Enterprise Performance

10K HDD

v8 SAS Product Manual

Standard Models

ST600MM0208

ST300MM0048

100799987 - Rev. A

July 2016

Self-Encrypting

Drive Models

ST600MM0218

ST300MM0058

Document Revision History

Revision Date Pages affected and Description of changes

Rev. A 07/14/2016 Initial release.

© 2016 Seagate Technology LLC. All rights reserved.

Publication number: 100799987, Rev. A July 2016

Seagate, Seagate Technology and the Spiral logo are registered trademarks of Seagate Technology LLC in the United States and/or other countries. Power Choice, Raid Rebuild and

SeaTools are either trademarks or registered trademarks of Seagate Technology LLC or one of its affiliated companies in the United States and/or other countries. The FIPS logo is a certification mark of NIST, which does not imply product endorsement by NIST, the U.S., or Canadian governments. All other trademarks or registered trademarks are the property of their

respective owners.

No part of this publication may be reproduced in any form without written permission of Seagate Technology LLC.

Call 877-PUB-TEK1 (877-782-8351) to request permission.

When referring to drive capacity, one gigabyte, or GB, equals one billion bytes and one terabyte, or TB, equals one trillion bytes. Your computer’s operating system may use a different

standard of measurement and report a lower capacity. In addition, some of the listed capacity is used for formatting and other functions, and thus will not be available for data storage.

Actual quantities will vary based on various factors, including file size, file format, features and application software. Actual data rates may vary depending on operating environment

and other factors. The export or re-export of hardware or software containing encryption may be regulated by the U.S. Department of Commerce, Bureau of Industry and Security (for

more information, visit www.bis.doc.gov), and controlled for import and use outside of the U.S. Seagate reserves the right to change, without notice, product offerings or specifications.

Contents

Seagate® Technology Support Services . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.0 Scope . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.0 Applicable standards and reference documentation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.1 Standards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.1.1 Electromagnetic compatibility. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.1.2 Electromagnetic compliance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

2.1.3 European Union Restriction of Hazardous Substances (RoHS). . . . . . . . . . . . . . . . . . . . . . . . . 9

2.1.4 China Requirements — China RoHS 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

2.2 Reference documents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

3.0 General description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

3.1 Standard features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

3.2 Media description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

3.3 Performance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

3.4 Formatted capacities . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

3.5 Programmable drive capacity. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

3.6 Factory-installed options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

4.0 Performance characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

4.1 Internal drive characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

4.2 Performance characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

4.2.1 Format command execution time (minutes) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

4.2.2 General performance characteristics. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

4.3 Start/stop time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

4.4 Prefetch/multi-segmented cache control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

4.5 Cache operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

4.5.1 Caching write data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

4.5.2 Prefetch operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

5.0 Reliability specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

5.1 Error rates. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

5.1.1 Recoverable Errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

5.1.2 Unrecoverable Errors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

5.1.3 Seek errors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

5.1.4 Interface errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

5.2 Reliability and service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

5.2.1 Annualized Failure Rate (AFR) and Mean Time Between Failure (MTBF). . . . . . . . . . . . . . .17

5.2.2 Preventive maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

5.2.3 Hot plugging the drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

5.2.4 S.M.A.R.T. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

5.2.5 Thermal monitor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

5.2.6 Drive Self Test (DST). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

5.2.7 Product warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

Seagate Enterprise Performance 10K HDD v8 Product Manual, Rev. A 2

Contents

6.0 Physical/electrical specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

6.1 PowerChoiceTM power management. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

6.1.1 PowerChoice reporting methods . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

6.2 AC power consumption . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

6.3 DC power consumption . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

6.3.1 Conducted noise immunity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

6.3.2 Power sequencing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

6.3.3 Current profiles . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

6.4 Power dissipation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

6.5 Environmental limits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

6.5.1 Temperature. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

6.5.2 Humidity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

6.5.3 Effective altitude (sea level) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

6.5.4 Shock and vibration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30

6.5.5 Air cleanliness . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31

6.5.6 Corrosive environment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31

6.5.7 Acoustics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31

6.5.8 Electromagnetic susceptibility. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31

6.6 Mechanical specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .32

7.0 About self-encrypting drives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

7.1 Data encryption . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

7.2 Controlled access . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

7.2.1 Admin SP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

7.2.2 Locking SP. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

7.2.3 Default password . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

7.3 Random number generator (RNG) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .34

7.4 Drive locking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .34

7.5 Data bands. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .34

7.6 Cryptographic erase . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .34

7.7 Authenticated firmware download . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .35

7.8 Power requirements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .35

7.9 Supported commands. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .35

7.10 RevertSP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .35

8.0 Defect and error management . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

8.1 Drive internal defects/errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .36

8.2 Drive error recovery procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .36

8.3 SAS system errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .37

8.4 Deferred Auto-Reallocation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .37

8.5 Protection Information (PI) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .37

8.5.1 Levels of PI . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .38

8.5.2 Setting and determining the current Type Level . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .38

8.5.3 Identifying a Protection Information drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .38

8.6 Seagate RAID Rebuild ™ . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .38

Seagate Enterprise Performance 10K HDD v8 Product Manual, Rev. A 3

Contents

9.0 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

9.1 Drive orientation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .39

9.2 Cooling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .39

9.3 Drive mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .40

9.4 Grounding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .40

10.0 Interface requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

10.1 SAS features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .41

10.1.1 Task management functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .41

10.1.2 Task management responses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .41

10.2 Dual port support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .41

10.3 SCSI commands supported . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .42

10.3.1 Inquiry data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .46

10.3.2 Mode Sense data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .47

10.4 Miscellaneous operating features and conditions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .50

10.4.1 SAS physical interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .50

10.4.2 Physical characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .53

10.4.3 Connector requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .53

10.4.4 Electrical description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .53

10.4.5 Pin descriptions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .53

10.4.6 SAS transmitters and receivers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .54

10.4.7 Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .54

10.5 Signal characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .54

10.5.1 Ready LED Out . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .54

10.5.2 Differential signals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .55

10.6 SAS-3 Specification compliance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .55

10.7 Additional information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .55

Seagate Enterprise Performance 10K HDD v8 Product Manual, Rev. A 4

Figures

Figure 1. Current profiles for 600GB models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Figure 2. Current profiles for 300GB models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Figure 3. 600GB (at 12Gb) DC current and power vs. input/output operations per second. . . . . . . . . . . . . . . . . . . 28

