Page 1

WARNING! Ensure any Health & Safety, Government, or local authority regulations are adhered to when using this equipment.

Familiarise yourself with the application and limitations, as well as the potential hazards, of the generator.

Maintain the generator in good condition (use an authorised service agent). Replace or repair damaged parts. Use genuine parts only.

Unauthorised parts may be dangerous and will invalidate the warranty.

This generator is designed and manufactured for specific applications. Do not attempt to modify the unit or use it for any application for

which it is not designed. If you have any questions regarding the application of the unit please contact your local Sealey dealer.

WARNING! DO NOT exceed the Wattage/Amperage capacity of the generator. Add rated wattage of all devices intended for connection

at anyone time. The total must not exceed rated wattage of generator (see specifications). In most cases the rated wattage of an electrical

device can be found on the nameplate. If the nameplate only gives voltage and amperage, multiply the two to give rated wattage (Volts x

Amps = Watts)

WARNING! Generator exhaust gases contain deadly carbon monoxide which must not be inhaled. Always allow sufficient

ventilation.

WARNING! If you decide to use an Earth Leakage Circuit Breaker (also referred to as an RCD or Ground Fault Circuit Interrupter),

it is imperative that the neutral end of the power winding is connected to the frame of the generator set and that the earth lug on

the frame is connected with a low impedance connector to the local earth via an earth spike or local protective earth conductor.

This connection should only be attempted by a qualified electrician, after first having consulted your local dealer.

DANGER! This generator is designed for outdoor use only. To use the generator inside any building or enclosure, including the

generator compartment of a caravan, may result in fire or an explosion. No user performed modifications, including venting of

the exhaust and/or cooling ventilation, will eliminate the danger.

DANGER! If this unit is used for back-up power in the event of a commercial power failure, the following steps must be taken.

Before connecting the generator to the electrical system, open the main circuit breaker to isolate the generator and system from

the commercial electric supply. Failure to do this may result in damage to the generator and may result in serious injury or

fatality, due to a back-feed of electrical energy.

DANGER! The generator produces a very powerful voltage that can cause a severe electrical shock. Avoid contact with bare

wires, terminals etc. Never allow any unqualified person to operate or service the generator.

WARNING! Petrol is highly flammable and petrol vapour is explosive. Do not permit smoking, naked flames, sparks or heat in the

vicinity while handling petrol. Avoid spilling petrol onto a hot engine. Comply with all laws regulating storage and handling of

fuels.

WARNING! NEVER refuel when the engine is running or when the engine is hot. Allow cool down time.

Operate the generator only on level surfaces (maximum allowable tilt is 10º) and where it will not be exposed to excessive moisture, dirt

or corrosive vapours or be in the proximity of combustible material (flammable liquids, solids or gases).

Remove ill fitting clothing, ties, watches, rings and other loose jewellery and contain long hair. Wear appropriate protective clothing.

Keep non-essential persons away from the working area.

WARNING! Never start or stop the generator while electrical loads are connected and switched on. Start the engine, let it

stabilise, then connect the electrical load. To stop engine, disconnect the electrical load and let engine stabilise before switching

off.

WARNING! Do not use worn, bare, frayed or otherwise damaged electrical cables with the generator. To do so may result in

electric shock.

DO NOT use the generator for any purpose other than that for which it is designed.

DO NOT operate the generator if any parts are missing or damaged, as this may cause failure and/or personal injury.

DO NOT over-fill fuel tank. Always leave room for fuel to expand.

DO NOT operate in the rain.

DANGER! Do not tamper with the engine governed speed setting. Higher operating speeds are dangerous and increase the risk

of personal injury and/or equipment damage. The generator supplies the correct rated frequency and voltage only when

running at the correct governed speed. Incorrect frequency and/or voltage can damage connected electrical loads.

Operating at excessively low speeds may result in shortened engine life. Over-speeding will invalidate the warranty.

DO NOT operate the generator when you are tired or under the influence of alcohol, drugs or intoxicating medication.

DO NOT store generator with fuel in tank where petrol vapours might reach an open flame or spark.

