User Guide

Sealing Machine SLCT-FAL5645

SeleCTech™

Model SLCT-FAL5645

Sealing Machine

This manual is a comprehensive reference for the SeleCTech™ Model SLCT-FAL5645

Sealing Machine. It includes information on machine specifi cations, safety, parts ordering,

system setup, operation, general maintenance, and general troubleshooting.

Table of Contents

SECTION A. SPECIFICATIONS ....................................................................A-1

SECTION 1. GENERAL INFORMATION ....................................................1-1

SECTION 2. INSTALLATION .......................................................................2-1

SECTION 3. OPERATION .............................................................................. 3-1

SECTION 4. GENERAL MAINTENANCE & TROUBLESHOOTING .....4-1

SECTION 5. REFERENCE DOCUMENTS ................................................... 5-1

This manual has been designed to serve as a reference guide for the SeleCTech™ Model

SLCT-FAL5645 Sealing Machine.

NOTICE

Copyright 2013 by Sealed Air Corporation (US). All rights reserved.

Sealed Air® and the 9 Dot Logo are registered trademarks of Sealed Air Corporation.

This document is copyrighted. The material contained herein is protected under the US Copyright Act of 1976.

This document, in whole or in part, may not be copied, photocopied, reproduced, translated or reduced to any

electronic or machine-readable form without the prior written permission of Sealed Air Corporation (US).

Manufactured in China exclusively for Sealed Air

Technology Enhanced by Shanklin® Engineering

Sealed Air Corporation assumes no responsibility for any errors that may appear in this document.

Section A. General Information

SLCT-FAL5645 Sealing Machine

SECTION A. SPECIFICATIONS

This section details information about machine specifi cations and machine parts illustrations.

A.1 SEALING MACHINE SPECIFICATIONS

A.1 SEALING MACHINE SPECIFICATIONS ................................. A-3

A.2 ILLUSTRATION OF MACHINE PARTS ...................................A-4

© Sealed Air Corporation (US)

MM-0110; Revision 1-A: 11/01/2013

A-1

Section A. General Information

SLCT-FAL5645 Sealing Machine

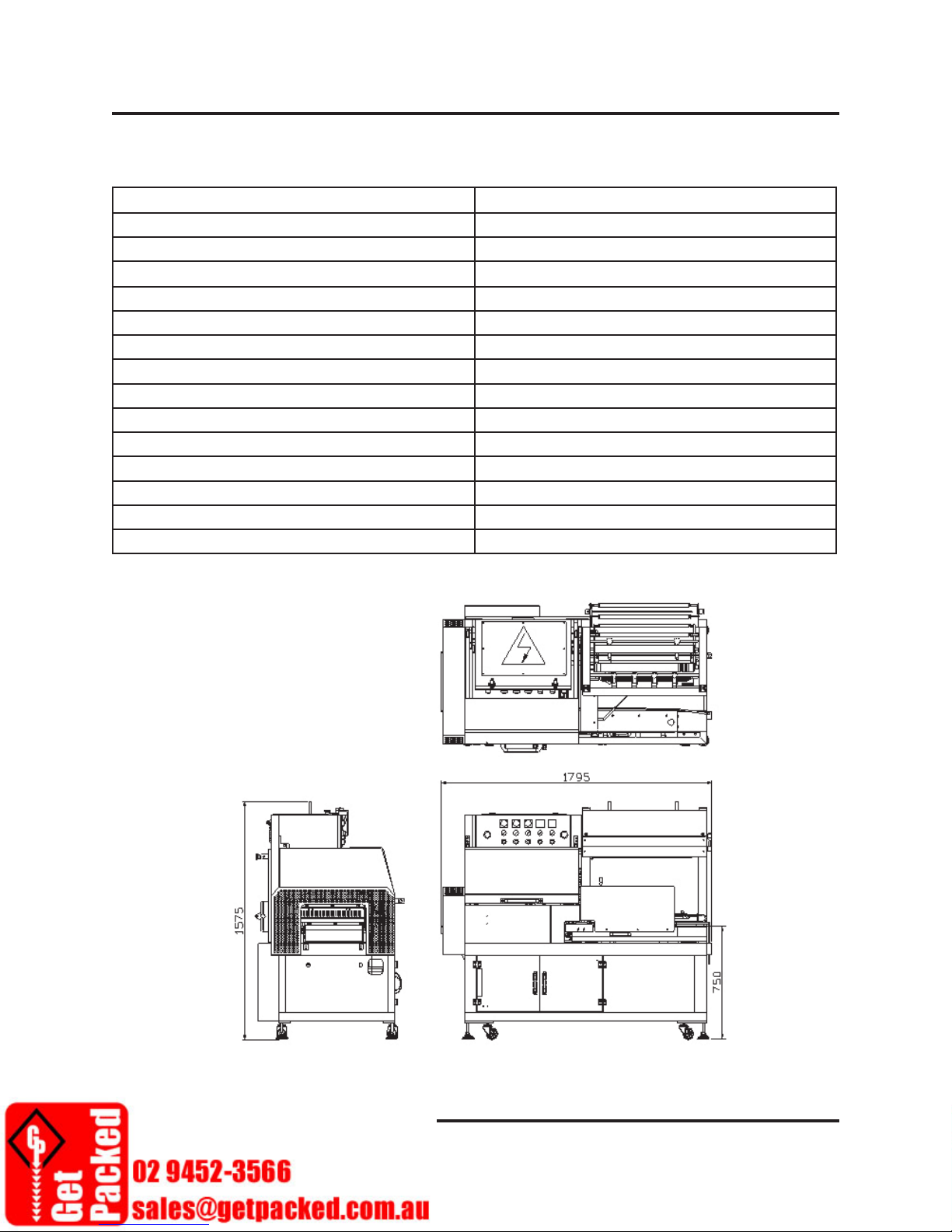

A.1 SEALING MACHINE SPECIFICATIONS

Specifi cation Description

Machine dimensions (L) x (W) x (H) 1795 mm x 985 mm x 1570 mm

Packing dimensions (L) x (W) x (H) (100~450) x mm x (60~350) mm x (5~120 ) mm

Sealing bars size (L) x (H) 565 mm x 460 mm

Packing fi lm 23 in

Packing capacity 30 pcs/min

Conveyor speed 26 m/min

Film POF, PE

Sealing blade temperature 180°C to 230°C

Voltage 240 V/1P 3 kW

Motor power 320 W

Electric power 2.5 KW

Weight 330 kg

Pressure 4 kg

Noise Emission 70 dB(A)

Figure A–1 Sealing Machine Dimensions

© Sealed Air Corporation (US)

MM-0110; Revision 1-A: 11/01/2013

A-3

Section A. General Information

SLCT-FAL5645 Sealing Machine

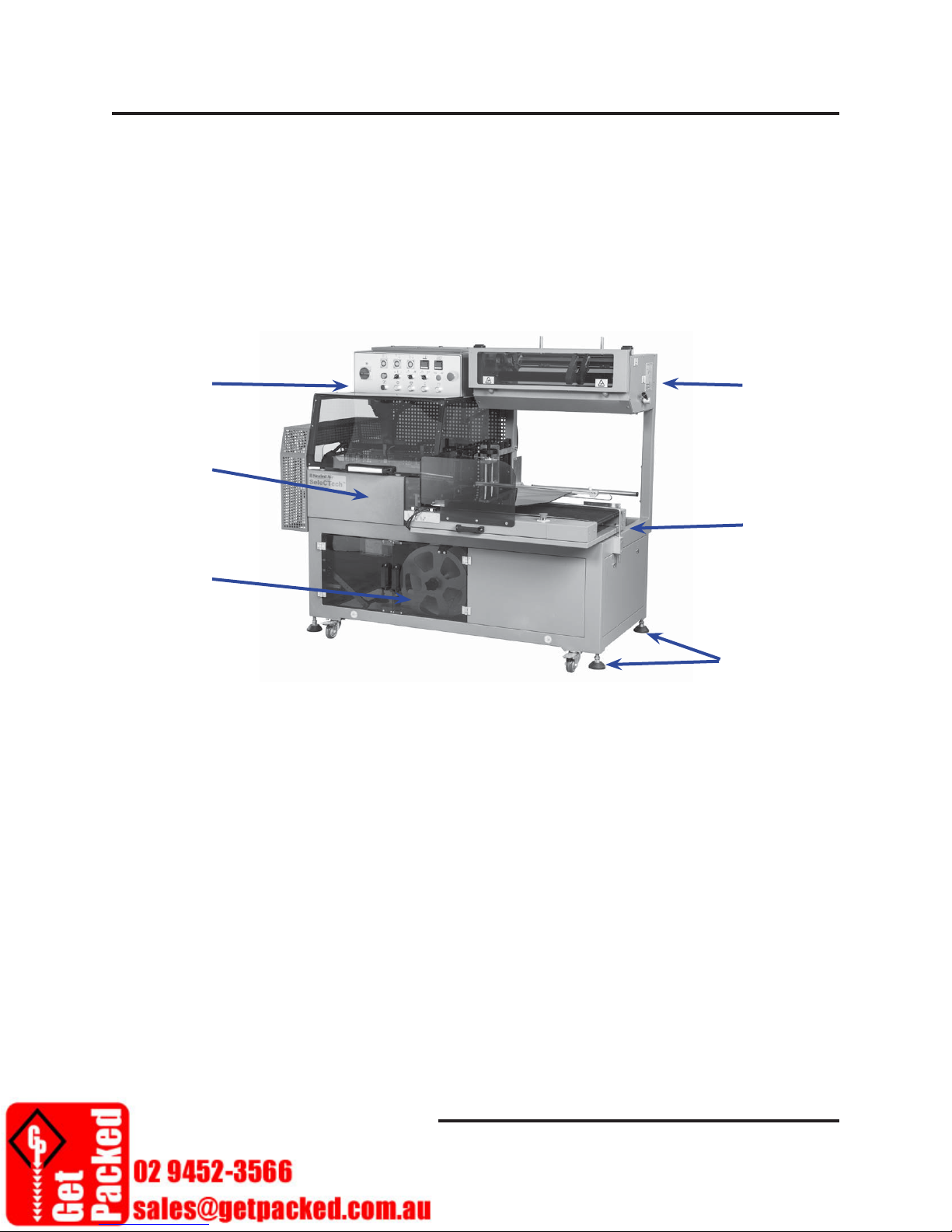

A.2 ILLUSTRATION OF MACHINE PARTS

Use Figure A-2 to identify the major parts of the machine:

1. Control Panel 2. Seal Area 3. Selvage Winder

4. Film Unwind 5. Infeed Conveyor 6. Leveling Feet

1

4

2

5

3

6

Figure A–2 Machine Parts Illustration

A-4

© Sealed Air Corporation (US)

MM-0110; Revision 1-A: 11/01/2013

Section 1. General Information

SLCT-FAL5645 Sealing Machine

SECTION 1. GENERAL INFORMATION

This section details information about safety , transporting, technical support, warranty information,

and equipment certifi cation(s).

IMPORTANT

The Safety section contains information for operating and working on the equipment.

ALL personnel working on or around the equipment are urged to read and understand

the Safety Section and any additional safety information placed throughout this manual.

