. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. . . . .

Medalist Pro Family

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. . . . .

Medalist Pro 2520 (ST52520A)

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. . . . .

Medalist Pro 2160 (ST52160A)

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. . . . .

ATA Interface drives

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. . . . .

Product Manual

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. . . . . . . . . . .

Medalist Family

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Medalist Pro 2520 (ST52520A)

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. . . . . . .

Medalist Pro 2160 (ST52160A)

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. . . . . . .

ATA Interface drives

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. . . . . . .

Product Manual

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. . . . . . .

© 1997 Seagate Technology, Inc. All rights reserved

Publication Number: 36347-101, Rev. C, February 1997

Seagate, Seagate Technology and the Seagate logo are registered

trademarks of Seagate Technology, Inc. Medalist is a trademark of

Seagate Technology, Inc. Other product names are trademarks or registered trademarks of their owners.

Seagate reserves the right to change, wi thout notice, product of ferings

or specifications. No part of this publication may be reproduced in any

form without written permission from Seagate Technology, Inc.

Medalist Pro 2520/2160 Product Manual, Rev. C iii

Contents

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Quick specification chart . . . . . . . . . . . . . . . . . . . . . . 3

1.0 Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.1 Formatted Capacity . . . . . . . . . . . . . . . . . . . . . . 5

1.1.1 Standard Configuration . . . . . . . . . . . . . . . . . . 5

1.2 Physical organization . . . . . . . . . . . . . . . . . . . . . 6

1.3 Functional specifications . . . . . . . . . . . . . . . . . . . 6

1.4 Physical dimensions . . . . . . . . . . . . . . . . . . . . . . 7

1.5 Seek time . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.6 Multisegmented cache buffer . . . . . . . . . . . . . . . . . 7

1.7 Start and stop times . . . . . . . . . . . . . . . . . . . . . . 8

1.8 Typical power-up and power-down sequence . . . . . . . . . 8

1.9 Power-up sequence . . . . . . . . . . . . . . . . . . . . . 9

1.9.1 Power-down sequence . . . . . . . . . . . . . . . . . . 9

1.10 Auto-park . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

1.11 Power specifications . . . . . . . . . . . . . . . . . . . . . 9

1.11.1 Power management . . . . . . . . . . . . . . . . . . . 9

1.11.2 Power consumption . . . . . . . . . . . . . . . . . 11

1.12 Input noise . . . . . . . . . . . . . . . . . . . . . . . . . 11

1.13 Environmental specifications . . . . . . . . . . . . . . . . 11

1.13.1 Ambient temperature . . . . . . . . . . . . . . . . . 11

1.13.2 Temperature gradient . . . . . . . . . . . . . . . . . 12

1.13.3 Altitude . . . . . . . . . . . . . . . . . . . . . . . . 12

1.13.4 Relative humidity . . . . . . . . . . . . . . . . . . . 12

1.14 Shock and vibration . . . . . . . . . . . . . . . . . . . . 12

1.15 Acoustics . . . . . . . . . . . . . . . . . . . . . . . . . . 13

1.16 Reliability . . . . . . . . . . . . . . . . . . . . . . . . . . 13

1.17 Agency listings . . . . . . . . . . . . . . . . . . . . . . . 13

1.18 Electromagnetic Compliance for the European Union . . . 14

iv Medalist Pro 2520/2160 Product Manual, Rev. C

1.19 FCC verificatio n . . . . . . . . . . . . . . . . . . . . . . 14

2.0 Configuring and mounting the drive . . . . . . . . . . . . . 17

2.1 Handling and static-discharge precautions . . . . . . . . . 17

2.2 I/O cable and connector. . . . . . . . . . . . . . . . . . . 18

2.3 Power connector . . . . . . . . . . . . . . . . . . . . . . . 18

2.4 Options jumper block . . . . . . . . . . . . . . . . . . . . 19

2.4.1 Master/slave configuration . . . . . . . . . . . . . . 20

2.4.2 Alternate capacity jumper . . . . . . . . . . . . . . . . 21

2.4.3 Remote LED connection . . . . . . . . . . . . . . . . 21

2.4.4 Cable-select option . . . . . . . . . . . . . . . . . . . 21

2.5 Mounting the drive . . . . . . . . . . . . . . . . . . . . . . 22

3.0 ATA interface . . . . . . . . . . . . . . . . . . . . . . . . . 25

3.1 ATA Interface connector pin assignments . . . . . . . . . . 25

3.2 Command set . . . . . . . . . . . . . . . . . . . . . . . . 27

3.2.1 Identify drive command (EC

3.2.2 Set Features command (EF

. . . . . . . . . . . . . 29

H)

) . . . . . . . . . . . . . 32

H

3.2.3 Standby timer timeout period . . . . . . . . . . . . . . 34

3.2.4 Sleep command (99

, E6H) . . . . . . . . . . . . . . 34

H

3.2.5 Auto Relocation . . . . . . . . . . . . . . . . . . . . . 34

3.2.6 S.M.A.R.T. command (B0

) . . . . . . . . . . . . . . 35

H

Appendix. Timing diagrams . . . . . . . . . . . . . . . . . . . . 37

Medalist Pro 2520/2160 Product Manual, Rev. C v

Figures

Figure 1. Typ i cal startup cur rent profile . . . . . . . . . . . . . . . . 8

Figure 2. ATA interface connector . . . . . . . . . . . . . . . . . 18

Figure 3. Connectors . . . . . . . . . . . . . . . . . . . . . . . . 19

Figure 4. Configuration settings . . . . . . . . . . . . . . . . . . . 20

Figure 5. Connecting cable-selected drives . . . . . . . . . . . . . 22

Figure 6. Mounting dimensions . . . . . . . . . . . . . . . . . . . 23

Figure 7. ATA interface connector pin assignments . . . . . . . . 26

Figure 8. Programmed I/O timing without IORDY . . . . . . . . . . 37

Figure 9. Programmed I/O timing with IORDY . . . . . . . . . . . 38

Figure 10. Multiword DMA timing . . . . . . . . . . . . . . . . . . 39

Medalist Pro 2520/2160 Product Manual, Rev. C 1

Introduction

This manual describes the functional, mechanical and interface specifications for the Medalist

®

Pro 2520 and Medalist Pro 2160 hard disc

drives. The drives are referred to throughout this manual by their model

numbers, ST52520A for the Medalist Pro 2520 and ST52160A for the

Medalist Pro 2160.

Seagate

®

desktop products take a step into the future with the ST52520A

and ST52160A. These drives feature MR heads and PRML recording

technology, Fast ATA-2 performance, segmented cache, embedded

servo technology, low noise, power management and S.M.A.R.T. capabilities.

MR heads and PRML recording technology provide the drives with

increased areal density. This means that more data can be stored on a

single disc. Only two discs are used in the ST52520A and ST52160A

drives.

Fast ATA-2 performance means that the drives support P IO mode 4,

multiword DMA mode 2 transfer modes and multiple block read/write.

When the host chooses either transfer mode, the driv es provide burs ttransfer rates of up to 16.6 Mbytes per second. The multiple block

read/write feature allows the drives to store several blocks of data in

cache and transfer them in a single burst.

These drives use a 128-Kbyte segmented cache. Segmenting the cache

provides a designated area where blocks of contiguous read or write data

can be staged for transfer in a single burst.

The ST52520A and ST52160A drives have other features that ensure

fast data throughput. Embedded servo technology allows the drives to

position the heads for data retrieval efficiently and accurately while

eliminating the periodic thermal recalibration t hat can interrupt during

data transfers. These drives also use a 16-bit microprocessor and an

intelligent controller t hat provides data streaming: direct data transfers

between the drive and the host without microprocessor intervention.

These features allow for a sus tained data-transfer rate that facilitates

video playback and other multimedia operations.

These drives support Active, Idle and Standby power-management

modes. Power-saving modes can be controlled by the host computer.

Standby mode reduces power consumption to 1 watt (typical) while

retaining drive accessibility.

Self-Monitoring, Analysis and Reporting Technology (S.M.A.R.T.) is

available on these drives. Implementation of this feature is discussed on

page 35. To use the feature, you must have a BIOS, a software driver or

application software that supports S.M.A.R.T.

