Seagate ST31250N, ST31250ND, ST31250W, ST31250WD, ST31250WC Product Manual

...

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

Barracuda 2LP Disc Drive

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

ST31250N/ND, ST31250W/WD,

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

ST31250WC/DC, ST32550N/ND,

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

ST32550W/WD, ST32550WC/DC

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

Product Manual, Volume 1

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

Barracuda 2LP Disc Drive

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

ST31250N/ND, ST31250W/WD,

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

ST31250WC/DC, ST32550N/ND,

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

ST32550W/WD, ST32550WC/DC

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

Product Manual, Volume 1

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

© 1996 Seagate Technology, Inc. All rights reserved

Publication number: 83328930, Rev. D

January 1996

Seagate®, Seagate Technology®, and the Seagate logo are registered

trademarks of Seagate Technology, Inc. Barracuda™ is a trademark of

Seagate Technology, Inc. Other product names are registered trademarks

or trademarks of their owners.

Seagate reserves the right to change, without notice, product offerings or

specifications. No part of this publication may be reproduced in any form

without written permission from Seagate Technology, Inc.

Revision status summary sheet

Sheets

Revision Date Writer/Engineer Affected

A 7/14/94 L. Newman/J. Olson All

B 9/21/94 L. Newman/J. Olson 36, 37, 43, 51, 57, 61,

64, 66

C 3/20/95 L. Newman/J. Olson 1, 9, 12, 14, 24, 25, 26, 27,

28, 29, 33, 34, 35, 36, 39,

41, 42, 47, 48, 50, 52, 55,

57, 58, 59, 60, 61, 62, 63,

64, 66, 68, 69, 70, 71, 73,

80, 82

D 1/9/96 L. Newman/J. Olson 3, 18, 36, 39, 40, 41, 48, 50,

51, 53, 54, 57, 65, 72

Note. Product Manual 83328930 is Volume 1 of a two-volume

document with the SCSI interface information in the

SCSI-2 Interface Product Manual,

Part Number 77738479.

Volume 2

Contents

1.0 Scope .............................................................................................................................. 1

2.0 Applicable standard and reference documentation ...................................................... 3

2.1 Standards ................................................................................................................. 3

2.2 Applicable reference documents............................................................................... 3

3.0 General description.......................................................................................................... 5

4.0 Standard features ............................................................................................................. 7

4.1 Performance ............................................................................................................. 7

4.1.1 Reliability ...................................................................................................... 7

4.2 Unformatted and formatted capacities ...................................................................... 8

4.3 Options ..................................................................................................................... 8

4.4 Installation................................................................................................................. 9

5.0 Performance characteristics ........................................................................................... 11

5.1 Internal drive characteristics ..................................................................................... 11

5.2 SCSI seek performance characteristics .................................................................... 11

5.2.1 Seek time...................................................................................................... 13

5.2.2 Format drive command execution time ......................................................... 13

5.3 General performance characteristics ........................................................................ 14

5.4 Start/stop time........................................................................................................... 15

5.5 Prefetch/multi-segmented cache control ................................................................... 15

5.6 Caching write data .................................................................................................... 16

5.7 Synchronized spindle operation ................................................................................ 17

6.0 Reliability specifications.................................................................................................. 21

6.1 Error rates................................................................................................................. 21

6.1.1 Environmental interference ........................................................................... 21

6.1.2 Write errors................................................................................................... 21

6.1.3 Seek errors ................................................................................................... 22

6.2 Reliability and service ............................................................................................... 22

6.2.1 Mean time between failures (MTBF) ............................................................. 22

6.2.2 Air flow.......................................................................................................... 22

6.2.3 Preventive maintenance ............................................................................... 30

6.2.4 Service life .................................................................................................... 30

6.2.5 Service philosophy........................................................................................ 30

6.2.6 Installation..................................................................................................... 30

6.2.7 Service tools ................................................................................................. 30

6.2.8 Hot plugging Barracuda 2LP disc drives ....................................................... 30

vi Barracuda 2LP Product Manual, Rev. D

7.0 Physical/electrical specifications.................................................................................... 33

7.1 AC power requirements ............................................................................................ 33

7.2 DC power requirements ............................................................................................ 33

7.2.1 Conducted noise immunity............................................................................ 34

7.2.2 Power sequencing ........................................................................................ 34

7.2.3 12V current profile ........................................................................................ 35

7.3 Heat/power dissipation.............................................................................................. 36

7.4 Environmental limits.................................................................................................. 36

7.4.1 Temperature ................................................................................................. 36

7.4.2 Relative humidity .......................................................................................... 36

7.4.3 Effective altitude (sea level) .......................................................................... 37

7.4.4 Shock and vibration ...................................................................................... 37

7.4.5 Air cleanliness............................................................................................... 38

7.4.6 Acoustics ...................................................................................................... 38

7.5 Electromagnetic compatibility.................................................................................... 38

7.6 Mechanical specifications ......................................................................................... 39

7.6.1 Drive orientation............................................................................................ 42

7.6.2 Cooling ......................................................................................................... 42

7.6.3 Drive mounting.............................................................................................. 42

8.0 Media characteristics ....................................................................................................... 43

8.1 Media description...................................................................................................... 43

9.0 Defect and error management......................................................................................... 45

9.1 Defects and errors .................................................................................................... 45

10.0 Option/configuration headers ......................................................................................... 47

10.1 Drive ID/option select headers .................................................................................. 47

10.1.1 ST31250N/ND and ST32550N/ND configuration .......................................... 47

10.1.2 ST31250W/WD and ST32550W/WD configuration ....................................... 50

10.1.3 ST31250WC/DC and ST32550WC/DC configuration.................................... 53

10.2 Synchronized spindles interface ............................................................................... 55

10.2.1 Electrical description ..................................................................................... 55

10.3 Grounding ................................................................................................................. 57

11.0 Interface requirements ..................................................................................................... 59

11.1 General description................................................................................................... 59

11.2 SCSI interface messages supported......................................................................... 59

11.3 SCSI interface commands supported........................................................................ 60

11.3.1 Inquiry data ................................................................................................... 62

11.3.2 Mode sense data .......................................................................................... 63

11.4 SCSI bus conditions and miscellaneous features supported..................................... 66

Barracuda 2LP Product Manual, Rev. D vii

11.5 Synchronous data transfer........................................................................................ 67

11.5.1 Synchronous data transfer periods supported .............................................. 67

11.5.2 REQ/ACK offset............................................................................................ 67

11.6 DC cable and connector ........................................................................................... 68

11.7 SCSI physical interface............................................................................................. 68

11.7.1 Physical characteristics ................................................................................ 70

11.7.2 Connector requirements ............................................................................... 71

11.7.3 Electrical description ..................................................................................... 72

11.8 SCSI non-wide physical interface ............................................................................. 76

11.9 SCSI wide physical interface..................................................................................... 79

11.10 SCSI single-connector attachment (SCA) physical interface..................................... 82

Index .......................................................................................................................................... 87

