seagate ST31055N, ST31051N, ST32151N, ST32155N Installation guide

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Hawk 2XL Disc Drive

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ST32151N/W/WC, ST31051N/W/WC

ST32155N/W/WC, ST31055N/W/WC

Product Manual, Volume 1

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Hawk 2XL Disc Drive

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ST32151N/W/WC, ST31051N/W/WC

ST32155N/W/WC; ST31055N/W/WC

Product Manual, Volume 1

© 1996 Seagate Technology, Inc. All right s reserved

April 1996

Publication number: 77767489, Rev. B

Seagate®, Seagate Technology® , and the Seagate logo are r egistered tradema rks of Seagate

TM

Technology, Inc. Elite

, SeaFAXTM, SeaFONETM, SeaTDDTM, and SeaBOARDTM are trademarks of Seagate Technology, Inc. Other product names are registered trademarks or trademarks of their owners.

No part of this publication may be reproduced in any form without written permission from

Seagate Technology, Inc.

Printed in the United States of America

Revision status summary sheet

Revision Date Writer/Engineer Sheets Affected

A 5/2/96 D. Ashby 1-75

B Ashby and Kiene 9, 23 and 25

Product Man ual 77767489 is V olum e 1 of a two Vol ume docu ment w ith the SCS I In terface in formati on

in the Volume 2 SCSI Interface Product Manu al, P/N 7773847 9.

If the SCSI Interface information is needed the Volume 2 Interface Manual should be ordered, P/N

77738479.

Hawk 2XL Product M anu al, Rev. B vii

Conten ts

1.0 Scope . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

2.0 Applicable standards and reference documentati on. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2.1 Standards. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2.1.1 Electromagnetic com pati bili ty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2.1.2 Electromagnetic susceptibility . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2.2 Electromagne tic Com plia nce for the European Uni on . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2.3 Reference documents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

3.0 General descri p tion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

3.1 Standard features. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3.2 Media characteristic s . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3.3 Performance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3.4 Reliability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3.5 Unformatt ed and formatt ed capacit ies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

3.6 Factory installed accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

3.7 Options (factory install ed ) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

3.8 Accessories (user installed) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

4.0 Performa nce cha racteri sti c s . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

4.1 Internal drive characteristics (transparent to user). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

4.2 SCSI Seek performance characteristics (visible to user) [6]*. . . . . . . . . . . . . . . . . . . . . . . . . . 9

4.2.1 Access time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

4.2.2 Format command executi on time (min ute s) [1] . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

4.2.3 Generalized performance characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

4.3 Start/st op tim e . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

4.4 Prefetch/multi-segmented cache control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

4.5 Cache operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

4.5.1 Caching write data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

4.5.2 Prefetch operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

5.0 Reliability sp eci ficati on s . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

5.1 Error rates . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

5.1.1 Environmental interference. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

5.1.2 Read errors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

5.1.3 Write errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

5.1.4 Seek errors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

5.2 Reliability and service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

5.2.1 Mean time between failure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

5.2.2 Preventive maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

5.2.3 Service life . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

5.2.4 Service philosophy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

5.2.5 Service tools. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

5.2.6 Product warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

6.0 Physical/electrical specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

6.1 AC power requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

6.2 DC power requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

6.2.1 Conducted noise immunity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

6.2.2 Power sequencing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

6.2.3 Current profile . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

6.3 Power dissipation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

6.4 Environmenta l limits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

6.4.1 Temperature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

6.4.2 Relative humidit y . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

6.4.3 Effective altitude (sea level) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

6.4.4 Shock and vibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

6.4.5 Air cleanliness. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

viii Hawk 2XL Pr odu ct Man ual , Rev. B

6.4.6 Electromagnetic susceptibility . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

6.5 Mechanical specif icati ons . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

7.0 Defect and error man agem e nt . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

7.1 Drive internal defects and erro rs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

7.2 SCSI systems errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

8.0 Installati on . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31

8.1 Drive ID/option select h ea der . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31

8.1.1 Notes for Figures 7a, 7b, 7c, 7d and 7e. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .36

8.1.2 Function description. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .37

8.2 Drive orientation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .38

8.3 Cooling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .38

8.3 .1 Air fl o w . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .38

8.4 Drive mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .38

8.5 Grounding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .38

9.0 Interface requirem en ts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .41

9.1 General description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .41

9.2 SCSI interface messag es supported. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .41

9.3 SCSI interface command s supported . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .42

9.3.1 Inquiry data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .44

9.3.2 Mode Sense data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .45

9.4 SCSI bus conditions and miscellaneous features support ed . . . . . . . . . . . . . . . . . . . . . . . . .48

9.5 Synchronous data transfer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .49

9.5.1 Synchronous data transfer periods supported. . . . . . . . . . . . . . . . . . . . . . . . . . . . .49

9.5.2 REQ/ACK offset. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .49

9.6 Physica l interf ac e . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .49

9.6.1 DC cable and connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .49

9.6.2 SCSI Interface physical description. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .52

9.6.3 SCSI Interface Cable requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .52

9.6.4 Mating connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .53

9.7 Terminator re quirem ents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .63

9.8 Terminator power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .63

9.9 Disc drive SCSI timing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .64

10.0 Technical supp or t service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .67

Hawk 2XL Product M anu al, Rev. B ix

List of Figures

Figure 1. Hawk 2XL family drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Figure 2. Hawk 2XL family drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Figure 3. Typical Hawk 2XL family drive +5 V and +12 V current profile . . . . . . . . . . . . . . . . . . . . . . . 20