2 Medalist Pro 2520/2160 Product Manual, Rev. C

The ATA commands with specific applications for these drives and the

Seagate-unique commands the drives use are discussed in Section 3.0

on page 25. A complete list of the commands the drives support are found

in the table on page 27.

The following is a summary of the drives’ features:

Capacity

• 2. 564 and 2.113 Gbytes formatted

• LBA translation support

• Av ailable software driver that surpasses the 528-Mbyte barrier and

4,096 cylinder barrier limited by some system BIOSs

• Av ailable software driver that provides expanded 32-bit disk access

support for Windows 3.

Performance

• Fast ATA-2 (Supports multiword DMA mode 2 and P IO mode 4 for up

to 16.6-Mbyte-per-second burst transfer rates. Supports multiple

block read/write.)

• 128-K byte segmented buffer

• 12-msec average read seek time

x

• 13-msec average write seek time

• Data streaming

Energy efficiency

• Activ e, Idle and Standby power-management modes

• 1 watt typical power dissipation rating in Standby mode

Medalist Pro 2520/2160 Product Manual, Rev. C 3

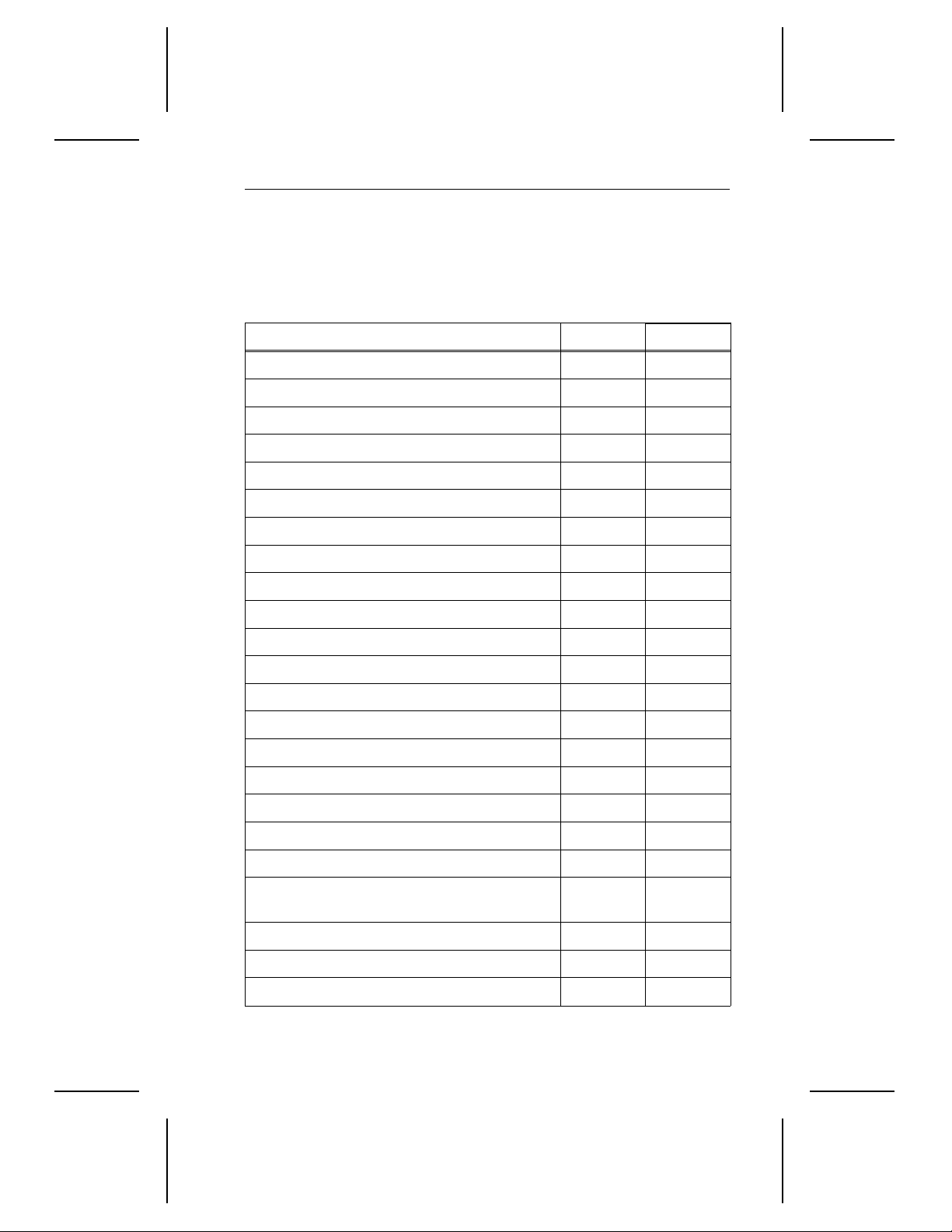

Quick specification chart

The following table serves as a quick reference for the drives’ performance specifications. These and other specifications are discussed in

“Specifications” on page 5.

