○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

Elite Disc Drive

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

ST43401N/ND

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

ST43402ND

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

User ’s Manual

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

Contents

Preface ................................................................................................... iii

Electrostatic discharge protection....................................................... iii

Important safety information and precautions..................................... iv

Wichtige Sicherheitshinweise ......................................................... vi

Technical support services ............................................................. ix

Section 1. General description............................................................... 1

Section 2. Installation............................................................................. 7

Abschnitt 2. Installation................................................................... 7

Section 3. Operation.............................................................................. 43

Section 4. Parts data ............................................................................. 49

Section 5. Maintenance ......................................................................... 51

© 1994 Seagate Technology, Inc. All rights reserved

Publication number: 83327720, Rev. B

December 1994

Seagate®, Seagate Technology®, and the Seagate logo are registered

trademarks of Seagate Technology, Inc. Elite™, SeaFAX™, SeaFONE™,

SeaTDD™, and SeaBOARD™ are trademarks of Seagate Technology, Inc.

Other product names are registered trademarks or trademarks of their

owners.

Seagate reserves the right to change, without notice, product offerings or

specifications. No part of this publication may be reproduced in any form

without written permission from Seagate Technology, Inc.

ST43401N/ND, ST43402ND User’s Manual, Rev. B iii

Preface

This manual contains information for users of Seagate® ST43401N/ND and

ST43402ND Elite™ disc drives. It provides instructions to all personnel who

operate the drive and to customer engineers who install and check out the

drive. Additional information is available in the reference manual (publication

83327730).

Electrostatic discharge protection

Caution. Removal of circuit boards by personnel not performing depot repair

will damage components and may void the warranty.

All drive electronic assemblies are sensitive to static electricity due to the

electrostatically sensitive devices used within the drive circuitry. Although

some devices such as metal-oxide semiconductors are extremely sensitive,

all semiconductors, as well as some resistors and capacitors, may be

damaged or degraded by exposure to static electricity.

Electrostatic damage to electronic devices may be caused by the direct

discharge of a charged conductor, or by exposure to the static fields surrounding charged objects. To avoid damaging drive electronic assemblies, service

personnel must observe the following precautions when servicing the drive:

• Ground yourself to the drive whenever the drive electronics are or will be

exposed. Connect yourself to ground with a wrist strap (Seagate part

number 12263496). Connection may be made to any grounded metal

assembly. As a general rule, remember that you and the drive electronics

must all be grounded to avoid potentially damaging static discharges.

• Turn off power before removing or installing the DC power cable.

• Do not remove any circuit boards from the drive.

• Never use an ohmmeter on any circuit boards.

iv ST43401N/ND, ST43402ND User’s Manual, Rev. B

Important safety information and precautions

Caution. Use forced-air ventilation when bench-testing the drive to ensure

proper cooling of drive components.

Use proper safety and repair techniques for safe, reliable operation of this unit.

Service should be done only by qualified persons. We recommend the

procedures in this manual as effective ways of servicing the unit. Some

procedures require the use of special tools. For proper maintenance and

safety, you must use these tools as recommended.

The procedures in this manual and labels on the unit contain warnings and

cautions that must be carefully read and followed to minimize or eliminate the

risk of personal injury. The warnings point out conditions or practices that may

endanger you or others. The cautions point out conditions or practices that

may damage the unit, possibly making it unsafe for use.

You must also understand that these warnings and cautions are not exhaustive. We cannot possibly know, evaluate, and advise you of all the ways in

which maintenance might be performed or the possible risk of each technique.

Consequently, we have not completed any such broad evaluation. If you use

a non-approved procedure or tool, first ensure that the method you choose will

not risk either your safety or unit performance.

Always observe the following warnings and precautions:

• Perform all maintenance by following the procedures in this manual.

• Follow all cautions and warnings in the procedures.

• Use sound safety practices when operating or repairing the unit.

• Use caution when troubleshooting a unit that has voltages present. Remove

power from the unit before servicing it.

• Wear safety shoes when removing or replacing heavy parts.

• Ensure that the internal temperature of the rack or cabinet will not exceed

the limits defined for the drive when the drive is mounted in an equipment

rack or cabinet. When units are stacked vertically, pay special attention to

the top where temperatures are usually highest.

• Follow the precautions listed under “Electrostatic discharge protection.”

ST43401N/ND and ST43402ND User’s Manual, Rev. B v

• Do not remove any circuit boards from the drive chassis. Return the entire

drive for depot repair if any circuit board is defective. Removal of circuit

boards by personnel not performing depot repair will damage components

and may void the warranty.

• Do not remove the head and disc assembly (HDA) from the drive chassis.

Return the entire drive for depot repair if the HDA is defective.

• Do not attempt to disassemble the HDA. It is not field repairable. If the sealed

HDA is opened by personnel not performing depot repair, this will damage

components and void the warranty.

• As a component, this drive is designed to be installed and operated in

accordance with UL1950, IEC950, EN60950, CSA C22.2 950, and VDE0805.

• Ensure that the power supply meets the specifications in this manual and

is designed to be used in accordance with UL1950, IEC950, EN60950, CSA

C22.2 950, and VDE0805.

Seagate takes all reasonable steps to ensure that its products are certifiable

to currently accepted standards. Typical applications of these disc drives

include customer packaging and subsystem design. Safety agencies conditionally certify component assemblies, such as the Elite disc drive, based on

their final acceptability in the end-use product. The subsystem designers are

responsible for meeting these conditions of acceptability in obtaining safety/

regulatory agency compliance in their end-use products and in certifying

where required by law. A necessary part of meeting safety requirements is the

provision for overcurrent protection on drive SELV supply voltages.

This unit is a component part and as such is not meant to comply with FCC

or similar national requirements as a stand-alone unit. Engineering radiated

and conducted emissions test results are available through the Seagate

Safety Department to assist the subsystem designer.

vi ST43401N/ND, ST43402ND User’s Manual, Rev. B

Wichtige Sicherheitshinweise

Vorsicht. Beim Testen des Laufwerks auf dem Prüftisch ist Fremdbelüftung

vorzusehen, um eine ausreichende Kühlung der Laufwerkkomponenten

sicherzustellen.

Verwenden Sie geeignete Sicherheits- und Reparaturverfahren, um den

sicheren, zuverlässigen Betrieb dieser Einheit zu gewährleisten. Reparaturen

dürfen nur von qualifiziertem Fachpersonal vorgenommen werden. Wir

empfehlen die Verfahren in diesem Handbuch als effektive Methoden zur

Wartung und Reparatur der Einheit. Einige Verfahren erfordern

Spezialwerkzeuge; diese müssen zur sachgemäßen Ausführung der

Wartungsarbeiten und aus Sicherheitsgründen den Empfehlungen

entsprechend verwendet werden.

Die Verfahren in diesem Handbuch und die Aufkleber auf dem Gerät enthalten

Warn- und Vorsichtshinweise. Diese Hinweise sind sorgfältig durchzulesen

und zu beachten, um das Risiko von Verletzungen auf ein Mindestmaß zu

beschränken oder ganz zu vermeiden. Die Warnhinweise machen auf

Situationen oder Praktiken aufmerksam, die Sie oder andere gefährden

könnten. Die Vorsichtshinweise machen auf Situationen oder Praktiken

aufmerksam, die die Einheit beschädigen können, so daß deren Gebrauch mit

Risiko behaftet ist.

Die Warn- und Vorsichtshinweise sind nicht allumfassend! Es ist uns einfach

nicht möglich, alle Wartungsmethoden oder die eventuellen Risiken jeder

Methode zu kennen, zu beurteilen und Sie entsprechend zu beraten. Aus

diesem Grund haben wir auf eine derartige umfassende Beurteilung verzichtet.

Falls Sie ein hier nicht beschriebenes Verfahren oder Werkzeug verwenden,

stellen Sie zuerst sicher, daß das gewählte Verfahren weder Ihre persönliche

Sicherheit noch die Leistung der Einheit gefährdet.

Beachten Sie in jedem Fall die folgenden Warn- und Vorsichtshinweise:

• Führen Sie alle Wartungsarbeiten entsprechend den Anweisungen in

diesem Handbuch aus.

• Beachten Sie alle Warn- und Vorsichtshinweise in diesem Handbuch.

• Treffen Sie beim Betrieb oder bei der Reparatur der Einheit angemessene

Sicherheitsvorkehrungen.

• Wenn eine Einheit unter Spannung steht, gehen Sie bei der Fehlerdiagnose

besonders vorsichtig vor. Schalten Sie die Einheit aus, bevor Sie mit den

Reparaturarbeiten beginnen.

ST43401N/ND, ST43402ND User’s Manual, Rev. B vii

• Tragen Sie Sicherheitsschuhe, wenn Sie schwere Teile aus- bzw. einbauen.

• Wenn das Laufwerk in einem Einbaugestell oder Gehäuse montiert ist,

sorgen Sie dafür, daß die Temperatur im Inneren des Gestells oder

Gehäuses die für das Laufwerk vorgegebenen Grenzwerte nicht übersteigt.

Wenn Einheiten vertikal gestapelt werden, achten Sie besonders auf den

oberen Stapelbereich, da dort die Temperatur gewöhnlich am höchsten ist.

• Befolgen Sie die oben unter “Electrostatic Discharge Protection”

angegebenen Sicherheitsmaßnahmen.

• Nehmen Sie keine Platinen aus dem Laufwerkgehäuse. Wenn eine Platine

defekt ist, muß das gesamte Laufwerk zur Reparatur eingeschickt werden.

Die Herausnahme von Platinen durch andere Personen als die für die

werkseitige Reparatur zuständigen kann zu einer Beschädigung der

Komponenten und Erlöschen des Garantieanspruchs führen.

• Die vormontierte Kopf- und Festplatteneinheit (HDA) nicht aus dem

Laufwerkgehäuse nehmen! Falls die HDA beschädigt ist, schicken Sie das

gesamte Laufwerk zur Reparatur ein.