Figure 4. Locations of components (listed in Table 3). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Figure 5. Recommended mounti ng (Appl icable to all Hawk 2XL family models) . . . . . . . . . . . . . . . . . 24

Figure 6a. Mounting confi gurati on dim ensions for m odel “ N” . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Figure 6b. Mounting confi gurati on dim ensions for m odel “W ”. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Figure 6c. Mo unti ng co nfi gurati on dim ensions for model “WC” . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Figure 7a. Hawk 2XL family drive ID select header for model “N”. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Figure 7b. Hawk 2XL family drive ID select for models “W” and “WC” . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Figure 7c. Hawk 2XL family drive ID select header J1-auxiliary for model “W” (J1-Aux. Pins 1A-12A) . 34

Figure 7d. Hawk 2XL family drive option select header for models “N” and “W”. . . . . . . . . . . . . . . . . . . 35

Figure 7e. Hawk 2XL family drive option select header for model “WC”. . . . . . . . . . . . . . . . . . . . . . . . . 35

Figure 8. Air flow (suggested) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Figure 9a. Physical interface for “N” model drives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Figure 9b. Model “W” drive physical interface (68 pin J1 SCSI I/O connector) . . . . . . . . . . . . . . . . . . . . 51

Figure 9c. Mo del “WC” drive physical interface (80 pin J1 SCS I I/O connector / DC power connector) 51

Figure 10. SCSI Daisy-chain interface cabling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Figure 11a. Nonshielded 50 pin S CSI device connector. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Figure 11b. Nonshielded 68 pin S CSI device connector. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Figure 11c. Nonshielded 80 pin SCSI connector, used on “WC” model . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Figure 12. Single-ended transmitters and receivers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Hawk 2XL Product M anu al, Rev. B 1

1.0 Scope

This manual describes the Seagate Technology, Inc. Hawk 2XL fam ily of disc drives. This high capacity, hig h

performance member of the Seagate 1-inch high 3.5-inch rigid disk family is a next generation product from the

Hawk 2LP (ST34230) disc drive. The Hawk 2XL features a new cost-optimized HDA, reduced cost SCSI code,

reduced header fields and t he use of innovat ive technology i n the embedde d servo, R/W heads, read circuits

and SCSI controller. Sectio n 5 lists performance informati on for this drive. The Hawk 2XL drive operates an

interface to the ho st defined by a subset of AN SI SCSI 2/SCSI 3 as described in Section 9 of this manual

(Vol.1) and the Seagate SCSI Interface manual 77738479 (V ol. 2).

The Hawk 2XL family consists of ST32151, ST31 051, ST32155 and ST31055 product s. Models of fered are N,

W, and WC.

Table 1 lists the salient features that differentiate the different Hawk 2XL model num bers.

Table 1: Drive model number vs. differentiati ng feature s

Fast SCSI-3

Model number # Heads I/O Ckts

#I/O

connector

I/O data bus bits

ST32151N 8 single-ended 50 8 10

ST32151W 8 single-ended 68 16 20

ST32151WC 8 single-ended 80 16 20

ST31051N 4 single-ended 50 8 10

ST31051W 4 single-ended 68 16 20

ST31051WC 4 single-ended 80 16 20

ULTRA SCSI-3 [1]

Model number # Heads I/O Ckts

#I/O

connector

I/O data bus bits

ST32155N 8 single-ended 50 8 20

ST32155W 8 single-ended 68 16 40

ST32155WC 8 single-ended 80 16 40

ST31055N 4 single-ended 50 8 20

ST31055W 4 single-ended 68 16 40

ST31055WC 4 single-ended 80 16 40

Interface Data

transfer rate

(Mbytes/sec)

Interface Data

transfer rate

(Mbytes/sec)

From this point on in this Product Manual the reference to Hawk 2XL family models is referred to as “the drive”

(unless reference to individual models are necessary).

The drive printed circuit board is referred to as a PCB.

[1] ULTRA SCSI is Seaga te’ s name for th e ANS I propo se d “FAS T -20” i nterf ace.