Drive specification ST52520A ST52160A

9

Guaranteed capacity (Gbytes) (×10

Guaranteed sectors 5,009,760 4,127,760

Bytes per sector 512 512

Sectors per track 63 63

Logical read/write heads 16 16

Logical cylinders 4,970 4,095

Physical cylinders 6,536 6,536

Physical read/write heads 4 4

Physical discs 2 2

Areal density (Mbits/sq. in) 928.8 805.2

bytes) 2.564 2.113

Data zones 19 19

Recording density (bits per inch) 138,011 119,609

Track density (tracks per inch) 6,730 6,730

Spindle speed (RPM) 5,397 5,397

Track-to-track se ek time (msec typical) 3.5 3.5

Average read seek time (msec typical) 12 12

Average write seek time (msec typical) 13 13

Full-stroke seek time (msec typical) 25 25

Average latency (msec) 5.58 5.58

Internal data-transfer rate

(Mbits per sec max) 63 to 116

External transfer rate (Mbytes per sec max) 16.6 16.6

Cache buffer (Kbytes) 128 128

ECC on-the-fly (bits) 65 65

continued

55 to 97

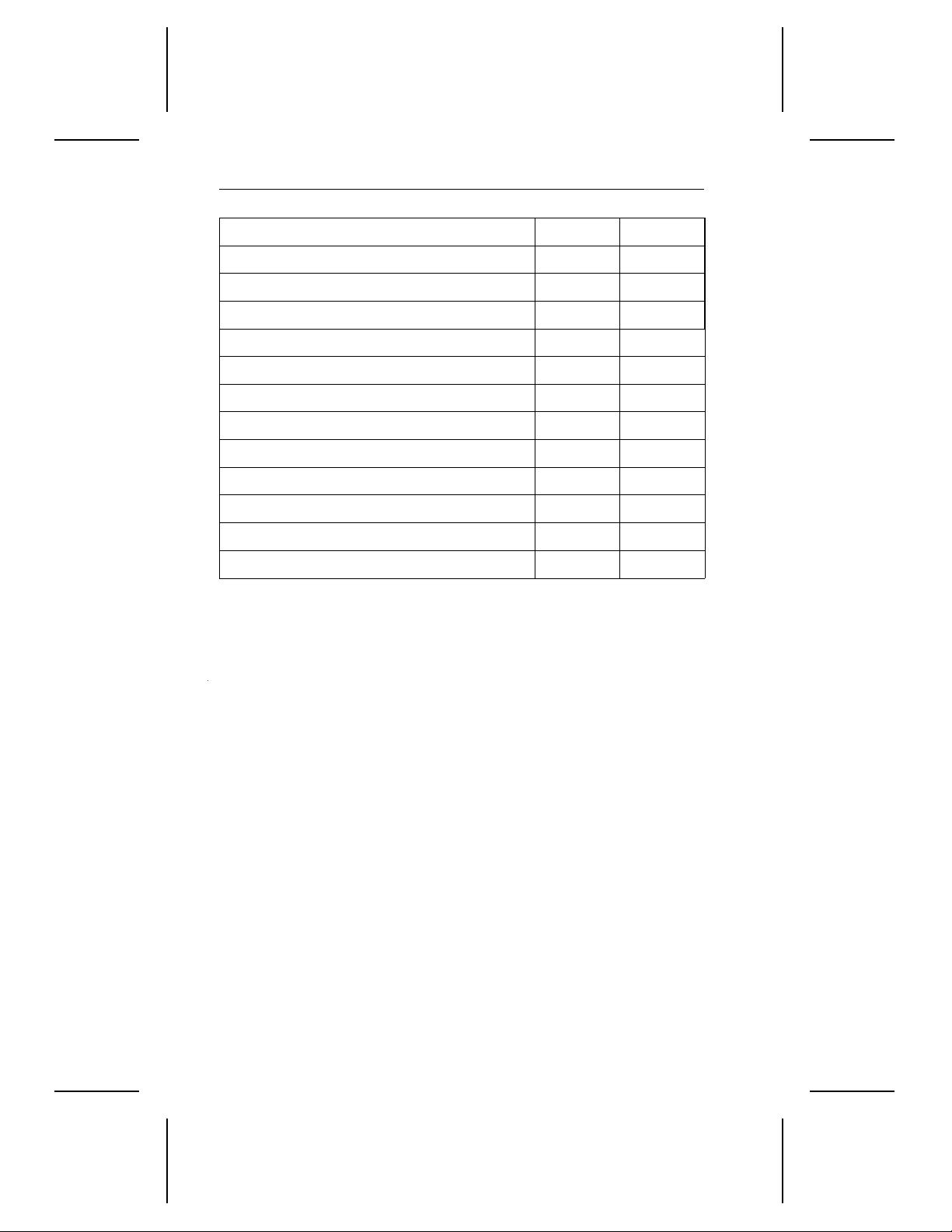

4 Medalist Pro 2520/2160 Product Manual, Rev. C

Drive specification ST52520A ST52160A

Height (inches max) 0.748 0.748

Width (inches max) 4.01 4.01

Depth (inches max) 5.38 5.38

Typical weight (lb) 1.0 1.0

Spinup current (max) 1.9A 1.9A

Seek power (typical) 7.9W 7.9W

Read/Write power and current (typical) 7.5W 7.5W

Idle total power (typical) 7.5W 7.5W

Standby/Sleep total power (typical) 4.3W 4.3W

Voltage tolerance (including noise): +5V ± 5% ± 5%

Voltage tolerance (including noise): +12V ± 5% ± 5%

Operating temperature (°C) 5 to 55°C 5 to 55°C

Medalist Pro 2520/2160 Product Manual, Rev. C 5

1.0 Specifications

1.1 Formatted Capacity

Medalist Pro drives are low-level formatted at the factory. You cannot

low-level format them.

These drives suppo rt cylinder-he ad-sec tor (CHS) and log ical-bloc k addre ssing (LBA) translatio n modes . You can use the Ident ify drive (EC

to verify the address modes the drives support, the number of cylinders,

sectors per track, t ot al num ber of sectors, heads and other paramete rs . Th e

Identify drives param eters ar e listed in Section 3.2.1 on page 29.

Notes:

. DOS cannot acce ss more t han 2.14 7 Gbytes per partition. Yo u

1

must create 2 or mo re partitions to access the drive’s full ca pacity.

One Mbyte equals one million bytes.

2.

. If the system BIOS does not support more than 4,096 cylin-

3

ders, it can cause the computer to hang during boot, or it can

truncate or wrap the cylinders. To resolve this issue the system BIOS needs to be modified: the cylinder register or variable must be increased from 12-bits to 16-bits to

accommodate more than 4,096 cylinders.

) comma nd

H

1.1.1 Standard Configuration

ST52160A CHS LBA

Cylinders 4,095 N/A

Heads 16 N/A

Sectors 63 N/A

Guaranteed sectors 4,127,760

Guaranteed capacity (Gbytes) 2.113

ST52520A CHS LBA

Cylinders 4,970 N/A

Heads 16 N/A

Sectors 63 N/A

Guaranteed sectors 5,009,760

Guaranteed capacity (Gbytes) 2.564

6 Medalist Pro 2520/2160 Product Manual, Rev. C

1.2 Physical organization

ST52520A ST52160A

Read/write heads 4 4

Discs 2 2

1.3 Functional specifications

ST52520A ST52160A

Interface ATA ATA

Recording method PRML (0,4,4) PRML (0,4,4)

External data burst transfer rate:

DMA mode 2 (Mbytes per sec)

PIO mode 4 (Mbytes per sec)

Internal data-transfer rate

(Mbits per sec)

Spindle speed (RPM) 5,397 ± 0.5% 5,397 ± 0.5%

Cache size (Kbytes) 128 128

Logical cylinders 4,970 4,095

Physical cylinders 6,536 6,536

Bytes per sector 512 512

Areal density (Mbytes/sq. in) 928.8 805.2

Data zones 19 19

Recording density, max (BPI) 138,011 119,609

Track density (TPI) 6, 730 6,730

See Figure 10 on page 39 for mutilword DMA timing specifications

Note.

See Figure 8 on page 37 and Figure 9 on page 38 for PIO timing

specifications.

16.6

16.6

63 to 116 55 to 97

16.6

16.6

.

Medalist Pro 2520/2160 Product Manual, Rev. C 7

1.4 Physical dimensions

The mounting dimensions are shown in Figure 6 on page 23.

Height, max 0.748 inch (19 mm)

Width, max 4.01 inches (101.8 mm)

Depth, max 5.38 inches (136.6 mm)

Weight 1.0 lb (0.45 Kg)

1.5 Seek time

Seek value is the interval between the time the actuator begins to move

and the time the head has settled over the target track. Seek time is a

true statistical average of at least 10,000 measurements of seek time.

All measurements are taken under nominal conditions of temperature

and voltage with the drive mounted horizontally. The specifications in the

table below are defined as follows:

• Track -to-track seek time is the average of all possible s ingle-track

seeks in both directions.

• Average seek time is measured by executing seeks in both directions

between random cylinders.

• Ful l-stroke seek time is half the time needed to seek from track 0 to

the maximum track and back to track 0.

Track-to-track

seek time

3.5 msec typ

4.5 msec max

Host overhead varies between systems and cannot be specified.

Note.

Drive internal overhead is measured by issuing a no-motion seek.

Overhead is typically less than 0.5 msec.

Average/typical

seek time

11 msec seek

12 msec read

13 msec write

Full-stroke

seek time

25 msec typ

27 msec max

Average

latency

5.58 msec

1.6 Multisegmented cache buffer

The Medalist Pro ST52520A and ST52160A drives are available with a

128-Kbyte, multisegmented cache buffer that improves performance by

reducing access times.

Read look-ahead.

logical sectors, after the last requested sector, into a buffer befor e the

computer requests the additional sectors. The c ache buffer stor es data

The drive uses the read segments to store additional

)

8 Medalist Pro 2520/2160 Product Manual, Rev. C

from the start of a read until the buffer segment is full or until another

command is received.

Write immediate

. The drive uses the write segment to store write

commands and data. After the drive receives all of the data for the

command, it issues a write complete. Then, the drive writes the data to

the disc.

Write merging.

The drive accepts contiguous write commands and

executes them as one command.

1.7 Start and sto p times

Within 20 seconds after power is applied, the drive is ready. Within 15

seconds after power is removed, the drive spindle stops rotating.