• Die HDA ist nicht vor Ort reparierbar und darf nicht auseinandergenommen

werden! Öffnen der versiegelten HDA durch andere Personen als die für die

werkseitige Reparatur zuständigen hat eine Beschädigung der Komponenten

und Erlöschen des Garantieanspruchs zur Folge.

• Als Teilkomponente ist dieses Laufwerk für die Installation und den Betrieb

in Übereinstimmung mit UL 1950, IEC950, EN60950, CSA C22.2 950 und

VDE0805 vorgesehen.

• Achten Sie darauf, daß Ihr Netzteil den technischen Daten in diesem

Handbuch entspricht und für den Betrieb in Übereinstimmung mit UL 1950,

IEC950, EN 60950, CSA C22.2 950 und VD0805 vorgesehen ist.

Seagate ist ständig bemüht, die Zulassungsfähigkeit von Seagate-Produkten

im Rahmen der gegenwärtig geltenden Standards zu gewährleisten. Zu den

typischen Anwendungen dieser Festplattenwerke zählen Systemeinbau durch

den Kunden und die Konstruktion von Untersystemen. Sicherheitsbehörden

gewähren eine bedingte Zulassung für Komponenten wie das EliteFestplattenlaufwerk vorbehaltlich der endgültigen Zulasssung im Endprodukt.

Designer von Untersystemen sind dafür verantwortlich, die Voraussetzungen

für die Einhaltung sicherheits- oder aufsichtsbehördlicher Vorschriften in

ihren Endprodukten und - falls gesetzlich vorgeschrieben - für die Zulassung

zu schaffen. Eine Grundvoraussetzung zur Einhaltung der

Sicherheitsanforderungen ist die Bereitstellung eines Überlastschutzes auf

den SELV-Versorgungsspannungen des Laufwerks.

viii ST43401N/ND, ST43402ND User’s Manual, Rev. B

Dieses Gerät ist eine Baugruppe und unterliegt als solche nicht den

Anforderungen der FCC oder ähnlicher nationaler Behörden für eigenständige.

Technische Testergebnisse zu Frequenz- und Elektrizitätsemissionen sind

für Designer von Untersystemen auf Anfrage von der SeagateSicherheitsabteilung erhältlich.

ST43401N/ND, ST43402ND User’s Manual, Rev. B ix

Technical support services

Seagate Technology provides technical support literature and diagnostic

utilities to authorized distributors. Please contact your dealer for technical

support and installation troubleshooting. Product technical support is available for all Seagate products by calling the SeaFAX™, SeaFONE™,

SeaTDD™, or SeaBOARD™ services. These are toll calls if you dial from

outside of the number’s local dialing area.

SeaFAX:

USA (408) 438-2620; England 44-62-847-7080

Use a touch-tone telephone to access Seagate’s automated FAX system and

select technical support information by return FAX. This service is available

24 hours a day, 7 days a week.

SeaFONE: (408) 438-8222

Technical support specialists are av ailable between 8:00 A.M. and 5:00 P.M.

PST, Monday through Friday. Recorded technical information for selected

Seagate products is accessible 24 hours a day, 7 days a week.

SeaTDD: (408) 438-5382

TDD is a telecommunication device for the deaf where two people can

communicate using a keyboard connected to the phone line. A TDD device is

required to access this service, which is available from 8:00 A.M. to 5:00 P.M.

PST, Monday through Friday.

SeaBOARD:

The Seagate Technical Support Bulletin Board System (BBS) is available 24

hours a day, 7 days a week. A modem is required to access this service. The

communications software must be set for 8 data bits, no parity, and 1 stop bit

(8N1). All BBS numbers operate at 9600 baud max. With this service you can

access:

• Specifications and jumper configurations for Seagate products

• Reprints of Seagate documentation

• A directory of information and helpful utilities that you can download to your

own computer

x ST43401N/ND, ST43402ND User’s Manual, Rev. B

Telephone

Location number

USA, Mexico, Latin America (408) 438-8771

England 44-62-847-8011

Germany 49-89-140-9331

Singapore 65-292-6973

Australia 61-2-756-2359

Canada (416) 856-5581

France 33-1-40-67-1034

Korea 82-2-556-7294

ST43401N/ND, ST43402ND User’s Manual, Rev. B 1

Section 1. General description

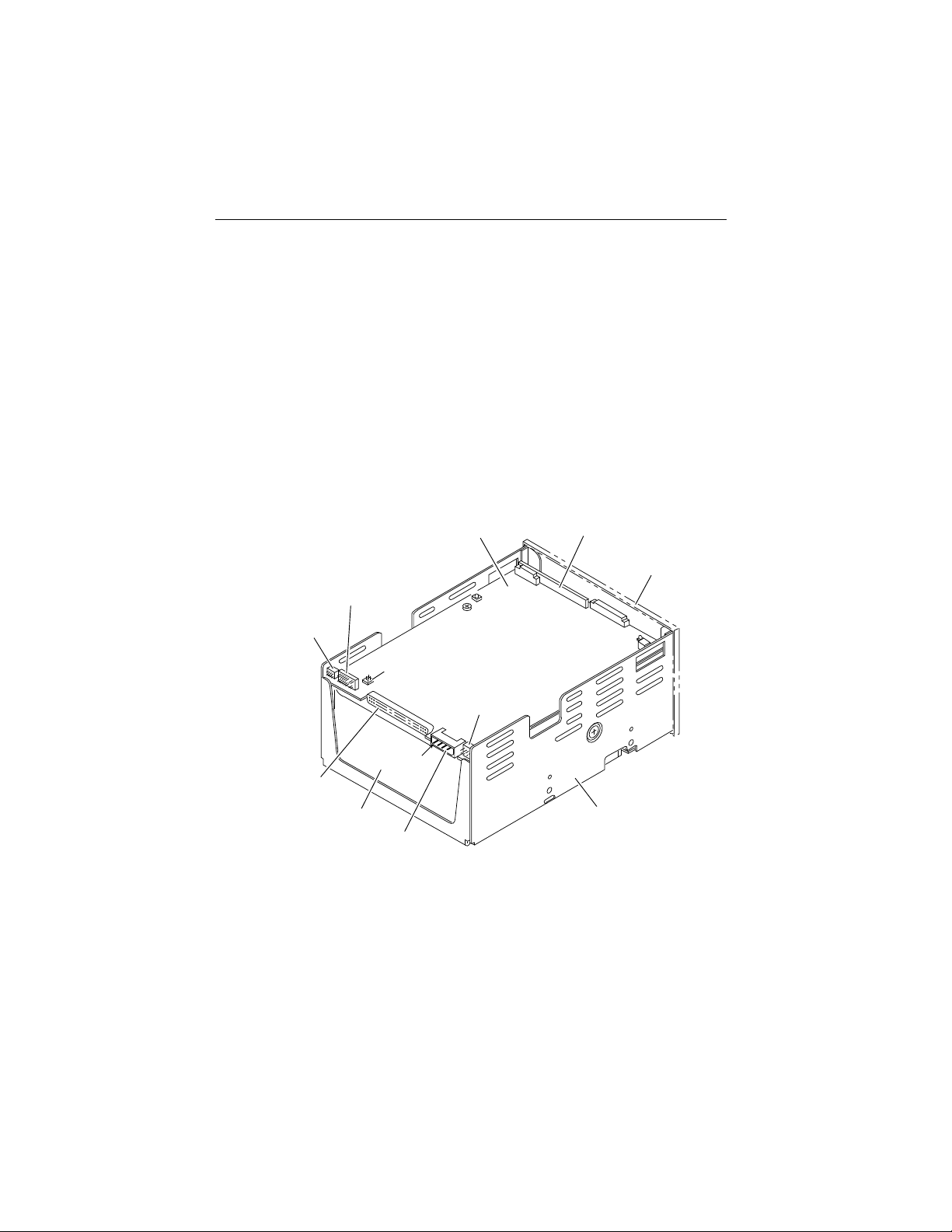

Seagate ST43401N/ND and ST43402ND Elite 3 disc drives are high speed,

random access digital data storage devices. They communicate with an

initiator using the fast and wide (16-bit) Small Computer System Interface

(SCSI-2). The ST43401N/ND disc drive is shown in Figure 1, and the

ST43402ND (dual port) disc drive is shown in Figure 2. Specifications for

these drives are listed in Table 1 following the figures.

The drive is a component for installation in an enclosure designed for the drive.

The enclosure design must ensure adequate cooling for the drive, and it must

address the requirements for grounding and for shielding of emissions. The

reference manual (publication 83327730) presents guidelines for a properly

designed enclosure.