2 Hawk 2XL Product Man ual , Rev. B

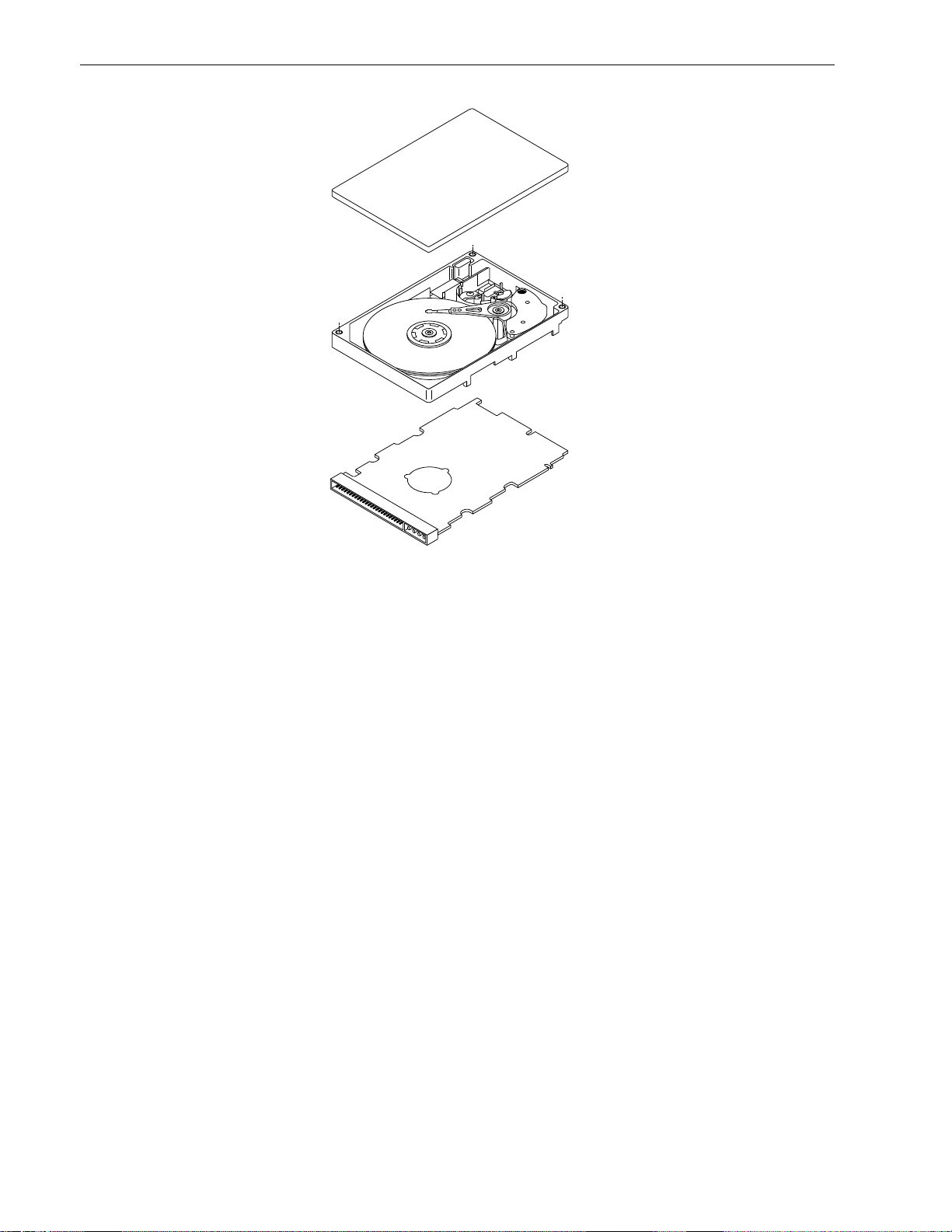

.

*

*Model “N” version with 50 pin SCSI I/O connector

Figure 1. Hawk 2XL family dri ve

Hawk 2XL Product M anu al, Rev. B 3

2.0 Applicable standards and reference documentation

The drive has been developed as a system peripheral to the highest standards of design and construction. The

drive depends upon its host equipm ent to provide adequate power and environm ent in order to achieve optimum performance a nd compliance with applicable indust ry and governmental regulations. Specia l attention

must be given in the areas of safety, power distribution, shield ing, audible noise control, and t emp erature regulation. In particular, the drive must be securely mounted in order to guarantee the specified performance characteristics. Mounting by bott om holes must meet the requirement s of Section 8.4.

2.1 Standards

The Hawk 2XL Family comp lies with Seagate standards as note d in the appropriate sections of this Manual

and the Seagate SCSI Interface Manual, P/N 77738479 (Vol. 2).

The Hawk 2XL Family is a UL R eco gnized com pone nt per UL 1950 and a CSA Certified com ponen t per CAN/

CSA-C22.2 No. 950-M89. It also meets the requirements of DIN VDE 0805/05 .90 and EN60950: 1988 (IEC

950).

2.1.1 Electromagnetic compatibility

The drive, as delivered, is designed for s ystem integrati on and installation into a suitable enclosure prior to

use. As such the drive is supplied as a subas sembly and is not subject to Subpart J of Part 15 of the FCC

Rules and Regulations nor the Radio Interference Regulations of the Canadian Departmen t of Communications. However, the un it has been test ed using proper shiel ding and groun ding a nd found t o be compl iant wit h

Class A limits of the FCC Rules and the Regulations of the Canadian Departme nt of Comm unicat ions.

The physical design characteristi cs of the drive serve to minim ize radia tion when installed in an enclosure that

provides reasonable shielding. As such, the drive is capable of meeting the Class B limits of the FCC Rules

and Regulations o f the Canadian Department of Communi cation. However, it is the user’s responsibility to

assure that the drive m eets the appropriate EMI requirements in their system. S hielded I/O cables may b e

required if the enclosure does not provide adequate shielding. If the I/O cables are external to the enclosure,

shielded cables should be used, with the shields grounded to the enclosure or to the host controller, but not

both.

2.1.2 Electromagnetic susceptibility

As a component assembly, the drive is not required to meet any susceptibility performance requirements. It is

the responsibility of those inte grati ng the drive wi thin their system s t o perform t hose test s required a nd desig n

their system to ensure that equipmen t operating in the same system as the drive or external to the system

does not adversely affect the performance of the drive. See Section 5.1.1 and Table 2, DC power requirements.

2.2 Electromag netic Com plia nce for the E uro pe an Uni on

If this model has the CE Marking it complies with the European Union requirements of the Electrom agnetic

Compatibility Di re ctive 89/3 36/ EEC o f 03 M ay 1989 as am ende d by Dire ctive 92/3 1/EEC of 28 A pril 1 992 an d

Directive 93/68/E E C of 22 Jul y 199 3.

Seagate uses an indepen dent laboratory t o confirm compli ance to the above d irectives. The drive was t ested

in a representative system for typical appl ications. The select ed system represents the most pop ular characteristics for test platforms The system configurat ions includ e:

• 486, Pentium, and PowerPC Microprocessors

• 3.5-inch Floppy Disc Drive

• Keyboard

• Monitor/Display

Although the test system with this Seagat e model com plies to the direct ives, we cannot guarant ee that al l sys-

tems will compl y. The computer manuf acturer or system integrator shall conform EMC compliance and provide

CE Marking for their product.

