Seagate STU62001LW Viper,STU62001WD Viper,STU42001LW Viper,STU42001WD Viper Product Manual

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . .

Viper® 200 LTO Tape Drive

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . .

STU42001LW, STU42001WD

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . .

STU62001LW, STU62001WD

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . .

Product Manual

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

h

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . .

Viper® 200 LTO Tape Drive

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . .

STU42001LW, STU42001WD

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . .

STU62001LW, STU62001WD

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . .

Product Manual

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . .

© 2001 Seagate Removable Storage Solutions, LLC. All rights reserved

Part Number 100125702, Rev. B

Seagate and the Seagate logo are registered trademarks of Seagate Technology, LLC. Viper and

the Viper logo are trademarks or registered trademarks of Seagate Removable Storage Solutions,

LLC. Linear Tape-Open, LTO, Ultrium, and the Ultrium logo are U.S. trademarks of HP, IBM, and

Seagate. Other product names are trademarks or registered trademarks of their owners.

Seagate reserves the right to change, without notice, product offerings or specifications. No part

of this publication may be reproduced in any form without written permission from Seagate

Removable Storage Solutions, LLC.

Publication Number 10006955-003, February 1, 2001

FCC notice

This equipment generates and uses radio frequency energy and, if not installed and

used properly—that is, in strict accordance with the manufacturer’s instructions—

may cause interference to radio communications or radio and television reception. It

has been tested and found to comply with the limits for a Class B computing device

in accordance with the specifications in Part 15 of FCC Rules, which are designed to

provide reasonable protection against such interference in a residential installation.

However, there is no guarantee that interference will not occur in a particular

installation. If this equipment does cause interference to radio or television reception,

which can be determined by turning the equipment on and off, you are encouraged

to try to correct the interference by one or more of the following measures:

• Reorient the receiving antenna.

• Relocate the computer with respect to the receiver.

• Move the computer into a different outlet so that the computer and receiver are

on different branch circuits.

If necessary, you should consult the dealer or an experienced radio/television

technician for additional suggestions. You may find the booklet,

Resolve Radio-TV Interference Problems,

Commission, helpful. This booklet (Stock No. 004-000-00345-4) is available from the

U.S. Government Printing Office, Washington, DC 20402.

prepared by the Federal Communications

How to Identify and

Warning.

Further, this equipment complies with the limits for a Class B digital apparatus in

accordance with Canadian Radio Interference Regulations.

Cet appareil numérique de la classe B est conforme au Règlement sur brouillage

radioélectrique, C. R. C., ch. 1374.

The external device drive described in this manual requires shielded interface cables

to comply with FCC emission limits.

Additional Warnings:

• To prevent fire or electrical shock hazard, do not expose the unit to rain or

• To avoid electrical shock, do not open the cabinet.

• Refer servicing to qualified personnel.

Changes or modifications made to this equipment which have not been

expressly approved by Seagate may cause radio and television

interference problems that could void the user’s authority to operate the

equipment.

moisture.

About this manual

Seagate provides this manual “as is,” without warranty of any kind, either expressed

or implied, including, but not limited to, the implied warranties of merchantability and

fitness for a particular purpose. Seagate reserves the right to change, without

notification, the specifications contained in this manual.

Seagate assumes no responsibility for the accuracy, completeness, sufficiency, or

usefulness of this manual, nor for any problem that may arise from the use of the

information in this manual.

Following are brief descriptions of the sections in this manual.

Introduction

Specifications

Installation

Operation and

maintenance

Theory of operations

SCSI interface

Ultrium tape format

Customer support

Services

Provides an overview of LTO and Ultrium technology, and

summarizes the drive’s key features and technical specifications, and

summarizes the drive’s Management/Diagnostic Software.

Lists detailed drive and cartridge specifications, as well as

summarizing regulatory approvals and compatibility with various

hardware and software.

Provides cautions, unpacking tips, and installation instructions for the

internal and external drives, as well as a summary of cabling and

connectors.

Explains the use and operation of the drive and describes

maintenance procedures, including emergency catridge removal.

