. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. . . . .

Decathlon Family

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. . . . .

ST5660N, ST5660NC

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. . . . .

SCSI Interface Drives

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. . . . .

Product Manual

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. . . . .

Decathlon Family

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. . . . .

ST5660N, ST5660NC

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. . . . .

SCSI Interface Drives

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. . . . .

Product Manual

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. . . . .

© 1994 Seagate Technology, Inc. All rights reserved

Publication Number: 36245-004, Rev. B

September 1994

®

Seagate

, Seagate Technology® and the Seagate logo are registered

trademarks of Seagate Technology, Inc. Other product names are trademarks or registered trademarks of their owners.

Seagate reserves the right to change, without notice, product offerings

or specifications. No part of this publication may be reproduced in any

form without written permission from Seagate Technology, Inc.

Decathlon Family Product Manual, Rev. B iii

Contents

1.0 Specifications summary . . . . . . . . . . . . . . . . . . . . 1

1.1 Formatted capacity . . . . . . . . . . . . . . . . . . . . . . 1

1.2 Physical geometry . . . . . . . . . . . . . . . . . . . . . . . 1

1.3 Functional specifications . . . . . . . . . . . . . . . . . . . 1

1.4 Physical dimens ions . . . . . . . . . . . . . . . . . . . . . . 2

1.5 Reliability . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1.6 Acoustics . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1.7 Seek time . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1.7.1 Read look-ahead and caching . . . . . . . . . . . . . . 3

1.8 Environmental . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.8.1 Ambient temperature . . . . . . . . . . . . . . . . . . . 3

1.8.2 Temperature gradient . . . . . . . . . . . . . . . . . . . 3

1.8.3 Relative humidity . . . . . . . . . . . . . . . . . . . . . 3

1.8.4 Altitude . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.9 Shock and vibration . . . . . . . . . . . . . . . . . . . . . . 4

1.10 Start and stop time . . . . . . . . . . . . . . . . . . . . . . 4

1.10.1 Power-up sequence . . . . . . . . . . . . . . . . . . . 5

1.10.2 Power-down sequence . . . . . . . . . . . . . . . . . 5

1.10.3 Auto-park . . . . . . . . . . . . . . . . . . . . . . . . 6

1.11 DC power . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.11.1 Input noise . . . . . . . . . . . . . . . . . . . . . . . . 6

