Product Manual

Lyrion Series IDE

ST760211DE

ST740211DE

ST730212DE

100441946

Rev. F

September 2007

Revision history

Revision Date Sheets affected or comments

Rev. A 01/04/07 Initial Release.

Rev. B 01/31/07 5.

Rev. C 04/11/07 1, 3, 4, 7, 11, 17 and 29.

Rev. D 05/04/07 Front cover, 1, 3 and 4.

Rev. E 06/22/07 22.

Rev. F 09/20/07 Front cover, 1, 3-4 and 25-26.

Copyright © 2007 Seagate Technology LLC. All rights reserved. Printed in U.S.A.

Publication number: 100441946, Rev. F September 2007

Seagate, Seagate Technology and the Wave logo are registered trademarks of Seagate Technology LLC

in the United States and/or other countries. Lyrion Series, SeaTools and SeaTDD are either trademarks or

registered trademarks of Seagate Technology LLC or one of its affiliated companies in the United States

and/or other countries. All other trademarks or registered trademarks are the property of their respective

owners.

One gigabyte, or GB, equals one billion bytes when referring to hard drive capacity. Accessible capacity

may vary depending on operating environment and formatting. Seagate reserves the right to change, with

out notice, product offerings or specifications.

-

Contents

1.0 Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.1 Disclaimer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.2 Drive care . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

2.0 Drive specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2.2 Formatted capacity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2.3 Default logical geometry . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2.4 Recording and interface technology . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2.5 Physical characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2.6 Time to ready. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2.7 Power specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.7.1 Power consumption . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.7.2 Conducted noise . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.7.3 Voltage tolerance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.7.4 Power-management modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.8 Environmental specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.8.1 Ambient temperature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.8.2 Temperature gradient. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.8.3 Humidity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.8.4 Altitude . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.8.5 Shock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2.8.6 Vibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2.8.7 Corrosive environment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

2.9 Acoustics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

2.10 Electromagnetic immunity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

2.11 Reliability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

2.12 Agency certification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

2.12.1 Safety certification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

2.12.2 Electromagnetic compatibility. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

2.12.3 European Union Restriction of Hazardous Substances (RoHS) Directive . . . . . 15

2.12.4 China Restriction of Hazardous Substances (RoHS) Directive . . . . . . . . . . . . . 15

2.12.5 FCC verification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

3.0 Configuring and mounting the drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

3.1 Handling and static discharge precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

3.2 Drive installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

3.3 Mounting considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

4.0 Interface description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

4.1 Connector interface signals and connector pins . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

4.2 Supported ATA commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

4.2.1 Identify Device command. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

4.2.2 Set Features command . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

5.0 Seagate Technology support services. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Lyrion Series IDE Product Manual, Rev. F i

ii Lyrion Series IDE Product Manual, Rev. F

List of Figures

Figure 1. Lyrion Series (IDE interface) disc drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Figure 2. Typical 3.3V startup and operation current profile . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Figure 3. Location where tri-axial accelerometer will be placed on Lyrion Series drives . . . . . . . . . . . . 10

Figure 4. Drive axis definition for Lyrion Series drives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Figure 5. Lyrion Series breather hole location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Figure 6. Lyrion Series proper handling example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Figure 7. Lyrion Series mechanical dimensions—top, side and end view . . . . . . . . . . . . . . . . . . . . . . . 19

Figure 8. Lyrion Series FPC dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Figure 9. Lyrion Series Area for Protective Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Lyrion Series IDE Product Manual, Rev. F iii

iv Lyrion Series IDE Product Manual, Rev. F

1.0 Introduction

This manual describes the functional, mechanical and interface specifications for the following Seagate® Lyrion

®

Series

• ST760211DE-60GB, ST740211DE-40GB and ST730212DE-30GB disc drives with an IDE interface.

These drives provide the following key features.

• 3,600-RPM spindle speed and a 2-Mbyte buffer combined for superior read/write performance.

• Quiet operation. Fluid Dynamic Bearing (FDB) motor.

• Perpendicular recording heads and EPRML technology, which provide the drives with increased areal density.

• State-of-the-art cache and on-the-fly error-correction algorithms.

• 1500 G nonoperating shock, and 500 G operating shock.

• SeaTools™ diagnostic software performs a drive self-test that eliminates unnecessary drive returns.

IDE drives:

Figure 1. Lyrion Series (IDE interface) disc drive

1.1 Disclaimer

Seagate Technology LLC makes no warranties whatsoever, including any warranty of merchantability, noninfringement, fitness for any particular purpose, or any warranty otherwise arising out of any proposal,

specification or sample. Seagate may not be held liable for any direct, indirect, incidental, special, exemplary,

or consequential damages (including, but not limited to, loss of use, data, or profits; procurement of substitute

goods or services; or business interruptions) however caused and on any theory of liability, whether in contract,

strict liability, or tort (including negligence or otherwise) arising in any way from the use of this kit, even if

advised of the possibility of such damage.

1.2 Drive care

Do not use the Lyrion Series disc drives outside of the ranges of environmental conditions found in Section 2.8,

"Environmental specifications." Doing so may void the warranty of the Lyrion Series disc drive.

Lyrion Series IDE Product Manual, Rev. F 1

2 Lyrion Series IDE Product Manual, Rev. F

2.0 Drive specifications

Unless otherwise noted, all specifications are measured under ambient conditions, at 25°C, and nominal

power. For convenience, the phrases the drive and this drive are used throughout this manual to indicate

ST760211DE, ST740211DE and ST730212DE model drives.

2.1 Overview

The specifications listed in this table are for quick reference. For details on specification measurement or

definition, see the appropriate section of this manual.

