Sealey ER1700PD Instructions Manual

INSTRUCTIONS FOR:

POLISHER DIGITAL Ø 180mm 1100W/230V

LIGHTWEIGHT

MODEL NO: ER1700PD

Thank you for purchasing a Sealey product. Manufactured to a high standard, this product will, if used according to these instructions

and properly maintained, give you years of trouble free performance.

IMPORTANT: PLEASE READ THESE INSTRUCTIONS CAREFULLY. NOTE THE SAFE OPERATIONAL REQUIREMENTS, WARNINGS & CAUTIONS. USE THE

PRODUCT CORRECTLY AND WITH CARE FOR THE PURPOSE FOR WHICH IT IS INTENDED. FAILURE TO DO SO MAY CAUSE DAMAGE AND/OR

PERSONAL INJURY AND WILL INVALIDATE THE WARRANTY. KEEP THESE INSTRUCTIONS SAFE FOR FUTURE USE.

1. SAFETY

1.1. ELECTRICAL SAFETY.

WARNING! It is the user’s responsibility to read, understand and comply with the following:

You must check all electrical equipment and appliances to ensure they are safe before using. You must inspect power supply leads, plugs and

all electrical connections for wear and damage. You must ensure the risk of electric shock is minimised by the installation of appropriate safety

devices. An RCCB (Residual Current Circuit Breaker) should be incorporated in the main distribution board. We also recommend that an RCD

(Residual Current Device) is used with all electrical products. It is particularly important to use an RCD with portable products that are plugged

into an electrical supply not protected by an RCCB. If in doubt consult a qualified electrician. You may obtain a Residual Current Device by

contacting your Sealey dealer. You must also read and understand the following instructions concerning electrical safety.

1.1.1. The Electricity At Work Act 1989 requires all portable electrical appliances, if used on business premises, to be tested by a

qualified electrician, using a Portable Appliance Tester (PAT), at least once a year.

1.1.2. The Health & Safety at Work Act 1974 makes owners of electrical appliances responsible for the safe condition of the appliance and

the safety of the appliance operator. If in any doubt about electrical safety, contact a qualified electrician.

1.1.3. Ensure the insulation on all cables and the product itself is safe before connecting to the mains power supply. See 1.1.1. & 1.1.2.

above and use a Portable Appliance Tester (PAT).

1.1.4. Ensure that cables are always protected against short circuit and overload.

1.1.5. Regularly inspect power supply, leads, plugs for wear and damage and all electrical

connections to ensure that none are loose.

1.1.6. Important: Ensure the voltage marked on the product is the same as the electrical power

supply to be used and check that plugs are fitted with the correct capacity fuse.

A 13 amp plug may require a fuse smaller than 13 amps for certain products

(subject to 1.1.10. below), see fuse rating at right.

1.1.7. DO NOT pull or carry the powered appliance by its power supply lead.

1.1.8. DO NOT pull power plugs from sockets by the power cable.

1.1.9. DO NOT use worn or damaged leads, plugs or connections. Immediately replace or have

repaired by a qualified electrician. A UK 3 pin plug with ASTA/BS approval is fitted. In case of

damage, cut off and fit a new plug according to the following instructions (discard old plug

safely).