Figures

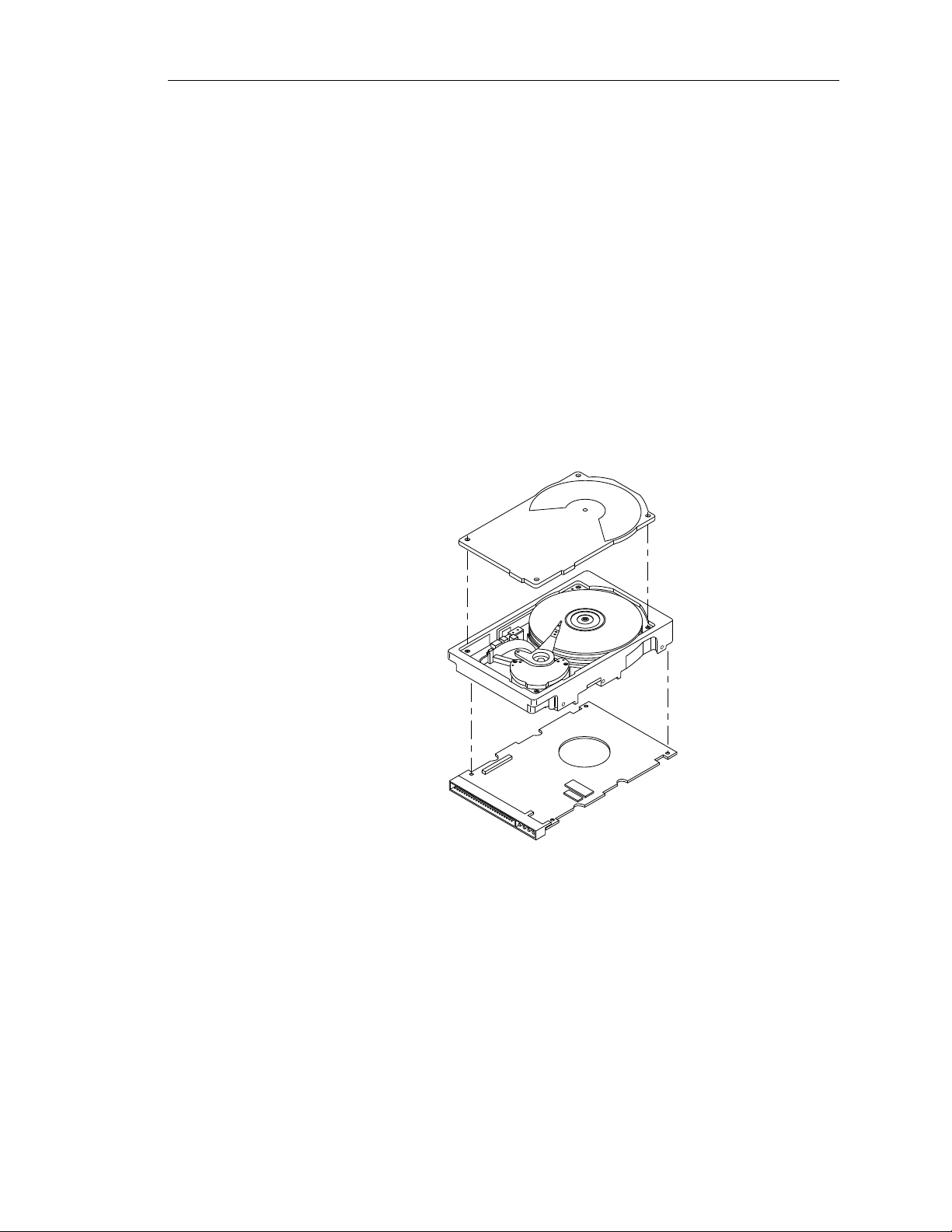

Figure 1. Barracuda 2LP disc drive (ST32550N drive shown) .................................................. 1

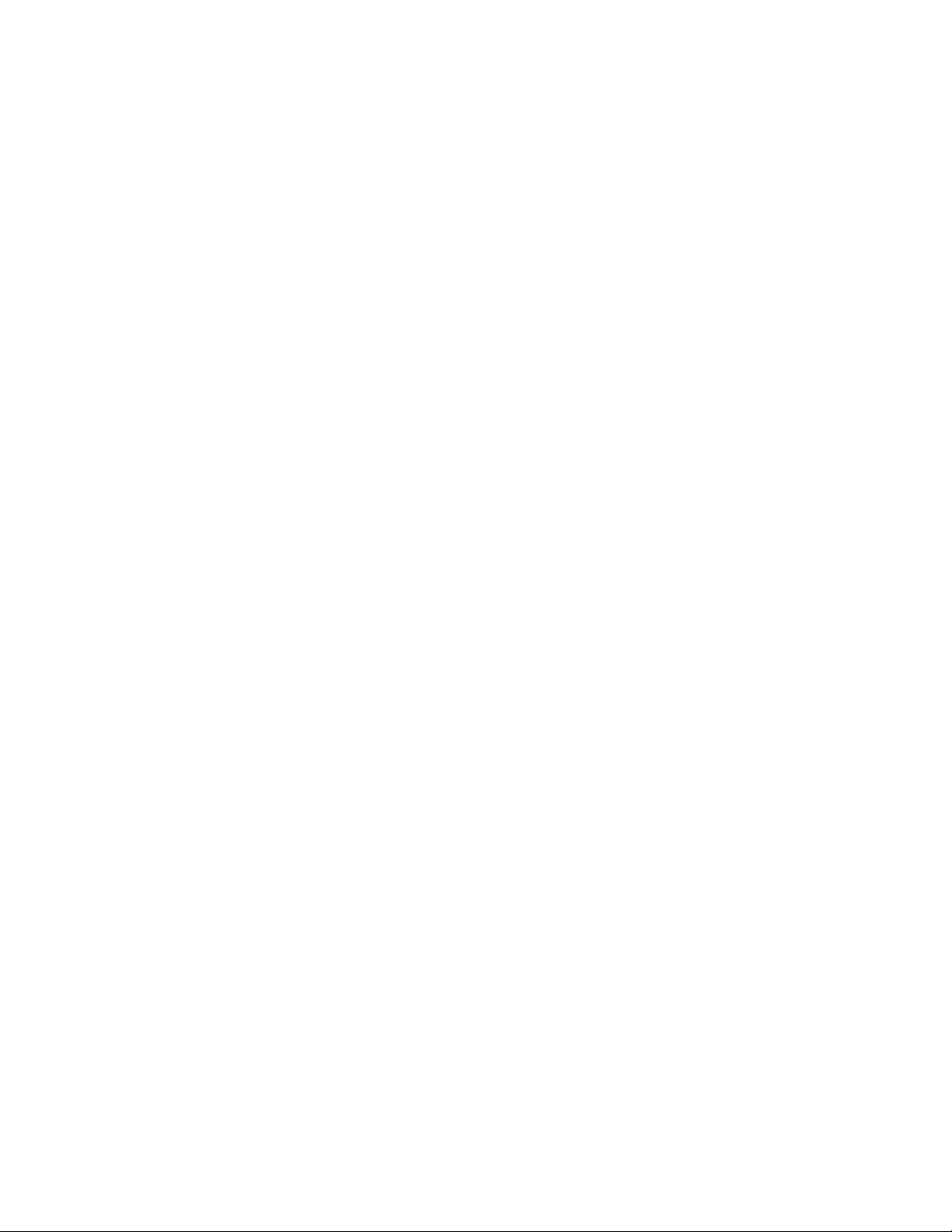

Figure 2. Barracuda 2LP disc drive (exploded view)................................................................. 5