1. SAFETY INSTRUCTIONS

Motor Power: ....................................6HP

Motor Type:...................................4 Stroke

Output: ...................................230V - 50Hz

Maximum Current Rating: . . . . . . . . . . . . . . . . . . . . . . . . . . .10A

Continuous Current Rating: . . . . . . . . . . . . . . . . . . . . . . . . . 8.7A

Maximum Power Rating: . . . . . . . . . . . . . . . . . . . . . . . . . 2300W

Continuous Power Rating: . . . . . . . . . . . . . . . . . . . . . . . . 2000W

Fuel Tank Capacity: ...............................12ltr

Max Running Time: ...............................9hrs

Noise Rating: ..................................95LWA

Dry Weight:.................................... 41.5kg

Dimensions (L x W x H): ...............515 x 410 x 430mm

2. INTRODUCTION & SPECIFICATION

Heavy-duty frame design provides full protection and portability. Suitable for running power tools and lighting units etc. Long running, up to 9

hours on a full tank. Fitted with two 230V 3-pin sockets. Powerful and reliable generator fitted with maintenance-free brushless alternator.

Smooth running unit fitted with anti-vibration mountings. Low oil cut-out feature and fuel gauge.

INSTRUCTIONS FOR:

GENERATOR 2300W-230V

MODEL No: G2300.V2

Thank you for purchasing a Sealey product. Manufactured to a high standard this product will, if used according to these instructions and

properly maintained, give you years of trouble free performance.

IMPORTANT: PLEASE READ THESE INSTRUCTIONS CAREFULLY. NOTE THE SAFE OPERATIONAL REQUIREMENTS, WARNINGS, AND

CAUTIONS. USE THIS PRODUCT CORRECTLY, AND WITH CARE FOR THE PURPOSE FOR WHICH IT IS INTENDED. FAILURE TO DO SO MAY

CAUSE DAMAGE AND/OR PERSONAL INJURY AND WILL INVALIDATE THE WARRANTY.

Original Language Version

G2300.V2 (S)Issue: 2 - 25/10/12

Page 2

3. OPERATING INSTRUCTIONS

WARNING! Before use, ensure you read, understand and comply with the safety instructions in this document. Ensure you

fully understand the application and limitations, as well as the potential hazards, of the generator.

WARNING! Never connect the generating set earth lead to pipes. Pipes may carry inflammable substances such as gas or

domestic fuel and there is a risk of fire or explosion in the event of a short circuit.

WARNING! Never run the engine without an air filter fitted.

3.1 PRE START-UP OF THE GENERATOR

Check the air filter element to ensure it is clean and in good condition. Clean or replace as necessary.

WARNING! NEVER refuel when the engine is running or when the engine is hot. Allow cool down time.

WARNING! Petrol is highly flammable and petrol vapour is explosive.

3.2 STARTING THE GENERATOR

WARNING! The output sockets will be live once the engine has started.

