Page 1

·...

,I

~

J

ST225

-

OEM MANUAL II

PLEASE NOTE

SPECIFICATIONS OF THE ST213 HALF HEIGHT

10MB DRIVE CAN BE FOUND AT THE BACK OF

THIS MANUAL.

f

.I

, c'o._•. ~•.. H_W" ; _.",..'_, ', _, _ • '. ,_. _..:. ••• ;": •• ~':';::. ;••• ,', ••••~.:i-'...,--..•.;~;l7''t~;~':'"t:.;".:.."••.•_:".'' ."!,;,,;~,,,-,~,,::;,;,,_~,,,",..;,c.~':-:':;,:~':'i:";...!'~::":~";.'~~_:••.~;_L·..;', '~"'~'':';';'-:''i-',!~~ ~.,;..::; ....~.:'~;~ '::",.. ,..:. ,~_.-

• t •••

95066-4544,USA. 408/438-6550

'y,

--

Seayate I]

~ --~~':':!.I~

I]

~II

Page 2

"

Page 3

Appendix 3: S1213

Specifications

UNroltMAmD CAPACITY

Pet Driw:

~rCrlindor.

•••• Trocl.:

roRMAmD CA'ACT\'

Per Drtw:

P.rCylindet:

An Tnc:k:

IW SectOl':

SeetON per

lrKk:

PHYSICAL ORGANI7.ATION

TrKu: t.210

Cylinden: 815

Red/Write He•••• : 2

DIK': 1

fUNCnONALSP£CnCATIONS

Rot.honlll Speed: 3.600 RPM

Record!n. Scheme: MFM

Recordihl Den.U,: '.827 BPI

Flu Den.lty: '.827 Fa

TrackDen.II,: 588TPI

Interface: ST412

o.'a Tr.Mr., tt.,.: S.O Mes.bUslleC

ACaSS TIME

1rKk·lo·TrKk; 20mMIC

Aver'lIt8: aSmRC

Full Strub: UOmaec

Lalency: I.JJmsec; noml •••1

EnOR RATES

RKowf.bI.

Non.rtICowr.W. RlrIHf Enon:

Seek Erron:

·1itK.~~wHhlll"ret""

u No4I NCCftIftlbie ."hlll •• ,.., ••

REWlnsrY S'WnCATIONS

MTBf: 20.000 A7wer~ Houn

PM: Not Requhod

M1TR: 30Mlnul••

SeI'YlceU": S

OP£RATIONAL ENVIRONMENT

AmbMtnI1empefllturo: ttrC 10 45"'C ISD-Flo 113-F,

Temperalure C,.ch.nt:

Rel,liw HumidUy: • 1080'" nonconden.lnl

Maximum Wet Bulb: 28'1: 1'•.•

DC!'OWU REQUIREMENTS

.IZVOC f: 5'" .1 AmIN 'yp.

• ,VOC

PowItr: 14.11

PHYSICAL SP£anCATIONS

U.lahl: 1.131nchet ma•. lfI..mm'

\Vkllh: S_lS = Inchet 1148.0S ~ mm'

Depth: 1.00 Inc:hee mu:.1203.Zmmt

WelSh': US II.. IUS kal

lIad. -U •• ,

ReIHl Enon:

t,•••. 1 Amptlyp.

12.1' Mea_byt"

20.'32 Bytee

Xl.416 Byt ••

Moa.by1"

MJ.n

11.4088)1"

•.••048)1"

512 8y1"

"

t''''

1per H)-bll. ,ud •

per lO'tbit.rv.d··

I

J per to"seeb

'lean

1O"'Cthr. (1S·''''r.1

·'1nonconden.lnf;

2.2 Ampl

mall .•• power·up

W.'IJIYp.

Ii

f)

{

.•

~

ST225 OEM MANUAL

October 22, 1985©

36005-001, Rev. F

Seagate'" reserves the right to change, without

notice. the specifications contained in this manual.

J

t-

920 Disc Drive. Scotts Valley. Calirornia 9S066-4S44. USA

040

mlJ OEAl/~",,

Telephone: (408) 4)8·6SS0 Telex: I764SSSEt\GATE SCVL

Page 4

o :-:-

..