Summarizes the technology used in various drive components.

Provides general information about the drive’s SCSI interface.

Summarizes the features and technical elements of the LTO tape

format.

Lists service and support programs to ensure customer satisfaction,

including Internet web addresses and telephone and fax numbers.

Contents

Contents

Introduction 1

About the Ultrium tape format......................................................................................1

About the Viper 200.....................................................................................................2

Features and benefits............................................................................................2

Specification summary ..........................................................................................4

Management/diagnostic software..........................................................................5

Specifications 6

Physical specifications.................................................................................................6

Power specifications....................................................................................................8

Voltage and current...............................................................................................8

Power dissipation ..................................................................................................8

Power connector ...................................................................................................8

Drive performance specifications.................................................................................9

Environmental requirements......................................................................................10

Injected noise ......................................................................................................10

Reliability....................................................................................................................10

Mean time between failures ................................................................................11

Mean time to repair .............................................................................................11

LTO cartridge specifications ......................................................................................11

Environmental considerations .............................................................................11

Cartridge memory................................................................................................12

Cartridge reliability...............................................................................................12

Regulatory compliance ..............................................................................................13

Safety compliance...............................................................................................13

Electromagnetic compatibility (EMC): .................................................................14

Hardware and software compatibility.........................................................................15

Compatible operating systems............................................................................15

Compatible native backup software ....................................................................15

Compatible network backup software .................................................................15

i

Installation 16

Introduction................................................................................................................16

Unpacking and inspection..........................................................................................16

ii Viper 200 LTO Product Manual

Installing an internal Viper drive................................................................................ 17

Guidelines and cautions ..................................................................................... 17

1. Configuring an internal Viper drive ................................................................. 17

2. Mounting an internal Viper drive..................................................................... 18

3. Connecting the SCSI interface cable.............................................................. 19

Installing an external Viper drive............................................................................... 21

1. Configuring an external drive.......................................................................... 21

2. Connecting the SCSI interface cable.............................................................. 21

3. Connecting the power cord............................................................................. 22

Interface, cabling and connectors............................................................................. 23

Interface summary.............................................................................................. 23

Cabling and connectors...................................................................................... 24

Operation and maintenance 25

Front panel display.................................................................................................... 25

Using an LTO cartridge............................................................................................. 27

Loading a cartridge............................................................................................. 27

Unloading a cartridge ......................................................................................... 27

Write-protecting a cartridge................................................................................ 27

Cartridge care and maintenance ........................................................................ 28

Drive maintenance.................................................................................................... 29

Cleaning the tape drive....................................................................................... 29

Emergency cartridge removal................................................................................... 30

Before you start.................................................................................................. 30

Case 1: Cartridge Is loaded and seated............................................................. 31

Case 2. Cartridge is loaded and seated and tape is threaded ........................... 32

Theory of operations 35

Track layout............................................................................................................... 35

Recording method..................................................................................................... 36

Data buffer ................................................................................................................ 36

Data integrity............................................................................................................. 36

Error-correction code (ECC)............................................................................... 36

Servo-tracking faults........................................................................................... 37

Data compression..................................................................................................... 37

Background ........................................................................................................ 37

Intelligent data compression............................................................................... 39

SCSI interface 40

Introduction ............................................................................................................... 40

Contents

SCSI-2 interface.........................................................................................................40

SCSI message codes..........................................................................................40

SCSI status codes...............................................................................................41

SCSI-2 commands..............................................................................................41

SCSI-3 commands..............................................................................................42

Tape Alert flags ...................................................................................................42

SCSI-2 ANSI X3.131, 1994 conformance statement.................................................43

General features of interface...............................................................................43

Typical system configurations....................................................................................43

Ultrium tape format 44

Overview of LTO tape formats...................................................................................44

Ultrium technology overview......................................................................................44

The Ultrium cartridge...........................................................................................44

Customer support services 47

iii

World-wide services:..................................................................................................47

Regional services.......................................................................................................47

Support services in the Americas ..............................................................................47

Support services in Europe........................................................................................48