4 Hawk 2XL Product Man ual , Rev. B

2.3 Reference documents

Installation Guide Seagate P/N 77767490

SCSI Interface Manual Seagate P/N 77738479

ANSI Small Co mputer System Interface (SCSI): Document Numbe r ANSI3.131-1986 (X3T9/84.40 Rev. 1B)

(X3T9.2/82-2 Rev. 17B), X3T9.2/86-109 Revision 10H (SCSI-2) and X3T9.2-184 Rev. 4 (SCSI-3).

ANSI - draft proposed: Document Number X3T10/ 1071 D, SCSI-3 FA ST-20 revision 6.

Package Test Specification Seagate P/N 30190-001 (under 100 lb.)

Package Test Specif icati on Seagate P/N 30191-001 (over 100 lb.)

In case of conflict between this document and any referenced documen t, this document takes precedence.

Hawk 2XL Product M anu al, Rev. B 5

3.0 General description

The drives are a member of a family of low cost, high performance, highly reliable , random access storage

devices designed to meet the needs of the OEM marketplace.

The drive records and recovers data on 3.5 inch (89 mm) fixed discs.

The drive supports the Sma ll Computer S ystem Interface a s described in the ANSI SCSI-2 and SCS I-3 Int er-

face Manuals to the e xtent described in this product Man ual (Vol. 1), which def ines the product perform ance

characteristics of the Hawk 2XL Family of drives, and the SCSI Interface Product Manual P/N 77738479

(Vol.2, Version 2) which describes the general interface characteristics of this and other fa milies of Seagate

3.5-inch drives.

The drive interface supports multiple initiators, disconnect/reconn ect, self-configuring host software and auto-

matic features th at relieve the host from the necessity of knowing the physical characteristics of the targets

(logical block addressing is used).

TheHead/Disc Assembly (HDA ) is environm entally seal ed at the factory. Air recirculates wit hin the Head/ Disc

(HDA) through a nonreplaceable filter to maintain a contam inat ion free head/d isc environmen t.

Refer to Figure 2, an exploded view of the drive. NEVER disassemble the Head/Disc Assembly (HDA). This

exploded view is for inf ormation on ly. Do not att empt to service items in t he sealed environm ental encl osure

(heads, media, actuat or, e tc. ) as t his requires special faci lities. The drive contains no pa rts repl aceable by th e

user. The drive warranty is voided if the HDA is opened.

The Hawk 2XL Fam ily drives use a dedicated landing zon e at the innermost radius of the m edia to eliminate

the possibility of destroying or d e grading data by landing in the d ata zone. The drive automatical ly goes t o the

landing zone when the power is removed.

The Hawk 2XL Fam ily drives incorporate an au tomatic shipping lock which p revents potent ial damage to the

heads and dis cs that result from movement during shipping an d handling. The sh ipping lock is autom atically

disengaged when power is applied to the drive and the head load process begins.

The Hawk 2XL Fam ily drives decode track lo cation from the servo data embedded on each surface to el iminate mechanical transducer adjustm ent s and related reliabilit y concern s.

The Hawk 2XL Fam ily drives use a high performance actuat or assembly that consists of a low inertia, b alanced, patented, straigh t arm design that provides excellent performance w ith minim um power dissipation.

6 Hawk 2XL Product Man ual , Rev. B

Figure 2. Hawk 2XL family dri ve

Hawk 2XL Product M anu al, Rev. B 7

3.1 Standard features

The Hawk 2XL Family has the following standard f eatu res:

• Integrated SCSI Contro ller wit h reduce d comple xity SCS I code

• Single-ended SCSI drivers and receivers

• Asynchronous and Synchronous data transfer protocol

• Firmware downloadable via SCSI interfa ce

• Flawed sector reallocation at format time

• Programmable auto write and read reallocation

• Reallocation of defects on comm and (P ost Format )

• 96 bit Reed-Solomon error correcting code

• Sealed Head/Disc Assembly

• No preventative maintenance or adjust men t required

• Dedicated head landing zone

• Embedded servo data rather than a separate servo data surfa ce

• Self diagnostics performe d at power on

• 1:1 Interleave

• Zoned Bit Recording (ZBR)

• Vertical, horizontal, or top down mounting

• Dynamic spindle brake

• Permanentl y mount ed term inators on “N” and “W” mode ls, enabl ed by install ati on of a jumper plug.

• 256 K byte data buffer (512K byte data buf fer for “W” and “W C” models and all Ultra SCSI mod els)

• Hot Plug compatibility (Sect ion 9.6.4.3 lists proper host connector needed)

• SCAM plug-n-play complia nt [1]

• ULTRA SCSI (Models ST3 2155 and S T310 55 )

3.2 Media characteristics

The media used on the drive has a diameter of approximately 3.5 inches (89 mm). The aluminum substrate is

coated with a thin film magnet ic m ateri al, overcoate d with a propriet ary prot ective layer for im proved durab ility

and environmental protectio n.

3.3 Performa nce

• Programmable multi-segmentable cache buffer

• 5411 RPM Spindle. Average lat ency = 5.54 msec

• Command Queuing of up to 64 commands

• Background processing of queue

• Supports start and stop commands (spindle stops sp innin g)

• Low audible noise for office environment

• Low power consumption

3.4 Reliability

• 800,000 hour MTBF

• Adaptive servo calibration for improved seek performance

• LSI circuitry

• Balanced low mass rotary voice coil actuator

• 5 year warranty for ST32151 and ST32155; 3 year warranty for ST31051 and ST31055

[1] Supports SCAM L evel 1 at the moment. Will support Level 2 when all prese ntly unresolved requirements

are fully defined. As a factory instal led option SC AM can be turned off.