Option Jumpers and

Spindle Sync

Connector

Option

Jumpers

Option

Jumpers

Pin 1

I/O

Connector

Head and Disc

Assembly (HDA)

DC Power

Connector

Figure 1. ST43401N/ND disc drives

Control

Board

Option

Jumpers

Power

Board

Optional

Bezel

Chassis

2 ST43401N/ND, ST43402ND User’s Manual, Rev. B

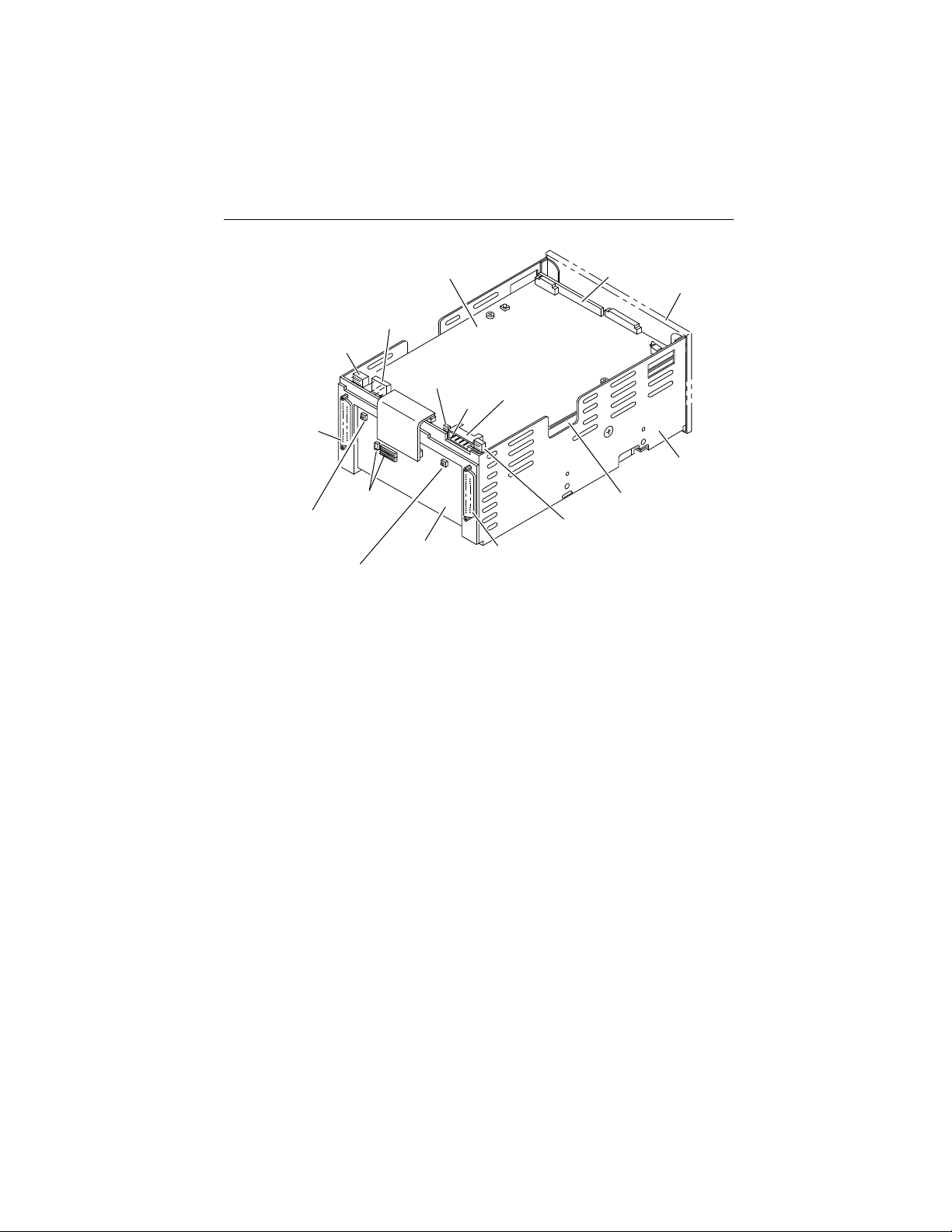

Control

Board

Spindle Sync

Remote Operator

Panel Connector

Port B

I/O Connector

Port B

Terminator

Power

Terminator

Figure 2. The ST43402ND disc drive

Connector

Option

Jumpers

Port A

Power

I/O Board

Power

I/O

Board

DC Power

Pin 1

Connector

Port A

I/O Connector

Option

Jumpers

Power

Board

Head and Disc

Assembly (HDA)

Optional

Bezel

Chassis

ST43401N/ND, ST43402ND User’s Manual, Rev. B 3

Table 1. Drive specifications

Characteristics Conditions Specifications

Size Dimensions See “Space requirements”

in Section 2

Weight (drive only) 3.6 kg (8.0 lb)

Interface Fast and wide (16-bit) SCSI-2

Recording Total capacity (unformatted) 3,554,871,600 bytes

Bytes per track (unformatted)

Inner track 49,000 bytes

Outer track 72,800 bytes

Formatted capacity*

(256-byte sectors) 2,536,189,440 bytes

(512-byte sectors) 2,912,484,864 bytes

(1,024-byte sectors) 3,142,281,216 bytes

Number of discs 11

Recording heads 21

Servo heads 1

Physical heads per surface 1

Cylinders per head/disc assy 2,738

Cylinders available to user 2,735

Spare cylinders 1 (default/programmable)

System cylinders 1

Diagnostic cylinders 1

Spare sectors per cylinder 9 (default/programmable)

Modulation RLL 1,7 code

* Excluding spare sectors, spare cylinders, diagnostic cylinders, and

system cylinders.

continued

4 ST43401N/ND, ST43402ND User’s Manual, Rev. B

continued from previous page

Characteristics Conditions Specifications

SCSI transfer rate, burst 20.0 Mbytes/sec max

Seek time (time required Typical full 23.5 msec

to move heads to a different Typical average 11.5 msec

track address—excluding Typical one-track 1.7 msec

SCSI I/O overhead)

Typical access times Write Read

msec msec

Single track seek 1.7 0.9

Average seek 11.5 10.5

Maximum seek 23.5 22.5

Latency (time required Average 5.55 msec

to reach a particular (disc rotation

track address after head at 5,400 RPM)

positioning is complete)

Maximum 11.17 msec

(disc rotation

at 5,373 RPM)

Start time** 30 sec max

Stop time 30 sec max

** Following the power sequence delay, once DC power is applied and

start conditions are present.

ST43401N/ND, ST43402ND User’s Manual, Rev. B 5

The drive contains all the circuits and mechanical devices necessary to record

data on and recover it from its discs. The drive requires DC voltage inputs from

an external power supply, which you must supply. The DC power cable is

available as an accessory.

The ST43401N/ND drives consist of a head and disc assembly (HDA) with two

circuit boards, and the ST43402ND drive consists of an HDA and three circuit

boards. Each drive’s HDA and circuit boards are mounted on a common

chassis. The circuit boards contain the electronics required for drive operation. The HDA is a sealed unit containing the electromechanical components

used for data retrieval and storage . These components include the discs,

spindle, drive motor, actuator, heads, and preamplifiers.

The eleven discs provide the recording medium for the drive. These discs are

mounted on a spindle, and the spindle is coupled directly to the drive motor.

The drive motor rotates the discs at 5,400 RPM and produces a circulation of

air within the sealed HDA.

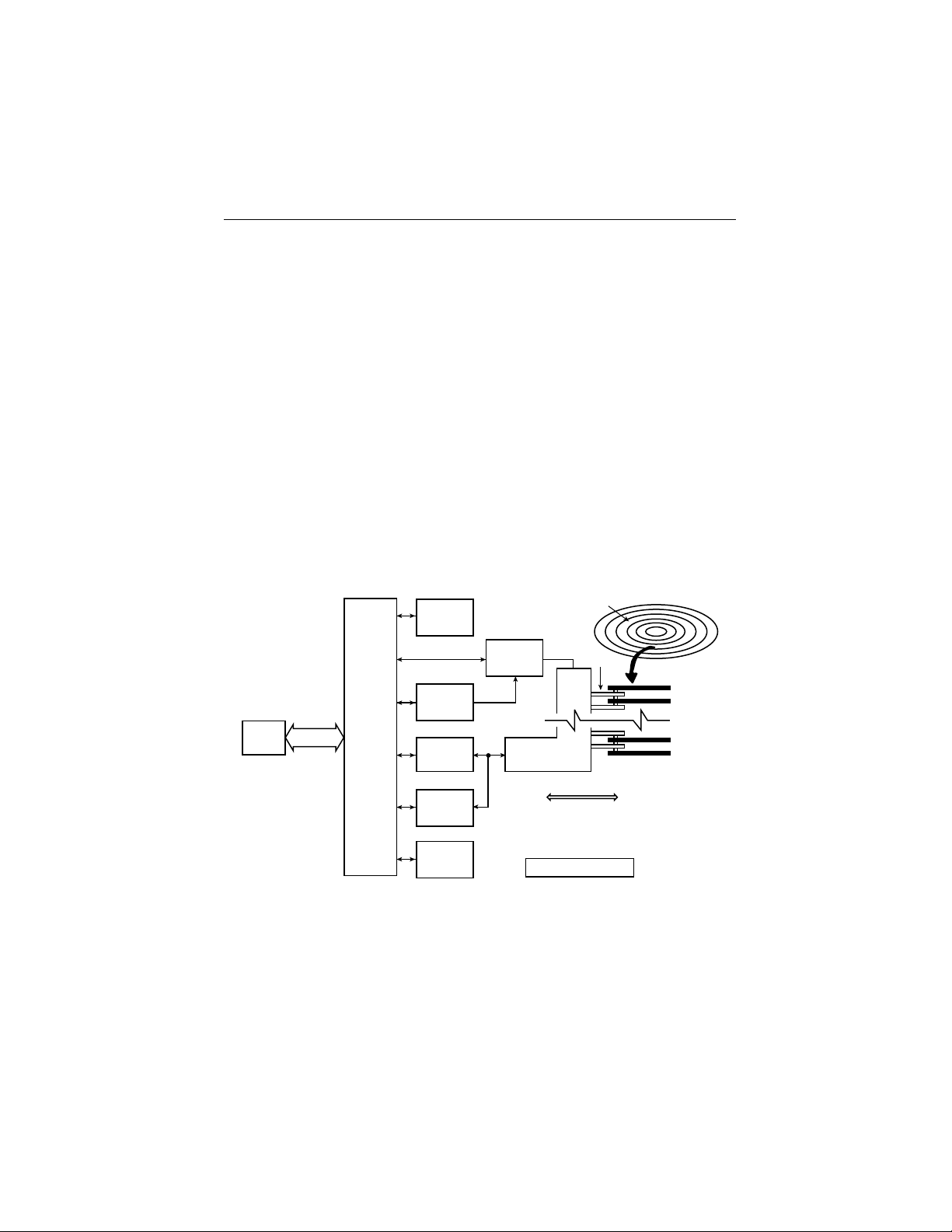

The built-in SCSI controller directs all drive functions, receives commands

from the initiator (host computer), interprets them, and then transfers the

necessary commands to the drive. The controller therefore allows the initiator

to start an operation and then disconnect to service another device. Refer to

the reference manual for a description of interface functions.