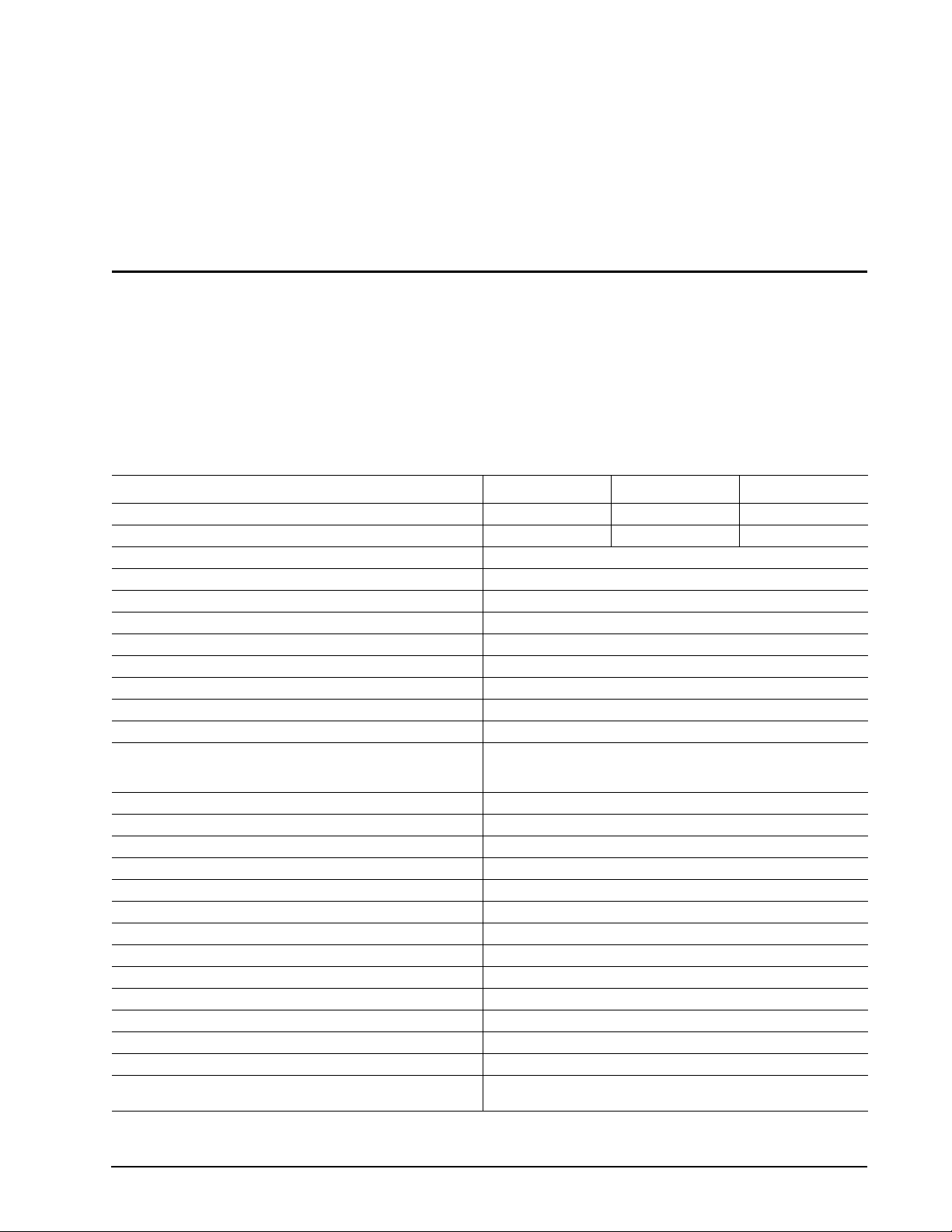

Table 1: Specifications

Drive specification ST760211DE ST740211DE ST730212DE

Formatted Gbytes 60 40 30

Guaranteed sectors 117,210,240 78,130,080 58,605,120

Bytes per sector (logical) 512

Cache (Mbytes) 2

Recording density, BPI (bits/inch average) 1,025,000

Track density. TPI (tracks/inch average) 165,000

2

Areal density (Gbits/inch

Spindle speed (RPM) 3,600

Internal data transfer rate OD (Mbits/sec max) 350

Sustained data transfer rate OD (Mbytes/sec) 24.5

I/O data-transfer rate (Mbytes/sec max) 66.7 (UDMA 4)

ATA data-transfer modes supported PIO modes 0–4;

Height 5.0 + 0.15 mm(0.1968 + 0.006 inches)

Width 54.0 +/-0.3 mm (2.1260 +/-0.0118 inches)

Length 71.0 +/-0.3 mm (2.7953 +/-0.0118 inches)

Weight 48.0 gm - 0.1058 lb. (typ)

Average latency (msec) 8.3

Power-on to ready (sec typical) 1.8

Standby to ready (sec typical) 1.8

Startup power (peak at 3.3v) (maximum RMS in 10ms window) 1.15 W

Read/write power (typical 3.3V) 1.0/0.9 W

Performance idle power (typical 3.3V) 0.5 W

Low power idle power (typical 3.3V) 0.3 W

Standby/Sleep power (typical 3.3V) 0.08 W

Voltage tolerance (including noise) 3.3V ± 5%

Ambient temperature 0° to 60°C (operating)

average) 169

Multiword DMA modes 0-2;

Ultra DMA modes 0–4

–40° to 70°C (nonoperating)

Lyrion Series IDE Product Manual, Rev. F 3

Table 1: Specifications

Drive specification ST760211DE ST740211DE ST730212DE

Temperature gradient (°C per hour max) 20°C (operating)

Relative humidity (noncondensing) 5% to 90% (operating)

Relative humidity gradient 30% per hour max

Wet bulb temperature (°C max) 33°C (operating)

Altitude, operating –60.98 m to 3,048 m (–200 ft to 10,000+ ft)

Altitude, nonoperating (below mean sea level, max) –60.98 m to 12,192 m (–200 ft to 40,000+ ft)

Shock, operating (Gs max at 2 msec) 500

Shock, nonoperating (Gs max at 1 msec) 1500

Vibration, operating

(max displacement may apply below 10 hz)

Vibration, nonoperating

(max displacement may apply below 22 hz)

Idle sound power (bels) (typical) 1.6

Operational sound power (bels) (typical) 2.2

Nonrecoverable read errors 1 per 10

Load/Unload (LUL) cycles 300,000 software-controlled

Warranty Per agreement

30°C (nonoperating)

5% to 95% (nonoperating)

40°C (nonoperating)

1.0 Gs (0 to peak, 10–500 Hz) @ 2 oct/min sweep rate

5.0 Gs (0 to peak, 10–500 Hz) @ 0.5 oct/min sweep rate

14

bits read

20,000 power loss

2.2 Formatted capacity

Model Formatted

capacity

ST760211DE 60 Gbytes 117,210,240 512

ST740211DE 40 Gbytes 78,130,080 512

ST730212DE 30 Gbytes 58,605,120 512

LBA mode addressing

When addressing these drives in LBA mode, all blocks (sectors) are consecutively numbered from 0 to n–1,

where n is the number of guaranteed sectors as defined above.

Guaranteed

sectors

Bytes per

sector (logical)