Figure 3. ASA I OEM thermal calibration ................................................................................. 13

Figure 4. Synchronized drive interconnect diagram .................................................................. 17

Figure 5. Synchronized reference signal characteristics ........................................................... 18

Figure 6. Air flow pattern (ST32550N drive shown) .................................................................. 23

Figure 7. WYGX temperature measurement locations.............................................................. 24

Figure 8. HYHX temperature measurement locations............................................................... 25

Figure 9. JYHX temperature measurement locations ............................................................... 26

Figure 10. KYHX temperature measurement locations............................................................... 27

Figure 11. ZYHX temperature measurement locations ............................................................... 28

Figure 12. PYJX temperature measurement locations................................................................ 29

Figure 13. Temperature measurement location (ST32550N shown)........................................... 29

Figure 14. Barracuda 2LP drives typical +12V current profile ..................................................... 35

Figure 15. ST31250N/ND and ST32550N/ND mounting configuration dimensions..................... 39

Figure 16. ST31250W/WD and ST32550W/WD mounting configuration dimensions.................. 40

Figure 17. ST31250WC/DC and ST32550WC/DC mounting configuration dimensions.............. 41

Figure 18. Recommended mounting........................................................................................... 42

Figure 19. ST31250N/ND and ST32550N/ND jumper connectors .............................................. 47

Figure 20. ST31250W/WD and ST32550W/WD jumper connectors........................................... 50

Figure 21. ST31250WC/DC and ST32550WC/DC jumper connectors ....................................... 53

Figure 22. SCSI reference index signal driver/receiver combination ........................................... 55

Figure 23. ST31250N/ND and ST32550N/ND configuration select header................................. 56

Figure 24. ST31250W/WD and ST32550W/WD configuration select header.............................. 56

viii Barracuda 2LP Product Manual, Rev. D

Figure 25. ST31250WC/DC and ST32550WC/DC configuration select header .......................... 57

Figure 26. ST31250N/ND and ST32550N/ND physical interface................................................ 68

Figure 27. ST31250W/WD and ST32550W/WD physical interface............................................. 69

Figure 28. ST31250WC/DC and ST32550WC/DC physical interface ......................................... 69

Figure 29. Single-ended transmitters and receivers.................................................................... 73

Figure 30. Typical differential I/O line transmitter/receiver and terminators................................. 74

Figure 31. Non-shielded SCSI device connector ........................................................................ 76

Figure 32. Wide SCSI device connector ..................................................................................... 79

Figure 33. Non-shielded, 80-pin I/O and DC power single-connector attachment (SCA) ............ 82

Tables

Table 1. SCSI interface messages supported ......................................................................... 59

Table 2. Supported commands............................................................................................... 60

Table 3. Barracuda 2LP family drive inquiry data–ASA I ......................................................... 62

Table 4. Barracuda 2LP family drive inquiry data–ASA II ........................................................ 62

Table 5. Mode sense data, ST31250 default values–ASA I (SCSI-1 implementation) ............. 63

Table 6. Mode sense data, ST32550 default values–ASA I (SCSI-1 implementation) ............. 63

Table 7. Mode sense data, ST31250 default values–ASA I (SCSI-2 implementation) ............. 64

Table 8. Mode sense data, ST32550 default values–ASA I (SCS-2 implementation) .............. 64

Table 9. Mode sense data, ST31250 default values–ASA II (SCSI-2 implementation) ............ 65

Table 10. Mode sense data, ST32550 default values–ASA II (SCSI-2 implementation) ............ 65

Table 11. SCSI bus conditions and other miscellaneous features ............................................. 66

Table 12. Synchronous data transfer periods............................................................................ 67

Table 13. Mating connector parts .............................................................................................. 68

Table 14. Single-ended cable pin assignments for ST31250N and ST32550N drives ............... 77

Table 15. Differential cable pin assignments for ST31250ND and ST32550ND drives.............. 78

Table 16. Single-ended contact assignments for ST31250W and ST32550W drives ................ 80

Table 17. Differential contact assignments for ST31250WD and ST32550WD drives ............... 81

Table 18. SCA contact assignments for ST31250WC and ST32550WC drives......................... 83

Table 19. SCA contact assignments for ST31250DC and ST32550DC drives .......................... 84

Table 20. Disc drive SCSI timing............................................................................................... 85

Barracuda 2LP Product Manual, Rev. D 1

1.0 Scope

This manual describes Seagate Technology®, Inc. Barracuda™ 2LP (low

profile) disc drives.

Barracuda drives support the small computer system interface-2 (SCSI-2) as

described in the ANSI SCSI and SCSI-2 interface specifications to the extent

described in this manual. The

77738479) describes general SCSI interface characteristics of this and other

families of Seagate drives.

SCSI-2 Interface Product Manual

(part number

Figure 1. Barracuda 2LP disc drive (ST32550N drive shown)

2 Barracuda 2LP Product Manual, Rev. D

Barracuda 2LP Product Manual, Rev. D 3

2.0 Applicable standard and

reference documentation

Seagate takes all reasonable steps to ensure that its products are certifiable

to currently accepted standards. Typical applications of these disc drives

include customer packaging and subsystem design.

Safety agencies conditionally certify component parts, such as the Barracuda disc drive, based on their final acceptability in the end-use product. The

subsystem designer is responsible for meeting these conditions of acceptability in obtaining safety/regulatory agency compliance in their end-use

product and certifying where required by law.

2.1 Standards

The Barracuda disc drive is a UL recognized component per UL1950, CSA

certified to CSA C22.2 No. 950-M89, and VDE certified to VDE 0805 and

EN60950.

If this model has the CE Marking, it complies with the European Union

requirements of the Electromagnetic Compatibility Directive 89/336/EEC of

03 May 1989 as amended by Directive 92/31/EEC of 28 April 1992 and

Directive 93/68/EEC of 22 July 1993.

Seagate uses an independent laboratory to confirm compliance to the above

directives. Drives are tested in representative systems for typical applications. The selected system represents the most popular characteristics for

test platforms. The system configurations include:

• 486, Pentium, and PowerPC Microprocessors

• 3.5-inch floppy disc drive

• Keyboard

• Monitor/display

Although the test system with this Seagate model complies to the directives,

we cannot guarantee that all systems will comply. The computer manufacturer or system integrator shall confirm EMC compliance and provide CE

Marking for their product.

The Barracuda disc drive is supplied as a component part. It is the

responsibility of the subsystem designer to meet EMC/regulatory requirements. Engineering test characterizations of radiated emissions are available from the Seagate safety department.

2.2 Applicable reference documents

Barracuda 2LP Installation Guide

Seagate part number: 83328920

SCSI-2 Interface Product Manual (volume 2)

Seagate part number: 77738479

ANSI small computer system interface (SCSI) documents

ANSI X3.131-1986 (SCSI-1)

X3T9.2/86-109 Rev. 10H (SCSI-2)

X3T9.2/91-010 Rev. 10 (SCSI-3) Parallel Interface

4 Barracuda 2LP Product Manual, Rev. D

Barracuda 2LP Product Manual, Rev. D 5

3.0 General description

Barracuda drives are low-cost, high-performance, random-access storage

devices designed to meet the needs of the original equipment manufacturer

(OEM) marketplace.

