Page 1

infrared paraffin / kerosene / diesel

MPORTANT:

PLEASE READ THESE INSTRUCTIONS CAREFULLY. NOTE THE SAFE OPERATIONAL REQUIREMENTS, WARNINGS & CAUTIONS. USE

THE PRODUCT CORRECTLY AND WITH CARE FOR THE PURPOSE FOR WHICH IT IS INTENDED. FAILURE TO DO SO MAY CAUSE DAMAGE AND/OR

PERSONAL INJURY AND WILL INVALIDATE THE WARRANTY. KEEP THESE INSTRUCTIONS SAFE FOR FUTURE USE.

heater

model no: ir20.V4

thank you for purchasing a sealey product. Manufactured to a high standard, this product will, if used according to these

instructions, and properly maintained, give you years of trouble free performance.

Refer to

instructions

Wear protective

gloves

electrical

shock

hazard

Hot surfaces

do not cover

Keep in dry area

protect from rain

1. safety

1.1. eleCtriCal safety

WarninG! It is the user’s responsibility to check the following:

Check all electrical equipment and appliances to ensure that they are safe before using. Inspect power supply leads, plugs and

all electrical connections for wear and damage. Sealey recommend that an RCd (Residual Current device) is used with all electrical

products. You may obtain an RCd by contacting your local Sealey stockist.

If used in the course of business duties, it must be maintained in a safe condition and routinely PAT (Portable Appliance Test) tested.

electrical safety information, it is important that the following information is read and understood.

9 ensure that the insulation on all cables and on the appliance is safe before connecting it to the power supply.

9 Regularly inspect power supply cables and plugs for wear or damage and check all connections to ensure that they are secure.

9 Ensure that the voltage rating on the appliance suits the power supply to be used and that the plug is tted with the correct fuse - see

fuse rating in these instructions.

8 do not pull or carry the appliance by the power cable.

8 do not pull the plug from the socket by the cable.

8 do not use worn or damaged cables, plugs or connectors. ensure that any faulty item is repaired or replaced immediately by a

qualied electrician.

9 This product is tted with a BS1363/A 13 Amp 3 pin plug.

If the cable or plug is damaged during use, switch the electricity supply and remove from use.

Ensure that repairs are carried out by a qualied electrician.

Replace a damaged plug with a BS1363/A 13 Amp 3 pin plug. If in doubt contact a qualied electrician.