2.3 Default logical geometry

Model Cylinders Heads Sectors

ST760211DE 116,280 16 63

ST740211DE 77,510 16 63

ST730212DE 58,149 16 63

4 Lyrion Series IDE Product Manual, Rev. F

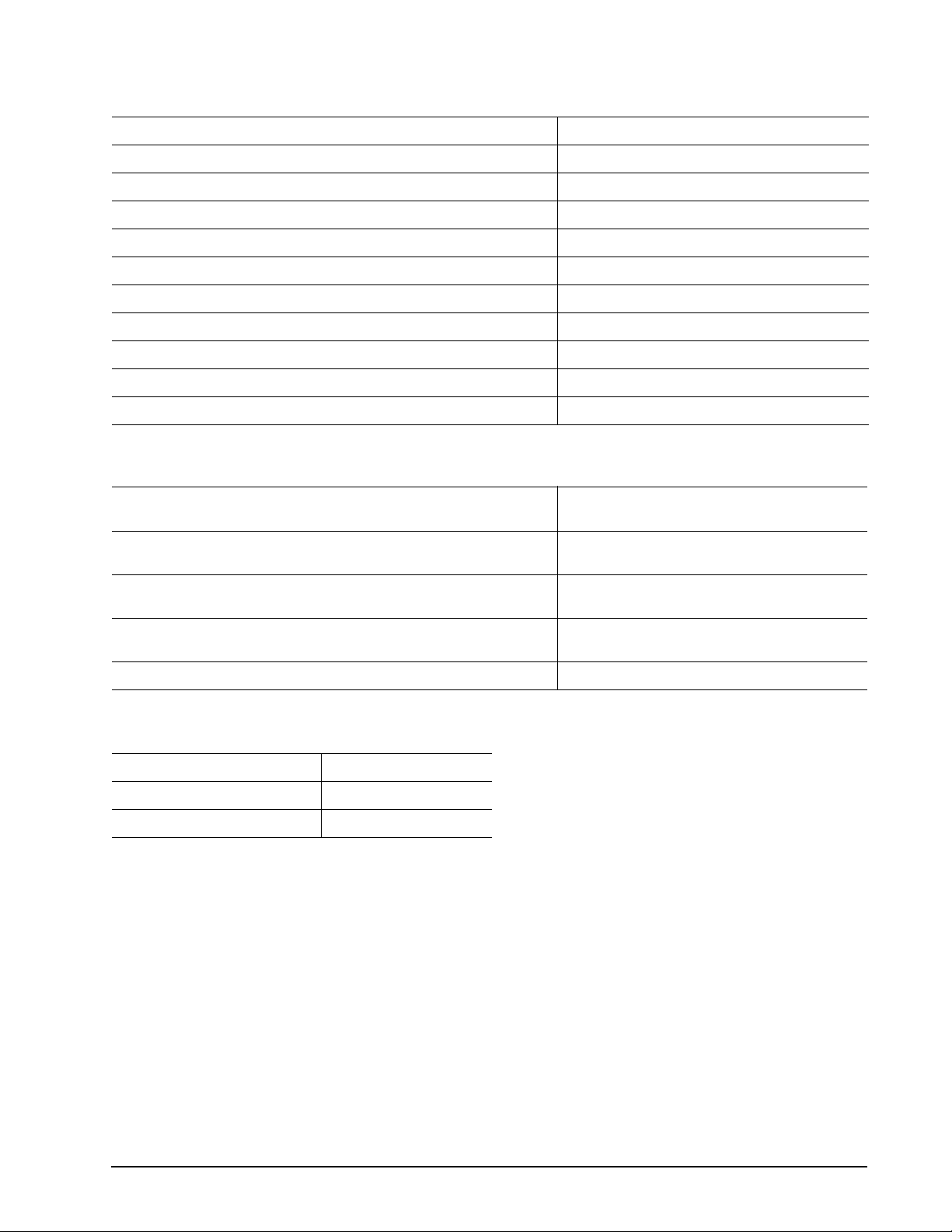

2.4 Recording and interface technology

Technology Specification

Interface IDE (Parallel ATA)

Recording method Perpendicular Magnetic Recording

Recording density BPI (bits/inch average) 1,025,000

Track density TPI (tracks/inch average) 165,000

Areal density (Gbits/inch2 average) 169

Spindle speed (RPM) (± 0.2%) 3,600

Internal data-transfer rate OD (Mbits/sec max) 350

Sustained data transfer rate OD (Mbytes/sec max) 24.5

I/O data-transfer rate (Mbytes/sec max) 66.7 (UDMA 4)

Cache buffer (Mbytes) 2

2.5 Physical characteristics

Height (mm)

(inches)

Width (mm)

(inches)

Length (mm)

(inches)

Typical weight (grams)

(pounds)

Interface Connector 40-way ZIF

5.0 + 0.15

0.1968 + 0.006

54.0 +/-0.3

2.1260 +/-0.0118

71.0 +/-0.3

2.7953 +/-0.0118

48.0 (typ)

0.1058 lb. (typ))

2.6 Time to ready

Time to ready Typical

Power-On to Ready (sec) 1.8

Standby to Ready (sec) 1.8

Lyrion Series IDE Product Manual, Rev. F 5

2.7 Power specifications

The drive receives DC power (+3.3V) through the ZIF connector (IDE interface).

2.7.1 Power consumption

Power requirements for the drives are listed in the table on page 7. Typical power measurements are based on

an average of drives tested, under nominal conditions, using +3.3V input voltage at 25°C ambient temperature.

• Startup mode

Startup power is measured from the time of power-on to the time that the drive spindle reaches operating speed.

• Seek mode

During seek mode, the read/write actuator arm moves toward a specific position on the disc surface and does

not execute a read or write operation. Servo electronics are active. Seek power is measured based on three

random seek operations every 100 msecs.

• Read/write mode

Read/write power is measured with the heads on track, while the head is reading/writing from/to disc. It is

performed with 100 percent duty cycle of read/write operation.

• Performance Idle mode

During Performance Idle mode, the heads are on track but no reading or writing is done. The spindle motor is

spinning at full speed.

• Low power idle mode

During Low power Idle mode, the heads are unloaded but the spindle motor is spinning at full speed. Servo

and read/write electronics are in powered down mode.

• Standby / Sleep mode

During Standby/Sleep mode, the spindle motor is not spinning, and the servo and read/write electronics are

in powered down mode.

6 Lyrion Series IDE Product Manual, Rev. F

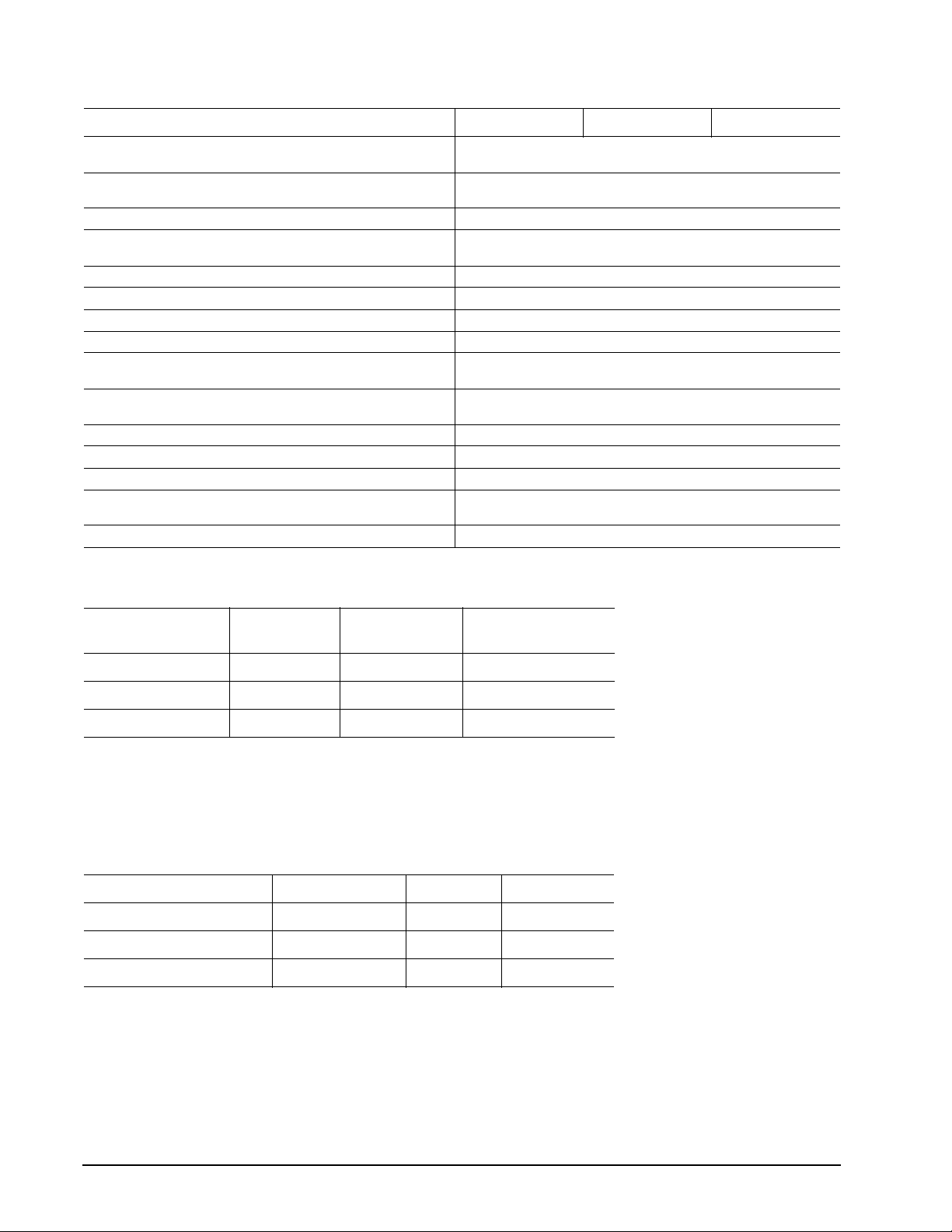

Table 2: DC power

Power Consumption at 3.3V Average (W)

Startup (max*) 1.15

Read 1.0

Write 0.9

Performance idle (typical) 0.5

Low power idle (typical) 0.3

Standby/Sleep (typical) 0.08

*Maximum is the average of the peak value in 10 msec window

2.7.1.1 Typical current profile

Figure 2. Typical 3.3V startup and operation current profile

Lyrion Series IDE Product Manual, Rev. F 7

2.7.2 Conducted noise

Input noise ripple is measured at the host system power supply across an equivalent 15-ohm resistive load on

the +3.3 volt line.