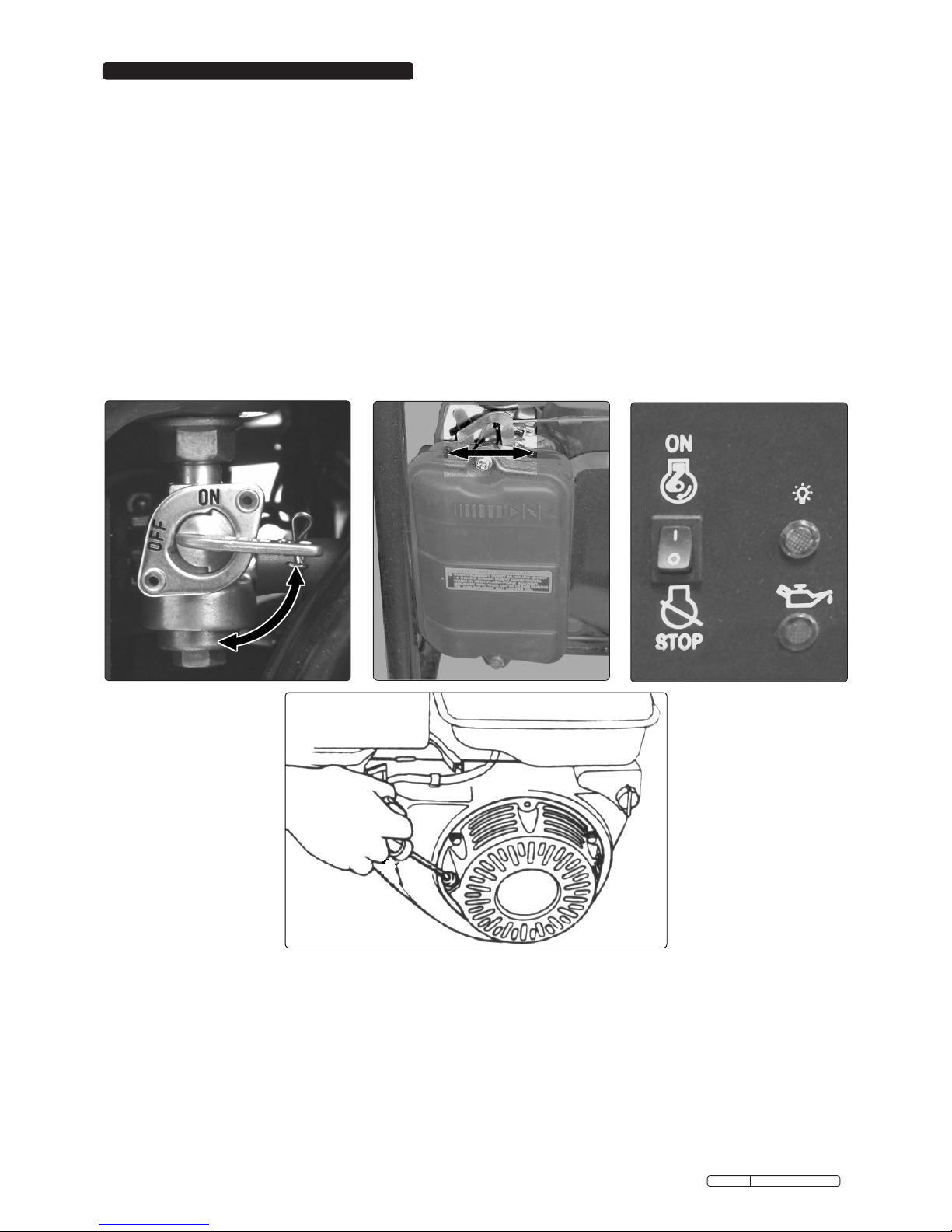

3.2.1 Turn the fuel valve to the ON position (fig.1).

Note: If starting a warm engine or when the ambient temperature is high, move the choke control to the OPEN position.

3.2.2 Close the choke (fig 2).

3.2.3 Set the Engine Switch to the 1 position (fig 3).

3.2.4 Grasp the recoil handle and pull cord slowly until some resistance is felt. Let cord rewind slowly, then pull with a rapid full arm

stroke (fig 4). Let cord slowly return.

Note: Ensure there is sufficient free area behind to prevent personal injury when pulling the cord.

3.2.5 When engine starts, move choke lever to half choke position until engine runs smoothly and then to the OPEN position.

3.2.6 If engine fails to start, repeat the procedure from paragraph 3.2.4. If it still will not start, refer to ’Trouble-Shooting’ section. If necessary

contact your authorised Sealey service agent.

3.3 USING THE GENERATOR

WARNING!: Do not exceed the wattage capacity of the generator.

3.3.1 Allow the engine to warm up (approximately 3 minutes).

3.3.2 Connect the equipment to the generator socket.

3.3.3 Always observe the safety instructions of the equipment being used.

3.3.4 Carry out the following checks whilst the generator is in use:

Is there any vibration or abnormal noise?

Is there any backfiring or is the engine not running smoothly?

What colour is the exhaust gas? (Is it black or too white.)

3.3.5 If you notice any of the above points stop the generator (paragraph 3.4) and contact your local servicing agent.

3.4 TO STOP THE GENERATOR

3.4.1 Disconnect the electrical load.

3.4.2 Allow the engine to run unloaded for 1 - 2 mins.

3.4.3 Stop engine by moving the engine switch to the 0 position (fig 3).

3.4.4 Turn off the fuel valve (fig 1).

fig 1

fig 3

fig 4

fig 2

OPEN

CLOSED

Original Language Version

G2300.V2 (S)Issue: 2 - 25/10/12

Page 3

Note: Service more often if used in dusty environments.

