Page 1

INSTRUCTIONS FOR:

HEAVY DUTY STEEL WORKBENCH

WITH 4 DRAWERS & 2 TOP CABINETS

MODEL No: AP1205

Thank you for purchasing a Sealey product. Manufactured to a high standard this product will, if used according to these instructions and

properly maintained, give you years of trouble free performance.

IMPORTANT: PLEASE READ THESE INSTRUCTIONS CAREFULLY. NOTE THE SAFE OPERATIONAL REQUIREMENTS, WARNINGS & CAUTIONS.

USE THE PRODUCT CORRECTLY AND WITH CARE FOR THE PURPOSE FOR WHICH IT IS INTENDED. FAILURE TO DO SO MAY CAUSE

DAMAGE AND/OR PERSONAL INJURY AND WILL INVALIDATE THE WARRANTY. PLEASE KEEP INSTRUCTIONS SAFE FOR FUTURE USE.

1. SAFETY INSTRUCTIONS1. SAFETY INSTRUCTIONS

WARNING! Ensure Health & Safety, local authority, and

general workshop practice regulations are adhered to when

assembling and using this bench.

Locate bench in a suitable, well lit work area.

Use adequate manpower when assembling and moving this

bench.

WARNING! Use bench on level and solid ground only,

preferably concrete.

DO NOT use the bench outdoors and DO NOT get the bench

wet or use in damp or wet locations or areas where there is

condensation.

Keep the work area clean, uncluttered and ensure there is

adequate lighting.

Keep the bench clean and tidy in accordance with good

workshop practice.

Keep children and unauthorised persons away from the work area.

DO NOT use the bench for any purpose other than that for

which it is designed.

DO NOT undertake work on the bench without the workpiece

being adequately secured. Use clamps or a vice (not included -

available from your Sealey dealer) to secure the workpiece.

Lower heavy loads onto the worktop gently to avoid excessive

impacts to the worktop.

DO NOT clean the bench with any solvents which may damage

the surface or the protective coating on the worktop.

DO NOT stand on this product.

DO NOT use excessive force to open and close drawers.

DO NOT exceed weight limits - see specifications.

2. INTRODUCTION & SPECIFICATION

Heavy-duty steel powder-coated workbench with laminated

worktop. Four drawers on smooth 25mm roller ball-bearings

and two top storage cupboards. Pegboard back panel with

hooks for convenient tool storage.

Original Language Version

Dimensions:

Overall size (W x D x H): ..........1205mm x 620mm x 1735mm

Overall worktop size(W x D): ............... 1205mm x 590mm

Small drawer (W x D x H): ........... 430mm x 455mm x 80mm

Large drawer (W x D x H): .......... 430mm x 455mm x 222mm

Maximum Weight Limits:

Workbench: ...................................... 545kg

Drawers - (small): ....................................11kg

(large): ................................... 16kg

Pegboard:......................................... 29kg

Top shelf: ......................................... 27kg

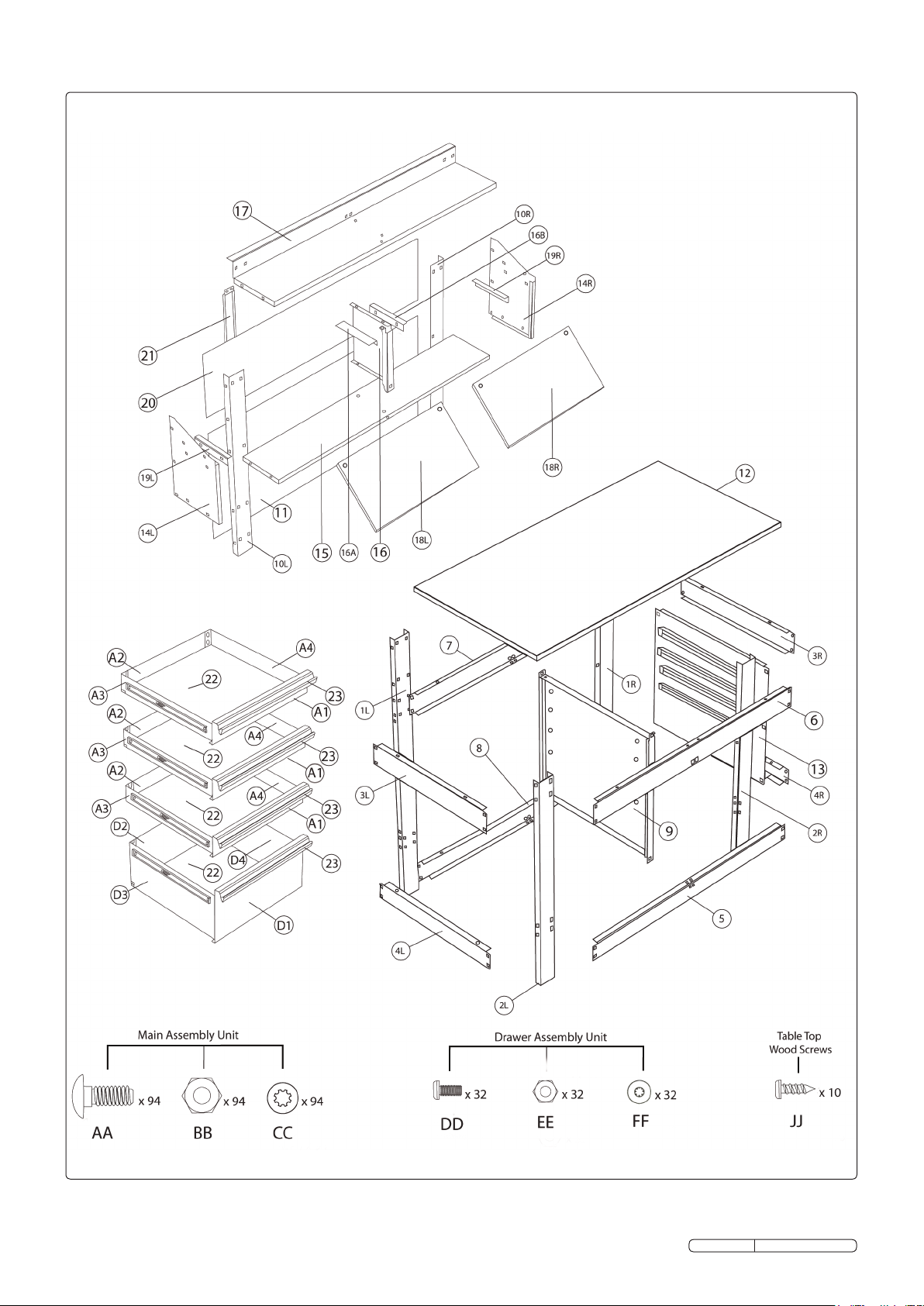

3. CONTENTS

Unpack the product and check the contents against the list below

and the illustration overleaf. Should any items be missing or

damaged contact your Sealey dealer.

ITEM DESCRIPTION

01L Support back leg (left)

01R Support back leg (right)

02L Support front leg (left)

02R Support front leg (right)

03L Short cross bracing (left)

03R Short cross bracing (right)

04L Short cross bracing (left)

04R Short cross bracing (right)

5 Long cross bracing (front-down)

6 Long cross bracing (front-up)

7 Long cross bracing (back-up)

8 Long cross bracing (back-down)

9 Centre wall with drawer rails

10L Left extension post

10R Right extension post

11 Pegboard

12 Worktop

13 Drawer side

14L Shelf bracing (left)

14R Shelf bracing (right)

15 Shelf bottom

16 Middle divider of shelf

16A Middle shelf divider rail (left)

16B Middle shelf divider rail (right)

17 Upper shelf

18L Top left door

18R Top right door

19L Rail of top left door

19R Rail of top right door

20 Back board of shelf

21 Pegboard support bar

22 Drawer Bottom (x4)

23 Aluminium handle cover for drawer (x4)

A1 Drawer front (x3)

A2 Drawer rear (x3)

A3 Drawer - Left side (x3)

A4 Drawer - Right side (x3)

D1 Drawer front

D2 Drawer rear

D3 Drawer - Left side

D4 Drawer - Right side

AA M6 bolt (x94)

BB M6 nut (x94)

CC M6 washer (x94)

DD M5 bolt (x32)

EE M5 nut (x32)

FF M5 washer (x32)

JJ Screw (x10)

AP1205 Issue No.1 - 26/09/11

Page 2

Original Language Version

AP1205 Issue No.1 25/09/11

Page 3

4. ASSEMBLY

Fig.1

NOTE: Tools required for assembly: spanner (included),

#2 cross-head screwdriver and pliers (not included).

