Page 1

Seagate® Nytro® 3731, 3531, 3331, and 3131

SAS SSD

Product Manual

Nytro 3731: Write Intensive (10 DWPD) Nytro 3531: Mixed Use (3 DWPD)

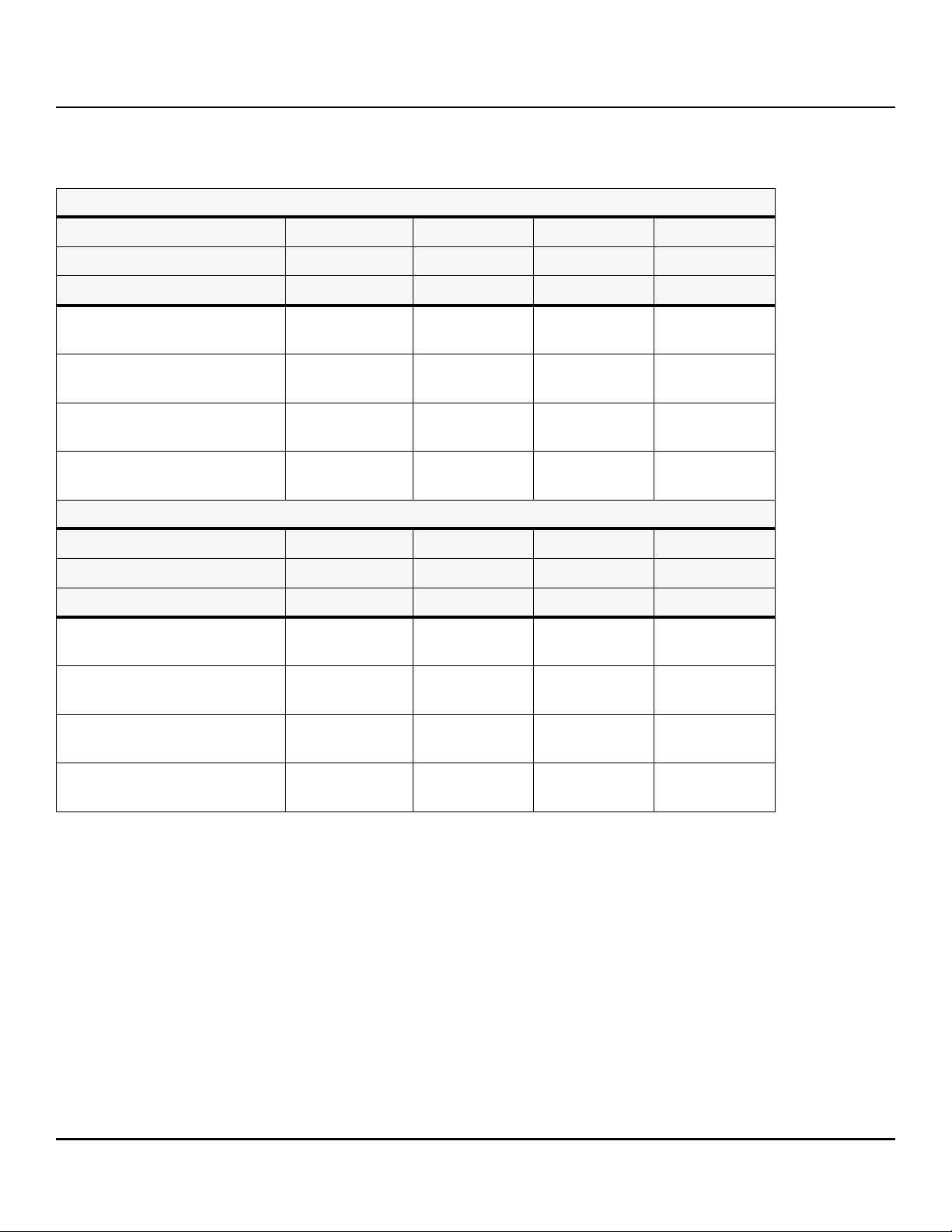

Capacity Standard Self-Encrypting FIPS 140-2 Standard Self-Encrypting FIPS 140-2

6400 GB -- -- -- XS6400LE70004 XS6400LE70014 --

3200 GB XS3200ME70004 XS3200ME70014 XS3200ME70024 XS3200LE70004 XS3200LE70014 XS3200LE70024

1600 GB XS1600ME70004 XS1600ME70014 XS1600ME70024 XS1600LE70004 XS1600LE70014 XS1600LE70024

800 GB XS800ME70004 XS800ME70014 -- XS800LE70004 XS800LE70014 XS800LE70024

400 GB XS400ME70004 XS400ME70014 -- -- -- --

Nytro 3331: Read Intensive (1 DWPD) Nytro 3131: Very Read Intensive (<1 DWPD)

Standard Self-Encrypting FIPS 140-2 Standard Self-Encrypting FIPS 140-2

15360 GB -- -- -- XS15360TE70004 XS15360TE70014 XS15360TE70024

7680 GB XS7680SE70004 XS7680SE70014 XS7680SE70024 XS7680TE70004 XS7680TE70014 --

3840 GB XS3840SE70004 XS3840SE70014 XS3840SE70024 XS3840TE70004 XS3840TE70014 --

1920 GB XS1920SE70004 XS1920SE70014 XS1920SE70024 -- -- --

960 GB XS960SE70004 XS960SE70014 XS960SE70024 -- -- --

100848978, Rev.C

August 2019

Page 2

Revision History

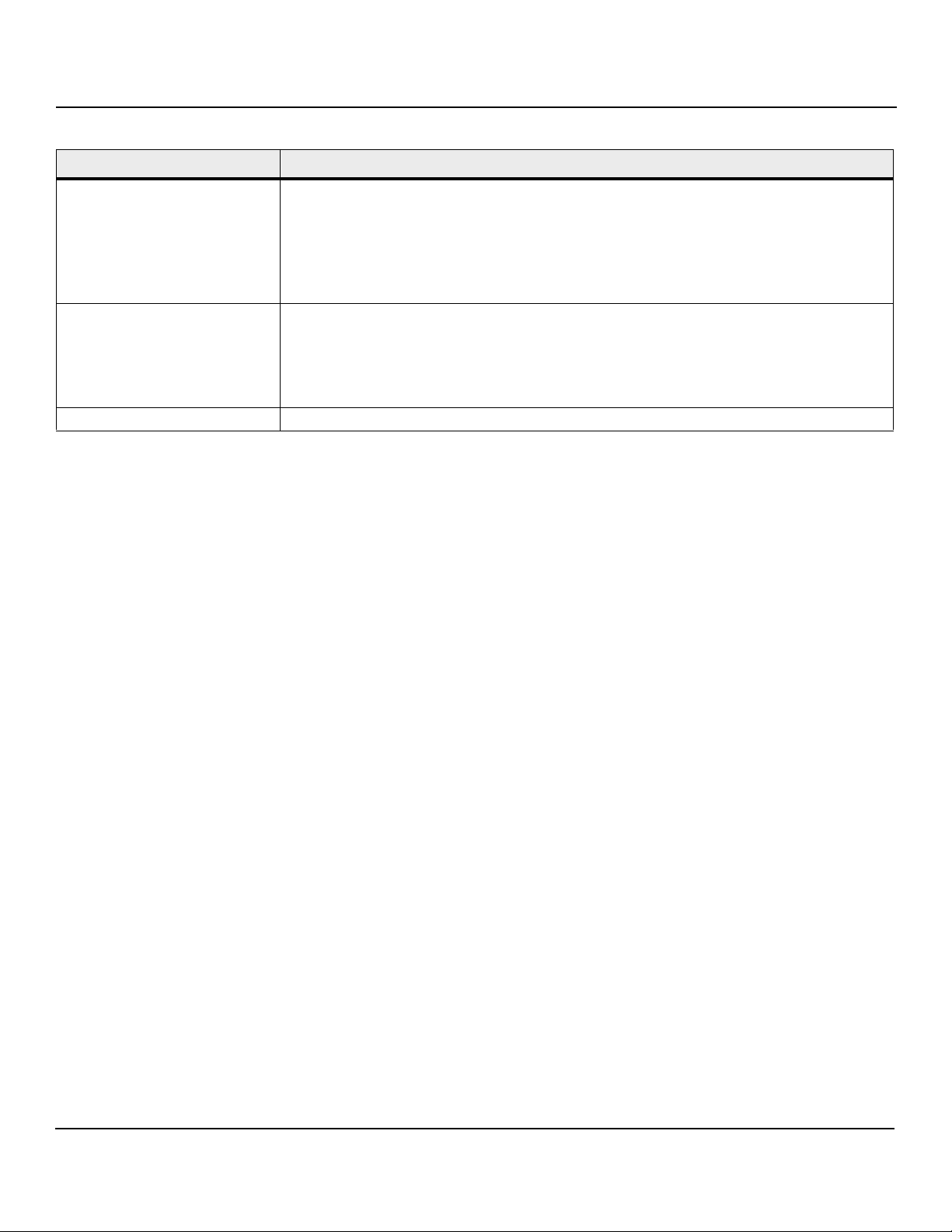

Version and Date Description of Changes

Rev C, August 2019 Updated the following sections:

Cover

Section 2, Models

Section 5.2.3, Throughput Performance

Section 6.2, Endurance

Section 4.2, Performance

Rev B, April 2019 Copy-edited throughout for readability.

Updated content in the following sections:

Section 3.1, Agency and Safety Certifications

Section 4.6, Programmable drive capacity

Section 5.2.3, Throughput Performance

Rev A, January 2019 First release of the document.

© 2019, Seagate Technology LLC All rights reserved. Publication number: 100848978, Rev.C, August 2019

Seagate Technology reserves the right to make changes to the product(s) or information disclosed herein at any time without notice.

Seagate, Seagate Technology and the Spiral logo are registered trademarks of Seagate Technology LLC in the United States and/or other countries. Nytro and SeaTools are either trademarks or registered trademarks of

Seagate Technology LLC or one of its affiliated companies in the United States and/or other countries. All other trademarks or registered trademarks are the propert y of their respective owners.

No part of this publication may be reproduced in any form without written permission of Seagate Technology LLC. Call 877-PUB-TEK1(877-782-8351) to request permission.

The NVMe word mark and/or NVMExpress design mark are trademarks of NVMExpress, Inc. The PCIe word mark and/or PCIExpress design mark are registered trademarks and/or ser vice marks of PCI-SIG.

When referring to drive capacity, one gigabyte, or GB, equals one billion bytes and one terabyte, or TB, equals one trillion bytes. Your computer’s operating system may use a different standard of measurement and report

a lower capacity. In addition, some of the listed capacity is used for formatti ng and other func tions, and thus wil l not be available for data storage. Actual quantities will vary based on various factors, including file size, file

format, features and application software. Actual data rates may vary depending on operating environment and other factors. The export or re-export of hardware or software containing encryption may be regulated by

the U.S. Department of Commerce, Bureau of Industry and Security (for more information, visit www.bis.doc.gov), and controlled for import and use outside of the U.S. Seagate reserves the right to change, without notice,

product offerings or specifications.