Support services for Africa and the Middle East........................................................48

Support services in Asia and the Western Pacific .....................................................48

iv Viper 200 LTO Product Manual

Figures

Figure 1. Internal Viper Drive—dimensions .......................................................................................................7

Figure 2. Ultrium cartridge................................................................................................................................ 12

Figure 3. Back view of the Viper 200 internal drive, showing jumper settings.................................................18

Figure 4. Acceptable mounting orientations for internal Viper 200................................................................... 18

Figure 5. Back view of the Viper 200 internal drive, showing connectors........................................................ 19

Figure 6. Two SCSI termination examples for internal Viper drive. ................................................................. 20

Figure 7. Back of external Viper 200 showing switches and connectors......................................................... 21

Figure 8. SCSI termination examples for external tape drives.........................................................................22

Figure 9. Generic front panel display for Viper 200..........................................................................................25

Figure 10. Ultrium cartridge showing write-protect switch...............................................................................27

Figure 11. Diagram of Viper 200 showing leader pin inside LTO cartridge..................................................... 30

Figure 12. Diagram of Viper 200 showing worm gear..................................................................................... 31

Figure 13. Diagram of Viper 200 showing key components used in manual cartridge tape removal. ............ 32

Figure 14. Diagram of Viper 200 showing lead screw (tape threaded on take-up reel).................................. 32

Figure 15. Diagram of underside of Viper 200 showing supply motor access hole ........................................ 33

Figure 16. Diagram of underside of Viper 200 showing tape grabber near cartrdige ..................................... 33

Figure 17. Diagram of Viper 200 showing worm gear..................................................................................... 34

Figure 18. Layout of tracks on LTO Ultrium tape............................................................................................ 35

Figure 19. LTO cartridge with door open to show leader pin. ......................................................................... 45

Figure 20. LTO cartridge showing cartridge memory and write-protect switch............................................... 46

Installation

Introduction

About the Ultrium tape format

The Viper 200 complies with the LTO Ultrium 8-channel format specification U-18.

The Ultrium tape format is specifically designed for maximum data storage capacity.

The Ultrium format achieves this high capacity by using long (600-meter) and wide

(1/2-inch) tape media. Data is recorded in 384 tracks, grouped in four bands, each

bounded by two servo tracks, for extreme reliability.

The Ultrium tape cassette uses just one tape reel, instead of two. This maximizes the

amount of tape that can fit in a single cartridge, since space within the cartridge is

taken up by the tape, not by tape reels. Despite its ultra-high capacity, the Ultrium

cartridge is thinner than other existing single-reel cartridges. It measures about 4

inches square and is a little more than 3/4 of an inch thick. For more information, see

“Ultrium Tape Format“ on page 45.

1

1

Open format, open opportunities

One of the missions of LTO technology was to provide an open-format specification

where multiple manufacturers could obtain a license, providing the foundation for

new, improving Ultrium products. This goal has been reached, with more than 25

licensees supporting the Ultrium format.

The key advantages of a dynamic open format include the following

• Multiple independent technology sources

• Extensive industry support from manufacturers, OEMs and automation suppliers

• Shorter technology-development cycles

• Greater competition, increasing innovation and value.

2 Viper 200 LTO Product Manual

g

Four generations of storage solutions

The Ultrium format of LTO technology defines a four-generation technology

roadmap, which provides aggressive, attainable specifications based on the current

technologies in use today.