The Barracuda drive’s interface supports disconnect/reconnect, multiple

initiators, self-configuring host software, and automatic features that relieve

the host from knowing the physical characteristics of the targets (logical

block addressing is used).

The head and disc assembly (HDA) is sealed at the factory. Air circulates

within the HDA through a non-replaceable filter to maintain a contaminationfree HDA environment.

Refer to Figure 2 for an exploded view of the drive. This exploded view is for

information only—never disassemble the HDA and do not attempt to service

items in the sealed enclosure (heads, media, actuator, etc.) as this requires

special facilities. The drive contains no replaceable parts. Opening the HDA

voids your warranty.

Figure 2. Barracuda 2LP disc drive (exploded view)

6 Barracuda 2LP Product Manual, Rev. D

Barracuda drives use a dedicated landing zone at the innermost radius of the

media to eliminate the possibility of destroying or degrading data by landing

in the data zone. The drive automatically goes to the landing zone when the

power is removed.

An automatic shipping lock prevents potential damage to the heads and

discs. The shipping lock disengages when power is applied to the drive and

the head load process begins.

Barracuda drives decode track 0 location data from the dedicated servo

surface to eliminate mechanical transducer adjustments and rel ate d reliability concerns.

A high-performance actuator assembly with a low-inertia, balanced, patented, straight-arm design provides excellent performance with minimal

power dissipation.

Barracuda 2LP Product Manual, Rev. D 7

4.0 Standard features

Barracuda 2LP drives have the following standard features:

• Integrated SCSI controller

• Single-ended or differential SCSI drivers and receivers

• Asynchronous and synchronous data-transfer protocols

• Firmware downloadable using a SCSI interface

• Selectable sector size from 180 to 4,096 bytes per sector

• Programmable sector-reallocation scheme

• Flawed sector reallocation at format time

• Programmable auto-write and auto-read reallocation

• Reallocation of defects on command (post format)

• 96-bit Reed-Solomon error-correction code

• Sealed head and disc assembly (HDA)

• No preventive maintenance or adjustments required

• Dedicated head-landing zone

• Automatic shipping lock

• Automatic thermal compensation

• Embedded Grey Code track address to eliminate seek errors

• Self-diagnostics performed at power-on

• 1:1 interleave

• Zone bit recording (ZBR)

• Vertical, horizontal, or top-down mounting

• Dynamic spindle brake

• Active IC terminators (N/W models only)

• Synchronous spindle capability

• 512 Kbyte data buffer (see Section 5.5)

• Low audible noise for office environment

• Low power consumption

4.1 Performance

• Programmable multi-segmentable cache buffer

• 7,200 RPM spindle; average latency = 4.17 msec

• Command queuing of up to 64 commands

• Background processing of queue

• Supports start and stop commands

• Provides synchronized spindle capability

• Adaptive seek velocity; improved seek performance

4.1.1 Reliability

• 800,000 hour MTBF

• LSI circuitry

• Balanced low-mass rotary voice-coil actuator

8 Barracuda 2LP Product Manual, Rev. D

4.2 Unformatted and formatted capacities

Standard OEM models are formatted to have 512-byte sectors.

Barracuda 2LP drives have nine (9) spare sectors per cylinder and one (1)

spare cylinder per unit.

Formatted Unformatted

ST31250 1,020.9 Mbytes 1,205.3 Mbytes

ST32550 2,147.4 Mbytes 2,541.3 Mbytes

Users having the necessary equipment may modify the data block size

before issuing a f ormat command to obtain different formatted capacities.

User-available capacity also depends on the spare realloca tion scheme

selected. See the Mode Se lect command and the Forma t command in the

SCSI-2 Inte rfac e P r oduct Manual

(part numbe r 77738479).

4.3 Options

The capacity shown in Section 4.2 is normally provided. Other capacities

can be ord ered depend ing on the spar ing scheme an d sector size requested.

The following options are incorporated at the time of production or are

available separately.

• Front panel (green lens), part number 73497151

The standard front panel is black plastic. You may order other colors. Each

panel has a single rectangular green LED indicator lens that, when

glowing, indicates the drive is selected.

•

Barracuda 2LP Installation Guide,

This manual provides basic installation information for persons not

familiar with the product. It also includes information on obta ining technical support and service for the drive.

• SCSI interface terminating resistors (N/W models only, enabled by jumper)

To enable internal drive termination, install a jumper on J1 pins 5 and 6.

Refer to Section 10.1.

• Single-unit shipping pack kit

The drive is shipped in bulk packaging to provide maximum protection

against transit damage. Units shipped individually require additional

prot ection as provided by the s i ngle-unit shippin g pack.

• Adapter accessory frame kit, part number 75790701

This kit contains a frame, which allows a 3.5-inch drive to be mounted

in a 5.25-inch drive bay. It includes mounting hardware, front panel with

a green lens, an LED with cable that connects to the remote LED

connector, and installation instructions.

part number 83328920

Barracuda 2LP Product Manual, Rev. D 9

4.4 Installation

For option jumper locations and definitions refer to Section 10.1. Drive default

mode parameters are not normally needed for installation. Refer to

Section 11.3.2 for default mode parameters if you need them.

• Ensure that the SCSI ID of the drive is not the same as the host adapter.

• If multiple devices are on the bus, set the drive’s SCSI ID to one that is not

presently used by other devices on the bus.

• If the drive is the only device on the bus, attach it to the end of the SCSI

bus cab le. Inte rnal ter min ati on is availabl e on ST31250N, ST31250W,

ST32550N, and ST32550W drives by enabling this feature with a jumper

(see Section 1 0.1).

External terminators are required for ST31250ND, ST31250WD,

ST31250WC, ST31250DC, ST32550ND, ST32550WD, ST32550WC,

and ST3 2550DC drives. These external terminators must be provided by

the user, systems integ ra t or, or h o s t equipme nt manufacturer.

• If you attach the drive to a bus that contains other devices, and the new

drive is not attached to the end of the bus, remove termination from the new

drive.

• Set all a ppropria te option jumpers prior to appl ying pow er to the d riv e. If

you change j umpers after applying power, recycle the drive’s power to

make th e new se tti ngs effectiv e .

Formatting

• It is not necessary to low-level format this drive. The drive is shipped from

the factory low-level formatted in 512-byte sectors.

• Reformat the drive if:

a. You select a different sector size.

b. You select a different spare-sector allocation scheme.

10 Barracuda 2LP Product Manual, Rev. D

Barracuda 2LP Product Manual, Rev. D 11

5.0 Performance characteristics

This section provides performance-related characteristics and features of

Barracuda 2LP drives.

5.1 Internal drive characteristics

ST31250 ST32550

Drive capacity, Mbytes unformatted 1,205.3 2,541.3

Read/write data heads, 5 11

maximum (physical)

Bytes per track, average bytes 64,160 64,160

Bytes per surface, Mbytes unformatted 232.4 231.03

Cylinders/tracks per surface, 3,711 3,510

user accessible

Tracks per inch 4,048 4,048

Bits per inch 73,820 72,680

Servo heads 1 1

Internal data rate per physical head, 47.5 to 72.0 49.4 to 72.0

Mbits/sec, variable with zone

Disc rotation speed 7,200 ± 0.5% 7,200 ± 0.5%

Average rotational latency, msec 4.17 4.17

5.2 SCSI seek performance characteristics

This section first describes the thermal calibration algorithms used by ASA

I and ASA II download code. Section 5.2.1 provides actual seek times and

section 5.2.2 provides drive format execution times.