1.1 SAFETY SECTION .........................................................................1-3

1.1.1 Residual Risks ....................................................................1-3

1.1.2 Pictogram Label Warning Defi nitions .............................1-3

1.1.2.1 General Hazard Pictogram ............................... 1-4

1.1.2.2 Electrical Hazard Pictogram ............................1-4

1.1.2.4 Lifting Hazard Pictogram ................................. 1-4

1.1.2.5 Entanglement Hazard Pictogram ..................... 1-4

1.1.2.6 Pinch Point Hazard Pictogram .........................1-5

1.1.2.7 Shear Hazard Pictogram ................................... 1-5

1.1.2.8 Hidden Knife Warning Pictogram ...................1-5

1.1.2.9 Crushing Hazard Pictogram ............................. 1-5

1.1.2.10 Safety Glove Pictogram ................................... 1-6

1.1.2.11 Safety Eye Wear Pictogram .............................1-6

1.1.3 General Warnings ..............................................................1-7

1.1.4 Energy Isolation .................................................................1-7

1.2 MACHINE TRANSPORT & CRATING ......................................1-11

1.2.1 Uncrating the Machine ......................................................1-11

1.3 TECHNICAL AND CUSTOMER SERVICE SUPPORT ............1-12

1.3.1 Technical Service Support .................................................1-12

1.3.2 Ordering Spare Parts.........................................................1-12

1.3.3 International Customer Service Contacts........................1-12

1.4 CERTIFICATION ...........................................................................1-13

© Sealed Air Corporation (US)

MM-0110; Revision 1-A: 11/01/2013

1-1

Section 1. General Information

SLCT-FAL5645 Sealing Machine

1.1 SAFETY SECTION

DO NOT place this packaging system into operation or undertake maintenance and/or

troubleshooting procedures until all personnel associated with the equipment have become

aware of the warnings and potential hazards outlined in the Safety Section and throughout this

document. It is further advised that the user of this equipment follow the manufacturer’s Safety

statements, cautions, warnings, and energy isolation recommendations while taking the extra

precaution of performing their own safety inspection on the equipment before putting it into

operation or servicing it.

1.1.1 Residual Risks

Although extensive precautions have been taken in the design and manufacture of this packaging

system, all risk of potential hazards cannot be removed and operation of this equipment involves

certain residual risks. To minimize exposure to any residual risks associated with operating or

servicing the machine, ensure that all employees read and understand the safety policies and

instructions for working on and around this machine.

CAUTION

If in doubt about a hazard associated with this machine, contact a

Sealed Air Account Representative prior to operating or working on the

machinery.

WARNING

It is the employer’s responsibility to ensure that:

• Personnel are properly trained

• Personnel follow proper safety procedures.

Under no circumstance should this machine be run with:

• Any of its guards removed

• Any non-functioning safety devices.

1.1.2 Pictogram Label Warning Defi nitions

This paragraph defi nes the meaning of each of the pictograms used on the equipment and in the

machine warnings and cautions outlined in the Safety Section and throughout this manual.

© Sealed Air Corporation (US)

MM-0110; Revision 1-A: 11/01/2013

1-3

Section 1. General Information

SLCT-FAL5645 Sealing Machine

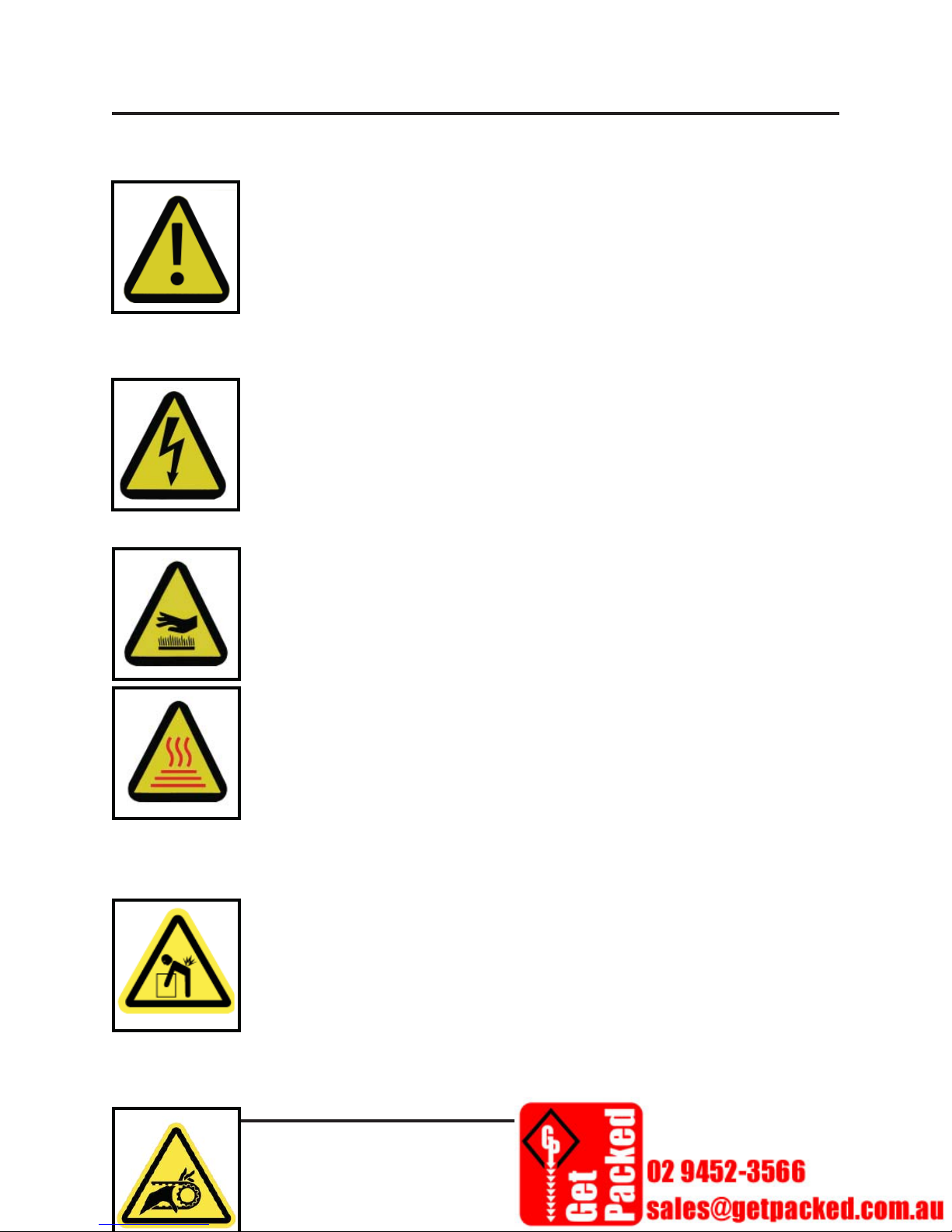

1.1.2.1 General Hazard Pictogram

This symbol is used to signify the presence of a hazard to personnel working

on or around the equipment.

Use caution when following instructions and/or when working around

machine parts labeled with this symbol. Refer to the contents of this manual

for specifi c hazards and concerns.

1.1.2.2 Electrical Hazard Pictogram

This symbol is used to signify the presence of an electrical hazard to personnel

working on or around the equipment.

Turn off and lock out system power before servicing equipment or when

following instructions labeled with this symbol.

1.1.2.3 Heat Warning Pictogram

These symbols are used to signify the presence of a thermal hazard to personnel

working on or around the equipment.

Do not remove any protective guards and keep extremities clear of parts

labeled with this symbol. Allow the system to cool completely and turn off and

lock out system power and air before servicing equipment when this safety

label is present or when following instructions labeled with this symbol.

1.1.2.4 Lifting Hazard Pictogram

This symbol is used to signify the presence of a lifting hazard. Personal

injury hazard may occur if an object is lifted without the proper technique or

assistance.

Use assistance and/or proper technique when moving or lifting objects

labeled with this symbol or when following instructions labeled with this

symbol.

1.1.2.5 Entanglement Hazard Pictogram

1-4

© Sealed Air Corporation (US)

MM-0110; Revision 1-A: 011/01/2013

Section 1. General Information

SLCT-FAL5645 Sealing Machine

This symbol is used to signify the presence of moving parts that may present an Entanglement

hazard to personnel working on or around the equipment.

Moving parts can crush and cut. Do not remove protective guards and keep extremities clear

of moving parts at all times when this safety label is present. Turn off and lock out system

power before servicing equipment or when following instructions labeled with this symbol.

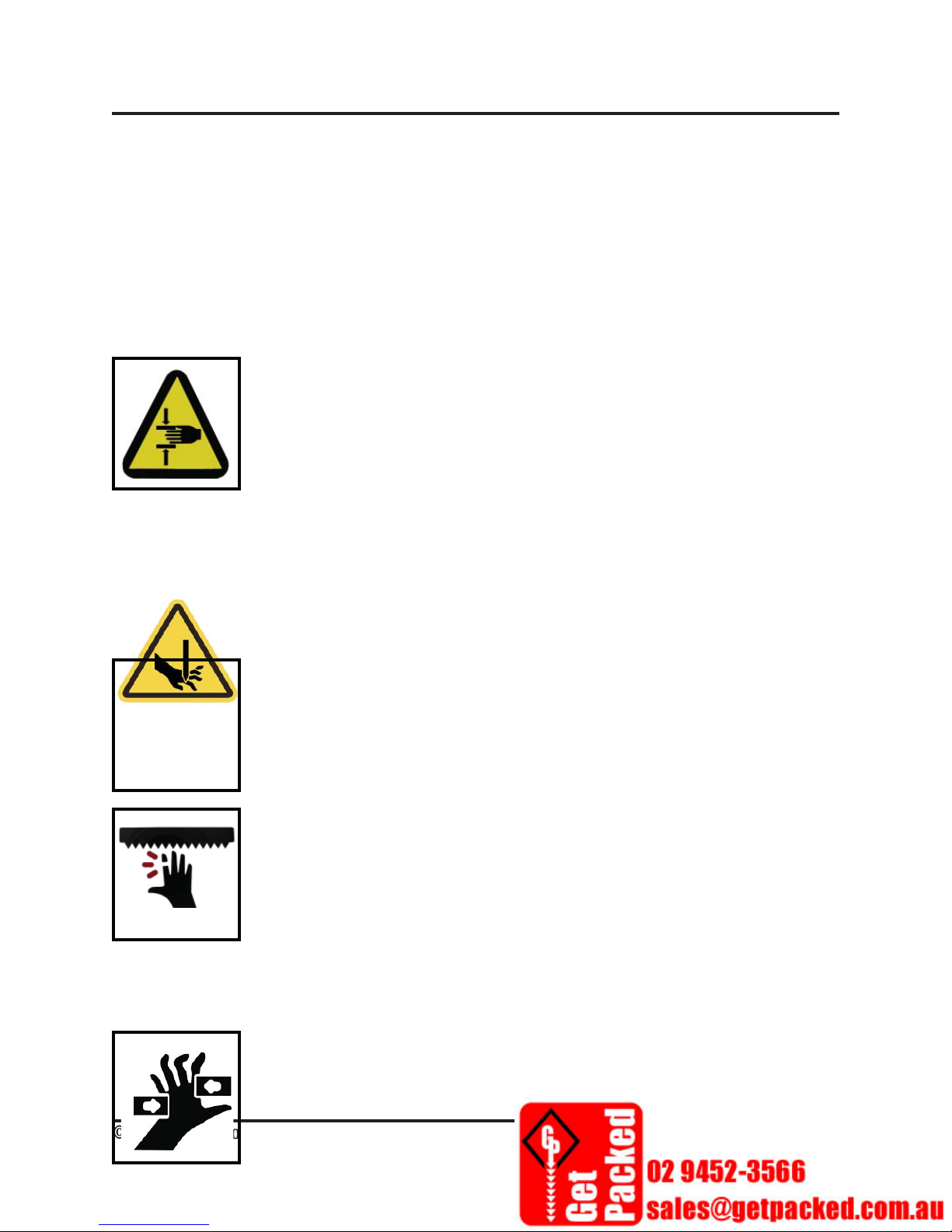

1.1.2.6 Pinch Point Hazard Pictogram

This symbol is used to signify the presence of moving parts that may present a

pinch point hazard to personnel working on or around the equipment.