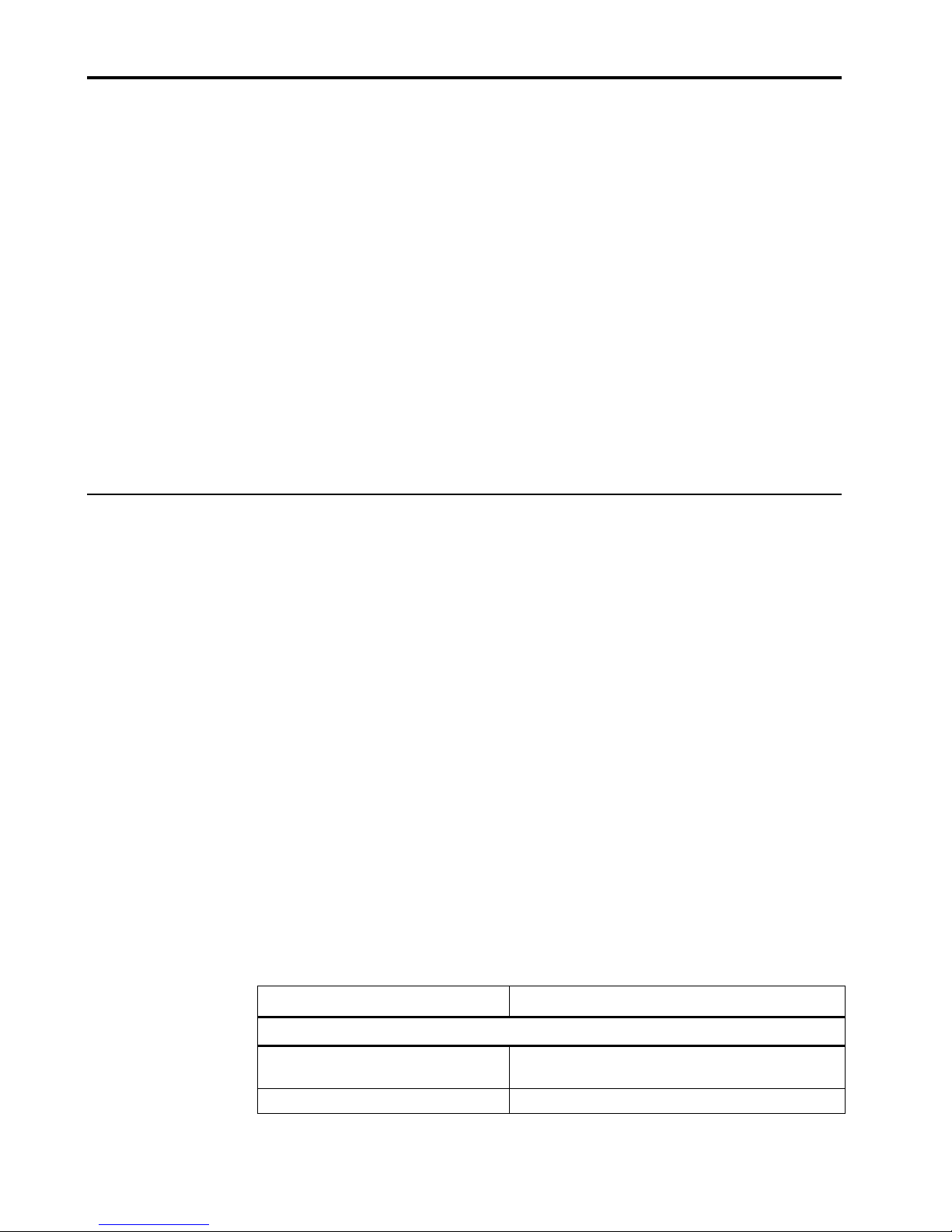

Generation 1 Generation 2 Generation 2 Generation 4

Capacity

Speed

200 Gbytes 400 Gbytes 800 Gbytes 1,600 Gbytes

Up to 40

Mbytes/sec

Up to 80

Mbytes/sec

Up to 160

Mbytes/sec

To 320

Mbytes/sec

Media

Encoding

Note 1. Capacity and speed based on 2:1 data compression

Note 2. Seagate, Hewlett-Packard and IBM reserve the right to change the

information in this migration path without notice.

About the Viper 200

The Viper 200 is a high-performance eight-channel LTO tape drive that uses ½-inch

Ultrium tape cartridges with a native capacity of up to 100 Gbytes (for a 609m tape).

It supports Read While Write (RWW) and intelligent hardware data compression as

well as cartridge soft load. The drive’s native sustained user data transfer rate is 16

Mbytes per second. The tape capacity and transfer rate are maximized through the

use of intelligent data compression. The Viper 200 design is well suited for mid-range

to high-end servers, mainframe systems, and tape library automation systems.