1.12 Power management . . . . . . . . . . . . . . . . . . . . . 6

1.12.1 Power consumption . . . . . . . . . . . . . . . . . . . 7

1.13 Agency listings . . . . . . . . . . . . . . . . . . . . . . . . 9

1.14 FCC verification . . . . . . . . . . . . . . . . . . . . . . . 9

2.0 Hardware and interface . . . . . . . . . . . . . . . . . . . . 11

2.1 SCSI-2 compatibility . . . . . . . . . . . . . . . . . . . . . 11

2.2 Handling and static-discharge precautions . . . . . . . . . 11

2.3 Electrical interface . . . . . . . . . . . . . . . . . . . . . . 12

iv Decathlon Family Product Manual, Rev. B

2.4 Interface and connector configuration . . . . . . . . . . . . 13

2.4.1 ST5660N interface connector . . . . . . . . . . . . . 13

2.4.2 ST5660N interface connector pin assignments . . . . 15

2.4.3 ST5660NC interface connector . . . . . . . . . . . . . 16

2.4.4 ST5660NC interface connector pin assignments . . . . 16

2.5 Interface cable requirements . . . . . . . . . . . . . . . . 18

2.5.1 Interface cable length for asynchronous operation . . . 19

2.5.2 Interface cable for Fast SCSI operation . . . . . . . . 19

2.6 Options jumper block . . . . . . . . . . . . . . . . . . . . 19

2.6.1 Active Termination . . . . . . . . . . . . . . . . . . . 20

2.6.2 SCSI address . . . . . . . . . . . . . . . . . . . . . . 20

2.6.3 Terminator power source selection . . . . . . . . . . . 20

2.6.4 Parity enable option . . . . . . . . . . . . . . . . . . 22

2.6.5 Start/stop option . . . . . . . . . . . . . . . . . . . . 22

2.6.6 Remote LED connection . . . . . . . . . . . . . . . . 22

2.7 Auxiliary SCSI ID block . . . . . . . . . . . . . . . . . . . 22

2.8 Daisy chaining . . . . . . . . . . . . . . . . . . . . . . . . 22

2.9 Hot-plugging . . . . . . . . . . . . . . . . . . . . . . . . . 24

2.10 Mounting the drive . . . . . . . . . . . . . . . . . . . . . 24

3.0 Command set . . . . . . . . . . . . . . . . . . . . . . . . . 27

3.1 Command descriptor block . . . . . . . . . . . . . . . . . 27

3.2 Status byte codes . . . . . . . . . . . . . . . . . . . . . . 27

3.3 Supported commands . . . . . . . . . . . . . . . . . . . . 29

3.4 Group 0 commands . . . . . . . . . . . . . . . . . . . . . 30

3.4.1 Test Unit Ready command (00

3.4.2 Rezero Unit command (01

3.4.3 Request Sense command (03

3.4.4 Format Unit command (04

3.4.5 Reassign Blocks command (07

3.4.6 Read command (08

3.4.7 Write command (0A

) . . . . . . . . . . . . . . . . . 39

H

) . . . . . . . . . . . . . . . . . 40

H

) . . . . . . . . . . . . 30

H

) . . . . . . . . . . . . . . 30

H

) . . . . . . . . . . . . 31

H

) . . . . . . . . . . . . . . 32

H

) . . . . . . . . . . . 37

H

Decathlon Family Product Manual, Rev. B v

3.4.8 Seek command (0BH) . . . . . . . . . . . . . . . . . 41

3.4.9 Inquiry command (12

3.4.10 Mode Select command (15

3.4.11 Reserve command (16

3.4.12 Release command (17

3.4.13 Mode Sense command (1A

3.4.14 Start/Stop Unit command (1B

3.4.15 Receive Diagnost ic Results command (1C

3.4.16 Send Diagnost ic command (1D

) . . . . . . . . . . . . . . . . . 41

H

) . . . . . . . . . . . . . 42

H

) . . . . . . . . . . . . . . . 46

H

) . . . . . . . . . . . . . . . 47

H

) . . . . . . . . . . . . . 48

H

) . . . . . . . . . . . . 52

H

) . . . . . 53

H

) . . . . . . . . . . . 55

H

3.5 Group 1 commands . . . . . . . . . . . . . . . . . . . . . 56

3.5.1 Read Capacity command (25

3.5.2 Read Extended command (28

3.5.3 Write Extended command (2A

3.5.4 Seek Extended command (2B

3.5.5 Write and Verify command (2E

3.5.6 Verify command (2F

) . . . . . . . . . . . . . . . . . 62

H

3.5.7 Read Defect Data command (37

3.5.8 Write Data Buffer command (3B

3.5.9 Read Data Buffer command (3C

3.5.10 Read Long command (3E

3.5.11 Write Long command (3F

) . . . . . . . . . . . . 56

H

) . . . . . . . . . . . . 57

H

) . . . . . . . . . . . . 58

H

) . . . . . . . . . . . . 60

H

) . . . . . . . . . . . . 60

H

) . . . . . . . . . . . 63

H

) . . . . . . . . . . . 65

H

) . . . . . . . . . . . 66

H

) . . . . . . . . . . . . . . 68

H

) . . . . . . . . . . . . . . 69

H

3.6 Group 2, 3 and 4 commands . . . . . . . . . . . . . . . . 70

3.7 Group 5 and 6 commands . . . . . . . . . . . . . . . . . 70

3.8 Group 7 commands . . . . . . . . . . . . . . . . . . . . . 70

Appendix A. Supported messages . . . . . . . . . . . . . . . . 71

A.1 Single-byte messages . . . . . . . . . . . . . . . . . . . . 71

A.2 Synchronous data transfer request message (01

) . . . . . 72

H

Appendix B. Sense data . . . . . . . . . . . . . . . . . . . . . . 73

B.1 Additional sense data . . . . . . . . . . . . . . . . . . . . 73

B.2 Sense key . . . . . . . . . . . . . . . . . . . . . . . . . . 74

B.3 Additional sense code and additional sense code qualifier . 76

vi Decathlon Family Product Manual, Rev. B

Appendix C. Mode pages . . . . . . . . . . . . . . . . . . . . . 81

A.1 Error Recovery page (01

A.2 Disconnect/Reconnect page (02

A.3 Format Device page (03

A.4 Rigid Disc Geometry page (04

A.5 Caching page (08

H

) . . . . . . . . . . . . . . . . . 83

H

) . . . . . . . . . . . . . 85

H

) . . . . . . . . . . . . . . . . . 87

H

) . . . . . . . . . . . . . . 90

H

) . . . . . . . . . . . . . . . . . . . . . 91

A.5.1 Read look-ahead and read caching . . . . . . . . . . 91

A.5.2 Write caching and write merging . . . . . . . . . . . . 92

A.5.3 Caching page description . . . . . . . . . . . . . . . 93

A.6 Control Mode page (0A

A.7 Notch page (0C

) . . . . . . . . . . . . . . . . . . . . . . 98

H

A.8 Cache Control page (38

A.9 Soft ID page (Flash memory) (3C

A.10 Operating page (Flash memory) (00

) . . . . . . . . . . . . . . . . . . 96

H

) . . . . . . . . . . . . . . . . . 100

H

) . . . . . . . . . . . . 101

H

) . . . . . . . . . . 102

H

Appendix D. Inquiry data . . . . . . . . . . . . . . . . . . . . 105

D.1 Inquiry data . . . . . . . . . . . . . . . . . . . . . . . . 105

D.2 Vital product data pages . . . . . . . . . . . . . . . . . 108

D.2.1 Unit Serial Number page (80

D.2.2 Implemented Operating Definition page (81

D.2.3 Firmware Numbers page (C0

D.2.4 Date Code page (C1

) . . . . . . . . . . . . . . . . 111

H

D.2.5 Jumper Settings page (C2

) . . . . . . . . . . . . 109

H

) . . . . 109

H

) . . . . . . . . . . . 110

H

) . . . . . . . . . . . . . 111

H

Appendix E. Timing diagrams . . . . . . . . . . . . . . . . . . 113

Decathlon Family Product Manual, Rev. B vii

Figures

Figure 1.Typical startup current profile . . . . . . . . . . . . . . . . 8

Figure 2. Singled-ended transmitter and receiver . . . . . . . . . . 12

Figure 3. ST5660N connectors . . . . . . . . . . . . . . . . . . . 14

Figure 4. ST5660NC connectors . . . . . . . . . . . . . . . . . . 18

Figure 5. Options jumper block (J8) settings . . . . . . . . . . . . 21

Figure 6. ST5660N auxiliary SCSI ID jumper block (J5) settings . . 23

Figure 7. ST5660N mounting dimensions . . . . . . . . . . . . . . 25

Figure 8. ST5660NC mounting dimensions . . . . . . . . . . . . . 26

Figure 9. Arbitration, selection (without ATN) and command . . . 113

Figure 10. Arbitration, selection (with ATN) and message out . . 114

Figure 11. Identify message out to command . . . . . . . . . . . 115

Figure 12. Command descriptor block transfer . . . . . . . . . . 116

Figure 13. Command, status, command complete message and

bus free . . . . . . . . . . . . . . . . . . . . . . . . 117

Figure 14. Last command byte, disconnect message, bus free

and reselection . . . . . . . . . . . . . . . . . . . . 118

Figure 15. Arbitration, reselection and message in . . . . . . . . 119

Figure 16. Reselection, status, command complete and bus free 120

Figure 17. Last command byte to data in . . . . . . . . . . . . . 121

Figure 18. Last command byte to data out . . . . . . . . . . . . 122

Figure 19. Reselect identify message to data in . . . . . . . . . 123

Figure 20. Data in block transfer . . . . . . . . . . . . . . . . . 124

Figure 21. Data out block transfer . . . . . . . . . . . . . . . . . 125

Figure 22. Last data byte, save pointer message and disconnect

message . . . . . . . . . . . . . . . . . . . . . . . . 126

Figure 23. Data in, status, command complete message and bus

free . . . . . . . . . . . . . . . . . . . . . . . . . . . 127

Figure 24. Synchronous timing . . . . . . . . . . . . . . . . . . 128

Figure 25. Synchronous write timing . . . . . . . . . . . . . . . 129

1 Decathlon Family Product Manual, Rev. B

1.0 Specifications summary

1.1 Formatted capacity

The capacities specified here do not include spare sectors and cylinders.

The media contains one spare sector per track and two spare cylinders

per drive.

Formatted capacity (Mbytes*) 545.29

Total sectors 1,065,036

* One Mbyte equals one million bytes.

1.2 Physical geometry

Discs 2

Read/write heads 4

Cylinders 3,002

1.3 Functional specifications

Interface Fast SCSI-2

Zone Bit Recording method RLL (1,7)

External data transfer rate

(Mbytes per sec, avg)

Internal data transfer rate

(Mbits per sec)

Spindle speed (RPM) 4,500 ± 0.5%

Bytes per sector 512

Track density (TPI) 3,309

Recording density

(BPI, max)

5.0 asynchronous

10.0 synchronous

27.6 to 47.2

52,602

Decathlon Family Product Manual, Rev. B 2

1.4 Physical dimensions

Height (max) 0.748 inches (19 mm)

Width (max) 4.00 inches (102.1 mm)

Depth (max) 5.00 inches (127.0 mm)

Weight (max) 1.0 lb (0.45 Kg)

1.5 Reliability

Read error rates are measured with automatic retries and data correction

with ECC enabled and all flaws reallocated. MTBF is measured at

nominal power at sea level and 40°C ambient temperature.

13

Nonrecoverable read errors 1 per 10

Seek errors 1 per 10

MTBF 300,000 power-on hours

Service life 5 years

bits transferred

7

physical seeks

1.6 Acoustics

Sound pressure is measured at idle from 1 meter above the drive top

cover.

Sound pressure, typ 26 dBA

Sound pressure, max 29 dBA

1.7 Seek time

All seek time measurements are taken under nominal conditions of

temperature and voltage with the drive mounted horizontally. In the

following table:

Track-to-track

•

seeks in both directions.

•

Average/typical

least 5,000 measurements of seeks in both directions between random cylinders, less overhead.