-""\oOD

!!.;O 0

:; ~~

",,'

eN •••

N-Uil UII

n"

g ":':1

n

S8~=

ell

0

~

';- tii°

fA

••

Q,

@

"'I

-

...•

W

m

::Iaaa

"CI

"C

~~~§

fJ)

-...

C'''''

.. ""

:;==

~g

Q.

~

;C'

CJ)

"C

"t'J

Q)

::::I

W

Q.

>

:=

(I)

.,~

3:11I..,..,

""'.

I'

Page 5

·,·.· ....'4..-.....~

~,o.~ .•..,:.•.••:.•.•.\...

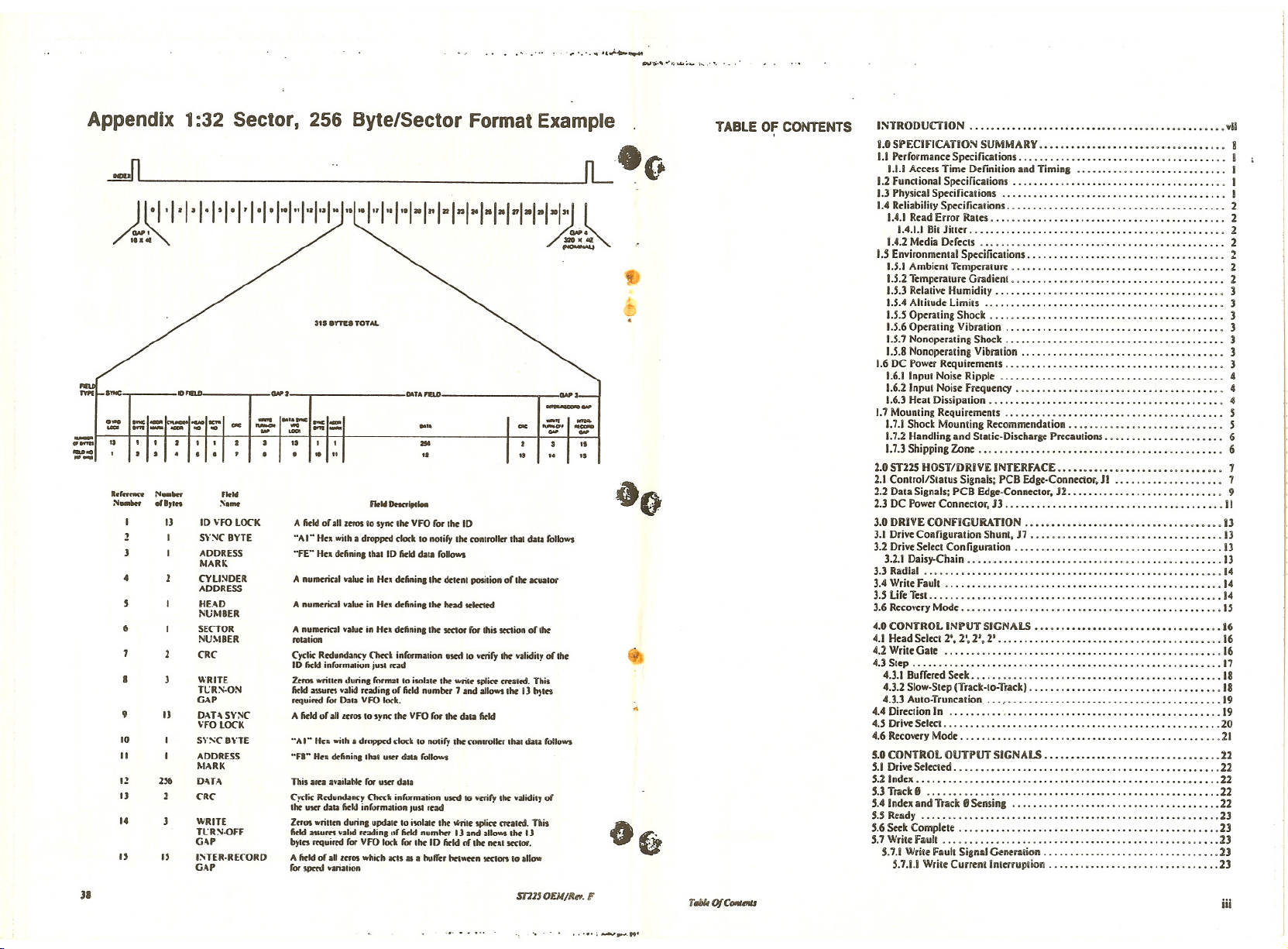

Appendix 1:32 Sector, 256 Byte/Sector Format Example

~ ~fLOO

A:~I·I·I·I·I·I·I·I·I·H;tJ·~1·1·1·1+1·1·1·1·1·1·'jj~~

315 Ims TOTAL

'::

=1=

:=1--;;

-..•

..-

IdHNn N_1N<r fleW

N•• 1N<r eI.,ln s.rnt

4

6 I SECiOR

9 IJ OAH SYNC

10 I SYSC BHE

II I ADDRESS

12 256 O-\T..••

IJ

14 J WRITE

" " 1:o;rER·RECORD

II

-:Ol~

IJ ID \'FO LOCK

I SY:-IC BYTE

I ADDRESS

MARK

2 CYU:-IDER

ADDRESS

HE.-\D

NUMBER

NUMBER

CRC

WRITE

Tt: R S·ON

GAP

\'FO LOCK

MARK

2 CRC

Tl: R:-I'()ff

G-\P

GAP

....,

I\-.cIIIt IIfO ent_

- ....

-1 •..'.•IftCIPCI••••

tI I' I'• It tI

A field or .1I,etOS 10 sync lhe VfO for lhe 10

••AI"

H•• wilh • dropptd clock 10 nOliry lhe conlrol •••.lhal dal. "IIOWI

Hex dtfinin. Ih.1 10 Mid dal. follows

"Fr

A nu••••ric.1 •• Iu. in Hex dtfinin. lhe dtl.nl posilion or lhe lCualor

A nu••••ric21•• 1•• in Hex dtfinin. lhe hoad ••lcc1ed

A num.rical •• Iu. in

rotation

Cyclic Redundancy (1)<ck inrormalion uoed 10••riry lhe ••Iidily of Ih.