Using 3.3-volt power, the drive is expected to operate with a maximum of 70 mV

peak-to-peak square-wave

injected noise at up to 20 MHz.

Note. Equivalent resistance is calculated by dividing the nominal voltage by the typical RMS read/write

current.

2.7.3 Voltage tolerance

Voltage tolerance (including noise):

3.3V ± 5%

2.7.4 Power-management modes

The drive provides programmable power management to provide greater energy efficiency. The drive features

the following power-management modes:

Table 3: Power-management modes

Power modes Heads Spindle Buffer

Active (read/write/seek) Tracking Rotating Enabled

Idle, performance Tracking Rotating Enabled

Idle, low power Parked Rotating Disabled

Standby/Sleep Parked Stopped Disabled

• Active mode

The drive is in Active mode during the read/write and seek operations.

• Performance idle mode

The drive enters this mode once the read/write/seek activity is completed. The buffer remains enabled, and

the drive accepts all commands and returns to Active mode any time disc access is necessary.

• Low power idle mode

Drive enters Low Power Idle mode from Performance Idle mode when the Advanced Power Management

Level is set between 80h and FDh, and the Idle timer reaches 2 seconds (default setting). Disc is spinning

and heads are parked and drive accepts all commands and returns to Active mode any time disc access is

necessary.

• Standby/Sleep mode

The drive enters Standby mode when the host sends a Standby Immediate command. When the Advanced

Power Management Level is set lower than 80h (default setting), the drive enters the Standby state after 2

seconds of interface inactivity. If the host has set the standby timer, the drive may also enter the Standby

mode after the expiry of the standby timer. The standby timer can be set using the Standby or Idle command.

In Standby mode, the drive buffer is disabled, the heads are parked and the spindle is at rest. The drive accepts

all commands and returns to Active mode any time disc access is necessary.

8 Lyrion Series IDE Product Manual, Rev. F

2.8 Environmental specifications

2.8.1 Ambient temperature

Ambient temperature is defined as the temperature of the environment immediately surrounding the drive.

Actual drive case temperature should not exceed

temperature of the drive operating at 60°C ambient may hit a maximum of 70°C at certain parts of the casing.

Above 1,000 feet (305 meters), the maximum operating temperature is derated linearly by 1°C every 1000 feet.

Operating 0° to 60°C (32° to 140°F) (70°C max case temperature)

Nonoperating –40° to 70°C (–40° to 158°F)

2.8.2 Temperature gradient

Operating 20°C per hour (36°F per hour max), without condensation

Nonoperating 30°C per hour (54°F per hour max), without condensation

2.8.3 Humidity

2.8.3.1 Relative humidity

70°C (158°F) within the operating ambient conditions. Case

Operating 5% to 90% noncondensing (30% per hour max)

Nonoperating 5% to 95% noncondensing (30% per hour max)

2.8.3.2 Wet bulb temperature

Operating 33°C (91.4°F max) [1]

Nonoperating 40°C (104°F max) [2]

[1] Operating: Wet bulb temperature is calculated by the operating Temperature and the Relative Humidity levels.

[2] Nonoperating: Wet bulb temperature is calculated by the nonoperating Temperature and the Relative Humidity levels.

2.8.4 Altitude

Operating –60.98 m to 3,048 m (–200 ft to 10,000+ ft)

Nonoperating –60.98 to 12,192 m (–200 ft to 40,000+ ft)

Lyrion Series IDE Product Manual, Rev. F 9

2.8.5 Shock

All shock measurements in this section are carried out at drive level. For all linear shock test, operating or

nonoperating, the input shock level is measured at the frame of the drive at the specific location as indicated in

Figure 3 below.

Shock Monitoring PositionShock Monitoring Position

Figure 3. Location where tri-axial accelerometer will be placed on Lyrion Series drives

All shock test cover all the 6 directions, +/- x, y and z axes. The drive axis definition in shown in Figure 4 below.

-Z

-Y

-X

+X

+Y

+Z

Figure 4. Drive axis definition for Lyrion Series drives

2.8.5.1 Operating shock

The drive is subjected to 10 shocks for each direction. During the shocks, there must be a minimum delay of 3

seconds between shock pulses. Soft errors and automatic retries are allowed during the test. No data loss or

permanent damage occurs during a half sine shock pulse of:

500 G, 2 msec

2.8.5.2 Nonoperating shock

The nonoperating shock level that the drive can experience without incurring any physical damage when subsequently put into operation is 1500 Gs. The same applies for shock levels of 1500 G, 1 msec pulse duration

on fresh drives for each level.

2.8.6 Vibration

All vibration specifications assume that the drive is mounted securely in a fixture that does not have fixture

resonances in the frequency test range.

10 Lyrion Series IDE Product Manual, Rev. F

2.8.6.1 Operating sweep sine vibration

The following lists the maximum operating sweep sine vibration levels that the drive may experience while

meeting the performance standards specified. It consists of a forward and backward sweep from 10 Hz to

500 Hz to 10 Hz. The drive operates without a hard error while being subjected to the following vibration levels.

10 Hz to 500 Hz @ 2 oct/min 1.0 Gs (0 to pk). Maximum displacement may apply below 10 Hz.

2.8.6.2 Operating random vibration

The test consists of 30 minutes of random vibration using the power spectral density (PSD) levels specified in

the table below. The vibration test level is 0.67

Gs RMS. The drive operates without a hard error while being

subjected to the following vibration levels.

Table 4: Operating random vibration profile

Frequency (Hz) G2/Hz

17 1.1 x E-03

45 1.1 x E-03

48 8.0 x E-03

62 8.0 x E-03

65 1.0 x E-03

150 1.0 x E-03

200 5.0 x E-04

500 5.0 x E-04

2.8.6.3 Nonoperating sweep sine vibration

The following table lists the maximum nonoperating sweep sine vibration levels that the drive may experience

while meeting the performance standards specified. It consists of a forward and backward sweep from 5 Hz to

500 Hz to 5 Hz. The drive does not incur any physical damage when subsequently put into operation.

10 Hz to 500 Hz @ 0.5 oct/min 5.0 Gs (0 to pk). Maximum displacement may apply below 22 Hz.

5 Hz to 10 Hz 25.4 mm peak to peak displacement.

Lyrion Series IDE Product Manual, Rev. F 11

2.8.6.4 Nonoperating random vibration

The test consists of 15 minutes of random vibration using the power spectral density (PSD) levels specified in

the table below. The vibration test level is 3.01 Gs RMS. The drive does not incur any physical damage when

subsequently put into operation.

Table 5: Nonoperating random vibration profile.