•

Full-stroke

block address zero (LBA 0) to the maximum LBA and back to LBA 0.

seek time is the average of all possible single-track

seek time is a true statistical random average of at

seek time is one-half the time needed to seek from logical

3 Decathlon Family Product Manual, Rev. B

Track-to-track

seek time

3.5 msec typ

4.0 msec max

Note. Host overhead varies between systems and cannot be specified.

Drive internal overhead is measured by issuing a no-motion seek.

Drive overhead is typically less than 1.0 msec.

Average/typical

seek time

12.0 msec read

14.0 msec write

Full-stroke

seek time

25.0 msec max 6.67 msec

Average

latency

1.7.1 Read look-ahead and caching

The drive uses algorithms that improve seek performance by storing data

in a buffer and processing it at a more convenient time. Three methods

are used: read look-ahead, read caching and write caching. These are

described in Appendix C.5.

1.8 Environmental

This section specifies acceptable environmental conditions for the drive.

The operating specifications assume that the drive is powered up. The

nonoperating specifications assume that the drive is packaged as it was

shipped from the factory.

1.8.1 Ambient temperature

Operating 5°C to 55°C (41°F to 131°F)

Nonoperating –40°C to 70°C (–40°F to 158°F)

1.8.2 Temperature gradient

Operating 20°C per hour (36°F per hour)

Nonoperating 30°C per hour (54°F per hour)

1.8.3 Relative humidity

Operating 8% to 80% noncondensing

Maximum wet bulb 26°C (79°F)

Operating gradient, max 10% per hour

Nonoperating 5% to 95% noncondensing

Maximum wet bulb 26°C (79°F)

Decathlon Family Product Manual, Rev. B 4

1.8.4 Altitude

Operating –1,000 ft to 10,000 ft (–305 m to 3,048 m)

Nonoperating –1,000 ft to 40,000 ft (–305 m to 12,192 m)

1.9 Shock and vibration

All shock and vibration specifications assume that the inputs are measured

at the drive mounting screws. Shock measurements are based on an

11-msec, half sine wave shock pulse, not to be repeated more than twice

per second.

During normal operating shock and vibration, there is no physical damage to the drive or performance degradation.

During abnormal operating shock and vibration, there is no physical

damage to the drive, although performance may be degraded during the

shock or vibration episode. When normal operating shock levels resume,

the drive meets its performance specifications.

During nonoperating shock and vibration, the read/write heads are

positioned in the shipping zone.

Normal

operating

Shock 2 Gs 10 Gs 75 Gs

5–22 Hz vibration 0.020-inch

displacement

22–400 Hz vibration 0.50 Gs 0.75 Gs 4.00 Gs

Abnormal

operating Nonoperating

0.030-inch

displacement

0.160-inch

displacement

1.10 Start and stop time

If the motor start option is disabled, the drive becomes ready within

20 seconds after power is applied. If the motor start option is enabled,

the drive becomes ready within 20 seconds after it receives the Motor

Start command. If the drive receives a command to spin down or power

is removed, the drive stops within 15 seconds.

5 Decathlon Family Product Manual, Rev. B

1.10.1 Power-up sequence

The following typical power-up sequence is provided to assist in evaluating drive performance. This information does not constitute a specification or a performance guarantee.

1. Power is applied to the disc drive.

2. The LED comes on for about 5 seconds.

3. Depending on whether there is a jumper installed on pins 15 and 16

of the options jumper block (J8) shown in Figure 5 on page 21, either

of the following sequences occurs:

a. If a jumper is not installed, the remote start option is not enabled,

and the drive begins to spin up as soon as power is applied.

b. If a jumper is installed, the remote start option is enabled and the

drive begins to spin up when the host commands the motor to start.

4. Within 250 msec after power is applied, the drive responds to the Test

Unit Ready, Request Sense, Mode Sense and Inquiry commands.

5. The drive begins to lock in speed-control circuits.

6. The actuator lock releases the actuator.

7. The spindle motor reaches operating speed in about 5 seconds. After

5 seconds, there are no speed variations.

8. The drive performs velocity adjustment seeks.

9. The drive seeks track 0 and becomes ready.

1.10.2 Power-down sequence

The following typical power-down sequence is provided to assist in

evaluating drive performance. This information does not constitute a

specification or a performance guarantee.

1. The power cable is unplugged from the drive, or the drive receives a

command to spin down.

2. Within 3 seconds after the motor begins to spin down, the actuator

lock engages, producing an audible sound.

3. The spindle stops within 15 seconds, whether the power cable is

unplugged from the drive or the drive receives the power-down

command.

Decathlon Family Product Manual, Rev. B 6

1.10.3 Auto-park

Upon power-down, the read/write heads automatically move to the

shipping zone. The heads park inside the maximum data cylinder. When

power is applied, the heads recalibrate to track 0.

Caution. Do not move the drive until the spindle motor has come to a

complete stop; otherwise, you may damage the drive.

1.11 DC power

Except during the write procedure, you can apply power to the drive or

remove power from the drive, in any sequence, without losing data or

damaging the drive. If you remove power from the drive during the write

procedure, you may lose the data currently being written.

1.11.1 Input noise

+5V +12V

Voltage tolerance

(including noise)

Input noise frequency

(max)

Input noise

(max, peak-to-peak)

± 5% ± 5%

25 MHz 25 MHz

100 mV 240 mV

1.12 Power management

The drive supports power-management modes that reduce its overall

power consumption. The drive automatically changes from one mode to

another in response to interface activity. You do not need to change any

parameters or send any special commands to make the drive change

modes. The power-management modes are described below.