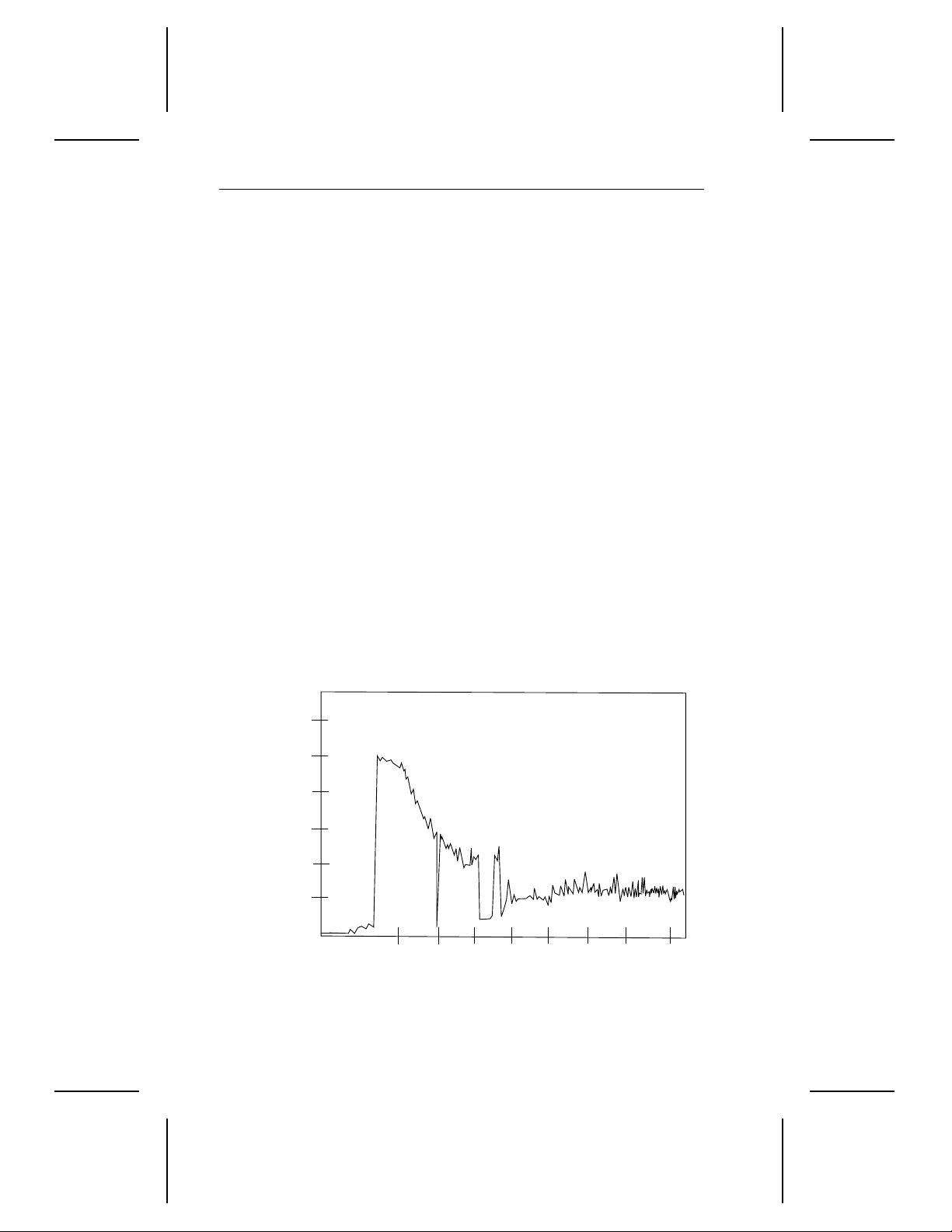

1.8 Typical power-up and power-down sequence

This section describes typical power-up and power-down sequences to

assist you in evaluating the dri ve’s performance. They are not performance specifications. A typical startup current profile is shown in Figure 1.

Startup current profiles are unique for each drive.

Current (mA)

1,200

1,000

800

600

400

200

2 4

Figure 1. Typical startup current p rofi l e

8

6

Time (seconds

10

12

14

16

Medalist Pro 2520/2160 Product Manual, Rev. C 9

1.9 Power-up sequence

Power is applied to the drive.

1.

When power is applied, the LED stays on for about 1 second.

2.

The spindle motor reaches operating speed in about 4 seconds.

3.

The magnetic actuator-lock releases the actuator.

4.

The drive achieves final speed-control lock.

5.

The heads position over track 0 and the drive is ready.

6.

1.9.1 Power-down sequence

Caution.

The power is turned off.

1.

Within 15 seconds, the drive spindle stops rotating.

2.

The read/write heads automatically move to the landing zone, which

3.

is inside the maximum data cylinder.

The magnetic actuator-lock mechanism locks the arm. This completes

4.

the power-down sequence.

Do not move the drive until the motor has come to a complete

stop.

1.10 Auto-park

During power-down, the read/write heads automatically move to the

landing zone. The heads park inside the maximum data cylinder and the

magnetic actuator-lock engages. When power is applied, the heads

recalibrate to track 0.

1.11 Power specifications

1.11.1 Power management

The drive supports Active, Idle and Standby power-management modes.

The power-management commands the drive supports are listed in the

table on page 27. The table on page 11 shows the average typical power

consumption rates for each power-management mode. The test criteria

for each mode is defined below. The Idle and Standby timers are disabled

at the factory.

All measurements were taken at t he dr ive power c onnector. A true RMS

10 Medalist Pro 2520/2160 Product Manual, Rev. C

meter is used to measure all modes except Standby. A DMM is us ed for

Standby measurements.

1.11.1.1 Active mode

During the Active mode, the drive is involved in spinup, seeking or

read/write activities. The table on page 11 shows the typical power-consumption rates for these activities.

•

Spinup

brings the spindle and discs up to operating speed. Power in this mode

is defined as the peak power after starting spinup.

•

Seeking.

are moved to a specific location on the disc surface in preparation for

reading from or writing to the disc. Read/write electronics are powered

down but servo electronics are active. Typical power is defined as the

power average of executing random seeks with a 2-revolution (22.2

msec) dwell between Seek commands.

•

Read/write.

electronics are activated and t he servo is on track. The driv e reads

from or writes to the disc.

. Spinup mode is entered from the Standby mode. The drive

Seek mode is entered from Idle mode. The read/write heads

Read/write mode is entered from Idle mode. Read/write

1.11.1.2 Idle mode

The Idle mode is entered 1 minute after the last disk I/O act ivity. The

motor is up to speed and the actuator is repositioned once every minute.

This mode uses an algorithm that minimizes head media interface

stresses. The drive can enter Idle mode from eit her Active or Standby

mode.

1.11.1.3 Standby mode

The spindle is stopped, t he heads are parked in the landing zone, the

actuator is latched and some of the drive electronics are powered down.

When recovering from Standby or Sleep mode, you must allow

Note.

the drive to post ready before reporting a timeout. The drive can

take up to 20 seconds to post ready. In a master and slave

configuration, the master can wait up to 31 seconds for the slave

to complete diagnostics before posting ready.

1.11.1.4 Sleep mode

The sleep mode implementation is the same as Standby mode.

Medalist Pro 2520/2160 Product Manual, Rev. C 11

1.11.2 Power consumption

In the table below, the values apply at the drive power connector. Current

was measured with an RMS DC ammeter.

Read/

Spinup Seeking

Current at +12V

write Idle Standby

Amps max

RMS amps typ

Watts typ

Current at +5V

RMS amps typ

Watts typ

Power

Total watts typ

1.12 Input noise

Voltage tolerance

(including noise)

Input noise frequency

(max)

Input noise

(max, peak-to-peak)

1.9A — — — —

— .49 .45 .45 .19

— 5.8 5.4 5.4 2.3

— .42 .42 .42 .40

— 2.1 2.1 2.1 2.0

— 7.9W 7.5W 7.5W 4.3W

+5V +12V

± 5% ± 5%

25 MHz 25 MHz

100 mV 240 mV

1.13 Environm ental specifications

1.13.1 Ambient temperature

Operating

Nonoperating –40° to 70°C (–40° to 158°F)

The system must provide sufficient air movement to maintain a

Note.

surface temperature of the aluminum base below 55°C.

5° to 55°C (41°to 131°F)

12 Medalist Pro 2520/2160 Product Manual, Rev. C

1.13.2 Temperature grad ient

Operating 20°C per hour (36°F per hour)

Nonoperating 30°C per hour (54°F per hour)

1.13.3 Altitude

Operating –1,000 ft. to 10,000 ft. (–305 m to 3,048 m)

Nonoperating –1,000 ft. to 40,000 ft. (–305 m to 12,192 m)

1.13.4 Relative humidity

Operating 8% to 80% noncondensing

Maximum wet bulb 29.4°C (85°F)

Maximum operating

gradient

Nonoperating 5% to 95% noncondensing

10% per hour

Maximum wet bulb 35°C (95°F)

1.14 Shock and vibration

All shock and vibration specifications apply when the drive is mounted

as recommended in Section 2.5 on page 22, with the input levels

measured at the drive mounting screws. Shock measurements are based

on an 11 msec, half sine wave shoc k pulse, not to be repeated m ore than

twice per second.