Page 3

Contents

Seagate Technology Support Services . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1. Scope . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2. Models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

3. Safety, Standards, and Compliance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

3.1 Agency and Safety Certifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

3.1.1 Regulatory Model . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

3.2 Reference documents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

4. General description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

4.1 Standard features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

4.2 Performance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

4.3 Media description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

4.4 Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

4.5 Formatted capacities . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

4.6 Programmable drive capacity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

4.7 Factory-installed options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

4.8 Logical Block Provisioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

4.8.1 UNMAP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

4.8.2 FORMAT UNIT command . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

4.8.3 Protection Information (PI) and Security (SED) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

5. Performance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

5.1 Internal drive characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

5.2 Performance characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

5.2.1 Response time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

5.2.2 FORMAT UNIT command execution time for 512-byte LBA's (minutes) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

5.2.3 Throughput Performance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

5.3 Start/stop time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

5.3.1 Caching write data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

5.3.2 Prefetch operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

6. Reliability specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

6.1 Read error rates . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

6.2 Endurance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

6.3 Error rates . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

6.3.1 Unrecoverable Errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

6.3.2 Interface errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

6.4 Endurance management . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

6.4.1 Wear leveling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

6.4.2 Garbage collection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

6.4.3 Write amplification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

6.4.4 UNMAP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

6.4.5 Data retention . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

6.4.6 Write stream tagging . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

6.4.7 SSD percentage used endurance indicator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Seagate Nytro 3731, 3531, 3331, 3131 SAS SSD Product Manual, Rev. C 3

Page 4

Contents

6.5 Reliability and service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

6.5.1 Annualized Failure Rate (AFR) and Mean Time Between Failure (MTBF) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

6.5.2 Preventive maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

6.5.3 Hot plugging the drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

6.5.4 S.M.A.R.T. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

6.5.4.1 Controlling S.M.A.R.T. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

6.5.4.2 Performance impact . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

6.5.4.3 Reporting control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

6.5.4.4 Determining rate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

6.5.4.5 Predictive failures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

6.5.5 Thermal monitor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

6.5.6 Drive Self Test (DST) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

6.5.6.1 DST failure definition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

6.5.6.2 Implementation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

6.5.6.3 State of the drive prior to testing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

6.5.6.4 Invoking DST . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

6.5.6.5 Log page entries . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

6.5.6.6 Abort . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

6.5.7 Product warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

6.5.8 Shipping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

6.5.8.1 Product repair and return information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

6.5.8.2 Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

7. Physical and electrical specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

7.1 Power specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

7.1.1 Conducted noise immunity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

7.1.2 Power sequencing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

7.2 Power consumption . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

7.2.1 Direct Current Consumption by Voltage Rail . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

7.2.1.1 Power Consumption . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

7.2.2 Current profiles . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

7.3 Environmental limits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

7.3.1 Temperature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

7.3.1.1 Operating . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

7.3.1.2 Non-operating . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

7.3.2 Relative humidity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

7.3.3 Effective altitude (sea level) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

7.3.4 Shock and vibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

7.3.4.1 Shock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

7.3.4.2 Vibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

7.3.5 Air cleanliness . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

7.3.6 Corrosive environment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

7.4 Mechanical specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

7.4.1 Weight . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

8. About FIPS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

8.1 Purpose . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

8.2 Validation Program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

8.3 Seagate Enterprise SED . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

8.4 Security Level 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

9. About self-encrypting drives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

9.1 Data encryption . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

9.2 Controlled access . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

9.2.1 Admin SP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

9.2.2 Locking SP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

9.2.3 Default password . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

9.3 Random number generator (RNG) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Seagate Nytro 3731, 3531, 3331, 3131 SAS SSD Product Manual, Rev. C 4

Page 5

Contents

9.4 Drive locking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

9.5 Data bands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

9.6 Cryptographic erase . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

9.7 Authenticated firmware download . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

9.8 Power requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

9.9 Supported commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

9.10 Sanitize - Cryptographic Erase . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

9.11 RevertSP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

10. Defect and error management . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

10.1 Drive internal defects/errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

10.2 Drive error recovery procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

10.3 SAS system errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

10.4 Auto-Reallocation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

10.5 Protection Information (PI) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

10.5.1 Levels of PI . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

10.5.2 Setting and determining the current Type Level . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

10.5.3 Identifying a Protection Information drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

11. Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

11.1 Drive orientation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

11.2 Cooling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

11.3 Drive mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

11.4 Grounding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

12. Interface requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

12.1 SAS features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

12.1.1 Task management functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

12.1.2 Task management responses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

12.2 Dual port support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

12.3 SCSI commands supported . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

12.3.1 INQUIRY data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

12.3.2 MODE SENSE data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

12.4 Miscellaneous operating features and conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

12.4.1 SAS physical interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

12.4.2 Physical characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

12.4.3 Connector requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

12.4.4 Electrical description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

12.4.5 Pin descriptions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

12.4.6 SAS transmitters and receivers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

12.4.7 Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

12.5 Signal characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

12.5.1 Ready LED Out . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

12.5.2 Differential signals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

12.6 SAS-3 Specification compliance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

12.7 Additional information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

Seagate Nytro 3731, 3531, 3331, 3131 SAS SSD Product Manual, Rev. C 5

Page 6

Seagate Technology Support Services

For Internal SSD Support, visit: https://www.seagate.com/support/products/

For Firmware Download and Tools Download for Secure Erase, visit: https://www.seagate.com/support/downloads/

For information regarding online support and services, visit: http://www.seagate.com/contacts/

For information regarding Warranty Support, visit: http://www.seagate.com/support/warranty-and-replacements/

For information regarding data recovery services, visit:

http://www.seagate.com/services-software/seagate-recovery-services/recover/

For Seagate OEM and Distribution partner and Seagate reseller portal, visit: http://www.seagate.com/partners

Seagate Nytro 3731, 3531, 3331, 3131 SAS SSD Product Manual, Rev. C 6

Page 7

www.seagate.com

1. Scope

This manual describes Seagate Nytro® 3000 SAS (Serial Attached SCSI) Solid State Drives (SSD).

Seagate Nytro® 3000 SSDs support the SAS Protocol specifications described in this manual. The SAS Interface Manual

(part number 100293071) describes the SAS characteristics of this and other Seagate SAS drives. The Self- Encrypting

Drive Reference Manual, part number 100515636, describes the interface, general operation, and security features

available on Self-Encrypting Drive (SED) models.

Product data in this manual refers only to the model numbers listed in this manual. The data in this manual may

predict future generation specifications or requirements. If you are designing a system using one of the models listed

or future generation products and you need further assistance, please contact the Field Applications Engineer (FAE) or

our global support services group.

Unless otherwise stated, the information in this manual applies to standard Secure Download and Diagnostic (SD&D)

and SED models.