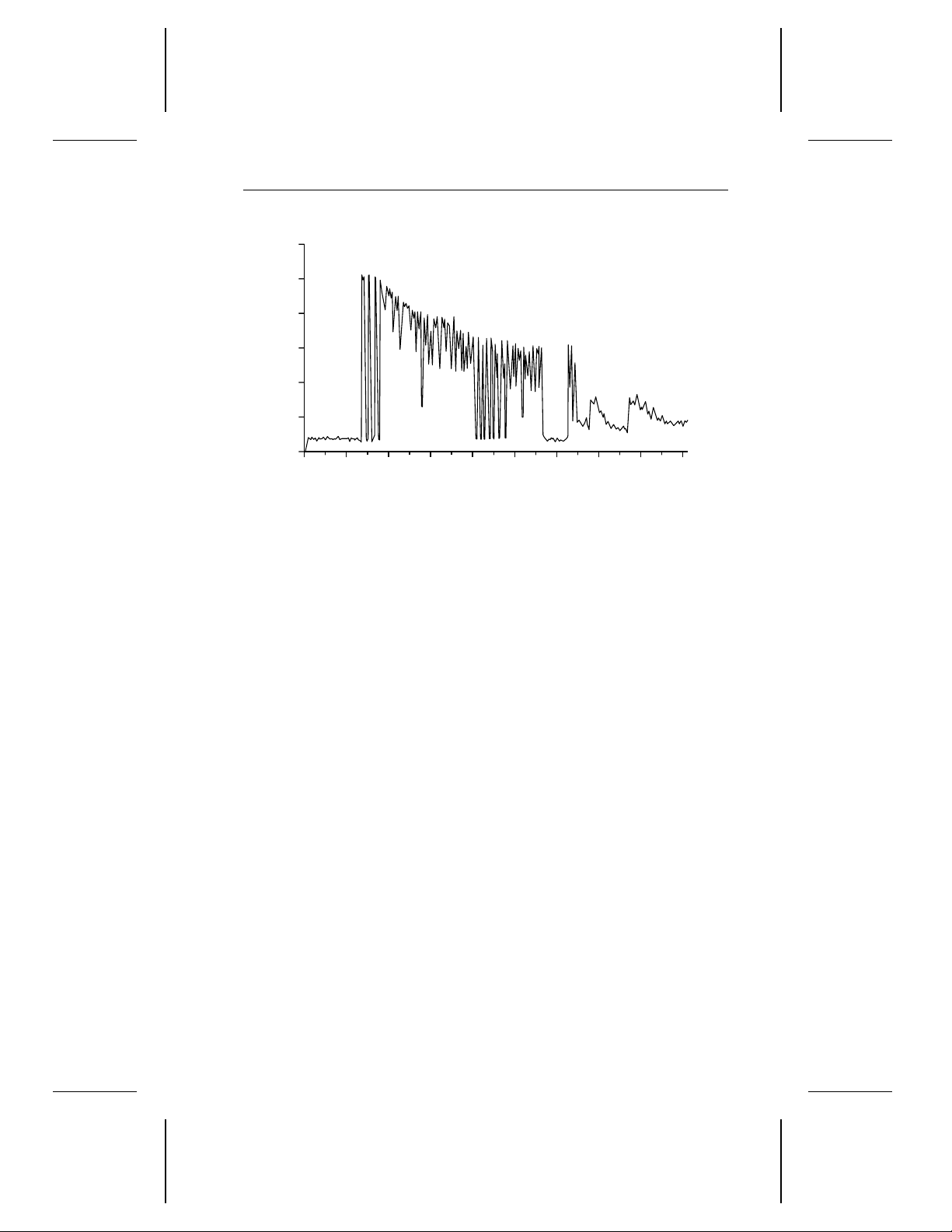

• Spinup. Spinup is defined as the period during which the spindle is

coming up to operating speed. The power consumed in this mode is

equivalent to the average power during the first 10 seconds after the

drive begins to spin up. Refer to the startup current chart in Figure 1

on page 8 for a typical representation of power consumption during

spinup.

7 Decathlon Family Product Manual, Rev. B

• Seeking. The servo electronics are active and the heads are moving

to a specific location on the disc. The read/write electronics are

powered-down. The power consumed in this mode is equivalent to the

average power measured while executing random seeks with a 2revolution (26.6 msec) dwell between seeks. The drive enters this

mode from the Idle mode.

• Read/Write. The drive is reading or writing. All electronics are active

and the heads are on track. The drive enters this mode from the Idle

mode.

• Idle. The spindle is spinning, the heads are parked, and the servo and

read/write electronics are powered down. The drive is ready to accept

and execute any command after the heads recalibrate. The drive

enters this mode from the Read/Write mode.

• Standby. This mode is not implemented.

1.12.1 Power consumption

Values in the table below were measured at the drive power connector

with an RMS DC ammeter. The terminating resistor packs are removed

and terminator power is supplied through the SCSI connector. All values

are measured 10 minutes after the drive spins up except as noted.

During

Spinup

Current at +12V

Amps peak 1.25 — — —

RMS amps typ — 0.354 0.208 0.116

Watts typ — 4.25 2.50 1.394

Current at +5V

RMS amps typ — 0.35 0.40 0.221

Watts typ — 1.75 2.00 1.106

Power

Total watts typ — 6.00 4.50 2.50

Seeking

Read/

Write

Idle

0

0

0.2

0.4

0.6

0.8

1.0

1.2

1

T1

T2

T3

T4 T5

T6

T7

2 3 4 5 6 7 8 9

Amps

Seconds

Decathlon Family Product Manual, Rev. B 8

Figure 1. Typical startup current profile

T1 Voltage is applied to the drive.

T2 After a delay, the startup current is applied and the spindle

begins to turn.

T3 The accelerating current is applied, causing the spindle speed

to increase.

T4 The spindle speed is close to the final, correct value. The drive

begins to lock in the speed-control circuits.

T5 The actuator lock releases the actuator.

T6 The final speed- control lock is achieved.

T7 The servo locks in on track 0 and the drive is ready.

9 Decathlon Family Product Manual, Rev. B

1.13 Agency listings

This drive is listed by agencies as follows:

• Recognized in accordance with UL 478 and UL 1950

• Certified to CSA C22.2 No. 220-M1986 and CSA C22.2 No. 950

• Certified to VDE 0805/05.90 and EN 60950/1.88 as tested by VDE

1.14 FCC verification

Decathlon family drives are intended to be contained solely within a

personal computer or similar enclosure (not attached to an external

device). As such, a drive is considered to be a subassembly even when

individually marketed to the customer. As a subassembly, no Federal

Communications Commission authorization, verification or certification

of the device is required.

Seagate Technology, Inc. has tested these drives in an enclosure as

described above to ensure that the total assembly (enclosure, disc drive,

motherboard, power supply, etc.) does comply with the limits for a

Class B computing device, pursuant to Subpart J of Part 15 of the FCC

rules. Operation with noncertified assemblies is likely to result in interference to radio and television reception.

Radio and television interference. This equipment generates and uses

radio frequency energy and, if not installed and used in strict accordance

with the manufacturer’s instructions, may cause interference to radio and

television reception.

This equipment is designed to provide reasonable protection against

such interference in a residential installation. However, there is no

guarantee that interference will not occur in a particular installation. If this

equipment does cause interference to radio or television, which can be

determined by turning the equipment on and off, you are encouraged to

try one or more of the following corrective measures:

• Reorient the receiving antenna.

• Move the device to one side or the other of the radio or TV.

• Move the device farther away from the radio or TV.

• Plug the equipment into a different outlet so that the receiver and

computer are on different branch outlets.

Decathlon Family Product Manual, Rev. B 10

If necessary, you should consult your dealer or an experienced radio/television technician for additional suggestions. You may find helpful the

following booklet prepared by the Federal Communications Commission:

How to Identify and Resolve Radio-Television Interference Problems.

This booklet is available from the Superintendent of Documents, US

Government Printing Office, Washington, DC 20402. Refer to publication

number 004-000-00345-4.

Note. This digital apparatus does not exceed the Class B limits for radio

noise emissions from computer equipment as set out in the radio

interference regulations of the Canadian Department of communications.

Le présent appareil numérique n′émet pas de bruits radioélectriques

dépassant les limites applicables aux appareils numériques de Classe B

prescrites dans le règlement sur le brouillage radioélectrique édicté par

le Ministère des Communications du Canada.

Sicherheitsanleitung

1. Das Gerrät ist ein Einbaugerät, das für eine maximale Umegebung-

stemperatur von 55°C vorgesehen ist.

2. Zur Befestigung des Laufwerks werden 4 Schrauben 6-32 UNC-2A

benötigt. Bei seitlicher Befestigung darf die maximale Länge der

Schrauben im Chassis nicht mehr als 5,08 mm und bei Befestigung

an der Unterseite nicht mehr als 5,08 mm betragen.