During normal operating shock and vibration, there is no phys ic al damage to the drive or performance degradation. During nonoperating shock

and vibration, the read/write heads are positioned in the landing zone.

During abnormal operating shock and vibration, there is no physical

damage to the drives although performance may be degraded during the

shock or vibration episode. When normal operating shock levels resume,

the drive meets its performance specifications.

Operating Abnormal Nonoperating

Shock 2 Gs 10 Gs 75 Gs

5–22 Hz vibration 0.020-inch

displacement

22–350 Hz vibration 0.50 Gs 0.75 Gs 4.00 Gs

0.030-inch

displacement

0.160-inch

displacement

Medalist Pro 2520/2160 Product Manual, Rev. C 13

1.15 Acoustics

This table shows the overall A-weighted acoustic sound power and sound

pressure levels for the drives. All measurements are generally consistent

with ISO document 7779. Acoustic measurements are taken under

essentially free-field conditions over a reflecting plane. The drive is

oriented with the top cover up for all tests.

Overall A-weighted Value Idle Seek

Sound power, typ (bels) 3.4 4.0

Sound power, max (bels) 3.7 4.3

Sound pressure, typ (dBA) 27 30

Sound pressure, max (dBA) 30 33

1.16 Reliability

Read error rates are measured with automatic retries and data correction

with ECC enabled and all flaws r e-allocated. The mean time between

failures (MTBF) is measured at nominal power at sea level and an

ambient temperature of 25°C.

Nonrecoverable read errors 1 per 10

Seek errors 1 per 10

Contact start/stops 50,000 cycles

MTBF 500,000 power-on hours

Service life 5 years

13

bits transferred

7

physical seeks

1.17 Agency listings

This drives are listed by agencies as follows:

• Recognized in accordance with UL478 and UL1950

• Certified to CSA C22.2 No. 220-M1986 and CSA C22.2 No. 950

• Certified to VDE 0805/05.90 and EN 60950/1.88 as tested by VDE

14 Medalist Pro 2520/2160 Product Manual, Rev. C

1.18 Electromagnetic Compliance for the European

Union

If this model has the CE Marking, it complies with the European Union

requirements of the Electromagnetic Compatibility Directive 89/336/EEC

of 03 May 1989 as amended by Directive 92/31/EEC of 28 April 1992

and Directive 93/68/EEC of 22 July 1993.

Seagate uses an independent laboratory to confirm compliance to the

above directives. The drive was tested in a representative system for

typical applications. T he selected system r epresents the most popular

characteristics for test platforms. The system configurations include:

• 486, Pentium, and PowerPC microprocessors

• 3. 5-i nch floppy disc drives

• Key board

• Monitor/display

Although the test system with this Seagate model complies to the

directives, we cannot guarantee that al l systems will comply. The computer manufacturer or system integrator shall c onfirm EMC compliance

and provide CE Marking for their product. The drive is not meant for

external use (without properly des igned enclosure, shielded I/O cable,

etc.) and that a terminator should be used on all unused I/O ports.

1.19 FCC verification

The Medalist Pro ATA interface drives are intended to be contained

solely within a personal computer or s imilar enclosure (not at tached to

an external device). As such, a drive is c onsidered to be a subassembly

even when individually marketed to the customer. As a subassembly, no

Federal Communications Commission authorization, verification or certification of the device is required.

Seagate Technology, Inc. has tested these drives in an enclosure as

described above to ensure that the total assembly (enclosure, disc

drives, motherboard, power supply, etc.) does comply with the limits for

a Class B computing device, pursuant to Subpart J of Part 15 of the FCC

rules. Operation with noncertified assemblies is likely to result in interference to radio and television reception.

Radio and television interference.

radio frequency energy and, if not installed and used in strict accordance

with the manufacturer’s instructions, may cause interference to radio and

television reception.

This equipment is designed to provide reasonable protection against

This equipment generates and uses

Medalist Pro 2520/2160 Product Manual, Rev. C 15

such interference in a residential installation. However, there is no

guarantee that interference will not occur in a particular installation. If this

equipment does cause interference to radio or television, which c an be

determined by turning the equipment on and off, you are encouraged to

try one or more of the following corrective measures:

• Reorient the receiving antenna.

• Move the device to one side or the other of the radio or TV.

• Move the device farther away from the radio or TV.

• Plug the equipment into a different outlet so that the receiver and

computer are on different branch outlets.

If necessary, you should consult your dealer or an experienced radio/television technician for additional suggesti ons. You may find helpful the

following booklet prepared by the Federal Communications Commission:

How to Identify and Resolve Radio-Television Interference Problems

This booklet is available from the Superintendent of Documents, US

Government Printing Office, Washington, DC 20402. Refer to publication

number 004-000-00345-4.

This digital apparatus does not exceed the Class B limits for radio

Note.

noise emissions from computer equipment as set out in the radio

interference regulations of the Canadian Department of communications.

Le présent appareil numérique n′émet pas de bruits radioélectri-

ques dépassant les limites applicables aux appareils numériques

de Classe B prescrites dans le règlement sur le brouillage radioélectrique édicté par le Ministère des Communications du

Canada.

.

16 Medalist Pro 2520/2160 Product Manual, Rev. C

Sicherheitsanleitung

Das Gerrät ist ein Einbaugerät, das für eine maximale Umgebung-

1.

stemperatur von 55°C vorgesehen ist.

Zur Befestigung des Laufwerks werden 4 Schrauben 6-32 UNC-2A

2.

benötigt. Bei seitlicher Befestigung darf die maximale Länge der

Schrauben im Chassis nicht mehr als 5,08 mm und bei Befestigung

an der Unterseite nicht mehr als 5,08 mm betragen.

Als Versorgungsspannugen werden benötigt:

3.

+5V æ 5% 0.55A

+12Væ 5% 0.35A (1, 9A fur ca . 30 Sek. fur ± 10%)

Die Versorgungsspannung muss SELV entsprechen.

4.

Alle Arbeiten an der Festplatte dürfen nur von ausgebildetem Serv-

5.

icepersonal durchgeführt werden. Bitte entfernen Sie nic ht die Aufschriftenschilder des Laufwerkes.

. Der Einbau des Laufwerkes muss den Anforderungen gemäss DIN

6

IEC 950 V DE 0805/05.90 entsprechen.

Medalist Pro 2520/2160 Product Manual, Rev. C 17

2.0 Configuring and mounting the drive

This section contains the specifications and instructions for configuring

and mounting the drive.

2.1 Handling and static-discharge precautions

After you unpack the drive, and before you install it in a system, be careful

not to damage it through mishandling. Observe the f ollowing standard

handling and static-discharge precautions:

Caution:

• Keep the drive in its static-shielded bag until you are ready to complete

the installation. Do not attach any cables to the drive while it is in its

static-shielded bag.

• Before handling the drive, put on a grounded wris t strap, or ground

yourself frequently by touching the metal chassis of a computer that

is plugged into a grounded outlet. Wear a grounded wrist strap

throughout the entire installation procedure.

• Handle the drive by its edges or frame only.

• The drive is extremely fragile—handle it with care. Do not press down

on the drive top cover.

• Always rest the drive on a padded, antistatic surface until you mount

it in the computer.

• Do not touch the connector pins or the printed circuit board.

• Do not remove the factory-installed labels from the drive or cover them

with additional labels. Rem oval voids the warranty. Some factory-installed labels contain information needed t o service the driv e. Other

labels are used to seal out dirt and contamination.

18 Medalist Pro 2520/2160 Product Manual, Rev. C

2.2 I/O cable and connector

The drive uses a 40-pin, male I/O connector with two rows of twenty pins

each and a notch for keying. Pin 20 is removed for keying purposes. A

drawing of the I/O connector is shown in Figure 2. Pin 1 is located near

the 4-pin power connector when the I/O connector is mounted.

