Product Manual

Cheetah® 15K.7 SAS

Standard models

ST3600057SS

ST3450857SS

ST3300657SS

Self-Encrypting Drive models

ST3600957SS

ST3450757SS

ST3300557SS

SED FIPS 140-2 models

ST3600857SS

ST3450657SS

ST3300457SS

100516226

Rev. F

December 2012

© 2012 Seagate Technology LLC. All rights reserved.

Publication number: 100516226, Rev. F December 2012

Seagate, Seagate Technology and the Wave logo are registered trademarks of Seagate Technology LLC in the United States and/or

other countries. Cheetah and SeaTools are either trademarks or registered trademarks of Seagate Technology LLC or one of its

affiliated companies in the United States and/or other countries. The FIPS logo is a certification mark of NIST, which does not imply

product endorsement by NIST, the U.S., or Canadian governments.All other trademarks or registered trademarks are the property of

their respective owners.

No part of this publication may be reproduced in any form without written permission of Seagate Technology LLC.

Call 877-PUB-TEK1 (877-782-8351) to request permission.

When referring to drive capacity, one gigabyte, or GB, equals one billion bytes and one terabyte, or TB, equals one trillion bytes. Your

computer’s operating system may use a different standard of measurement and report a lower capacity. In addition, some of the listed

capacity is used for formatting and other functions, and thus will not be available for data storage. Actual quantities will vary based on

various factors, including file size, file format, features and application software. Actual data rates may vary depending on operating

environment and other factors. The export or re-export of hardware or software containing encryption may be regulated by the U.S.

Department of Commerce, Bureau of Industry and Security (for more information, visit www.bis.doc.gov), and controlled for import

and use outside of the U.S. Seagate reserves the right to change, without notice, product offerings or specifications.

CONTENTS

SEAGATE® TECHNOLOGY SUPPORT SERVICES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.0 SCOPE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

2.0 STANDARDS, COMPLIANCE AND REFERENCE DOCUMENTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2.1 STANDARDS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2.1.1 Electromagnetic compatibility. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2.2 COMPLIANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2.2.1 Electromagnetic compliance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2.3 EUROPEAN UNION RESTRICTION OF HAZARDOUS SUBSTANCES (ROHS) . . . . . . . . . . . . . . . . . 4

2.4 REFERENCE DOCUMENTS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

3.0 GENERAL DESCRIPTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

3.1 STANDARD FEATURES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

3.2 MEDIA DESCRIPTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

3.3 PERFORMANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

3.4 RELIABILITY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3.5 FORMATTED CAPACITIES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3.6 PROGRAMMABLE DRIVE CAPACITY. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3.7 FACTORY-INSTALLED OPTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

4.0 PERFORMANCE CHARACTERISTICS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

4.1 INTERNAL DRIVE CHARACTERISTICS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

4.2 SEEK TIME . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

4.2.1 Access time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

4.2.2 Format command execution time (minutes). . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

4.2.3 General performance characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

4.3 START/STOP TIME . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

4.4 PREFETCH/MULTI-SEGMENTED CACHE CONTROL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

4.5 CACHE OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

4.5.1 Caching write data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

4.5.2 Prefetch operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

5.0 RELIABILITY SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

5.1 ERROR RATES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

5.1.1 Recoverable Errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

5.1.2 Unrecoverable Errors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

5.1.3 Seek errors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

5.1.4 Interface errors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

5.2 RELIABILITY AND SERVICE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

5.2.1 Annualized Failrue Rate (AFR) and Mean time between failure (MTBF). . . . . . 13

5.2.2 Preventive maintenance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

5.2.3 Hot plugging the drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

5.2.4 S.M.A.R.T. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

5.2.5 Thermal monitor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

5.2.6 Drive Self Test (DST). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

5.2.7 Product warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

6.0 PHYSICAL/ELECTRICAL SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

6.1 AC POWER REQUIREMENTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

6.2 DC POWER REQUIREMENTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

6.2.1 Conducted noise immunity. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

CHEETAH 15K.7 SAS PRODUCT MANUAL, REV. F I

CONTENTS

6.2.2 Power sequencing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

6.2.3 Current profiles. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

6.3 POWER DISSIPATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

6.4 ENVIRONMENTAL LIMITS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

6.4.1 Temperature. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

6.4.2 Relative humidity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

6.4.3 Effective altitude (sea level) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

6.4.4 Shock and vibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

6.4.5 Acoustics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

6.4.6 Air cleanliness . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

6.4.7 Corrosive environment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

6.4.8 RoHS compliance statement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

6.4.9 Electromagnetic susceptibility . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

6.5 MECHANICAL SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

7.0 ABOUT FIPS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

8.0 ABOUT SELF-ENCRYPTING DRIVES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

8.1 DATA ENCRYPTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

8.2 CONTROLLED ACCESS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

8.2.1 Admin SP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

8.2.2 Locking SP. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

8.2.3 Default password . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

8.3 RANDOM NUMBER GENERATOR (RNG) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

8.4 DRIVE LOCKING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

8.5 DATA BANDS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

8.6 CRYPTOGRAPHIC ERASE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

8.7 AUTHENTICATED FIRMWARE DOWNLOAD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

8.8 POWER REQUIREMENTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

8.9 SUPPORTED COMMANDS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

9.0 DEFECT AND ERROR MANAGEMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

9.1 DRIVE INTERNAL DEFECTS/ERRORS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

9.2 DRIVE ERROR RECOVERY PROCEDURES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

9.3 SAS SYSTEM ERRORS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

9.4 BACKGROUND MEDIA SCAN . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

9.5 MEDIA PRE-SCAN . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

9.6 DEFERRED AUTO-REALLOCATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

9.7 IDLE READ AFTER WRITE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

10.0 INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

10.1 DRIVE ORIENTATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

10.2 COOLING. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

10.3 DRIVE MOUNTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

10.4 GROUNDING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

11.0 INTERFACE REQUIREMENTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

11.1 SAS FEATURES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

11.1.1 task management functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

11.1.2 task management responses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