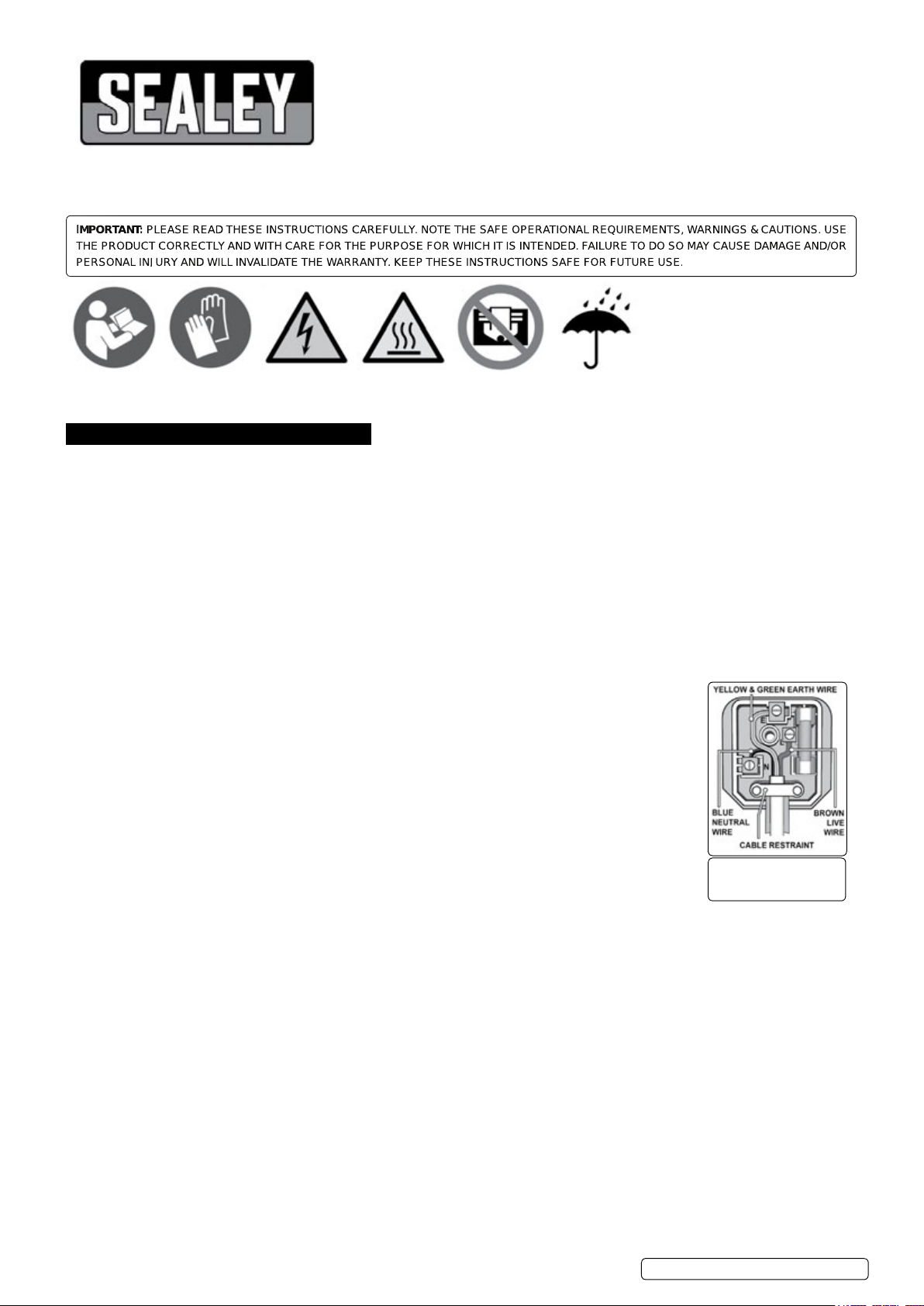

a) Connect the GREEN/YELLOW earth wire to the earth terminal ‘E’.

b) Connect the BROWN live wire to the live terminal ‘L’.

c) Connect the BLUE neutral wire to the neutral terminal ‘N’.

ensure that the cable outer sheath extends inside the cable restraint and that the restraint is tight.

Sealey recommend that repairs are carried out by a qualied electrician.

1.2. General safety

▲ danGer! Risk of carbon monoxide poisoning. Failure to provide proper ventilation could result in

serious illness or death.

9 Check that the heater is in sound condition and good working order. Take immediate action to repair

or replace damaged parts.

9 Use recommended parts only. Unauthorised parts may be dangerous and will invalidate the warranty.

9 Only use parafn, diesel or kerosene to fuel this heater, in accordance with instructions contained in this manual.

9 locate heater on a level and stable surface.

WarninG! only use heater in well ventilated areas. ensure continuous ventilation is provided to the heater operating area via

windows and doors etc. If people are not required to be present in the heated area, the volume of air to be heated (m³)/heat output

(kW) ratio must be at least 10:1 and people must be advised not to remain in the heated area for prolonged periods. If people

are required to be present in the heated area, the volume of air to be heated (m³)/heat output (kW) ratio must be at least 30:1.

Ventilation must be to the outside of the premises in which the heater is to be operated. The total open area (m²) must be at least

0.003 times the total heat output (kW). The volume concentration of

WarninG! do not use the heater near ammable material, liquids, solids, gases or compressed gas cylinders etc.

8 do not stand or place any object less than 3m from the heater output and keep the heater a minimum of 2m from any walls or

objects.

8 do not use the heater in closed rooms, living areas, basements or below ground level.

8 do not allow untrained persons to operate the heater and do not operate the heater without the safety guard.