All drive operations are related to data recovery and storage (normally

referred to as reading and writing). The actual reading and writing is performed

by heads that are positioned over the rotating discs’ recording surfaces. There

is one head for each data surface. The heads are positioned in such a way that

data is written in concentric tracks around the disc surfaces (see Figure 3).

Before any read or write operation can be performed, the controller must

instruct the drive to position the heads over the desired cylinder (called

seeking) and use the head located over the surface (head selection) where the

operation is to be performed.

The heads are mounted on the actuator, and the actuator moves the heads

over the rotating discs. There are 22 heads—a servo head to sense actuator

positioning, and 21 data heads used for data transfers to and from the discs.

The actuator has a voice coil that moves in a permanent magnetic field in

response to signals from the servo positioning circuitry. The voice coil moves

the heads in an arc across the rotating discs.

6 ST43401N/ND, ST43402ND User’s Manual, Rev. B

When the drive is not powered on, the heads rest on the disc surface in a

preassigned landing zone beyond the data zone. The actuator automatically

latches in this position at shutdown for moving or shipping protection. When

the drive is activated to bring the discs up to speed, the heads fly on a cushion

of air close to the disc surface.

After arriving at the data track and selecting a head, the controller locates the

portion of the track where the data is to be read or written. This is called track

orientation. Signals from the drive indicate the beginning of each track. The

controller uses these signals to determine the position of the head on the track.

When the head is above the desired track location, the controller commands

the drive to actually read or write the data. During a read operation, the drive

retrieves data from the discs, processes it, and transmits it to the controller.

During a write operation, the drive receives data from the controller, processes

it, and stores it on the discs.

The drive can recognize certain errors that may occur during its operation.

When an error is detected, it is indicated to the initiator by the SCSI controller.

Unit

Selection

Logic

SCSI

Initiator

Controller

I/0 Lines

Read/Write

Logic

Seek

Logic

Track

Orientation

Logic

Error

Detection

Logic

Figure 3. Drive functional block diagram

Data recorded in

concentric tracks

Head

Selection

Logic

Heads

Discs

Power Supply

ST43401N/ND, ST43402ND User’s Manual, Rev. B 7

Section 2. Installation/Abschnitt 2. Installation

The information contained in this section describes installation and initial

checkout of the drive.

Site requirements

The site requirements considered are environment, airflow, space, power,

grounding, and interface.

Voraussetzungen am Aufstellungsort

Zu den Voraussetzungen am Aufstellungsort gehören Umgebung,

Luftfluß, Raum, Strombedingungen, Erdung und Schnittstelle.

Environmental requirements

All environmental requirements for the drive are listed in Table 2.

Umgebungsbedingungen

Alle Umgebungbedingungen für das Laufwerk sind in der

nachstehenden Tabelle 2 aufgelistet.

8 ST43401N/ND, ST43402ND User’s Manual, Rev. B

Table 2. Environmental requirements

Conditions Specifications

Operating environment

Temperature Range of 5°C to 50°C (41°F to 122°F) with a

maximum change of 20°C (36°F) per hour

Humidity Range of 5% to 95% relative

A maximum wet bulb temperature of 26°C (79°F)

Barometric pressure

Non-operating environment (unpacked)

Temperature Range of –40°C to 60°C (–40°F to 140°F) with a

Humidity Range of 5% to 95% relative

Barometric pressure

Transit and storage environment (packed)

Temperature Range of

Humidity Range of 5% to 95% relative

Barometric pressure

– 305 m to 3,048 m (– 1,000 ft to 10,000 ft)

104 kPa to 69 kPa (30 in Hg to 20 in Hg)

maximum change of 20°C (36°F) per hour

A maximum wet bulb temperature of 26°C (79°F)

– 305 m to 12,192 m (–1,000 ft to 40,000 ft)

104 kPa to 19 kPa (30 in Hg to 6 in Hg)

–40°C to 60°C (– 40°F to 140°F) with a

maximum change of 20°C (36°F) per hour

– 305 m to 12,192 m (–1,000 ft to 40,000 ft)

104 kPa to 19 kPa (30 in Hg to 6 in Hg)

ST43401N/ND, ST43402ND User’s Manual, Rev. B 9

Tabelle 2. Umgebungsbedingungen des Laufwerkes

Bedingungen Technische Daten

Betriebsumgebung

Temperatur 5°C bis 50°C mit einer maximalen

Schwankung von 20°C pro Stunde

Relative Luftfeuchtigkeit 5% bis 95%

Maximale Naßthermometertemperatur

von 26°C

Luftdruck

–305 m bis 3.048 m; 104 kPa bis 69 kPa

Umgebungsbedingungen bei Nichtbetrieb (unverpackt)

Temperatur

– 40°C bis 60°C mit einer maximalen

Schwankung von 20°C pro Stunde

Relative Luftfeuchtigkeit 5% bis 95%

Maximale Naßthermometertemperatur

von 26°C

Luftdruck

–305 m bis 12.192 m; 104 kPa bis 19 kPa

Lager-/Transportbedingungen (verpackt)

Temperatur –40°C bis 60°C mit einer maximalen

Schwankung von 20°C pro Stunde

Relative Luftfeuchtigkeit 5% bis 95%

Luftdruck

–305 m bis 12.192 m; 104 kPa bis 19 kPa

10 ST43401N/ND, ST43402ND User’s Manual, Rev. B

Air-flow requirements

The enclosure design must ensure adequate cooling for the drive. Note that

the fan in the power supply cools only the power supply’s internal parts.

The drive’s product specification (document 64403603) describes how to

evaluate the air-flow design. The evaluation consists of ensuring that the case

temperatures of certain critical components remain within acceptable limits

during drive operation.

We recommend orienting the drive or directing the air flow in a way that

creates the least amount of air-flow resistance while providing air flow

above the circuit boards and around the head and disc assembly (HDA).

Also, choose the shortest possible path between the air inlet and exit. This

minimizes the distance traveled by air that is heated by the drive and by

other nearby heat sources.

Figure 4 shows two design approaches with one or more fans used to

generate airflow. The air-flow patterns can be created by the fans either

pushing or drawing air. The overall flow pattern can be directed from front to

back, back to front, or side to side.

ST43401N/ND, ST43402ND User’s Manual, Rev. B 11

Above unit

Under unit

Note. Air flows in the direction shown (front to back)

or in reverse direction (back to front)

Above unit

Note. Air flows in the direction shown or

in reverse direction (side to side)

Figure 4. Suggested air flow/Empfohlener Luftstromverlauf

Under unit

12 ST43401N/ND, ST43402ND User’s Manual, Rev. B

Space requirements

The drive is designed to be mounted in one of the three orientations shown in

Figure 5. The drive may be mounted on its base or on either side. The

physical dimensions of the drive are shown in Figure 6. The drive weighs

3.6 kg (8.0 lb).

For details about designing an enclosure to match the drive mounting

dimensions, refer to the drive’s product specification.

Räumliche Anforderungen

Das Laufwerk ist für die Montage in einer der drei in Abbildung 5

gezeigten Orientierungen vorgesehen. Das Laufwerk kann entweder

auf der Bodenplatte oder auf einer der beiden Seiten montiert

werden. Andere als die hier gezeigten Orientierungen sind nicht

zulässig. Die Abmessungen des Laufwerkes sind in Abbildung 6

gezeigt. Das Laufwerk wiegt 3,6 kg.

Einzelheiten zur Konstruktion eines auf die Montageabmessungen

des Laufwerkes abgestimmten Gehäuses entnehmen Sie bitte den

Produktspezifikationen für das Laufwerk.

ST43401N/ND, ST43402ND User’s Manual, Rev. B 13

Up

Up

Up

Figure 5. Mounting orientations/

Montageorientierungen

14 ST43401N/ND, ST43402ND User’s Manual, Rev. B

82.55 mm

3.25 in

203.20 mm

149.35 mm

5.88 in

Figure 6. Dimensions of the drive/

Laufwerkabmessungen

8.00 in max

ST43401N/ND, ST43402ND User’s Manual, Rev. B 15

Power requirements

The voltage and current requirements for a single drive at cylinder 0 are shown

in Table 3. Ensure that your power supply meets these requirements.

Table 3. Single drive voltage and current requirements

Current without Internal Current with Internal

Terminator Terminator

Seeking Contin- Seeking Contin-

Voltage Idle Reading Reading Idle Reading Reading

SCSI single-ended interface (ST43401N)

+5V 1.8A 1.9A 1.9A 1.8A 1.9A 1.9A

+12V 1.8A 1.8A 1.8A 1.8A 1.8A 1.8A

Watts 30.6W 31.1W 31.1W 30.6W 31.1W 31.1W

SCSI differential interface (ST43401ND)

+5V 1.9A 2.2A 2.3A

+12V 1.8A 1.8A 1.8A

Watts 31.1W 32.6W 33.1W

SCSI dual-port differential (ST43402ND)

+5V 3.0A 3.6A 3.7A

+12V 1.8A 1.8A 1.8A

Watts 36.6W 39.6W 40.1W

continued

and uous and uous

16 ST43401N/ND, ST43402ND User’s Manual, Rev. B

continued from previous page

Without Internal With Internal

Terminator Terminator

Maximum Current Limits +5V

Regulation ± 5%

3,4,8,9

5,7

Amps Amps

SCSI single-ended interface (ST43401N)

Maximum operating current

Average idle current

1

Maximum starting current

Maximum seek current

2

1,2,6

1,2

1.9 1.8 2.3 1.8

1.8 1.8 1.9 1.8

1.9 4.5 2.3 4.5

1.9 3.2 1.9 3.2

SCSI differential interface (ST43401ND)

Maximum operating current

Average idle current

Maximum starting current

Maximum seek current

SCSI dual-port differential (ST43402ND)

Maximum operating current

Average idle current

Maximum starting current

Maximum seek current

1

Measured with an average reading DC ammeter.