4.1. Use 8 AA bolts, 8 BB nuts and 8 CC washers. Align holes

on cross bracing (3L) and (4L) to table legs (1L and 2L).

Insert 8 (AA) bolts through matching holes as shown above

- four bolts per cross bracing. Fasten with 8 washers (CC)

and 8 nuts (BB).

Do not over tighten.

Fig.2

4.2. Use 8 AA bolts, 8 BB nuts and 8 CC washers.

Align holes on cross bracing (3R) and (4R) to table legs

(1R) and (2R). Insert 8 (AA) bolts through matching holes

as shown above - four bolts per cross bracing.

Fasten with 8 washers (CC) and 8 nuts (BB).

Do not over tighten.

Fig.3

4.3. Use 16 AA bolts, 16 BB nuts and 16 CC washers.

Align holes from cross bracing pieces (5 and 8) to the

complete table leg ends from previous steps. Ensure labels

on pieces (5 and 8) have arrows facing up and square holes

are on the top. Insert 2 (AA) bolts through left and right side

of lower front cross bracings (5) - Fasten with 2 washers

(CC) and 2 nuts (BB). Repeat for lower back cross bracing

(8). Repeat steps for top cross bracing pieces (6 and 7),

ensure labels on pieces (6 and 7) have arrows facing up

and round holes are on the top. Do not over tighten.

Fig.4

NOTE: If you wish to install the drawers on the LEFT side, go to

steps 4.22 to 4.27.

Installation of drawers on left side will take an additional

1 hour approximately.

4.4. Use 4 AA bolts, 4 BB nuts and 4 CC washers.

Take centre wall (9), with drawer rails facing to the right of

the table, and fasten to frame of table using 4 (AA) bolts,

4 (CC) washers and 4 (BB) nuts.

Do not over tighten.

Original Language Version

AP1205 Issue No.1 25/09/11

Page 4

Fig.5

Fig.6

4.5. Use 8 AA bolts, 8 BB nuts and 8 CC washers.

Align holes on cross bracing (3L) and (4L) to table legs

(1L and 2L). Insert 8 (AA) bolts through matching holes as

shown above - four bolts per cross bracing.

Fasten with 8 washers (CC) and 8 nuts (BB).

Do not over tighten.

Fig.7

4.6. Use 8 AA bolts, 8 BB nuts and 8 CC washers.

Align holes on cross bracing (3L) and (4L) to table legs

(1L and 2L). Insert 8 (AA) bolts through matching holes as

shown above - four bolts per cross bracing.

Fasten with 8 washers (CC) and 8 nuts (BB).

Do not over tighten.

Fig.8

4.7. Use 8 AA bolts, 8 BB nuts and 8 CC washers.

With drawer rails facing inward, take drawer frame (13) and

fasten to body of frame using 8 (AA) bolts, 8 (CC) washers

and 8 (BB) nuts.

Do not over tighten.

Original Language Version

4.8. Use 3 AA bolts, 3 BB nuts and 3 CC washers.

Align holes of the left side shelf bracing (14L), and match

them to the peg board frame (10L). Fasten using 3 (AA)

bolts, 3 (CC) washers and 3 (BB) nuts.

Do not over tighten.

AP1205 Issue No.1 25/09/11

Page 5

Fig.9

Fig.10

4.9. Use 3 AA bolts, 3 BB nuts and 3 CC washers.

Align holes of the right side shelf bracing (14R), and

match them to the pegboard frame (10R).

Fasten using 3 (AA) bolts, 3 (CC) washers and 3 (BB) nuts.

Do not over tighten.

Fig.11

4.10. Use 4 AA bolts, 4 BB nuts and 4 CC washers.

Align the holes of the bottom of the shelving unit (15) and

match them to the side shelf bracing (14L) and (14R).

Fasten using 4 (AA) bolts, 4 (CC) washers and 4 (BB) nuts.

Do not over tighten.

Fig.12

4.11. Use 4 AA bolts, 4 BB nuts and 4 CC washers.

Take the middle shelf divider (16) and align holes with the

bottom shelving. Fasten using 2 (AA) bolts, 2 (CC) washers

and 2 (BB) nuts.