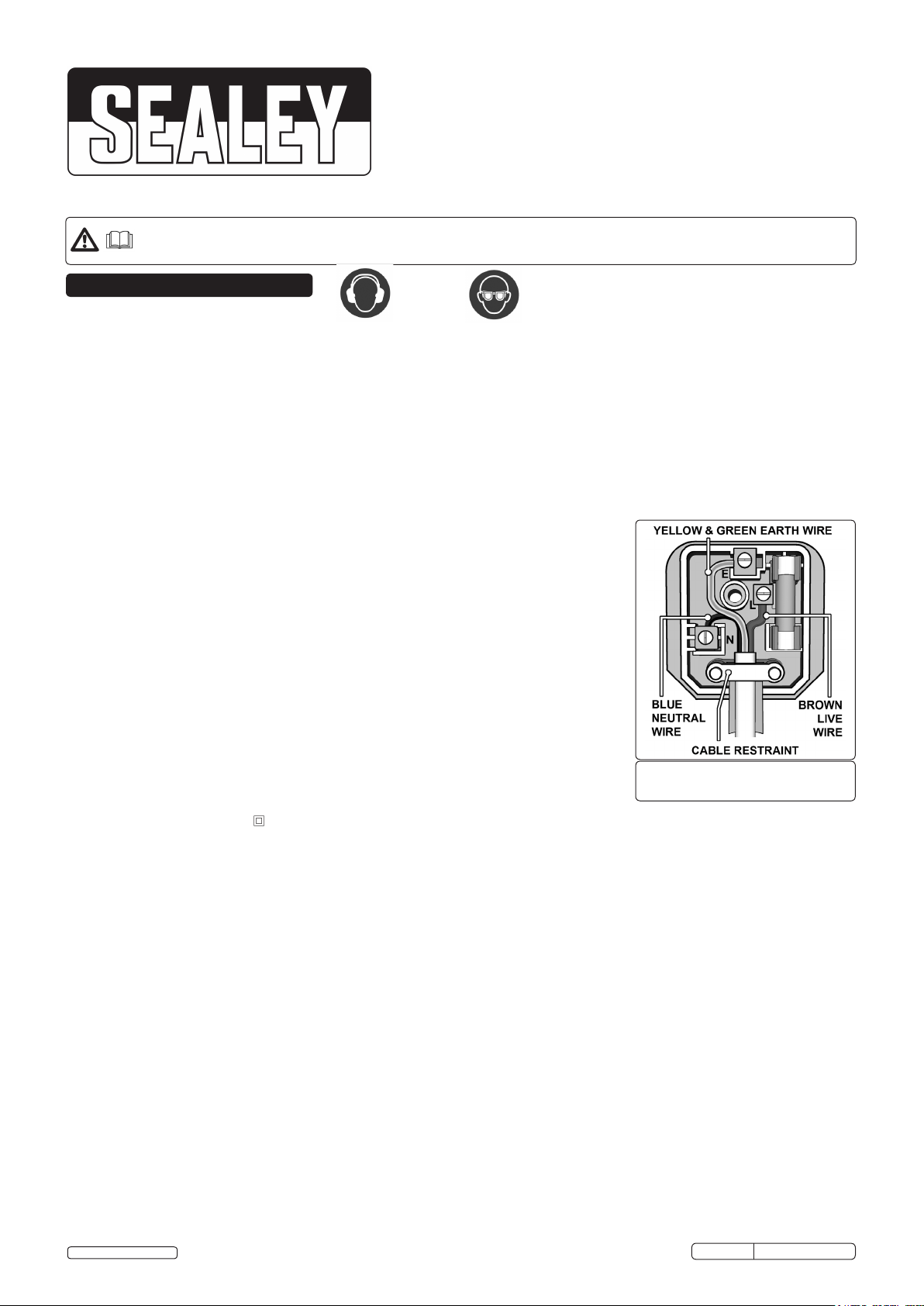

(UK only - see diagram at right). Ensure the unit is correctly earthed via a three-pin plug.

a) Connect the GREEN/YELLOW earth wire to the earth terminal ‘E’.

b) Connect the BROWN live wire to live terminal ‘L’.

c) Connect the BLUE neutral wire to the neutral terminal ‘N’.

d) After wiring, check there are no bare wires, that all wires have been connected

correctly, that cable outer insulation extends beyond the cable restraint and that the restraint is tight.

Double insulated products are often fitted with live (BROWN) and neutral (BLUE) wires only. Double insulated products are always

marked with this symbol . To re-wire, connect the brown & blue wires as indicated above. DO NOT connect the brown or blue

to the earth terminal.

1.1.10. Cable extension reels. When a cable extension reel is used it should be fully unwound before connection. A cable reel with an RCD

fitted is recommended since any product which is plugged into the cable reel will be protected. The section of the cores of the cable

is important. We suggest 1.5mm2 section as a minimum but to be absolutely sure that the capacity of the cable reel is suitable for this

product and for others that may be used in the other output sockets, we recommend the use of 2.5mm2 section cable.

NOTE: The ER1700PD has an electronic speed control, which requires a ‘clean’ and stable power supply. Normal 230V mains

supply is suitable. However, the output from many petrol driven generators may not be suitable for this tool. ‘Inverter’ type

power supplies provide a much more stable output and should present no problem.

1.2 GENERAL SAFETY

Wear

Ear

Protection

Wear

Eye

Protection

SUGGESTED FUSE

RATING: 13A

WARNING! Ensure Health & Safety, local authority, and general workshop practice regulations are adhered to when using this equipment.

Familiarise yourself with the application and limitations of the product, as well as the specific potential hazards peculiar to the polisher.

WARNING! Disconnect from the mains power and ensure the disc is at a complete standstill before changing accessories, servicing or

performing any maintenance.

Maintain the polisher in good condition (use an authorised service agent).

Replace or repair damaged parts. Use genuine parts only. Non-authorised parts may be dangerous and will invalidate the warranty.

WARNING! Keep all guards and holding screws in place, tight and in good working order. Check regularly for damaged parts. A guard or

any other part that is damaged must be repaired/replaced before the tool is next used.

Locate polisher in a suitable working area, keep area clean and tidy and free from unrelated materials. Ensure there is adequate

lighting.