11.2 DUAL PORT SUPPORT. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

11.3 SCSI COMMANDS SUPPORTED . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

11.3.1 Inquiry data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

11.3.2 Mode Sense data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

CHEETAH 15K.7 SAS PRODUCT MANUAL, REV. F II

CONTENTS

11.4 MISCELLANEOUS OPERATING FEATURES AND CONDITIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

11.4.1 SAS physical interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

11.4.2 Physical characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

11.4.3 Connector requirements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

11.4.4 Electrical description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

11.4.5 Pin descriptions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

11.4.6 SAS transmitters and receivers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

11.4.7 Power. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

11.5 SIGNAL CHARACTERISTICS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

11.5.1 Ready LED Out . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

11.5.2 Differential signals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

11.6 SAS-2 SPECIFICATION COMPLIANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

11.7 ADDITIONAL INFORMATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

CHEETAH 15K.7 SAS PRODUCT MANUAL, REV. F III

Seagate® Technology Support Services

For information regarding online support and services, visit

Available services include:

• Presales & Technical support

• Global Support Services telephone numbers & business hours

• Authorized Service Centers

For information regarding Warranty Support, visit

For information regarding data recovery services, visit

For Seagate OEM and Distribution partner portal, visit

For Seagate reseller portal, visit

http://spp.seagate.com

http://www.seagate.com/support/warranty-and-returns/

http://www.seagate.com/www/en-us/about/contact_us/

http://www.seagate.com/services-software/data-recovery-services/

https://direct.seagate.com/portal/system

Cheetah 15K.7 SAS Product Manual, Rev. F 1

1.0 SCOPE

This manual describes Seagate Technology® LLC, Cheetah® 15K.7 SAS (Serial Attached SCSI) disk drives.

Cheetah 15K.7 drives support the SAS Protocol specifications to the extent described in this manual. The SAS Interface

Manual (part number 100293071) describes the general SAS characteristics of Cheetah 15K.7 and other Seagate SAS

drives. The Self-Encrypting Drive (SED) Users Guide, part number 100515636 describes the interface, general operation

and security features available on SED drives.

Table 1:

MODEL NUMBER CAPACITY

ST3600057SS 600GB No No

ST3600957SS Yes No

ST3600857SS Yes Yes

ST3450857SS 450GB No No

ST3450757SS Yes No

ST3300457SS Yes Yes

ST3300657SS 300GB No No

ST3300557SS Yes No

ST3300457SS Yes Yes

Note. Previous generations of Seagate Self-Encrypting Drive models were called Full Disk Encryption (FDE) models

before a differentiation between drive-based encryption and other forms of encryption was necessary.

Note. The Self-Encrypting Drive models indicated on the cover of this product manual have provisions for “Security of

Data at Rest” based on the standards defined by the Trusted Computing Group (see www.trustedcomputing-

group.org).

For more information on FIPS 140-2 Level 2 certification see Section 7.0 on page 30.

For product certification status visit - http://csrc.nist.gov/groups/STM/cmvp/documents/140-1/1401vend.htm.

SELF-ENCRYPTING DRIVE

(SED)

FIPS 140-2 LEVEL 2

CERTIFIED

CHEETAH 15K.7 SAS PRODUCT MANUAL, REV. F 2

2.0 STANDARDS, COMPLIANCE AND REFERENCE DOCUMENTS

The drive has been developed as a system peripheral to the highest standards of design and construction. The drive

depends on its host equipment to provide adequate power and environment for optimum performance and compliance with

applicable industry and governmental regulations. Special attention must be given in the areas of safety, power distribution,

shielding, audible noise control, and temperature regulation. In particular, the drive must be securely mounted to guarantee

the specified performance characteristics. Mounting by bottom holes must meet the requirements of Section 10.3.

2.1 STANDARDS

The Cheetah 15K.7 SAS family complies with Seagate standards as noted in the appropriate sections of this manual and the

Seagate SAS Interface Manual, part number 100293071.

The drives are recognized in accordance with UL 60950-1 and CSA 60950-1 as tested by UL and EN60950-1 as tested by

TUV.

The security features of Cheetah 15K.7 SAS SED models are based on the “TCG Storage Architecture Core Specification”

and the “TCG Storage Workgroup Security Subsystem Class: Enterprise_A” specification with additional vendor-unique

features as noted in this product manual.

2.1.1 Electromagnetic compatibility

The drive, as delivered, is designed for system integration and installation into a suitable enclosure prior to use. The drive is

supplied as a subassembly and is not subject to Subpart B of Part 15 of the FCC Rules and Regulations nor the Radio

Interference Regulations of the Canadian Department of Communications.

The design characteristics of the drive serve to minimize radiation when installed in an enclosure that provides reasonable

shielding. The drive is capable of meeting the Class B limits of the FCC Rules and Regulations of the Canadian Department

of Communications when properly packaged; however, it is the user’s responsibility to assure that the drive meets the

appropriate EMI requirements in their system. Shielded I/O cables may be required if the enclosure does not provide

adequate shielding. If the I/O cables are external to the enclosure, shielded cables should be used, with the shields

grounded to the enclosure and to the host controller.

2.1.1.1 Electromagnetic susceptibility

As a component assembly, the drive is not required to meet any susceptibility performance requirements. It is the

responsibility of those integrating the drive within their systems to perform those tests required and design their system to

ensure that equipment operating in the same system as the drive or external to the system does not adversely affect the

performance of the drive. See Tables 3, 4 and 5, for DC power requirements.

2.2 COMPLIANCE

2.2.1 Electromagnetic compliance

Seagate uses an independent laboratory to confirm compliance with the directives/standards for CE Marking and C-Tick

Marking. The drive was tested in a representative system for typical applications. The selected system represents the most

popular characteristics for test platforms. The system configurations include:

• Typical current use microprocessor

• Keyboard

• Monitor/display

• Printer

• Mouse

Although the test system with this Seagate model complies with the directives/standards, we cannot guarantee that all

systems will comply. The computer manufacturer or system integrator shall confirm EMC compliance and provide the

appropriate marking for their product.

Electromagnetic compliance for the European Union

If this model has the CE Marking it complies with the European Union requirements of the Electromagnetic Compatibility

Directive 89/336/EEC of 03 May 1989 as amended by Directive 92/31/EEC of 28 April 1992 and Directive 93/68/EEC of 22

July 1993.