Refer to Table 22 in Section 11.10 and to the

Manual

ASA I thermal calibration

All performance characteristics assume that autom atic adaptive thermal

compensation is not in process when the drive rec eives the SCSI command.

Automatic adaptive thermal compensation will not interrupt an active SCSI

command. I f adaptive thermal compensation is in process when a SCSI

command is received, the command is queued until compensation completes. When compensation completes for the head, the first queued SCSI

com mand execu tes, and the drive co ntinues compensation for the remaining

heads.

(part numbe r 77738479 ) f or additional timing deta il s .

SCSI-2 Interface Product

The above procedure continues until compensation for all heads has

completed, or until 10 minutes have elapsed. The drive initiates an automatic

adaptive thermal compensation cycle once on power-up before completing

its initialization sequence, once after 1 minute from the end of initialization,

and then once approximately every 10 minutes. Automatic thermal compensation occurs at other times but should be transparent to the user (e.g.,

12 Barracuda 2LP Product Manual, Rev. D

during format, at Re-Zero command, at spindle-up, during read-error recovery, and during reassign-block functions) . Y ou can use the Re-Zero command to reset the thermal compensation timer to let the host know when the

interruption for thermal compensation will occur.

ASA II thermal calibration

At power up and following a SCSI reset, the drive calibrates the heads using

the SCSI Rezero Unit command before processing read and write commands. The drive then delays a fixed period of time (D) before performing any

additional thermal calibrations. This ensures a specific time interval when no

thermal calibration interruptions will occur.

After the delay interval (D) expires, a single head thermal calibration (t-cal)

is scheduled every N1 seconds. Refer to the equation below.

N1 = (T - D) / (2 * H)

T = 600 seconds (the maximum allowable thermal calibration period for any

single head)

D = 300 seconds (period after the power-up/reset calibration before initiating

subsequent thermal calibrations)

H = Number of heads in the drive

After the drive has cycled once through all of the heads (H) at the N1 time

interval, the scheduling of single head thermal calibrations switches to an N2

time interval. Refer to the equation below.

N2 = T / (2 * H)

When a single head thermal calibration is scheduled, the drive attempts to

find an idle period of 25 to 50 milliseconds prior to performing the thermal

calibration. If the thermal calibration has not been performed after another N1

or N2 seconds elapse (whichever is the current time interval), the drive forces

a thermal calibration to occur at the next command boundary (even during

a read lookahead sequence), and immediately restarts the N2 or N2 second

timer–this guarantees that no head will remain uncalibrated for more than T

seconds and that no thermal calibrations will occur closer together in time

than approximately every N1 or N2 seconds.

Any thermal calibration performed during the standard retry sequence will be

limited to the misaligned head, and will be disabled if the host has selected

a retry count of zero.

Barracuda 2LP Product Manual, Rev. D 13

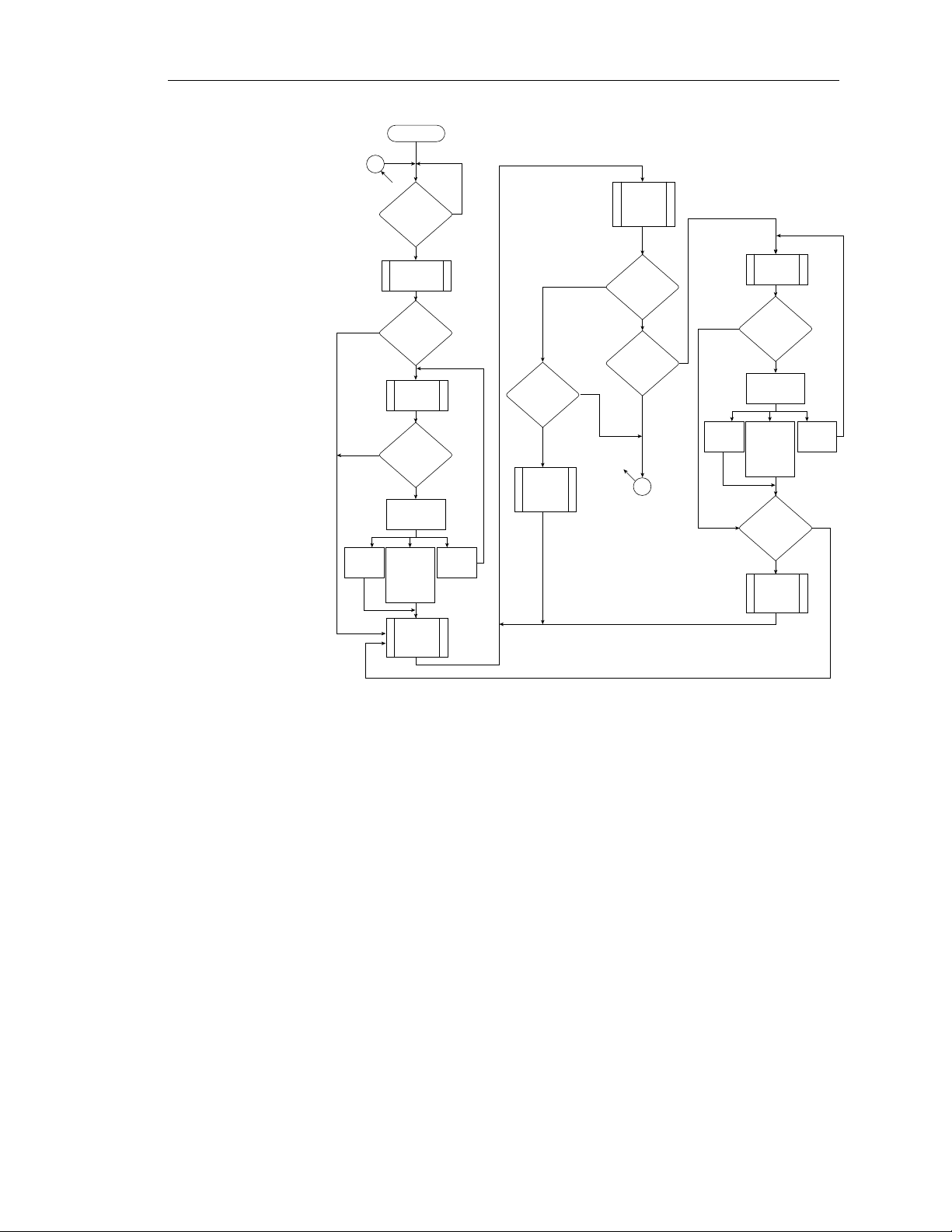

Start

A

No

No

Write/Read

Miss

command

Has

10 min. TCAL

timer

expired?

Yes

Reset

10 minute

TCAL timer

Is

SCSI

command in

progress?

Yes

Complete

command

Read

ahead

pending?