Seagate Nytro 3731, 3531, 3331, 3131 SAS SSD Product Manual, Rev. C 7

Page 8

www.seagate.com

2. Models

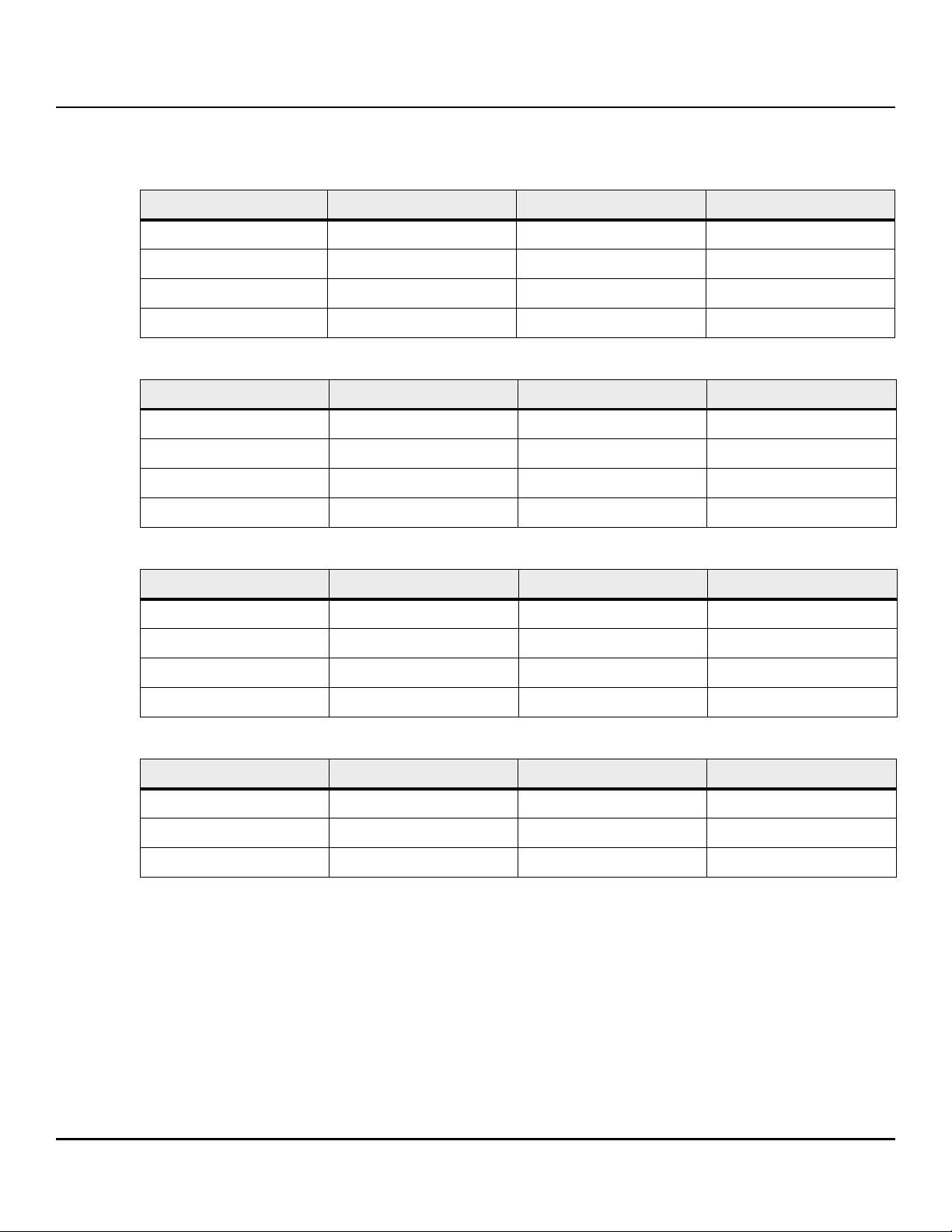

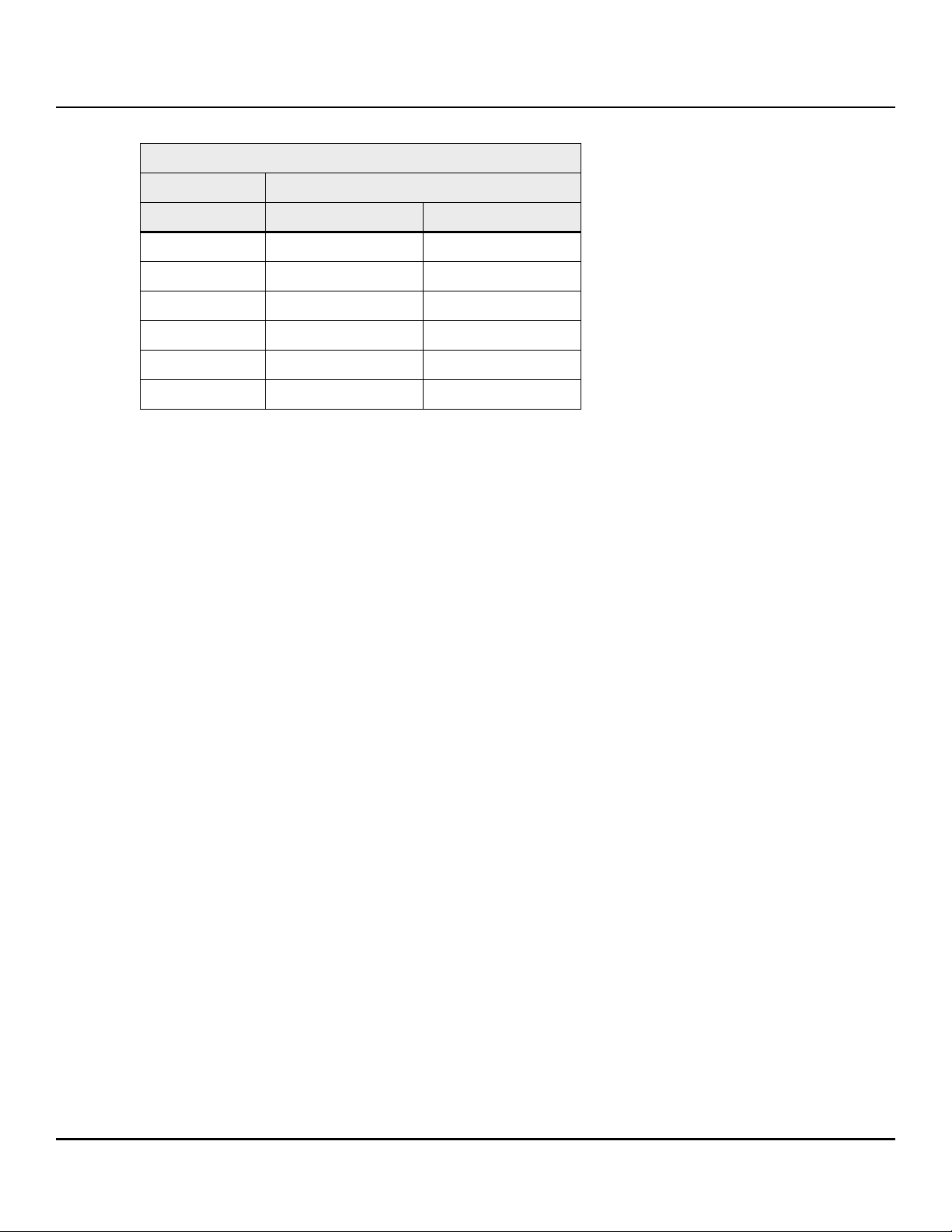

Table 1 - Nytro 3731: Write Intensive (10 DWPD)

3200GB XS3200ME70004 XS3200ME70014 XS3200ME70024

1600GB XS1600ME70004 XS1600ME70014 XS1600ME70024

800GB XS800ME70004 XS800ME70014

400GB XS400ME70004 XS400ME70014

Table 2 - Nytro 3531: Mixed Use (3 DWPD)

6400GB XS6400LE70004 XS6400LE70014

3200GB XS3200LE70004 XS3200LE70014 XS3200LE70024

1600GB XS1600LE70004 XS1600LE70014 XS1600LE70024

800GB XS800LE70004 XS800LE70014 XS800LE70024

Capacity Standard Self-Encrypting FIPS 140-2

Capacity Standard Self-Encrypting FIPS 140-2

Table 3 - Nytro 3331: Read Intensive (1 DWPD)

Capacity Standard Self-Encrypting FIPS 140-2

7680GB XS7680SE70004 XS7680SE70014 XS7680SE70024

3840GB XS3840SE70004 XS3840SE70014 XS3840SE70024

1920GB XS1920SE70004 XS1920SE70014 XS1920SE70024

960GB XS960SE70004 XS960SE70014 XS960SE70024

Table 4 - Nytro 3131: Very Read Intensive (<1 DWPD)

Capacity

15360GB XS15360TE70004 XS15360TE70014 XS15360TE70024

7680GB XS7680TE70004 XS7680TE70014

3840GB XS3840TE70004 XS3840TE70014

Standard

Self-Encrypting FIPS 140-2

NOTE Previous generations of Seagate SED models were called Full Disk Encryption

(FDE) models before a differentiation between drive-based encryption and

other forms of encryption was necessary.

NOTE The SED models indicated on the cover of this product manual have provisions

for "Security of Data at Rest" based on the standards defined by the Trusted

Computing Group (see http://www.trustedcomputinggroup.org).

For more information on FIPS 140-2 Level 2 certification see Section 8. About FIPS, on page 57.

For product certification status visit - http://csrc.nist.gov/groups/STM/cmvp/documents/140-1/1401vend.htm.

Seagate Nytro 3731, 3531, 3331, 3131 SAS SSD Product Manual, Rev. C 8

Page 9

www.seagate.com

3. Safety, Standards, and Compliance

This section describes applicable safety, certification, and compliance requirements for this device.

3.1 Agency and Safety Certifications

As a global supplier Seagate strives to deliver products compliant to many standards. Please see the document titled

‘HDD and SSD Regulatory Compliance and Safety’ found on the following Seagate website:

https://www.seagate.com/files/www-content/forms/compliance/regulatory-compliance-and-safety-100838899-A.pdf

3.1.1 Regulatory Model

The following regulatory model numbers represent all features and configurations in these series:

Table 5 - STT004 Series

XS400ME70004 XS800ME70004 XS960SE70004 XS1600ME70004

XS400ME70014 XS800ME70014 XS960SE70014 XS1600ME70014

XS800LE70004 XS960SE70024 XS1600ME70024

XS800LE70014 XS1600LE70004

XS800LE70024 XS1600LE70014

Table 6 - STT005 Series

XS3200ME70004 XS3840SE70004 XS6400LE70004 XS7680SE70004

XS3200ME70014 XS3840SE70014 XS6400LE70014 XS7680SE70014

XS3200ME70024 XS3840SE70024 XS7680SE70024

XS3200LE70004 XS3840TE70004 XS7680TE70004

XS3200LE70014 XS3840TE70014 XS7680TE70014

Seagate Nytro 3731, 3531, 3331, 3131 SAS SSD Product Manual, Rev. C 9

Page 10

www.seagate.com

3.2 Reference documents

Seagate Documents

SCSI Commands

Reference Manual

SAS Interface Manual Seagate part number: 100293071

ANSI SAS documents

SFF-8144 54mm x 78.5mm Form Factor with micro serial connector

SFF-8223 2.5" Drive Form Factor with Serial Connector

SFF-8447 LBA Count for Disk Drives

SFF-8460 HSS Backplane Design Guidelines

SFF-8470 Multi Lane Copper Connector

SFF-8482 SAS Plug Connector

ISO/IEC 14776-154 Serial Attached SCSI (SAS-3) Standard (T10 INCITS 519)

ISO/IEC 14776-416 SCSI Architecture Model-6 (SAM-6) Standard (T10 INCITS 546)

ISO/IEC 14776-455 SCSI Primary Commands-5 (SPC-5) Standard (T10 INCITS 502)

ISO/IEC 14776-432 SCSI Block Commands-4 (SBC-4) Standard (T10 INCITS 506)

ISO/IEC 14776-263 SCSI Protocol Layer-3 (SPL-3) Standard (T10 INCITS 492)

Seagate part number: 100293068

NOTE SFF document available on SNIA's website:

https://ta.snia.org/higherlogic/ws/public/documents

ANSI Small Computer System Interface (SCSI) Documents

X 3 . 2 7 0 - 1 9 9 6 ( S C S I - 3 ) A r c h i t e c t u r e M o d e l

Trusted Computing Group (TCG) Documents (apply to Self-Encrypting Drive models only)

TCG Storage Architecture Core Specification, Rev. 2.01

TCG Storage Security Subsystem Class Enterprise Specification, Rev. 1.01

Self-Encrypting Drives Reference Manual

Seagate part number: 100515636

In case of conflict between this document and any referenced document, this document takes

precedence.

Seagate Nytro 3731, 3531, 3331, 3131 SAS SSD Product Manual, Rev. C 10

Page 11

www.seagate.com

4. General description

Seagate Nytro 3000 SAS SSDs provide high performance, high capacity data storage for a variety of systems with a

Serial Attached SCSI (SAS) interface. The SAS interface meets next-generation computing demands for performance,

scalability, flexibility, and high-density storage requirements.

Seagate Nytro 3000 SAS SSDs are random access storage devices that support the SAS Protocol as described in the

ANSI specifications, this document, and the SAS Interface Manual (part number 100293071) which describe the

general interface characteristics of this drive. Seagate Nytro 3000 SAS SSDs are intelligent peripherals that provide

level 2 conformance (highest level) with the ANSI SCSI-1 standard. The SAS system connectors, cables, and electrical

interface are compatible with Serial ATA (SATA). This gives future users the choice of populating their systems with SAS

or SATA drives. Users can leverage their existing investment in SCSI while gaining a 12Gb/s serial data transfer rate.

The SED models described in this product manual provide "Security of Data at Rest" based on the standards defined

by the Trusted Computing Group (see www.trustedcomputinggroup.org).

NOTE Never disassemble and do not attempt to service items in the enclosure. The

drive does not contain user-replaceable parts. Opening the encolosure, for any

reason, voids the drive warranty.

4.1 Standard features

Nytro 3000 SSDs have the following standard features:

3.0 / 6.0 / 12.0 Gb SAS interface

Single port or Dual port operation of the two interfaces

Support for SAS expanders and fanout adapters

T10 Write Stream support

128 - deep task set (queue)

Supports up to 32 initiators

Jumperless configuration

User-selectable logical block size (512, 520, 528, 4096, 4160, or 4224 bytes per logical block)

Industry standard SFF 2.5-inch dimensions

ECC and Micro-RAID Error Recovery

No preventive maintenance or adjustments required

Self diagnostics performed when power is applied to the drive

Vertical, horizontal, or top down mounting

Drive Self Test (DST)

Power loss data protection

Thin Provisioning with Block Unmap Support

Seagate Nytro 3731, 3531, 3331, 3131 SAS SSD Product Manual, Rev. C 11

Page 12

www.seagate.com

Nytro 3000 SSD SED models have the following additional features:

Automatic data encryption/decryption

Controlled access

Random number generator

Drive locking

Up to 16 independent data bands

Cryptographic erase of user data for a drive that will be repurposed or scrapped

Authenticated firmware download

SANITIZE command support

4.2 Performance

Nytro 3000 SSDs have a firmware-controlled, multi-segmentable cache buffer that provides:

Up to 2000MB/s maximum instantaneous data transfers on dual 12Gb capable configurations.

Background processing of queue

Non-Volatile Write Cache

NOTE There is no significant performance difference between SED and standard

(non-SED) models.

4.3 Media description

The block storage media used on the Nytro 3000 is Enterprise-grade, 3D NAND Flash of eTCL cell characteristics.

4.4 Warranty

Consult a Seagate sales representative for warranty terms and conditions.

4.5 Formatted capacities

Seagate Nytro 3000 models are formatted to 512 bytes per block at time of manufacturing. The block size is

user-selectable at format time. Supported block sizes are 512, 520, 528, 4096, 4160, and 4224. Users who have the

necessary equipment can modify the data block size before issuing a format command. These users can obtain

different formatted capacities from those listed.

For models with capacities less than 8TB, the LBA count is based on the IDEMA document LBA1-03. Larger capacities

follow the SFF-8447 specification

The capacity stated is identical when the drive is formatted with or without PI enabled.