CHEETAH 15K.7 SAS PRODUCT MANUAL, REV. F 3

Australian C-Tick

If this model has the C-Tick Marking it complies with the Australia/New Zealand Standard AS/NZS3548 1995 and meets the

Electromagnetic Compatibility (EMC) Framework requirements of Australia’s Spectrum Management Agency (SMA).

Korean KCC

If this model has the Korean Communications Commission (KCC) logo, it complies with paragraph 1 of Article 11 of the

Electromagnetic Compatibility (EMC) Control Regulation and meets the Electromagnetic Compatibility Framework

requirements of the Radio Research Laboratory (RRL) Ministry of Information and Communication Republic of Korea

Taiwanese BSMI

If this model has two Chinese words meaning “EMC certification” followed by an eight digit identification number, as a

Marking, it complies with Chinese National Standard (CNS) 13438 and meets the Electromagnetic Compatibility (EMC)

Framework requirements of the Taiwanese Bureau of Standards, Metrology, and Inspection (BSMI).

2.3 EUROPEAN UNION RESTRICTION OF HAZARDOUS SUBSTANCES (ROHS)

The European Union Restriction of Hazardous Substances (RoHS) Directive restricts the presence of chemical substances,

including Lead (Pb), in electronic products effective July 2006.

A number of parts and materials in Seagate products are procured from external suppliers. We rely on the representations of

our suppliers regarding the presence of RoHS substances in these parts and materials. Our supplier contracts require

compliance with our chemical substance restrictions, and our suppliers document their compliance with our requirements by

providing material content declarations for all parts and materials for the disk drives documented in this publication. Current

supplier declarations include disclosure of the inclusion of any RoHS-regulated substance in such parts or materials.

Seagate also has internal systems in place to ensure ongoing compliance with the RoHS Directive and all laws and

regulations which restrict chemical content in electronic products. These systems include standard operating procedures that

ensure that restricted substances are not utilized in our manufacturing operations, laboratory analytical validation testing,

and an internal auditing process to ensure that all standard operating procedures are complied with.

2.4 REFERENCE DOCUMENTS

SCSI Commands Reference ManualSeagate part number: 100293068

SAS Interface Manual Seagate part number: 100293071

ANSI SAS documents

SFF-83233.5” Drive Form Factor with Serial Connector

SFF-8460HSS Backplane Design Guidelines

SFF-8470Multi Lane Copper Connector

SFF-8482SAS Plug Connector

ANSI INCITS.xxx Serial Attached SCSI (SAS-2) Standard (T10/1562-D)

ISO/IEC 14776-xxxSCSI Architecure Model-4 (SAM-4) Standard (T10/1561-D)

ISO/IEC 14776-xxxSCSI Primary Commands-3 (SPC-3) Standard (T10/1416-D)

ISO/IEC 14776-xxxSCSI Block Commands-2 (SBC-2) Standard (T10/1417-D)

Trusted Computing Group (TCG) Documents (apply to SED models only)

TCG Core Specification, version 0.9

TCG SSC Specification (draft)

Self-Encrypting Drives Users Guide‘Seagate part number: 100515636

Specification for Acoustic Test Requirement and ProceduresSeagate part number: 30553-001

Package Test Specification Seagate P/N 30190-001 (under 100 lb.)

Package Test Specification Seagate P/N 30191-001 (over 100 lb.)

In case of conflict between this document and any referenced document, this document takes precedence.

CHEETAH 15K.7 SAS PRODUCT MANUAL, REV. F 4

3.0 GENERAL DESCRIPTION

Cheetah 15K.7 drives provide high performance, high capacity data storage for a variety of systems including engineering

workstations, network servers, mainframes, and supercomputers. The Serial Attached SCSI interface is designed to meet

next-generation computing demands for performance, scalability, flexibility and high-density storage requirements.

Cheetah 15K.7 drives support the Serial Attached SCSI Protocol as described in the ANSI specifications, this document, and

the SAS Interface Manual (part number 100293071) which describes the general interface characteristics of this drive.

Cheetah 15K.7 drives are classified as intelligent peripherals and provide level 2 conformance (highest level) with the ANSI

SCSI-1 standard. The SAS connectors, cables and electrical interface are compatible with Serial ATA (SATA), giving future

users the choice of populating their systems with either SAS or SATA hard disk drives. This allows you to continue to

leverage your existing investment in SCSI while gaining a 3Gb/s serial data transfer rate.

Cheetah 15K.7 SAS SED models have provisions for “Security of Data at Rest” based on the standards defined by the

Trusted Computing Group (see www.trustedcomputinggroup.org).

Note. Never disassemble the HDA and do not attempt to service items in the sealed enclosure (heads, media, actuator,

etc.) as this requires special facilities. The drive does not contain user-replaceable parts. Opening the HDA for

any reason voids your warranty.

Cheetah 15K.7 drives use a dedicated landing zone at the innermost radius of the media to eliminate the possibility of

destroying or degrading data by landing in the data zone. The heads automatically go to the landing zone when power is

removed from the drive.

An automatic shipping lock prevents potential damage to the heads and disks that results from movement during shipping

and handling. The shipping lock disengages and the head load process begins when power is applied to the drive.

The drives also use a high-performance actuator assembly with a low-inertia, balanced, patented, straight arm design that

provides excellent performance with minimal power dissipation.

CHEETAH 15K.7 SAS PRODUCT MANUAL, REV. F 5

3.1 STANDARD FEATURES

Cheetah 15K.7 drives have the following standard features:

• 1.5 / 3 / 6 Gbit Serial Attached SCSI (SAS) interface

• Integrated dual port SAS controller supporting the SCSI protocol

• Support for SAS expanders and fanout adapters

• Firmware downloadable using the SAS interface

• 128 - deep task set (queue)

• Supports up to 32 initiators

• Jumperless configuration.