Moving parts can crush and cut. Do not remove any protective guards and

keep extremities clear of moving parts at all times when this safety label is

present. Turn off and lock out system power before servicing equipment or

when following instructions labeled with this symbol.

1.1.2.7 Shear Hazard Pictogram

This symbol is used to signify the presence of moving parts that may present a cutting or shear

hazard to personnel working on or around the equipment.

Moving parts can shear and cut. Do not remove any protective guards and

keep extremities clear of moving parts at all times when this safety label is

present. Turn off and lock out system power before servicing equipment or

when following instructions labeled with this symbol.

1.1.2.8 Hidden Knife Warning Pictogram

This symbol is used to signify the presence of a hidden knife that may present

a cutting hazard to personnel working on or around the equipment.

Moving parts can crush and cut. Do not remove any protective guards and

keep extremities clear of moving parts at all times when this safety label is

present. Turn off and lock out system power before servicing equipment or

when following instructions labeled with this symbol.

1.1.2.9 Crushing Hazard Pictogram

This symbol is used to signify the presence of moving parts that may present

crushing hazards to personnel working on or around the equipment.

© Sealed Air Corporation (US)

MM-0110; Revision 1-A: 11/01/2013

1-5

Section 1. General Information

SLCT-FAL5645 Sealing Machine

Moving parts can crush. Do not remove any protective guards and keep extremities clear of

moving parts at all times when this safety label is present. Turn off and lock out system power

before servicing equipment or when following instructions labeled with this symbol.

1.1.2.10 Safety Glove Pictogram

This symbol is used to signify the presence of a possible hand hazard injury as

a result of working on or around the equipment. In conjunction with safe work

practices, Personal Protective Equipment (PPE) is required when this label is

present. Wear the most appropriate type of safety glove for protection against

cuts, scrapes, punctures, and lacerations when this label is present.

Safety glove selection should be based on the gloves performance

characteristics relative to the specifi c task(s) to be performed, conditions

present, duration of use, and the actual and potential hazards identifi ed.

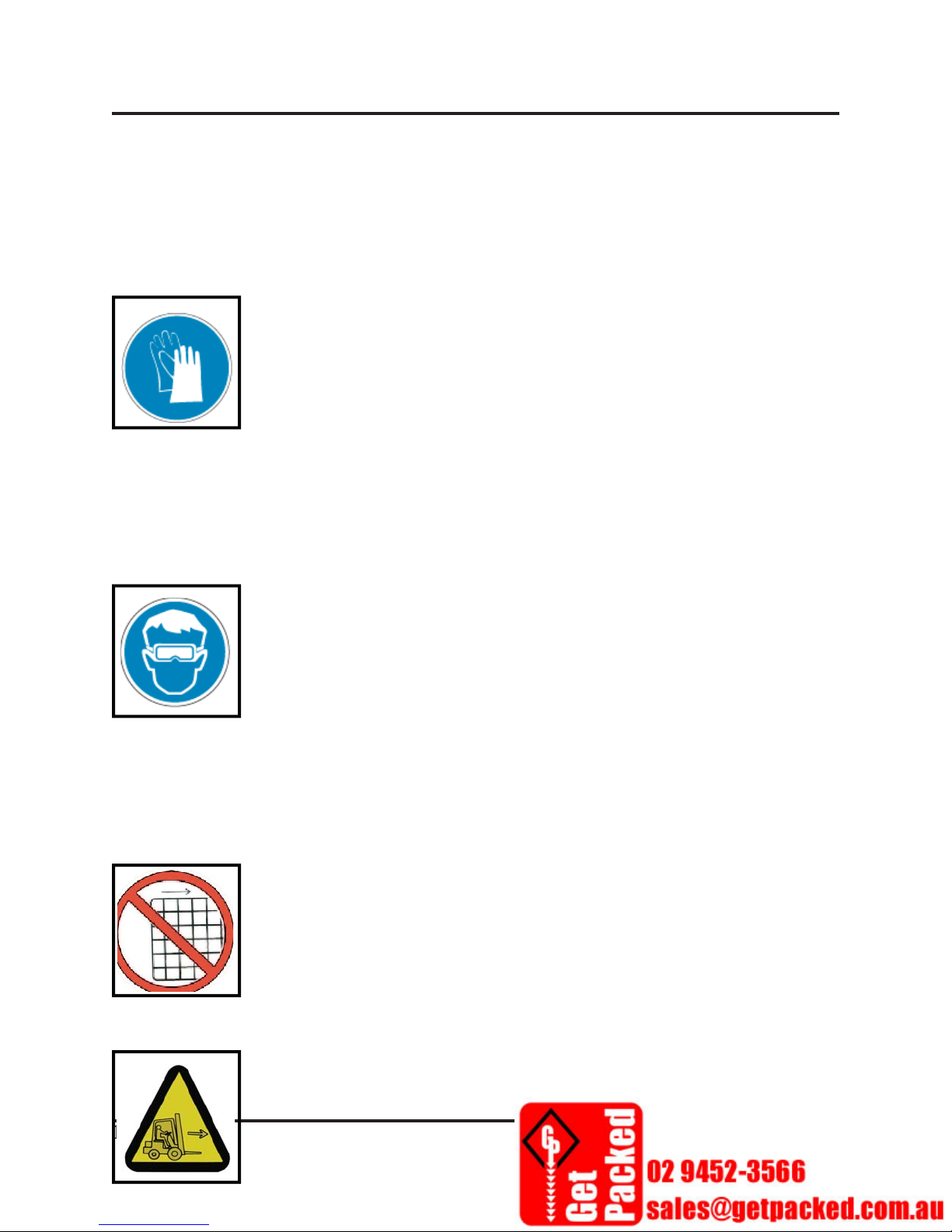

1.1.2.11 Safety Eye Wear Pictogram

This symbol is used to signify the presence of a possible eye injury hazard as

a result of working on or around the equipment. In conjunction with safe work

practices, Personal Protective Equipment (PPE) is required when this label is

present.

Personal protective eye equipment must meet certain design criteria to be

used as safety equipment and must be worn when workers are at risk from

fl ying particles, liquid/caustic/ acid chemicals or vapors, or operations that

may emit light.

1.1.2.12 Machine Guard Pictogram

This symbol is used to signify the presence of a hazard to personnel working

on or around the equipment when a machine guard(s) is not in place.

Do NOT operate this equipment when guards are missing or open. Serious

injury could occur!

1.1.2.13 Machine Handling Pictogram

This symbol is used to signify the need for a certifi ed forklift operator and

is also used to indicate the correct forklift tine placement when lifting the

machine.

1-6

© Sealed Air Corporation (US)

MM-0110; Revision 1-A: 011/01/2013

Section 1. General Information

SLCT-FAL5645 Sealing Machine

Do not attempt to move this system from its crate manually; a trained operator should use the

appropriate machine handling equipment to move the machine. Serious injury and/or damage

to the machine could occur!

1.1.3 General Warnings

This paragraph contains general warnings and cautions. In addition to these warnings, other

pertinent warnings and cautions have been placed in relevant places throughout this manual.

WARNING

To minimize potential for personal injuries, ensure that machine operators

and others working on or around the machinery are properly trained in

correct equipment use and safe operating procedures.

WARNING

The use of plastic fi lms in sealing and/or shrinking equipment may result

in the release of hazardous fumes due to the degradation of the fi lm at

high temperatures. Before using any plastic fi lm in this equipment, the

manufacturer or supplier of the fi lm should be contacted for specifi c

information on the potential release of hazardous fumes.

Adequate ventilation should be provided at all times.

WARNING

Keep all extremities, loose clothing, jewelry, and hair away from moving

assemblies and conveyors.

WARNING

Worn or frayed conveyor belts are hazardous and should be replaced

promptly.

© Sealed Air Corporation (US)

MM-0110; Revision 1-A: 11/01/2013

1-7

Section 1. General Information

SLCT-FAL5645 Sealing Machine

WARNING

Never operate this or any moving equipment without all covers and

guards in place. The internal mechanisms of packaging machinery contain

numerous shear, pinch, and in-running nip points capable of causing

severe injury and permanent disfi gurement.

WARNING

Do not place pressurized containers or volatile, fl ammable, or explosive

materials on, into, or through a shrink tunnel. Resulting fi re or explosion

can cause serious injury.

WARNING

Heat sealing jaws and shrink tunnel openings on packaging machines

get very hot. Keep hands away while machinery is in operation and use

caution if the machine has been running recently.

WARNING

Only approved packaging specifi cations and parts should be used with this

system.

Use of other packaging materials and/or parts on the system may

cause unforeseen damage to the machinery and pose safety hazards.

When unauthorized use of parts or materials has occurred, Sealed Air

Corporation reserves the right to refuse services including but not limited

to: maintenance, troubleshooting, supplies, and parts provided by Sealed

Air (US).

WARNING

In order to prevent injury to personnel and/or machinery, do not increase

settings on either electrical or mechanical overload safety devices.

1-8

© Sealed Air Corporation (US)

MM-0110; Revision 1-A: 011/01/2013

Section 1. General Information

SLCT-FAL5645 Sealing Machine

WARNING

Do not make any modifi cations to the programmable logic controller’s

(PLC’s) control program, the electrical circuitry, or the mechanical

assemblies of this machinery. Such modifi cations may introduce hazards

not associated with this machinery.

Sealed Air Corporation cannot be held responsible for malfunctions,

personal injury, or property damage resulting from such unauthorized

modifi cations.

WARNING

Use of extension cords to connect the system to a power supply is

prohibited. The system’s power cord MUST be plugged into a grounded

source.

WARNING

In order to prevent injury to personnel and/or machinery, proper

equipment ground, in accordance with the national, state, and local

electric codes, must be applied to the machine.

WARNING

Do not tamper with, or make any modifi cations to, the programmable

logic controller’s (PLC’s) control program, the electrical circuitry, the

electrical wiring or the mechanical assemblies of this machinery. Such

modifi cations may introduce hazards not associated with this machinery.

Shanklin Corporation cannot be held responsible for malfunctions,

personal injury, or property damage resulting from such unauthorized

modifi cations.

© Sealed Air Corporation (US)

MM-0110; Revision 1-A: 11/01/2013

1-9

Section 1. General Information

SLCT-FAL5645 Sealing Machine

1.1.4 Energy Isolation

The following guidelines are provided to establish a minimum requirement for the disconnection/

isolation of energy sources whenever maintenance or service is performed on equipment and

associated parts. It is further advised that an independent safety study be performed on the

machinery, its installation, and Lockout/Tagout procedures.

CAUTION

Prior to following any maintenance or troubleshooting procedures

outlined in this manual, review these important steps.

1. Read all warnings and cautions listed in this manual’s Safety Section (“1.1 Safety Section”

on page 1-3) and throughout this manual.

2. Shut the equipment down using normal stopping procedure then engage the Emergency Stop

(E-Stop) push button switch by pushing it down.

3. Ensure that all controls are in a neutral or OFF position.

4. The equipment may be isolated from its energy sources by unplugging the main power cord.

5. Then applicable, the equipment may be isolated from pneumatic sources by disconnecting

the main air line.