Frequency (Hz) G2/Hz

2.5 1.0 x E-03

5 3.0 x E-02

40 1.8 x E-02

500 1.8 x E-02

2.8.7 Corrosive environment

Seagate electronic drive components pass accelerated corrosion testing equivalent to ten years of exposure to

light industrial environments containing sulfurous gases, chlorine and nitric oxide, classes G and H per ASTM

B845. However, this accelerated testing cannot duplicate every potential application environment.

Users should use caution exposing any electronic components to uncontrolled chemical pollutants and corrosive chemicals as electronic drive component reliability can be affected by the installation environment. The silver, copper, nickel and gold films used in Seagate products are especially sensitive to the presence of sulfide,

chloride, and nitrate contaminants. Sulfur is found to be the most damaging. In addition, electronic components

should never be exposed to condensing water on the surface of the printed circuit board assembly (PCBA) or

exposed to an ambient relative humidity greater than 95 percent. Materials used in cabinet fabrication, such as

vulcanized rubber, that can outgas corrosive compounds should be minimized or eliminated. The useful life of

any electronic equipment may be extended by replacing materials near circuitry with sulfide-free alternatives.

2.9 Acoustics

Drive acoustics are measured as overall A-weighted acoustic sound power levels (no pure tones). Discrete

tone penalties are added to the A-weighted sound power (LW) with the following formula only when determining compliance:

LWt(spec) == LW + 0.1Pt + 0.3 < 4.0 (Bels)

where

LW = A-weighted sound power level

pt == Value of discrete tone penalty [==dLt-6.0 (dBA)]

dLt = Tone-to-noise ratio taken in accordance with ISO 7779 at each octave band.

All measurements are consistent with ISO document 7779. Sound power measurements are taken under

essentially free-field conditions over a reflecting plane. For all tests, the drive is oriented with the cover facing

upward.

Table 6: Drive level acoustics

Acoustic mode

Idle Operational

1.6 bels (typ) 2.2 bels (typ)

)

12 Lyrion Series IDE Product Manual, Rev. F

2.10 Electromagnetic immunity

When properly installed in a representative host system, the drive operates without errors or degradation in

performance when subjected to the radio frequency (RF) environments defined in the following table:

Table 7: Electromagnetic immunity

Performance

Test Description

Radiated RF immunity 80 to 1,000 MHz, 3 V/m,

80% AM with 1 kHz sine

900 MHz, 3 V/m, 50% pulse modulation @ 200

Hz

Electrical fast transient ± 1 kV on AC mains, ± 0.5 kV on external I/O B EN 61000-4-4: 95

Surge immunity ± 1 kV differential, ± 2 kV common, AC mains B EN 61000-4-5: 95

Conducted RF immunity 150 kHz to 80 MHz, 3 Vrms, 80% AM with 1

kHz sine

Voltage dips, interrupts 0% open, 5 seconds

0% short, 5 seconds

40%, 0.10 seconds

70%, 0.01 seconds

level

A EN 61000-4-3: 96

A EN 61000-4-6: 97

C

C

C

B

Reference

standard

ENV 50204: 95

EN 61000-4-11: 94

2.11 Reliability

Measurement type Specification

Nonrecoverable read errors 1 per 1014 bits read, max.

Load/Unload (LUL) cycles 300,000 software-controlled

20,000 power loss

Power On Hours (POH) per year 500 hours

Warranty Per agreement

Lyrion Series IDE Product Manual, Rev. F 13

2.12 Agency certification

2.12.1 Safety certification

The drives are recognized in accordance with UL60950-1, CAN/CSA-C22.2 No.60950-1, EN60950 and IEC

60950.

2.12.2 Electromagnetic compatibility

Hard drives that display the CE mark comply with the European Union (EU) requirements specified in the Electromagnetic Compatibility Directive (89/336/EEC). Testing is performed to the levels specified by the product

standards for Information Technology Equipment (ITE). Emission levels are defined by EN 55022, Class B and

the immunity levels are defined by EN 55024.

Seagate uses an independent laboratory to confirm compliance with the EC directives specified in the previous

paragraph. Drives are tested in representative end-user systems. Although CE-marked Seagate drives comply

with the directives when used in the test systems, we cannot guarantee that all systems will comply with the

directives. The drive is designed for operation inside a properly designed enclosure, with properly shielded I/O

cable (if necessary) and terminators on all unused I/O ports. Computer manufacturers and system integrators

should confirm EMC compliance and provide CE marking for their products.

Korean RRL

If these drives have the Korea Ministry of Information and Communication (MIC) logo, they comply with paragraph 1 of Article 11 of the Electromagnetic Compatibility control Regulation and meet the Electromagnetic

Compatibility (EMC) Framework requirements of the Radio Research Laboratory (RRL) Ministry of Information

and Communication Republic of Korea.

These drives have been tested and comply with the Electromagnetic Interference/Electromagnetic Susceptibility (EMI/EMS) for Class B products. Drives are tested in a representative, end-user system by a Korean-recognized lab.

• Family name: Lyrion Series

• Certificate numbers: STX-S181 (B)

Australian C-Tick (N176)

If these models have the C-Tick marking, they comply with the Australia/New Zealand Standard AS/NZS3548

1995 and meet the Electromagnetic Compatibility (EMC) Framework requirements of the Australian Communication Authority (ACA).

14 Lyrion Series IDE Product Manual, Rev. F

2.12.3 European Union Restriction of Hazardous Substances (RoHS) Directive

Seagate designs its products to meet environmental protection requirements worldwide, including regulations

restricting certain chemical substances. A new law, the European Union Restriction of Hazardous Substances

(RoHS) Directive, restricts the presence of chemical substances, including Lead, Cadmium, Mercury,

Hexavalent Chromium, PBB and PBDE, in electronic products, effective July 2006. This drive is manufactured

with components and materials that comply with the RoHS Directive.

2.12.4 China Restriction of Hazardous Substances (RoHS) Directive

2.12.4

This product has an Environmental Protection Use Period (EPUP) of 20 years. The following

table contains information mandated by China's "Marking Requirements for Control of Pollution

Caused by Electronic Information Products" Standard.

"O" indicates the hazardous and toxic substance content of the part (at the homogenous material level) is lower

than the threshold defined by the China RoHS MCV Standard.

“O”

"X" indicates the hazardous and toxic substance content of the part (at the homogenous material level) is over

the threshold defined by the China RoHS MCV Standard.

中国限制危险物品的指令

表示该部件(于同类物品程度上)所含的危险和有毒物质低于中国

RoHS MCV

标准所定义的门槛值。

“X”

表示该部件(于同类物品程度上)所含的危险和有毒物质超出中国

Lyrion Series IDE Product Manual, Rev. F 15

RoHS MCV

标准所定义的门槛值。

2.12.5 FCC verification

These drives are intended to be contained solely within a personal computer or similar enclosure (not attached

as an external device). As such, each drive is considered to be a subassembly even when it is individually marketed to the customer. As a subassembly, no Federal Communications Commission verification or certification

of the device is required.

Seagate Technology LLC has tested this device in enclosures as described above to ensure that the total

assembly (enclosure, disc drive, motherboard, power supply, etc.) does comply with the limits for a Class B

computing device, pursuant to Subpart J, Part 15 of the FCC rules. Operation with noncertified assemblies is

likely to result in interference to radio and television reception.

Radio and television interference. This equipment generates and uses radio frequency energy and if not

installed and used in strict accordance with the manufacturer’s instructions, may cause interference to radio

and television reception.

This equipment is designed to provide reasonable protection against such interference in a residential installation. However, there is no guarantee that interference will not occur in a particular installation. If this equipment

does cause interference to radio or television, which can be determined by turning the equipment on and off,

you are encouraged to try one or more of the following corrective measures:

• Reorient the receiving antenna.