NOTE Some block sizes with PI enable might cause minor reductions in endurance

and random performance with the SE and TE models.

Seagate Nytro 3731, 3531, 3331, 3131 SAS SSD Product Manual, Rev. C 12

Page 13

www.seagate.com

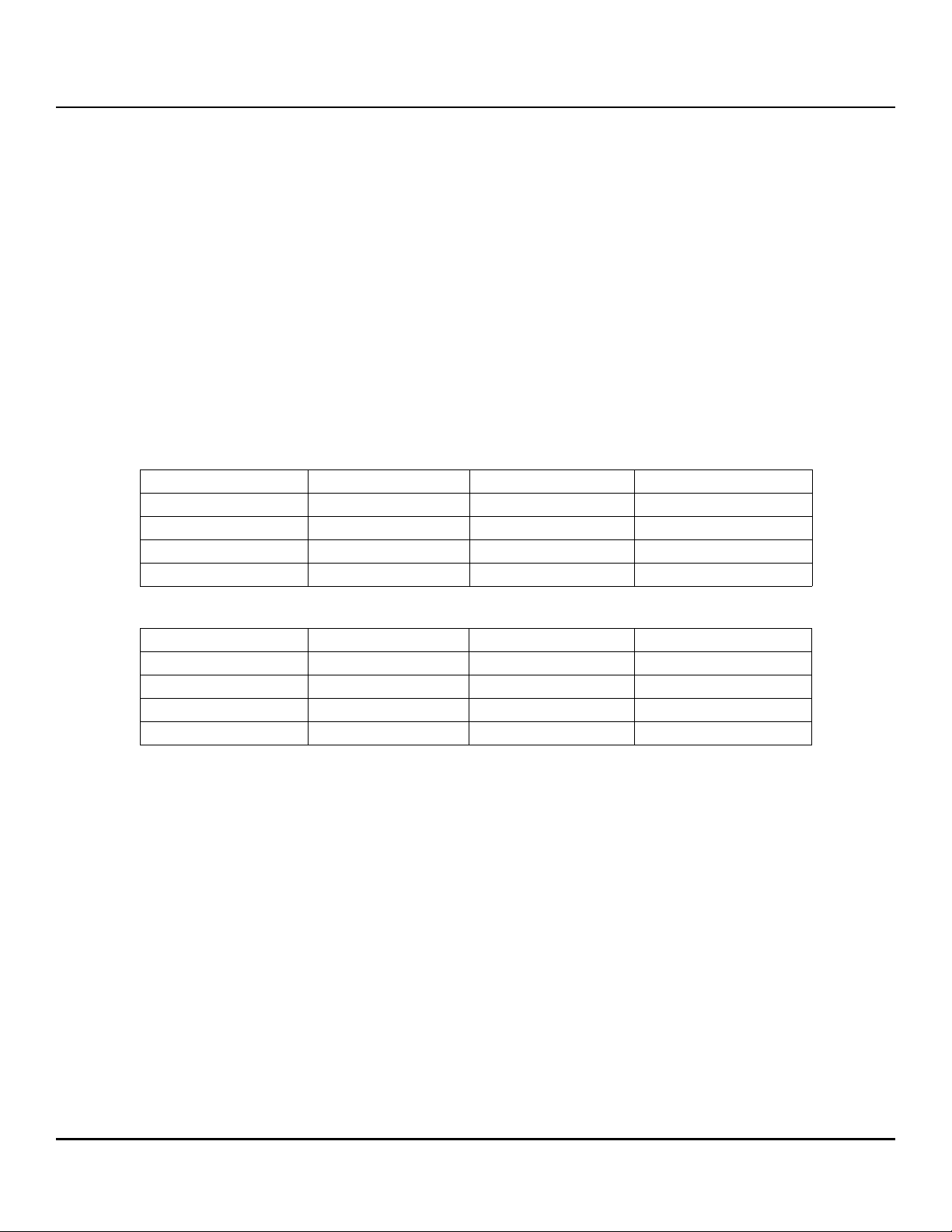

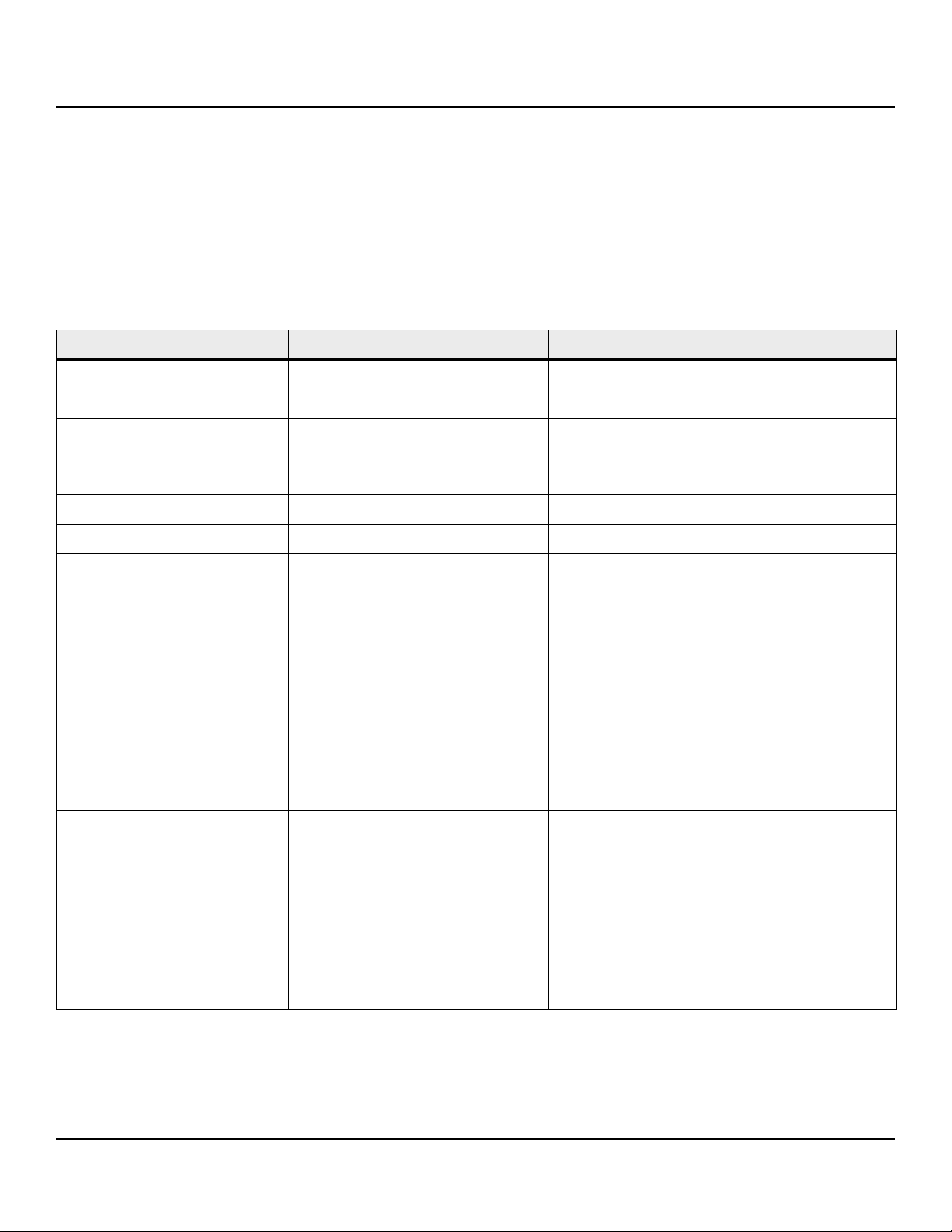

Table 7 - Formatted Capacity Block Count (15360 GB, 7680 GB and 6400 GB models)

Table 8 - Formatted Capacity Block Count (3840GB, 3200GB, 1920GB models)

Last Logical Block Address

Block 15360 GB 7680 GB 6400 GB

Size Decimal Hex Decimal Hex Decimal Hex

512 30,001,856,512 6FC400000 15,002,931,887 37E3E92AF 12,502,446,767 2E93432AF

520 29,391,585,280 6D7E00000 14,685,538,511 36B5388CF 12,237,948,759 2D9704757

528 28,946,989,056 6BD600000 14,281,594,319 3533FD5CF 12,074,833,071 2C55FDCD7

4096 3,750,232,064 DF880000 1,854,502,927 6E89780F 1,562,805,845 5D268655

4160 3,673,948,160 DAFC0000 1,838,769,231 6D99644F 1,532,307,695 5B5528EF

4224 3,618,373,632 D7AC0000 1,801,818,183 6B659047 1,501,515,151 597F4D8F

Last Logical Block Address

Block 3840 GB 3200 GB 1920 GB

Size Decimal Hex Decimal Hex Decimal Hex

512

520

528

4096

4160

4224

Table 9 - Formatted Capacity Block Count (1600GB, 960GB, 800GB models)

Block 1600 GB 960 GB 800 GB

Size Decimal Hex Decimal Hex Decimal Hex

512

520

528

4096

4160

7,501,476,527 1BF1F72AF 6,251,233,967 1749A42AF 3,750,748,847 DF8FE2AF

7,342,769,255 1B5A9C467 6,118,974,383 16CB823AF 3,671,384,631 DAD4E237

7,140,797,159 1A99FEAE7 5,950,664,303 162AFEE6F 3,570,398,583 D4CFF577

937,684,565 37E3EE55 781,404,245 2E934855 468,843,605 1BF1FC55

919,384,615 36CCB227 772,709,551 2E0E9CAF 463,625,735 1BA25E07

900,909,095 35B2C827 756,488,551 2D171967 453,893,135 1B0DDC0F

Last Logical Block Address

3,125,627,567 BA4D4AAF 1,875,385,007 6FC81AAF 1,562,824,367 5D26CEAF

3,059,487,191 B65C11D7 1,835,692,319 6D6A711F 1,529,743,599 5B2E08EF

2,975,332,151 B157F737 1,785,199,295 6A67FABF 1,487,666,079 58ABFB9F

390,703,445 1749A955 234,423,125 DF90355 195,353,045 BA4D9D5

383,076,927 16D54A3F 229,846,159 DB32C8F 191,538,463 B6AA51F

4224

Seagate Nytro 3731, 3531, 3331, 3131 SAS SSD Product Manual, Rev. C 13

375,378,791 165FD367 225,227,279 D6CB20F 187,689,399 B2FE9B7

Page 14

www.seagate.com

Table 10 - Formatted Capacity Block Count (400GB models)

Last Logical Block Address

Block 400 GB

Size Decimal Hex

512

520

781,422,767 2E9390AF

764,871,799 2D970477

528

4096

4160

4224

743,833,039 2C55FDCF

97,677,845 5D27215

95,769,231 5B5528F

93,844,703 597F4DF

4.6 Programmable drive capacity

Using the MODE SELECT command, the drive can change its capacity to less than maximum. See the MODE SELECT (6)

parameter list table in the SAS Interface Manual, part number 100293071. A value of zero in the Number of Blocks field

indicates that the drive does not change the capacity it is currently formatted to have. A number other than zero and

less than the maximum number of LBAs in the Number of Blocks field changes the total drive capacity to the value in

the Number of Blocks field. A value greater than the maximum number of LBAs is rounded down to the maximum

capacity.