8 do not move or handle the heater when hot, without wearing protective gloves. never move the heater whilst it is operating.

8 do not leave the heater unattended for prolonged periods of time when in use. Switch the heater off and unplug from the mains

before leaving work area.

8 do not ll the fuel tank whilst the heater is running or still hot. do not over-ll the fuel container. Wipe up any spilt fuel

immediately.

8 do not obstruct the air inlet (rear) and air outlet (front) of the heater and do not use duct work in front or at the rear of the heater.

© Jack Sealey limited

Original Language Version

oxygen (o

) in the heated room, must always remain above 17%.

2

IR20.V4 | Issue 2 (7) 25/01/19

Recommended fuse rating

3 Amp

Page 2

8 do not allow children or animals near the heater when in use, or whilst still hot.

WarninG! RISK oF eleCTRIC SHoCK. do not expose the heater to water spray, rain, dripping water or wind.

8 do not operate the heater when you are tired or under the inuence of alcohol, drugs or intoxicating medication.

8 do not touch the heater outlet or cone when in use, or for a period of time after it’s switched off, as these are VeRY hot and will

take time to cool down.

8 do not switch the heater off by disconnecting it from the mains. ALWAYS set the switch on the burner to the ‘OFF’ position and

allow the cooling cycle to nish, before disconnecting from the mains.

8 do not use an external fuel tank. Only use the tank that is tted to the heater, and only ll it when the heater has cooled down.

9 ensure that the heater is correctly turned off

9 When not in use for an extended period, store in a safe, dry area, out of reach of children.

note: This appliance is not intended for use by persons (including children) with reduced physical, sensory or mental capabilities or

lack of experience and knowledge, unless they have been given supervision or instruction concerning the use of the appliance by a

person responsible for their safety.

Children should be supervised to ensure that they do not play with the appliance.

2. introduCtion

Infrared heater suitable for well ventilated indoor applications. Clean burning unit operates on paraffin, kerosene or diesel.

Unit produces an impressive 70,000Btu/hr. 15ltr fuel tank allows a max of 7hrs running time, making this unit extremely economical. Complies with

rigorous standards and is fitted with a safety cut-out.

3. speCifiCation

model no ................................................................... IR20.V4

output ....................................................................... 20.5KW

output ................................................................70,000Btu/hr

Tank Capacity ...............................................................15ltrs

Fuel .................................................Parafn/Kerosene/Diesel

Supply ....................................................................230V - 3A

Running Time per Filling maximum ...................................7hr

Transport Wheels .............................................................. no

Automatic Shut-Off ........................................................... Yes

Heated Area .............................................................14,000ft

Heated Area .................................................................396m