Yes

Hold

(wait for next

command)

Independent

10 Minute

Periodic

Abortive Read

Lookahead

Timer

Seek to

TCAL cyl

and select

head zero

No

Read

Sequential

command

All

heads

calibrated?

No

Select

next

head

No

Yes

TCAL

head

Has

target

received a SCSI

command?

Yes

All

heads

calibrated?

Yes

A

No

No

Write/Read

Miss

command

Complete

command

Read

ahead

pending?

Yes

Hold

(wait for next

command)

Independent

10 Minute

Periodic

Abortive Read

Lookahead

Timer

Has

10 min. TCAL

timer

expired?

No

Seek to

TCAL cyl

and select

next head

Read

Sequential

command

Yes

Figure 3. ASA I OEM thermal calibration

5.2.1 Seek time

Drive including

controller overhead

Drive level (msec) without disconnect (msec)

read write read write

Average typical* 8.0 9.0 9.0 10.0

Single track typical* 0.6 0.9 1.6 1.9

Full stroke typical* 17 19 18.0 20.0

*Typical seek values are measured under nominal conditions of tempera-

ture, voltage, and horizontal orientation on a representative sample of

drives .

5.2.2 Format drive command execution time

≥≥

for

≥ 512-byte sectors

≥≥

ST31250 ST32550

Maximum (with verify) 15 minutes 30 minutes

Maximum (without verify) 10 minutes 20 minutes

14 Barracuda 2LP Product Manual, Rev. D

5.3 General performance characteristics

Minimum sector interleave 1 to 1

Data buffer to/from disc media 512-byte sector

Data transfer rate (≤ 1 sector)

Minimum 5.30 Mbytes/sec*

Maximum 8.94 Mbytes/sec*

Data transfer rate (< 1 track)

Minimum 3.56 Mbytes/sec*

Maximum 7.65 Mbytes/sec*

SCSI interface data

Asynchronous transfer rate * 5.0 Mbytes/sec**

(maximum instantaneous) 10.0 Mbytes/sec***

Synchronous transfer rate fast 2.5 to 10 Mbytes/sec

(ST31250N/ND and ST32550N/ND)

Synchronous transfer rate wide 5.0 to 20 Mbytes/sec

(ST31250W/WD/WC/DC and

ST32550W/WD/WC/DC)

Sector sizes

Default 512-byte data blocks

Variable in even-sector sizes 180 to 4,096 bytes

Read/write consecutive sectors on a track Yes

Flaw reallocation performance impact

Spare sectors per track reallocation Negligible

Spare sectors per cylinder reallocation Negligible

Spare tracks per volume reallocation 35 msec (typical)

Overhead time for head switch 0.7 msec

Overhead time for one-track cylinder switch 1.6 msec (typical)

Average rotational latency 4.17 msec

* Rate measured from the start of the first sector transfer to or from the host.

** Assumes system ability to support 5.0 Mtransfers/sec, 1 byte wide, and

no cable loss.

***Assumes system ability to support 5.0 Mtransfers/sec, 2 bytes wide, and

no cable loss.

Barracuda 2LP Product Manual, Rev. D 15

5.4 Start/stop time

Disabling the Motor Start option causes the motor to start as soon as power

is applied, causing the drive to become ready within 30 seconds after DC

power is applied at nominal voltage. If a recoverable error condition is

detected during the start sequence, the drive executes a recovery procedure

which may cause the drive to become ready in excess of 30 seconds. During

the start sequence the drive responds to some commands over the SCSI

interface. Stop time is less than 30 seconds (maximum) from removal of DC

power.

Enabling the Motor Start option causes the internal controller to accept the

commands listed in the

than 3 seconds after applying DC power. After receiving the Motor Start

command, the drive becomes ready for normal operation within 30 seconds

(excluding the error recovery procedure). The Motor Start command can

also be used to command the drive to stop the spindle (see the Start/Stop

command information in the

There is no power control switch on the drive.

SCSI-2 Interface Product Manual

SCSI-2 Interface Product Manual

(77738479) less

).

5.5 Prefetch/multi-segmented cache control

The drive provides a prefetch/multi-segmented cache algorithm, which in

man y c ase s e nhan ces sys tem perf orma nce . T o sele ct th is f ea ture, the host

sends the Mode Select command with the proper values in the applicable

bytes in page 08h (see the

prefetch and cache operation enabled.

Of the 512 Kbytes physical buffer space, approximately 480 Kbytes can be

used as a cache. The cache can be divided into logical segments from which

data is read and to which data is written.

The drive keeps track of the logical block addresses of the data stored in each

segment of the cache. If the cache is enabled (see RCD bit, Table 5.2.1-27

in the

SCSI-2 Interface Product Manual),

read command is retrieved from the cache before any disc access is initiated.

Data in contiguous logical blocks immediately beyond that requested by the

Read command can be retrieved and stored in the cache for immediate

transfer to the initiator on subsequent read commands. This is referred to as

the prefetch operation. Since data that is prefetched may replace data

already in the cache segment, an initiator can limit the amount of prefetch

data to optimize system performance. The drive never prefetches more

sectors than the number specified in bytes 8 and 9 of Mode page 08h (see

the

SCSI-2 Interface Product Manual

Kbytes of the buffer are used as a circular buffer for read/writes, with no

prefetch operation and no segmented cache operation.

The following is a simplified description of the prefetch/cache operation:

SCSI-2 Interface Product Manual

data requested by the host with a

). If the cache is not enabled, 480

). Default is

Case A. A read command is received and the first logical block is already in

the cache.

1. The drive transfers to the initiator the first logical block requested plus all

subsequent contiguous logical blocks that are already in the cache. This

data may be in multiple segments.

16 Barracuda 2LP Product Manual, Rev. D

2. When a re quest ed logica l block is rea ched that is not in an y s egment,

the d ri ve fetch es it and any remaining requested lo gical block addres ses

from the d isc and p uts them in a se gment of the cach e. The d rive

transfers the remaining requested logical blocks fro m the cac he to the

initiator in accordance with the “buffer-full” ratio specification given in

Mode Select Disconnect/Reconnect parameters, page 02h (see the

SCSI-2 Int erfac e Pr o duct Man ual

3. The drive prefetches additional logical blocks contiguous to those

transferred in step 2 above and stores them in the segment. The drive

stops filling the segment when the maximum prefetch value has been

transferred (s ee the

Case B. A read command is received and the first logical block address

requested is not in any segment of the cache.

1. The drive fetches the requested logical blocks from the disc and

transfers them into a segment, then from there to the initiator in

accordance with the “buffer-full” ratio specification given in Mode Select

Disconnect/Reconnect parameters, page 02h (see the

face Pr oduct Manual

2. The drive prefetches additional logical blocks contiguous to those transferred in Case A, step 2 above and stores them in the segment. The drive

stops filling the segment when the maximum prefetch value has been

transferred.

SCSI-2 Inter fac e Pr oduct Manual

).

).

).

SCSI-2 Inter-

During a prefetch, the drive crosses a cylinder boundary to fetch data only

if the Discontinuity (DISC) bit is set to 1 in bit 4 of byte 2 of the Mode Select

parameters page 8h. Default is zero for bit 4 (see the

Pro duct Manual

Each cache segment is actually a self-contained circular buffer whose

length is a n integer number of sect ors. The drive supports operation with

any integer number of segments 1 to 16. Divide the 491,520 bytes in the

buffer by the number of segments to get the segment size; default is 3

segments (see the

capability of the individual segments greatly enhances the cache’s overall

performance, allowing a wide range of user-selectable configurations

including a pure prefetch strategy.