8 Hawk 2XL Product Man ual , Rev. B

3.5 Unformatted and formatted cap aci ties

Formatted ca pacity depends on the number of spare real location sectors reserved and the number o f bytes

per sector. The following table shows some typical 512 byte sector size [1] formatted capacit ies (rounded off).

ST32151 GB

ST32155 GB

ST31051 GB

ST31055 GB

Spare Sector or Cylinders

Reserved for reallocation

No Spares 2.18 1.07

Five Spare Sectors per Cylinder [2] - 1.0 6

Ten Spare Sectors per Cylinder [2] 2.15 -

The standard OEM model is as follows:

Formatted

Data Block Size

512 Byte/Sector

Unformatted

ST32151/ST32155 2.148 GB[4] 2.54 GB

ST31051/ST31055 1.060 GB[5] 1.26 GB

Notes.

[1] Sector size selectable when formatted at factory.

[2] All spare sectors are on one track.

[3] Spare cylinders are on the two inner tracks.

[4] Sparing equivalent t o eight spare sect or per c ylinder (all spare sectors are on one track), two spa re cylin-

ders/unit.[3]

[5] Sparing equivalent to five sp are sectors per cylinde r (all spa re sectors a re on o ne track), two spare cyl in-

ders/unit.[3]

3.6 Factory installed accesso rie s

OEM Standard drives are shipped with Installation Guide P/ N 77767490 (unles s otherwise specified). The factory also ships with the drive a s ma ll bag of the two j um per plug types used for the o ption select jum per he aders.

3.7 Options (factory in stal led )

All customer requested options are incorporated during production o r packaged at the manufacturing f acility

before shipping. Some of the options availabl e are (not an exhausti ve list of possible options):

• The capacities shown in Section 3.5 . Other capacities can be ordered depending on sparing scheme and

sector size requested.

• Black plastic front panel. Other panel colors may be specially ordered. Panel has a green, rectangular LED

drive activity indicator lens. The indicator glows whe n the drive is selected.

• Single unit ship ping pack. The dri ve is normally shipped in bulk packag ing to provide maxim um protectio n

against transit damage. Units shipped individually require additional protection as provided by the single unit

shipping pack. Users planning single unit distribut ion should specif y this option.

• The Installa tion Gui de (P /N 77767490 ) is usuall y included with each st andard O EM dri ve shipped , but extra

copies may be ordered.

3.8 Accessories (user installe d)

The following accessories are available. All accessories may be installed in the field.

• Front Panel Kit (with green rectangular LED lens).

• Single unit shipping pack.

• Adapter Accessory Frame Kit P/N 75790701. This kit ad apts a 3.5 inch Model “N” and “W” drives to fit in a

5.25 inch drive mounting space. The frame does not work for “WC” model drives which plug directly into a

bulkhead or backplane connector.

Hawk 2XL Product M anu al, Rev. B 9

4.0 Performance characteristics

4.1 Internal drive characteristic s (transp arent to use r)

ST32151/ST32155 ST31051/ST31055

Drive Capacity 2.54 1.2 6 GByt e (UNF) (Rounded off values)

Read/Write Heads 8

Bytes/Track 75,900 75,900 Bytes (Avg) (Rounded off values)

Bytes/Surface 318 315 Mbytes (UNF) (Rounded off values)

Tracks/Surface, Total 4176 4176 Tracks (user accessible)

Tracks/Inch 4800 4800 TPI

Servo Heads 0 0 (embedded servo)

Internal Data Rate 44 - 66 44 - 66 Mbits/sec (variable with zone )

Disc Rotational Speed 5411 ± 0.5% 5411 ± 0.5 % r/min

Average Rotational Lat ency 5.54 5.54 ms

4.2 SCSI Seek performance character isti cs (visi ble to user ) [6]*

The values given in Section 4.2.1 apply to all models of the Hawk 2XL family unless otherwise specified. Refer

to Section 9.9 and to the SCSI-2 Interface Product Manual 77738 479 for addit ion al timing detail s.

4.2.1 Access time

Including Controller Overhead

(without disconnect) [1] [4]

Drive Level

Read Write

ms

Average - Typical [3] 10.4 11.4

Max. [ 2] 11.9 13.4

Single Track - Typical [3] 2.7 2.9

Max. [2] 3.8 4.3

Full Stroke - T ypical [3] 20.4 21.4

Max. [ 2] 23.9 24.9

*[] All notes for Sections 4.2 are listed at end of Section 4 .2.3.

10 Hawk 2XL Produ ct Ma n ual , Rev. B

4.2.2 Format comman d executio n time (m inutes) [1 ]

ST32151/ST32155 ST31051/ST31055

Maximum (with verify) 30 20

Maximum (no verify) 20 10

4.2.3 Generalized performance characteristics

Minimum Sector Int erleave (all Hawk 2XL model s) 1 to 1

Data Transfer Rate (1 sector) - 512 Byte Sector, Data Buffer To/From Disc Media:

ST32151/ST32155 ST31051/ST31055

Min. [4]* 5. 1 MByte/se c 5.1 MByte/se c

Avg. [4] 7.1 MByte/ se c 7.1 MByte/sec

Max. [4] 8.2 MB yte/ se c 8.2 M Byte/ s e c

Data Transfer Rate (< 1 Track) - 512 Byte Sector, Data Buffer To/From Dis c Media:

ST32151/ST32155 ST31051/ST31055

Min. [ 4] 3.8 MByte/secs 3.8 MByte/sec divided by (Interleave Factor)

Avg. [4] 5.6 MByte/secs 5.6 MByte/sec divided by (Interleave Factor)

Max. [4] 6.4 MByte/secs 6.4 MByte/sec divided by (Interleave Factor)

SCSI Interface Data Transfer Rate (Asynchronous ) [5] (all Hawk 2XL models):

Maximum Instantaneo us 6.0 [6] MBytes/sec

Maximum Average 6.0 MBytes/sec

The remainder of the specifications of Section 4.2.3 apply to all Hawk 2X L models:

Sector Sizes Variable (180 to 4096 bytes per sector, but factory configurable only

) in even

number of bytes per sector.