6. Follow the appropriate Lockout/Tagout recommendations at your facility during shutdown,

maintenance, and restart of the equipment.

1-10

© Sealed Air Corporation (US)

MM-0110; Revision 1-A: 011/01/2013

Section 1. General Information

SLCT-FAL5645 Sealing Machine

1.2 MACHINE TRANSPORT & CRATING

Follow these guidelines for uncrating and recrating the machine.

1.2.1 Uncrating the Machine

1. Use the appropriate machine handling equipment to transport the crated machine.

2. Remove the top and sides of the packing crate and all secondary packing material

surrounding

the machine (shrink wrap, zip ties, cardboard etc).

3. When applicable, smaller components such as zip-tied pneumatic lines and electrical wiring

may be secured on top of the machine’s conveyor. Remove those components and set them

aside for installation.

4. Note that a tool box is shipped with each machine. Locate and remove the tool box along

any associated packing material.

with

5. There are circular forklift icons on each side of the machine. These icons indicate the correct

location for the forklift tines to be placed when moving the machine.

6. Have a qualifi ed operator move the machine off of the shipping pallet to where it will be

stationed.

© Sealed Air Corporation (US)

MM-0110; Revision 1-A: 11/01/2013

1-11

Section 1. General Information

SLCT-FAL5645 Sealing Machine

1.3 TECHNICAL AND CUSTOMER SERVICE SUPPORT

Follow these guidelines to obtain support from Technical Service or to order spare parts from

Customer Service.

1.3.1 Technical Service Support

• Order parts by contacting a Sealed Air Representative or Distributor.

• Have the following information available:

• Company name and contact information.

• Equipment model and serial number.

• A detailed description of the technical issues experienced.

1.3.2 Ordering Spare Parts

• Order parts by contacting a Sealed Air Representative or Distributor.

• Have the following information available:

• Company name and contact information including: shipping address, department (when

applicable), phone number, and shipping address.

• The equipment’s model and serial number.

• Part number information obtained from: an assembly drawing (contained in the back of

this manual) - or - the part data from the nameplate of the specifi c part being replaced.

1.3.3 International Customer Service Contacts

International contact information for replacement parts and technical assistance:

• Sealed Air Africa (Pty) Ltd. +27 11 923 4600 Fax: +27 11 392 1025

• Sealed Air Australia Ltd. +1 800 0808 481 Fax: 1 800 250 650

• Sealed Air Packaging (Shanghai) Co. Ltd. +86 21 3920 2988 Fax: +86 21 3920 2999

• Diversey Gulf FZE +971 4 8819470/31 Fax: +971 4 8819488

• Sealed Air Hong Kong Ltd. +852 2178 7876 Fax: +852 2407 3385

• Sealed Air (India) Pte. Ltd. +91 80 4050 7333 Fax: +91 80 4117 1301

• Sealed Air HK Ltd.-Indonesia Rep +62 21 5793 8858 Fax: +62 21 5793 8859

• Sealed Air (Israel) Ltd. +972 2 5337438 Fax: +972 2 5337439

• Sealed Air (Japan) Ltd. +81 3 5644 1110 Fax: +81 3 5644 1160

• Diversey Eastern & Central Africa Ltd. (Kenya) +254 703 040 247 Fax: +254 703 040 888

• Sealed Air (Korea) Ltd. +82 31 763 1716 Fax: +82 31 763 4744

• Sealed Air (Malaysia) Sdn Bhd +60 3 5569 6363 Fax: +60 3 5569 2682

• Diversey Maroc s.a. (Morocco) +212 522 756 506 Fax: +212 522 756 572/73

• Sealed Air New Zealand +64 9 813 9800 Fax: +64 9 813 9801

• Diversey West Africa Limited (Nigeria) +234 1 825 5511 Fax: +234 813 086 5000-6

1-12

© Sealed Air Corporation (US)

MM-0110; Revision 1-A: 011/01/2013

Section 1. General Information

SLCT-FAL5645 Sealing Machine

• Sealed Air Philippines, Inc. +63 2 845 9400 Fax: +63 2 2811 6679

• Diversey KSA-Arabian Modern Company (Saudi Arabia) +966 3 847 6986-7 Fax: 966 3 847 6989

• Sealed Air (Singapore) Pte. Ltd. +65 6861 1828 Fax: +65 6861 5221

• Sealed Air (Taiwan) Ltd. +886 3 324 2988 Fax: +886 3 324 3088

• Sealed Air (Thailand) Ltd. +66 2 834 6800 Fax: +66 2 834 6888

• Diversey Kimya Sanayi ve Ticaret A.S. (Turkey) +90 216 578 6400 Fax: +90 216 578 6401

• Sealed Air (Singapore) Pte. Ltd.-Vietnam Rep Offi ce +84 8 6292 4251 Fax: +84 8 6296 2606

• Czech Republic +420 224 315 863

• France, Osny +33 (0)3 86 92 04 58

• Germany, Alsfeld +49 (0)6631 96680

• Greece, Shimatari Viotias +30 22620 32551

• Hungary, Újhartyán +36 (06)29 573 300

• Italy, Bellusco +39 039 6835 1

• The Netherlands, Nijmegen +31 (0)24 3710111

• Poland, Ozarów Mazowiecki +48 (0)22 7217 530

• South Africa, Spartan +27 (0)11 923 4600

• Spain, Abrera +34 93 773 8325

• Sweden, Aneby +46 (0)380 47100

• UK, Kettering +44 (0)1536 315700

•

1.3.4 Regulatory Compliance

The SeleCTech SLCT-FAL5645 sealing machine meets essential health and safety requirements

and is in conformity with the relevant EC Directives.

.

© Sealed Air Corporation (US)

MM-0110; Revision 1-A: 11/01/2013

1-13

Section 2. General Information

SLCT-FAL5645 Sealing Machine

SECTION 2. INSTALLATION

This section details information about installing and adjusting the sealing machine.

The machine has already been careully checked and tuned Before leaving the factory. Only

trained operators are allowed to make the adjustments necessary in order to pack products of

different dimensions.

2.1 SELECT THE MACHINE INSTALLATION LOCATION ........ 2-3

2.2 ADJUSTING THE HEIGHT OF THE SEALING MACHINE ... 2-3

2.3 LOADING THE SHRINK FILM ...................................................2-4

2.3.1 Film Loading. .....................................................................2-4

2.3.2 Adjusting Film ....................................................................2-4

2.3.3 Front Conveyor Belt Adjustment ....................................2-5

2.3.4.1 Film Sealing ........................................................ 2-6

2.4 SEALING SAFETY SENSOR ........................................................2-7

2.5 REMOVING THE WASTED SIDE FILM .................................... 2-8

© Sealed Air Corporation (US)

MM-0110; Revision 1-A: 11/01/2013

2-1

Section 2. General Information

SLCT-FAL5645 Sealing Machine

2.1 SELECT THE MACHINE INSTALLATION LOCATION

The sealing machine should placed well-lit and dry place. It should be positioned away from

dusty, fl ammable, explosive and corrosive areas.

Placing the sealing machine too close to the ventilation system may cause unstable fi lm delivery.

.

2.2 LEVELING THE SEALING MACHINE

Refer to Figure 2-1 for the following system leveling/height adjustment procedure. The steps

apply to all four (4) feet on the base of the system.

1. Use a spanner to loosen the lock nut (1) at the sealing machine base.

2. Use a spanner to

is at the required height, tighten the lock nut

turn the nut on the height adjustment screw (2). When the sealing machine

Figure 2–1 Sealing Machine Leveling/Height Adjustment

(1) up to the base of the machine.

1

2

© Sealed Air Corporation (US)

MM-0110; Revision 1-A: 11/01/2013

2-3

Section 2. General Information

SLCT-FAL5645 Sealing Machine

2.1 LOADING THE SHRINK FILM

When the fi lm is properly loaded the motorized fi lm unwind assembly provides fi lm as required

by the packing process.

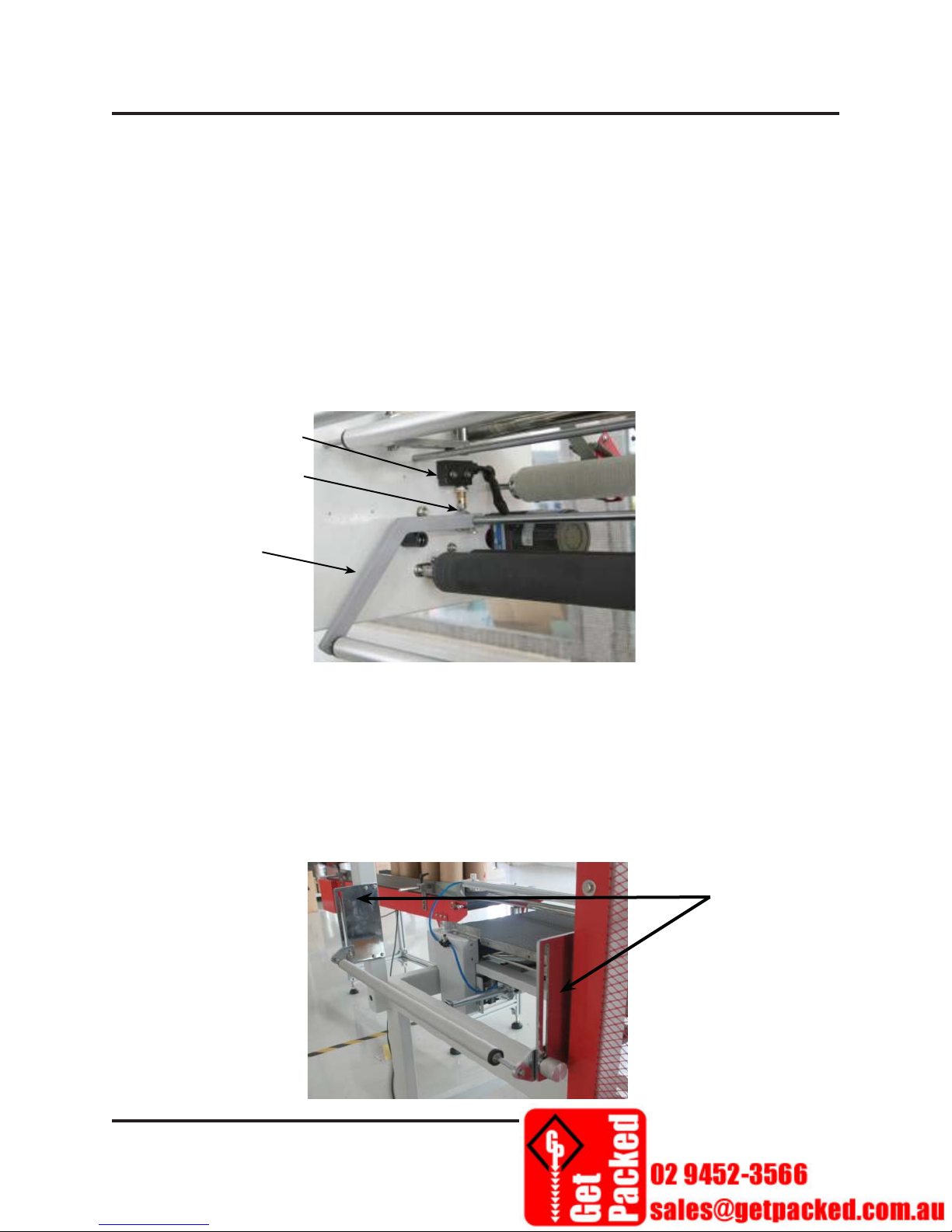

2.1.1 Film Loading Micro-switch and Contact Wheel

The micro switch located above the left side of the dancer assembly controls the operation of the

fi lm delivery motor. When the actuator wheel on the side of the arm touches the micro-switch,

the fi lm delivery motor starts running. When the fi lm pressure relaxes, the arm lowers, the

actuator wheel no longer touches the micro-switch, and the motor stops. The actuator should just

slightly touch the micro-switch.