• Move the device to one side or the other of the radio or TV.

• Move the device farther away from the radio or TV.

• Plug the computer into a different outlet so that the receiver and computer are on different branch outlets.

If necessary, you should consult your dealer or an experienced radio/television technician for additional suggestions. You may find helpful the following booklet prepared by the Federal Communications Commission:

How to Identify and Resolve Radio-Television Interference Problems. This booklet is available from the Superintendent of Documents, U.S. Government Printing Office, Washington, DC 20402. Refer to publication number 004-000-00345-4.

16 Lyrion Series IDE Product Manual, Rev. F

3.0 Configuring and mounting the drive

This section contains the specifications and instructions for configuring and mounting the drive.

3.1 Handling and static discharge precautions

After unpacking, and before installation, the drive may be exposed to potential handling and electrostatic

discharge (ESD) hazards. Observe the following standard handling and static-discharge precautions:

Caution:

• Do not cover or seal the breather hole! Covering or sealing the breather hole may result in loss of data.

Figure 5. Lyrion Series breather hole location

• Keep the drive in the electrostatic discharge (ESD) bag until you are ready for installation to limit the drive’s

exposure to ESD.

• Before handling the drives, put on a grounded wrist strap, or ground yourself frequently by touching the metal

chassis of a computer that is plugged into a grounded outlet. Wear a grounded wrist strap throughout the entire

installation procedure.

• Handle the drive only by its edges or frame.

Figure 6. Lyrion Series proper handling example

• The drive is fragile—handle it with care. Do not press down on the drive top cover or attempt to use a pen to

write on the drive’s label.

• Do not apply more than 6.8N of force to the top cover.

• Always rest the drives on a padded, antistatic surface until you mount it in the system.

Lyrion Series IDE Product Manual, Rev. F 17

• Do not remove the factory-installed labels from the drive or cover them with additional labels. Removal voids

the warranty. Some factory-installed labels contain information needed to service the drive. Other labels are

used to seal out dirt and contamination.

• If provided, store drive in the protective casing when not in use.

• Turn the power off before installing or removing the drive.

• Do not apply any force to the drive during handling or installation.

• Do not touch the connector pins or the printed circuit board.

• Do not drop the drive.

• Do not expose the drive to wet conditions.

• Do not place the drive near a strong magnetic field.

• Do not expose the drive to extreme temperatures.

• The drive may become hot during operation. Be careful when removing the drive from the host device

immediately after operation.

18 Lyrion Series IDE Product Manual, Rev. F

3.2 Drive installation

See Figure 7 for drive mechanical dimensions.

Follow these installation precautions when inserting the drive:

• Follow instructions for the installation of data storage devices, provided with your device’s user manual.

• Do not obstruct the breather hole on the drive (see Figure 5).

• Handle the drive only by its edges or frame or designated finger grip region during mounting (see Figure 6).

71.00 ± .30

38.00 ± .20

6.21

BREATHER

HOLE

5.92

3.20

X2

54.00 ± .30

6.92

3.20

7.78

3.20

6.59

16.6 ± .20

3.20

2.23

ø1.00 ± .20

6.80

X2

5.00+.15

X2

DETAIL 'A'

25.65

*

( .80 )

DETAIL 'A'

CONNECTOR

CENTERLINE

3.23

Figure 7. Lyrion Series mechanical dimensions—top, side and end view

Lyrion Series IDE Product Manual, Rev. F 19

Figure 8. Lyrion Series FPC dimensions

3.3 Mounting considerations

• Use an elastic mounting material to protect drives so as to ensure that more shock can be absorbed.

• There are guides along the side for mounting. Refer to figure on areas (refer to Figure 9, shaded area)

where the mounting material can rest for mounting.

• As the drive is a sensitive device, it is not recommended to have any mounting force on the top and bottom

surface of the drive other than the recommended mounting surfaces. Mounting force on non recommended

surfaces shall not exceed 6.8N.”

• The drive can be operated in any orientation but horizontal or vertical orientation is preferred.

• Allow a minimum clearance of 0.012 inches (0.30 mm) around the entire perimeter of the drive for cooling,

with the exception of the mounting edges for better airflow.

• In case the system design warrants bending of the FPC to the hard disc drive, care should be taken to

maximize the radius.

• Mounting materials are available from many third-party vendors.

• The 40-way connector is design to meet minimum 6N Horizontal FPC retention after mating.

• The connector has a specification of 20 insertion cycles.

Figure 9. Lyrion Series Area for Protective Mounting

20 Lyrion Series IDE Product Manual, Rev. F

4.0 Interface description

The drives use the industry-standard ATA (IDE) interface. It supports ATA programmed input/output (PIO)

modes 0–4; multiword DMA modes 0–2, and Ultra DMA modes 0–4.

4.1 Connector interface signals and connector pins

The following table summarizes the signals on the 40-way ZIF ATA interface connector.

Table 8: 40-way ZIF (IDE interface) connector signals

Pin number Signal Name Description

1 Reserved -

2 Reserved -

3 RESET- Hard Reset

4 GROUND Ground

5 DD07 Data bus bit 7

6 DD08 Data bus bit 8

7 DD06 Data bus bit 6

8 DD09 Data bus bit 9

9 DD05 Data bus bit 5

10 DD10 Data bus bit 10

11 DD04 Data bus bit 4

12 DD11 Data bus bit 11

13 DD03 Data bus bit 3

14 DD12 Data bus bit 12

15 DD02 Data bus bit 2

16 DD13 Data bus bit 13

17 DD01 Data bus bit 1

18 DD14 Data bus bit 14

19 DD00 Data bus bit 0

20 DD15 Data bus bit 15

21 GROUND Ground

22 DMARQ DMA request

23 GROUND Ground

24 DIOW- /

25 DIOR- /

26 GROUND Ground

STOP

HDMARDY- /

HSTROBE

I/O Write to write to device registers or the data port

Stop during Ultra DMA burst

I/O Read to read device registers or the data port

Flow control during Ultra DMA data-in burst

Data-out strobe signal for Ultra DMA data-out burst

Lyrion Series IDE Product Manual, Rev. F 21

Table 8: 40-way ZIF (IDE interface) connector signals

27 IORDY /

28 GROUND Ground

29 DMACK- DMA Acknowledge

30 INTRQ Interrupt Request

31 DA01 Address bus bit 1

32 PDIAG- -

33 DA00 Address bus bit 0

34 DA02 Address bus bit 2

35 CS0- Chip Select 0

36 CS1- Chip Select 1

37 DASP- Used to drive external LED when drive is accessed

38 3.3V Voltage input

39 3.3V Voltage input

40 Reserved -

DDMARDY- /

DSTROBE

I/O Channel Ready during register access

Flow control during Ultra DMA data-out burst

Data-in strobe signal for Ultra DMA data-in burst

22 Lyrion Series IDE Product Manual, Rev. F

4.2 Supported ATA commands

The following table lists ATA-standard commands that the drive supports. For a detailed description of the ATA

commands, refer to ATA version 7 specification, Volume 1. (www.t13.org)