Seagate also provides SeaChest, a CLI tool for Windows and Linux operating systems to adjust capacity and perform

other drive management operations. Go to this page to download the tool:

https://www.seagate.com/support/software/seachest/

Or go here: https://github.com/Seagate/ToolBin/tree/master/SeaChest

4.7 Factory-installed options

OEMs may order the following items which are incorporated at the manufacturing facility during production or

packaged before shipping. Some options are (not an exhaustive list of possible options):

Other capacities can be ordered depending on LBA size requested and other factors.

Single-unit shipping pack. The drive is normally shipped in bulk packaging to provide maximum protection

against transit damage. Units shipped individually require additional protection as provided by the single unit

shipping pack. Users planning single unit distribution should specify this option.

The Safety and Regulatory Agency Specifications, part number 75789512, is usually included with each standard

OEM drive shipped, but extra copies may be ordered.

Seagate Nytro 3731, 3531, 3331, 3131 SAS SSD Product Manual, Rev. C 14

Page 15

www.seagate.com

4.8 Logical Block Provisioning

The drive follows SAS logical block provisioning where each LBA is either mapped or unmapped to physical NAND

media blocks based on user writes and unmap operations.

Behavior of logical block provisioning is found but send a READ CAPACITY 16 (9Eh) command to the drive.

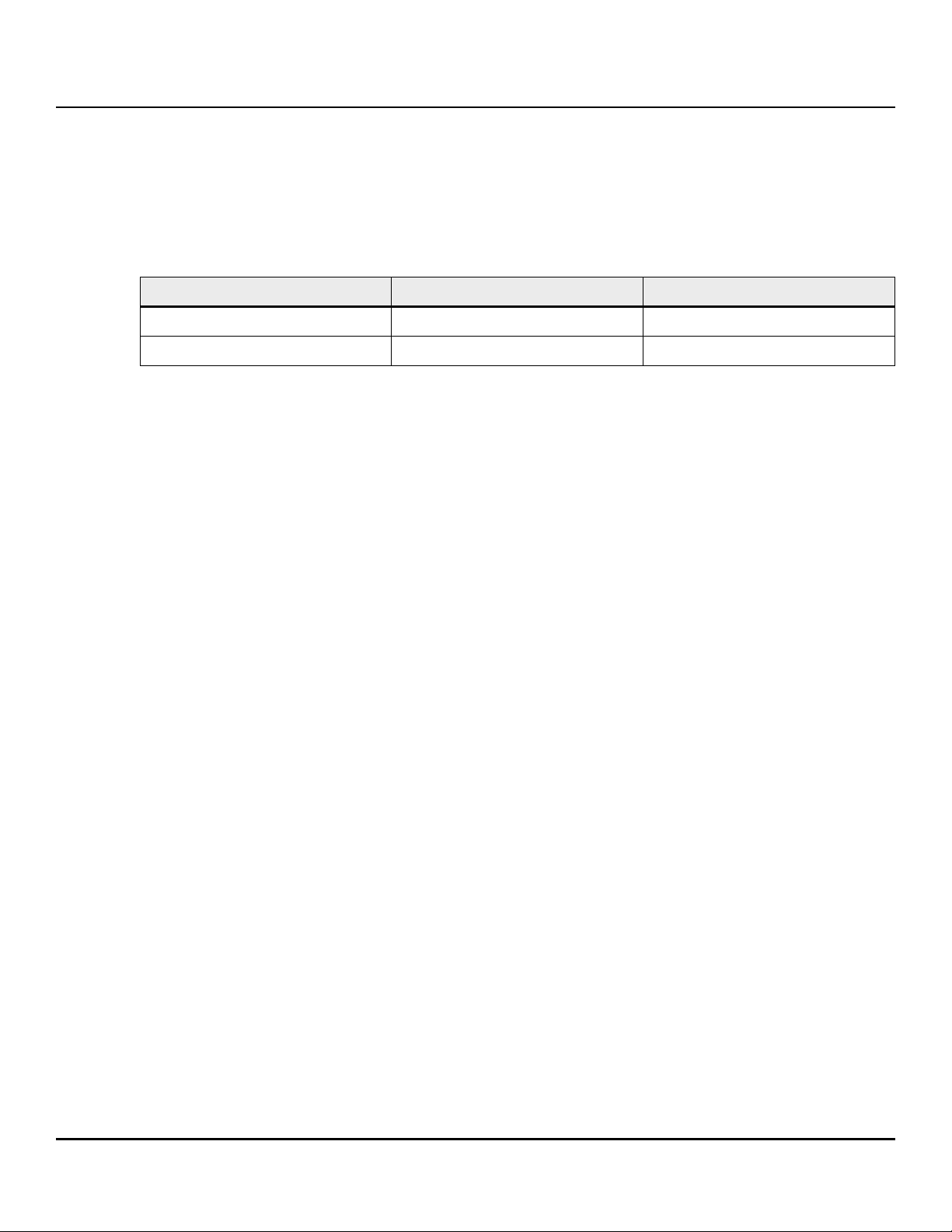

Table 11 - Logical block provisioning options

Product Configuration LBPME LBPRZ

Non-SED Supported Supported

SED Supported Supported

A logical block provisioning management enabled (LBPME) bit set to one indicates that the logical unit implements

logical block provisioning management. An LBPME bit set to zero indicates that the logical unit is fully provisioned

and does not implement logical block provisioning management.

A logical block provisioning read zeros (LBPRZ) bit set to one indicates that, for an unmapped LBA specified by a read

operation, the device server sends user data with all bits set to zero to the data-in buffer. An LBPRZ bit set to zero

indicates that, for an unmapped LBA specified by a read operation, the device server may send user data with all bits

set to any value to the data-in buffer.

4.8.1 UNMAP

The UNMAP command asks the device server to break the association of a specific Logical Block address from a

Physical Block. This frees up the Physical Block from use and no longer requires it to contain user data. An unmapped

block responds to a READ command with data that is determined by the setting of the LBPRZ bit in the READ

CAPACITY parameter data.

4.8.2 FORMAT UNIT command

A device which supports Thin Provisioning is capable of performing a SCSI FORMAT UNIT command which allocates

Logical Blocks Addresses that are not linked to Physical Block Locations. A FORMAT command causes all LBAs to

become unmapped.

4.8.3 Protection Information (PI) and Security (SED)

In SCSI devices, umapped LBAs are defined as part of the Logical Block Provisioning model. Support of this model is

indicated by the LBPME bit having a value of '1' in the READ CAPACITY (16) parameter data.

When a region of LBA's are erased through cryptographic erase, as part of the erase, the LBAs are not unmapped.

If the host attempts to access an unmapped or trimmed LBA, the drive returns 0 data for unmapped LBAs. The drive

shall report a value of '0' in the LBPRZ field returned in the READ CAPACITY (16) parameter data.

If the host attempts to access an unmapped LBA on a drive that has been formatted with Protection Information (PI),

the drive shall return scrambled PI data for that LBA. Depending on the value of the RDPROTECT field in the

data-access command CDB, this may result in the drive returning a standard PI error to the host.

If the host reduces the addressable capacity of the drive via a MODE SELECT command, the drive shall unmap or trim

any LBA within the inaccessible region of the device.

Seagate Nytro 3731, 3531, 3331, 3131 SAS SSD Product Manual, Rev. C 15

Page 16

www.seagate.com

Additionally, an UNMAP command is not permitted on a locked band.

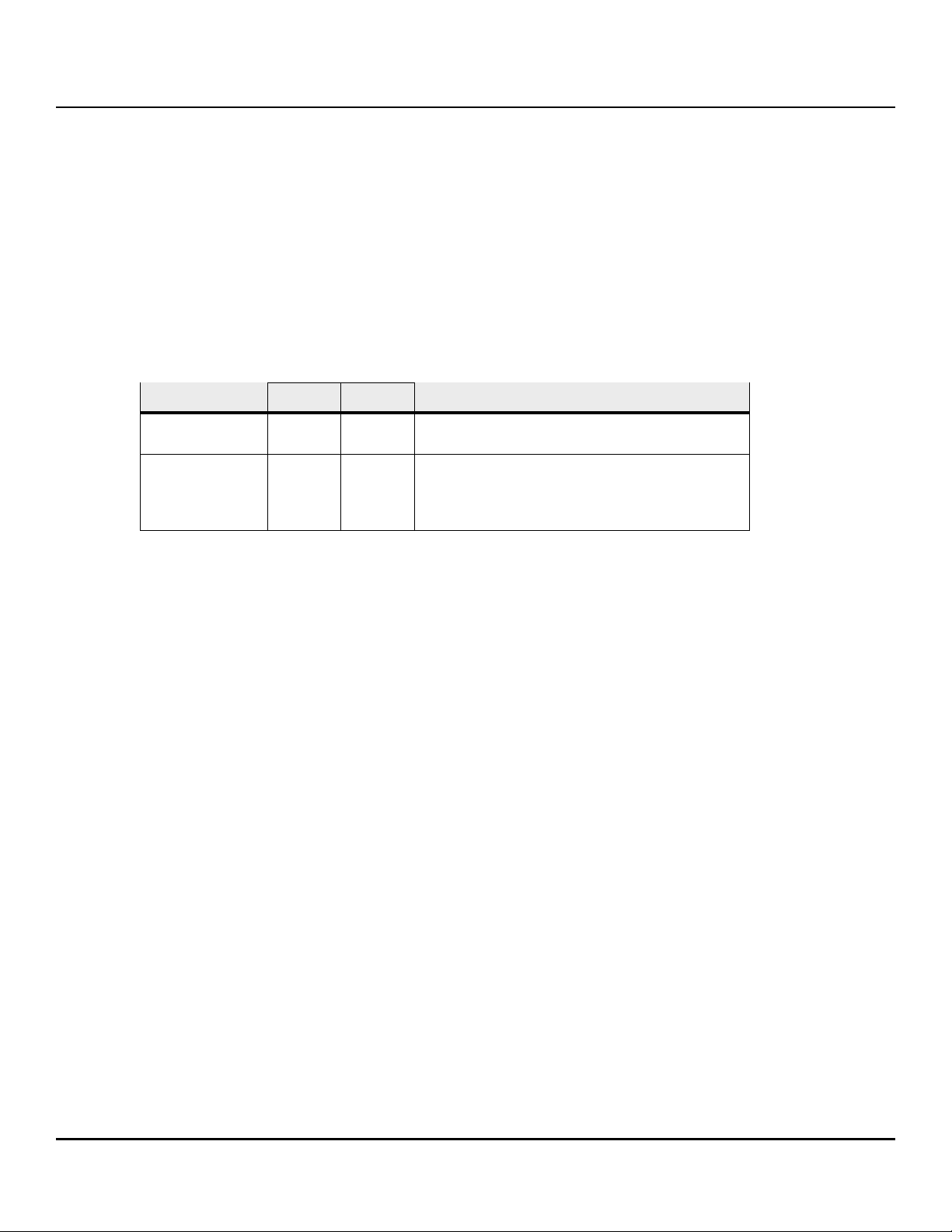

Table 12 - Protection Information behavior

PI Setting Disabled En able d

PROT_EN bit 0 1

LBPME bit 1 1

LBPRZ bit 1 1

PI Check Requested N/A Yes No

DATA Returned for mapped LBA 0x00 0x00 0x00

PI Returned for mapped LBA None None Scrambled PI data

PI Check Performed N/A Yes No

Error reported to Host No Yes No

Seagate Nytro 3731, 3531, 3331, 3131 SAS SSD Product Manual, Rev. C 16

Page 17

www.seagate.com

5. Performance

This section provides detailed information on performance-related characteristics and features of

Seagate Nytro 3000 SAS SSDs.