Take the left middle shelf divider rail (16A) and align it with

the right middle shelf divider rail (16B) making sure the

middle shelf divider (16) is in between. Fasten using 2 (AA)

bolts, 2 (CC) washers and 2 (BB) nuts.

Do not over tighten.

Original Language Version

4.12. Use 8 AA bolts, 8 BB nuts and 8 CC washers.

Taketheuppershelf(17)andlayatsothatitisrestingon

top of the shelf divider. Align holes of upper shelf (17) to

match the left and right side shelf bracing.

Take 3 (AA) bolts and insert them into the left shelf bracing,

fasten with 3 (CC) washers and 3 (BB) nuts.

Repeat previous step to attach the upper shelf (17) to the

right shelf bracing.

Take 2 (AA) bolts and insert them into the top part of shelf

divider, fasten with 2 (CC) washers and 2 (BB) nuts.

NOTE: Now tighten all fasteners on the workbench

upon completion of Step 4.12.

AP1205 Issue No.1 25/09/11

Page 6

Fig.13

Fig.14

4.13. Take the top left door (18L) and place onto rail of the middle

shelf divider (16).

Ensure that the wheel is resting onto the rail of middle shelf

divider.

You may have to insert the door at an angle to ensure it sits

securely on the rail of the middle shelf divider.

Fig.15

4.14. Use 2 AA bolts, 2 BB nuts and 2 CC washers.

Taketheleftshelfrail(19L)andtontothewheelofthetop

left door (left side). Lifting both the left shelf rail (19L) and

the top left door (18L), align the holes of (19L) with

the holes of the left side shelf bracing (14L). Fasten 19L to

14L with 2 (AA) bolts, with 2 (CC) washers and 2 (BB)

nuts.

Do not over tighten.

Fig.16

4.15. Take the top right door (18R) and place onto rail of the

middle shelf divider (16). Ensure that the wheel is resting

onto the rail of middle shelf divider.

You may have to insert the door at an angle to ensure it sits

securely on the rail of the middle shelf divider.

Original Language Version

4.16. Use 2 AA bolts, 2 BB nuts and 2 CC washers.

Taketherightshelfrail(19R)andtontothewheelofthe

top right door (right side). Lifting both the right shelf rail

(19R) and the top left door (18R), align the holes of (19R)

with the holes of the right side shelf bracing (14R).

Fasten 19R to 14R with 2 (AA) bolts, with 2 (CC) washers

and 2 (BB) nuts

Do not over tighten.

AP1205 Issue No.1 25/09/11

Page 7

Fig.17 Fig.18

4.17. Use 4 AA bolts, 4 BB nuts and 4 CC washers.

Rest the drawer backing (20) on top of the pegboard (11).

Take 4 (AA) bolts and place through pegboard frame (10R)

and (10L). Fasten and tighten with 4 (CC) washers and 4

(BB) nuts.

Do not over tighten.

Fig.19

4.18. Use 4 AA bolts, 4 BB nuts and 4 CC washers.

Align the holes of the pegboard support bar (21) to the

holes of the cross bracing piece (7) as well as the upper

shelf (17). Insert 4 (AA) bolts through holes and fasten

using 4 (CC) washers and 4 (BB) nuts.

Do not over tighten.

Fig.20

4.19. Align holes of front drawer (A1) with left and right side of

drawer (A3 & A4). Insert 2 (DD) bolts per side. Fasten

using 2 (FF) lock washers and 2 (EE) nuts.

Align holes of rear drawer (A2) with left and right side of

drawer (A3 & A4). Insert 2 (DD) bolts per side. Fasten

using 2 (FF) lock washers and 2 (EE) nuts.

Tighten all fasteners - Do not over tighten.

Insert wooden drawer bottom (22) so that it rests on lip of

drawers.

Slide aluminium handle cover (23) over the top of the front

drawer. Repeat for remaining small drawers.

Original Language Version

4.20. Align holes of front drawer (D1) with left and right side of

drawer (D3 & D4). Insert 2 (DD) bolts per side. Fasten

using 2 (FF) lock washers and 2 (EE) nuts.

Align holes of rear drawer (D2) with left and right side of

drawer (D3 & D4). Insert 2 (DD) bolts per side. Fasten

using 2 (FF) lock washers and 2 (EE) nuts.

Tighten all fasteners - Do not over tighten.

Insert wooden drawer bottom (22) so that it rests on lip of

drawers.