3

3

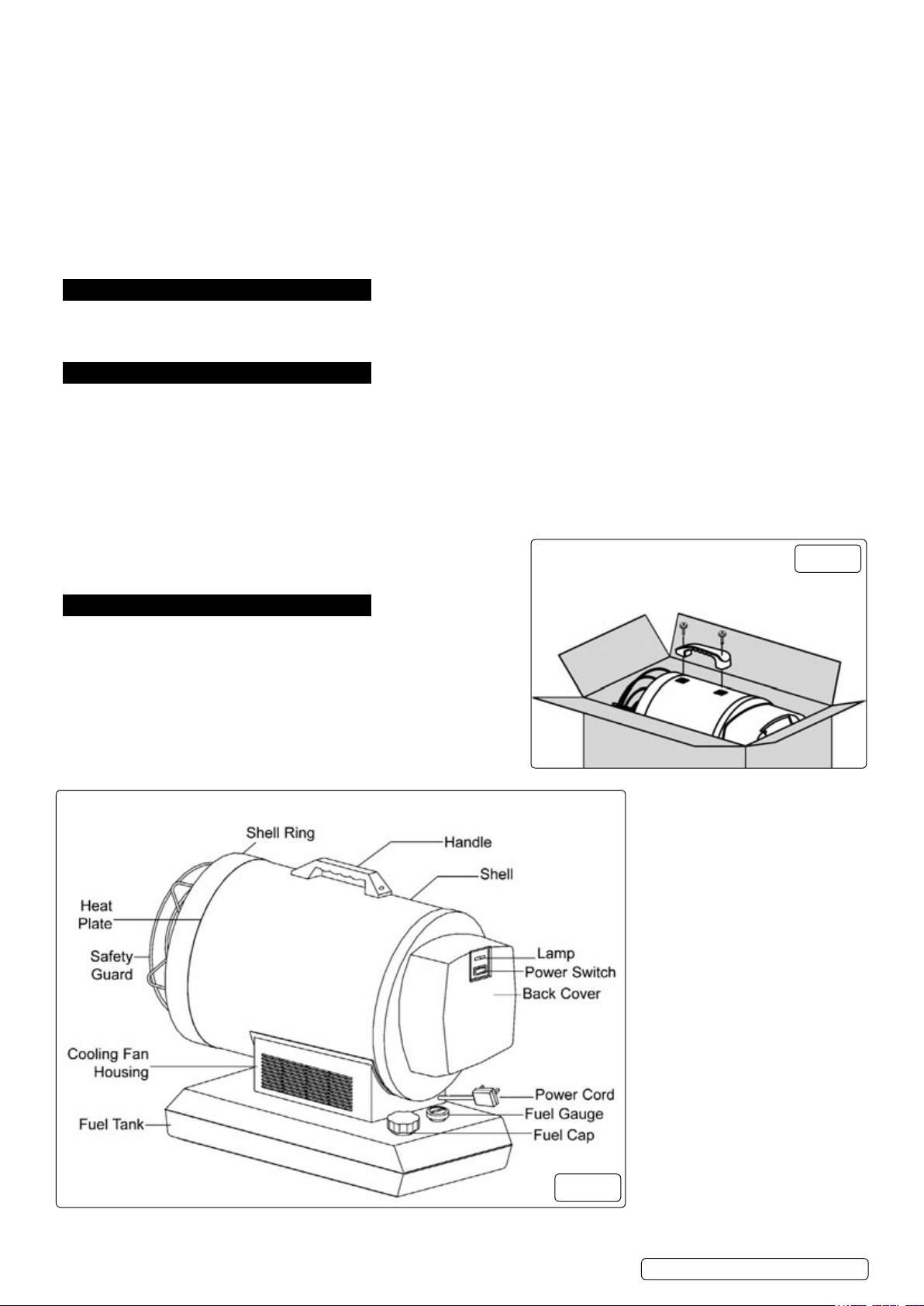

g.1

4. asseMbly

4.1. Unpack the heater and check contents. Should there be any

damaged or missing parts contact your Sealey stockist immediately.

4.2. Attach handle by lining up the holes in the handle with the holes in

the upper shell of the heater (Fig.1).

4.3. Insert screws and tighten.

4.4. Remove heater and packaging material from the carton.

© Jack Sealey limited

Original Language Version

g.2

IR20.V4 | Issue 2 (7) 25/01/19

Page 3

5. operation

5.1. fuellinG the heater:

5.1.1. This appliance is designed to operate safely at a minimum ambient temperature of -20°C.

5.1.2. For optimal performance of this heater, use parafn. Parafn has been rened to virtually eliminate contaminants, such as sulphur, which

can cause a rotten egg odor during the operation of the heater. Using diesel fuel can cause excess soot production. do not use bio-

diesel as this fuel will damage your heater’s seals and lter.

8 do not use fuel such as, benzene, alcohol, white glass, camp stove fuel, paint thinners, or other oil compounds in this heater.

these are volatile fuels that can cause a re or explosion.

8 do not store parafn in the living space. Parafn should be stored in a well ventilated area outside the living area.

8 do not store parafn in direct sunlight or near a source of heat.

8 do not use parafn that has been stored from one season to the next. Parafn deteriorates over time, old parafn will not burn

properly in this heater.

5.2. Ventilation:

5.2.1. risk of indoor air pollution and carbon monoxide poisoning. use

heater only in well ventilated areas.