4.2 MAINTAINING THE AIR FILTER

Note: If the air filter is dirty, air passing towards the carburettor will be restricted. To avoid the carburettor malfunctioning,

clean the air filter regularly. Clean more often when the engine is used in extremely dusty places.

WARNING! Never use fuel or solvent to clean the foam element. This can cause a fire or an explosion.

4.2.1 Unscrew the securing screws and remove the air filter cover.

4.2.2 Carefully check the element for tears or holes and replace if damaged.

4.2.3 Clean the element using compressed air. Replace the element if it is very dirty.

Note: Never attempt to remove dirt with a brush as brushing could imbed the dirt into the fibres.

4.2.4 Wash the foam element in household detergent diluted in warm water, rinse with plenty of water and dry thoroughly.

4.2.5 Dip the foam element into some clean engine oil and press out to remove any excess oil.

Note: The engine will start smoking during the first start up if too much oil is left on the foam.

4.2.6 The refitting procedure is the reverse of the above.

4.3 CLEANING THE FUEL FILTER

4.3.1 Close the fuel valve .

4.3.2 Remove the fuel filter.

4.3.3 Wash the fuel filter with a non flammable high flash point solvent.

4.3.4 Dry thoroughly and refit ensuring the lid is fully tightened.

4.3.5 Open the fuel valve and check for leaks.

4.4 MAINTAINING THE SPARK PLUG

WARNING! If the engine has just been running, the exhaust and spark plug will be very hot. Allow to cool.

WARNING! The spark plug must be correctly tightened. If the plug is not well tightened, it can overheat and damage the engine.

Note: To ensure that the engine performs correctly, the spark plug must not have any deposits on it and its gap must be correct.

4.4.1 Remove the spark plug cap and the spark plug using the spark plug wrench supplied.

4.4.2 Inspect the spark plug and discard it if the electrodes are worn or if the porcelain is cracked or scaled. If the spark plug is to be

re-used, clean with a wire brush.

4.4.3 Measure the electrodes gap using a feeler gauge. The gap must be between 0.7mm and 0.8mm. Adjustment of the gap is

achieved by bending the side electrode.

4.4.4 Check the spark plug washer is in good condition and screw the plug in by hand to avoid cross threading the threads.

4.4.5 Once the spark plug is installed, tighten it using a spark plug wrench to compress the washer.

Note: In the case of a new spark plug being fitted, screw it in by hand and tighten it by 1/2 turn with a spark plug wrench to

compress the washer. If the spark plug has already been used, screw it in by hand and only tighten it by 1/8 to 1/4 turn to

compress the washer.

4. MAINTENANCE

4.1 GENERAL MAINTENANCE SCHEDULE

WARNING! All maintenance work is carried out when the engine is stopped. If the engine must run, ensure that the working area is

well ventilated. Exhaust gases contain carbon monoxide; exposure to this toxic gas can cause loss of consciousness and can be fatal.

WARNING! If the engine has just been running, the exhaust will be very hot, take care not to touch it.

Ensure the spark plug HT lead has been disconnected prior to commencing maintenance.

The oil, air filter and spark plug must be changed regularly. All other maintenance must be carried out by qualified staff, contact your

local Sealey service agent.

Original Language Version

G2300.V2 (S)Issue: 2 - 25/10/12

Items Remarks

Daily

(pre-operation)

1st Month

(or 20Hrs)

3 Months

(or 50 Hrs)

6 Months

(or 100 Hrs)

12 Months

(or 300 Hrs)

Spark Plug

Adjust gap

Replace if necessary

Engine Oil

Check oil level

Replace

Air Filter

Clean

Replace if necessary

Fuel Filter

Check and adjust

when engine is cold

Valve Clearance

Clean

Replace if necessary

Fuel Line

Check for damage

Replace if necessary

Exhaust System

Check gasket

Replace if necessary

Check exhaust

Replace if necessary

Carburettor Check choke

Cooling System

Check fan for

damage

Starting System

Check starter

operation

Decoking

Increase frequency if

necessary

Fittings/Fasteners

Check for damage

Replace if necessary

Page 4

5. STORAGE OF MORE THAN 30 DAYS

Note: If you store the generator for more than 30 days it is essential to protect the fuel system. This can be done by either draining

all the fuel or using a fuel additive such as “STA-BIL¨, “Fuel Fresh¨, or equivalent to prevent fuel gum deposits from forming.