• User-selectable logical block size (512, 520, or 528 bytes per logical block)

• Programmable logical block reallocation scheme

• Flawed logical block reallocation at format time

• Programmable auto write and read reallocation

• Reallocation of defects on command (Post Format)

• ECC maximum burst correction length of 320 bits

• No preventive maintenance or adjustments required

• Dedicated head landing zone

• Embedded servo design

• Automatic shipping lock

• Self diagnostics performed when power is applied to the drive

• Zone bit recording

• Vertical, horizontal, or top down mounting

• Dynamic spindle brake

• 16 Mbyte data buffer

• Drive Self Test

• Background Media Scan

• Power Save

Cheetah 15K.7 SAS SED models have the following additional features:

• Automatic data encryption/decryption on all writes and reads to and from the media

• Controlled access

• Random number generator

• Drive locking

• Two independent data bands which each have it’s own ownership credential and encryption key

• Cryptographic erase of user data for a drive that will be repurposed or scrapped

• Authenticated firmware download

3.2 MEDIA DESCRIPTION

The media used on the drive has an aluminum substrate coated with a thin film magnetic material, overcoated with a

proprietary protective layer for improved durability and environmental protection.

3.3 PERFORMANCE

• Programable multi-segmented cache buffer

• 600 Mbytes/sec maximum instantaneous data transfers

• 15k RPM spindle. Average latency = 2.0 msec

• Background processing of queue

• Supports start and stop commands (spindle stops spinning)

• Adaptive seek velocity; improved seek performance

Note. There is no significant performance difference between Self-Encrypting Drive and standard (non-Self-Encrypting

Drive models.

CHEETAH 15K.7 SAS PRODUCT MANUAL, REV. F 6

3.4 RELIABILITY

• 1,600,000 hour MTBF (Annualized Failure Rate (AFR) of 0.55%)

• Incorporates industry-standard Self-Monitoring Analysis and Reporting Technology (S.M.A.R.T.)

• 5-year warranty

3.5 FORMATTED CAPACITIES

Standard OEM models are formatted to 512 bytes per block. The block size is selectable at format time and must be one of

the supported sizes listed in the table below.

Seagate designs specify capacity points at certain block sizes that Seagate guarantees current and future products will

meet. We recommend customers use this capacity in their project planning, as it ensures a stable operating point with

backward and forward compatibility from generation to generation. The current guaranteed operating points for this product

are:

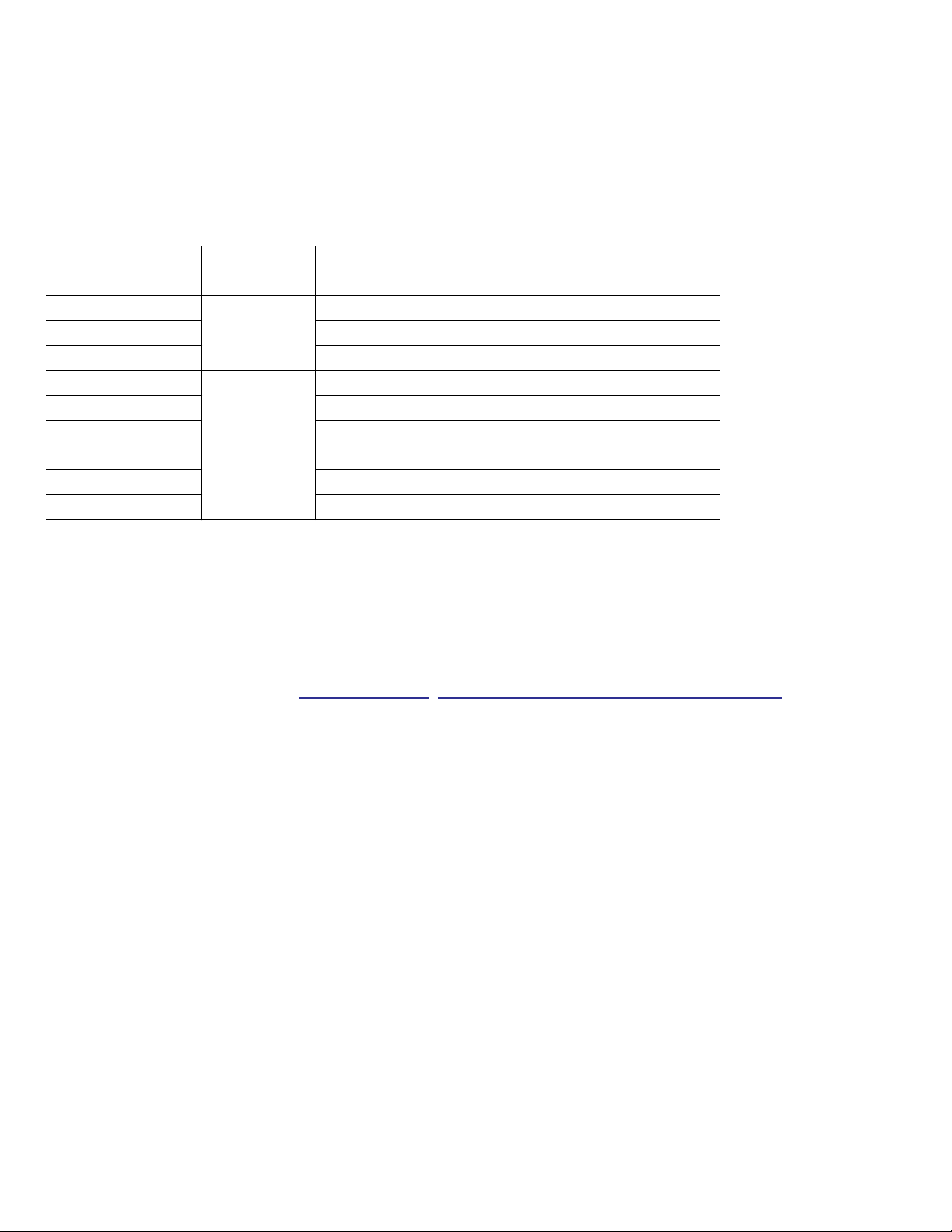

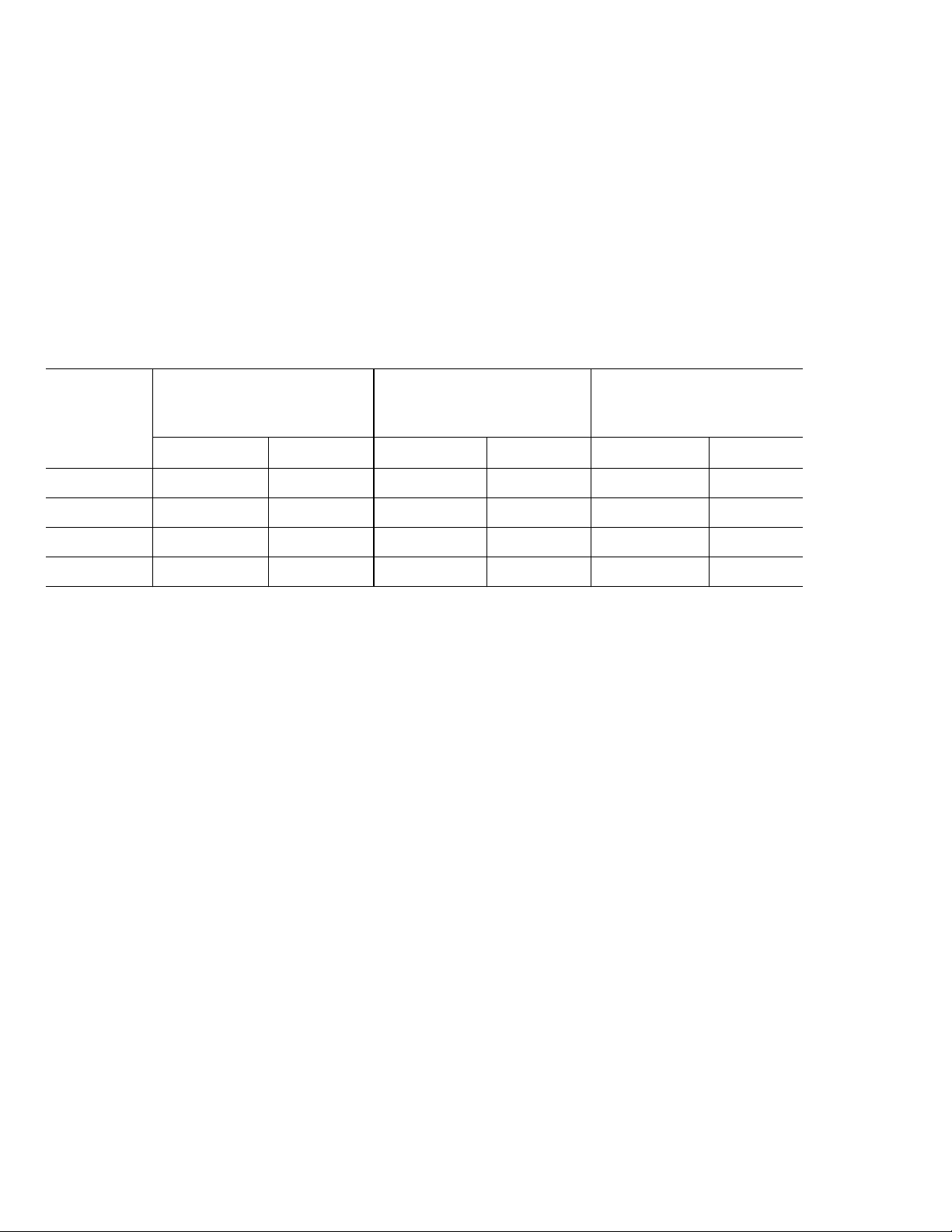

Table 1:

ST3600057SS

ST3600957SS

SECTOR SIZE

512 1,172,123,568 45DD2FB0 879,097,968 3465F870 585,937,500 22ECB25C

520 1,147,307,694 446286AE 860,480,771 3349E503 573,653,848 22314358

524 1,132,015,600 43792FF0 849,011,700 329AE3F4 566,007,800 21BC97F8

528 1,115,749,560 4280FCB8 836,812,167 31E0BD87 557,874,778 21407E5A

ST3600857SS

D

ECIMAL HEX DECIMAL HEX DECIMAL HEX

ST3450857SS

ST3450757SS

ST3450657SS

ST3300657FC

ST3300557FC

ST3300457SS

3.6 PROGRAMMABLE DRIVE CAPACITY

Using the Mode Select command, the drive can change its capacity to something less than maximum. See the Mode Select

(6) parameter list table in the SAS Interface Manual, part number 100293071. A value of zero in the Number of Blocks field

indicates that the drive will not change the capacity it is currently formatted to have. A number other than zero and less than

the maximum number of LBAs in the Number of Blocks field changes the total drive capacity to the value in the Number of

Blocks field. A value greater than the maximum number of LBAs is rounded down to the maximum capacity.

3.7 FACTORY-INSTALLED OPTIONS

You may order the following items which are incorporated at the manufacturing facility during production or packaged before

shipping. Some of the options available are (not an exhaustive list of possible options):

• Other capacities can be ordered depending on sparing scheme and sector size requested.

• Single-unit shipping pack. The drive is normally shipped in bulk packaging to provide maximum protection against transit

damage. Units shipped individually require additional protection as provided by the single unit shipping pack. Users planning single unit distribution should specify this option.

• The Safety and Regulatory Agency Specifications, part number 75789512, may be included with each standard OEM drive

shipped.

CHEETAH 15K.7 SAS PRODUCT MANUAL, REV. F 7

4.0 PERFORMANCE CHARACTERISTICS

This section provides detailed information concerning performance-related characteristics and features of Cheetah 15K.7

drives.

4.1 INTERNAL DRIVE CHARACTERISTICS

ST3600057SS ST3450857SS ST3300657SS

ST3600957SS ST3450757SS ST3300557SS

ST3600857SS ST3450657SS ST3300457SS

Drive capacity 600 450 300 Gbytes (formatted, rounded off value)

Read/write data heads 8 6 4

Tracks per inch 165,000 165,000 165,000 TPI

Peak bits per inch 1,361 1,361 1,361 KBPI

Areal Density 225 225 225 Gbits/inch

Internal data rate 1.49 - 2.37 1.49 - 2.37 1.49 - 2.37 Gbits/sec (max)

Disk rotation speed 15k 15k 15k RPM

Avg rotational latency 2.0 2.0 2.0 msec

*One Gbyte equals one billion bytes when referring to hard drive capacity. Accessible capacity may vary depending on operating environment and formatting.