10 fieldinrorm'lion juS! ••• d

lam wrinen durin, format to isolale the ViniC' !Plitt (~;litd. Thii

fielda$SUm •• Iid ••adin. of field numhor 7 .nd .11owslhe IJ 1»1<5

r<quirtd ror Dal. VfO lock.

A field of .11'''0110 sync 1M VFO rot lhe d••• fitld

"AI" H•• wilh • dropped clock 10 notiry lhe con,roIk, lhal dall rollow>

"fA"

H•• dtfinin. lhai UKr clata rollow,

This am .,waibbk for UKr Ibl,;

Cyclic Redu ••••ncy Check inrorm.,ion uKd 10•.nry lhe •• Iidity of

the UKr data Mid informillion JUst read

Z••OI wriuon durin. updol' to i•• I.lo tho writ. splitt eft.,td. This

field '$SUm ••Iod••:odin. IIr field oumher lJ.nd .11owslhe IJ

byl•• '«Iuired rot VfO lock rot ,he ID fitld of lhe ••• 1 KC'ot.

A fitld of.II •••.01 which acts II •bulf•• Ioti"un •••• 0<110.11_

for ~ "'arialion

MTA f1ELD

"'::'

tI

,

.•.•

".

"

floW Dnnl" •••

H•• d.finin. lhe •••• or rot Ihi, ••••ion of 1M

-..

...•..

--

tI

3tI

••

""::'"

.~

,

•..

~o

~

o~

TABLE OF CONTENTS

I:'WTRODUcriON •.••••••••.••••••••••••••••••••••••.••••••.•••••

i.OSi'ECiHCATiOS SUMMARY •••••••••••••••••••••••••••••••••.• 8

1.1 Perrormance Specificalions ........•.•.••••..••.•.•...•...•••....• i

1.1.1 Access Time Ddinition and Timins .•.••..•.•..•.•..•...•..••.. I

1.2 Funclional Specifica.ions .••.•.•••.••.••••.•.•..•..••.•.•.•.••••. I