Figure 4. 300GB (at 12Gb) DC current and power vs. input/output operations per second. . . . . . . . . . . . . . . . . . . 28

Figure 5. Recommended mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Figure 6. Mounting configuration dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Figure 7. Physical interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Figure 8. Air flow . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Figure 9. Physical interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Figure 10. SAS device plug dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Figure 11. SAS device plug dimensions (detail) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Figure 12. SAS transmitters and receivers. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Seagate Enterprise Performance 10K HDD v8 Product Manual, Rev. A 5

Seagate® Technology Support Services

For information regarding online support and services, visit: http://www.seagate.com/contacts/

For information regarding Warranty Support, visit: http://www.seagate.com/support/warranty-and-replacements/

For information regarding data recovery services, visit: http://www.seagate.com/services-software/data-recovery-services/

For Seagate OEM, Distribution partner and reseller portals, visit: http://www.seagate.com/partners/

Seagate Enterprise Performance 10K HDD v8 Product Manual, Rev. A 6

1.0 Scope

This manual describes Seagate® Enterprise Performance 10K HDD v8 (Serial Attached SCSI) disk drives.

Seagate Enterprise Performance 10K HDD drives support the SAS Protocol specifications to the extent described in this manual. The

SAS Interface Manual (part number 100293071) describes the general SAS characteristics of this and other Seagate SAS drives. The

Self-Encrypting Drive Reference Manual, part number 100515636, describes the interface, general operation, and security features

available on Self-Encrypting Drive models.

Product data communicated in this manual is specific only to the model numbers listed in this manual. The data listed in this manual

may not be predictive of future generation specifications or requirements. If integrators are designing a system which will use one of

the models listed or future generation products and need further assistance, please contact the Field Applications Engineer (FAE) or

our global support services group as shown on “Seagate® Technology Support Services” on page 6.

Unless otherwise stated, the information in this manual applies to standard and Self-Encrypting Drive models.

Note

Note

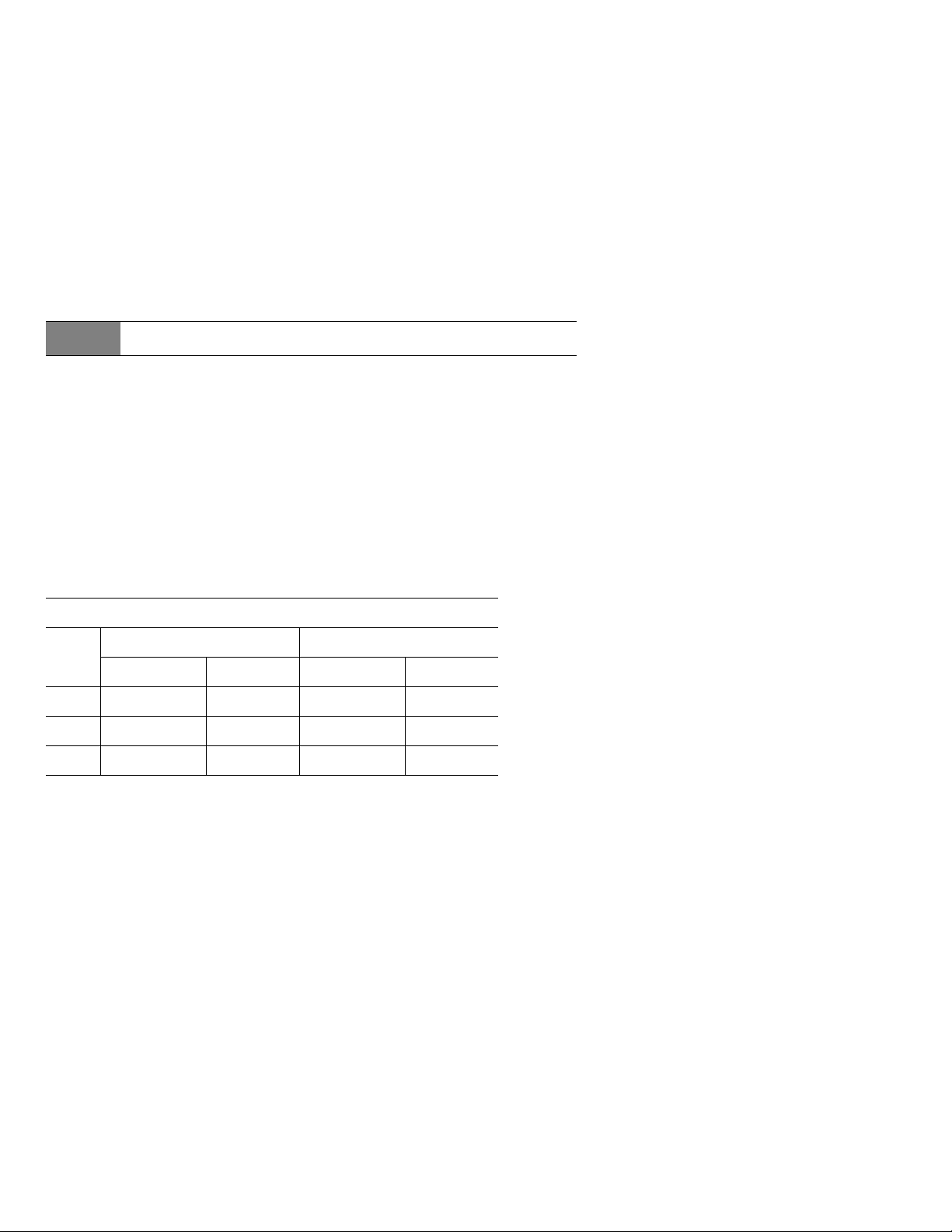

Standard Models

512 Native

Self-Encrypting Drive

(SED) Models

ST600MM0208 ST600MM0218

ST300MM0048 ST300MM0058

Previous generations of Seagate Self-Encrypting Drive models were called Full Disk Encryption (FDE) models

before a differentiation between drive-based encryption and other forms of encryption was necessary.