2

4.2 SEEK TIME

See Section 11.4.1, "SAS physical interface" on page 47 and the SAS Interface Manual (part number 100293071) for

additional timing details.

*

4.2.1 Access time

1

NOT INCLUDING CONTROLLER OVERHEAD2 (MSEC)

,

READ WRITE

Average Typical 3.4 3.9

Single track Typical 0.2 0.44

Full stroke Typical 6.6 7.4

1. Typical access times are measured under nominal conditions of temperature, voltage, and horizontal

orientation as measured on a representative sample of drives.

2. Access to data = access time + latency time.

4.2.2 Format command execution time (minutes)

When changing sector sizes, the format times shown below may need to be increased by 30 minutes.

600GB 450GB 300GB

Maximum (with verify) 119 90 58

Maximum (without verify) 60 45 29

Note. There is approximately a 1.5 increase in time to format a SED drive versus a non-SED drive of the same capacity.

Execution time measured from receipt of the last byte of the Command Descriptor Block (CDB) to the request for a Status

Byte Transfer to the Initiator (excluding connect/disconnect).

CHEETAH 15K.7 SAS PRODUCT MANUAL, REV. F 8

4.2.3 General performance characteristics

Sustainable disk transfer rate*:

Minimum 122 Mbytes/sec (typical)

Maximum 204 Mbytes/sec (typical)

SAS Interface maximum instantaneous transfer rate 600 Mbytes/sec* per port

Logical block sizes

Default is 512-byte data blocks

Sector sizes variable to 512, 520, and 528 kbytes.

Read/write consecutive sectors on a track Yes

Flaw reallocation performance impact (for flaws reallocated at format time using

the spare sectors per sparing zone reallocation scheme.)

Average rotational latency 2.0 msec

*Assumes system ability to support the rates listed and no cable loss.

1 MB/sec = 1,000,000 bytes/sec

Negligible

4.3 START/STOP TIME

The drive accepts the commands listed in the SAS Interface Manual less than 3 seconds after DC power has been applied.

If the drive receives a NOTIFY (ENABLE SPINUP) primitive through either port and has not received a START STOP UNIT

command with the START bit equal to 0, the drive becomes ready for normal operations within 20 seconds (excluding the

error recovery procedure).

If the drive receives a START STOP UNIT command with the START bit equal to 0 before receiving a NOTIFY (ENABLE

SPINUP) primitive, the drive waits for a START STOP UNIT command with the START bit equal to 1. After receiving a

START STOP UNIT command with the START bit equal to 1, the drive waits for a NOTIFY (ENABLE SPINUP) primitive.

After receiving a NOTIFY (ENABLE SPINUP) primitive through either port, the drive becomes ready for normal operations

within 20 seconds (excluding the error recovery procedure).

If the drive receives a START STOP UNIT command with the START bit and IMMED bit equal to 1 and does not receive a

NOTIFY (ENABLE SPINUP) primitive within 5 seconds, the drive fails the START STOP UNIT command.

The START STOP UNIT command may be used to command the drive to stop the spindle. Stop time is 30 seconds

(maximum) from removal of DC power. There is no power control switch on the drive.

4.4 PREFETCH/MULTI-SEGMENTED CACHE CONTROL

The drive provides a prefetch (read look-ahead) and multi-segmented cache control algorithms that in many cases can

enhance system performance. Cache refers to the drive buffer storage space when it is used in cache operations. To select

this feature, the host sends the Mode Select command with the proper values in the applicable bytes in page 08h. Prefetch

and cache operations are independent features from the standpoint that each is enabled and disabled independently using

the Mode Select command; however, in actual operation, the prefetch feature overlaps cache operation somewhat as

described in sections 4.5.1 and 4.5.2.

All default cache and prefetch mode parameter values (Mode Page 08h) for standard OEM versions of this drive family are

given in Section 11.3.2.1.

CHEETAH 15K.7 SAS PRODUCT MANUAL, REV. F 9

4.5 CACHE OPERATION

Note. Refer to the SAS Interface Manual for more detail concerning the cache bits.

Of the 16 Mbytes physical buffer space in the drive, approximately 13,000 kbytes can be used as a cache. The buffer is

divided into logical segments from which data is read and to which data is written.

The drive keeps track of the logical block addresses of the data stored in each segment of the buffer. If the cache is enabled

(see RCD bit in the SAS Interface Manual ), data requested by the host with a read command is retrieved from the buffer, if

possible, before any disk access is initiated. If cache operation is not enabled, the buffer is still used, but only as circular

buffer segments during disk medium read operations (disregarding Prefetch operation for the moment). That is, the drive

does n ot ch eck i n the b uffe r seg men ts fo r the re que ste d rea d data , but g oes d irec tly t o the m edi um to re tri eve i t. Th e

retrieved data merely passes through some buffer segment on the way to the host. All data transfers to the host are in

accordance with buffer-full ratio rules. See the explanation provided with the information about Mode Page 02h (disconnect/

reconnect control) in the SAS Interface Manual.

The following is a simplified description of the prefetch/cache operation:

Case A—read command is received and all of the requested logical blocks are already in the cache:

1. Drive transfers the requested logical blocks to the initiator.

Case B—A Read command requests data, and at least one requested logical block is not in any segment of the cache:

1. The drive fetches the requested logical blocks from the disk and transfers them into a segment, and then from there to

the host in accordance with the Mode Select Disconnect/Reconnect parameters, page 02h.

2. If the prefetch feature is enabled, refer to section 4.5.2 for operation from this point.

Each cache segment is actually a self-contained circular buffer whose length is an integer number of logical blocks. The

drive dynamically creates and removes segments based on the workload. The wrap-around capability of the individual

segments greatly enhances the cache’s overall performance.