Keep the polisher clean for best and safest performance.

Before each use check abrasive attachments for condition. If worn or damaged replace immediately.

Ensure there are no flammable or combustible materials near the work area.

WARNING! Wear approved eye safety protection, ear defenders and if dust is generated, respiratory protection.

Maintain correct balance and footing. Ensure the floor is not slippery and wear non-slip shoes.

© Jack Sealey Limited

Original Language Version

ER1700PD Issue:1 - 15/10/14

Remove ill fitting clothing. Remove ties, watches, rings, and other loose jewellery and tie back long hair.

Keep children and unauthorised persons away from the working area.

Secure non-stable work piece with a clamp, vice or other adequate holding device.

Remove adjusting keys and wrenches from the machine and its vicinity before turning it on.

DO NOT use equipment for any purpose other than that for which it is designed.

DO NOT operate the polisher if any parts are damaged or missing as this may cause failure or possible personal injury.

WARNING! DO NOT sand any materials containing asbestos.

DO NOT switch the polisher on whilst the head is in contact with the work piece and avoid unintentional starting.

DO NOT get the polisher wet or use in damp or wet locations or areas where there is condensation.

DO NOT allow untrained persons to operate the polisher.

DO NOT operate the polisher when you are tired, under the influence of alcohol, drugs or intoxicating medication.

DO NOT use the polisher where there are flammable liquids, solids or gases such as paint solvents, etc.

DO NOT leave the polisher operating unattended.

DO NOT carry the polisher with your finger on the power switch.

DO NOT pull the cord to remove the plug from the power supply.

Use a qualified person to lubricate and maintain the polisher.

When not in use unplug from the mains power supply and store in a safe, dry, childproof area.

LEAD PAINT WARNING! Paint once contained lead as a traditional ingredient. Contact with the dust from the removal of such paint is toxic

and must therefore be avoided. The following action must be taken before using machine as a sander:

1. User must determine potential hazard relating to age of paint to be removed. (Modern paints do not have lead content).

2. DANGER! Keep all persons and pets away from the working area. The following are particularly vulnerable to the effects of lead

paint dust: pregnant women, babies and children.

3. Wear appropriate Personal Protective Equipment. A full range of Personal Protective Equipment is available from your Sealey Dealer.

4. Take adequate measures to contain paint dust, flakes and scrapings. Wear safety equipment, as in (3) above and thoroughly clean

all areas when task is complete.

5. Ensure the paint waste is disposed of in sealed bags or containers according to local regulations.

2. INTRODUCTION

Powerful 1100W motor enclosed in a lightweight housing. Maintains high torque levels at low speeds, ideal for polishing. Digital display for

variable speed control from 1000-3000rpm, stepping-up in 500rpm increments. Features a slide button on/off switch allowing for a smooth,

comfortable main handle grip. Spindle lock for fast and easy pad/foam head changes. Choice of two side handles:. traditional or over-the-top

style. Supplied in robust storage case.

3. SPECIFICATIONS

Model ..............................ER1700PD

Pad Size:..............................Ø180mm

Thread Size: .........................M14 x 2mm

No Load Speed: ...................... 0-3000rpm

Power: ..................................1100W

Supply: ..................................230V

Weight: ..................................2.5kg

Noise Power:.............................82dBA

Noise Pressure:...........................71dBA

Vibration: .............................. 3.36m/s²

Uncertainty: ............................ 1.68m/s²

4. ASSEMBLY

WARNING! Ensure unit is not plugged into mains before

attempting any assembly.

4.1. Attaching the side handle.

4.1.1. Traditional Handle (fig.1):

Attach the side handle to either side by screwing into the

desired fixing hole in the head.

4.1.2. Over the Top Handle (fig.2):

Slide both sides of the handle over the fixing holes (fig.3)

and secure with the hex nuts supplied.

4.2. Attaching the backing pad.

4.2.1. With the machine disconnected from the electrical supply,

spin the backing pad onto the spindle until resistance from

the motor is felt. The disc will tighten itself sufficiently when in

use.

4.3. Removing the backing pad.

With the machine disconnected from the electrical supply,

depress the spindle lock button (fig.5). Turn the backing pad

by hand until the spindle lock is felt to engage. Turn the

backing pad clockwise (viewed from above) to release and

remove.

4.4. Attaching the lambswool bonnet.

Turn the edge of the bonnet back (fig.4), then place the backing

disc centrally on the `hook and loop fixing. When fixed, turn the

edge of the bonnet back over the edge of the backing pad.

g.1

g.2

g.3

© Jack Sealey Limited

Original Language Version

ER1700PD Issue:1 - 15/10/14

Loading...

Loading...