Page 1

InstructIons for:

industrial steel workbenches

MoDEL nos: aPi1500, aPi1800, aPi2100

thank you for purchasing a sealey product. Manufactured to a high standard this product will, if used according to these instructions and properly maintained,

give you years of trouble free performance.

IMPORTANT: Please read these instructions careFullY. note the saFe oPerational reQuireMents, warninGs & cautions.

use the Product correctlY and with care For the PurPose For which it is intended. Failure to do so MaY cause

daMaGe and/or Personal inJurY and will inValidate the warrantY. Please keeP instructions saFe For Future use.

1. saFetY instructions

1.1 General saFetY

warninG! Ensure Health & Safety, local authority, and

general workshop practice regulations are adhered to when

using this workbench.

warninG! use workbench on level and solid ground, preferably

concrete. Avoid tarmacadam since the workbench may sink into

the surface.

Locate workbench in a suitable working area.

Keep the work area clean, uncluttered and ensure there is

adequate lighting.

Keep the workbench clean and tidy in accordance with good

workshop practice.

Keep children and unauthorised persons away from the

working area.

do not use the workbench for any purpose other than that for

which it is designed.

do not undertake work on the workbench without the

workpiece being adequately secured. use clamps or a vice (not

included) to secure the workpiece. Available from your sealey

dealer.

do not use the workbench out of doors.

do not get the workbench wet or use in damp or wet

locations or areas where there is condensation.

do not clean the workbench with any solvents which may

damage the work surface or the painted surfaces.

Note! The assembly of this product will require assistance.

2. introduction and sPeciFications

2.1 introduction: Manufactured from heavy gauge steel,

these benches are the top end of our range with a weight

capacity of 1000kg (evenly distributed). fitted with adjustable

feet to ensure work surface is level even if your floor is not.

40mm thick laminate worktop is edged with double thick trim.

optional single or two drawer unit, vice support or back

panels easily attach converting the workbench into a

workstation.

2.2 sPeciFication:

Model no: ................width ....depth...height

API1500 ..................1500 ......750 .......850mm

API1800....................1800 ......750 .......850mm

API2100....................2100 ......750 .......850mm

3. workbench asseMblY

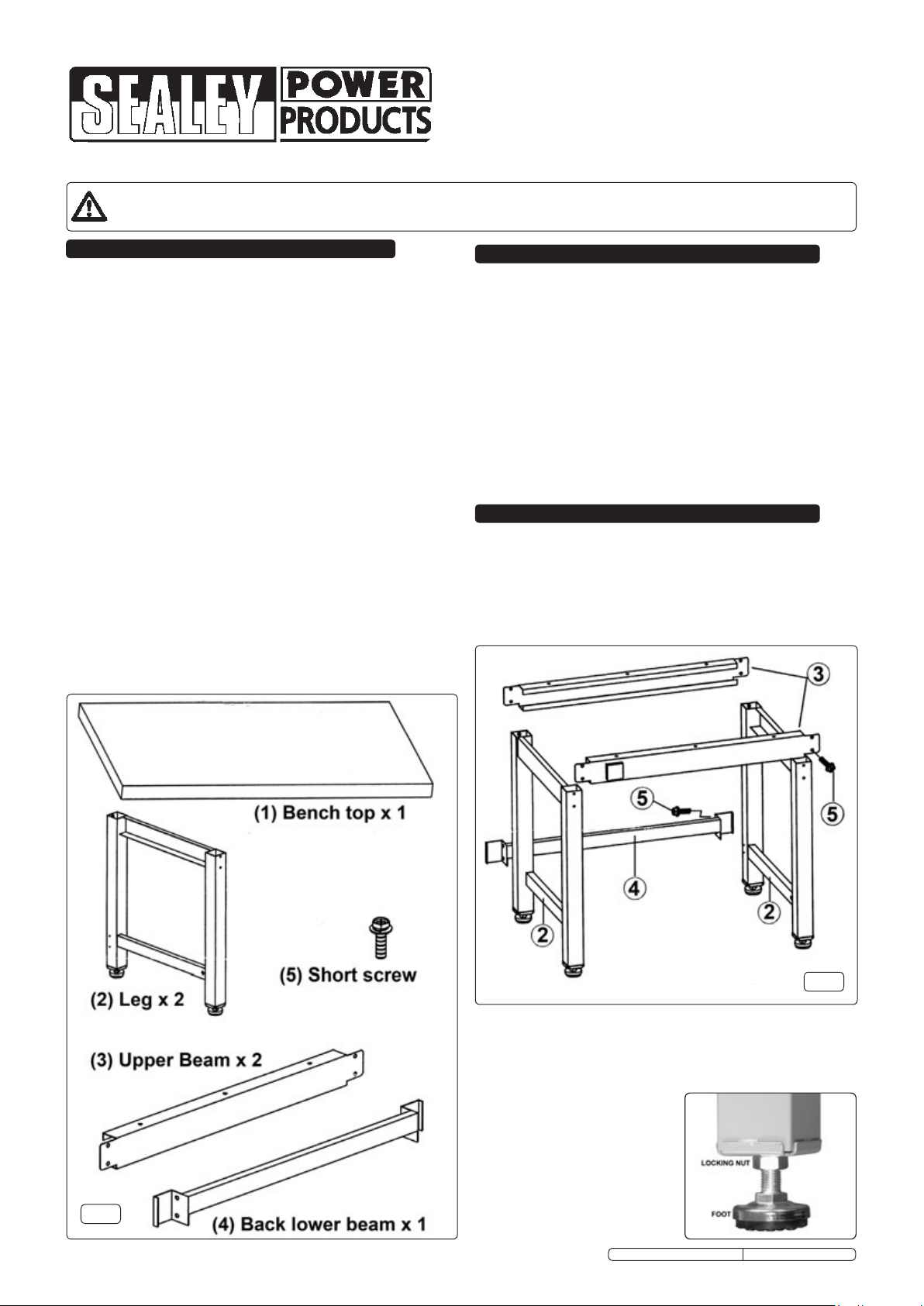

3.1 see fig.2. Join the two leg frames (2) together using one of

the upper beams (3) and four short screws (5). Ensure that

the open sections on all components are facing inwards. fix

the second upper beam (3) in place using four short screws

(5). Align the fixing holes in the lower beam with the holes in

the two leg frames and fix in place using four short screws (5).

fig.1

3.2 see fig.3. Lay the bench top (1) face down on a smooth

clean surface. Invert the assembled frame and place it

centrally onto the bench top. Align the holes in the upper

beams with the holes in the underside of the bench top and

fix the frame onto the bench top using six short screws (5).

3.3 turn the assembled bench

onto its feet as shown in fig.4.

3.4 site the bench in the

workplace observing the

advice given in section 1.

3.5 Adjust the feet to compensate

for uneven surfaces and lock

each foot using the locking

nut shown in the adjacent

diagram.