Note: Store the generator in a safe, dry, childproof area, free of excessive humidity and dust.

WARNING! Petrol is highly flammable and petrol vapour is explosive. Do not permit smoking, naked flames, sparks or heat in

the vicinity while handling petrol. Avoid spilling petrol onto a hot engine. Comply with all laws regulating storage and handling

of fuels.

5.1 CLEAN

5.1.1 Remove debris and dust accumulations from the generating set surfaces.

5.2 DRAINING ALL THE FUEL

5.2.1 Turn the fuel valve ON and siphon the fuel into an approved container.

5.3 USING A FUEL ADDITIVE

5.3.1 Fill the fuel tank with fresh fuel.

Note: If only partially filled, air in the tank will promote fuel deterioration during storage.

5.3.2 Add the fuel stabiliser following the manufacturer’s instructions.

5.3.3 Run the engine outdoors for ten minutes to ensure that all untreated fuel has been used.

5.3.4 Stop the engine and move the fuel valve to the OFF position.

5.4 BORE LUBRICATION

5.4.1 Remove the spark plug and pour approximately one tablespoon of clean engine oil into the cylinder.

5.4.2 Crank the engine several times in order to circulate the oil into the cylinder, then refit the spark plug.

5.4.3 Slowly pull the recoil starter cord until some resistance is felt, then keep pulling until the arrow on the starter pulley aligns with the hole

on the recoil starter.

6. TROUBLESHOOTING

NOTE: It is our policy to continually improve products and as such we reserve the right to alter data, specifications and component parts without prior notice.

IMPORTANT: No liability is accepted for incorrect use of this product.

WARRANTY: Guarantee is 12 months from purchase date, proof of which will be required for any claim.

INFORMATION: For a copy of our latest catalogue and promotions call us on 01284 757525 and leave your full name and address, including postcode.

01284 757500

01284 703534

sales@sealey.co.uk

Sole UK Distributor, Sealey Group,

Kempson Way, Suffolk Business Park,

Bury St. Edmunds, Suffolk,

IP32 7AR

www.sealey.co.uk

Web

email

Original Language Version

G2300.V2 (S)Issue: 2 - 25/10/12

4.5 CLEANING THE GENERATING SET

4.5.1 Clean the generating set using a brush and cloth (water jet cleaning is not recommended). Remove dust and debris around the

exhaust exhaust and the cooling fins.

4.5.2 Clean the engine and alternator air inlets and outlets. Make the most of this cleaning by checking the general condition of the

generating set and change any defective or worn parts.

4.6 CHANGING THE OIL

4.6.1 Warm up the engine on level ground, then switch the engine off.

4.6.2 Remove the oil filler cap.

4.6.3 Place a drain pan under the unit and open the drain plug, letting the oil completely drain out.

4.6.4 Check the gaskets and replace if required.

4.6.5 Refit the drain plug and refill the engine with 0.6ltr of clean engine oil.

4.6.6 Replace the filler cap.

PROBLEM CAUSE ACTION

Engine will not start. Fuel tap not turned on.

No fuel in tank.

Oil not filled to correct level.

Engine run switch not turned on.

Choke not set correctly.

Spark plug fouled.

Air filter blocked.

Turn fuel on.

Fill fuel tank.

Fill oil to correct to level.

Set engine control correctly.

Set choke control correctly.

Clean/replace spark plug.

Clean/replace air filter.

Engine runs rough. Air filter blocked.

Spark plug fouled.

Choke set incorrectly.

Dirty/stale fuel.

Clean/replace air filter.

Clean/replace spark plug.

Set choke control correctly.

Drain and replace fuel.

Environmental Protection

Recycle unwanted materials instead of disposing of them as waste. All tools, accessories and packaging should be sorted, taken to

a recycle centre and disposed of in a manner which is compatible with the environment.

When the product is no longer required, it must be disposed of in an environmentally protective way.

Parts support is available for this product.

To obtain a parts listing and/or diagram, please log on to www.sealey.co.uk,

email sales@sealey.co.uk or phone 01284 757500.

Loading...

Loading...