Note. The size of each segment is not reported by Mode Sense command page 08h, bytes 14 and 15. The value

0XFFFF is always reported regardless of the actual size of the segment. Sending a size specification using the

Mode Select command (bytes 14 and 15) does not set up a new segment size. If the STRICT bit in Mode page

00h (byte 2, bit 1) is set to one, the drive responds as it does for any attempt to change an unchangeable param-

eter.

CHEETAH 15K.7 SAS PRODUCT MANUAL, REV. F 10

4.5.1 Caching write data

Write caching is a write operation by the drive that makes use of a drive buffer storage area where the data to be written to

the medium is stored while the drive performs the Write command.

If read caching is enabled (RCD=0), then data written to the medium is retained in the cache to be made available for future

read cache hits. The same buffer space and segmentation is used as set up for read functions. The buffer segmentation

scheme is set up or changed independently, having nothing to do with the state of RCD. When a write command is issued, if

RCD=0, the cache is first checked to see if any logical blocks that are to be written are already stored in the cache from a

previous read or write command. If there are, the respective cache segments are cleared. The new data is cached for

subsequent Read commands.

If the number of write data logical blocks exceed the size of the segment being written into, when the end of the segment is

reached, the data is written into the beginning of the same cache segment, overwriting the data that was written there at the

beginning of the operation; however, the drive does not overwrite data that has not yet been written to the medium.

If write cac hing is en abled ( WCE=1) , then th e drive m ay retur n Good st atus on a w rite co mmand af ter the d ata has b een

transferred into the cache, but before the data has been written to the medium. If an error occurs while writing the data to the

medium, and Good status has already been returned, a deferred error will be generated.

The Synchronize Cache command may be used to force the drive to write all cached write data to the medium. Upon

completion of a Synchronize Cache command, all data received from previous write commands will have been written to the

medium.

Table 11.3.2.1 shows the mode default settings for the drive.

4.5.2 Prefetch operation

If the Prefetch feature is enabled, data in contiguous logical blocks on the disk immediately beyond that which was requested

by a Read command are retrieved and stored in the buffer for immediate transfer from the buffer to the host on subsequent

Read commands that request those logical blocks (this is true even if cache operation is disabled). Though the prefetch

operation uses the buffer as a cache, finding the requested data in the buffer is a prefetch hit, not a cache operation hit.

To enable Prefetch, use Mode Select page 08h, byte 12, bit 5 (Disable Read Ahead - DRA bit). DRA bit = 0 enables prefetch.

The drive does not use the Max Prefetch field (bytes 8 and 9) or the Prefetch Ceiling field (bytes 10 and 11).

When prefetch (read look-ahead) is enabled (enabled by DRA = 0), the drive enables prefetch of contiguous blocks from the

disk when it senses that a prefetch hit will likely occur. The drive disables prefetch when it decides that a prefetch hit is not

likely to occur.

CHEETAH 15K.7 SAS PRODUCT MANUAL, REV. F 11

5.0 RELIABILITY SPECIFICATIONS

The following reliability specifications assume correct host and drive operational interface, including all interface timings,

power supply voltages, environmental requirements and drive mounting constraints.

8

Seek error rate: Less than 10 errors in 10

Read Error Rates

Recovered Data Less than 10 errors in 1012 bits transferred (OEM default settings)

Unrecovered Data Less than 1 sector in 1016 bits transferred

Miscorrected Data Less than 1 sector in 10

Interface error rate: Less than 1 error in 1012 bits transferred

MTBF 1,600,000 hours

AFR 0.55%

Preventive maintenance: None required

5.1 ERROR RATES

The error rates stated in this manual assume the following:

• The drive is operated per this specification using DC power as defined in this manual (see Section 6.2).

• Errors caused by host system failures are excluded from error rate computations.

• Assume random data.

• Default OEM error recovery settings are applied. This includes AWRE, ARRE, full read retries, full write retries and full retry

time.

• Error rate specified with automatic retries and data correction with ECC enabled and all flaws reallocated

seeks

21

bits transferred

5.1.1 Recoverable Errors

Recoverable errors are those detected and corrected by the drive, and do not require user intervention.

Recoverable Data errors use retries and correction. Application of ECC on-the-fly correction alone is not considered a

Recovered Data error.

Recovered Data error rate is determined using read bits transferred for recoverable errors occurring during a read, and using

write bits transferred for recoverable errors occurring during a write.

5.1.2 Unrecoverable Errors

Unrecoverable Data Errors (Sense Key = 03h) are specified at less than 1 sector in error per 1016 bits transferred.

Unrecoverable Data Errors resulting from the same cause are treated as 1 error for that block.

5.1.3 Seek errors

A seek error is defined as a failure of the drive to position the heads to the addressed track. After detecting an initial seek

error, the drive automatically performs an error recovery process. If the error recovery process fails, a seek positioning error

(Error code = 15h or 02h) will be reported with a Hardware error (04h) in the Sense Key. Recoverable seek errors are

specified at Less than 10 errors in 108 seeks. Unrecoverable seek errors (Sense Key = 04h) are classified as drive failures.

5.1.4 Interface errors

An interface error is defined as a failure of the receiver on a port to recover the data as transmitted by the device port

connected to the receiver. The error may be detected as a running disparity error, illegal code, loss of word sync, or CRC

error.

5.2 RELIABILITY AND SERVICE

You can enhance the reliability of Cheetah disk drives by ensuring that the drive receives adequate cooling. Section 6.0

provides temperature measurements and other information that may be used to enhance the service life of the drive. Section

10.2 provides recommended air-flow information.

CHEETAH 15K.7 SAS PRODUCT MANUAL, REV. F 12

5.2.1 Annualized Failrue Rate (AFR) and Mean time between failure (MTBF)

These drives shall achieve an AFR of 0.55% (MTBF of 1,600,000 hours) when operated in an environment that ensures the

HDA case temperatures do not exceed the values specified in Section 6.4.

Operation at case temperatures outside the specifications in Section 6.4 may increase the AFR (decrease the MTBF). AFR

and MTBF statistics are population statistics that are not relevant to individual units.

AFR and MTBF specifications are based on the following assumptions for Enterprise Storage System environments:

• 8,760 power-on hours per year.

• 250 average on/off cycles per year.

• Operations at nominal voltages.