5.2.2. Always provide a fresh air opening in the heated space of at least

2,800 cm2 (3 sq. ft) for each 29 kw / hr. of heater output.

5.2.3. Provide a larger opening if more heaters are being used.

5.2.4. Minimum Ventilation Opening Needed for this heater is 64cm

5.3. starting the heater: (ignition)

5.3.1. Fill the tank with paran or other approved fuel until needle on fuel

gauge points to “F”. Replace fuel cap and tighten rmly.

5.3.2. Connect the heater to a power source. You must use extension cable

that is at least 1.8 meters long and is a minimum of 14 AWG rating.

5.3.3. Push the power switch to the “on” position. The power indicator lamp

will light and heater will ignite g.3.

note: On rst ignition or after refueling you may hear a grinding

sound just before ignition. This is the fuel pump removing the air from

the fuel line. Your heater will start up within seconds. If it does not

start repeat start-up procedures with fuel gauge reading at least 1/2 tank.

note: The electrical components of these heaters are protected by a fuse mounted in the PC board. If the heater fails to ignite check this

fuse rst and replace if necessary. Also check the power source to be sure the proper voltage is being provided to the heater.

5.4. stopping the heater:

5.4.1. Turn the power switch to the “oFF” position. Combustion will stop and the Cooling Cycle will begin. approx. 7 mins.

5.4.2. When the Cooling Cycle is complete the fan will stop running and it will be safe to unplug the heater.

note: Unplugging the heater before the Cooling Cycle has been completed may cause overheating, possible damage to the heater and

heat plate.

5.5. restarting the heater:

5.5.1. Wait ten seconds after Cooling Cycle has been completed.

5.5.2. Follow all start-up procedures above.

2

.

g.3

6. MaintenanCe

WarninG! Unplug unit from mains power supply ensure heater is cold before opening or

servicing heater.

WarninG! do not tamper with the u n i t , h a v e a n experienced serviceman make any necessary

adjustment or repairs.

6.1. lonG terM storaGe:

6.1.1. Unscrew the fuel cap.

6.1.2. Using an approved siphon, remove the Parafn or diesel.

6.1.3. Using a small amount of Parafn or diesel, rinse and swirl the fuel inside the fuel tank

6.1.4. empty the tank completely.

note: never mix water with fuel, it will cause rust inside the tank.

iMportant: Never store leftover Parafn between seasons, using old fuel can damage heater.

6.1.5. Store Heater in a dry, well ventilated area. Be sure that the storage area is free of dust and

corrosive vapors. Repack the heater in the original packaging and keep user’s manual in an

easily accessible place.

6.2. fuel / fuel tank:

6.2.1. Flush tank every 200 hours of operation or as needed. do not ush with water, use fresh

parafn only.

6.3. spark plug:

Clean and re-gap every 600 hours of operation or replace as needed. After removing the spark

plug, clean the terminals with a wire brush, re-gap the terminals to 0.140” (3.5mm) g.4.

6.4. fan blades:

6.4.1. The fan blades should be cleaned at least once per heating season, depending on conditions.

remove all accumulated dust and dirt with a burst of condensed air g.5.

g.4

© Jack Sealey limited

Original Language Version

g.5

IR20.V4 | Issue 2 (7) 25/01/19

Page 4

6.5. nozzles:

6.5.1. nozzles should be cleaned or replaced at least once per heating season.

Contaminated fuel could make this necessary immediately.

6.5.2. To clean dirt from nozzle, blow compressed air through nozzle front. it may be

necessary to soak nozzle in clean parafn or diesel to help loosen any

particles g.6.

photocell:

6.5.3. The photocell should be cleaned at least once per heating season or more

depending on conditions, use a cotton swab and water or, alcohol to clean the

lens of the photocell. Be certain to reinstall the photocell in proper position as

shown below g.7.