5.1 Internal drive characteristics

Flash Memory Type NAND 3D eMLC and eTCL

Emulated LBA Size 512, 520, 528, 4096, 4160, or 4224

Native Programmable Page Size 8192 User Bytes

Map Unit Size 4096

Default Transfer Alignment Offset 0

Seagate Nytro 3731, 3531, 3331, 3131 SAS SSD Product Manual, Rev. C 17

Page 18

www.seagate.com

5.2 Performance characteristics

5.2.1 Response time

Response time measurements are taken with nominal power at 25°C ambient temperature. The typical values in the

table below are defined as follows:

Page-to-page response time is an average of all possible page-to-page accesses for a sequentially preconditioned

drive.

Average response time is a true statistical random average of at least 5000 measurements of accesses between

programmable pages on a randomly preconditioned drive.

Table 13 - Typical Response Time (μsec)

Page to Page 115 25

Read Write Notes

Execution time measured from receipt of the

Command to the Response. Assumes no errors.

Average Latency 115 25

Typical response times are measured under

nominal conditions of temperature and voltage

as measured on a representative sample of

drives.

These drives provide the highest possible performance under typical conditions. However, due to the nature of Flash

memory technologies there are many factors that can result in values different than those stated in this specification.

5.2.2 FORMAT UNIT command execution time for 512-byte LBA's (minutes)

The device may be formatted as either a Thin Provisioned device or a Fully Provisioned device.

The default format is Thin Provisioned and is recommended for most applications.

Thin Provisioning provides the most flexibility for the device to manage the flash medium to maximize endurance.

The duration of the FORMAT UNIT command is based on capacity. The format processing rate is typically 20GB per

second. For example the 3840GB XS3840SE70004 device completes formatting in 38 seconds.

Seagate Nytro 3731, 3531, 3331, 3131 SAS SSD Product Manual, Rev. C 18

Page 19

www.seagate.com

5.2.3 Throughput Performance

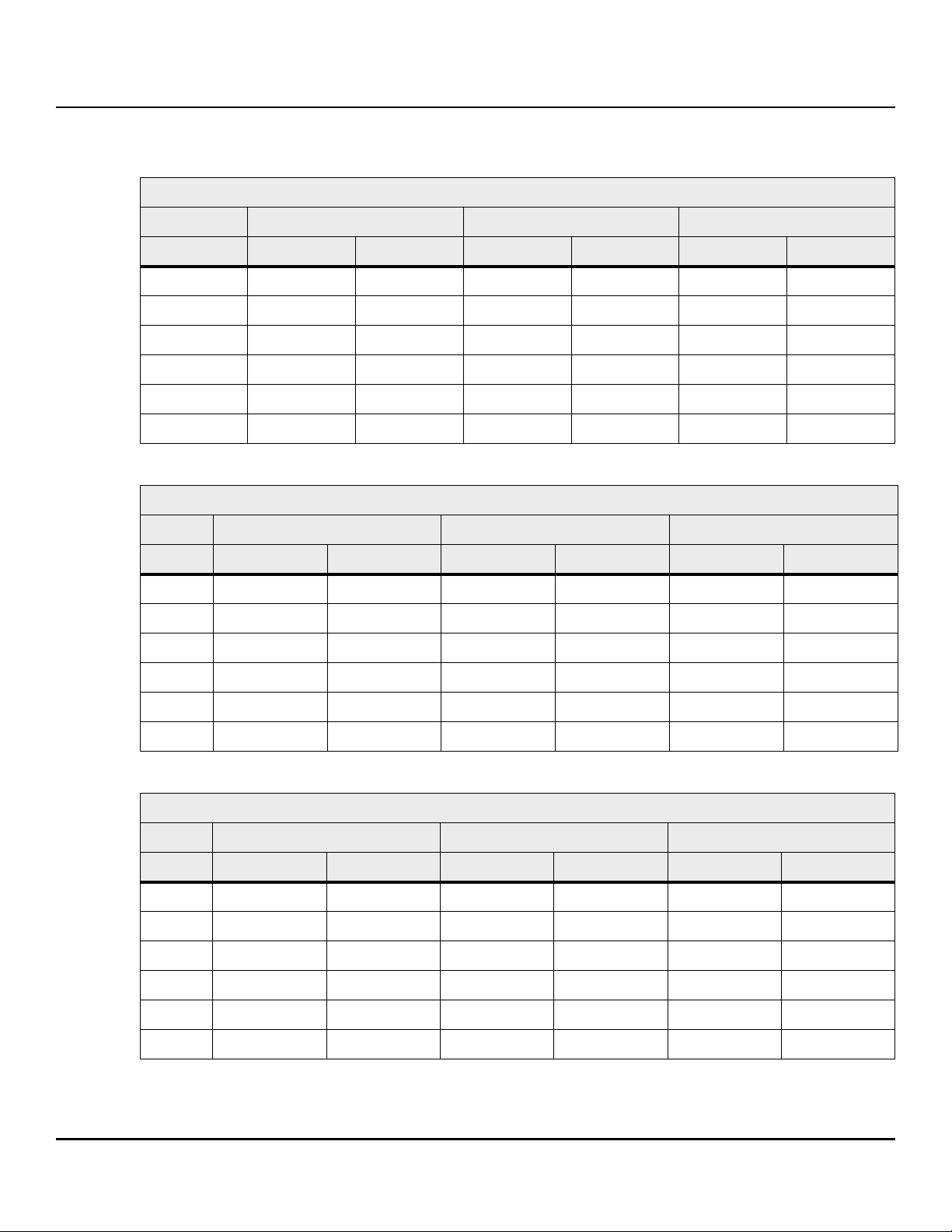

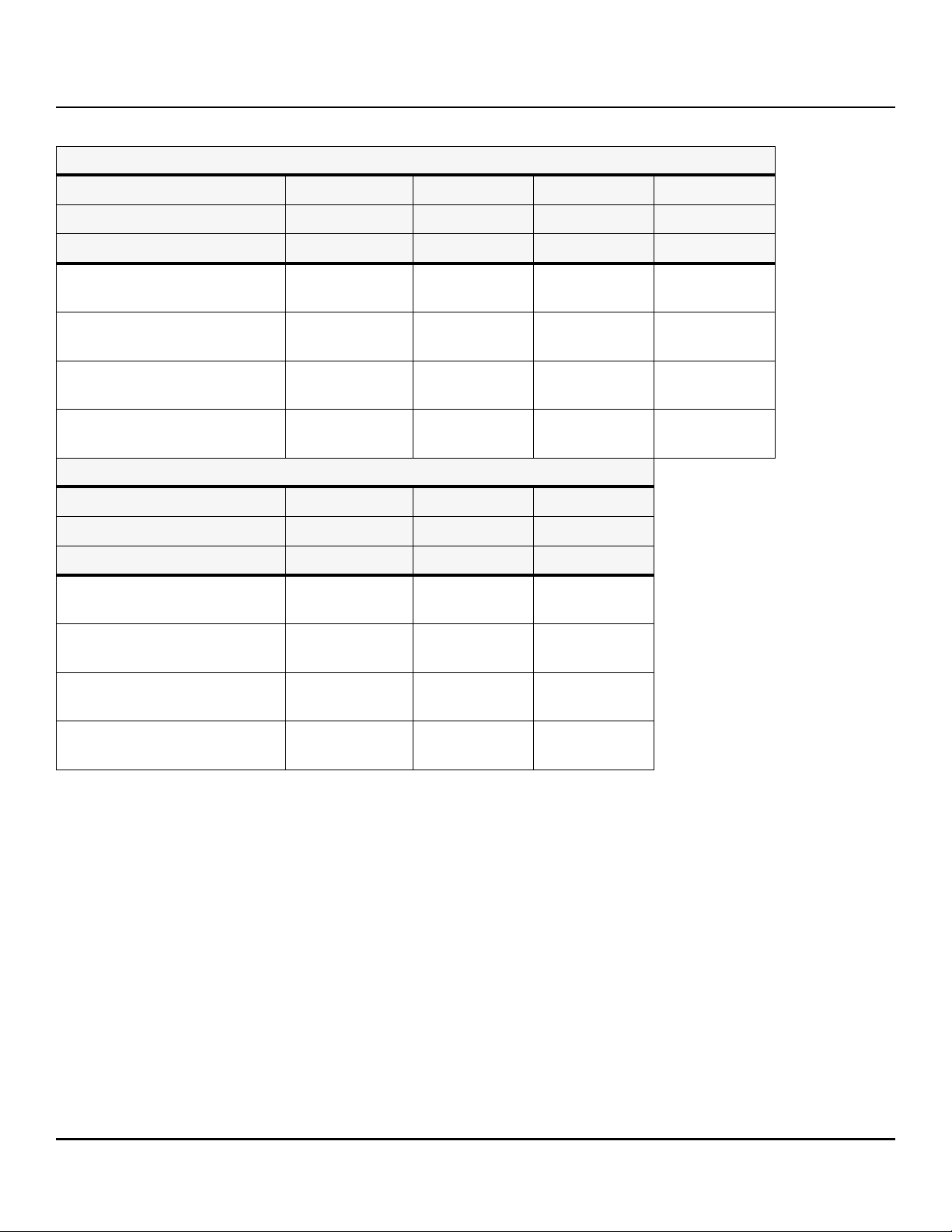

Tab le 1 4 - Perfo rma nce

a

Performance of 3731 Write Intensive Models

Standard Model

Seagate Secure Encryption

Seagate Secure FIPS 140-2

XS3200ME70004 XS1600ME70004 XS800ME70004 XS400ME70004

XS3200ME70014 XS1600ME70014 XS800ME70014 XS400ME70014

XS3200ME70024 XS1600ME70024

Sustained Sequential 128KB Read

Transfer Rate (MB/s)

b

Sustained Sequential 128KB Write

Transfer Rate (MB/s)

b.

Sustained Random 4KB Read

Trans fer Ra te (KI OPS)

c

Sustained Random 4KB Write

Trans fer Ra te (KI OPS)

c.

Performance of 3531 Mixed Use Models

Standard Model

Seagate Secure Encryption

XS6400LE70004 XS3200LE70004 XS1600LE70004 XS800LE70004

XS6400LE70014 XS3200LE70014 XS1600LE70014 XS800LE70014

Seagate Secure FIPS 140-2

2000 2200 2200 2150

1550 1550 1550 1000

230 230 230 210

180 180 180 140

XS3200LE70024 XS1600LE70024 XS800LE70024

Sustained Sequential 128KB Read

Transfer Rate (MB/s)

b.

Sustained Sequential 128KB Write

Transfer Rate (MB/s)

b.

Sustained Random 4KB Read

Trans fer Ra te (KI OPS)

c.

Sustained Random 4KB Write

Trans fer Ra te (KI OPS)

c.

2000 2200 2200 2150

1550 1550 1550 1000

230 230 230 210

110 120 120 100

Seagate Nytro 3731, 3531, 3331, 3131 SAS SSD Product Manual, Rev. C 19

Page 20

www.seagate.com

Tab le 1 4 - Perfo rma nce (continued)

Performance of 3331 Read Intensive Models

Standard Model

Seagate Secure Encryption

Seagate Secure FIPS 140-2

Sustained Sequential 128KB Read

Transfer Rate (MB/s)

Sustained Sequential 128KB Write

Transfer Rate (MB/s)

Sustained Random 4KB Read

Trans fer Ra te (KI OPS)

Sustained Random 4KB Write

Trans fer Ra te (KI OPS)

Performance of 3131 Very Read Intensive Models

Standard Model

Seagate Secure Encryption

Seagate Secure FIPS 140-2

b.

b.

c.

c.