3. Als Versorgungsspannugen werden benötigt:

+5V ± 5% 0,65A

+12V ± 5% 0,45A (1,9A fur ca. 10 Sek. fur ± 10%)

4. Die Versorgungsspannung m uβ SELV entsprechen.

5. Alle Arbeiten dürfen nur von ausgebildetem Servicepersonal durchge-

führt werden.

6. Der Einbaudes Drives muβ den Anforderungen gemäβ DIN IEC 950V

DC 0805/05.90 entsprechen.

Decathlon Family Product Manual, Rev. B 11

2.0 Hardware and interface

The Seagate Decathlon family drives use a SCSI-2 interface that consists

of a 9-bit bidirectional bus (8 data bits and 1 parity bit) and 9 control

signals. The interface supports multiple initiators, disconnect and reconnect, self-configuring host software and logical block addressing.

The interface employs a singled-ended driver/receiver configuration that

uses asynchronous or synchronous communication protocols. It supports asynchronous transfer rates of up to 5 Mbytes per second and

synchronous transfer rates of up to 10.0 Mbytes per second. The bus

protocol supports multiple initiators, disconnect and reconnect, additional

messages and 6-byte and 10-byte command descriptor blocks. The bus

cable can be up to 6 meters long for standard mode and up to 3 meters

long for Fast SCSI mode.

2.1 SCSI-2 compatibility

The drive interface is described in the

publication number 77738479. The drive complies with the mandatory

subset of the ANSI SCSI-2 Interface. The Fast SCSI-2 interface is based

on the ANSI Small Computer System Interface-2 (SCSI-2), document

x

number ANSI X3.131-199

(X3T9.2/86-109 Rev. 10h).

Seagate SCSI-2 Interface Manual

2.2 Handling and static-discharge precautions

The Decathlon family drives use static-sensitive devices. Avoid damaging the drive and these devices by observing the following standard

handling and static-discharge precautions:

Caution:

• Keep the drive in its static-shielded bag until you are ready to complete

the installation. Do not attach any cables to the drive while it is in its

static-shielded bag.

• Before handling the drive, put on a grounded wrist strap, or ground

yourself frequently by touching the metal chassis of a computer that

is plugged into a grounded outlet. Wear a grounded wrist strap

throughout the entire installation procedure.

Wool and synthetic clothes, carpets, plastics and Styrofoam are

contributors to electrostatic build-up. Static discharge can damage

sensitive components in your drive and computer.

• Handle the drive by its edges or frame only.

,

Line driver

(transmitter or transceiver)

+2.85V

110

ohms

+2.85V

110

ohms

Flat cable pair

Line receiver

ANSI SCSI

compatible

circuit

ANSI SCSI

compatible circuit

12 Decathlon Family Product Manual, Rev. B

• The drive is extremely fragile—handle it with care. Do not press down

on the drive top cover.

• Always rest the drive on a padded, antistatic surface until you mount

it in the host system.

• Do not touch the connector pins or the printed circuit board.

• Do not remove the factory-installed labels from the drive or cover them

with additional labels. If you do, you void the warranty. Some factoryinstalled labels contain information needed to service the drive. Others

are used to seal out dirt and contamination.

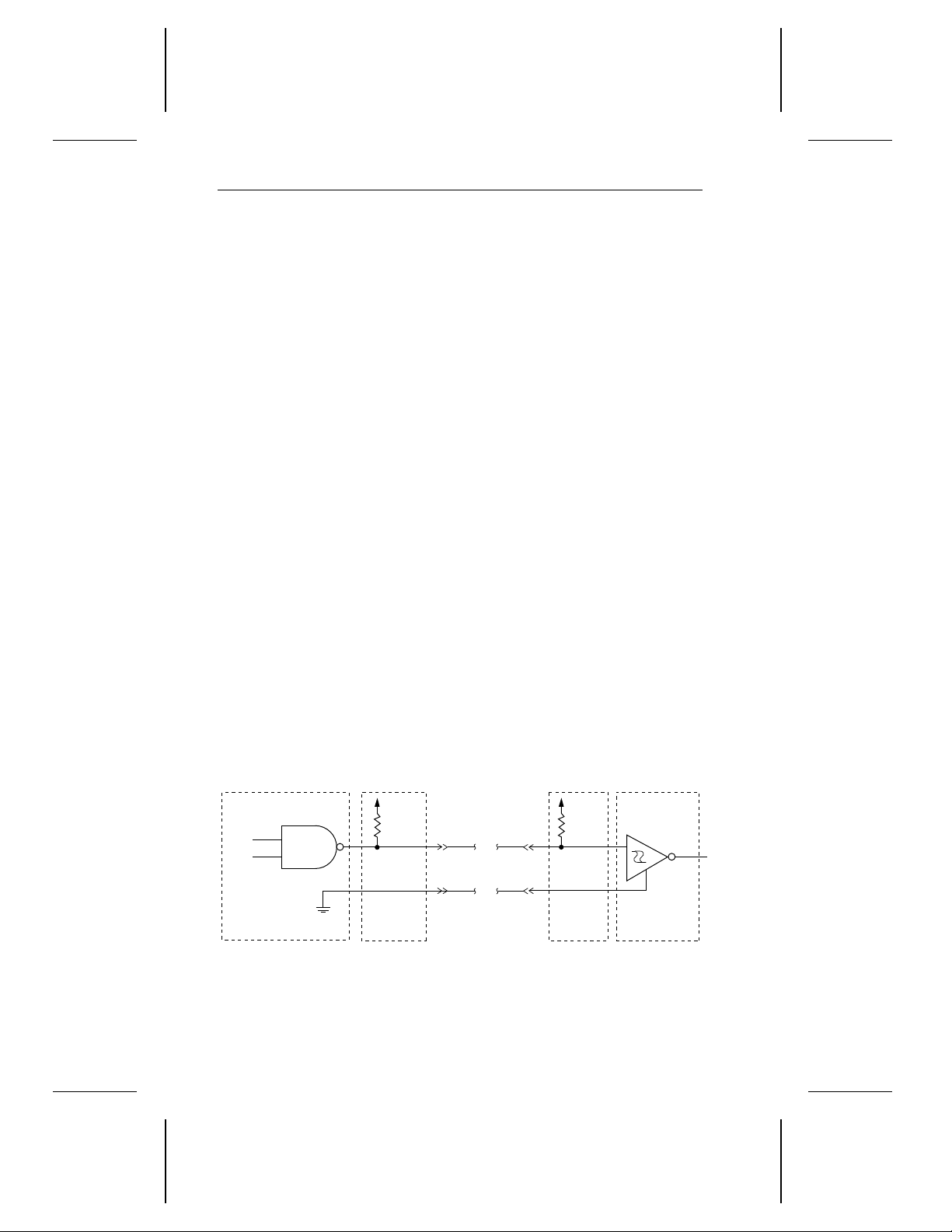

2.3 Electrical interface

Decathlon family drives are designed to use singled-ended interface

signals. They employ singled-ended drivers and receivers and active

terminator circuitry. Figure 2 shows a single-ended transmitter and

receiver without the active terminator circuitry.

• Transmitter characteristics. The drive uses an ANSI SCSI-compat-

ible, open-collector, single-ended driver. This driver is capable of

sinking a current of 48 mA with a low-level output voltage of 0.4 volts.

• Receiver characteristics. The drive uses an ANSI SCSI single-

ended receiver with hysteresis gate or equivalent as a line receiver.