Original Language Version

fig.2

API1500, API1800, API2100 Issue no.1 20/05/10

Page 2

fig.3

fig.4

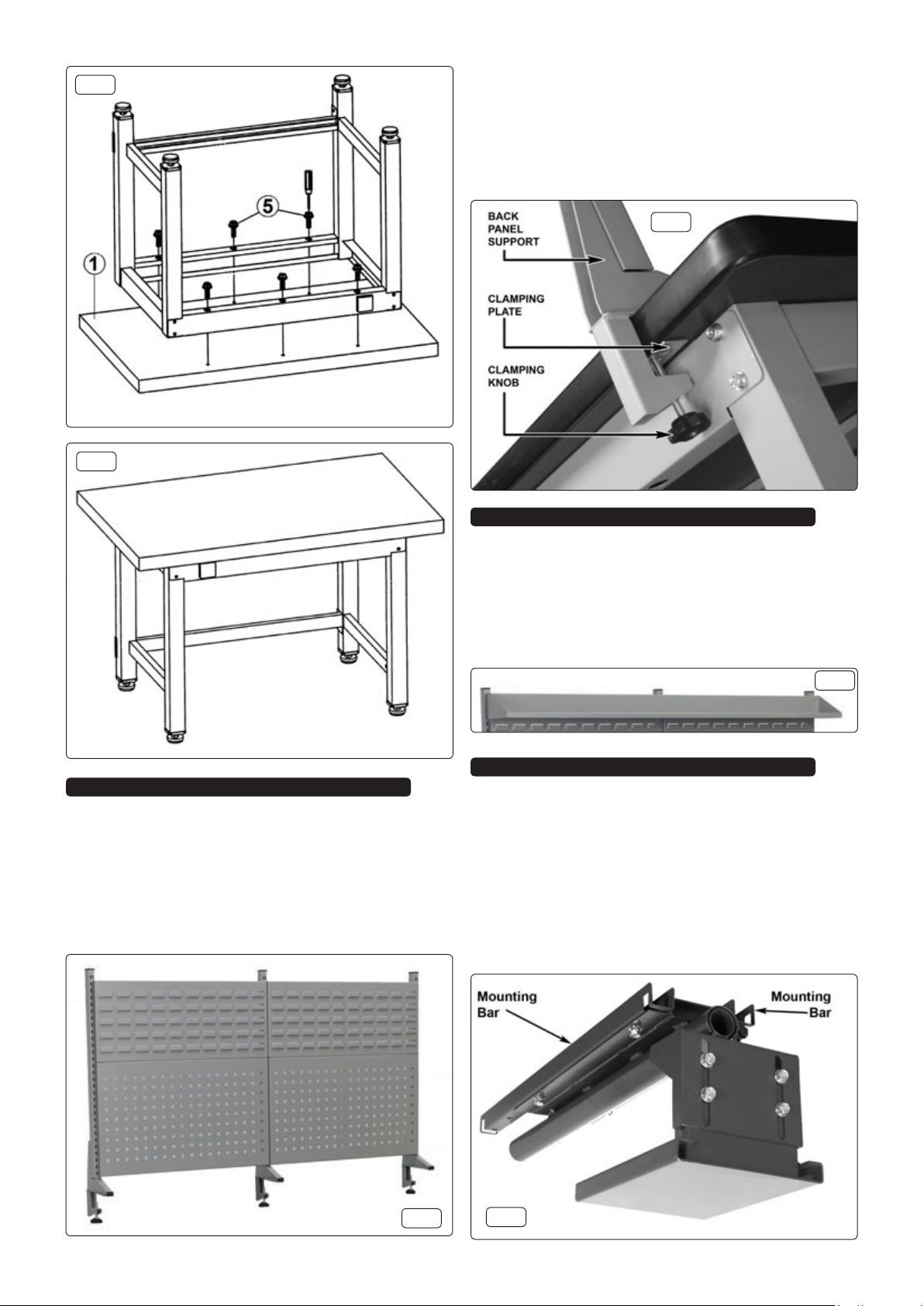

take the three back panel supports and clamp them to the

back edge of the bench ensuring that a clamping plate is

inserted between the clamping knob spindle and the underside

of the bench top as shown in fig.6. Adjust the positions of the

uprights until the tool panels can be slotted into position

followed by the bin panels above them as shown in fig.5 . on

the outer uprights the back panels should occupy the inner line

of slots leaving one row of slots visible.

fig.6

4. shelF asseMblY

4.1 three widths of shelf unit can be purchased as an optional

extra to match the three back panel kits. the shelves hook

into the outer uprights as shown in fig.7 and stand away from

the panels slightly allowing them to be put at any height.