The Viper 200 comes with an ULTRA SCSI LVD or HVD interface, as well as a serial

library interface. The internal Viper 200 drives (STU42001LW and STU42001WD)

are designed to fit in a 5¼-inch full-height drive bay. The external drives

(STU62001LW and STU62001WD) are standalone subsystems with built-in power

supplies. The table below shows the model numbers for the different drive

configurations.

MP MP MP Thin Film

RLL 1,7 PRML PRML PRML

Model

Mountin

Interface LVD HVD LVD HVD

Features and benefits

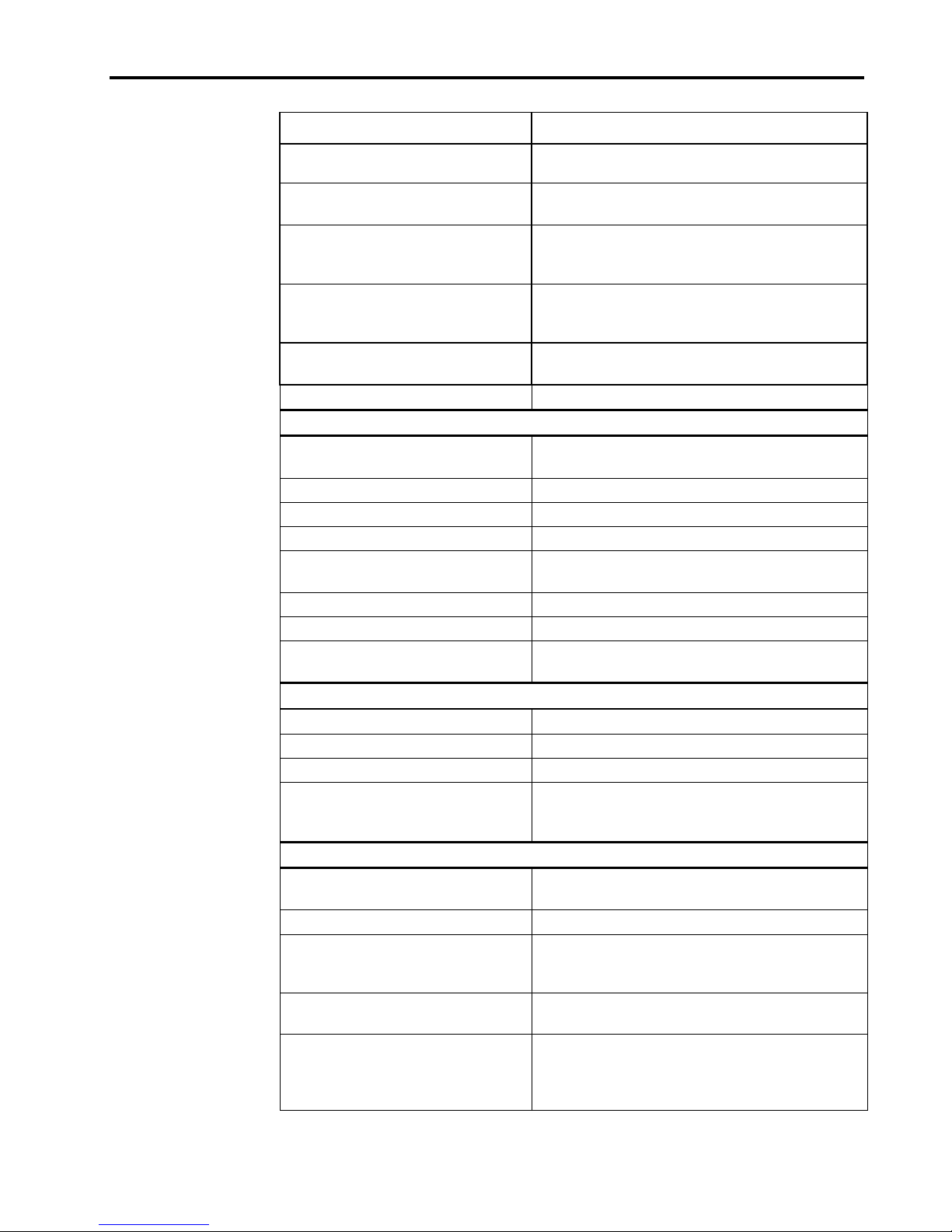

The following table summarizes the features and benefits of the Viper 200 drives.