Table 9: Supported commands

Command Name Command Op-Code Command Type

NOP 00h Non data

Recalibrate 10h Non data

Read Sector(s) 20h PIO data-in

Read Sector(s) Ext 24h PIO data-in

Read DMA Ext 25h DMA data-in

Read Native Max Address Ext 27h Non data

Read Multiple Ext 29h PIO data-in

Write Sector(s) 30h PIO data-out

Write Sector(s) Ext 34h PIO data-out

Write DMA Ext 35h DMA data-out

Set Max Address Ext 37h Non data

Write Multiple Ext 39h PIO data-out

Read Verify Sector(s) 40h Non data

Read Verify Sector(s) Ext 42h Non data

Execute Drive Diagnostics 90h Non data

Download Microcode 92h PIO data-out

SMART B0h

SMART Disable Operations Non data

SMART Enable/Disable Autosave Non data

SMART Enable Operations Non data

SMART Execute Off-Line Immediate Non data

SMART Read Data PIO data-in

SMART Read Log PIO data-in

SMART Return Status Non data

SMART Write Log PIO data-out

Device Configuration B1h

Device Configuration Restore Non data

Device Configuration Freeze Lock Non data

Device Configuration Identify PIO data-in

Device Configuration Set PIO data-out

Read Multiple C4h PIO data-in

Write Multiple C5h PIO data-out

Set Multiple Mode C6h Non data

Read DMA C8h DMA data-in

Lyrion Series IDE Product Manual, Rev. F 23

Table 9: Supported commands

Write DMA CAh DMA data-out

Standby Immediate E0h Non data

Idle Immediate E1h Non data

Standby E2h Non data

Idle E3h Non data

Read Buffer E4h PIO data-in

Check Power Mode E5h Non data

Sleep E6h Non data

Flush Cache E7h Non data

Write Buffer E8h PIO data-out

Identify Device ECh PIO data-in

Set Features EFh Non data

Security Set Password F1h PIO data-out

Security Unlock F2h PIO data-out

Security Erase Prepare F3h Non data

Security Erase Unit F4h PIO data-out

Security Freeze Lock F5h Non data

Security Disable Password F6h PIO data-out

Read Native Max Address F8h Non data

Set Max Address F9h Non data

24 Lyrion Series IDE Product Manual, Rev. F

4.2.1 Identify Device command

The Identify Device command (command code ECH) transfers information about the drive to the host following

power up. The data is organized as a single 512-byte (256 word) block of data, whose contents are as shown

in the following table.

Word ATA specification

Value

0 General configuration information bit-significant information

Bit 15: 0 = ATA device

Bit 7: 1 = removable media

Bit 6: 1 = non-removable/fixed device

10–19 Serial number: (20 ASCII characters) Serial number

23–26 Firmware revision (8 ASCII character string) Firmware revision

27–46 Drive model number:

(40 ASCII characters, padded with blanks to end of string)

47

49 Capabilities

53 Bit 2: 1= the fields reported in word 88 are valid

59 Bit 8: 1= Multiple sector setting is valid

60–61 Total number of user-addressable LBA sectors available 37E3E40h (30GB)

63 Bit 10: 1= Multiword DMA mode 2 is selected

64 Bits 7-0: PIO modes supported 0003h

Bits 7-0: Maximum number of sectors transferred per interrupt on

Read Multiple/ Write Multiple commands

Bit 13: 1= Standby timer values specified in ATA-7 are supported

Bit 11: 1= IORDY supported

Bit 10: 0= IORDY may not be disabled

Bit 9 : 1= LBA supported

Bit 8 : 1= DMA supported

Bit 1: 1= the fields reported in words (70:64) are valid

Bits 7-0: Current setting for number of sectors transferred during a

Read/Write Multiple command

0= Multiword DMA mode 2 is not selected

Bit 9: 1= Multiword DMA mode 1 is selected

0= Multiword DMA mode 1 is not selected

Bit 8: 1= Multiword DMA mode 0 is selected

0= Multiword DMA mode 0 is not selected

Bit 2: 1= Multiword DMA mode 2 and below are supported

Bit 1: 1= Multiword DMA mode 1 and below are supported

Bit 0: 1= Multiword DMA mode 0 is supported

0040h

Model number

8010h

2B00h

0007h

0110h

4A82BA0h (40GB)

6FC7C80h (60GB)

xxx7h

65 Minimum Multiword DMA transfer cycle time per word

Bits 15-0: Cycle time in nanoseconds

66 Recommended Multiword DMA transfer cycle time

Bits 15-0: Cycle time in nanoseconds

67 Minimum PIO transfer cycle time without flow control

Bits 15-0: Cycle time in nanoseconds

68 Minimum PIO transfer cycle time with IORDY flow control

Bits 15-0: Cycle time in nanoseconds

0078h

0078h

0078h

0078h

Lyrion Series IDE Product Manual, Rev. F 25

82 Command sets supported

Bit 14: 1= NOP command supported

Bit 13: 1= READ BUFFER command supported

Bit 12: 1= WRITE BUFFER command supported

Bit 10: 1= Host Protected Area feature set supported

Bit 6: 1= Look-ahead supported

Bit 5: 1= Write cache supported

Bit 3: 1= Mandatory Power Management feature set supported

Bit 1: 1= SECURITY Mode feature set supported

Bit 0: 1= SMART feature set supported

83 Command sets supported

Bit 13: 1= FLUSH CACHE EXT command supported

Bit 12: 1= Mandatory FLUSH CACHE command supported

Bit 11: 1= DEVICE CONFIGURATION overlay feature set supported

Bit 10: 1= 48-bit Address feature set supported

Bit 8: 1= SET MAX security extension supported

Bit 5: 1= Power up in Standby feature supported

Bit 3: 1= Advanced Power Management feature set supported

Bit 0: 1= DOWNLOAD MICROCODE command supported

84 Command set/feature supported extension

Bit 5: 1= General Purpose Logging feature supported

Bit 1: 1= SMART self-test supported

Bit 0: 1= SMART error logging supported

85 Command sets referred in word 82 enabled

746Bh

7D29h

6063h

xxxxh

86 Command sets referred in word 83 enabled

87 Command set/feature default

Bit 5: 1= General Purpose Logging feature supported

Bit 1: 1= SMART self-test supported

Bit 0: 1= SMART error logging supported

88

91 Current Advanced Power Management value (default) 4040h

100-103 Total number of user-addressable LBA sectors available for

Bit 12: 1= Ultra DMA mode 4 is selected

0= Ultra DMA mode 4 is not selected

Bit 11: 1= Ultra DMA mode 3 is selected

0= Ultra DMA mode 3 is not selected

Bit 10: 1= Ultra DMA mode 2 is selected

0= Ultra DMA mode 2 is not selected

Bit 9: 1= Ultra DMA mode 1 is selected

0= Ultra DMA mode 1 is not selected

Bit 8: 1= Ultra DMA mode 0 is selected

0= Ultra DMA mode 0 is not selected

Bit 4: 1= Ultra DMA mode 4 and below are supported

Bit 3: 1= Ultra DMA mode 3 and below are supported

Bit 2: 1= Ultra DMA mode 2 and below are supported

Bit 1: 1= Ultra DMA mode 1 and below are supported

Bit 0: 1= Ultra DMA mode 0 and below are supported

48-bit addressing feature (48-bit addressing not supported)

xxxxh

6063h

xx1Fh

37E3E40h (30GB)

4A82BA0h (40GB)

6FC7C80h (60GB)

26 Lyrion Series IDE Product Manual, Rev. F

4.2.2 Set Features command

This command is used by the host to establish parameters that affect the execution of certain drive features.

The supported features determined by the value in the Features register are as shown in Table 11. Read lookahead and write cache are enabled by default upon power on.

Table 10: Features register values

Feature Description

02h Enable Write Cache

03h Set DMA and PIO transfer modes based on the value in the Sector Count register.

Sector Count register values

08h: Set PIO Transfer Mode 0

09h: Set PIO Transfer Mode 1

0Ah: Set PIO Transfer Mode 2

0Bh: Set PIO Transfer Mode 3

0Ch: Set PIO Transfer Mode 4

20h: Set Multiword Transfer Mode 0.