Micro switch

Actuator Wheel

Dancer Bar Arm

Figure 2–2 Film Delivery Assembly

2.1.2 Film Feed Roller Height Adjustment

1. Loosen the locking nuts on each end of the fi lm feed roller,

2. Adjust the fi lm roller set up or down as required, based on

the height of sealing area.

2-4

Roller Locks

© Sealed Air Corporation (US)

MM-0110; Revision 1-A: 11/01/2013

Section 2. General Information

SLCT-FAL5645 Sealing Machine

Figure 2–3 Roller Locks

2. The proper height adjustment will be based on actual operating conditions. Irregular, jumping

motion of the fi lm delivery may indicate the need to adjust the delivery angle.

2.1.3 Conveyor Belt Adjustment

The conveyor belt tension is set at the factory, but may loosen over time. If the belt becomes

loose refer to Figure 2-4 as you use the belt tension adjustment procedure described here:

1. Loosen the Lock Nuts (1) and (2)

2. Turn the adjusting nut (3) clockwise to push the roller forward to increase the belt tension.

3. It is important to make the same adjustment on the other side of the conveyor.

(3)

(2)

(1)

Figure 2–4 Belt Tension Adjustment

© Sealed Air Corporation (US)

MM-0110; Revision 1-A: 11/01/2013

2-5

Section 2. General Information

SLCT-FAL5645 Sealing Machine

2.1.3.1 Film Sealing

Before operating the system, check to ensure that the seal wires and upper jaws are clean.

Any residual fi lm caught on or between the wires and the ceramic beads can cause poor seals.

The lower beds should also be kept in good condition. Over time the Tefl on tapes may show

impressions from the wire and some discoloration, this is normal, but burned or blackened tapes

should be replaced. This could be an indication of too much pressure or uneven pressure.

Contact between the sealing blade and the sealing base can be checked as follows:

1. Put a white paper between the sealing blade and base.

2. Manually operate the sealing and cutting process once to see if the force of the sealing and

cutting action is even on the white paper.

3. If it is uneven, loosen the lock nuts and turn the adjusting screws. (Caution this adjustment

must be made with the machine power off and the assembly cooled down.)

4. Tighten the locking nut

Adjustment

Screws

Adjustment

Screws

Figure 2–5 Sealing Assembly

2-6

© Sealed Air Corporation (US)

MM-0110; Revision 1-A: 11/01/2013

Section 2. General Information

SLCT-FAL5645 Sealing Machine

2.2 SEALING JAW SAFETY

To prevent injury, product crushing or machine damage the jaw is equipped with several safeties

that will stop the machine operation if a product or other object is inside the sealing area when

the sealing blade lowers.

The operation of the jaw safety circuit should be verifi ed at least once per day. The jaw safety

circuit is designed to reopen the jaws immediately whenever the jaws contact an object upon

closing. The test requires attempting to make a seal with a rubber test object between the jaws.

When functioning properly, the jaw safety circuit will force the machine into an Emergency Stop

state upon contact with the test object.

2.2.1 Jaw safety Verifi cation Test

1. Ensure that all guards are in place. All doors and hoods must be closed.

2. Connect the compressed air supply for the machine.

3. Power up the machine.

4. Press the E-STOP button.

5. Test object should be resilient. Preferably a spare piece seal bed material (3/8” thick silicone

rubber). Place the test object on the conveyor belt between the seal jaws.

6. Release the E-STOP button by twisting clockwise.

7. Put the machine into a READY state by pressing the READY button (Blue).

8. Perform the test by pressing the manual seal button. The button must be held down until the

jaws close completely.

• PASS INDICATION: Jaws close and then immediately reopen; the READY light Flashes.

• FAIL INDICATION: Jaws do not reopen immediately and/or READY light remains on.

9. Repeat Steps 4-8 several times with the rubber object at different points along the entire length

of each seal jaw to ensure the integrity of the Jaw Safety Circuit.

© Sealed Air Corporation (US)

MM-0110; Revision 1-A: 11/01/2013

2-7

Section 2. General Information

SLCT-FAL5645 Sealing Machine

Adjust Actuator

Figure 2–6 Safety Actuator

If the jaw safety does not work properly: Loosen the top actuator screw and raise or lower it

to allow the sensor to detect the packing product quickly. The distance between the two touch

screws should not be too long, otherwise, the sealing blade will alarm and stop operation before

completing the sealing and cutting action.

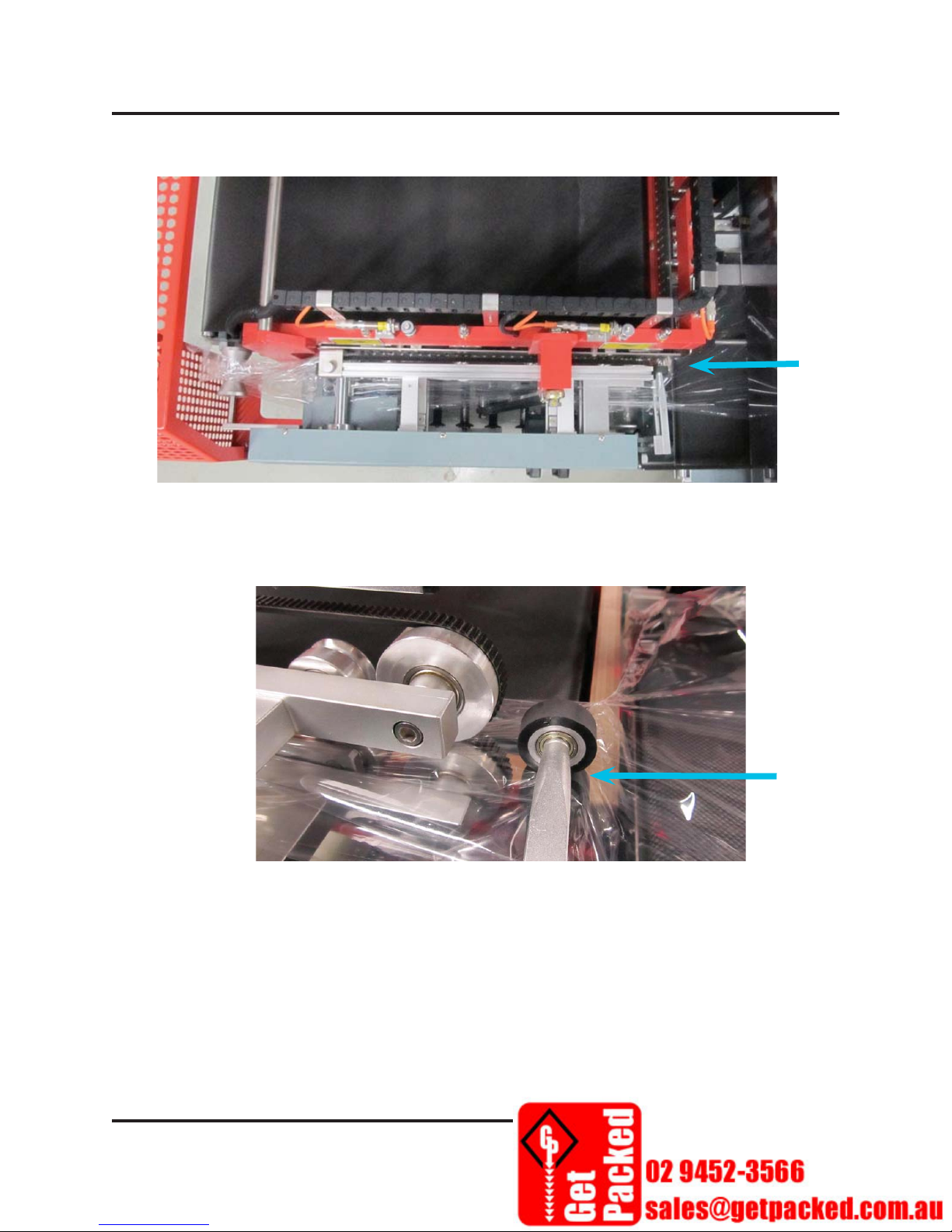

2.3 REMOVING THE WASTE FILM (SELVAGE)

The fi lm trimmed from the side during the packing process is called selvage. Selvage is collected

on a wheel located in a compartment at the front of the machine. Refer to Figure 2-7 and follow

the next procedure to remove the waste fi lm that has accumulated on the selvage winder.

1. Open the door to access the selvage winder.

2. Loosen the wheel lock on the front of the wheel, and remove the guide plate.

3. Remove the waste fi lm,

4. Replace the guide plate and tighten the locking cap.

5. Run out some fi lm and re feed the selvage to the wheel. If the wheel slips during the

receiving process, tighten the locking nut a little bit to increase the friction of the selvage

receiving reel

Wheel Lock

Selvage Winder

Location

Guide Plate

2-8

Figure 2–7 Selvage Winder

© Sealed Air Corporation (US)

MM-0110; Revision 1-A: 11/01/2013

Section 2. General Information

SLCT-FAL5645 Sealing Machine

© Sealed Air Corporation (US)

MM-0110; Revision 1-A: 11/01/2013

2-9

Section 3. Operation

SLCT-FAL5645 Sealing Machine

SECTION 3. OPERATION

This section details information about installing and adjusting the sealing machine.

Before machine delivery, the machine has already been precisely checked and tuned. “Do

not” change the setting unless it is necessary. However, trained operators are allowed to make

adjustments to some of the necessary settings in order to pack different dimensions of the

packing products.

3.1 CONTROL PANEL .........................................................................3-3

3.2 NAMEPLATE ..................................................................................3-4

3.3 INSTALLING THE SHRINK FILM .............................................3-5

3.4 FUNCTIONS ....................................................................................3-10

3.5 OPERATION .................................................................................... 3-12

© Sealed Air Corporation (US)

MM-0110; Revision 1-A: 11/01/2013

3-1

3.1 CONTROL PANEL

1234567

Section 3. Operation

SLCT-FAL5645 Sealing Machine

891011121314151617

Figure 3–1 Control Panel

Call

out

1 Main Circuit Breaker Switch turns ON/OFF the power input

2 Resets the machine (Flashes Blue light until pushed)

3 Starts the conveyor

4 Stops the conveyor

5 Cycles the sealing/cutting process once

6 Manually runs the fi lm feed motor until the button is released

7 Emergency stops the machine. Must be released to restart machine.

8 Not Used

9 Sets the temperature of the Front sealing blade

10 Selects Horizontal Sensor mode for rectangular or square products

11 Sets the temperature of the Side sealing blade

12 Sensor mode to control the packing process

13 Sets the conveyor run time for length of fi lm at the back of the product

14 Switches ON/OFF the heater for the sealing blades

15 Sets the sealing/cutting dwell time

16 Sets the conveyor run time for fi lm length at the front of the product

17 Power ON light (Green)

Description

© Sealed Air Corporation (US)

MM-0110; Revision 1-A: 11/01/2013

3-3

Section 3. Operation

SLCT-FAL5645 Sealing Machine

3.2 NAMEPLATE

Figure 3–2 Nameplate

Call out Description Call out Description

1

2

3

4

5

6

MODEL Number

Vn (Rated voltage)

FLA (Rated current)

S/N (Serial number)

Date of Manufacture

Short-circuit current (SCCR)

7

8

9

10

11

HZ (frequency)

SCHEMATIC

LARGEST LOAD (Amps)

WEIGHT

MAXPSI

3-4

© Sealed Air Corporation (US)

MM-0110; Revision 1-A: 11/01/2013

Section 3. Operation

SLCT-FAL5645 Sealing Machine

3.3 INSTALLING THE SHRINK FILM

The dimensions of the packing product are width (W), the height (H), and the length (L) as

shown in Figure 3–33.