The loss in the cable is defined as the difference between the voltages

of the input and output signals, as shown below:

Logic level Driver output (x) Receiver input (x)

Asserted (1)

Negated (0)

Figure 2. Singled-ended transmitter and receiver

≤

x ≤ 0.4V 0.0V ≤ x ≤ 0.8V

0.0V

2.5V

≤ x ≤ 5.25V 2.0V ≤ x ≤ 5.25V

Decathlon Family Product Manual, Rev. B 13

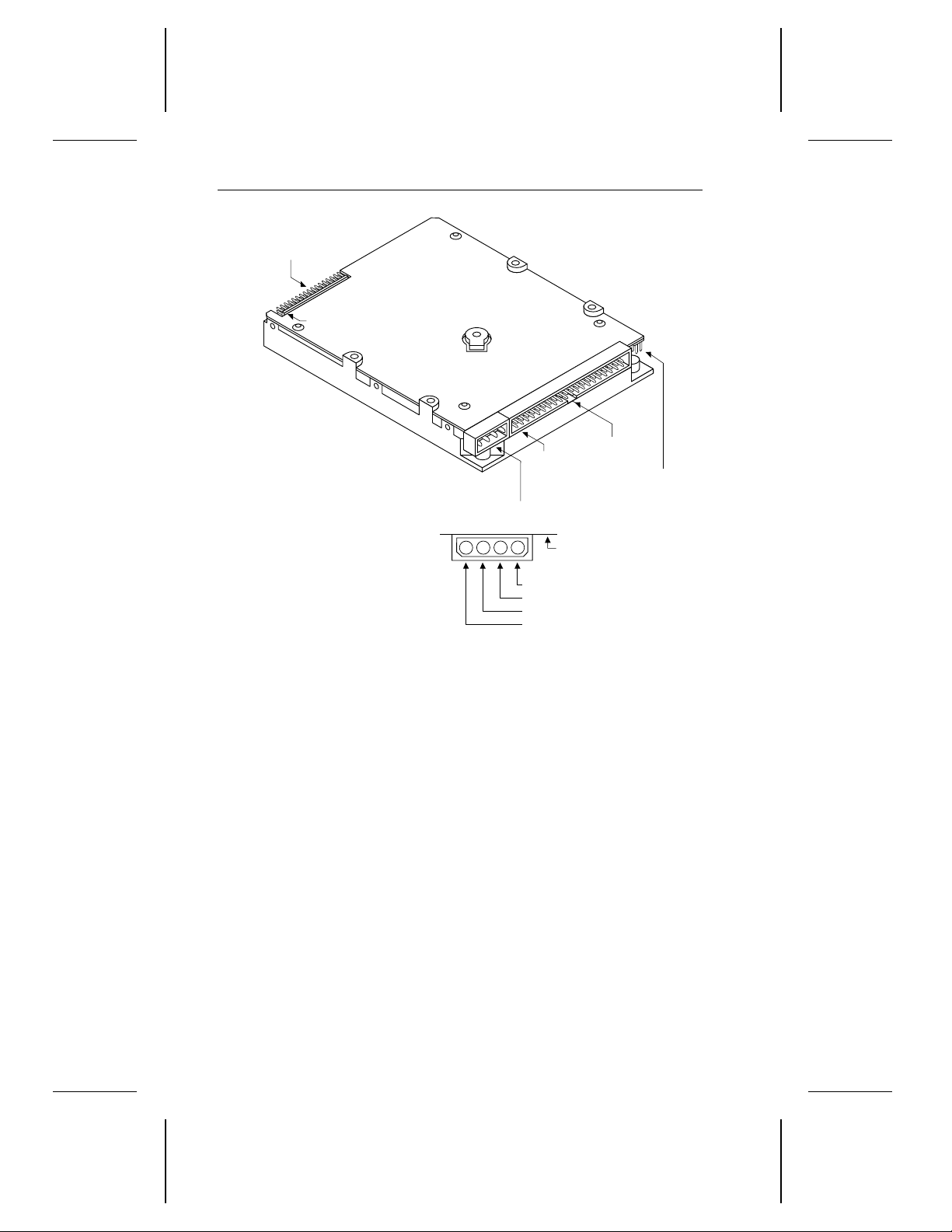

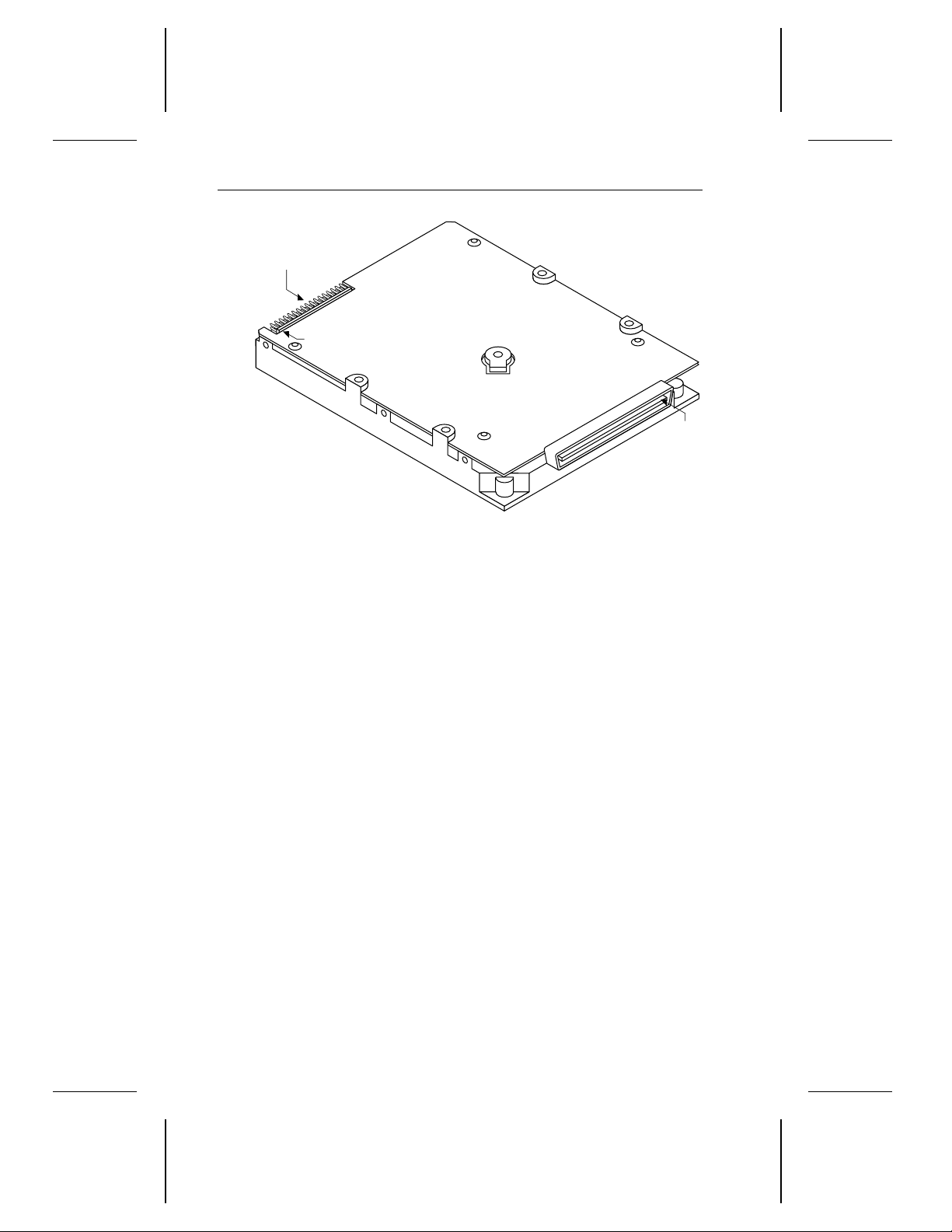

2.4 Interface and connector configuration

The Seagate ST5660N and ST5660NC drives are differentiated by their

connectors. The ST5660N comes with a standard 50-pin interface connector, a standard 4-pin power connector and an auxiliary SCSI ID block.