Features Benefits

Performance

32 Mbyte-per-second compressed

transfer rate

FastSense™ Optimization of data transfers resulting in shorter

STU42001LW STU42001WD STU62001LW STU62001WD

Internal Internal External External

Highest announced rate, over 115 Gbytes per hour

compressed

Installation

Features Benefits

backup times and increased reliability due to fewer

stops and starts.

Intelligent Data Compression Maximizes performance and capacity by analyzing

compressibility prior to recording

Multiple interface options:

LVD, HVD, Fibre Channel

Fast Search Tape search speeds between 6 and 9 meters per

Cartridge Memory Enables fast loading of cartridges; stores pertinent

64-Mbyte data buffer Extra fast backups on high-performance systems.

Reliability

Tape Alert drive performance

monitoring and reporting

3rd generation read channel Increased maturity and data integrity

Patented head Positioner Increased data integrity

Shock dampened isolated chassis Increased shock tolerance and reliability

Managed airflow dynamics with

isolated HTI chamber

Hard error rate of 1 in 1017 bits Built-in reliability

Two levels of ECC Extra data safety and protection from errors.

Reliable tape picking implementation Increased reliability and proof of strong

Electrical

Very low RF emissions Ease of agency certifications

Low power consumption Typically only 23 to 34 watts operating range

Low heat rating Increased reliability

Controlled tape path during power

interruption

Software / Firmware / Interface

Custom designed LSI circuitry Seagate-designed and tested for fast, efficient data

RISC processors Fast, efficient data processing

Second generation LVD firmware Mature SCSI firmware decreases the number of

Supports native firmware of a wide

variety of UNIX platforms

Support for Ultra SCSI-2,

Low Voltage Differential,

High Voltage Differential, and

Single-ended interfaces

Provides maximum flexibility to system integrators

allowing optimization of the Viper 200 drive and

their system

second, equating to average time to file between

32 and 48 seconds

information regarding the media

Remote monitoring of device performance

Increased data integrity and reliability through

decreasing contaminants

engineering

Disaster avoidance technology; saves data during

unplanned power outages and prevents

unnecessary field service.

processing

revisions, increasing the ease of ongoing

qualifications.

Reduced set-up and configuration time

Compatible with the today’s and tomorrow’s highperformance interfaces.

3

4 Viper 200 LTO Product Manual

Features Benefits

Remote diagnostics Increases data safety through monitoring and

testing capabilities. Individual feature set or private

label capabilities for each system OEM and

automation manufacturer.

Support for SCSI-2 and some SCSI-3

instructions

Extra control of drive from the host system.

Specification summary

Specification Value

Tape Format

Capacity

Performance

Models

Form Factor

Interfaces

Tape Speed

Search Speed

Recording

Error Rate

Power Consumption

(typical)

Reliability

LTO (Ultrium)

100 Gbytes (native) 609m cartridge

50 Gbytes (native) 319m cartridge

30 Gbytes (native) 203m cartridge

10 Gbytes (native) 87m cartridge

16 Mbytes per second (native) with FastSense™

Dynamically adjustable to: 14, 12, 10, 8 Mbyte/s

Internal - LVD: STU42001LW; HVD: STU42001WD

External - LVD: STU62001LW; HVD: STU62001WD

5.25” Full-Height (internal drive)

LVD

HVD

RS-422 Serial Port

4 m/sec @ 16 Mbytes per second

4 m/sec

Heads: 8 channel

Recording Density: 93K fci

Data Density: 124K bpi

Data Tracks: 384

Data Track Density: 768 tracks per inch

Servo Tracks: 5

-17

10

bit error rate corrected

(Error rate before ECC: 6 errors in 10-7 bits read)