0.70 ± 0.010

0.100 ± 0.010

0.235 ± 0.025

pin 1

0.230 ± 0.003

0.025 ± 0.002

0.025

± 0.002

0.160

1.90

2.00

Figure 2. ATA inte rface connector

0.100 typ

0.070 ± 0.010

The table below lists recommended parts for the mating connector. You

can use equivalent parts.

Part Description 3M part number

Connector 40-pin 3M-3417-7000

Connector 40-pin 3M-3448-2040

Flat cable AWG28 (stranded) 3M-3365-40

To ensure the integrity of your data, use a 40-connector, nonshielded I/O

cable with a maximum length of 18 inches (46 centimeters).

2.3 Power connector

The drive uses a standard 4-pin, male power connector. We recommend

the following part number or their equivalents for the mating connector.

Part Description Part number

Connector Housing AMP 1-480424-0

Connector Pin (loose piece) AMP 60619-4

Connector Pin (Reel) AMP 6117-4

Cable 18 AWG

Medalist Pro 2520/2160 Product Manual, Rev. C 19

2.4 Options jumper block

The options jumper block (J5), shown in Figure 3, is used to configure

the drives for operation. It is the 8-pin dual header between the I/O

connector and the power connector. Pin 1 is l ocated next to the power

connector and is farthest from the printed circuit board. It accepts

0.1-inch jumpers. The options jumper block is used to:

• Configure the drive for single-drive operation

• Configure the drive as master with an ATA-compatible slave

• Configure the drive as the slave

• Configure the drive for alternate capacity

• Configure the drive for cable select

• I nstall a remote LED

The jumper settings for these options are shown in Figure 4 on page 20.

The drive is shipped with a spare jum per att ached to pins 6 and 8. Use

this jumper to configure the drive.

Figure 3. Conne ct ors

Standard

power connector

3

1

4

2

+5V

+5V return

+12V return

+12V

Circuit board

Pin 1

(J5)

Pin 1

Interface

connector

20 Medalist Pro 2520/2160 Product Manual, Rev. C

Options jumper block (J5)

Spare

Jumper

Single drive

Drive is slave

Master with an

ATA-compatible

slave

Alternate Capacity

(AC)

Cable select

Remote LED

connection

1753

684

Figure 4. Confi gur at io n Set tings

2.4.1 Master/slave configuration

Use the following settings to configure the drive as master or slave.

One drive only.

operation. No jumpers are required for single-drive operation. The spare

jumper on pins 6 and 8 does not affect drive operation.

Drive as master with an ATA-compatible slave.

pins 5 and 6.

Drive as slave

. Place a jumper on pins 7 and 8.

2

The drive is configured at the factory for single-drive

Circuit Board

Place a jumper on

Medalist Pro 2520/2160 Product Manual, Rev. C 21

2.4.2 Alternate cap acit y jum pe r

This jumper lowers the drive capacity by setting the default translation to

1,024 cylinders. Some BIOSs that only auto-detect may require this

jumper. Place a jumper on pins 3 and 4 of the J5 options jum per bl ock

to enable this option. When installing this jumper, you may need thirdparty partitioning software to achieve full capacity of the drive.

2.4.3 Remote LED

You can connect a remote LED to pins 1(–) and 2(+) of the options jumper

block (J5). Do not install a shunt jumper on these pins.

Because the jumper block uses a 0.1-inch connector, you may need to

replace the current connector. Use Seagate connector part number

10562-001 or an equivalent.

2.4.4 Cable-select option

Computers that use cable-select determine the master and slave drives

by selecting or deselecting pin 28, CSEL, on the interface bus. Master

and slave drives are determined by their physical position on the cable.

• The drive plugged into the I/O connector that carries the CSEL signal

is the master.

• The drive plugged into the I/O connector that does not carry the CSEL

signal is the slave.

To configure the drives for computers that use cable select:

• I nstall jum pers on pins 5 and 6 and pins 7 and 8 as shown in

Figure 4 on page 20.

• Connect the drives to the cable as shown in Figure 5 on page 22.

22 Medalist Pro 2520/2160 Product Manual, Rev. C

Slave

CSEL not carried

to pin 28 of

this connector

Master

Pin 28 grounded

at computer

Computer

Figure 5. Connect in g cabl e- selected drives

2.5 Mounting the drive

You can mount the drive in any orientation.

Use the set of mounting guidelines below that are appropriate to the type

of mounting holes used: either bottom mounting holes or side mounting

holes. Refer to Figure 6 on page 23 for mounting dimensions.

Bottom mounting holes.

mounting holes as shown in Figure 6.

Caution.

Do not insert the bottom mounting screws more than

0.20 inches (6 turns) into the drive frame.

Side mounti ng holes.

available side mounting holes as shown in Figure 6. Use two mounting

holes on each side of the drive.

Caution.

Do not insert the side mounting screws more than 0.20

inches (6 turns) into the drive frame. If you use a screw that is

too long, you risk damaging the drive’s circuit board.

Insert four 6-32 UNC screws in the four bottom

Use four 6-32 UNC screws in four of the six

Medalist Pro 2520/2160 Product Manual, Rev. C 23

In the following figure, all dimensions are in inches and millimeters (mm).

Six 6-32 NC-2B threaded hole

Max screw insertion depth: 0.20 inches

0.748 max

(19.000)

2.362 ± 0.010

(59.995. ± 0.254)

0.240 ± 0.020 (6.096

4.000 ± 0.010 (101.60

1.985 ± 0.020

(50.419 ± 0.508)

Four 6-32 NC-2B threaded hole

Max screw insertion depth: 0.20 inches

0.175 (4.445)

± 0.508)

5.380 max (136.652)

1.750 ± 0.010

(44.450 ± 0.254)

1.645 (41.783)

1.045 (25.543)

± 0.254)

0.250 ± 0.010

(6.350 ± 0.254)

1.625 ± 0.020

(41.275 ± 0.508)

4.010 max (101.854)

3.750 ± 0.010 (95.250 ± 0.254)

0.238

(6.045)

0.188 (4.775)

Figure 6. Mount ing di m ensions

Pin 1Pin 1Pin 1

24 Medalist Pro 2520/2160 Product Manual, Rev. C

Medalist Pro 2520/2160 Product Manual, Rev. C 25

3.0 ATA interface

The drives use an ATA-3 interface. The interface complies with

ATA (AT Attachment) Interface X3T10 Rev. 6.0

Extension for Local Bus Attachments, Rev. 2. 0

drives Data for drives Under 8 GB

support are listed on pages 27 and 28. Commands and features with

specific applications for these drives are also discussed in this section.

The ATA interface consists of single-ended, TTL-compatible receivers

and drivers that use an asynchronous interface protocol. The drivers can

sink up to 24 mA and drive a load up to 300 pF. The integrity of the ATA

interface is affected by the interface cable. It is designed to support a

40-conductor, nonshielded interface cable with a maximum length of 18

inches (46 centimeters).

. The ATA commands that the drives

;

SFF 8011: ATA Timing

and SFF 8019:

ANSI

Identify

3.1 ATA Interface connector pin assignments

The signal name and signal direction for each I/O connector pin is shown

in Figure 7 on page 26. See the

Manual

each pin.

Signal names are shown in upper-case letters. If the signal name is

followed by a minus sign (–), the signal is active low. Otherwise, the signal

is active high.