XS15360TE70004 XS7680TE70004 XS3840TE70004

XS15360TE70014 XS7680TE70014 XS3840TE70014

XS15360TE70024

a

XS7680SE70004 XS3840SE70004 XS1920SE70004 XS960SE70004

XS7680SE70014 XS3840SE70014 XS1920SE70014 XS960SE70014

XS7680SE70024 XS3840SE70024 XS1920SE70024 XS960SE70024

2000 2200 2200 2150

1550 1550 1550 1000

230 230 230 210

70 80 80 65

Sustained Sequential 128KB Read

Transfer Rate (MB/s)

Sustained Sequential 128KB Write

Transfer Rate (MB/s)

Sustained Random 4KB Read

Trans fer Ra te (KI OPS)

Sustained Random 4KB Write

Trans fer Ra te (KI OPS)

a. Power limit unconstrainted using both SAS ports.

b. Testing performed at Queue Depth = 32 after Sequential Preconditioning.

c. Testing performed at Queue Depth = 64 after Random Preconditioning.

b.

b.

c.

c.

2100 2000 2100

1000 1550 1550

145 230 220

13 45 50

Due to the nature of Flash memory technologies there are many factors that can result in values different from those

stated in this specification. Some discrepancies can be caused by bandwidth limitations in the host adapter, operating

system, or driver limitations. This manual does not try to cover all possible causes of performance discrepancies.

When evaluating performance of SSD devices, it is recommended to measure performance of the device in a way that

resembles the targeted application using real world data and workloads. Test time should also be large enough to

make sure sustainable metrics and measures are obtained.

Seagate Nytro 3731, 3531, 3331, 3131 SAS SSD Product Manual, Rev. C 20

Page 21

www.seagate.com

5.3 Start/stop time

The drive accepts the commands listed in the SAS Interface Manual less than four seconds after DC power is applied.

If the drive receives a NOTIFY (ENABLE SPINUP) primitive through either port and has not received a START STOP UNIT

command with the START bit equal to 0, the drive becomes ready for normal operations within 10 seconds (excluding

the error recovery procedure).

If the drive receives a START STOP UNIT command with the START bit equal to 0 before receiving a NOTIFY (ENABLE

SPINUP) primitive, the drive waits for a START STOP UNIT command with the START bit equal to 1. After receiving a

START STOP UNIT command with the START bit equal to 1, the drive waits for a NOTIFY (ENABLE SPINUP) primitive.

After receiving a NOTIFY (ENABLE SPINUP) primitive through either port, the drive becomes ready for normal

operations within 5 seconds.

If the drive receives a START STOP UNIT command with the START bit and IMMED bit equal to 1 and does not receive a

NOTIFY (ENABLE SPINUP) primitive within 5 seconds, the drive fails the START STOP UNIT command.

The START STOP UNIT command may be used to command the drive to stop. Stop time is three seconds (maximum)

from removal of DC power. SCSI stop time is three seconds.

The drive support pin 3 POWER DISABLE as defined by the SAS4 specification.

5.3.1 Caching write data

All write data is stored in non-volatile memory before acknowledging the SAS write operation. Non-volatile memory is

both NAND and DRAM that is written to NAND during any power interruption.

The drive never sends a deferred write error status.

The Write Cache Enable (WCE) bit in mode page 08h may be set to 0 or 1 but does not change the operation of the

drive.

The SYNCHRONIZE_CACHE command does not alter the state or location of written data. The response from the drive

for this command indicates that all prior write commands have been completed and acknowledged.

Section Section 12.3.2 MODE SENSE data, on page 78 shows the mode default settings for the drive.

Seagate Nytro 3731, 3531, 3331, 3131 SAS SSD Product Manual, Rev. C 21

Page 22

www.seagate.com

5.3.2 Prefetch operation

If the Prefetch feature is enabled, data in contiguous logical blocks on the medium immediately beyond what was

requested by a Read command are retrieved and stored in the buffer for immediate transfer from the buffer to the

host on subsequent Read commands that request those logical blocks (this is true even if cache operation is disabled).

Though the prefetch operation uses the buffer as a cache, finding the requested data in the buffer is a prefetch hit, not

a cache operation hit.

To enable Prefetch, use Mode Select page 08h, byte 12, bit 5 (Disable Read Ahead - DRA bit). DRA bit = 0 enables

prefetch.

The drive does not use the Max Prefetch field (bytes 8 and 9) or the Prefetch Ceiling field (bytes 10 and 11).

When prefetch (read look-ahead) is enabled (enabled by DRA = 0), the drive enables prefetch of contiguous blocks

from the medium when it senses that a prefetch hit will likely occur. The drive disables prefetch when it decides that a

prefetch hit is not likely to occur.

Seagate Nytro 3731, 3531, 3331, 3131 SAS SSD Product Manual, Rev. C 22

Page 23

www.seagate.com

6. Reliability specifications

These reliability specifications assume correct host and drive operational interface, including all interface timings,

power supply voltages, environmental requirements, and drive mounting constraints.

6.1 Read error rates

Table 15 - Read Error Rates

Error Rates Notes

Unrecovered Data

Miscorrected Data

Interface error rate

Mean Time Between Failure

(MTBF)

Annualized Failure Rate (AFR) 0.35%

Preventive maintenance None required

Typical Data Retention with Power

removed (at 40C up to 90% of

write endurance)

Endurance Rating Method 2: TBW (per JEDEC JESD218)

Less than 1 LBA in 1017 bits transferred

Less than 1 LBA in 10

Less than 1 error in 10

21

12

2.5M hours

3 months

bits transferred

bits transferred

As NAND Flash devices age with use, the capability

of the media to retain a programmed value begins

to deteriorate. This deterioration is affected by the

number of times a particular memory cell is

programmed and subsequently erased. When a

device is new, it has a powered off data retention

capability of up to several years. With use the

retention capability of the device is reduced.

Temperature also has an effect on how long a Flash

component can retain its programmed value with

power removed. At high temperature the retention

capabilities of the device are reduced. Data

retention is not an issue with power applied to the

SSD. The SSD drive contains firmware and hardware

features that can monitor and refresh memory cells

when power is applied.

Endurance rating is the expected amount of host

data that can be written by product when

subjected to a specified workload at a specified

operating and storage temperature over the

specified product life. For the specific workload to

achieve this level of endurance, please reference

JEDEC Specification JESD218. TBW is defined as

1x1012 Bytes.

Limited Warranty with Media Usage provides

coverage for the warranty period or until the SSD

Percentage Used Endurance Indicator, as defined in

Section 3.2.6, reaches 100 whichever comes first.

NOTE Error rate specified with automatic retries and data correction with ECC

enabled and all flaws reallocated.