21h: Set Multiword Transfer Mode 1.

22h: Set Multiword Transfer Mode 2.

40h: Set Ultra DMA mode 0.

41h: Set Ultra DMA mode 1.

42h: Set Ultra DMA mode 2.

44h: Set Ultra DMA mode 4.

05h Enable Advanced Power Management (APM) with APM level as in the Sector Count register .

Sector Count register values

0h : Reserved

1h – 7Fh : Allow Spin-Down (Standby Mode)

80h – FEh : Disallow Spin-Down (Low Power Idle Mode)

FFh : Reserved

55h Disable Read Look-Ahead.

82h Disable Write Cache.

85h Disable Advanced Power Management (APM)

AAh Enable Read Look-Ahead .

Lyrion Series IDE Product Manual, Rev. F 27

28 Lyrion Series IDE Product Manual, Rev. F

5.0 Seagate Technology support services

Internet

For information regarding Seagate products and services, visit www.seagate.com. Worldwide support is

available 24 hours daily by email for your questions.

Presales Support:

Presales@Seagate.com

Technical Support:

DiscSupport@Seagate.com

Warranty Support:

http://www.seagate.com/support/service/index.html

mySeagate

my.seagate.com is the industry's first Web portal designed specifically for OEMs and distributors. It provides

self-service access to critical applications, personalized content and the tools that allow our partners to

manage their Seagate account functions. Submit pricing requests, orders and returns through a single,

password-protected Web interface-anytime, anywhere in the world.

spp.seagate.com

spp.seagate.com supports Seagate resellers with product information, program benefits and sales tools. You

may register for customized communications that are not available on the web. These communications contain

product launch, EOL, pricing, promotions and other channel-related information. To learn more about the

benefits or to register, go to spp.seagate.com, any time, from anywhere in the world.

Seagate Service Centers

Presales Support

Our Presales Support staff can help you determine which Seagate products are best suited for your specific

application or computer system, as well as product availability and compatibility.

Technical Support

Seagate technical support is available to assist you online at support.seagate.com or through one of our call

centers. Have your system configuration information and your “ST” model number available.

SeaTDD™ (+1-405-324-3655) is a telecommunications device for the deaf (TDD). You can send questions or

comments 24 hours daily and exchange messages with a technical support specialist during normal business

hours for the call center in your region.

Lyrion Series IDE Product Manual, Rev. F 29

Customer Service Operations

Warranty Service

Seagate offers worldwide customer support for Seagate products. Seagate distributors, OEMs and other direct

customers should contact their Seagate Customer Service Operations (CSO) representative for warrantyrelated issues. Resellers or end users of drive products should contact their place of purchase or Seagate

warranty service for assistance. Have your serial number and model or part number available.

Data Recovery Services

Seagate offers data recovery services for all formats and all brands of storage media. Our data recovery

services labs are currently located throughout the world. . Additional information, including an online request

form and data loss prevention resources, is available at http://services.sea

gate.com/index.aspx

Authorized Service Centers

Seagate Service Centers are available on a global basis for the return of defective products. Contact your

customer support representative for the location nearest you.

USA/Canada/Latin America support services

For an extensive list of telephone numbers to technical support, presales and warranty service in USA/

Canada/Latin America, including business hours, go to the "Contact Us" page on www.sea

gate.com.

Europe, the Middle East and Africa Support Services

For an extensive list of telephone numbers to technical support, presales and warranty service in Europe, the

Middle East and Africa, go to the "Contact Us" page on www.sea

gate.com.

Asia/Pacific Support Services

For an extensive list of telephone numbers to technical support, presales and warranty service in Asia/Pacific,

go to the "Contact Us" page on www.sea

gate.com.

Publication feedback survey

We are interested in your comments and suggestions regarding this publication. Please take a few minutes to

participate in our survey at the following URL:

http://survey.sea

Thank you for your time and comments.

gate.com/survey/techpubs.nsf

30 Lyrion Series IDE Product Manual, Rev. F

Index

A

acoustics 12

Active mode 8

agency certification (regulatory) 14

altitude 9

ambient conditions 3

ambient temperature 9

areal density 1, 5

ATA-standard commands 23

Australian C-Tick 14

EU RoHS directive 15

European Union 14

F

FCC verification 16

Features register 27

formatted capacity 4

FPC dimensions 20

frequency 13

G

guaranteed sectors 4

B

BPI 5

buffer 1, 5

C

cache 1, 5

case temperature 9

CE mark 14

certification 14

China RoHS directive 15

commands 23

compliance 14

conducted noise 8

conducted RF immunity 13

configuring the drive 17

connector pins 21

consumption 7

Corrosive environment 12

C-Tick 14

current profile 7

D

DC power 6, 7

density 5

diagnostic software 1

disclaimer 1

drive care 1

drive self-test 1

E

electrical fast transient 13

electromagnetic compatibility 14

Electromagnetic Compatibility Directive 14

electromagnetic immunity 13

EMC compliance 14

enclosures 16

environmental specifications 9

EPRML 1

error-correction algorithms 1

errors 13

H

handling 17

heads 1

height 5

humidity 9

I

I/O data-transfer rate 5

Identify Device command 25

Idle mode power, low 6

Information Technology Equipment 14

interface 5

interface connector signals 21

Interface description 21

interface signals 21

interference 16

internal data-transfer rate OD 5

Introduction 1

ISO document 7779 12

K

Korean RRL 14

L

LBA mode 4

length 5

logical geometry 4

low power idle 7

Low power idle mode 8

M

maximum temperature 9

mechanical dimensions 19

modes 21

Mounting considerations 20

mounting the drive 17, 19

Lyrion Series IDE Product Manual, Rev. F 31

N

noise 8

nominal power 3

nonoperating random vibration 12

nonoperating shock 1, 10

Nonoperating sweep sine vibration 11

nonrecoverable read errors 13

O

Operating random vibration 11

operating shock 1, 10

Operating sweep sine vibration 11

P

performance idle 7

Performance idle mode 8

performance Idle mode 6

perpendicular recording heads 1

physical characteristics 5

pins 21

PIO 21

power consumption 6, 7

power management 8

power specifications 6

power-management modes 8

Power-on to Ready 5

precautions 19

programmable power management 8

protective mounting 20

R

radiated RF immunity 13

radio and television interference 16

radio frequency (RF) 13

read errors 13

read/write mode 6

recording and interface technology 5

recording density 5

recording heads 1

recording method 5

register 27

relative humidity 9

reliability 13

resistance 8

RF 13

RoHS 15

shock 10

signals 21

sleep mode 6

sound 12

specifications 3

spindle speed 1, 5

Spinup 7

standby mode 6

Standby to Ready 5

Standby/Sleep 7

Standby/Sleep mode 8

startup mode 6

static-discharge precautions 17

subassembly 16

support services 29

surge immunity 13

sustained data transfer rate 5

T

technical support services 29

temperature 9

temperature gradient 9

theory of liability 1

time to ready 5

tort 1

track density 5

V

Vibration 10

voltage 8

voltage dips, interrupts 13

voltage tolerance 8

W

Warranty 13

warranty 1

weight 5

wet bulb temperature 9

width 5

S

safety certification 14

SeaTools 1

sectors 4

seek mode 6

Set Features command 27

32 Lyrion Series IDE Product Manual, Rev. F

Seagate Technology LLC

920 Disc Drive, Scotts Valley, California 95066-4544, USA

Publication Number: 100441946, Rev. F, Printed in U.S.A.

Loading...

Loading...