Figure 3–3 Packing Product Dimensions

1. Start the conveyor.

2. Check that the belt is tracking at the center of the bed. If not, follow the adjustment procedure

on Page 2-5 to adjust the belt.

3. Select the appropriate shrink fi lm:

Width of shrink fi lm = W (Product Width) + H (Product Height) + 5” ~ 7” (depends on the

height of the packing product).

4. Adjust the infeed conveyor Height (see Figure 3–4): Rotate the conveyor adjusting wheel to

adjust the height of the triangular plate. The correct position is about 1/2 H (Product Height)

+ 5~10mm.

5. Adjust of the infeed conveyor relative to the product guide (Figure 3-4)by placing a product

on the belt and then squeezing the handle on the front of conveyor unit. This will enable

movement of the conveyor unit to the appropriate width which is W (Product Width) plus

one-third of the product height.

© Sealed Air Corporation (US)

MM-0110; Revision 1-A: 11/01/2013

3-5

Section 3. Operation

SLCT-FAL5645 Sealing Machine

Product Guide

is mounted

to side of the

machine

Inverting Heads

above and

below infeed

conveyor

Figure 3–4 View FAL 5645 from the Infeed end

6. Put the shrink fi lm onto the Film Unwind rollers (see Figure 3–5).

a. Loosen the locking nut of the left side fi lm positioning rod (1) and adjust the fi lm

location. Tighten the locking nut after adjustment

b. Loosen the locking nut of the right side fi lm positioning rod (2) and adjust the rod to

width of the shrink fi lm + 5 mm. Tighten the locking nut after adjustment.

c. The open side of the shrink fi lm must face to the fi lm positioning rod (2).

3-6

© Sealed Air Corporation (US)

MM-0110; Revision 1-A: 11/01/2013

Section 3. Operation

SLCT-FAL5645 Sealing Machine

Folded Film Open Side

Film Positioning

Rod 1

Film Positioning

Rod 2

Web Separator

Inverting Heads

above and

below infeed

conveyor

7. Switch the Temperature Controllers ON and adjust the temperature of the front and side

sealing wires for the type of fi lm being used.

Film Type Required Temperature Film Type Required Temperature

PE Film 220°C~240°C POF Film 200°C~220°C

© Sealed Air Corporation (US)

MM-0110; Revision 1-A: 11/01/2013

Figure 3–5 Film Unwind Assembly

3-7

Section 3. Operation

SLCT-FAL5645 Sealing Machine

8. Loading the Shrink Film (see Figure 3–6 and Figure 3–7).

Feed Film

here

Figure 3–6 Overhead View of Film Puller Assembly

Start Film Feed

here

Figure 3–7 Film Assembly

9. After the sealer reaches the set temperature, press the Manual operation button once, the

Sealer will move once, and jaws will remain open.

10. Turn on the conveyor, and place a product on the infeed conveyor. The machine should

advance fi lm and cycle the sealer once. The wrapped product will exit the machine.

11. Continue to run the fi lm feed, while pulling the selvage end of the fi lm until the selvage can

be wound 2~3 times on the receiving reel (Figure

process automatically.

3-8

3–8). Now the machine can run the packing

© Sealed Air Corporation (US)

MM-0110; Revision 1-A: 11/01/2013

Selvage Path

Illustration

12. Switch the conveyor ON, put the packing product on the conveyor and make sure that your

hands are completely away from the conveyor surface.

Section 3. Operation

SLCT-FAL5645 Sealing Machine

Selvage Reel

Cover Lock

Figure 3–8 Selvage Reel

13. Adjust the sealing and cutting process as necessary. (Figure

3–9).

Film Seal Line

Conveyor Direction

Figure 3–9 Sealing and Cutting Adjustment

14. Adjust of the front extra fi lm length (Length A of Figure 3–9), to the best length

approximately 1/3 H. The adjustment procedure is as follows:

a. When A is too long, shorten the distance between the sensor and the sealing blade by

increasing the conveyor time setting on switch #16 in Figure 3-1.

b. If A is too short, adjust the conveying time for the extra fi lm length at the front of the

product, increasing the conveying time to increase the extra fi lm length at the front of the

box.

© Sealed Air Corporation (US)

MM-0110; Revision 1-A: 11/01/2013

3-9

Section 3. Operation

SLCT-FAL5645 Sealing Machine

Sealing and Cutting

Blade

Sealing and Cutting Base

Packing Product

Optical Sensor

Figure 3–10 Horizontal Sensors

15. The best rear extra fi lm length (B of Figure 3–9), is 1/2 H between the product and the rear

seal. Adjust the

conveyor time setting on switch #13 in Figure 3-1 to increase the fi lm length

at the rear of the package.

16. Different shrink fi lms have different sealing time (Typically 0.3~0.6 seconds). The fi lm

must be sealed and cut completely and steadily without holes. Poor fi lm cutting may be

caused by overheating on the sealing process. Adjusting the sealing dwell time or the sealing

temperature should eliminate this issue.

17. When the sealing and cutting line is good, the adjustment process is fi nished.

3.4 FUNCTIONS

• The machine includes a warning system, and a safety function.

• The sealing and cutting process can operate continuously.

• Simple machine operation can match various sizes of packing products.

• PLC and optical sensor control are applied on this machine.

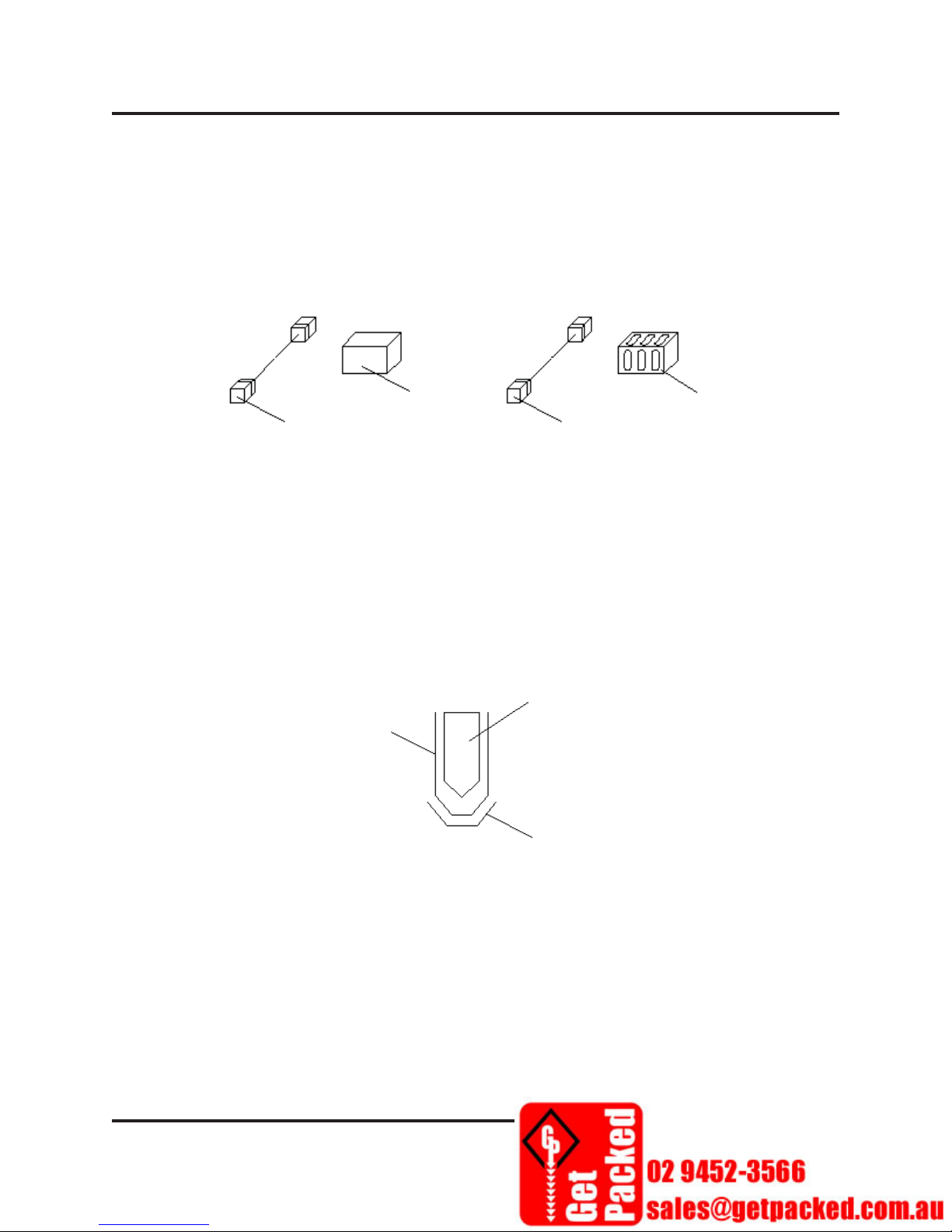

• Two types of optical sensors (Horizontal type and Vertical type): Horizontal type optical

sensors (as shown in

Figure 3–10) are applied on packing square or rectangular product.

It includes a wait function. The Vertical optical sensor is mostly used for packing thinner

products, but there is no wait function on this sensor.

• According the characteristics of the product, there are two types of the sensor mode selection:

Standard type and point-to-point compensation type (as shown on

3-10

Figure 3–11):

© Sealed Air Corporation (US)

MM-0110; Revision 1-A: 11/01/2013

Section 3. Operation

SLCT-FAL5645 Sealing Machine

• When the products are in rectangular or square shape, Standard sensor mode should be

applied.

• If the packing products are an irregular shape or transparent, then the Point-to-point

Compensation sensor mode should be applied and the Conveying Time switch adjusted to

control the fi lm length.

Packing Product

Optical Sensor

Packing Product

Optical Sensor

Figure 3–11 Packing Product Sensor Mode

18. The sealing blade of this machine can be used on the POF and PE Shrink Film. When using

on the PE Shrink Film, the sealing blade must be covered by heat-resisted adhesive tape to

prevent the blade from directly contacting the PE fi lm.

Sealing Blade

Protective Plate

Heat-resisted Adhesive Tape

© Sealed Air Corporation (US)

MM-0110; Revision 1-A: 11/01/2013

3-11

Section 3. Operation

SLCT-FAL5645 Sealing Machine

3.5 OPERATION

3.5.1 Typical Operation

The machine employs an infeed conveyor and a discharge conveyor mounted at the same

elevation to convey product through the machine. The upper seal jaws and lower seal beds

both pivot such that they meet at the center line of the package when a seal is being made. The

infeed conveyor carries product through the fi lm inverting head where it is surrounded with

plastic shrink fi lm supplied by a powered fi lm unwind assembly. When the product reaches

the proper position in the sealing area, the conveyors stop and the Sealer cycles, making a seal

and cutting fi lm on two edges of the package. After sealing is completed, the seal jaws open

and the discharge conveyor carries the product out of the machine while the infeed conveyor

simultaneously delivers the next product to the sealing area.