1.3 Physical Specificalions ...•..........•.••••.•..•..••..•....•••... !

1.4 RtiiabililY Specificalions ..........•...••••..•.•.•.•..•••..•.•••.. 2

1.4.1 Read Error Rales ....•.......•.•..•••••.•••.•....••..•.•..... 2

1.4.1.1 Bil Jiner •....•.....•......••..••....•.•.•...•..•......•. 2

1.4.2 Media DereCIS ••••........••.•.••••.•..•.......••••..•••.... 2

I.S Environmental Specifications ...........•••...........••.••.•.••.. 2

1.5.1 Ambien. Temperalure ..........•..••.•...•..••.••••..••....•. 2

1.5.2 TemperaiUre Gradi.ni. ......•...•...••..••..•..........•.••.• 2

1.5.3 Relalive HumidilY ......•..•.••......••.•.•.•.•..........•••• 3

I.SA Ahilude Limi.s .........••......•••.••..••......•...••.•.••• 3

I.S.S Optrating Shock ....•....••.....••••..••......•.••••••.•.... 3

1.5.6 Operaling Vibralion ........•.....•...•.••......••...•..•..•• 3

1.5.7 Nonope,ating Shock ..•...•.•......•......•.......•..•..•.•.. 3

!.S.8 Nonoperaling Vibralion ...........••.......••....••••••••.•.. 3

1.6 DC Power Requiremenls ...•.....•..•..••..•.•..•..•....•••...•.• 3

1.6.1 Inpu. Noise Ripple •....•..•.•....•.....•.•••.•.....•.••..•.. 4

1.6.2 Inpu. Noise Frequency •..•..•....•••••...•.......•.•..•.••••• 4

1.6.3 H.al Dissipation ••...•••..•.•..••.•.••.•••..•...••.••.•...•. 4

1.7 Mounling Requirements ...•.....••.••.•.•.••••.•.•.•••...••••... 5

1.7.1 Shock Mounring Recommendalion .•••....••...•.•....••.•••... 5