Synchronous Transfer Rate for ULTRA SCSI-2 models from 1.25 MBytes/sec to 20.0 MBytes/sec for 8 bit data

bus and 40.0 MBytes/sec for 16 bit data bus. (see Section 9.5)

Synchronous Transfer Rate for Fast SCSI-2 models from 1.25 MByte s/sec to 10.0 MBytes/sec for 8 bit data

bus and 20.0 MBytes/ sec fo r 16 bi6t dat a bu s. (see Secti on 9.5)

Read/Write consecutive sectors on a track Yes

Flaw reallocation perf orm ance impa ct (For flaws reallocated at format time using

Negligible

the spare sectors per cylinder reallocatio n scheme.) [7]

Flaw reallocation perf orm ance impa ct (For flaws reallocated at format time using

22.16 msec (typical)

the spare tracks per volume reallocation schem e.)[7]

Overhead time for head switch (512 byte sectors) 1 msec

Overhead time for one track cylinder switch <3 msec Typical

Average rotational latency 5.54 msec

Hawk 2XL Product M anu al, Rev. B 11

Notes for Sections 4.2.

[1] Execution time measured from receipt of the last Byte of the Command Descriptor B lock (CDB) to the

request for a Status Byte Transfer to the Initiator (excluding connect/ disconne ct).

[2] Maximum times are specified o ver the worst case conditions of temperature, voltage margins and drive

orientation. W hen compari ng speci fied access t imes, care shoul d b e taken to disti nguish bet ween typica l

access times and maximum access times. The best com parison i s obt ained by s ystem be nchmark te sts

conducted under identical condition s. Maximum times do not include error recovery.

[3] Typical Access times are measured under nom inal condit ions o f temperat ure, vol tage, a nd horizontal ori-

entation as measured on a representat ive samp le of drives.

[4] Assumes no errors and no sector has been relocated.

[5] Rate measured from the start of the first sector transfe r to or from the Host.

[6] Assumes system ability to support the rate given and no cable loss.

[7] Simulated.

4.3 Start/stop time

After DC power has been applied, the drive b e comes ready wi thin 20 seconds if the M otor Start Option is disabled (i.e. the motor starts as soon as the power has been applied). During this time the drive responds to

some commands over the SCSI interface in less than 3 seconds. St op time is 20 seconds from rem oval of D C

power.

If the Motor Start Option is enabled , the internal con troller a ccepts the comm ands listed in the SCSI Interf ace

Product Manual* less than 3 seconds after DC power has been applied. After the Motor Start Command h as

been received the drive becomes ready for normal operations within 13 seconds typically. The Motor Start

Command can also be used to command the drive to stop the spindle*.

There is no power control switch on the drive.

4.4 Prefetch/multi-se gmen ted cach e contro l

The drive provides prefetch (read look-ahead) and multi-segmented cache control algorithms that in many

cases can enhance system performance. “Cache” as used herein refers to the drive buffer storage space when

it is used in “cache” operations. To select prefetch and cache features the ho st sends the Mode Select command with the proper values in the applicable bytes in Mode Page 08h. Prefetch and cache operation are independent features from the standpoi nt that each is enabled and disabled independe ntly via the Mode Select

command. However, in actual operation the prefetch feature overlaps cache operation somewhat as is noted in

Sections 4.5.1 and 4.5.2.

All default cache and prefetch Mode parameter values (Mode Page 08h) for standard OE M versions of this

drive family are given in Tables 8a and 8b.

4.5 Cache operation

In general, on “N” models 202,448 bytes of the 256 Kbyte physical buffer space, and on “W” and “WC” models,

431,136 Kbytes of the 512 Kbytes of physical buffer space in the drive can be used as storage space for cache

operations. The buf fer can be divided into logical s eg men ts (Mode S el ect Pag e 08h, byte 13) from whi ch dat a

is read and to which dat a i s writt en. T he drive ma intains a tabl e of lo gical b lock disk mediu m addresses of th e

data stored in each segment of the buffer. If cache operation is enabled (RCD bit = 0 in Mode Page 08h, byte

2, bit 0. See SCSI Interface Product Manual P/N 77738479), data requested by the host with a Read command

is retrieved from the buffer (if it is there), before any disc access is initiated. If cache operation is not ena bled,

the buffe r (still segmented with required number of segments) is still used, but only as circular buffer segments

during disc medium read operatio ns (disregarding Prefetch opera tion for the moment ). That is, the drive does

not check in the buffer segments for the requested read data, but goes directly to the medium to retrieve it. The

retrieved data m erely passes through some buff er segment on the way to the ho st. On a cache “miss”, all

datatransfers to the h ost are in accordance with “buf fer-full” ratio rules. On a cache “hit” t he drive ign ores the

“buffer-full” ratio rule s. See expl anat ions associated wi th Mode page 0 2h (disconne ct/reco nnect co n trol) in th e

SCSI Interface Product Manual P/N 77738479.

