Page 1

INSTRUCTIONS FOR:

SUPERCHARGE

BATTERY

CHARGERS

SUPERCHARGE 10/1.V4 SUPERCHARGE 15/1.V4 SUPERCHARGE 30/1.V4 SUPERCHARGE 40/1.V4

Thank you for purchasing a Sealey product. Manufactured to a high standard this product will give you years of trouble free performance if these instructions are carefully followed and the

product is correctly maintained.

IMPORTANT: PLEASE READ THESE INSTRUCTIONS CAREFULLY. NOTE THE SAFE OPERATIONAL REQUIREMENTS, WARNINGS AND CAUTIONS. USE THIS

PRODUCT CORRECTLY AND WITH CARE FOR THE PURPOSE FOR WHICH IT IS INTENDED. FAILURE TO DO SO MAY CAUSE DAMAGE OR PERSONAL INJURY,

AND WILL INVALIDATE THE WARRANTY. PLEASE RETAIN THESE INSTRUCTIONS FOR FUTURE USE.

1. SAFETY INSTRUCTIONS

1.1. ELECTRICAL SAFETY

WARNING! It is the responsibility of the owner and the operator to read, understand and comply with the following:

You must check all electrical products, before use, to ensure that they are safe. You must inspect power cables, plugs, sockets and

any other connectors for wear or damage. You must ensure that the risk of electric shock is minimised by the installation of

appropriate safety devices. A Residual Current Circuit Breaker (RCCB) should be incorporated in the main distribution board. We also

recommend that a Residual Current Device (RCD) is used. It is particularly important to use an RCD with portable products that are

plugged into a supply which is not protected by an RCCB. If in any doubt consult a qualified electrician. You may obtain a Residual

Current Device by contacting your Sealey dealer.

You must also read and understand the following instructions concerning electrical safety.

1.1.1. The Electricity at Work Act 1989 requires that all portable electrical appliances, if used on business premises, are tested by a qualified

electrician, using a Portable Appliance Tester (PAT), at least once a year.

1.1.2. The Health & Safety at Work Act 1974 makes owners of electrical appliances responsible for the safe condition of those appliances

and the safety of the appliance operators. If in any doubt about electrical safety, contact a qualified electrician.

1.1.3. Ensure that the insulation on all cables and on the appliance is safe before connecting it to the power supply. See 1.1.1. and 1.1.2.

and use a Portable Appliance Tester.

1.1.4. Ensure that cables are always protected against short circuit and overload.

1.1.5. Regularly inspect power supply cables and plugs for wear or damage and check all

connections to ensure that none is loose.

1.1.6. Important: Ensure that the voltage marked on the appliance matches the power supply

to be used and that the plug is fitted with the correct fuse - see fuse rating at right.

1.1.7. DO NOT pull or carry the appliance by the power cable.

1.1.8. DO NOT pull the plug from the socket by the cable.

1.1.9. DO NOT use worn or damaged cables, plugs or connectors. Immediately have any faulty

item repaired or replaced by a qualified electrician. When a BS 1363/A UK 3 pin plug is

damaged, cut the cable just above the plug and dispose of the plug safely.