6.6. filters:

6.6.1. The fuel lter and oil lter should be cleaned at least twice per heating season

by rinsing it in clean parafn or diesel. Contaminated or old fuel could make

cleaning necessary immediately g.8.

g.6

g.7

g.8

7. troubleshootinG

problem possible Cause solution

Heater res, but shuts down

after a short period of time.

Heater will not operate, or

motor

runs for short time.

1. Dirty Fuel Filter. 1. Clean/replace Fuel Filter.

2. nozzle dirty. 2. Clean/replace Nozzle

3. Photocell Dirty. 3. Clean/replace Photocell .

4. Photocell not installed properly. 4. Adjust Photocell position.

5. Photocell Defective . 5. Replace Photocell.

6. Improper electrical connection between Circuit

Board and Photocell.

7. Cooling Fan is obstructed 7. Check to be sure cooling fan is not obstructed.

1. No parafn/ diesel in fuel tank. 1. Fill tank with fresh parafn/ diesel.

2. Corroded Spark Plug or incorrect plug gap. 2. Clean/replace Spark Plug.

6. Check wiring connections

© Jack Sealey limited

3. Dirty Fuel Filter. 3. Clean/replace Fuel Filter.

4. Dirty Nozzle 4. Clean/replace Nozzle.

5. Moisture in Fuel/Fuel Tank. 5. Rinse out fuel tank with clean fresh parafn/ diesel.

6. Improper electrical connection between

Transformer and Circuit Board.

7. Transformer Wires not connected to Spark

Plug.

8. defective Transformer . 8. Replace Transformer.

Original Language Version

6. Inspect all electrical connections.

7. Re-attach Transformer wires to Spark Plug.

IR20.V4 | Issue 2 (7) 25/01/19

Page 5

problem possible Cause solution

Fan does not operate when

heater is plugged in and

operating Switch

is in the “on” position.

Heater makes grinding noise. 1. Air in fuel pump. 1. Sound will stop after 3 seconds. If grinding sound

Heater does not turn on and

the lamp is not lit.

Poor combustion and / or soot

production.

1. Broken electrical connection

between Circuit Board and motor.

2. not enough amps available to power heater. 2. Use a new extension cord or try another electrical

1. Temperature limit sensor has overheated. 1. Push Operating Switch to “OFF” and allow heater to

2. no electrical power. 2. Check power cord and extension cord to insure of

3. Fuse break down. 3. Check/replace Fuse.

4. Improper electrical connection between

Temperature Limit Sensor and Circuit Board.

1. Pump Pressure. 1. Be sure pump pressure is adjusted correctly.

2. Poor fuel quality. 2. Be sure parafn/ diesel is not old or contaminated.

Athough our heaters operate with diesel fuel, when the temperatures are

below 0°C, diesel additives are required to maintain the diesel’s viscosity.

Typically diesel can cloud in freezing conditions and will start to gel. You

will need additives for your fuel in these conditions.

Kerosene/Parafn does not start to gel until the ambient temperature is

around (-40°C).

1. Inspect all electrical connections on

Wiring Diagrams.

socket.

continues, add fuel to tank.

cool for 5 minutes. Push Operating Switch back to “ON”.

proper connection. Test power supply.

4. Inspect all electrical connections.

Weee reGulations

Dispose of this product at the end of its working life in compliance with the EU Directive on Waste Electrical and Electronic Equipment

(WEEE). When the product is no longer required, it must be disposed of in an environmentally protective way. Contact your local solid

waste authority for recycling information.

enVironMent proteCtion

Recycle unwanted materials instead of disposing of them as waste. All tools, accessories and packaging should be sorted, taken to

a recycling centre and disposed of in a manner which is compatible with the environment. When the product becomes completely

unserviceable and requires disposal, drain any fluids (if applicable) into approved containers and dispose of the product and fluids

according to local regulations.

sealey Group, kempson Way, suffolk business park, bury st edmunds, suffolk. ip32 7ar

01284 757500 01284 703534 sales@sealey.co.uk www.sealey.co.uk

© Jack Sealey limited

Original Language Version

IR20.V4 | Issue 2 (7) 25/01/19

Loading...

Loading...