Idle (tape loaded): 14 watts

Streaming RWW: 25 watts

Ramp up (peak): 35 watts (0.8 sec)

Ramp down (peak): 27 watts (0.8 sec)

Load/Unload (peak): 15 watts (0.2 sec)

Thread/Unthread

23 watts (0.2 sec)

(peak):

MTBF: 250K hours @ 100% Duty cycle

Loads/Unloads: 300K cycles

Threads/Unthreads: 100K cycles

Head Life: 30K hours

Cartridge

Media life: 25K passes

Loads/Unloads: 5K cycles

Installation

Management/diagnostic software

5

The Viper 200 includes

includes the following capabilities:

Drive settings

• Set maximum drive speed

• Select Power-On Self-Test mode (on/off)

• Select data compression mode

• Select cartridge autoload mode

• Select cartridge auto-unload mode

Drive commands

• Retension tape

• Download firmware

• Show remaining cartridge capacity

Diagnostics

• Read-Write test, with user-selectable data lengths

• Media interchange test

• Drive electronics test

• Advanced drive diagnostics

SeaTools Tape Diagnostic Utility

software. This software

6 Viper 200 LTO Product Manual

Specifications

2

This chapter provides technical specifications for the internal and external SCSI

drives. This information covers the following specifications and requirements:

• Physical specifications

• Power requirements

• Drive performance specifications

• Environmental requirements

• Reliability

• Ultrium cartridge specifications

• Regulatory compliance

• Hardware and software compatibility

Physical specifications

The physical specifications of the Viper 200 drives are listed in the following table:

Specification Internal dri ve

Height

Width

Length

Weight

1

Notes:

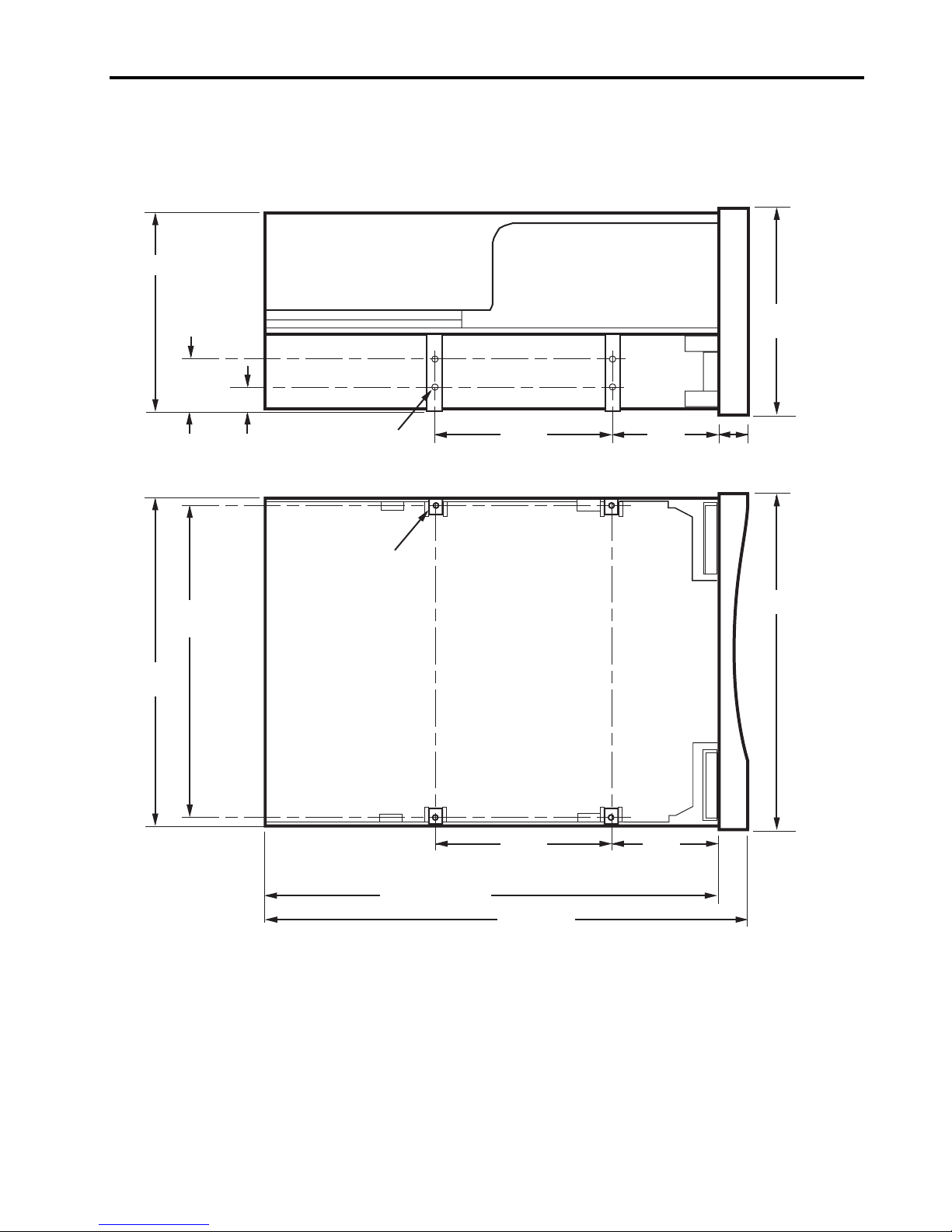

Figure 1 on the following page shows the dimensions of the internal Viper 200 drive.

Includes rubber feet (case alone is 6.45 inches high)

2

Includes fan grill on back of drive (case alone is 11.9 inches long)

Internal drive

without bezel

3.25 inches

(82.6 mm) max

5.75 inches

(146.05 ± 0.25 mm)

8.06 inches

(205 mm) max

6.2 lb. (2.82 kg) 6.5 lb. (2.95 kg) 9.5 lb (5.44 kg)

with bezel

3.32 inches

(84.26 mm)

5.82 inches

(147.75 mm)

8.346 inches

(212 mm)

External

drive

6.75 inches

(171.4 mm)

7.5 inches

(190.5 mm)

12 inches

(304.8 mm)

1

2

Installation

Figure 1. Internal Viper Drive—dimensions

7

82.6 mm (max)

21.80

± 0.20 mm

139.70 mm

± 0.20 mm

146.05

± 0.25 mm

9.90

± 0.20 mm

M3 X 5.0

4X Near side

4X Far side

4X M3 X 5.0

79.24

± 0.20 mm

Bottom View

Side View

± 0.20 mm

84.26 mm

(max)

48.9

7 mm

147.75 mm

205 mm (max)

79.24

± 0.20 mm

212 mm

48.9

± 0.20 mm

8 Viper 200 LTO Product Manual

Power specifications

The external Viper 200 drives (STU62001LW and STU62001WD) come with a builtin 90-260VAC (47-63 Hz) automatic switching power supply.

Maximum voltage and power specifications for the internal Viper 200 drives

(STU42001LW and STU62001WD) are listed in the tables below.

Voltage and current

+12 VDC +5 VDC

DC Voltage Tolerance + or – 10% + or – 5 %

Non-operating max voltage 14 Volts peak 7 Volts peak

Max Operating current

Continuous:

Peak:

Standby current (max) 0.5 amps RMS 2.0 amps RMS*

1.0 amps RMS

3.0 amps (1 sec max)

3.5 amps max RMS*

NA

Ripple (peak-to-peak)

Power dissipation

Max Standby Power 14 watts RMS*

Max Continuous Operating Power 30 watts RMS*

Max Peak Operating Power 48.5 watts (1 sec max)

* RMS parameters measured at the power connector using a true RMS digital meter.

Power connector

The following table lists pin assignments of the power connector for the internal Viper

drive.

Pin Assignment

1 +12 VDC power

2 +12 VDC return

3 +5 VDC return

4 +5 VDC power

100 mV

≤

100 mV

≤

Loading...

Loading...