).

SCSI-2 In t e rface Product Manual

5.6 Caching write data

Write caching is a drive-write operation, which uses a drive’s buffer storage

area where data to be written to the disc is stored while the drive performs

the Write command.

Write caching is enabled along with read caching. Default is cache enabled.

For write caching, the same buffer space and segmentation is used as set

up for read functions. When a write command is issued, the cache is first

checked to see if any logical blocks to be written are already stored in the

cache from a previous read or write command. If there are, the respective

cache segments are cleared. The new data is cached for subsequent read

commands.

SCSI-2 Interface

). The wrap-around

If a 10-byte CDB write command (2Ah) is issued with the data page out (DPO)

bit set to 1, no write data is cached, but the cache segments are still checked

Barracuda 2LP Product Manual, Rev. D 17

and cleared, if needed, for any logical blocks that are being written (see the

SCSI-2 Interface Product Manual

).

If the number of write data logical blocks exceeds the size of the segment

being written into when the end of the segment is reached, data is written

into the beginning of the same cache segment, overwriting data that was

written there at the beginning of the operation. However, the drive does not

overwrite data that has not yet been written to the disc.

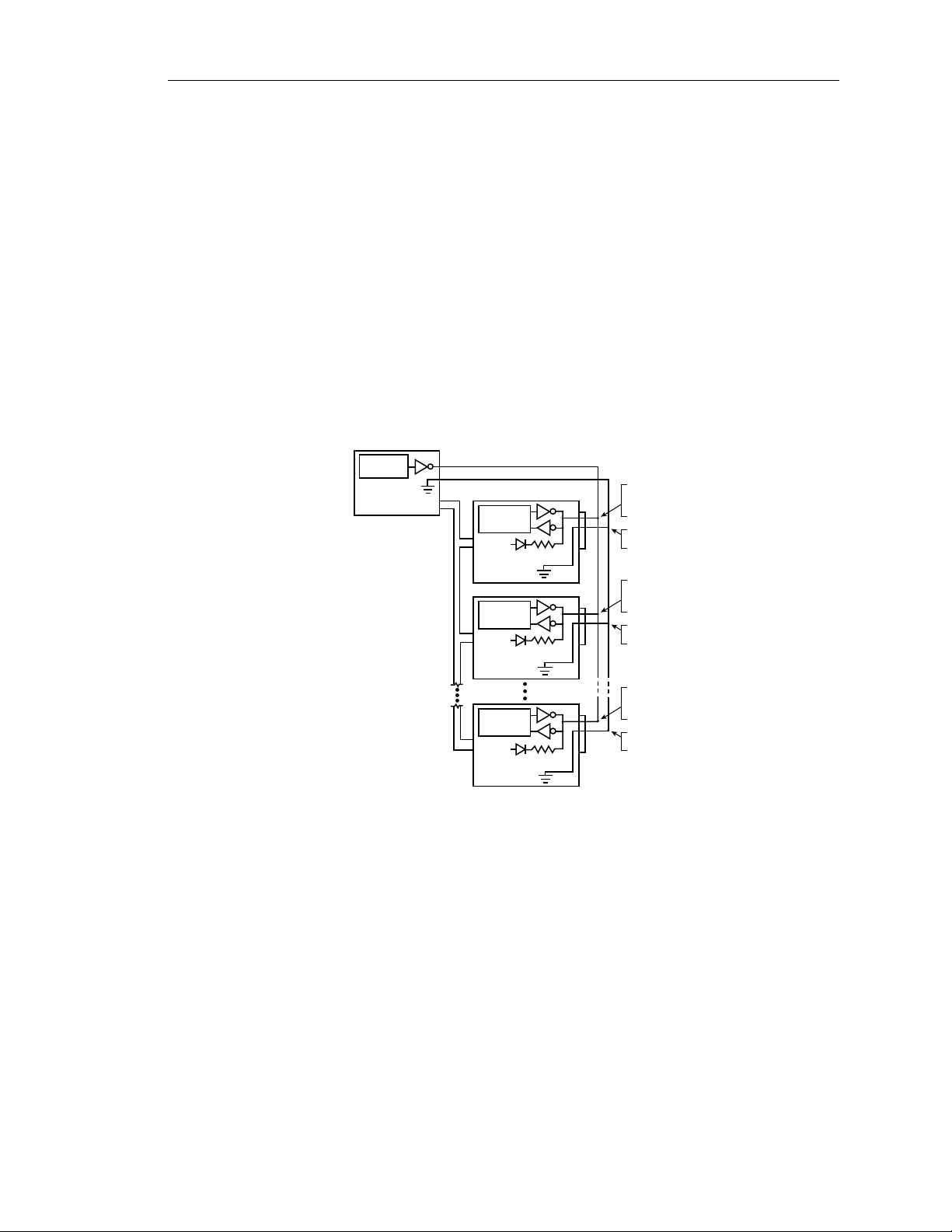

5.7 Synchronized spindle operation

The synchronized spindle operation allows several drives operating from the

same host to operate their spindles at the same synchronized rotational rate.

Drives operating in a system in synchronized mode increase the system’s

capacity and transfer rate in a cost-effective manner.

The interface consists of a twisted-pair cable, which connects the drives in

the synchronized system in a daisy-chain configuration as shown below.

Sync Interface

Master Sync

Source

(or other drive)

Host

System

Interface

Spindle

Control

+5V

Drive 1

Spindle

Control

+5V

Drive 2

Spindle

Control

+5V

Drive n

R

T

R

T

R

T

J4 Pin 1 on N/ND drives

J4 Pin 6 on WC/DC drives (+SSREF)

J5 Pin 11 on W/WD drives

J4 Pin 2 on N/ND drives

J5 Pin 12 on W/WD drives

J4 Pin 1 on N/ND drives

J4 Pin 6 on WC/DC drives (+SSREF)

J5 Pin 11 on W/WD drives

J4 Pin 2 on N/ND drives

J5 Pin 12 on W/WD drives

J4 Pin 1 on N/ND drives

J4 Pin 6 on WC/DC drives (+SSREF)

J5 Pin 11 on W/WD drives

J4 Pin 2 on N/ND drives

J5 Pin 12 on W/WD drives

Figure 4. Synchronized drive interconnect diagram

The host can reconfigure the drive any ti me after power-up to be the master

or a slave by using the Mode Select command on the Rigid Di sc Drive

Geometry page. The master provides the reference signal to which all other

drives phase-lock, including the master. There is only one master per

system, and that can be a drive or the hos t computer. All dri ves may be

configured as slaves allowing the host to provide the reference signal.

Each drive also can be configured for the non-synchronized mode in which

it ignores any reference signal that might be present—this is the default mode

as shipped from the factory. Connect t he synchronized ref erence si gnal to

the host only if the host provides the reference signal. If the host does not

provide the reference signal, do not connect the host.