, publication number 36111-

Seagate ATA Interface Reference

, for a complete description of

xxx

26 Medalist Pro 2520/2160 Product Manual, Rev. C

Drive

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

*34

35

36

37

38

*39

40

*

Drive-to-drive signals

Reset–

Ground

DD7

DD8

DD6

DD9

DD5

DD10

DD4

DD11

DD3

DD12

DD2

DD13

DD1

DD14

DD0

DD15

Ground

(removed)

DMARQ

Ground

DIOW–

Ground

DIOR–

Ground

IORDY

CSEL

DMACK–

Ground

INTRQ

IOCS16–

DA1

PDIAG–

DA0

DA2

CS1FX–

CS3FX–

DASP–

Ground

Host

1

Host Reset

2

Ground

3

Host Data Bus Bit 7

4

Host Data Bus Bit 8

5

Host Data Bus Bit 6

6

Host Data Bus Bit 9

7

Host Data Bus Bit 5

8

Host Data Bus Bit 10

9

Host Data Bus Bit 4

10

Host Data Bus Bit 11

11

Host Data Bus Bit 3

12

Host Data Bus Bit 12

13

Host Data Bus Bit 2

14

Host Data Bus Bit 13

15

Host Data Bus Bit 1

16

Host Data Bus Bit 14

17

Host Data Bus Bit 0

18

Host Data Bus Bit 15

19

Ground

(No Pin)

20

21

DMA Request

22

Ground

23

Host I/O Write

24

Ground

25

Host I/O Read

26

Ground

27

I/O Channel Ready

28

Cable Select

29

DMA Acknowledge

30

Ground

31

Host Interrupt Request

32

Host 16 Bit I/O

33

Host Address Bus Bit 1

34

Passed Diagnostics

35

Host Address Bus Bit 0

36

Host Address Bus Bit 2

37

Host Chip Select 0

38

Host Chip Select 1

39

Drive Active/

Drive 1 Present

40

Ground

Drive 1

(slave)

28

34

39

NC

Drive 0

(master)

28

34

39

CSEL

PDIAG

DASP–

Figure 7. ATA interface connector pin assi gnm ent s

Host

–

28

34

39

Medalist Pro 2520/2160 Product Manual, Rev. C 27

3.2 Comman d set

This section lists all of the ATA commands the drives use. Only the

commands with unique implementation for the dri ves are discussed in

this manual. For information about the ATA interface, refer to

Draft X3T10.2008D Rev. 6, Information Technology—AT Attachment-3

Interface ATA-3

features is provided in

,

xxx

Small Form Factor Specification, SFF-8011 Rev 1.1, September 18,

, and

1993

January 8,1996, Revision 1.0, Preliminary Document

The table below lists all commands implemented in the drives. It uses

the following abbreviations:

FR Features register

SC Sector Count register

SN Sector Number register

CY Cylinder register

DH Drive/Head register

n This register does not contain a valid parameter for this

command.

y This register contains a valid parameter for this command. In

the Drive/Head register, both the drive and head parameters

are valid for this command.

D The Drive/Head register contains a valid drive parameter for

this command. The head parameter is not valid for this

command.

Read DMA, Read Long, Read Sector, Read Verify Sector, Write

Note.

DMA, Write Long and Write Sector support with retry and without

retry commands.

. Additional information about the drive commands and

Seagate ATA Interface Reference Manual, 36311-

Small Form-Factor Committee Specification Draft SFF-8055i,

.

Working

Command name

Active and Set Idle Timer FB n y n n D

Active Immediate F9 nnnnD

Check Idle Mode FD n y n n D

Check Power Mode 98, E5 n y n n D

Execute Drives Diagnostic 90 nnnnD

continued

Command

code (in hex)

Parameters used

FR SC SN CY DH

28 Medalist Pro 2520/2160 Product Manual, Rev. C

continued from previous page

Command name

Command

code (in hex)

Parameters used

FR SC SN CY DH

Identify drives EC nnnnD

Idle 97, E3 n y n n D

Idle and Set Idle Timer FA n y n n D

Idle Immediate 95, F8, E1 nnnnD

Initialize Drive Parameters 91 n y n n y

Read DMA C8, C9 — yyyy

Read Long 22, 23 n yyyy

Read Multiple C4 n yyyy

Read Sector 20, 21 n yyyy

Read Sector Buffer E4 nnnnD

Read Verify Sector 40, 41 n yyyy

Recalibrate 1X nnnnD

Seek 7X n n y y y

Set Features E F y n n n D

Set Multiple Mode C6 n y n n D

Sleep 99, E6 nnnnD

S.M.A.R.T. B0 y y n y y

Standby 96, E2 nnnnD

Standby Immediate 94, E0 nnnnD

Write DMA CA, CB —yyyy

Write Long 32, 33 n yyyy

Write Multiple C5 n yyyy

Write Sector 30, 31 nyyyy

Write Sector Buffer E8 nnnnD

Medalist Pro 2520/2160 Product Manual, Rev. C 29

3.2.1 Identify drive command (ECH)

The Identify drive parameters for the drives are listed in the table below.

If the alternate capacity jumper is installed on the ST52520A, the

Note.

drive capacity is reduced in Word 1 to 1,024 cylinders.

Word Description STValue

0

1

Configuration 0040

0400

Number of logical

cylinders

ST52520A = 4.970

ST52160A = 4,095

Fixed drives

H

2

3

4

5

6

7–9

10–19

20

21

22

23–26

27–46

47

48

49

50

Reserved 0000

Number of logical heads 16

Vendor specific 36540

Vendor specific 580

Number of logical sectors

63

per track

Vendor specific 0000

Serial number (20 ASCII

drive-unique

characters)

Vendor specific 3

Vendor specific 224

ECC bytes (R/W Long) 0004

Firmware revision

drive-unique

(8 ASCII characters)

Model number (40 ASCII

characters)

ST52520A

ST52160A

Vendor specific 8010

Reserved 0000

Capabilities 0B01

0001H IORDY

supported

Reserved 0000

H

H

H

continued

30 Medalist Pro 2520/2160 Product Manual, Rev. C

continued from previous page

Word Description STValue

51

PIO data-transfe r cycle

0200

H

timing mode

52

Obsolete 0200

H

53

54

55

56

57–58

59

60–61

62

63

64

65

66

Current valid 0003

0001H words 54–58, 64–70

valid

Number of current logical

cylinders

Number of current logical

ST52520A = 4,970

ST52160A = 4,095

16

heads

Number of current

63

sectors

Current capacity in

sectors

= Current setting for

xx

H

ST52520A = 5,009,760 (CHS)

ST52160A = 4,127,760 (CHS)

0000

number of sector that

can be transferred per

interrupt on Read/Write

Multiple command

Total number of user

addressable LBA sectors

ST52520A = 5,009,760

ST52160A = 4,127,760

Obsolete 0000

Multiword DMA transfer

mode active

0107

Mode 0 is active

Modes 0, 1, and 2 supported

Advanced PIO transfer

mode supported

0003

Modes 3 and 4

supported

Minimum multiword DMA

120 nsec

transfer cycle time per

word

Mfg. Recommended

120 nsec

multiword DMA transfer

cycle time

H

H

H

Medalist Pro 2520/2160 Product Manual, Rev. C 31

Word Description STValue

67

Minimum PIO transfer

240 nsec

cycle time without flow

control

68

Minimum PIO transfer

120 nsec

with IORDY flow control

69–79

Reserved 0000

80

81

82

83

84–127

128

129–159

160–255

Major version number 0007

supports ATA-3

supports ATA-2

supports ATA-1

Minor version number 0000

Not supported

Command set support 0000

Not supported

Command set support 0000

Not supported

Reserved

Security status 0000

Vendor specific

Reserved

H

32 Medalist Pro 2520/2160 Product Manual, Rev. C

3.2.2 Set Features command (EFH)

The Set Features command (command code EFH) allows the user to

enable and disable the multisegmented cache and Auto Relocation

features and to identify the transfer modes the drive uses. The multisegmented buffer consists of Read Look-ahead and write-immediate and

write-merging features. The table below lists the features the drives

support. The features that are set to default by the factory are indicated

in the Feature column.

To use the command:

Write the Feature value to the Features register.

1.

Write the Set Features command to the command register.

2.

If the value in the Features register is not supported or is invalid,

Note.

the drives post an Aborted Command error.

At power-on or after a hard reset, the feature selections are r estored to

the factory-default values.

The table below shows alterable features that the drives support. Values

that are preset at the factory are indicated as default in the feature

description.

Feature Value Feature

Enable write cache (default)

02

H

03

04

55

82

84

AA

H

H

H

H

H

H

Set transfer mode

Enable Read Auto Relocation (default)

Disable read look-ahead cache

Disable write cache

Disable Read Auto Relocation

Enable read look-ahead cache (default)

Medalist Pro 2520/2160 Product Manual, Rev. C 33

3.2.2.1 PIO and DMA Data-Transfer Modes

You can set the multiword DMA mode and identify the PIO data-transfer

mechanism and transfer mode with the Set Features command. To set

the multiword DMA mode:

1.1.Write Set Features command value 03

(Set Data Transfer mode) to

H

the Features register.

