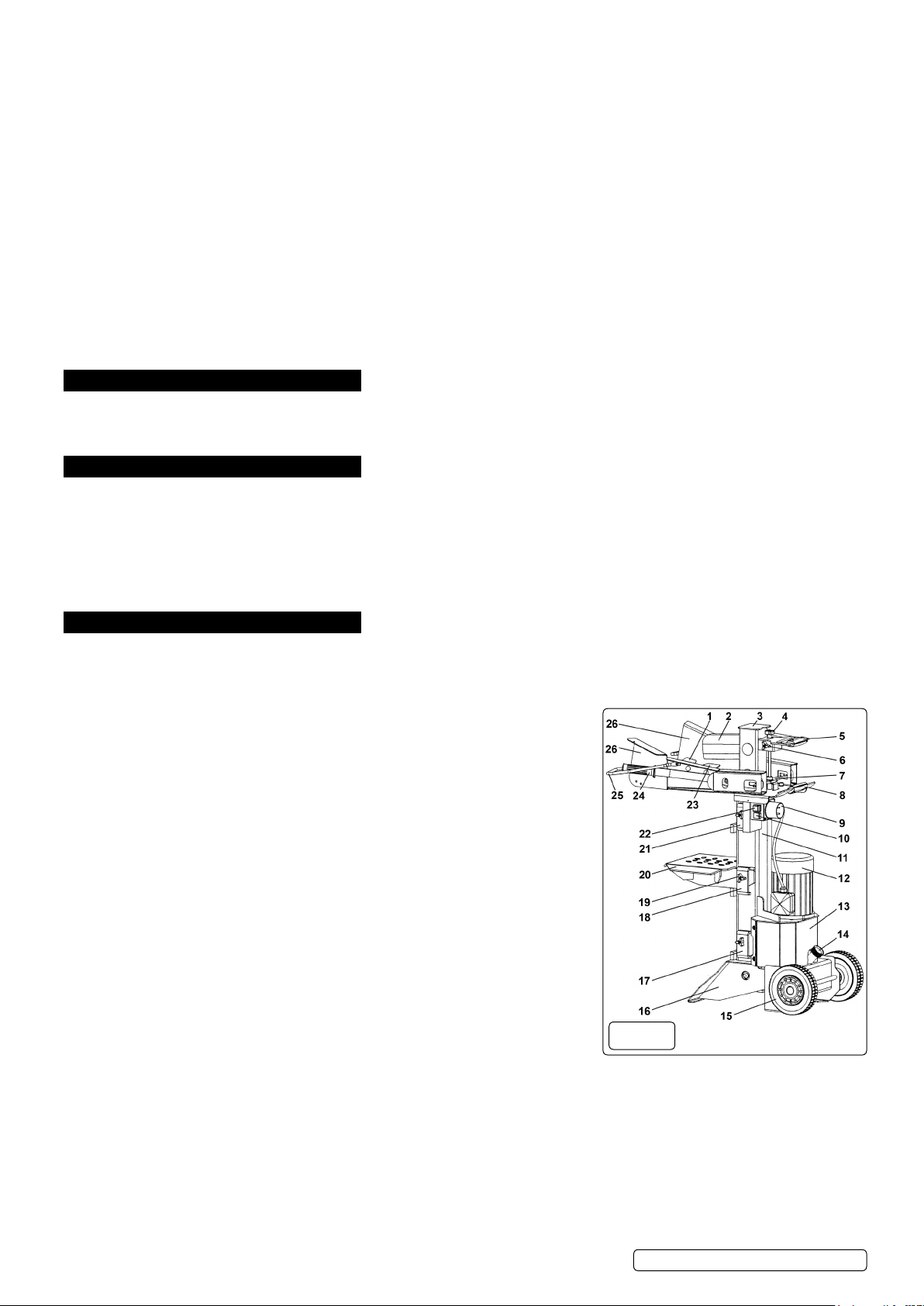

(Refer to fig.1 below). The log splitter has an electrically powered hydraulic ram situated inside the lower hollow upright steel section. The ram

is usually fully extended at rest and is connected to the upper hollow steel section behind the splitting wedge (2). When the motor is switched

on and the two control levers are operated the ram retracts and draws the splitting wedge downwards to split the log situated on the table.

4.1. Serrated Log Clamp. Grips log when pressure is applied through the control levers (24).

4.2. Splitting Wedge. After prolonged use it may be necessary to sharpen the wedge with

a fine toothed file.

4.3. Upper Steel Section (moving). Drawn downwards by ram action.

4.4. Adjustable Ram Travel Rod. Controls the ram starting point above the table.

4.5. Upper Transit Handle. Used in conjunction with lower transit handle (8) when unit

is moved

4.6. Ram Travel Rod Locking Knob. Locks ram travel rod when setting ram travel.

4.7. Control levers connection bracket. Transfers the action of the control levers to the

hydraulic system.

4.8. Lower Transit Handle. Used in conjunction with upper transit handle (8) when unit

is moved

4.9. Mains Connector Shield. Protects mains connector from ingress of dust and debris.

4.10. ON Switch. Starts electric motor.

4.11. Lower Steel Section (static). Houses the ram.

4.12. Motor. Drives pump to power hydraulic system.

4.13. Pump Housing Guard. Protects pump and hydraulic pipework.

4.14. Oil Tank Cap. Also acts as an air bleed when loosened by several turns.

4.15. Wheels. Only make contact with the ground when the unit is tipped backwards for

transit.

4.16. Base of unit. Ensure that the base is on a level and firm surface to ensure stability

of unit during use.

4.17. Lower Table Position. Ensure that table is fully inserted and hooked into position on

each side of beam.

4.18. Middle Table Position. Ensure that table is fully inserted and hooked into position on each side of beam.

4.19. Table Locking Knob. Screw fully in to lock table in each position.

4.20. Table. Ensure that table is fully inserted and hooked into position on each side of beam.

4.21. Upper Table Position. Ensure that table is fully inserted and hooked into position on each side of beam.

4.22. OFF Switch. Stops electric motor.

4.23. Serrated Log Clamp. Grips log when pressure is applied through the control levers (24).

4.24. Control levers. Used to grip the log and initiate the ram movement.

4.25. Control lever guard (Wire). Protects hands when using control levers.

4.26. Control lever shields. Protects hands when using control levers.

g.1

© Jack Sealey Limited

Original Language Version

LS1050V Issue 3 (HF) 25/06/18

Loading...

Loading...