The Self-Encrypting Drive models indicated on the cover of this product manual have provisions for “Security of Data

at Rest” based on the standards defined by the Trusted Computing Group (see www.trustedcomputin

ggroup.org).

Seagate Enterprise Performance 10K HDD v8 Product Manual, Rev. A 7

2.0 Applicable standards and reference documentation

The drives documented in this manual have been developed as system peripherals to the highest standards of design and

construction. The drives depend on host equipment to provide adequate power and environment for optimum performance and

compliance with applicable industry and governmental regulations. Special attention must be given in the areas of safety, power

distribution, shielding, audible noise control, and temperature regulation. In particular, the drives must be securely mounted to

guarantee the specified performance characteristics. Mounting by bottom holes must meet the requirements of Section 9.3.

2.1 Standards

The Seagate Enterprise Performance 10K HDD family complies with Seagate standards as noted in the appropriate sections of this

manual and the Seagate SAS Interface Manual, part number 100293071.

The drives are recognized in accordance with UL/cUL 60950-1, EN60950-1, EN62368-1 and IEC 60950-1. Product also fulfills the

requirements of UL/IEC 62368-1.

All features and configurations of this product are certified under the Regulatory Model number STT002.

The security features of Self-Encrypting Drive models are based on the “TCG Storage Architecture Core Specification” and the “TCG

Storage Workgroup Security Subsystem Class: Enterprise_A” specification with additional vendor-unique features as noted in this

product manual.

2.1.1 Electromagnetic compatibility

The drive, as delivered, is designed for system integration and installation into a suitable enclosure prior to use. The drive is supplied

as a subassembly and is not subject to Subpart B of Part 15 of the FCC Rules and Regulations.

The design characteristics of the drive serve to minimize radiation when installed in an enclosure that provides reasonable shielding.

The drive is capable of meeting the Class B limits of the FCC Rules and Regulations when properly packaged; however, it is the user’s

responsibility to assure that the drive meets the appropriate EMI requirements in their system. Shielded I/O cables may be required if

the enclosure does not provide adequate shielding. If the I/O cables are external to the enclosure, shielded cables should be used,

with the shields grounded to the enclosure and to the host controller.

2.1.1.1 Electromagnetic susceptibility

The drive as delivered is tested to meet susceptibility requirements in a representative enclosure. It is the responsibility of those

integrating the drive within their systems to perform those tests required and design their system to ensure that equipment

operating in the same system as the drive or external to the system does not adversely affect the performance of the drive. See

Section 6.3, "DC power consumption".

2.1.2 Electromagnetic compliance

Seagate uses an independent laboratory to confirm compliance with the directives/standards for CE Marking and RCM Marking. The

drive was tested in a representative system for typical applications and comply with the Electromagnetic Interference/

Electromagnetic Susceptibility (EMI/EMS) for Class B products. The selected system represents the most popular characteristics for

test platforms.

Although the test system with this Seagate model complies with the directives/standards, we cannot guarantee that all systems will

comply. The computer manufacturer or system integrator shall confirm EMC compliance and provide the appropriate marking for

their product.

Electromagnetic compliance for the European Union

If this model has the CE Marking it complies with the European Union requirements of the Electromagnetic Compatibility Directive.

Australian RCM

If this model has the RCM Marking it complies with the Australia/New Zealand Standard AS/NZ CISPR22 and meets the

Electromagnetic Compatibility (EMC) Framework requirements of the Australian Communications and Media Authority (ACMA).

Canada ICES-003

If this model has the ICES-003 Marking it complies with the Canadian Standard Association Standard CAN/CSA-CISPR 22- 10, Information Technology Equipment - Radio Disturbance Characteristics - Limits and Methods of Measurement.

Seagate Enterprise Performance 10K HDD v8 Product Manual, Rev. A 8

Korean KCC

20

If these drives have the Korean Communications Commission (KCC) logo, they comply with KN22, KN 24, and KN61000.

Taiwanese BSMI

If this model has the Taiwanese certification mark then it complies with Chinese National Standard, CNS13438.

2.1.3 European Union Restriction of Hazardous Substances (RoHS)

The European Union Restriction of Hazardous Substances (RoHS) Directive restricts the presence of chemical substances, including

Lead (Pb), in electronic products effective July 2006.

A number of parts and materials in Seagate products are procured from external suppliers. We rely on the representations of our

suppliers regarding the presence of RoHS substances in these parts and materials. Our supplier contracts require compliance with

our chemical substance restrictions, and our suppliers document their compliance with our requirements by providing material

content declarations for all parts and materials for the disk drives documented in this publication. Current supplier declarations

include disclosure of the inclusion of any RoHS-regulated substance in such parts or materials.

Seagate also has internal systems in place to ensure ongoing compliance with the RoHS Directive and all laws and regulations which

restrict chemical content in electronic products. These systems include standard operating procedures that ensure that restricted

substances are not utilized in our manufacturing operations, laboratory analytical validation testing, and an internal auditing process

to ensure that all standard operating procedures are complied with.

2.1.4 China Requirements — China RoHS 2

China RoHS 2 refers to the Ministry of Industry and Information Technology Order No. 32, effective July 1, 2016, titled Management

Methods for the Restriction of the Use of Hazardous Substances in Electrical and Electronic Products. To comply with China RoHS 2,

we determined this product's Environmental Protection Use Period (EPUP) to be 20 years in accordance with the Marking for the

Restricted Use of Hazardous Substances in Electronic and Electrical Products, SJT 11364-2014.