12 Hawk 2XL Produ ct Ma n ual , Rev. B

The following is a simplified description of a read operation with cache operation enabl ed:

Case A - A Read command is received and the fi r st logical blo c k (LB) is already in cache:

1. Drive transfers to the initiator the first LB requested plus all subsequent contiguous LB’s that are already in

the cache. This data may be in multipl e segmen ts.

2. When the requested LB is reached that is not in any cache segment, the drive fetches it and any rem aining

requested LB’s from t he disc and puts them i n a segment of the cache. The drive t ransfers the rem aining

requested LB’s from the cache to the host in accordance with the disconnect/reconnect specif icat ion m entioned above.

3. If the prefetch feature is enabled, refer to Section 4.5.2 for operat ion from this poin t.

Case B - A Read command requests data, the first LB of which is not in any segment of the cache:

1. The drive fetches the requested LB’s from the disc and transfers them into a segment, and from there to

the host in accordance with the disconnect/reconnect specificat ion referred to in case A.

2. If the prefetch feature is enabled, refer to Section 4.5.2 for operat ion from this poin t.

Each buffer segme nt is actually a self -contained circula r storage (wrap-around occurs), the length of which is

an integer number of disc medium sectors. The wrap-around capability of the individual segments greatly

enhances the buffer’s overall performance as a cache storage, allowing a wide range of user selectable configurations, which includes their use in the prefetch operation (if enabled), even when cache operation is disabled

(see Section 4.5.2). Th e number of segment s may be selected using the Mo de Select com mand, but the size

can not be directly selected. Size is selected only as a by-product of selecting the segment number specif ication. The size in Kbytes of each segment is reported by the Mode Sense command page 08h, bytes 14 and 15.

If a size specification is sent by the host in a Mode Select command (bytes 14 and 15) no new segment size is

set up by the drive, and if the “STRICT” bit in Mode page 00h (byte 2, bit 1) is set to one, the drive responds as

it does for any attempt to change unchangeable parameters (see SCSI I/O Product Manual P /N 77738479).

The drive supports operation of any integer number of segments from 1 to 16.6

4.5.1 Caching write data

Write caching is a write operation by th e drive that m akes use of a drive buffer storage area w here th e data to

be written to the medium is stored in one or more segments while th e drive performs the write com man d.

Write caching is enabled along wit h read caching. For write caching, the same buf fer spa ce and segm enta tion

is used as set up for read functions. The buffer segmentation scheme is set up or changed independently, having nothing to do with whether or not read and write caching is enable d or disabled. When a write comma nd is

issued, the cache is first checked to see if any logical blocks that are to be written are already stored in the

cache from a previous read or write comma nd. If there are, the respect ive cache segments are cleared. Th e

new data is cached for subsequent Read commands.

If the number of write data logical blocks exceeds the size of the segment being writ ten into when the end of

the segment is reached, the data is written into the beginning of the same cache segment, overwriting the data

that was written there at t he beginning of the operation. However, the drive does not overwrite data that has

not yet been written to the medium.

Tables 8a and 8b show Mode default settings for the drives.

4.5.2 Prefetch operation

If the Prefetch feat ure is enabled, dat a in co ntiguous log ical bl oc ks on the disc imme diat ely beyon d that wh ich

was requested by a Read comm and can be retrieve d and stored in the buffer for imm ediate transfe r from the

buffer to the host on subsequent Read commands that request those logical blocks (this is true even if “cache”

operation is disabled). Though the prefetch operat ion uses the buffer as a “cache”, finding the requested data

in the buffer is a prefetch “hit”, not a “cache” operation “hit”. Prefetch is enabled using Mode Select page 08h,

byte 12, bit 5 (Disabl e Read Ahead - D RA bit). DRA bit = 0 enables prefetch. Si nce data that is pref etched

replaces data already in some buf fer segment(s), the host can lim it the amount of prefetch d ata to optimize

system performance. The max prefetch field (b ytes 8 and 9) limits the amo unt of prefetch. The drive does not

use the prefetch “ceiling” field (bytes 10 and 11).

During a prefetch operation, the drive crosses a cylinder boundary to fetch more data only if t he Discontinuity

(DISC) bit is set to one in bit 4 of byte 2 of Mode paramet er s page 08h.

Hawk 2XL Product M anu al, Rev. B 13

Whenever prefetch (read look-ahead) is enab led (ena bled by DRA = 0), it operates u nder th e control of ARLA

( Adaptive Read Look-Ahead). If the host uses software interleave, ARLA enables prefetch of contiguous blocks

from the disk when it senses that a prefetch “hit” will likely occur, even if two consecutive read operations were

not for physically contiguous blocks of data (e.g. “software interleave”). ARLA disables prefetch when it

decides that a prefetch “hit ” will not likely o ccur. If the ho st is no t using sof tware interleave, and i f two sequential read operations are not for cont iguous blocks of data, ARLA disables prefetch, bu t as long as sequential

read operations request contiguous blocks of data, ARLA ke eps prefetch enabled.

Hawk 2XL Product M anu al, Rev. B 15

5.0 Reliability specifications

The following reliabilit y specifications assume correct host/drive operational interface, including all interface

timings, power supply voltages, environm ental requi remen ts and drive mountin g constraint s (see Section 8.4)

Seek Errors

Less than 1 in 10

Read Error Rates [1]

Unrecovered Data Less than 1 sector in 10

Miscorrected Data Less than 1 sector in 10

MTBF 800,000

Service Life 5 years

Preventive Maintenance None required

Note.

[1] Error rate specified with automat ic retries and data correct ion with ECC enabl ed and all flaws reallocated.