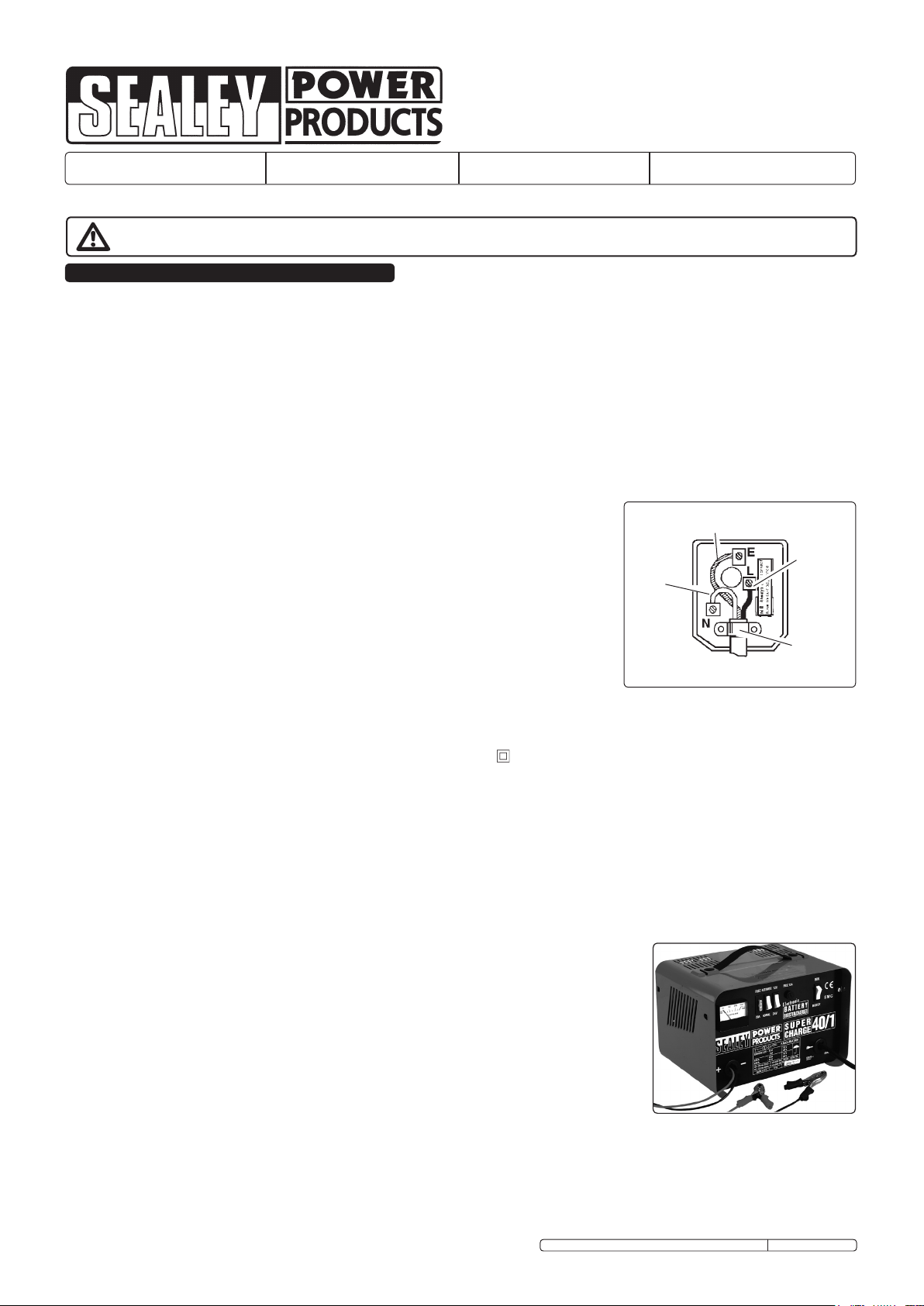

Fit a new plug according to the following instructions (UK only).

a) Connect the GREEN/YELLOW earth wire to the earth terminal ‘E’.

b) Connect the BROWN live wire to the live terminal ‘L’.

c) Connect the BLUE neutral wire to the neutral terminal ‘N’.

d) After wiring, check that there are no bare wires, that all wires have been correctly connected, that the cable outer insulation extends

beyond the cable restraint and that the restraint is tight.

Double insulated products, which are always marked with this symbol , are fitted with live (brown) and neutral (blue) wires only.

To rewire, connect the wires as indicated above DO NOT connect either wire to the earth terminal.

1.1.10. Products which require more than 13 amps are supplied without a plug. In this case you must contact a qualified electrician to ensure

that a suitably rated supply is available. We recommend that you discuss the installation of an industrial round pin plug and socket

with your electrician.

1.1.11. If an extension reel is used it should be fully unwound before connection. A reel with an RCD fitted is preferred since any appliance

plugged into it will be protected. The cable core section is important and should be at least 1.5mm², but to be absolutely sure that the

capacity of the reel is suitable for this product and for others which may be used in the other output sockets, we recommend the use

of 2.5mm² section cable.