1.7.2 Handling and Slatic·Discharge Precautions .••.••......••.•.•••.• 6

1.7.3 Shipping Zone .•.....•......•..••.••...••••.....••..•.•..•.• 6

USn25 HOST/DRiVE INTERFACE ••••••••••••••••••••••••••••••• 7

2.1 Conlrol/Slatus Signals: PCB Edge·Connector. JI .•..•...•••••.•....• 7

2.2 Dala Signals; PCB Edge·Conneclor, J2 ...•••..•...••.•...••••..••.• 9

2.3 DC Power Connector, J3 .•••.....•..••.•..•.•.•...•.....••....•.. II

3.0 DRIVE CONfiGURATION ••••••••••••••••••••.•• , ••••••••••••• 13

3.1 Drive Configuralion Shunt. J7 ..••••.•••••.••••••...•.•.••....••.. 13

3.2 Drive Seleci Configuralion .•••.......•.•••••..•..•.•.•.•.••..••.. 13

3.2.1 Daisy.Chain •...•••.•...••.•..•.•.•...••...•.•...••.•••..... 13

3.3 Radial ..•...•...••....•.•..•.•..•.•...•••••.••.•.•••.••.•..•.. 14

3.4 Write Fault ....••.•••...•.•.•...•.•.••••.•..•••..•...•••...•••• 14

3.5 lire Test. ...•.•••...•....•••..•.....••••...••..•••.••••.•.••••. 14

3.6 Recovery Mode ••.•.•........•....••..•..•..•..•...••••.•.••.... IS

4.0 CONTROL INi'UYSiGNALS ••••••••••••••••••••••••••••••••••• 16

4.1 Head Seleci 2", 2'. 2'. 2' ..•...•.....•....••.••••.....••..•...••..• i6

4.2 Wrile Gale •.......•....•......•.••..••..•.•......•.•••••..•... 16

4.3 Slep ....•.....••...•....•••.•..•••••••.•.••.•....•....•••••••• 17