3.5.2 Starting the Machine

1. Switch ON the Main Circuit Breaker to power the machine.

2. Turn ON or attach the air supply.

3. Switch ON the heater controls and allow the sealers to reach operating temperature.

4. Turn ON the conveyor.

5. Put a product onto the conveyor and the machine will pack the product automatically.

6. If abnormal machine operation occurs, then press the Emergency Stop switch to immediately

stop the sealing machine.

7. The blue Reset Button will fl ash until abnormal operation has been corrected and the E-Stop

has been released by twisting it clockwise.

3.5.3 Shutting Down the Machine

1. Turn off the heater control switches and allow the sealer unit to cool down.

2. Next, switch off the power supply.

3. If it is necessary to shut-down the air supply, be aware that it will cause the sudden

downward movement of the sealing/cutting jaws when the air is disconnected.

3-12

© Sealed Air Corporation (US)

MM-0110; Revision 1-A: 11/01/2013

Section 4. Maintenance & Troubleshooting

SLCT-FAL5645 Sealing Machine

SECTION 4. MAINTENANCE & TROUBLESHOOTING

This section details information about maintaining and troubleshooting the sealing machine.

4.1 MACHINE MAINTENANCE ........................................................ 4-3

4.2 TROUBLESHOOTING ..................................................................7

© Sealed Air Corporation (US)

MM-0110; Revision 1-A: 11/01/2013

4-1

Section 4. Maintenance & Troubleshooting

SLCT-FAL5645 Sealing Machine

4.1 MACHINE MAINTENANCE

Regular maintenance is the best way to ensure smooth operation and optimal machine life. The

following are the general machine maintenance guidelines. Only trained machine operators and

service technicians are authorized to perform maintenance on this machine.

IMPORTANT

Review and follow the Safety Guidelines in Chapter 1 of this Manual and site-specifi c

Lock Out/Tag Out Procedures when necessary.

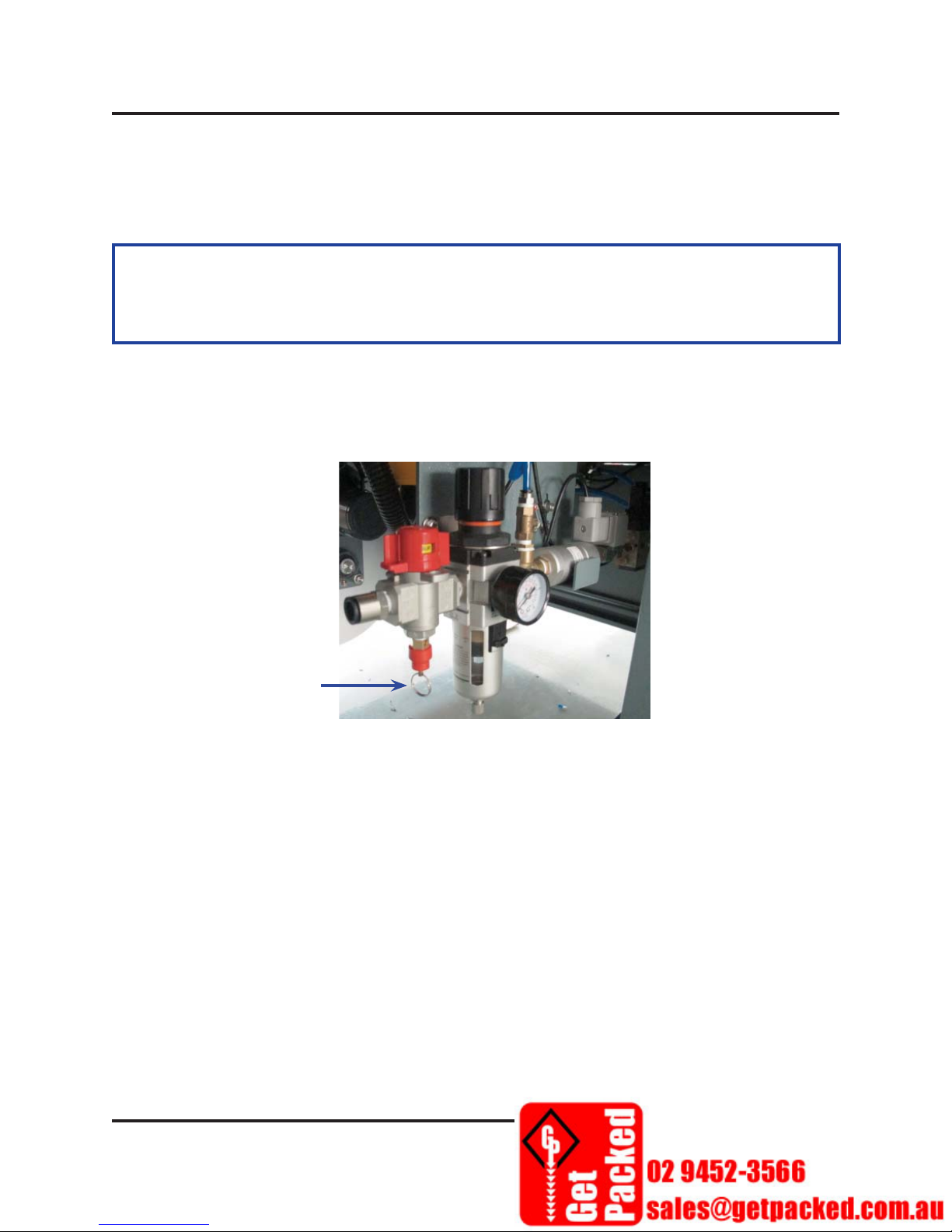

• Maintenance of Pneumatic Regulator Unit:

When the water level reaches 2/3 of the height of the water fi lter tank, the tank water must be

drained out. To drain water, pull down the ring on the water drain plug.

Water Drain

Figure 4–1 Pneumatic Regulator Unit

• Clean the Workstation before the start operation each day.

a. Use only compressed air to clean the work area.

b. Only use soft wood to clear the fi lm reside on the sealing blade. Do not use metal or other

abrasive materials.

• Monthly Maintenance of the Selvage Receiving Wheel

a. Remove the locking nut, take out the spring and the receiving wheel.

b. Lubricate the contact surfaces of the receiving wheel and the center rod for smooth wheel

rotation

c. Replace the spring and receiving wheel and tighten the locking nut.

© Sealed Air Corporation (US)

MM-0110; Revision 1-A: 11/01/2013

4-3

Section 4. Maintenance & Troubleshooting

SLCT-FAL5645 Sealing Machine

• Chain and wheel maintenance (every 3 months):

a. Take off the cover and put the grease oil onto the gap between the chain and the wheel.

b. Put the cover back on.

c. Bearing and bearing holder maintenance: Service once every 3 months, using the

hydraulic pressure oil to lubricate the bearings and its parts.

• Check Tension and Tracking of the Conveyor Belt.

a. After a period of operation, the conveyor belt may loosen. To adjust the belt tension,

loosen the two lock nuts on each tension adjustment screw. Turn the screw clockwise to

tighten.

b. If the conveyer belt is not tracking down the middle of the bed, slightly turn the adjusting

screw on the side where the belt is close, in a clockwise direction. Allow the belt to run

for a few minutes to see if it moves to the center. It may take several small adjustments

• If the Tefl on detaches from the sealing blade and fi lms easily stick onto the blade, re-stall the

new T efl on or change the new sealing blade.

• Check the Tefl on tape covering the silicon bar. If the tape is damage, replace it.

• Change the heater tube if the heater cannot heat-up the temperature:

a. Before replacement, check the watt and voltage of the heater, switch off the power and

wait the heater to cool-down.

b. Disconnect the heater wire at the electric and control box.

c. Loosen the locking screw of the heater tube and replace the heater tube.

d. Make sure that all screws are tightened, then re-connect the heater wire at electric and

control box.

4-4

© Sealed Air Corporation (US)

MM-0110; Revision 1-A: 11/01/2013

Section 4. Maintenance & Troubleshooting

SLCT-FAL5645 Sealing Machine

• Change the silicon bar and the heat-resistant adhesive tape:

Lower Sealing Frame

Heat-resistant Adhesive Tape

Silicon Bar

Sealing Base

Sealing Blade Base

Figure 4–2 Silicon Bar and the Heat-Resistant Adhesive Tape

a. Switch off the power and allow the sealing bars to cool-down Remove the old heat-

resistant adhesive tape.

b. Replace the silicon bar. Make sure the bar surface is fl at. If necessary, trim away any

excess silicon bar.

c. Apply new heat-resistant tape and make sure the tape surface is fl at.

• Replacement and adjustment of the sealing blades:

a. Remove the sealing blade shields.

Sealing Blade

Protective Shields

b. Remove the faulty sealing blade assembly

© Sealed Air Corporation (US)

MM-0110; Revision 1-A: 11/01/2013

Figure 4–3 Sealing Blade Shields

5

Section 4. Maintenance & Troubleshooting

SLCT-FAL5645 Sealing Machine

c. Replace the sealing blade and make sure the blade is between two guiding plates.

Figure 4–4 Front Sealing Blade without Shields

Sealing Blade

Figure 4–5 Sealing Blade.

Figure 4–6 Front blade alignment

d. Align the new front sealing blade by using the side sealing blade as a guide.

e. Tighten the front blade set after the aligning the blade.

f. Install the protective shields.

6

© Sealed Air Corporation (US)

MM-0110; Revision 1-A: 11/01/2013

Section 4. Maintenance & Troubleshooting

SLCT-FAL5645 Sealing Machine

4.2 TROUBLESHOOTING

Item Problem Possible Causes Recommended Action

Power not connected Connect the power cord

No power to the

1

machine

Main Circuit Breaker is OFF Turn “ON” the CB

ON/OFF switch is damaged Change the switch

Fuse is broken Change the fuse

E-Stop is pressed Release the E-Stop

Power connected but

2

the machine does not

work

PLC does not work Check the power

connection to PLC

PLC is not functioning Change the PLC

Door or Cover interlock open Check covers and doors

The heater switch is ”OFF” Switch “ON” the heater

Temperature is set too low Adjust the temperature

Heater switch is not

Change the heater switch

functioning

3 Heater does not work

The temperature controller is

not functioning

Change the temperature

controller

Relay (SSR) is not functioning Change the SSR

The heater tube is not

Change the heater tube

functioning

Relay (SSR) is not functioning Change the relay (SSR)

Temperature is out of

4

control

The fi lm conveying

5

motor does not run

The temperature detector is

loose out or not functioning

Temperature controller is not

functioning

Film conveying switch is not

functioning

The fi lm conveying relay is not

functioning

The fi lm conveying motor is

overloaded or overheated

The fi lm conveying motor is

not functioning

Tight back the detector or

change the detector

Change the temperature

controller

Change the fi lm conveying

switch

Change the fi lm conveying

relay

Remove the cause and

restart the system

Change the fi lm conveying

motor

© Sealed Air Corporation (US)