Seagate Nytro 3731, 3531, 3331, 3131 SAS SSD Product Manual, Rev. C 23

Page 24

www.seagate.com

6.2 Endurance

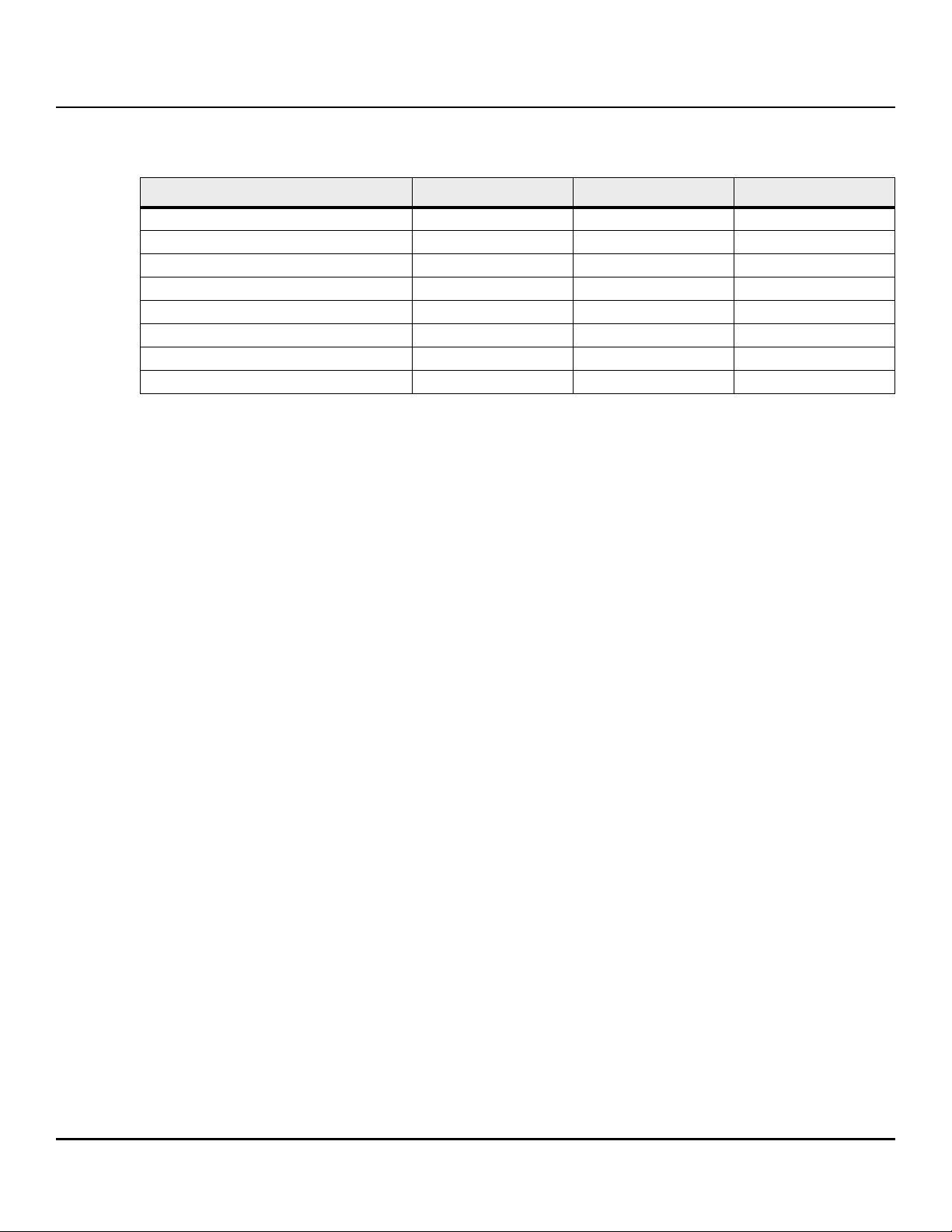

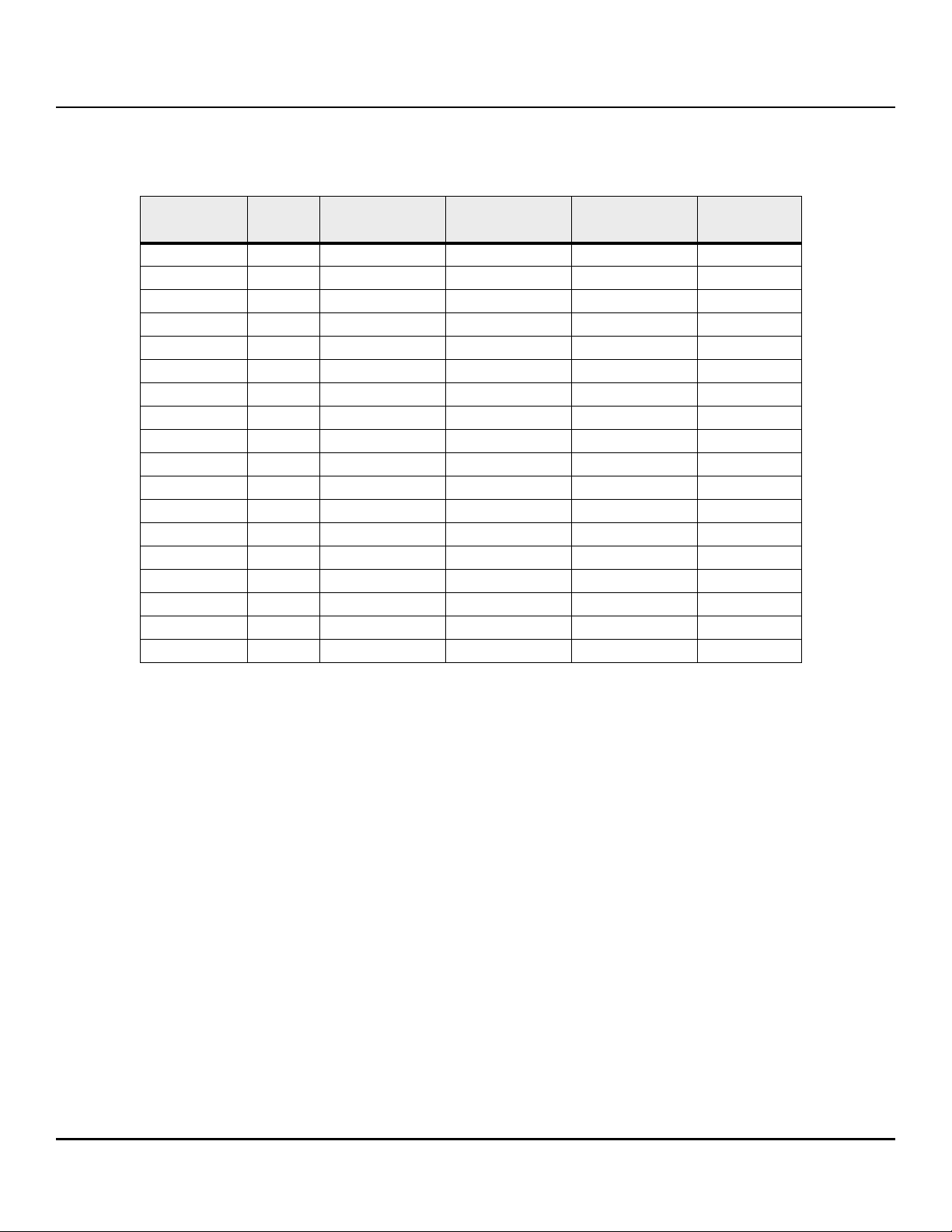

Table 16 - Lifetime write endurance by model

Endurance

Class

ME 3200 XS3200ME70004 XS3200ME70014 XS3200ME70024 58

ME 1600 XS1600ME70004 XS1600ME70014 XS1600ME70024 29

ME 800 XS800ME70004 XS800ME70014 14

ME 400 XS400ME70004 XS400ME70014 7.3

LE 6400 XS6400LE70004 XS6400LE70014 35

LE 3200 XS3200LE70004 XS3200LE70014 XS3200LE70024 17

LE 1600 XS1600LE70004 XS1600LE70014 XS1600LE70024 8.7

LE 800 XS800LE70004 XS800LE70014 4.3

SE 7680 XS7680SE70004 XS7680SE70014 XS7680SE70024 14

SE 3840 XS3840SE70004 XS3840SE70014 XS3840SE70024 7.0

SE 1920 XS1920SE70004 XS1920SE70014 XS1920SE70024 3.5

SE 960 XS960SE70004 XS960SE70014 XS960SE70024 1.7

TE 15360 XS15360TE70004 XS15360TE70014 XS15360TE70024 19

TE 7680 XS7680TE70004 XS7680TE70014 7.0

TE 3840 XS3840TE70004 XS3840TE70014 3.0

Capacity

in GB

Standard

Seagate Secure

SED

FIPS 140-2

Lifetime PB

JEDEC

For more information on FIPS 140-2 Level 2 certification see Section 8. About FIPS, on page 57.

Seagate Nytro 3731, 3531, 3331, 3131 SAS SSD Product Manual, Rev. C 24

Page 25

www.seagate.com

6.3 Error rates

The error rates stated in this manual assume the following:

The drive is operated in accordance with this manual using DC power as defined in Section 7.2 Power

consumption, on page 33.

Errors caused by host system failures are excluded from error rate computations.

Assume random data.

Default OEM error recovery settings are applied. This includes AWRE, ARRE, full read retries, full write retries and

full retry time.

6.3.1 Unrecoverable Errors

An unrecoverable data error is a failure of the drive to recover data from the media. These errors occur due to read or

write problems. Unrecoverable data errors are only detected during read operations, but not caused by the read. If an

unrecoverable data error is detected, a MEDIUM ERROR (03h) in the Sense Key is reported. Multiple unrecoverable

data errors resulting from the same cause are treated as one error.

6.3.2 Interface errors

An interface error is defined as a failure of the receiver on a port to recover the data as transmitted by the device port

connected to the receiver. The error may be detected as a running disparity error, illegal code, loss of word sync, or

CRC error.

6.4 Endurance management

Customer satisfaction with Solid State Drives can be directly related to the internal algorithms which an SSD uses to

manage the limited number of Program-Erase (PE) cycles that NAND Flash can withstand. These algorithms consist of

Wear Leveling, Garbage Collection, Write Amplification, Unmap, Data Retention, Lifetime Endurance Management.

6.4.1 Wear leveling

The drive uses Wear Leveling to make sure that all Flash cells are written to or exercised as evenly as possible to avoid

hot spots where some cells are used up faster than other locations. The drive automatically manages Wear Leveling

without user interaction. The Seagate algorithm operates only when needed to ensure reliable product operation.

6.4.2 Garbage collection

The drive uses Garbage Collection to consolidate valid user data into a common cell range freeing up unused or

obsolete locations to be erased and used for future storage needs. The drive automatically manages Garbage

Collection without user interaction. The Seagate algorithm operates only when needed to ensure reliable product

operation.

Seagate Nytro 3731, 3531, 3331, 3131 SAS SSD Product Manual, Rev. C 25

Page 26

www.seagate.com

6.4.3 Write amplification

While Write Amplification is not an algorithm, it is a major characteristic of SSDs. Write Amplification must be

accounted for by all the algorithms that the SSD implements. The Write Amplification Factor of an SSD is the ratio of

Host/User data requested to be written to the actual amount of data written by the SSD internal to account for the

user data and the housekeeping activities such as Wear Leveling and Garbage Collection. The Write Amplification

Factor of an SSD can also be directly affected by the characteristics of the host data being sent to the SSD to write. The

best Write Amplification Factor is achieved for data that is written in sequential LBAs that are aligned on 4KB

boundaries. The worst case Write Amplification Factor occurs for randomly written LBA's of transfer sizes that are less

than 4KB and that originate on LBA's that are not on 4KB boundaries.

6.4.4 UNMAP

Use of the UNMAP command reduces the Write Amplification Factor of the drive during housekeeping tasks such as

Wear Leveling and Garbage Collection. This happens because the drive does not need to retain data which has been

classified by the host as obsolete.

6.4.5 Data retention

Data Retention is another major characteristic of SSDs that must be accounted for by all the algorithms that the SSD

implements. While powered up, the Data Retention of SSD cells are monitored and rewritten if the cell levels decay to

an unexpected level. Data Retention when the drive is powered off is affected by Program and Erase (PE) cycles and

the temperature of the drive when stored.

6.4.6 Write stream tagging

The Write Stream command is an optional SAS bus command for the host to pass a contextual data tag to SSD. The

SSD stores data context together to minimize write amplification when data is unmapped or over written. The Nytro

3000 supports creating 32 streams but optimal benefit is achieved when 8 or less streams are concurrently active.

6.4.7 SSD percentage used endurance indicator

An application can interrogate the drive through the host to determine an estimate of the percentage of device life

that has been used. To accomplish this, issue a LOG SENSE command to log page 0x11. This allows applications to read

the contents of the Percentage Used Endurance Indicator parameter code. The Percentage Used Endurance Indicator

is defined in the T10 document SBC-4 available from the T10 committee.

6.5 Reliability and service

Integrators can enhance the reliability of Seagate Nytro 3000 SAS SSD drives by ensuring that the drive receives

adequate cooling. Section 12.4.2 Physical characteristics, on page 84 provides temperature measurements and other

information that may be used to enhance the service life of the drive. Section 11.2 Cooling, on page 66 provides

recommended air-flow information.

Seagate Nytro 3731, 3531, 3331, 3131 SAS SSD Product Manual, Rev. C 26

Page 27

www.seagate.com

6.5.1 Annualized Failure Rate (AFR) and Mean Time Between Failure (MTBF)

The production drive shall achieve an AFR of 0.35% (MTBF of 2,500,000 hours) when operated in an environment that

ensures the case temperatures do not exceed the values specified in Section 7.3 Environmental limits, on page 51.

Operation at case temperatures outside the specifications in Section 7.3 Environmental limits, on page 51 may increase

the product AFR (decrease the MTBF). The AFR (MTBF) is a population statistic not relevant to individual units.

The AFR (MTBF) specification is based on the following assumptions for Enterprise Storage System environments:

8760 power-on hours per year.

250 average on/off cycles per year.

Operations at nominal voltages.

Systems will provide adequate cooling to ensure the case temperatures specified in Section 11.2 Cooling, on page 66

are not exceeded. Temperatures outside the specifications in Section 11.2 Cooling, on page 66 will increase the

product AFR and decrease the MTBF.

6.5.2 Preventive maintenance

No routine scheduled preventive maintenance is required.

6.5.3 Hot plugging the drive

When a drive is powered on by switching the power or hot plugged, the drive runs a self test before attempting to

communicate on its' interfaces. When the self test completes successfully, the drive initiates a Link Reset starting with

the Out Of Band sequence (OOB). An attached device should respond to the link reset. If the link reset attempt fails, or

any time the drive looses sync, the drive initiated link reset. The drive will initiate link reset once per second but

alternates between port A and B. Therefore each port will attempt a link reset once per 2 seconds assuming both ports

are out of sync.

If the self-test fails, the drive does not respond to link reset on the failing port.

NOTE It is the responsibility of the systems integrator to assure that no temperature,

6.5.4 S.M.A.R.T.

S.M.A.R.T. is an acronym for Self-Monitoring Analysis and Reporting Technology. This technology is intended to

recognize conditions that indicate imminent drive failure and is designed to provide sufficient warning of a failure to

allow administrators to back up the data before an actual failure occurs.

NOTE The drive's firmware monitors specific attributes for degradation over time but

Each monitored attribute has been selected to monitor a specific set of failure conditions in the operating

performance of the drive and the thresholds are optimized to minimize "false" and "failed" predictions.

energy, voltage hazard, or ESD potential hazard is presented during the hot

connect/disconnect operation. Discharge the static electricity from the drive

carrier prior to inserting it into the system.

can't predict instantaneous drive failures.