4.3.1 Burrered Seek ..•..•.•.•.•..•..•..••••.••••.•.•.•.•••••.••••. 18

4.3.2 Slow·Slep (Track-Io-Tr:ack) .••..••••.••••.••••.••.••..••.•••.•. 18

4.3.3 AUlo·Truncation •.. , •....•...•.•..••.•.••••..•.•.••.••.•.••• 19

4.4 Direclion In •....••.•• , •.••..•..•..•••••..••.••..•.••.••.•..... 19

4.5 Drive Select. ......•.•••....••......•••.•.•....•....•..•..•.•••. 20

4.6 Recovery Mode ...••••......•......••••.•.••••..•.•..•.••.•..... 21

5.0 CONTROL OUTPUT SiGNALS ••••••••••••••••••••••••••••••••• 22

5.1 Drive Selected ....•..•••...••.....•...••.....••••.•....••••••.•. 22

5.2 Index ..•..•.•...•••••.•....•....••..•.•••.••..••..•.•••.••..•. 22

5.3 Track" .....•..•.......•.•......•••••••••.•....•.••.•.•••••..• 22

5.4 index and Track" Scnsinl ..•..•...••.••••.•.............•..•••.• 22

5.5 Ready .•..•.•...••.•.•..•••.••..••..••...•.•....•••....••.•... 23

5.6 Seck Complete ...••.•..•....•.....•..•••.•.••.•.•...••.••.•.••• 23

5.7 Writc f~uli ....•................•..•••••..••••........••.••••.. 23

S.7.1 Wriie fault Signll <lener.iion ......••••.••••...••...•..•..••.• 23

5.7.1.1 Wrile Curreni imerrupiioli .......•....•...•..........••.•. 23

'On

JI

mlS OEM/!lIf'I. F

,

..•.~-•..... ".

TJJkO/C_mu iil

Page 6

j.8 Faull D~t~':lion ., , , H

5.8.\ DC·Um'al~ Si8n~1 ~4

'.8.1.1 VoUla~~ Comparalor., ,

'.8.2 H~ad Select Comparators ., ............•..................... 24