中国电器电子产品有害物质限制使用管理办法

(Management Methods for the Restriction of the Use of Hazardous Substances in Electrical and Electronic

Products _ China RoHS)

产品中有害物质的名称及含量

(Name and Content of the Hazardous Substances in Product)

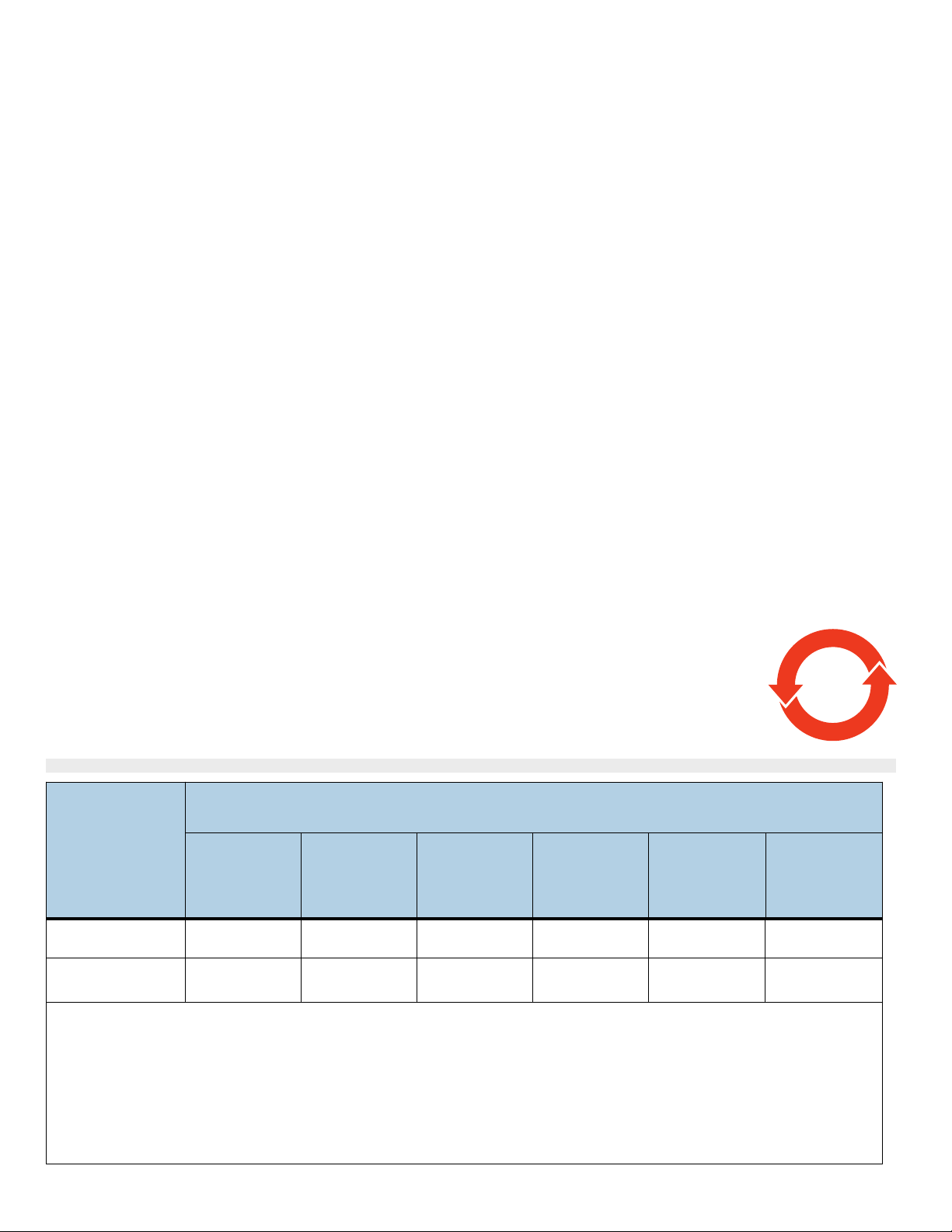

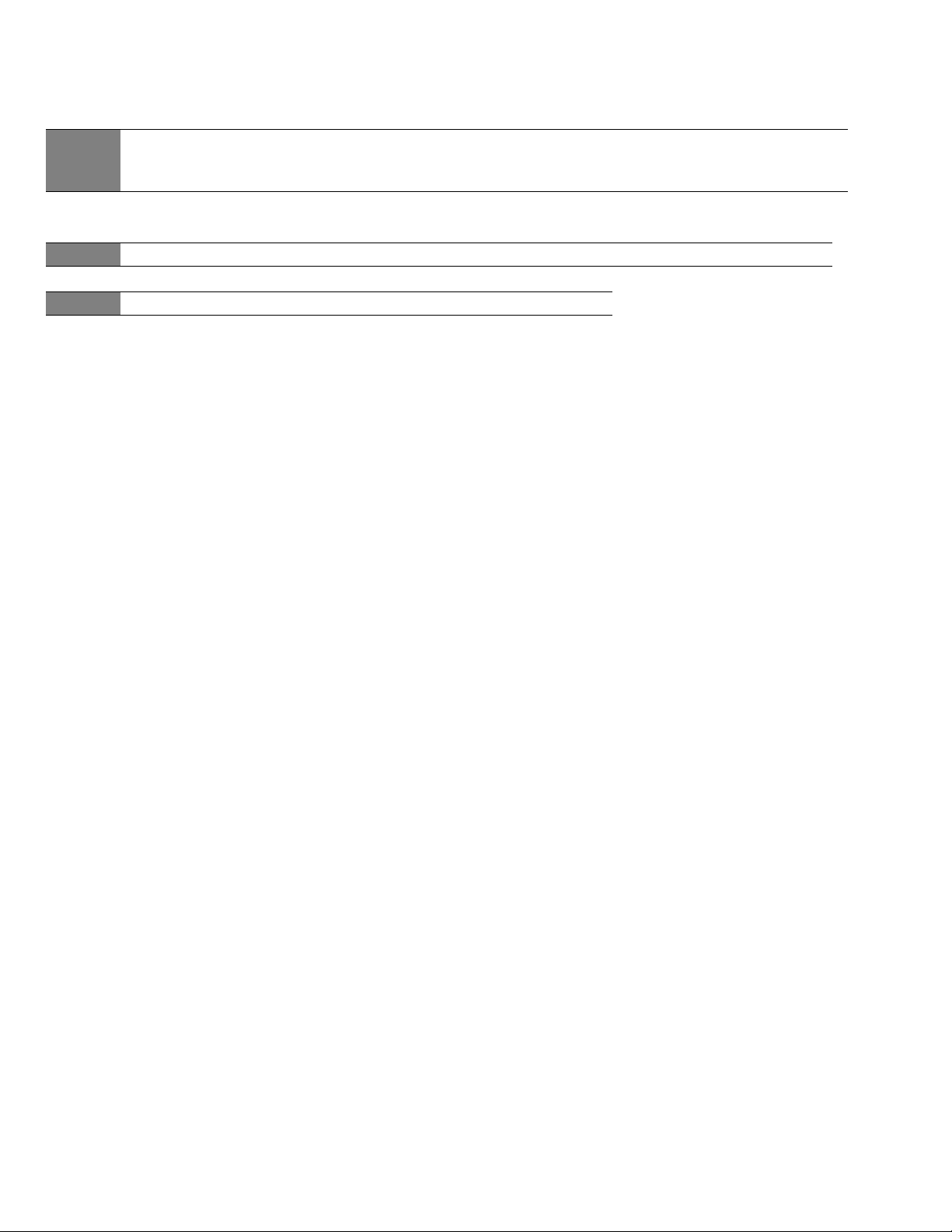

Table 1 Hazardous Substances

有害物质

Hazardous Substances

部件名称

Part Name

印刷电路板组装

PCBA

机壳

Chassis

本表格依据 SJ/T 11364 的规定编制。

This table is prepared in accordance with the provisions of SJ/T 11364-2014

O:表示该有害物质在该部件所有均质材料中的含量均在 GB/T 26572 规定的限量要求以下。

O: Indicates that the hazardous substance contained in all of the homogeneous materials for this part is below the limit requirement of

GB/T26572.

X:表示该有害物质至少在该部件的某一均质材料中的含量超出 GB/T 26572 规定的限量要求。

X: Indicates that the hazardous substance contained in at least one of the homogeneous materials used for this part is above the limit

requirement of GB/T26572.

铅

Lead

(Pb)

XOOOOO

XOOOOO

汞

Mercury

(Hg)

镉

Cadmium

(Cd)

六价铬

Hexavalent

Chromium

(CF (VI))

多溴联苯

Polybrominated

biphenyls (PBB)

多溴二苯醚

Polybrominated

diphenyl ethers

(PBDE)

Seagate Enterprise Performance 10K HDD v8 Product Manual, Rev. A 9

2.2 Reference documents

SCSI Commands Reference Manual Seagate part number: 100293068

SAS Interface Manual Seagate part number: 100293071

ANSI SAS Documents

SFF-8223 2.5” Drive Form Factor with Serial Connector

SFF-8460 HSS Backplane Design Guidelines

SFF-8470 Multi Lane Copper Connector

SFF-8482 SAS Plug Connector

ANSI INCITS.xxx Serial Attached SCSI (SAS-3) Standard (T10//BSR INCITS 519 rev. 06)

ISO/IEC 14776-xxx SCSI Architecture Model-3 (SAM-4) Standard (T10/1683-D)

ISO/IEC 14776-xxx SCSI Primary Commands-3 (SPC-3) Standard (T10/1416-D)

ISO/IEC 14776-xxx SCSI Block Commands-3 (SBC-2) Standard (T10/1417-D)

ANSI Small Computer System Interface (SCSI) Documents

X3.270-1996 (SCSI-3) Architecture Model

Trusted Computing Group (TCG) Documents (apply to Self-Encrypting Drive models only)

TCG Storage Architecture Core Specification, Rev. 1.00 r0.9

TCG Storage Security Subsystem Class Enterprise Specification, Rev. 1.01 r1.00

Self-Encrypting Drives Reference Manual Seagate part number: 100515636