2

Instantaneous +12V current peaks will exceed these values by up to 0.8A. The +12V average

current during a 15 ms portion of the actuator signal does not exceed 4.0A.

3

A ±10% tolerance on +12V is permissible during power-up.

4

Inclusive of ripple, noise, transient response (except for +12V), load variation, and environmental conditions. An overvoltage of the +5V (greater than 6V) must cause the power supply

to interrupt all DC voltages. Transient response assumes +12V changing from 1.0A to 7.2A

within 200 microsecs and all other voltages at a steady state.Transient response frequencies

above 30 kHz are now allowed.

5

The +12V ground return must be isolated from the +5V ground return in the power supply. The

+5V and +12V ground are shorted together in the drive. Where multiple units are powered on

simultaneously, the peak starting current must be available to each drive.

6

The drive requires overcurrent protection on all voltages. An overcurrent on the +12V must

cause the power supply to interrupt all DC voltages. Overcurrent on the +5V must reduce the

output current to zero and interrupt all DC voltages.

7

All voltages must meet specifications within 100 msecs after the first voltage reaches 10% of

its specified value.

8

Transient response frequencies above 30 kHz are not allowed.

9

Transient response assumes +12V changing from 1.0A to 7.2A within 200 microsecs and all

other voltages at a steady state.

1,2,6

1

1,2

9

1,2,6

1

1,2

2

1.9 1.8

1.8 1.8

1.9 4.5

1.9 3.2

2.3 1.8

1.9 1.8

2.3 4.5

2.2 1.8

+12V

5,7

+5V

5,7

+12V

5,7

ST43401N/ND, ST43402ND User’s Manual, Rev. B 17

Grounding requirements

A safety ground must be provided by the site AC power system. The green

wire (or green wire with yellow stripe) in the AC power cord provides the safety

ground connection between the power supply and the site AC power system.

The site AC power system must provide the safety ground to earth ground

connection.

All site AC power connection points, including convenience outlets for test

equipment, must be maintained at the same safety ground potential.

Interface requirements

An important part of site preparation is planning the layout and routing of I/O

cables. All drives and other SCSI devices are connected together and to

the host with an I/O cable. The SCSI bus can have up to 16 devices attached

to it as shown in Figure 7. The I/O cabling scheme used is called a daisy chain.

Each end of the SCSI bus must be terminated.

Term

SCSI

Device

0

SCSI

Device

1

SCSI

Device

2

SCSI

Device

3

Figure 7. SCSI bus configuration

Term

SCSI

Device

15

SCSI

Device

14

SCSI

Device

13

SCSI

Device

12

18 ST43401N/ND, ST43402ND User’s Manual, Rev. B

A connector (J6) at the back of the drive accepts the I/O cable that connects

it to the system. The daisy-chain cable is a continuous unshielded cable

having one connector for each drive it connects to.

Refer to the reference manual (publication 83327730) for guidelines on I/O

cabling. These guidelines discuss the use of unshielded cabling inside

cabinets and shielded cabling running between cabinets. They also contain

information about constructing continuous daisy-chain cabling (including part

numbers for the required cabling components).

Table 4 shows the pin assignments and signal names for the unshielded

single-ended I/O P cable. Table 5 shows the pin assignments and signal

names for the unshielded differential I/O P cable. Detailed information about

interface lines is provided in the reference manual.

ST43401N/ND, ST43402ND User’s Manual, Rev. B 19

Table 4. Unshielded single-ended I/O cabling (P cable)

Even pin Odd in

Signal name numbers Signal name numbers

DB– (12) 2 GROUND 1

DB– (13) 4 GROUND 3

DB– (14) 6 GROUND 5

DB– (15) 8 GROUND 7

DB– (P1) 10 GROUND 9

DB– (0) 12 GROUND 11

DB– (1) 14 GROUND 13

DB– (2) 16 GROUND 15

DB– (3) 18 GROUND 17

DB– (4) 20 GROUND 19

DB– (5) 22 GROUND 21

DB– (6) 24 GROUND 23

DB– (7) 26 GROUND 25

DB– (P) 28 GROUND 27

GROUND 30 GROUND 29

GROUND 32 GROUND 31

TERMPWR 34 TERMPWR 33

TERMPWR 36 TERMPWR 35

RESERVED 38 RESERVED 37

GROUND 40 GROUND 39

ATN– 42 GROUND 41

GROUND 44 GROUND 43

BSY– 46 GROUND 45

ACK– 48 GROUND 47

RST– 50 GROUND 49

MSG– 52 GROUND 51

SEL– 54 GROUND 53

C/D– 56 GROUND 55

REQ– 58 GROUND 57

I/O– 60 GROUND 59

DB– (8) 62 GROUND 61

DB– (9) 64 GROUND 63

DB– (10) 66 GROUND 65

DB– (11) 68 GROUND 67

Note. A minus sign indicates active low.

20 ST43401N/ND, ST43402ND User’s Manual, Rev. B

Table 5. Unshielded differential I/O cabling (P cable)

Even pin Odd pin

Signal name numbers Signal name numbers

DB– (12) 2 DB (12) 1

DB– (13) 4 DB (13) 3

DB– (14) 6 DB (14) 5

DB– (15) 8 DB (15) 7

DB– (P1) 10 DB (P1) 9

GROUND 12 GROUND 11

DB– (0) 14 DB (0) 13

DB– (1) 16 DB (1) 15

DB– (2) 18 DB (2) 17

DB– (3) 20 DB (3) 19

DB– (4) 22 DB (4) 21

DB– (5) 24 DB (5) 23

DB– (6) 26 DB (6) 25

DB– (7) 28 DB (7) 27

DB– (P) 30 DB (P) 29

GROUND 32 DIFFSENS 31

TERMPWR 34 TERMPWR 33

TERMPWR 36 TERMPWR 35

RESERVED 38 RESERVED 37

ATN– 40 ATN 39

GROUND 42 GROUND 41

BSY– 44 BSY 43

ACK– 46 ACK 45

RST– 48 RST 47

MSG– 50 MSG 49

SEL– 52 SEL 51

C/D– 54 C/D 53

REQ– 56 REQ 55

I/O– 58 I/O 5 7

Note. A minus sign indicates active low.

continued

ST43401N/ND, ST43402ND User’s Manual, Rev. B 21

continued from previous page

Even pin Odd pin

Signal name numbers Signal name numbers

GROUND 60 GROUND 59

DB– (8) 62 DB (8) 61

DB– (9) 64 DB (9) 63

DB– (10) 66 DB (10) 65

DB– (11) 68 DB (11) 67

Notes:

1. A minus sign indicates active low.

2. Eight-bit devices connected to the P cable must leave the following

signals open:

DB– (12) DB (12)

DB– (13) DB (13)

DB– (14) DB (14)

DB– (15) DB (15)

DB– (P1) DB (P1)

DB– (8) DB (8)

DB– (9) DB (9)

DB– (10) DB (10)

DB– (11) DB (11)

22 ST43401N/ND, ST43402ND User’s Manual, Rev. B

Unpacking, inspection, and repacking

After removing the packing material, inspect the drive for shipping damage.

Save all packing materials for future use.

The drive is shipped separately from any other items ordered for the

installation.

Unpacking

1. Allow the drive temperature to approach the ambient temperature of the

unpacking area. Ensure that the temperature stabilization period meets

the requirements printed on the drive container.

2. Open the package and remove the drive from its conductive static

shielding bag, using precautions described in “Electrostatic discharge

protection” in the preface.

3. Check all items against the shipping bill for the required equipment and

hardware to complete installation. Discrepancies, missing items, damaged equipment, etc. should be reported to the sales representative from

whom the drive was purchased.

Inspection

Inspect the drive for possible shipping damage. All claims for shipping

damage should be filed with the carrier involved.

Repacking

If it is necessary to ship the drive, repack the drive with the original packing

materials (saved during unpacking). Refer to Section 5 for instructions.

ST43401N/ND, ST43402ND User’s Manual, Rev. B 23

Installation procedures

With the site requirements completed, the enclosure designed, and the drive

unpacked you are ready to begin the installation. The following procedures are

included in drive installation:

• Setting the circuit board jumpers

• Installing a power supply

• Attaching an optional bezel

• Mounting the drive

• Connecting the system I/O cabling

• Grounding the system

• Synchronizing the spindle

Setting the control board jumpers

Caution. Do not remove the circuit boards to set jumpers.

The circuit boards on the drive contain a number of jumpers that must be set

correctly for normal operation of the drive. The termination must also be set

correctly for normal operation.

ST43401N and ST43401ND drives have two circuit boards—one control

board and one power board—but all of the necessary jumpers, including the

termination jumper and terminator resistor-pak sockets, are on the control

board. See Figure 8 to configure an ST43401N or ST43401ND drive.

The ST43402ND drive has two circuit boards—one control board and one

I/O board—which must be configured correctly for normal drive operation.

See Figures 9, 10, 11, and 12 to configure an ST43402ND drive.

Note. The option pin headers on J10 (see Figure 11) are provided for manual

drive configuration. This helps you connect the disc drive to an external

device such as a switch or connection. Ground should be provided by

the external device.