6.0 powt:R·B.\ SF.Ql'E;I;n: .•..•...........••....•••..••••••• :: ... 25

7.U UATATR.",;I;Sn:R U;I;t:s ...............••..••.•.....•••.....•. 26

7.1 WrileOper.ation., ......................•....................•.. 26

7.1.1 :\IFM \;vrile Data .............................•......•.•..... 27

7.\.2 Write Gale, .....................•....•........•......••.... 27

7.1.3 Line R"'cei\'~r . , 27

7.\04 Precorrnpensation ...........................•.......•....•... 27

7.2 R~ad Ope ••:"ion 28

7.2.\ M F~I Read Dala .............•.•...........•.•......•....... 28

7.2.2 Head Select 28

7.2.3 lSI Preamp , .................•..•..•....•.............. 28

7.204low·PatsS Filler ..................•........•..........•.•.. · .28

7.2.5 Phase Shifr~r 28

7.2.6 Z~ro·ClosS DCICclOr , ................••.................. 29

7.2.7 Time I>omain Fih~r ..................•.....•................ 29

1.2.8 Line Du-h'er ............................•.................. 29

1.0 TlIt:ORY OF OPERATIO;l;S .....•.....•..•......••.•.••.•••..•• 30

8.1 Microproc~sor .................................•............... 30

8.1.1 MPU·h,ilializing ............................•....•..•...•••. 30

8.1.2 MPU-Itdle ......................•.................•......... 30

8.\.3 Seeking: , ........................•.......................•.. 31