In case of conflict between this document and any referenced document, this document takes precedence.

Seagate Enterprise Performance 10K HDD v8 Product Manual, Rev. A 10

3.0 General description

Seagate® Enterprise Performance 10K HDD v8 drives provide high performance, high capacity data storage for a variety of systems

including engineering workstations, network servers, mainframes, and supercomputers. The Serial Attached SCSI interface is

designed to meet next-generation computing demands for performance, scalability, flexibility and high-density storage

requirements.

Seagate Enterprise Performance 10K HDD drives are random access storage devices designed to support the Serial Attached SCSI

Protocol as described in the ANSI specifications, this document, and the SAS Interface Manual (part number 100293071) which

describes the general interface characteristics of this drive. Seagate Enterprise Performance 10K HDD drives are classified as

intelligent peripherals and provide level 2 conformance (highest level) with the ANSI SCSI-1 standard. The SAS connectors, cables

and electrical interface are compatible with Serial ATA (SATA), giving future users the choice of populating their systems with either

SAS or SATA hard disk drives. This allows integrators to continue to leverage existing investment in SCSI while gaining a 12Gb/s serial

data transfer rate.

Note

The heads automatically go to the ramp load/unload when power is removed from the drive and during the deeper sleep modes.

An automatic shipping lock prevents potential damage to the heads and discs that results from movement during shipping and

handling. The shipping lock disengages and the head load process begins when power is applied to the drive.

The drives also use a high-performance actuator assembly with a low-inertia, balanced, patented, straight arm design that provides

excellent performance with minimal power dissipation in any orientation.

Never disassemble the HDA and do not attempt to service items in the sealed enclosure (heads, media, actuator, etc.) as this

requires special facilities. The drive does not contain user-replaceable parts. Opening the HDA for any reason voids the warranty.