18 Barracuda 2LP Product Manual, Rev. D

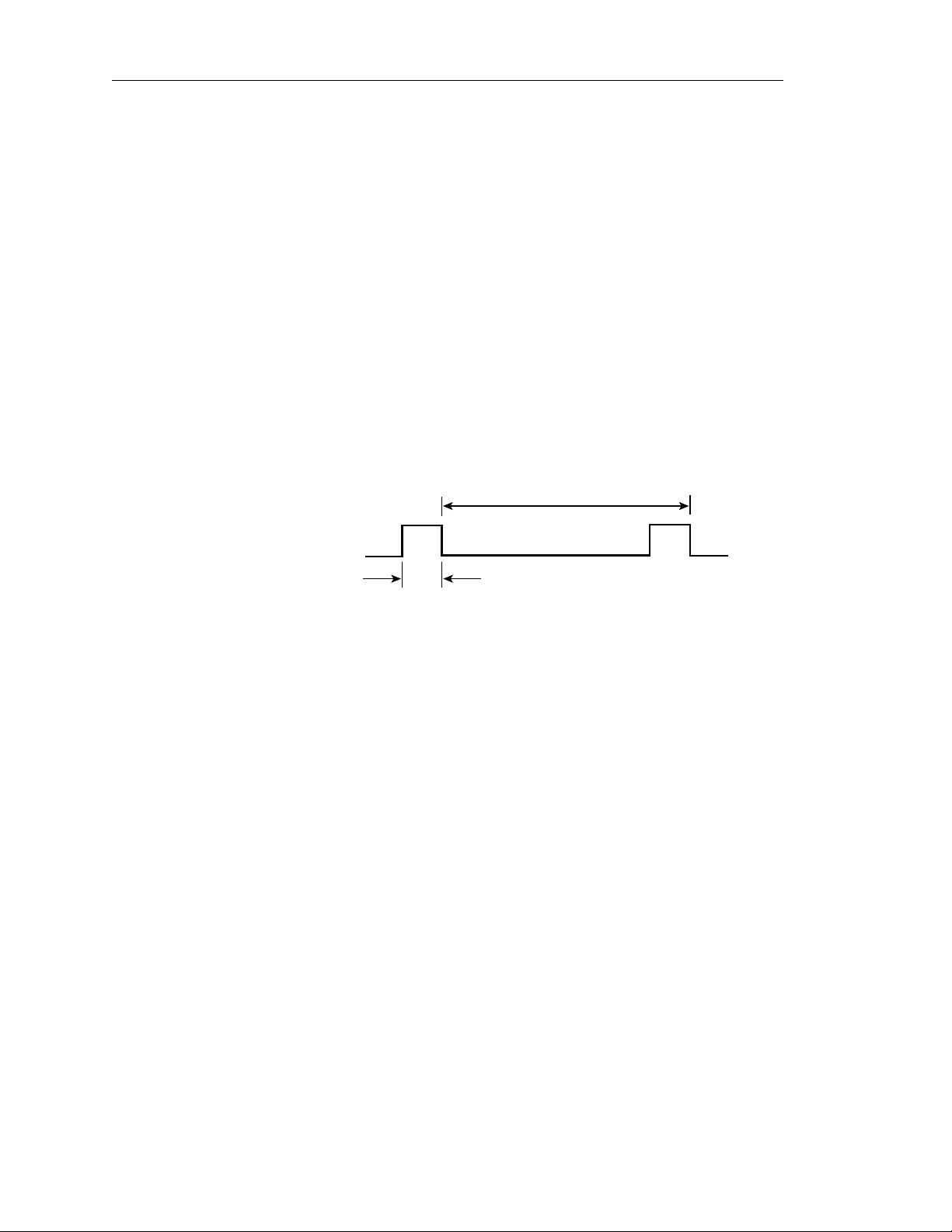

1.0 µsec min.

1.37 µsec max.

1.2 µsec ± 0.5

0

1

SSREF +

Rotational position locking

Note. Mode Select page 4, byte 17, bits 1 and 0.

RPL Description

00b Spindle synchronization is disabled (default value)

01b The target operates as a synchronized-spindle slave

10b The target operates as a synchronized-spindle master

11b The target operates as a synchronized-spindle master control

(not supported by the disc drive)

The Pike 2 LSI on the master drive provides the reference signal (SSREF+ ).

The index signal generates a 120 Hz signal. The signal is norm ally

false/negated (nominal 0V) and makes a transition to the true/asserted

(nominal +5V) l evel t o indicate t he refere nce position during the revol ution

period. Master and slave drives use the trailing (falling) edge of the

refere nce signal to phase- lock their spindles. A maximum of 10 seconds

is allo wed for a s la ve to s ynchroni ze with the r eferenc e sig nal. Figur e 5

shows the characteristics of the reference signal.

T = 0.0083 seconds (± 1.0% max)

± 10 microseconds cycle-to-cycle variance

± 20 microseconds phase error while synchronized

Figure 5. Synchronized reference signal characteristics

SCSI interface factors

The Rotational Position Locking (RPL) field in byte 17 (bits 0 a nd 1) of the

Rigid Disc Drive Geometry mode par amete rs page (p age 04h) i s used for

enabling and disabling spindle synchronization mode (see the

Interface P ro duct Manual

). If the target fails to synchroniz e, it creates a unit

SCSI-2

attention condition to all initiators. The sense key is set to Unit Attention and

the addi tion a l sense code is set to Spindle Synchronized (5C01).

After reaching synchronization, if the target detects a change of synchronization and:

1. If the logical unit is not executing an I/O process for the initiator, then the

target creates a unit attention condition. The sense key is set to Unit

Attention and the additional sense code is set to Spindle Synchronized

(5C01) or Spindle Not Synchronized (5C02).

2. If the logical unit is executing an I/O process and no other error occurs,

then the target returns Check Condition status. The sense key is set to

Recovered Error if the target is able to complete the I/O process or to

Hardware Error if the target is unable to complete the I/O process. The

additional sense code is set to Spindle Synchronized (5C01) or Spindle

Not Synchronized (5C02).

Barracuda 2LP Product Manual, Rev. D 19

You may operate the drive with a rotational skew when synchronized. The

rotational skew is applied in the retarded direction (lagging the synchronizedspindle master control). A rotational offset of up to 255/256 of a revolution

lagging may be selected. Select the amount of offset by using the Mode

Select command, Rigid Disc Drive Geometry page (page 04h), byte 18 (see

the

SCSI-2 Inter face Pr o duct Manual

numerator of a fractional multiplier that has 256 as the denominator. For

example, 40h selects 40h/FFh or 1/4 of a revolution lagging skew, 80h

selects 1/2 of a revolution lagging skew, etc. Since the drive supports all

offset values from 0 to 255, values sent by the initiator are not rounded off.

The drive’s translation of the digital offset values to physical rotational offsets

results in offset values whose phase error lies within the ± 20 microseconds

phase error with respect to the supplied 120 Hz reference signal.

The drive does not have the capability to adjust the rotational offset value

requested by the initiator to a physical offset in the drive that corresponds

in any way to sector boundaries or changes in ZBR zones. The initiator must

formulate these boundaries or changes, if required, to calculate the value of

offset it sends to the drive.

). The v alu e in byte 18 (0–FFh ) is the

20 Barracuda 2LP Product Manual, Rev. D

Loading...

Loading...