5.1 Error rates

The error rates stated in this specification assume the following :

a. The drive is operated per this specifica tion using DC Power as defined in this Manual (see Sect ion 6. 2).

b. The drive has been formatted with the SCSI FORMA T commands.

c. Errors cau sed by media defects or h ost system malfunctions are e xcluded from error rate compu tations.

Refer to Section 3.2, “Media Characteristics. ”

7

seeks

14

bits transferred

21

bits transferred

5.1.1 Environmental in te rferen c e

When evaluating s ystems operation under conditions of Electromag netic In terference (EM I), the perform ance

of the drive within the system shall be considere d acceptable if the drive does not generat e an unrecoverable

condition.

An unrecovera ble error, or unr ecove rable condit ion, is defin ed as one that:

1. Is not detected and corrected by the drive itsel f;

2. Is not capable of being detected from the error or fault status provided through the drive or SCSI interface;

or

3. Is no t capable of being recovered by normal drive or system recovery proced ures without operator intervention.

5.1.2 Read errors

Before determinat ion or measurem ent of read error rates:

a. The data that is to be used for measurement of read error rates must be verified as being writ ten correctly

on the media.

b. All media defect induced errors must be excluded from error rate calculations.

5.1.3 Write errors

Write errors can occur as a result of media defects, environmental interference, or equipment malfunction.

Therefore, write errors are not predictable as a function of the number of bits passed.

If an unrecoverable write error occurs because of an e q uipment m alfuncti on in the drive, the error is classified

as a malfunction affect ing MTBF. Unre coverable write errors are those which ca nnot be corrected with in two

attempts at writing the record with a read verify after each attempt (excluding media defects).

16 Hawk 2XL Produ ct Ma n ual , Rev. B

5.1.4 Seek errors

A seek error is defined as a failure of the drive t o positio n the heads to the add re ssed track. There s ha ll be no

7

more than one recovera ble seek error in 10

physical seek operations. A fter det ect ing an ini tial seek er ror, the

drive automatically rese eks to the addressed track up to 3 times. If a reseek is successful, the Extended Sense

reports a seek positioning error (1 5 h), n o seek complet e error (02 h), o r track f ollo w error (09h), and the se nse

key reports a recovered error (1h). If all three reseeks fail, a seek positioning error (15h) is reported with a

Medium error (3h) or Hardware error (4h) reported in the Sense Key. This is an unrecoverable seek error.

Unrecoverable seek errors are classifi ed as fai lures for M TBF calculat ions. Re fer t o Section 5. 1.1. 2 o f SCS I- 2

Interface Product Manual P/N 77738479 for Request Sense information.

5.2 Reliability an d servic e

5.2.1 Mean time between failure

The production disc drive shall achieve an MTBF of 800,000 hours when operate d in a benign atmosphere at

an average disc drive ambient temperat ure of 95° F (35°C) or less as m easured pe r this Product Manual , Section 6.4.1. Short-term excursions up to the specification limits of the operating environment will not affect MTBF

performance.

The following expression defines MTBF

Estimated power-on operating hours in the perio d

MTBF per measurement period =

Number of drive failures in the period

Estimated power-on operation hours means power-up hours per disc drive times the total number of disc

drives in service. Each disc drive shall have accumul ated at least nine mont hs of o p eration. Data shall be calculated on a rolling average base for a minimum period of six months.

Drive failure means any stoppage or substandard performa nce caused by drive malfunct ion.

5.2.2 Preventive mainten ance

No routine scheduled preventive mainten ance shall be required.

5.2.3 Service life

The drive shall have a useful service life of five years. Depot repair or replacement of major parts is permitted

during the lifetime (see Section 5.2.4 ).

5.2.4 Service philosophy

Special equipment is required to repair the drive HDA. In order to achieve the above service life, repairs must

be performed only at a properly equipped and st affed se rvice and repai r faci lity. Troubleshoo tin g and rep air of

PCBs in the field is not recommended, because of the extensive diagnostic equipment required for effective

servicing . Also, there are no spare parts available for this drive. Drive warranty is voided if the HDA is opened.

5.2.5 Service tools

No special tools are required for site installation or recomm ende d for site maint enance. Refer to Section 5.2. 4.

The depot repair philosophy of the drive precludes the necessity for special tools. Field repair of the drive is not

practical since there are no user purchasable parts in the drive.

5.2.6 Product warranty

Beginning on the date of shipment to customer and continuing for a period of five years, Seagate warrants that

each product (including components and subassemblies) or spare part that fails to function properly under normal use due to defect in materials on workmanship or due to nonconformance to the applicable specifications

will be repaired or replaced, at Seagate’s option and at no charge to custom er, if returned by custom er at customer’s expense to Seagate’s design ated facility in accordance with Seagate’s Warrant y Procedure. Seagate

will pay for transporting the repair or replacement item to custom er. For more detailed warranty information

refer to the Standard terms and conditions of Purchase for Seagate products.

Hawk 2XL Product M anu al, Rev. B 17

Shippi ng :

When transporting or shippi ng a drive, a Seagat e approved container must be used. Keep your origin al box.

They are easily identified by the Seagate Ap proved Package label. Shipping a drive in a non-approved container voids the drive warranty.

Seagate repair centers m ay refuse rece ipt of components i mprop erly packaged or o bviously dam aged in transit. Contact your Auth orized S eagate Di stribut or to purchase a ddit ional boxes. Se agat e recommen ds shippin g

by an air-ride carrier experienced in handling computer equipment.

Product repair and return informati on

Seagate customer service centers are the only facilities authorize d to service Seagate drives. Seagate does

not sanction any third-part repair facilities. Any unauthorized repair or tampering with the factory-seal voi ds the

warranty.

Loading...

Loading...