3.1 Standard features

Seagate Enterprise Performance 10K HDD drives have the following standard features:

• 128 - deep task set (queue)

• 128MB data buffer (see Section 4.5)

• 3.0 / 6.0 / 12.0 Gb Serial Attached SCSI (SAS) interface

• Drive Self Test (DST)

• Dynamic spindle brake

• ECC maximum burst correction length of 520 bits for 512 byte blocks

• Embedded servo design

• Firmware downloadable using the SAS interface

• Flawed logical block reallocation at format time

• Idle Read After Write (IRAW)

• Industry standard SFF 2.5-inch dimensions

• Integrated dual port SAS controller supporting the SCSI protocol

• Jumperless configuration

• No preventive maintenance or adjustments required

•Power Choice

• Programmable auto write and read reallocation

• Programmable logical block reallocation scheme

•RAID Rebuild ™

• Reallocation of defects on command (Post Format)

•SAS Power Disable

• Self diagnostics performed when power is applied to the drive

• Support for SAS expanders and fanout adapters

• Supports up to 32 initiators

• User-selectable logical block sizes for 512 native models (512, 520 or 528 bytes per logical block)

• Vertical, horizontal, or top down mounting

• Zone bit recording (ZBR)

Seagate Enterprise Performance 10K HDD Self-Encrypting Drive models have the following additional features:

• 16 independent data bands

• Authenticated firmware download

• Automatic data encryption/decryption

•Controlled access

• Cryptographic erase of user data for a drive that will be repurposed or scrapped

• Drive locking

•Random number generator

Seagate Enterprise Performance 10K HDD v8 Product Manual, Rev. A 11

3.2 Media description

The media used on the drive has an glass substrate coated with a thin film magnetic material, overcoated with a proprietary

protective layer for improved durability and environmental protection.

3.3 Performance

• 10K RPM spindle. Average latency = 2.9ms

• 1200MB/s maximum instantaneous data transfers.

• Adaptive seek velocity; improved seek performance

• Background processing of queue

• Firmware-controlled multisegmented cache designed to dynamically adjust segments for enhanced system performance

• Supports start and stop commands (spindle stops spinning)

Note

There is no significant performance difference between Self-Encrypting

Drive and standard (non-Self-Encrypting Drive) models.

3.4 Formatted capacities

Standard OEM models are formatted to 512 bytes per blocks. The block size is selectable at format time. Supported block sizes are

512, 520, and 528. Users having the necessary equipment may modify the data block size before issuing a format command and

obtain different formatted capacities than those listed.

To provide a stable target capacity environment and at the same time provide users with flexibility if they choose, Seagate

recommends product planning in one of two modes:

Seagate designs specify capacity points at certain block sizes that Seagate guarantees current and future products will meet. We

recommend customers use this capacity in their project planning, as it ensures a stable operating point with backward and forward

compatibility from generation to generation. The current guaranteed operating points for this product are shown below.

Capacity (Blocks)

Sector

Size

512

520

528

Decimal Hex Decimal Hex

1,172,123,568 45DD2FB0h 585,937,500 22ECB25Ch

1,147,307,696 446286B0h 573,653,848 22314358h

1,115,749,560 4280FCB8h 557,874,778 21407E5Ah

600GB 300GB

3.5 Programmable drive capacity

Using the Mode Select command, the drive can change its capacity to something less than maximum. See the Mode Select (6)

parameter list table in the SAS Interface Manual, part number 100293071. A value of zero in the Number of Blocks field indicates that

the drive will not change the capacity it is currently formatted to have. A number other than zero and less than the maximum

number of LBAs in the Number of Blocks field changes the total drive capacity to the value in the Number of Blocks field. A value

greater than the maximum number of LBAs is rounded down to the maximum capacity.

3.6 Factory-installed options

The following items may be ordered which are incorporated at the manufacturing facility during production or packaged before

shipping. Some of the options available are (not an exhaustive list of possible options):

• Other capacities can be ordered depending on sparing scheme and sector size requested.

• Single-unit shipping pack. The drive is normally shipped in bulk packaging to provide maximum protection against transit damage. Units shipped individually require additional protection as provided by the single unit shipping pack. Users planning single

unit distribution should specify this option.

•The Safety and Regulatory Agency Specifications, part number 75789512, is usually included with each standard OEM drive shipped,

but extra copies may be ordered.

Seagate Enterprise Performance 10K HDD v8 Product Manual, Rev. A 12

4.0 Performance characteristics

This section provides detailed information concerning performance-related characteristics and features of Seagate Enterprise

Performance 10K HDD drives.

4.1 Internal drive characteristics

600GB 300GB Models

Sector size 512 512

Native Native

Drive capacity 600 300 GB (formatted, rounded off value)

Read/write data heads 4 2

Bytes per track 997.9 997.9 KBytes (avg, rounded off values)

Bytes per surface 151,674 151,674 MBytes (unformatted, rounded off value)

Tracks per surface (total) 152 152 Ktracks (user accessible, rounded off values)

Tracks per inch 279 279 KTPI (avg, rounded off values)

Peak bits per inch 1925 1925 Kbits/in

Areal density 538 538 Gb/in2

Disk rotation speed 10K 10K rpm

Avg rotational latency 2.9 2.9 ms

4.2 Performance characteristics

4.2.1 Format command execution time (minutes)

512-byte sectors 600GB models 300GB models

Maximum (with verify)

Maximum (without verify)

122 61

61 31

Execution time measured from receipt of the last byte of the Command Descriptor Block (CDB) to the request for a Status Byte

Transfer to the Initiator (excluding connect/disconnect).

When changing sector sizes, the format times shown above may need to be increased by 30 minutes.

4.2.2 General performance characteristics

Sustained transfer rate for 512 native

SAS Interface maximum instantaneous transfer rate

Logical block sizes

512 (default), 520 or 528

Read/write consecutive sectors on a track Ye s

Flaw reallocation performance impact (for flaws reallocated at format time using the spare

sectors per sparing zone reallocation scheme.)

Average rotational latency 2.9ms

119 to 205 MiB/s **

125 to 215 MB/s

1200 MB/s* per port

(dual port = 2400 MB/s*)

Negligible

*Assumes no errors and no relocated logical blocks. Rate measured from the start of the first logical block transfer to or from the

host.

** MiB/s x 1.048 = MB/s

Seagate Enterprise Performance 10K HDD v8 Product Manual, Rev. A 13

4.3 Start/stop time

The drive accepts the commands listed in the SAS Interface Manual less than 3 seconds after DC power has been applied.