24 ST43401N/ND, ST43402ND User’s Manual, Rev. B

Write Protect/Enable (WRT)

Fault LED connector

Ready LED connector

Slave Select (SLV)

J4A

Write Protect/Enable (WRT)

Write protect (disable writing)

Write enable (enable writing)

Slave Select (SLV)

Master (master drive for spindle sync)

Slave (slave drive unless selected as

the master by a SCSI command)

ID3

ID2

ID1

ID0

Motor (MTR)

Ground (GND)

Key (no pins)

Spindle Sync Clock – (SSCLK–)

Spindle Sync Clock + (SSCLK+)

J7

SCSI Unit Selectors

Unit Select ID = 0

Unit Select ID = 1

Unit Select ID = 2

Unit Select ID = 3

Unit Select ID = 4

Unit Select ID = 5

Unit Select ID = 6

Unit Select ID = 7

Unit Select ID = 8

Unit Select ID = 9

Unit Select ID = A

Unit Select ID = B

Unit Select ID = C

Unit Select ID = D

Unit Select ID = E

Unit Select ID = F

WRT

Unit Selectors

ID3 ID1

ID2 ID0

MTR

SLV

Spindle

Sync Pins

Terminator Resistor-Paks (3)

(must be installed if drive is at

either end of the daisychain)

Pin 1

Pin 1

Pin 1

Spinup Delay Option (SDO)

Start Command Option (SCO)

SCSI Bus Parity Check Option (SCPAR)

Sweep Cycle Option (SWP)

Spinup Delay Option (SDO)

Immediate spinup

(if the Start Command Option jumper is disconnected)

Spinup delay equal to the SCSI bus ID multiplied

by 10 seconds (if the Start Command Option

jumper is disconnected)

Start Command Option (SCO)

Start spindle according to the Spinup Delay

Option jumper

Start spindle after the SCSI bus sends a Start

Unit command

SCSI Bus Parity Check Option (SCPAR)

Enable parity check of SCSI bus data

Ignore parity

Sweep Cycle Option (SWP)

Disable sweep cycles (recommendation – sweep cycles

should be enabled at the system or subsystem level)

Enable sweep cycles at the drive level

4

3

2

Assign the terminal power jumpers as shown below.

Internal terminator power source.

External terminator power source.

Internal terminator power to I/O.

J01

Terminator Power Source Jumper

1

J4B

= Jumper

connected

= Jumper not

connected

= Non-applicable

jumper (not

relevant to the

option discussed)

SDO SCPAR

SCO SWP

214

3

Figure 8. ST43401N/ND control board jumpers

ST43401N/ND, ST43402ND User’s Manual, Rev. B 25

= Jumper

connected

= Jumper not

connected

= Non-applicable jumper

(not relevant to the

option discussed)

Not used

Not used

Not used

Write Protect/Enable (WRT)

Slave Select (SLV)

J4A

N/A WRT

Write Protect/Enable (WRT)

Write protect (disable writing)

Write enable (enable writing)

Slave Select (SLV)

Master (master for spindle sync)

Slave (slave drive unless

selected as the master by a

SCSI command)

N/A N/A

SLV

Spinup Delay Option (SDO)

Immediate spinup

(if the Start Command Option jumper

is disconnected)

Spinup delay equal to the SCSI bus ID

multiplied by 10 seconds (if the Start

Command Option jumper is disconnected)

Start Command Option (SCO)

Start spindle according to the Spinup

Delay Option jumper

Start spindle after the SCSI bus sends

a Start Unit command

SCSI Bus Parity Check (SCPAR)

Enable parity check of SCSI bus data

Ignore parity

Sweep Cycle Option (SWP)

Disable sweep cycles (recommendation —

sweep cycles should be enabled at the

system or subsystem level)

Enable sweep cycles at the drive level

Figure 9. ST43402ND control board jumpers

Spinup Delay Option (SDO)

Start Command Option (SCO)

SCSI Bus Parity Check Option (SCPAR)

Sweep Cycle Option (SWP)

J4B

SDO SCPAR

SCO SWP

26 ST43401N/ND, ST43402ND User’s Manual, Rev. B

Ground (GND)

Pin 2

Pin 1

J09

SCSI Bus Select Mode (SBS)

ID_A0 (A0)

ID_A1 (A1)

ID_A2 (A2)

ID_A3 (A3)

ID_B0 (B0)

ID_B1 (B1)

ID_B2 (B2)

ID_B3 (B3)

Port A SCSI ID Selectors

Port B SCSI ID Selectors

GND

= Jumper

connected

= Jumper not

connected

= Non-applicable jumper

(not relevant to the

option discussed)

GND

Port A SCSI ID

Port A SCSI ID = 0

Port A SCSI ID = 1

Port A SCSI ID = 2

Port A SCSI ID = 3

Port A SCSI ID = 4

Port A SCSI ID = 5

Port A SCSI ID = 6

Port A SCSI ID = 7

Port A SCSI ID = 8

Port A SCSI ID = 9

Port A SCSI ID = A

Port A SCSI ID = B

Port A SCSI ID = C

Port A SCSI ID = D

Port A SCSI ID = E

Port A SCSI ID = F

Port B dictates Port A’s SCSI ID

(the drive ignores all Port A

jumpers and assigns Port A the

same SCSI ID as Port B)

B2 B0

A3 A1

A2 A0

SBSB3 B1

Figure 10. ST43402ND I/O board J09 jumpers

Port B SCSI ID

Port B SCSI ID = 0

Port B SCSI ID = 1

Port B SCSI ID = 2

Port B SCSI ID = 3

Port B SCSI ID = 4

Port B SCSI ID = 5

Port B SCSI ID = 6

Port B SCSI ID = 7

Port B SCSI ID = 8

Port B SCSI ID = 9

Port B SCSI ID = A

Port B SCSI ID = B

Port B SCSI ID = C

Port B SCSI ID = D

Port B SCSI ID = E

Port B SCSI ID = F

B2 B0

A3 A1

A2 A0

SBSB3 B1

ST43401N/ND, ST43402ND User’s Manual, Rev. B 27

LED 4 (L4)

Write Protect/Enable LED (WPL)

Port B Active LED (PB)

Port A Active LED (PA)

Ready LED (RL)

Pin 2

Pin 1

LED 6 N/A (L6)

Spinup Delay Option (SDO)

Fault LED (FL)

Not Assigned (NA)

J10

ID 03 (ID3)

Panel Start/Stop (PSS)

ID 00 (ID0)

SCSI Bus Select (SBS)

Self-Test (ST)

ID 01 (ID1)

ID 02 (ID2)

Write Protect/Enable (WRT)

Manual Reset (MR)

WPL PA

L6 FL

RL SDO

= Ground this pin to the

external device to activate

the option discussed

= Remove ground from this pin

using the external device to negate

this option

= Non-applicable pin (not relevant to the

option discussed)

WPL PA

NAL4 PB

RL SDO

L6 FL

NAL4 PB

ST ID0

Manual Reset (MR)

Ground this pin to manually reset the SCSI board.

Remove ground after reset.

Write Protect/Enable (WPL)

Write protect (disable writing)

Write enable (enable writing)

Panel Start/Stop (PSS)

Start spindle after the SCSI bus sends a

Start Unit command.

Start spindle according to the Spinup Delay

Option (SDO) pin on this I/O board.

Spinup Delay Option (SDO)

Used only if the PSS pin jumper is not connected.

Start turning spindle when power is applied.

Start spindle after a delay. The delay

(in seconds) is 10 seconds times the SCSI ID.

For example, when the SCSI ID is 4, a delay

of 40 seconds occurs before spinup starts.

SCSI Bus Select Mode Option (SBS)

Allow ports A and B to have different SCSI IDs.

Assign port A the same SCSI ID that port B has.

Self-Test (ST)

Use this pin to connect an indicator which will flash

when the drive is in the self-test mode of power up.

WRT ID1

SBS PSS

Figure 11. ST43402ND I/O board J10 jumpers

ID3MR ID2

SCSI Bus ID

SCSI ID = 0

SCSI ID = 1

SCSI ID = 2

SCSI ID = 3

SCSI ID = 4

SCSI ID = 5

SCSI ID = 6

SCSI ID = 7

SCSI ID = 8

SCSI ID = 9

SCSI ID = A

SCSI ID = B

SCSI ID = C

SCSI ID = D

SCSI ID = E

SCSI ID = F

WRT ID1

ST ID0

SBS PSS

ID3MR ID2

28 ST43401N/ND, ST43402ND User’s Manual, Rev. B

= Jumper

connected

= Jumper not

connected

= Non-applicable jumper

(not relevant to the

option discussed)

Port B I/O

J03

Enable/Disable Port A (EPA)

Enable/Disable Port B (EPB)

Enable/Disable Port A

Enable Port A

Disable Port A

Enable/Disable Port B

Enable Port B

Ground (GND)

Ground (GND)

EPA

GND

EPB

J01B

J01A

Port A I/O

J01

GND

Terminator Power J01A is for

Port A and J01B is for Port B.

Assign the terminal power

jumpers as shown below.

Internal terminator power source.

External terminator power source.

(A & B)

4

2

3

1

4

2

3

1

Disable Port B

Enable Port A and Port B

Simultaneously

Use jumpers to connect the four

pins as illustrated.

Internal terminator power to I/O.

Figure 12. ST43402ND I/O board J01 and J03 jumpers

ST43401N/ND, ST43402ND User’s Manual, Rev. B 29

Installing a power supply

A power supply is required to provide current to the disc drive. Several vendors

offer power supplies that meet the disc drive’s power requirements. Ensure

that the power supply you select meets these requirements as specified in

Table 3.

Setting the voltage range

Caution. Most power supplies will be damaged if the voltage select is set for

the low range (100–120 VAC) and a voltage in the high range (208–

240 VAC) is applied.

1. Ensure that the AC power cable is disconnected from the power supply.

2. Refer to the power supply documentation, or contact the supplier for

instructions.

Mounting the power supply

1. Mount the power supply in the desired location.

2. Connect a ground strap between the power supply and the cabinet ground.

3. Attach the AC power cord to the power supply connector. Do not connect

the power cord to site power until directed.

30 ST43401N/ND, ST43402ND User’s Manual, Rev. B

Attaching an optional bezel

Use the following procedure to attach an optional bezel to the drive. The bezel

is available as an accessory (see Section 4).

1. Remove the backing from the double-sticky tape attached to the rear

surface of the bezel.