Write a transfer types value to the Sector Count register. The upper 5

2.

bits of this value define the type of data transfer, and the lower 3 bits

encode the mode value.

This changes word 63 of the Identify Drive command to the mode you

enter in the Sector Count register.

The following table identifies allowable transfer types values:

Data-Transfer Mechanism Transfer Types value

Mechanism name

Mode

value

Data

Upper 5 bits

Lower 3 bits

PIO Transfer Mode (default) 2 00000 000

PIO Transfer Mode:

Set PIO Mode = 2

PIO Flow Control Transfer

Mode: Set PIO Mode = 0

PIO Flow Control Transfer

Mode: Set PIO Mode = 1

PIO Flow Control Transfer

Mode: Set PIO Mode = 2

PIO Flow Control Transfer

Mode: Set PIO Mode = 3

PIO Flow Control Transfer

Mode: Set PIO Mode = 4)

2 00000 001

0 00001 000

1 00001 001

2 00001 010

3 00001 011

4 00001 100

Multiword DMA Mode 0 00100 000

Multiword DMA Mode 1 00100 001

Multiword DMA Mode 2 00100 010

Reserved — 01000

If the drive does not support a commanded mode, it returns a 04

Note.

nnn

aborted command error.

34 Medalist Pro 2520/2160 Product Manual, Rev. C

3.2.3 Standby timer tim eo ut period

The Idle command and Standby command Sector Count registers are

used to activate t he Standby timer. The host can enable the Standby

timer by placing a value in the sector-count register of the Idle command

or Standby command. The value corresponds to a predetermined period

of drive inactivity. The table below lists the values the Seagate drives use

and their corresponding timeout period.

Sector Count Register contents Corresp onding timeout period

0 (0

) Timeout disabled

H

1–12 (1

) value = 60 seconds

H–CH

13–240 (DH–F0H) (value * 5) seconds

241–251 (F1

252 (FC

253 (FD

254 (FE

–FBH) (value – 240) * 30) minutes

H

) 21 minutes

H

) 8 hours

H

) Reser ved

H

255 (FFH) 21 minutes 15 seconds

The drives are shipped with the Standby timer disabled.

3.2.4 Sleep command (99H, E6H)

This command performs the same function as the Standby Immedi ate

command (94

, E0H).

H

3.2.5 Auto Relocation

This feature allows the drive to identify grown media defects and to

reallocate the sector without host intervention using both Read and Write

Auto Relocation.

The Read Relocation can be disabled by using the Set Feature command

Disable Read Auto Relocation, feature value 84

. This feature is not

H

implemented for the Read Long command.

Medalist Pro 2520/2160 Product Manual, Rev. C 35

The Write Relocation, in addition to write cache, can be disabled by using

the Set Feature command Disable Write Cache, f eature value 82

H.

This

feature is not implemented for the Write Long command.

Write Relocation and write cache are both disabled using value 82

H

These features are mutually exclusive.

3.2.6 S.M.A.R.T. command (B0H)

Self-Monitoring, Analysis and Reporting Technology (S.M.A.R.T.) is an

emerging technology that provides near-term failure prediction for disc

drives. When S.M.A.R.T. is enabled, the Seagate drive monitors predetermined attributes within its elf that are susceptible to degradation over

time. S.M.A.R.T. makes a status report available s o that the host can

prompt the user to back up the drive if self-monitoring determines that a

failure is likely. Not all failures are predictable. S.M.A.R.T. predictabil ity

is limited to only those attributes the drive can monitor.

The S.M.A.R.T. feature is disabled at the factory. You must have a BIOS,

software driver or application software that supports S.M.A.R.T. to

enable this feature. The table below shows the S.M.A.R.T. command

codes the Seagate drives use.

To implement a S.M.A.R.T. command, the host must write the

Note.

value 0x4F to Cylinder_lo register and the value 0xC2 to the

Cylinder_hi register at the same time it writes the S.M.A.R.T.

command code to the Features register. If these values are not

included with the command code, the command will be aborted

and 0x04 (abort) will be written to the Error register.

.

Command code Feature description

D2

D8

D9

DA

H

H

H

H

Enable/disable attribute autosave

Enable operation

Disable operation

Return S.M.A.R.T. status

36 Medalist Pro 2520/2160 Product Manual, Rev. C

Medalist Pro 2520/2160 Product Manual, Rev. C 37

Appendix. Timing diagrams

Without IORDY, the drives operate at programmed I/O timing specifications, as shown below.

Address valid

DIOR− and DIOW−

Write data valid

Read data valid

IOCS16−

T7

T1

T2

Figure 8. Programm ed I/O t i ming without IORDY

T0

T3

T5

T6

T4

T9 T8

Time Description Min Max

Cycle time 200 nsec —

T0

Drives address (CS1FX–, CS3FX–,

T1

30 nsec —

DA0, DA1 and DA2) valid and

DIOR– and DIOW setup

T2 DIOW– or DIOR– pulse width 80 nsec —

T3 DIOW– data setup 30 nsec —

T4 DIOW– data hold 15 nsec —

T5 DIOR– data setup 20 nsec

T6 DIOR– data hold 5 nsec —

T7 DIOW– or DIOR– to address valid hold — 40 nsec

T8 DIOW– false to write data hold — 30 nsec

T9 DIOR– false to read data hold 10 nsec

38 Medalist Pro 2520/2160 Product Manual, Rev. C

When using IORDY, the drives operate at programmed timing specifications, as shown below.

Address valid

IOCS16−

DIOR− or DIOW−

IORDY

Write data valid

Read data valid

T1

T2

T3

T5

T4

T0

T7

T6

T8

T9

T10

T11

Figure 9. Programmed I/O timing with IORDY

Time Description Min Max

T0 Cycle time 120 nsec —

T1 Address valid until IOCS16– is asserted — 30 nsec

Drive address (CS1FX–, CS3FX–,

T2

25 nsec —

DA0, DA1 and DA2) valid before DIOR–

or DIOW– setup

T3 IORDY s e tu p ti me — —

DIOW– or DIOR– pulse width (8-bit) 70 nsec —

T4

DIOW– or DIOR– pulse width (16-bit) 70 nsec —

T5 IORDY pulse width —

1,250

nsec

T6 DIOW– data setup 20 nsec —

T7 DIOR– data setup 20 nsec —

T8 DIOR– data hold 5 nsec —

T9 DIOW– data hold 10 nsec —

T10 DIOW– or DIOR– to address valid hold 5 nsec —

T11 Address valid until IOCS16– is negated — 25 nsec

Medalist Pro 2520/2160 Product Manual, Rev. C 39

The drives operate at multiword DMA mode 2 timing specifications, as

shown below.

DMARQ

DMARQ

DMARQ

DMACK−

DMACK−

DMACK−

DIOR− or DIOW−

DIOR− or DIOW−

DIOR− or DIOW−

Read data valid

Read data valid

Read data valid

Write data valid

Write data valid

Write data valid

TE

TE

TE

TF

TF

TF

TG

TH

TG

TH

TG

TH

T0

T0

T0

TK

TK

TK

TDTI TJ

TDTI TJ

TDTI TJ

TL

TL

TL

Figure 10. Multiword DMA timing

Time Description Min Max

T0 Cycle time 120 nsec —

TD DIOW– or DIOR– pulse width (16-bit) 70 nsec —

TE DIOR– data access — —

TF DIOR– data hold 5 nsec —

TG DIOW– data setup 20 nsec —

TH DIOW– data hold 10 nsec —

TI DMACK– to DIOR– or DIOW– setup 0 nsec —

TJ DIOR– or DIOW– to DMACK– hold 5 nsec —

DIOR– negated pulse width 25 nsec —

TK

R

TK

DIOW– negated pulse width 25 nsec —

W

DIOR– to DMARQ delay — 35 nsec

TL

R

TL

DIOW– to DMARQ delay — 25 nsec

W

Seagate Technology, Inc.

920 Disc Drive, Scotts Valley, California 95066, USA

Publication Number: 36347-101, Rev. C, Printed in USA

Loading...

Loading...