If the drive receives a NOTIFY (ENABLE SPINUP) primitive through either port and has not received a START STOP UNIT command with

the START bit equal to 0, the drive becomes ready for normal operations within 20 seconds (excluding the error recovery procedure).

If the drive receives a START STOP UNIT command with the START bit equal to 0 before receiving a NOTIFY (ENABLE SPINUP)

primitive, the drive waits for a START STOP UNIT command with the START bit equal to 1. After receiving a START STOP UNIT

command with the START bit equal to 1, the drive waits for a NOTIFY (ENABLE SPINUP) primitive. After receiving a NOTIFY (ENABLE

SPINUP) primitive through either port, the drive becomes ready for normal operations within 20 seconds (excluding the error

recovery procedure).

If the drive receives a START STOP UNIT command with the START bit and IMMED bit equal to 1 and does not receive a NOTIFY

(ENABLE SPINUP) primitive within 5 seconds, the drive fails the START STOP UNIT command.

The START STOP UNIT command may be used to command the drive to stop the spindle. Stop time is 20 seconds (maximum) from

removal of DC power. SCSI stop time is 20 seconds. There is no power control switch on the drive. However, power can be cycled on

the drive by utilizing SAS Power Disable feature defined by T10 (i.e. drive Pin 3 high).

4.4 Prefetch/multi-segmented cache control

The drive provides a prefetch (read look-ahead) and multi-segmented cache control algorithms that in many cases can enhance

system performance. Cache refers to the drive buffer storage space when it is used in cache operations. To select this feature, the

host sends the Mode Select command with the proper values in the applicable bytes in page 08h. Prefetch and cache operations are

independent features from the standpoint that each is enabled and disabled independently using the Mode Select command;

however, in actual operation, the prefetch feature overlaps cache operation somewhat as described in sections 4.5.1 and 4.5.2.

All default cache and prefetch mode parameter values (Mode Page 08h) for standard OEM versions of this drive family are given in

Section 10.3.2.

4.5 Cache operation

Note. Refer to the SAS Interface Manual for more detail concerning the cache bits.

The data buffer size in Section 3.1 is the total physical buffer space on the drive. The entire capacity is not available as user data

cache, some portion of the buffer space is reserved for internal drive use.

The drive keeps track of the logical block addresses of the data stored in each segment of the buffer. If the cache is enabled (see RCD

bit in the SAS Interface Manual ), data requested by the host with a read command is retrieved from the buffer, if possible, before any

disk access is initiated. If cache operation is not enabled, the buffer is still used, but only as circular buffer segments during disk

medium read operations (disregarding Prefetch operation for the moment). That is, the drive does not check in the buffer segments

for the requested read data, but goes directly to the medium to retrieve it. The retrieved data merely passes through some buffer

segment on the way to the host. All data transfers to the host are in accordance with buffer-full ratio rules. See the explanation

provided with the information about Mode Page 02h (disconnect/reconnect control) in the SAS Interface Manual.

The following is a simplified description of the prefetch/cache operation:

Case A—read command is received and all of the requested logical blocks are already in the cache:

1. Drive transfers the requested logical blocks to the initiator.

Case B—A Read command requests data, and at least one requested logical block is not in any segment of the cache:

1. The drive fetches the requested logical blocks from the disk and transfers them into a segment, and then from there to the host

in accordance with the Mode Select Disconnect/Reconnect parameters, page 02h.

2. If the prefetch feature is enabled, refer to section 4.5.2 for operation from this point.

Seagate Enterprise Performance 10K HDD v8 Product Manual, Rev. A 14

Each cache segment is actually a self-contained circular buffer whose length is an integer number of logical blocks. The drive

dynamically creates and removes segments based on the workload. The wrap-around capability of the individual segments greatly

enhances the cache’s overall performance.

The size of each segment is not reported by Mode Sense command page 08h, bytes 14 and 15. The value 0XFFFF is always

Note

reported regardless of the actual size of the segment. Sending a size specification using the Mode Select command (bytes

14 and 15) does not set up a new segment size. If the STRICT bit in Mode page 00h (byte 2, bit 1) is set to one, the drive

responds as it does for any attempt to change an unchangeable parameter.

4.5.1 Caching write data

Note

Note

Write caching in this section is the traditional SCSI write caching (WCE=1) where writes are not protected on power loss.

Refer to the SAS Interface Manual for more detail concerning the cache bits.

Write caching is a write operation by the drive that makes use of a drive buffer storage area where the data to be written to the

medium is stored while the drive performs the Write command.

If read caching is enabled (RCD=0), then data written to the medium is retained in the cache to be made available for future read

cache hits. The same buffer space and segmentation is used as set up for read functions. The buffer segmentation scheme is set up or

changed independently, having nothing to do with the state of RCD. When a write command is issued, if RCD=0, the cache is first

checked to see if any logical blocks that are to be written are already stored in the cache from a previous read or write command. If

there are, the respective cache segments are cleared. The new data is cached for subsequent Read commands.

If the number of write data logical blocks exceed the size of the segment being written into, when the end of the segment is reached,

the data is written into the beginning of the same cache segment, overwriting the data that was written there at the beginning of

the operation; however, the drive does not overwrite data that has not yet been written to the medium.

If write caching is enabled (WCE=1), then the drive may return Good status on a write command after the data has been transferred

into the cache, but before the data has been written to the medium. If an error occurs while writing the data to the medium, and

Good status has already been returned, a deferred error will be generated.

The Synchronize Cache command may be used to force the drive to write all cached write data to the medium. Upon completion of a

Synchronize Cache command, all data received from previous write commands will have been written to the medium. Section 10.3.2

shows the mode default settings for the drive.

4.5.2 Prefetch operation

If the Prefetch feature is enabled, data in contiguous logical blocks on the disk immediately beyond that which was requested by a

Read command are retrieved and stored in the buffer for immediate transfer from the buffer to the host on subsequent Read

commands that request those logical blocks (this is true even if cache operation is disabled). Though the prefetch operation uses the

buffer as a cache, finding the requested data in the buffer is a prefetch hit, not a cache operation hit.

To enable Prefetch, use Mode Select page 08h, byte 12, bit 5 (Disable Read Ahead - DRA bit). DRA bit = 0 enables prefetch.