• Systems will provide adequate cooling to ensure the case temperatures specified in Section 6.4.1 are not exceeded.

5.2.2 Preventive maintenance

No routine scheduled preventive maintenance is required.

5.2.3 Hot plugging the drive

When a disk is powered on by switching the power or hot plugged, the drive runs a self test before attempting to

communicate on its’ interfaces. When the self test completes successfully, the drive initiates a Link Reset starting with OOB.

An attached device should respond to the link reset. If the link reset attempt fails, or any time the drive looses sync, the drive

initiated link reset. The drive will initiate link reset once per second but alternates between port A and B. Therefore each port

will attempt a link reset once per 2 seconds assuming both ports are out of sync..

If the self-test fails, the does not respond to link reset on the failing port.

Note. It is the responsibility of the systems integrator to assure that no temperature, energy, voltage hazard, or ESD

potential hazard is presented during the hot connect/disconnect operation. Discharge the static electricity from

the drive carrier prior to inserting it into the system.

Caution. The drive motor must come to a complete stop prior to changing the plane of operation. This time is required to

insure data integrity.

5.2.4 S.M.A.R.T.

S.M.A.R.T. is an acronym for Self-Monitoring Analysis and Reporting Technology. This technology is intended to recognize

conditions that indicate imminent drive failure and is designed to provide sufficient warning of a failure to allow you to back up

the data before an actual failure occurs.

Note. The drive’s firmware monitors specific attributes for degradation over time but can’t predict instantaneous drive

failures.

Each monitored attribute has been selected to monitor a specific set of failure conditions in the operating performance of the

drive and the thresholds are optimized to minimize “false” and “failed” predictions.

Controlling S.M.A.R.T.

The operating mode of S.M.A.R.T. is controlled by the DEXCPT and PERF bits on the Informational Exceptions Control

mode page (1Ch). Use the DEXCPT bit to enable or disable the S.M.A.R.T. feature. Setting the DEXCPT bit disables all

S.M.A.R.T. functions. When enabled, S.M.A.R.T. collects on-line data as the drive performs normal read and write

operations. When the PERF bit is set, the drive is considered to be in “On-line Mode Only” and will not perform off-line

functions.

You can measure off-line attributes and force the drive to save the data by using the Rezero Unit command. Forcing

S.M.A.R.T. resets the timer so that the next scheduled interrupt is in two hours.

You can interrogate the drive through the host to determine the time remaining before the next scheduled measurement and

data logging process occurs. To accomplish this, issue a Log Sense command to log page 0x3E. This allows you to control

when S.M.A.R.T. interruptions occur. Forcing S.M.A.R.T. with the RTZ command resets the timer.

CHEETAH 15K.7 SAS PRODUCT MANUAL, REV. F 13

Performance impact

S.M.A.R.T. attribute data is saved to the disk so that the events that caused a predictive failure can be recreated. The drive

measu res an d save s para mete rs onc e ever y two ho urs su bjec t to an id le per iod o n the dr ive in terf aces . The pr oces s of

measuring off-line attribute data and saving data to the disk is uninterruptable. The maximum on-line only processing delay is

summarized below:

Table 2:

Maximum processing delay

S.M.A.R.T. delay times

On-line only delay

DEXCPT = 0, PERF = 1

42 milliseconds

Fully-enabled delay

DEXCPT = 0, PERF = 0

163 milliseconds

Reporting control

Reporting is controlled by the MRIE bits in the Informational Exceptions Control mode page (1Ch). Subject to the reporting

method , the fi rmwar e will i ssue to t he hos t an 01-5 Dxx se nse co de. The e rror c ode is pr eser ved thr ough b us rese ts and

power cycles.

Determining rate

S.M.A.R.T. monitors the rate at which errors occur and signals a predictive failure if the rate of degraded errors increases to

an unacceptable level. To determine rate, error events are logged and compared to the number of total operations for a given

attribute. The interval defines the number of operations over which to measure the rate. The counter that keeps track of the

current number of operations is referred to as the Interval Counter.

S.M.A.R.T. measures error rates. All errors for each monitored attribute are recorded. A counter keeps track of the number of

errors for the current interval. This counter is referred to as the Failure Counter.

Error rate is the number of errors per operation. The algorithm that S.M.A.R.T. uses to record rates of error is to set

thresholds for the number of errors and their interval. If the number of errors exceeds the threshold before the interval

expires, the error rate is considered to be unacceptable. If the number of errors does not exceed the threshold before the

interval expires, the error rate is considered to be acceptable. In either case, the interval and failure counters are reset and

the process starts over.

Predictive failures

S.M.A.R.T. signals predictive failures when the drive is performing unacceptably for a period of time. The firmware keeps a

running count of the number of times the error rate for each attribute is unacceptable. To accomplish this, a counter is

incremented each time the error rate is unacceptable and decremented (not to exceed zero) whenever the error rate is

acceptable. If the counter continually increments such that it reaches the predictive threshold, a predictive failure is signaled.

This counter is referred to as the Failure History Counter. There is a separate Failure History Counter for each attribute.

5.2.5 Thermal monitor

Cheetah 15K.7 drives implement a temperature warning system which:

1. Signals the host if the temperature exceeds a value which would threaten the drive.

2. Signals the host if the temperature exceeds a user-specified value.

3. Saves a S.M.A.R.T. data frame on the drive which exceeds the threatening temperature value.

A temperature sensor monitors the drive temperature and issues a warning over the interface when the temperature

exceeds a set threshold. The temperature is measured at power-up and then at ten-minute intervals after power-up.

The thermal monitor system generates a warning code of 01-0B01 when the temperature exceeds the specified limit in

compliance with the SCSI standard. The drive temperature is reported in the FRU code field of mode sense data. You can

use this information to determine if the warning is due to the temperature exceeding the drive threatening temperature or the

user-specified temperature.

This feature is controlled by the Enable Warning (EWasc) bit, and the reporting mechanism is controlled by the Method of

Reporting Informational Exceptions field (MRIE) on the Informational Exceptions Control (IEC) mode page (1Ch).

CHEETAH 15K.7 SAS PRODUCT MANUAL, REV. F 14

Loading...

Loading...