Blue

Neutral

Wire

Yellow & Green

Earth Wire

Brown

Live

Wire

Cable

Restraint

FUSE RATING 13 AMP

1.2. GENERAL SAFETY

WARNING!Disconnect the charger from the mains power before servicing or performing any maintenance.

Disconnect the charger from the mains power before connecting to, or disconnecting from, the battery.

Maintain the charger in good condition (use an authorised service agent only).

WARNING!Charger has components such as switches and relays which may cause sparks or arcs.

When using the charger in a garage or workshop, make sure it is in a safe location.

Keep the charger clean for best and safest performance.

WARNING!Ensure there are no sources of flammable ignition near the work area i.e. naked flames,

cigarettes, flame heaters etc as the charging process produces explosive gases.

WARNING! Ensure the working area is well ventilated as the gases produced are flammable and

harmful if inhaled.

Locate the charger in a suitable working area. Keep area clean and tidy and free from unrelated

materials and ensure there is adequate lighting.

Wear approved safety eye protection (standard spectacles are not adequate).

Remove ill fitting clothing. Remove ties, watches, rings, and other loose jewellery, and contain long hair.

Read vehicle manufacturer’s instructions manual to check for any specific battery charging information.

Disconnect the battery from the vehicle and move it to a safe, dry level area for charging. If the battery can not be removed from the

vehicle refer to manufacturer’s hand book.

Check the electrolyte fluid level in the battery is above the plates. If not add distilled water to cover them by 5 - 10mm. DO NOT

touch the battery fluid as it is corrosive

Clean the charger clamps and battery terminals to remove any oxidation before connecting charger to battery .

Original Language Version

SUPERCHARGE10/4.V4, 15/1.V4, 30/1.V4, 40/1.V4 Issue: 2 - 08/03/10

Page 2

Ensure the correct clamp polarity is attached to the correct terminal of the battery. POSITIVE is indicated by (+) and may be Red.

NEGATIVE is indicated by (-) and may be black. If there are no identifiable symbols, you can distinguish the NEGATIVE battery terminal as

the one which is connected from the battery directly to the vehicle body.

Remove the battery electrolyte cover or caps to allow the gases produced by charging to escape.

Keep children and unauthorised persons away from the working area.

DO NOT attempt to charge a non-re-chargeable battery.

DO NOT use the charger for any purpose other than that for which it is designed.

DO NOT allow untrained persons to operate the charger.

DO NOT allow the charger terminal clamps to touch each other when the power is on or the charger fuse will blow. Remember that gases

are produced which may ignite if sparks occur.

DO NOT place the charger inside the vehicle. Remove the battery to a safe distance for charging.

DO NOT get the charger wet or use in damp or wet locations or areas where there is condensation.

DO NOT operate the charger if damaged.

DO NOT attempt to modify or open the charger.

When not in use unplug from the mains power supply and store in a safe, dry, child proof area.

WARNING!Be vigilant and cautious during the operation of battery charging as the electrolyte is highly corrosive and emissions of gasses

are flammable and harmful to health.

DANGER! BE AWARE, LEAD-ACID BATTERIES GENERATE EXPLOSIVE GASES DURING NORMAL BATTERY OPERATION. FOR THIS

REASON, IT IS VERY IMPORTANT TO READ AND FOLLOW THESE INSTRUCTIONS CAREFULLY, EACH TIME YOU USE THE STARTER

CHARGER. Follow these instructions and those published by the battery and vehicle manufacturers and the manufacturer of any

equipment you intend to use in the vicinity of the battery. Remember to review warning marks on all products and on engines.

1.3. PERSONAL PRECAUTIONS

Ensure there is another person within hearing range of your voice, or close enough

to come to your aid, should a problem arise when working near a lead-acid battery.

Wear safety eye protection and protective clothing. Avoid touching eyes while working near battery.