The drive does not use the Max Prefetch field (bytes 8 and 9) or the Prefetch Ceiling field (bytes 10 and 11).

When prefetch (read look-ahead) is enabled (enabled by DRA = 0), the drive enables prefetch of contiguous blocks from the disk

when it senses that a prefetch hit will likely occur. The drive disables prefetch when it decides that a prefetch hit is not likely to occur.

Seagate Enterprise Performance 10K HDD v8 Product Manual, Rev. A 15

5.0 Reliability specifications

The following reliability specifications assume correct host and drive operational interface, including all interface timings, power

supply voltages, environmental requirements and drive mounting constraints.

Seek error rate: Less than 10 errors in 10

Read Error Rates

1

Recovered Data Less than 10 errors in 1012 bits transferred (OEM default settings)

Unrecovered Data Less than 1 sector in 10

Miscorrected Data Less than 1 sector in 10

Interface error rate: Less than 1 error in 10

Mean Time Between Failure (MTBF): 2,000,000 hours

Annualized Failure Rate (AFR): 0.44%

Preventive maintenance: None required

1. Error rate specified with automatic retries and data correction with ECC enabled and all flaws reallocated.

5.1 Error rates

The error rates stated in this manual assume the following:

• The drive is operated in accordance with this manual using DC power as defined in paragraph 6.3, "DC power consumption."

• Errors caused by host system failures are excluded from error rate computations.

• Assume random data.

• Default OEM error recovery settings are applied. This includes AWRE, ARRE, full read retries, full write retries and full retry time.

8

seeks

16

bits transferred

21

bits transferred

12

bits transferred

5.1.1 Recoverable Errors

Recoverable errors are those detected and corrected by the drive, and do not require user intervention.

Recoverable Data errors will use Error Correction when needed.

Recovered Data error rate is determined using read bits transferred for recoverable errors occurring during a read, and using write

bits transferred for recoverable errors occurring during a write.

5.1.2 Unrecoverable Errors

An unrecoverable data error is defined as a failure of the drive to recover data from the media. These errors occur due to head/media

or write problems. Unrecoverable data errors are only detected during read operations, but not caused by the read. If an

unrecoverable data error is detected, a MEDIUM ERROR (03h) in the Sense Key will be reported. Multiple unrecoverable data errors

resulting from the same cause are treated as 1 error.

5.1.3 Seek errors

A seek error is defined as a failure of the drive to position the heads to the addressed track. After detecting an initial seek error, the

drive automatically performs an error recovery process. If the error recovery process fails, a seek positioning error (Error code = 15h

or 02h) will be reported with a Hardware error (04h) in the Sense Key. Recoverable seek errors are specified at Less than 10 errors in

8

10

seeks. Unrecoverable seek errors (Sense Key = 04h) are classified as drive failures.

5.1.4 Interface errors

An interface error is defined as a failure of the receiver on a port to recover the data as transmitted by the device port connected to

the receiver. The error may be detected as a running disparity error, illegal code, loss of word sync, or CRC error.

Seagate Enterprise Performance 10K HDD v8 Product Manual, Rev. A 16

5.2 Reliability and service

The reliability of Seagate Enterprise Performance 10K HDD disk drives can be enhanced by ensuring that the drive receives adequate

cooling. Section 6.0 provides temperature measurements and other information that may be used to enhance the service life of the

drive. Section 9.2 provides recommended air-flow information.

5.2.1 Annualized Failure Rate (AFR) and Mean Time Between Failure (MTBF)

The production disk drive shall achieve an annualized failure-rate of 0.44% (MTBF of 2,000,000 hours) over a 5 year service life when

used in Enterprise Storage field conditions as limited by the following:

• 8760 power-on hours per year.

• HDA temperature as reported by the drive <= 50°C

• Ambient wet bulb temp <= 26°C

•Typical workload

• The AFR (MTBF) is a population statistic not relevant to individual units.

• ANSI/ISA S71.04-2013 G2 classification levels and dust contamination to ISO 14644-1 Class 8 standards (as measured at the

device)

The MTBF specification for the drive assumes the operating environment is designed to maintain nominal drive temperature and

humidity. Occasional excursions in operating conditions between the rated MTBF conditions and the maximum drive operating

conditions may occur without significant impact to the rated MTBF. However continual or sustained operation beyond the rated

MTBF conditions will degrade the drive MTBF and reduce product reliability.

5.2.2 Preventive maintenance

No routine scheduled preventive maintenance is required.

5.2.3 Hot plugging the drive

When a disk is powered on by switching the power or hot plugged, the drive runs a self test before attempting to communicate on

its’ interfaces. When the self test completes successfully, the drive initiates a Link Reset starting with OOB. An attached device should

respond to the link reset. If the link reset attempt fails, or any time the drive looses sync, the drive initiated link reset. The drive will

initiate link reset once per second but alternates between port A and B. Therefore each port will attempt a link reset once per 2

seconds assuming both ports are out of sync.

If the self-test fails, the drive does not respond to link reset on the failing port.

It is the responsibility of the systems integrator to assure that no temperature, energy, voltage hazard,

Note

Caution

shorting of PCBA to ground, or ESD potential hazard is presented during the hot connect/disconnect

operation. Discharge the static electricity from the drive carrier prior to inserting it into the system.

The drive motor must come to a complete stop prior to changing the

plane of operation. This time is required to insure data integrity.

5.2.4 S.M.A.R.T.

S.M.A.R.T. is an acronym for Self-Monitoring Analysis and Reporting Technology. This technology is intended to recognize conditions

that indicate imminent drive failure and is designed to provide sufficient warning of a failure to allow an application to back up the

data before an actual failure occurs.

Note

The drive’s firmware monitors specific attributes for degradation

over time but can’t predict instantaneous drive failures.

Each monitored attribute has been selected to monitor a specific set of failure conditions in the operating performance of the drive

and the thresholds are optimized to minimize “false” and “failed” predictions.

Seagate Enterprise Performance 10K HDD v8 Product Manual, Rev. A 17

Loading...

Loading...