The ST5660NC comes with a single, 80-pin SCA interface connector.

The connectors for both drives are discussed below. To minimize noise,

use unshielded mating connectors.

2.4.1 ST5660N interface connector

The ST5660N uses a standard 50-pin, nonshielded, keyed connector.

The connector consists of two rows of 25 male contacts 0.100 inches

apart. The location of Pin 1 is shown in Figure 3 on page 14. Recommended mating connectors are listed below with their part numbers.

Part numbers for mating 3M connectors compatible with the drive are

listed below. These connectors do not have a center key and are

available with or without a strain relief.

No strain relief

No center key

Closed end

(for cable ends)

Open end

(for daisy chain)

Part numbers for mating Molex connectors compatible with the drive

are listed below. These connectors have a center key.

Closed end

(for cable ends)

Open end

(for daisy chain)

Below are part numbers for strain reliefs that can be used with the Molex

connectors.

Molex strain relief,

preferred version

in Europe

Molex strain relief,

preferred version

in Japan

3M

3425-7000

3M

3425-6000

Molex

39-51-2504

Molex

39-51-2501

Molex 90170-0050

Molex 15-25-1503

With strain relief

No center key

3M

3425-7050

3M

3425-6050

J3. Standard

power connector

1

2

3

4

J1. Interface

connector

+5V

+5V return

+12V return

+12V

Circuit

board

pin 1

J8.

Options jumper block

pin 1

J5.

Auxiliary

selection

for

SCSI ID

14 Decathlon Family Product Manual, Rev. B

Figure 3. ST5660N connectors

Decathlon Family Product Manual, Rev. B 15

2.4.2 ST5660N interface connector pin assignments

The table below shows the pin assignment for the 50-pin interface

connector. A minus sign (−) indicates an active-low signal.

Signal

Signal name

DB(0)– 2 1

DB(1)– 4 3

DB(2)– 6 5

DB(3)– 8 7

DB(4)– 10 9

DB(5)– 12 11

DB(6)– 14 13

DB(7)– 16 15

DB(P)– 18 17

Ground 19–22 —

Reserved 23–25 —

Terminator power 26 —

Reserved 27–28 —

Ground 29–30 —

ATN– 32 31

Ground 33–34 —

BSY– 36 35

ACK– 38 37

RST– 40 39

MSG– 42 41

SEL– 44 43

C/D– 46 45

REQ– 48 47

I/O– 50 49

Caution. Do not connect pin 25 to ground. If you plug in the connector

upside down, the terminator power on pin 26 is shorted to

ground. This may damage the drive.

pin number

Ground

pin number

16 Decathlon Family Product Manual, Rev. B

2.4.3 ST5660NC interface connector

The ST5660NC uses an 80-pin, male, SCA connector. It is a single piece

connector that allows power for the drive to be transmitted through the

SCSI bus. The remote LED, motor start options and additional binary

codes are also placed on the SCSI bus. Pin 1 is shown in Figure 4 on

page 18.

We recommend the AMP Champ 50 mating connector (part number

94-0682-10-1).

2.4.4 ST5660NC interface connector pin assignments

The following table shows the pin assignments for the ST5660NC 80-pin

connector. A minus sign (−) indicates an active-low signal.

Signal Pin number Signal Pin number

+12V 1 12V GND 41

+12V 2 12V GND 42

+12V 3 12V GND 43

+12V 4 12V GND 44

NC 5 NC 45

NC 6 NC 46

NC 7 GND 47

NC 8 GND 48

NC 9 GND 49

NC 10 GND 50

IO− 11 GND 51

REQ− 12 GND 52

C/DQ− 13 GND 53

SEL− 14 GND 54

MSG− 15 GND 55

RST− 16 GND 56

ACK− 17 GND 57

BSY− 18 GND 58

ATN− 19 GND 59

DBP− 20 GND 60

DB7− 21 GND 61

DB6− 22 GND 62

DB5− 23 GND 63

DB4− 24 GND 64

DB3− 25 GND 65

Decathlon Family Product Manual, Rev. B 17

Signal Pin number Signal Pin number

DB2− 26 GND 66

DB1− 27 GND 67

DB0− 28 GND 68

NC 29 GND 69

NC 30 GND 70

NC 31 GND 71

NC 32 GND 72

NC 33 GND 73

+5V 34 5V GND 74

+5V 35 5V GND 75

+5V 36 5V GND 76

NC 37 LEDC

MTRON

SCSIA0

SCSIA2

2

4

4

38 DLYDST

39 SCSIA1

40 SCSIA3

1

3

4

4

77

78

79

80

Notes 1 to 4 indicate pins also represented on the options jumper block.

Notes:

1. Drive activity signal; same as remote LED setting.

2. Asserted by host to enable Motor Start option (starts motor

through the SCSI bus command). Settings are mutually exclusive option.

3. Asserted by host to enable the Delayed Motor Start option

(motor starts at power on or after a delay of 12 seconds times

the drive ID). This is a mutually-exclusive option.

4. Binary code on A0, A1, A2 and A3 asserted by host to set up

SCSI bus ID in drive.

pin 1

J8.

Options jumper block

pin 1

18 Decathlon Family Product Manual, Rev. B

Figure 4. ST5660NC connectors

2.5 Interface cable requirements

A characteristic impedance of 100 ohms +10% is recommended for the

unshielded flat or twisted pair interface cable. However, most available

cables have a somewhat lower characteristic impedance. To minimize

discontinuities and signal reflections, do not use cables of different

impedances in the same bus. Implementation may require tradeoffs in

wielding effectiveness, cable length, the number of loads and the transfer

rates to achieve satisfactory system operation. If shielded and unshielded cables are mixed within the same bus, the effect of impedance

mismatch must be carefully considered. This is especially important for

maintaining adequate margin for Fast SCSI transfer rates.

To minimize noise, use 28 AWG or larger 50-conductor flat cable or

25-conductor twisted pair ribbon cable. The following are part numbers

for nonshielded flat cables we recommend:

Part Manufacturer

Flat Cable 3M-3365-50

Twisted Pair Spectra Twist-N-Flat 455-248-50

Decathlon Family Product Manual, Rev. B 19

2.5.1 Interface cable length for asynchronous

operation

The SCSI interface cable must meet the following requirements for

normal operation:

• The cable cannot be longer than 6.0 meters.

• Cable stubs cannot be more than 0.1 meter long and must be

separated by at least 0.3 meter.