3. back Panel asseMblY

3.1 see fig.5. Back panel kits are available for all three sizes of

bench and are an optional extra to be purchased separately.

aPibP1500 ..............Back panel assembly for API1500

aPibP1800 ..............Back panel assembly for API1800

aPibP2100 ..............Back panel assembly for API2100

aPi11........................shelf for APIBP1500

aPi12 .......................shelf for APIBP1800

aPi13 .......................shelf for APIBP2100

fig.7

5. Vice MountinG claMP asseMblY

5.1 A Vice Mounting clamp aPi10 can be purchased as an

optional extra to provide a base plate to which a vice can be

mounted. the mounting clamp also allows the vice to be

stored out of the way, below the bench, when a full free work

surface is required.

5.2 fig.8 below shows the clamp in the stowed away orientation.

the mounting bars have to be removed from the clamp and

positioned under the bench as shown in fig.9-V. Place each

bar in a diagonal orientation under the bench top then turn it

so that the ends are over the upper beams. Allow the slots in

the ends of the mounting bars to rest over the upturned edges

of the beams.

fig.5

fig.8

Page 3

fig.9

5.3 the main clamp is attached to a tube which is a sliding fit

inside the main mounting tube. Withdraw the clamp from the

mounting tube and fix the mounting tube to the two bars 'V',

under the work top using four short bolts as shown in fig.10

fig.10

5.5 Loosen and remove the four bolts on the front of the clamp

and lift the top plate away. Bolt the chosen vice to the top plate

ensuring that the fixings are within the depth of the plate.

Place the vice and plate back onto the top of the bench over

the lower part of the clamp and bolt the two parts back

together again. tighten the clamping knob on the underside of

the clamp assembly. see fig.11-Z.

fig.12

5.6 to stow the vice under the bench loosen the clamping knob

on the underside of the clamp assembly. see fig.11-Z. Keeping

a firm hold on the assembly pull the vice and top plate

forwards until they are clear of the bench edge. Allow the

assembly to slowly rotate through 180º until it is hanging

downwards. Push the assembly under the front edge of the

bench until it is in the orientation shown in fig.8.

5.4 Insert the clamp tube into the mounting tube as shown in

fig.11-Y and rotate the clamp so that it is uppermost. Push the

clamp tube into the mounting tube until the clamp comes up

against the edge of the bench and laps over the top of it as

shown in fig.12.

fig.11

6. drawer oPtions

fig.13

6.1 Drawer units can be purchased as an optional extra. single

and double drawer units can be suspended from the underside

of the bench using two draw support bars as shown in fig.13.

Larger drawer units will be free standing under the bench. see

overleaf for other drawer options.

Original Language Version

fig.14

aPi8 single draw unit (bench mounted).

API1500, API1800, API2100 Issue no.1 20/05/10

Page 4

aPi9 double drawer unit (bench mounted).

see our website for full details and specification

for these drawer units as well as the other

optional extras found in this manual.

www.sealey.co.uk

aPi5655a Five drawer unit(Free standing) (Free standing)

(Free standing) (Free standing)

aPi5656 six drawer unit aPi7238 eight drawer unit

aPi5655b Five drawer unit

NOTE: It is our policy to continually improve products and as such we reserve the right to alter data, specifications and component parts without prior notice.

iMPortant: no liability is accepted for incorrect use of this product.

warrantY: Guarantee is 12 months from purchase date, proof of which will be required for any claim.

inForMation: for a copy of our latest catalogue and promotions call us on 01284 757525 and leave your full name and address, including postcode.

sole uk distributor, sealey Group,

Kempson Way, suffolk Business Park,

Bury st. Edmunds, suffolk,

IP32 7Ar

Original Language Version

01284 757500

01284 703534

API1500, API1800, API2100 Issue no.1 20/05/10

www.sealey.co.uk

Web

sales@sealey.co.uk

email

Loading...

Loading...