MM-0110; Revision 1-A: 11/01/2013

7

Section 4. Maintenance & Troubleshooting

SLCT-FAL5645 Sealing Machine

Item Problem Possible Causes Recommended Action

The connecting point [1001] of

PLC is not functioning

Change the connecting

point [1001] and the

program of PLC or Change

the PLC

Front conveyor motor

6

does not work

The relay of front conveyor

motor is not functioning

The front conveyor motor is

overloaded or overheated

The front conveyor motor is

not functioning

The connecting point [1002] of

PLC is not functioning

Change the relay of front

conveyor motor

Remove the cause and

restart the system

Change the front conveyor

motor

Change the connecting

point [1002] and the

program of PLC or Change

the PLC

Rear conveyor motor

7

does not work

Relay of rear conveyor motor

is not functioning

The rear conveyor motor is

overloaded or overheated

The rear conveyor motor is not

functioning

The connecting point [1003] of

PLC is not functioning

Replace the relay of rear

conveyor motor

Remove the cause and

restart the system

Replace the rear conveyor

motor

Change the connecting

point [1003] and the

program of PLC or Change

the PLC

The wasted fi lm

8

receiving motor does

not work

The sealing base unit

9

does not work

Relay of the wasted fi lm motor

is not functioning

Manual fi lm conveying switch

is not functioning

The wasted fi lm motor is over

loaded or overheated

The wasted fi lm motor is not

functioning

The connecting point [1004] of

PLC is not functioning

The manual sealing operation

switch is not functioning

Change the relay of the

wasted fi lm motor

Change the manual fi lm

conveying switch

Remove the cause and

restart the system

Change the wasted fi lm

motor

Change the connecting

point [1004] and the

program of PLC or Change

the PLC

Change the manual sealing

operation switch

4-8

© Sealed Air Corporation (US)

MM-0110; Revision 1-A: 11/01/2013

Section 4. Maintenance & Troubleshooting

SLCT-FAL5645 Sealing Machine

Item Problem Possible Causes Recommended Action

10

Warning Buzzer of the

sealing process is “ON”

The micro-switch of the sealing

process is blocked

Product is pressed by the

sealing blade

The machine stop when the

sealing blade presses down and

the buzzer is “ON”

Reposition the micro-

switch

Press the Manual sealing

operation switch to remove

the pressed product

Lower the actuator or

adjust the magnetic spring

switch of the cylinder

forwards to the normal

position

Sealing time is short Increase the sealing time by

0.1 second until the proper

sealing time is achieved

11

Incomplete sealing or

cutting, or the sealing

line is broken

The upper sealing blade and the

sealing base do not completely

contact each other

Tefl on tape is damaged Change the Tefl on tape

The silicon bar of the sealing

Adjust the sealing blade

position

Replace the silicon bar

base is damaged

The protective plates are not

Adjust the protective plates

completely contacted

12

The waste fi lm

conveying does not

stop

Too much fi lm residue is

sticking on the sealing wire

optical sensors are out of

alignment

Optical sensor is not

Clear the fi lm residue and

lower dwell time

Align the optical sensors

until the sensor light is ON

Change the optical sensor

functioning

13 Product pressed by the

side sealing blade

Product does not convey on the

guiding side

Put the product correctly

on the guiding side of the

conveyor

14 Product pressed by the

front sealing blade

The Conveying time of extra

fi lm at the rear is too short

and the product does not

Increase the conveying

time of extra fi lm at the

rear side of the product

completely pass through the

sealing blade unit

The packing product is

transparent or has an irregular

Try to use the point to point

compensation sensor mode

shape

© Sealed Air Corporation (US)

MM-0110; Revision 1-A: 11/01/2013

4-9

Section 4. Maintenance & Troubleshooting

SLCT-FAL5645 Sealing Machine

Item Problem Possible Causes Recommended Action

15 The front conveyor belt

Improper front roller tension Adjust the belt tension

is tracking to either side

during operation

16 Film loading is not

smooth or too tight to

Wrong fi lm unwind setup Reload the fi lm unwind,

see Fig. 4.3

load the fi lm

17 Position change of the

upper or lower fi lm

layer

The parallel fi lm roller set is

not level

Stabilization of the shrink fi lm

Adjust the parallel fi lm

roller set, see Fig. 4.4

Change the fi lm

is not good

18 Cannot remove the

wasted fi lm from the

wasted fi lm receiving

reel or too loose

The spring of the reel is too

tight or too loose

If the wasted fi lm is too

tight, release the screw

outside the spring a little

bit or tight the screw a little

bit if the fi lm is too loose.

4-10

© Sealed Air Corporation (US)

MM-0110; Revision 1-A: 11/01/2013

Section 4. Maintenance & Troubleshooting

SLCT-FAL5645 Sealing Machine

© Sealed Air Corporation (US)

MM-0110; Revision 1-A: 11/01/2013

4-11

Section 5. Reference Documents

SLCT-FAL5645 Sealing Machine

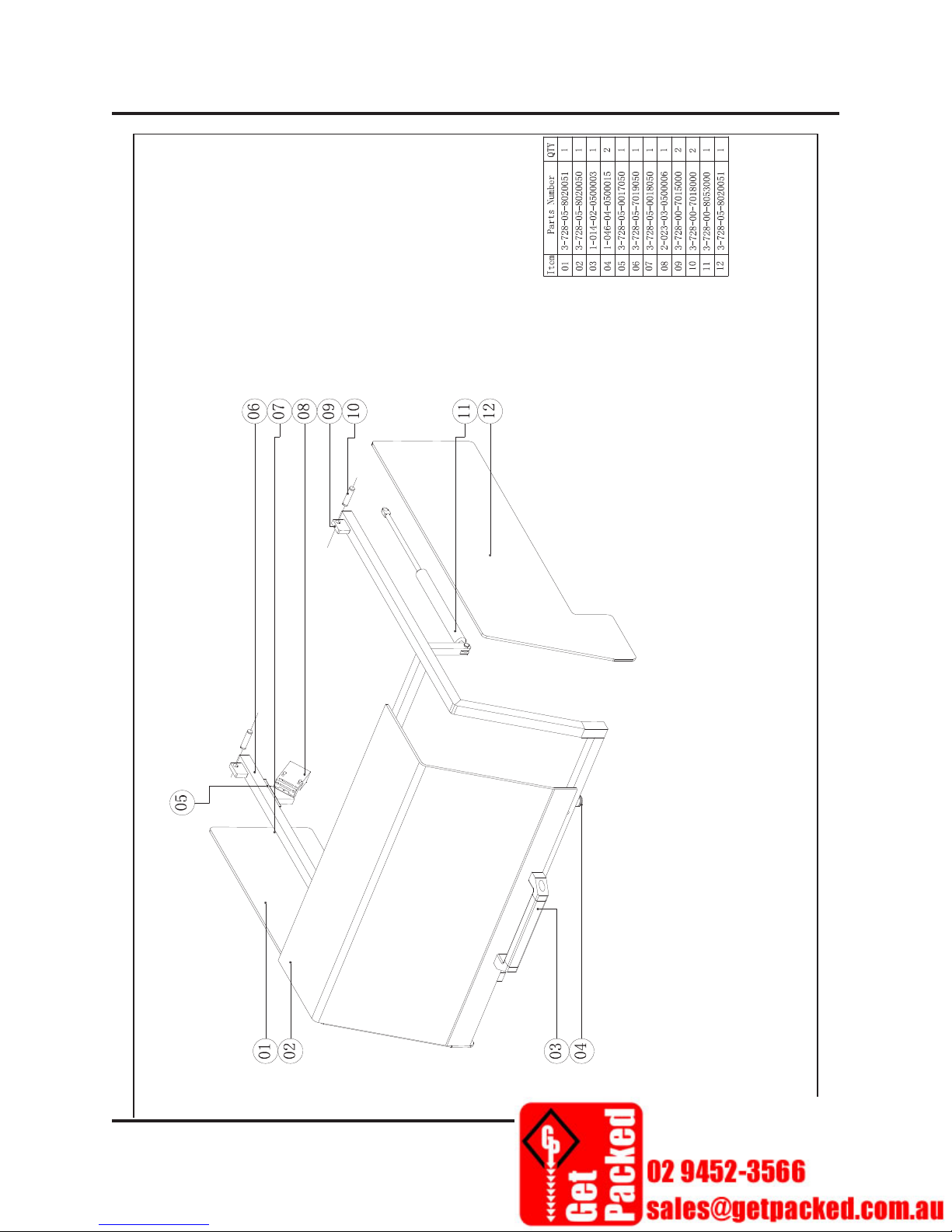

SECTION 5. REFERENCE DOCUMENTS

This section details information about circuit diagrams, mechanical parts lists, and a pneumatic

chart.

5.1 CIRCUIT DIAGRAMS ...................................................................5-3

5.2 MECHANICAL PARTS LIST ........................................................5-5

5.3 PNEUMATIC CHART ....................................................................5-19

© Sealed Air Corporation (US)

MM-0110; Revision 1-A: 11/01/2013

5-1

5.1 CIRCUIT DIAGRAMS

Section 5. Reference Documents

SLCT-FAL5645 Sealing Machine

© Sealed Air Corporation (US)

MM-0110; Revision 1-A: 11/01/2013

5-3

Section 5. Reference Documents

SLCT-FAL5645 Sealing Machine

5-4

© Sealed Air Corporation (US)

MM-0110; Revision 1-A: 11/01/2013

5.2 MECHANICAL PARTS LIST

Section 5. Reference Documents

SLCT-FAL5645 Sealing Machine

© Sealed Air Corporation (US)

MM-0110; Revision 1-A: 11/01/2013

5-5

Section 5. Reference Documents

SLCT-FAL5645 Sealing Machine

5-6

© Sealed Air Corporation (US)

MM-0110; Revision 1-A: 11/01/2013

Section 5. Reference Documents

SLCT-FAL5645 Sealing Machine

© Sealed Air Corporation (US)

MM-0110; Revision 1-A: 11/01/2013

5-7

Section 5. Reference Documents

SLCT-FAL5645 Sealing Machine

5-8

© Sealed Air Corporation (US)

MM-0110; Revision 1-A: 11/01/2013

Section 5. Reference Documents

SLCT-FAL5645 Sealing Machine

© Sealed Air Corporation (US)

MM-0110; Revision 1-A: 11/01/2013

5-9

Section 5. Reference Documents

SLCT-FAL5645 Sealing Machine

5-10

© Sealed Air Corporation (US)

MM-0110; Revision 1-A: 11/01/2013

Section 5. Reference Documents

SLCT-FAL5645 Sealing Machine

© Sealed Air Corporation (US)

MM-0110; Revision 1-A: 11/01/2013

5-11

Section 5. Reference Documents

SLCT-FAL5645 Sealing Machine

5-12

© Sealed Air Corporation (US)

MM-0110; Revision 1-A: 11/01/2013

Section 5. Reference Documents

SLCT-FAL5645 Sealing Machine

© Sealed Air Corporation (US)

MM-0110; Revision 1-A: 11/01/2013

5-13

Section 5. Reference Documents

SLCT-FAL5645 Sealing Machine

5-14

© Sealed Air Corporation (US)

MM-0110; Revision 1-A: 11/01/2013

Section 5. Reference Documents

SLCT-FAL5645 Sealing Machine

© Sealed Air Corporation (US)

MM-0110; Revision 1-A: 11/01/2013

5-15

Section 5. Reference Documents

SLCT-FAL5645 Sealing Machine

5-16

© Sealed Air Corporation (US)

MM-0110; Revision 1-A: 11/01/2013

Section 5. Reference Documents

SLCT-FAL5645 Sealing Machine

© Sealed Air Corporation (US)

MM-0110; Revision 1-A: 11/01/2013

5-17

Section 5. Reference Documents

SLCT-FAL5645 Sealing Machine

5-18

© Sealed Air Corporation (US)

MM-0110; Revision 1-A: 11/01/2013

5.3 PNEUMATIC DIAGRAM

Section 5. Reference Documents

SLCT-FAL5645 Sealing Machine

© Sealed Air Corporation (US)

MM-0110; Revision 1-A: 11/01/2013

5-19

Loading...

Loading...