2. Orient the drive and bezel as shown in Figure 13.

3. Align the mounting bosses on the rear of the bezel to the matching holes

in the drive chassis.

4. Press the bezel into place on the drive chassis ensuring that the mounting

bosses extend through the chassis holes and that the double-sticky tape

is in contact with both bezel and chassis.

5. Remove the selected LED (if present) from the LED socket and insert the

LED plug from the bezel into the socket.

Control

Board

LED

Socket

LED

Plug

Chassis Mounting Holes (2)

Active

LED

Figure 13. Attaching a bezel (ST43401N/ND shown)

Bezel

Mounting Boss

Chassis

ST43401N/ND, ST43402ND User’s Manual, Rev. B 31

Mounting the drive

Caution. When installing the drive, observe all precautions listed under

“Electrostatic discharge protection” in the preface. Failure to observe these precautions can result in serious damage to electronic

assemblies.

The drive may be secured to the enclosure using the tapped holes in either the

sides or the bottom of the drive chassis. Figure 14 shows two of the three

allowable orientations.

Note. The mounting screws must be completely engaged in the drive

chassis, but the portion that extends into the chassis must not exceed

3.5 mm (0.140 in) in length.

1. Place the drive into position in the enclosure and secure with four screws

as shown in Figure 14.

• For bottom mounting, use 6-32 screws.

• For side mounting, use either 6-32 screws or M4 x .70 (metric) screws.

There are tapped holes for each type.

2. Connect the 9-pin connector of the DC power cable to the output connector

on the power supply. Connect the 4-pin connector of the same cable to the

DC power connector J15 on the drive.

3. Connect the AC power cord to site power.

32 ST43401N/ND, ST43402ND User’s Manual, Rev. B

1

6-32

Bottom-Mounting

Screws (4)

DC power and pin

2

connector assignments

1234

Power Supply

Up

(9 pin)

Pin Number

7, 8

6, 9

3, 4

1, 2

Up

2

DC Power

Connector

J15

Drive

Pin

1

2

3

4

Power

+12 VDC

+12 Volts return

+5 Volts return

+5 VDC

Pin 1

DC Power

Cable

Note:

Either side- or bottom-mounting screws

1

can be used with each drive orientation

M4 x .70

(metric)

Figure 14. Mounting the drive (ST43401N/ND shown)

M4 x .70

(metric)

6-32

Screw

6-32

Screw

Side-Mounting

Screws (2 on

1

each side)

ST43401N/ND, ST43402ND User’s Manual, Rev. B 33

Connecting the system I/O cabling

Make sure the site has been prepared in accordance with the site requirements information provided earlier in this section. This procedure describes

how to cable the system in a daisy-chain configuration, which was discussed

earlier in this section in “Interface requirements.”

ST43401N/ND drives

The drive has one I/O connector on the control board. Figure 15 shows how

a typical I/O cable connects to the board.

If the drive is either the first or last device (at either end) in the daisy chain, it

must be terminated. Drives in the middle of the daisy chain must not be

terminated. Drives that are terminated have three terminator resistor-paks

installed as shown in Figures 17 (ST43401N) and 18 (ST43401ND).

I/O

Connector

Pin 1

Daisychain

I/O Cable

Figure 15. ST43401N/ND I/O cable attachment

34 ST43401N/ND, ST43402ND User’s Manual, Rev. B

ST43402ND drives

ST43402ND drives have two I/O connectors as shown in Figure 16. Both of

these I/O connectors (one for Port A and the other for Port B) are located on

the I/O board. Figure 16 shows how typical I/O cables connect to the I/O board.

You must use an adapter (part number 70935801) to terminate each I/O cable

following the last drive in the daisy chain. Refer to information earlier in this

section regarding the terminator power source jumpers and interface requirements.

Port B

Daisychain

I/O Cable

Port B

I/O Connector

I/O

Board

Figure 16. ST43402ND I/O cable attachment

Port A

I/O Connector

Port A

Daisychain

I/O Cable

ST43401N/ND, ST43402ND User’s Manual, Rev. B 35

Figure 17 shows how the terminator resistor-paks are attached on ST43401N

drives (single-ended I/O). The terminator resistor-paks, which are single inline

packages, mount in the rows of holes located in the control board. Ensure that

they are installed with the correct orientation (indicated by a dot above pin 1)

to terminate these drives.

Terminator

Resistor-Paks

(part number

96752447)

Terminator

Power

Source Jumper

Figure 17. ST43401N terminator attachment—single-ended I/O

Terminator

Resistor-Pak

(note orientation)

Mounting Holes

in Control Board

Pin

1

36 ST43401N/ND, ST43402ND User’s Manual, Rev. B

Figure 18 shows how the terminator resistor-paks are attached on ST43401ND

drives (differential I/O). These terminator resistor-paks, which are dual inline

packages, mount in sockets in the control board. These terminators are also

marked with a dot above pin 1.

If the drive is located at either end of the daisy chain, ensure that it has

resistor-pak(s) installed. Refer to information earlier in this section regarding the terminator power source jumper.

Terminator

Resistor-Paks

(part number

70906701)

Terminator

Power

Source Jumper

Figure 18. ST43401ND terminator attachment—differential I/O

Terminator

Resistor-Pak

(note orientation)

Terminator

Socket

Pin 1

ST43401N/ND, ST43402ND User’s Manual, Rev. B 37

Grounding the system

Grounding the system through the power cables and I/O cables is usually

sufficient to protect against noise and emissions.

Synchronizing the spindle

The spindle sync feature makes it possible to synchronize the spindle rotation

of a group of disc drives. This reduces the latency normally encountered when

the initiator switches between multiple disc drives.

Figure 19 shows two system configurations. In one type of system, one of the

disc drives in the system provides the reference clock. In the other type, an

external signal source provides the reference clock.

Internal Source

Spindle

Sync

Cable

Select

Plug

SP

J05

T

Drive

J05

Drive

(master)

✴

J05

Drive

SP

32 loads

maximum

Terminator

Master designated by jumper or by initiator

✴

J05

Drive

T

SP

Spindle

Sync

Cable

32 loads

maximum

Terminator

External Source

Signal Source

T

J05

Drive

SP

J05

Drive

SP

J05

Drive

T

SP

Figure 19. System diagram for spindle sync

38 ST43401N/ND, ST43402ND User’s Manual, Rev. B

To enable the feature, it is necessary to run an additional daisy-chain cable

from drive to drive and to make a master/slave selection for each drive.

Connector J7 is used by ST43401N/ND drives. Connector J5 on the control

board handles the cable connections on ST43402ND drives. Master/slave

selection is made by a jumper on connector J4A. Figure 20 shows the two

connectors for ST43401N/ND drives, and Figure 21 shows the two connectors for ST43402ND drives.

For a drive at the end of the daisy chain, the cable connects to one of the two

rows of pins (row A or row B), and a terminator connects to the other row of

pins. Both ends of the cable must be terminated.

Pin 1

J7

Cable from

Preceding Unit

A

B

Cable to

Next Unit

Control

Board

J4A

Select Plug

(removed = master)

Figure 20. Making ST43401N/ND spindle sync connections

Slave Select

ST43401N/ND, ST43402ND User’s Manual, Rev. B 39

Cable from

Preceding Unit

Cable to

Next Unit

J5

Pin 1

A

B

Control

Board

J4A

Select Plug

(removed = master)

Figure 21. Making ST43402ND spindle sync connections

Slave Select

40 ST43401N/ND, ST43402ND User’s Manual, Rev. B

For each drive in the middle of the daisy chain, the cable from the preceding

unit connects to one row of pins in (row A or row B), and the cable to the next

unit connects to the other row of pins.

There are two ways to establish a drive as a master (supplying the sync

reference signal to all drives connected for spindle sync).

• Remove the jumper connecting the master/slave pins on connector J4A

(the drives are shipped with the pins disconnected).

• Issue that drive a Mode Select command on the SCSI interface (The jumper

must be connecting the master/slave pins). The spindle sync is controlled

by the RPL bits in page 4, byte 17 of the Mode Select (or Mode Sense)

parameters.

Only one drive in the daisy chain can be established as the master. The master

drive can be located anywhere along the daisy-chain cable as long as both

ends of the cable are terminated.

ST43401N/ND, ST43402ND User’s Manual, Rev. B 41

Verification

After installing the drive, follow the sequence outlined below for initial startup.

1. Place the on/standby switch in the on ( l ) position. What follows

depends on the setting of the Start Command option and the Spinup

Delay option jumpers.

• If the Start Command option jumper was connected, the spindle spinup

begins immediately after a Start Unit command is received from the

SCSI bus.

• If the Spinup Delay option jumper and the Start Command option jumper

were both disconnected, the spindle spinup begins immediately.

• If the Spinup Delay option jumper was connected and the Start Com-

mand option jumper was disconnected, the spindle spinup begins after

a sequence delay interval. The length of this interval equals the SCSI

Bus ID number (Target ID) multiplied by 10 seconds.

For example: SCSI bus ID 0 = 0 second delay

SCSI bus ID 15 = 150 second delay

2. Observe that the Ready LED begins flashing when power is applied to the

spindle motor. The Ready LED is one of two green control board LEDs—

see Figure 22.

3. Observe that the Ready LED lights steadily within 30 seconds after the

power is applied to the spindle motor. This indicates that drive motor is up

to speed and that heads are at track 0.

4. Observe that the Heartbeat LED is blinking. This indicates that the

SCSI controller is operating properly. The Heartbeat LED is the other

green control board LED—see Figure 22.

If all of these events occurred, the drive is now ready for online operation. If

any event did not occur, a problem exists in the drive or its installation—refer

to maintenance information in Section 5.

ST43401N/ND, ST43402ND User’s Manual, Rev. B 43

Section 3. Operation

This section provides the information and instructions to operate the drive. It

is arranged as follows:

• LED indicators—locates and describes the switches and indicators used for

normal drive operation.