Slide aluminium handle cover (23) over the top of the front

drawer.

AP1205 Issue No.1 25/09/11

Page 8

Fig.21

Fig.22

Reversing Drawer Rails

for Left Hand Fitment

4.21. Empty the drawer and fully extend before removing.

Lift or lower (depending on the slide) the release lever on

both sides. Slowly pull the drawer out to remove from table.

To re-install, align the drawer rails and slowly push the

drawer into the table until the drawer stops.

Go to step 4.28.

Fig.23

4.22. Remove both screws attaching drawer rails to centre walls.

Flip drawer rails 180º to face the other direction and fasten

with both screws. Repeat the above steps for the other

three drawer rails.

Fig.24

4.23. Use 4 AA bolts, 4 BB nuts and 4 CC washers.

Take centre wall (9), with drawer rails facing to the left of

the table, and fasten to the frame of the table using 4 (AA)

bolts, 4 (CC) washers and 4 (BB) nuts.

Do not over tighten.

Original Language Version

4.24. Use 12 AA bolts, 12 BB nuts and 12 CC washers.

Take the pegboard (11) and place it against the back

of the table frame so that the power bar hole (PB) is on the

bottom right as shown above. Align screw holes

of pegboard (11) against the holes of the table frame.

Taking the left and right pegboard frame (10L and 10R),

sandwich the pegboard between (1L) and (10L). Repeat

this procedure, sandwiching Pegboard between (1R) and

(10R). Fasten pegboard frame against frame of table by

using 6 (AA) bolts, 6 (CC) washers and 6 (BB) bolts on each

side. Do not over tighten.

AP1205 Issue No.1 25/09/11

Page 9

Fig.25

Fig.26

4.25. Use 10 JJ screws.

Align pre-drilled holes on bottom of table top to the round

holes of the table frame. Using 10 (JJ) wood screws, fasten

table top to frame of table. Tighten screws using a

screwdriver.

Do not over tighten.

Fig.27 Fig.28

4.26. Slide the drawer rails in and out in order to remove both

screws attaching the drawer rails to the drawer frame.

Flip drawer rails 180º to face the other direction and fasten

with both screws.

Repeat the above steps for the other three drawer rails.

Do not over tighten.

4.27. Use 8 AA bolts, 8 BB nuts and 8 CC washers.

With drawer rails facing inward, take drawer frame (13) and

fasten to body of frame using 8 (AA) bolts, 8 (CC) washers

and 8 (BB) nuts.

Do not over tighten.

Now return to Step 4.8. to complete assembly.

Original Language Version

4.28. This workbench MUST be attached to a studded or concrete

wall. Only use material appropriate hardware per your

local building codes. Failure to do so may cause personal

injury or product damage.

Insert mounting hardware through the pre-drilled hole in

upper shelf (17). An additional pre-drilled hole is located in

cross bracing piece (7). If unable to secure through upper

shelf (17) securely mount workbench through cross bracing

piece (7). Use appropriate hardware only.

Do not over tighten.

AP1205 Issue No.1 25/09/11

Page 10

5. MAINTENANCE

5.1. Lubricate the slides of the drawers periodically with a smear of grease.

5.2. The drawer fronts, drawer trim, and other surfaces should be cleaned periodically with a mild detergent and water.

5.3. Carpolishwillpreservetheworkbench'snish.Applythepolishasyouwouldtoavehicle.Thepolishwillalsohelpprotectthe

workbench against scratches.

5.4. Greaseandoilcanberemovedwithmoststandardcleaninguids.Forsafetyreasons,useanonammablecleaninguid.

NOTE: It is our policy to continually improve products and as such we reserve the right to alter data, specifications and component parts without prior notice.

IMPORTANT: No liability is accepted for incorrect use of this product.

WARRANTY: Guarantee is 12 months from purchase date, proof of which will be required for any claim.

INFORMATION: For a copy of our latest catalogue and promotions call us on 01284 757525 and leave your full name and address, including postcode.

Sole UK Distributor, Sealey Group,

Kempson Way, Suffolk Business

Park, Bury St. Edmunds, Suffolk,

IP32 7AR

Original Language Version

01284 757500

01284 703534

www.sealey.co.uk

sales@sealey.co.uk

AP1205 Issue No.1 25/09/11

Loading...

Loading...