Have fresh water and soap nearby in case battery acid contacts skin, clothing, or eyes.

Wash immediately with soap and water if battery acid contacts skin or clothing. If acid enters eye, flush eye immediately with cool, clean

running water for at least 15 minutes and seek immediate medical attention.

Remove personal metallic items such as rings, bracelets, necklaces and watches. A lead-acid battery can produce a short-circuit current

high enough to weld a ring or the like to metal, which may cause severe burns.

Ensure hands, clothing (especially belts) are clear of fan blades and other moving or hot parts of engine, remove ties and contain long hair.

DO NOT smoke or allow a spark or flame in the vicinity of battery or engine.

2. SPECIFICATIONS

SUPERCHARGE MODEL NO: 10/1.V4 15/1.V4 30/1.V4 40/1.V4

Output 12V Peak (EN) 9A (6A) 14A (9A) 30A (20A) 18A (12A)

Output 24V peak (EN) - 8A(5A) 30A (20A) 12A(8A)

Input 230V 0.7A 230V 1.0A 230V 4.0A 230V 1.0A

Charging Rates 2 2 3 2

Output 12V 12V/24V 12V/24V 12/24V

Fuse Ref No 120/802256 10pcs 120/802256 10pcs 120/802256 10pcs 120/802257 10pcs

3. CHARGING INSTRUCTIONS

3.1. Preparation It is important to correctly prepare for charging ensuring you follow chapter 1 safety regulations carefully. Check that the

capacity of the battery is compatible with charger output.

3.1.1. Follow any vehicle manufacturer’s instructions for charging the battery. Note special instructions for charging of non removable vehicle

batteries.

3.1.2. Check the battery to ensure that the NEGATIVE & POSITIVE terminals are clearly identifiable before removing the battery from the

vehicle.

3.1.3. Subject to 3.1.1. above, disconnect and remove the battery from the vehicle and place in an appropriate safe area according to chapter

1 ready for charging.

3.1.4.If possible remove the battery electrolyte cover or caps to allow the gases produced by charging to escape.

3.1.5. Check that the electrolyte is covering the plates inside. If not add distilled water so that the plates are covered by 5-10mm.

3.1.6. The correct charging status of the battery may be determined by use of a hydrometer which will measure the specific density of the

electrolyte.

The following information indicates kgs/L at 20C: 1.28 = Fully charged 1.21 = Half charged 1.14 = Fully discharged.

WARNING! Be cautious and vigilant as the electrolyte is a highly corrosive acid.

3.2. Connecting the charger to the battery. Ensure the battery charger is unplugged from the mains power supply before connecting

power leads to the battery.

3.2.1. With the exception of model 10/1.V4 (which is 12volt only) set the charger voltage to match that of the battery voltage by setting the

rocker switch to either 12 or 24 Volts ( See figs B,C&D below.)

3.2.2. Set the rate of charge on models 10/1.V4,15/1.V4, and 40/1.V4 by setting the rocker switch to MIN or MAX as required ( See figs.

A,B&D ). On model 30/1.V4 three charge levels are available by using the charge level switches as shown in fig.C. ( Note that

when the charge level is set to MAX on the Supercharge 30/1.V4 the switch marked 1 & 2 is over-ridden.)

3.2.3. Check the charger clamps and battery terminals to ensure they are clean and free from oxidation.

3.2.4. Connect the charger’ s POSITIVE (Red or +) lead to the POSITIVE (+) terminal on the battery, and the NEGATIVE (Black or -) lead to

the NEGATIVE (-) terminal on the battery.

Original Language Version

SUPERCHARGE10/4.V4, 15/1.V4, 30/1.V4, 40/1.V4 Issue: 2 - 08/03/10

Page 3

3.3. Charging the battery. Connect the charger to the mains power supply.

3.3.1. Check the current delivery to the battery by reading the ammeter on the front of the battery charger. During the

charge the pointer on the ammeter will slowly decrease (move to the left) according to the capacity and condition of

the battery (See fig 3, dial face may vary according to model of charger).