2.5.2 Interface cable for Fast SCSI operation

When using fast synchronous data transfer rates, the SCSI interface

cable must meet the following additional requirements:

• The cable cannot be longer than 3.0 meters.

• The cable should not attenuate a 5 MHz signal more than 0.095 dB

per meter.

• The DC resistance at 20°C must not exceed 0.230 ohms per meter.

• A shielded, twisted-pair cable should not have a propagation delay

delta greater than 20 nsec per meter.

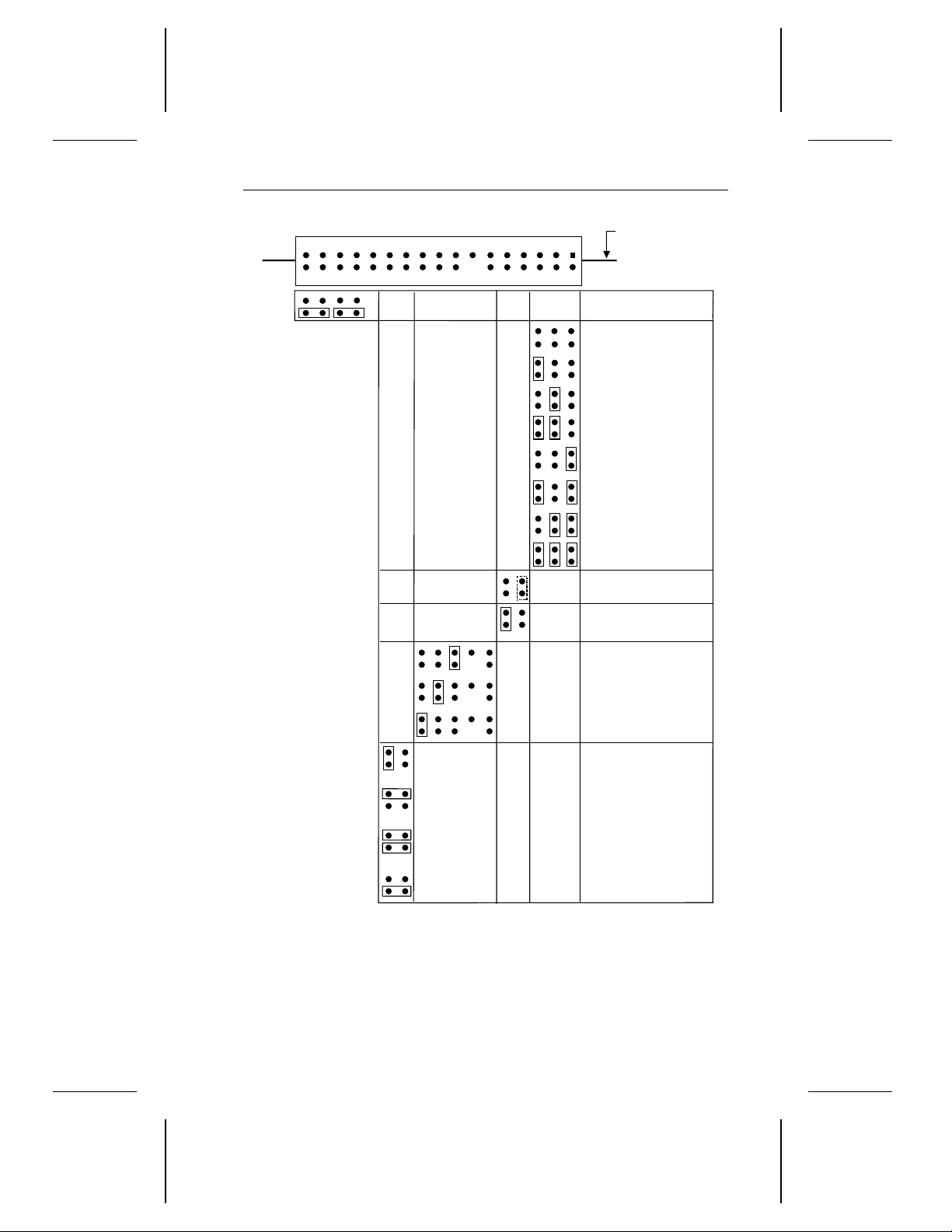

2.6 Options jumper block

Both ST5660N and ST5660NC have the options jumper block at J8 (see

Figure 3 on page 14 and Figure 4 on page 18 for its location). The options

jumper block allows you to manually:

• Enable or disable active termination

• Set the SCSI ID address

• Select the terminator power source

• Enable parity

• Activate the motor start/stop option

• Attach a remote LED

These functions are represented on the options jumper block for both

drives. Figure 5 on page 21 shows how to configure the jumpers.

However, the ST5660NC allows you to control some of these functions

through the SCSI bus (the pin assignment chart on page 17 shows the

functions that can be programmed through the bus).

20 Decathlon Family Product Manual, Rev. B

The jumper block accepts 2-mm jumpers. Spare jumpers are included

with the drive attached to the pins shown in the figure. If you need

additional jumpers, use the jumpers listed below or equivalent.

Manufacturer Part number

Seagate 13211-001

Du Pont 89133-001

Methode 8618-202-70

2.6.1 Active Termination

The ST5660N and ST5660NC use a jumper on the options jumper block

to enable active termination. You can order the drive with the active

termination enabled or disabled. Active termination is enabled when a

jumper is placed on pins 19 and 20 of the options jumper block. Active

termination is disabled when there is no jumper on pins 19 and 20 of the

options jumper block.

2.6.2 SCSI address

SCSI ID is set on the ST5660N and ST5660NC using pins 1 and 2, 3 and

4 and 5 and 6 on the options jumper block. The drives are shipped with

jumpers on pins 1 and 2 and pins 3 and 4 for configuring the SCSI ID.

This means the drives have a default address of SCSI ID 3. You may

need to reset the drive’s address for your operation. Refer to your host

adapter reference manual for its preferred addressing scheme.

2.6.3 Terminator power source selection

To select the termination power source, install jumpers as follows:

• To select the drive power connector as the termination power source

for the resistor packs, install a jumper on pins 23 and 24 of the options

jumper block.

• To select the SCSI connector as the termination power source for the

resistor packs, install a jumper on pins 21 and 23 of the options jumper

block.

• To provide terminator power to the SCSI connector and the drive

terminator packs, install jumpers on pins 21 and 23 and pins 22 and 24

of the options jumper block. This is the default.

• To provide terminator power to the SCSI connector from the drive

power connector only, install a jumper on pins 22 and 24 of the options

jumper block.

SCSI ID 0

SCSI ID 1

SCSI ID 2

SCSI ID 3

SCSI ID 4

SCSI ID 5

Note.

1. All other pins

are reserved. Do

not use them.

2. Jumpers on

pins 28 and 30

and 32 and 34

are spares; these

pins do not

require jumpers.

SCSI ID 6

SCSI ID 7

Remote LED

connection

Reserved

Do not use

Remote start

Parity enable

Terminator

disable

Power from drive

power connector

Power from

SCSI bus

Power from drive

power connector

and to SCSI bus

Power to SCSI

bus only

J8. Options jumper block

Circuit board

side up.

111291078563

4

13

14

1

2

15161718192021

22

3334313229302728252623

24

Spares

Decathlon Family Product Manual, Rev. B 21

Figure 5. Options jumper block (J8) settings

Loading...

Loading...