• Operating instructions—describes procedures for operating the drive.

LED indicators

Following initial checkout, the drive normally requires no attention from the

operator. Although power is usually left on, as the operator you should know

where the on/standby switch is located on the power supply. Also, you may

be asked to examine the LED indicators.

Two of the maintenance LEDs are located on the drive’s control board. The

third maintenance LED is located either on the control board or on an optional

bezel (if the bezel is installed). Figure 22 shows the LED indicators on

ST43401N/ND drives, and they are explained in Table 6. Figure 23 shows the

LED indicators on ST43402ND drives; they are explained in Table 7.

44 ST43401N/ND, ST43402ND User’s Manual, Rev. B

Socket for Active LED (red)

Heartbeat LED (green)

Active LED

(on optional

bezel)

Ready LED (green)

Control

Board

Figure 22. LEDs on ST43401N/ND drives

ST43401N/ND, ST43402ND User’s Manual, Rev. B 45

Table 6. LED functions for ST43401N/ND drives

LED indicator Function

Drive control board

Ready LED This LED flashes during the power-on sequence until

(green) the discs are up to speed and the heads are loaded.

It is on steady with power-on complete, assuming that

there are no fault conditions.

It flashes during a power-off sequence. This occurs

when the drive receives a Start/Stop Unit command

after it has once been started.

Heartbeat LED This LED blinks when the SCSI controller is operating

(green) properly.

If the LED is constantly on or off, it indicates one of two

things:

• The SCSI controller is not functioning properly.

• The SCSI controller is executing diagnostics and

should be ready in a few seconds.

Active LED This LED socket is provided for units which do not use

(socket) the optional bezel. When the active LED is inserted

into this socket, it indicates SCSI command activity.

When it is on, the drive is executing a SCSI command.

When it is off, the drive does not have a SCSI

command to execute.

Optional bezel on drive

Active LED This LED indicates command activity by the drive.

(color unspecified)

When it is on, the drive is executing a SCSI command.

When it is off, the drive does not have a SCSI

command to execute.

46 ST43401N/ND, ST43402ND User’s Manual, Rev. B

Socket for Active LED (red)

Heartbeat LED (green)

Ready LED (green)

Control

Board

Port A Enabled LED (green)

Port B Active LED (red)

Port B Enabled LED (green)

Figure 23. LEDs on ST43402ND drives

Optional

Bezel

ST43401N/ND, ST43402ND User’s Manual, Rev. B 47

Table 7. LED functions for ST43402ND drives

LED indicator Function

Drive control board

Ready LED This LED flashes during the power-on sequence until

(green) the discs are up to speed and the heads are loaded.

It is on steady with power-on complete, assuming that

there are no fault conditions.

It flashes during a power-off sequence. This occurs

when the drive receives a Start/Stop Unit command

after it has once been started.

Heartbeat LED This LED blinks when the SCSI controller is operating

(green) properly.

If the LED is constantly on or off, it indicates one of two

things:

• The SCSI controller is not functioning properly.

• The SCSI controller is executing diagnostics and

should be ready in a few seconds.

Active LED This LED socket is provided for units which do not use

(socket) the optional bezel. When the active LED is inserted

into this socket, it indicates SCSI command activity.

When it is on, the drive is executing a SCSI command.

When it is off, the drive does not have a SCSI

command to execute.

Optional bezel on drive

Active LED This LED indicates command activity by the drive.

(color unspecified)

When it is on, the drive is executing a SCSI command.

When it is off, the drive does not have a SCSI

command to execute.

continued

48 ST43401N/ND, ST43402ND User’s Manual, Rev. B

continued from previous page

LED or indicator Function

SCSI I/O board

SCSI port A enabled This LED is on steady when port A is enabled to

(green) receive SCSI commands and to transfer data on

this port.

SCSI port B enabled This LED is on steady when port B is enabled to

(green) receive SCSI commands and to transfer data on

this port.

SCSI port A active This LED is on when port B is actively executing a

(red) SCSI command.

This LED is off when port B does not have a SCSI

command to execute.

Operating instructions

Following initial checkout, the drive normally requires no attention from the

operator. DC power is available to the drive, as the On/Standby switch on the

power supply is normally left in the On (l ) position.

If you wish to verify that the drive has completed its power-on sequence,

access the drive and then check that its Ready LED is on steady and that the

Heartbeat LED is blinking (see Figure 22 for ST43401N/ND drives or Figure

23 for ST43402ND drives).

If the Start Command option was selected (using a circuit board jumper), the

Stop/Start Unit command must be used to start and stop the drive.

If the Start Command option was not selected, once the drive has been

started, the Stop/Start Unit command can be used to stop and later restart the

drive.

ST43401N/ND, ST43402ND User’s Manual, Rev. B 49

Section 4. Parts data

This section lists part numbers of options and accessories that can be used

in a drive installation. Because the drive is depot repairable, there are no fieldreplaceable parts. If the drive requires maintenance, refer to the instructions

in Section 5.

Table 8 lists the part numbers for options and accessories for system

installation.

50 ST43401N/ND, ST43402ND User’s Manual, Rev. B

Table 8. Options and accessories

Part

number Description

12263496 Static ground wrist strap, 6 1/2 to 8-inch wrist

** I/O cables (unshielded)

** External terminators

96752447 Terminator resistor-pak, single-ended

70906701 Terminator resistor-pak, differential

70935801 Terminator adapter cable assembly, differential

75168323 AC power cord set, 100–120V, 60 Hz, 5-15P

75168334 AC power cord set, 208–240V, 60 Hz, 6-15P

75168324 AC power cord set, 208–240V, 50 Hz

89500420 DC power cable, 24 inches (609.6 mm) long

(power supply to drive)

89500422 DC power cable, 6 inches (15.2 cm) long (power supply to drive)

70553701 Bezel, black (with red LED, cable, and double-sticky tape)

70553702 Bezel, black (with green LED, cable, and double-sticky tape)

70703929 Spindle sync cable*, 1.5 feet (0.46 meter) long

70703921 Spindle sync cable*, 3 feet (0.92 meter) long

70703922 Spindle sync cable*, 5 feet (1.52 meter) long

70703923 Spindle sync cable*, 7 feet (2.12 meter) long

70703924 Spindle sync cable*, 10 feet (3.05 meter) long

70703925 Spindle sync cable*, 20 feet (6.10 meter) long

70703926 Spindle sync cable*, 30 feet (9.14 meter) long

70703927 Spindle sync cable*, 40 feet (12.20 meter) long

70703928 Spindle sync cable*, 50 feet (15.24 meter) long

70574221 Spindle sync terminator

97630051 Shunt, two-pin (2 mm)

(used to select options on circuit board jumpers)

70935801 Adapter cable assembly

* A custom cable may be needed for spindle sync connection between a drive

and an external source.

** See the reference manual (publication 83327730) for part numbers of

terminators, complete I/O cables, and connectors and cabling needed to

create custom I/O cables.

ST43401N/ND, ST43402ND User’s Manual, Rev. B 51

Section 5. Maintenance

This section contains the following maintenance information:

• Observing maintenance precautions

• Arranging for depot repair

• Removing and replacing a drive

• Packing a drive for shipment

Observing maintenance precautions

Because the drive is depot repairable, there are no field-replaceable parts.

Before beginning any maintenance activities, observe the following precautions:

• Follow the precautions listed under “Electrostatic discharge protection” in

the preface.

• Do not remove any circuit boards from the drive chassis. Return the entire

drive for depot repair if any circuit board is defective. Removal of circuit

boards by personnel not performing depot repair will damage components

and may void the warranty.

• Do not remove the head and disc assembly (HDA) from the drive chassis.

Return the entire drive for depot repair if the HDA is defective.

• Do not attempt to disassemble the HDA. It is not field repairable. If the sealed

HDA is opened by personnel not performing depot repair, this will damage

components and void the warranty.

• Use forced-air ventilation when bench-testing the drive to ensure proper

cooling of drive components.

• Do not handle the drive while powered up, due to the gyroscopic motion

produced by discs that have not completed spinning down.

• Do not connect or disconnect I/O cables while power is applied to the drive

or other SCSI devices. If the SCSI bus is active, this will cause errors.

• Do not connect or disconnect the DC power cable while the power supply

is energized.

52 ST43401N/ND, ST43402ND User’s Manual, Rev. B

Arranging for depot repair

Before returning any units to Seagate, it is necessary to obtain a returned

material authorization (RMA) number. To get the number, you will need to

know the part number and serial number of the unit. These numbers appear

on a label located on the side of the HDA. Then contact:

Seagate Technology, Inc.

Customer Services

Phone: 1-800-468-3472

Removing and replacing a drive

Caution. When servicing the drive, observe all precautions listed under

“Electrostatic discharge protection” in the preface. Failure to observe these precautions can result in serious damage to electronic

assemblies.

Warning. Be sure that the drive has completed spinning down before remov-

ing it from its mounting. You may be physically harmed by the

gyroscopic motion produced by discs which have not completed

spinning down.

To remove a drive for maintenance, perform the following steps:

1. Remove power from the drive by setting the On/Standby switch on the

power supply to the Standby position.

2. Disconnect the AC power cable from site power.

3. Disconnect the I/O cable and spindle sync cables (if used) from the drive.

4. Disconnect the DC power cable from the DC power connector on the drive.

5. Remove the mounting screws that secure the drive chassis to the cabinet.

7. Carefully lift the drive from its mounting and move it to the desired location.

To install a replacement drive, follow the procedures in Section 2.

Packing a drive for shipment

If it is necessary to ship the drive, repack the drive with the original packing

materials (saved during installation). Comply with the packing instructions to

ensure that the drive will be undamaged in shipment.

Seagate Technology, Inc.

920 Disc Drive, Scotts Valley, CA 95066-4544, USA

Publication Number: 83327720, Rev. B, Printed in USA

Loading...

Loading...