3.3.2. To indicate that the battery is fully charged the reading on the ammeter should be at the “0” output indicator. To

correspond with this the electrolyte in the battery will begin to gas. Stop charging at this point in order to protect the

battery plates and keep the battery in good condition.

3.3.3. Unplug the charger from the mains power supply. Disconnect the power clamps, clean and store the charger in a safe, dry area.

fig.1

3.3.4. Replace the battery electrolyte cover or caps. Wipe up any splashes or spillage (remember the electrolyte is a corrosive acid).

Return the battery to the vehicle and secure according the manufacturer’s instructions, and re-connect the power leads. Check to

ensure all tools and non related items are removed before closing the bonnet or boot.

3.4. WARNING! LOW or SEALED “NO MAINTENANCE” BATTERY CHARGING

3.4.1. ALL MODELS EXCEPT THE 40/1.V4.

Should you need to charge a low, or no maintenance battery take very special care to ensure you use only a “LOW” slow charge. Use a

battery tester to continually check the voltage input where the clamps attached to the battery. When the input reaches 14.4Volts stop the

charging process.

3.4.2. MODEL SUPERCHARGE 40/1.V4.

The 40/1.V4 has been designed for charging fully sealed, No, or low maintenance batteries to overcome the dangers mentioned in

3.4.1. Press switch to “Automatic” (fig D) and the unit will automatically stop when battery is fully charged. A standard battery may be

charged by switching to “Normal”.

5. SIMULTANEOUS CHARGING

5.1. A number of batteries may be charged at the same time. To do so we recommend

the use of parallel connection as shown in fig.2A

5.2. Two 12 volt batteries may be charged simultaneously in series using a 24volt output

as shown in fig.2B. This is only recommended if both batteries are in a similar state

of discharge.

6. SAFETY CUT OUT

Your charger is equipped with a safety cut-out protection which will cut the output

in the following circumstances:

a) Overload: too high a current to the battery.

b) Short circuit: clamps touch, or the polarity on battery is reversed.

c) Prolonged starting attempts.

Should the fuse blow take the following action:

fig.2

6.1. Turn the unit off and disconnect from the mains power supply.

6.2. Allow the unit to cool down, establish the reason for failure and correct the situation.

6.3. Replace the fuse using only Sealey replacement parts.

DO NOT use a fuse with copper bridges or similar as these will damage your equipment.

Refer to chapter 2 for fuse information and part numbers.

6.4. The Superboost 40/1.V4 has an additional fuse on the mains supply side to protect the unit when left on automatic mode. Should this

fuse blow, investigate your mains supply for any faults. To access the fuse which is mounted on the front panel (See FUSE T2A) insert

a screwdriver in the slot and gently turn the fuse holder about 20° anti-clockwise until it pops forward slightly. Take hold of the end of the

holder and pull it forwards. Remove the old fuse and replace it with a new one. Insert the holder back into the panel. Fully depress the

holder and turn it clockwise until it locks.

Environmental Protection.

Recycle unwanted materials instead of disposing of them as waste.

All tools, accessories and packaging should be sorted, taken to a recycle centre and disposed of in a manner which is compatible

with the environment.

When the product is no longer required, it must be disposed of in an environmentally protective way. Contact your local solid waste

authority for recycling information.

NOTE: It is our policy to continually improve products and as such we reserve the right to alter data, specifications and component parts without prior notice.

IMPORTANT: No liability is accepted for incorrect use of this product.

WARRANTY: Guarantee is 12 months from purchase date, proof of which will be required for any claim.

INFORMATION: For a copy of our latest catalogue and promotions call us on 01284 757525 and leave your full name and address, including postcode.

Sole UK Distributor, Sealey Group,

Kempson Way, Suffolk Business Park,

Bury St. Edmunds, Suffolk,

IP32 7AR

Original Language Version

01284 757500

01284 703534

SUPERCHARGE10/4.V4, 15/1.V4, 30/1.V4, 40/1.V4 Issue: 2 - 08/03/10

www.sealey.co.uk

Web

sales@sealey.co.uk

email

Loading...

Loading...