8.2 Spindle M01er Conllel .........•....•...•.............•.......•. 31

9.0 fIELD SERVICE ....•••...•......••..••.••..••••.••••...•....• 3J

9.1 PC Board Removal ....................•..•..................... JJ

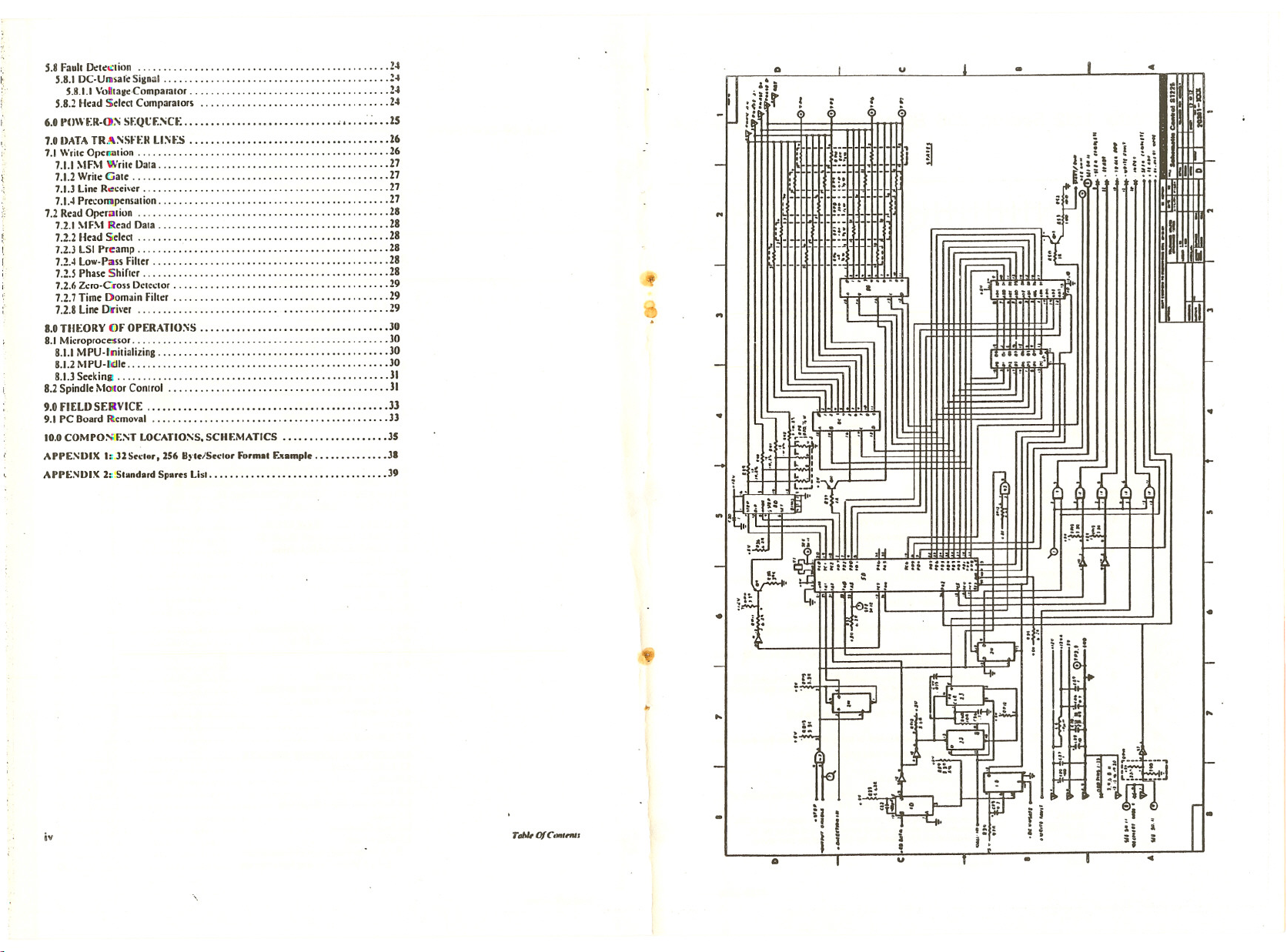

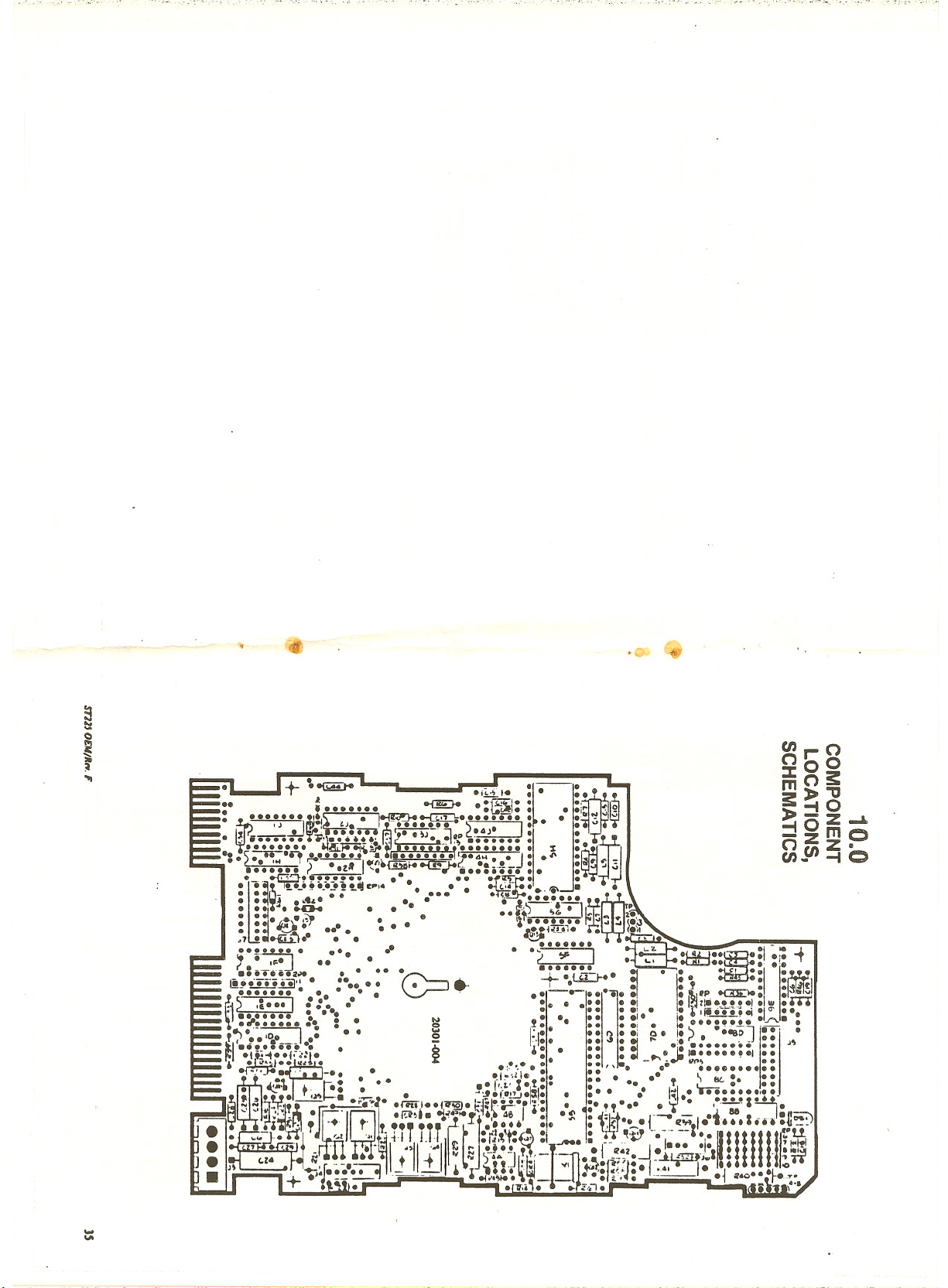

10.0COMPOSf.:\T LOCATIO:\S. SCm:MATICS .....•.......•.•...• J5

APPE:IODIX

APPE:-IDIX 2~ Siandard Spares List. ..........••.......•••.........•. 39

I::J2Srclnr. 256 D)'le/Se<lor Formal Eumple •....••••.•••• 31

u

c

H

ElmMB

;~lft~l_

J

m

"

~,-

..

,~

~

..

;,

=!}

IH:

I!':

:!

:.I

l

~11I111,a

111t

IIII

I!l11!m~

i

I

II.•

..

it:::::::....

•

!H",!

"

~

..

.

.

iv

\,

T,,}II,OfC ••••

rnNl

o

I

~

u

, :J:

;":

;

•

c

•

..

•

Page 7

. ' -..•....""

G

·

·

..

• f':I!':r~

u

.

:'

i

,.

..

!!

.

.•

I • IIIIII

I tit i. III

••

'I~'

if'

-,-

e(

'()

.•

e(.

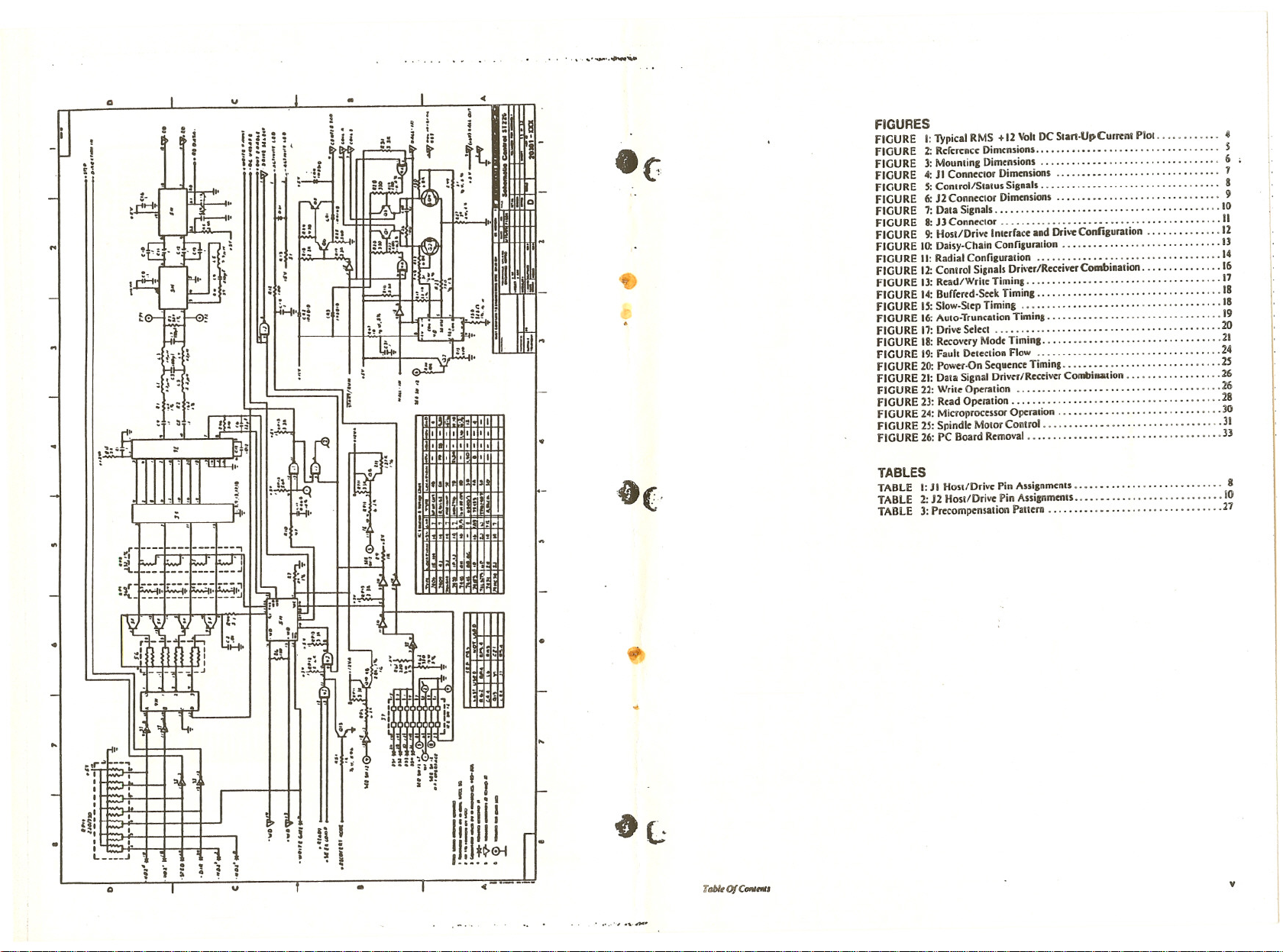

FIGURES

FIGURE I: lYrical RMS + 12Voh DC Slan-UpCurn:ni Pial .........•.. ~

FIGURE 2: Reference Dimensions •.•..•.••..••.•..•...•...•.••..•.•.

FIGURE 3: Mounling Dimensions ...........•...................... 6

FIGURE 4: JI ConneclOr Dimensions ......••.•..................... 7

FIGURE S:Control/S.alus Signals ..........••...................•.. 8

FIGURE 6: J2 Connector Dimensions _................•.•... 9

FIGURE 7: Dala Signals .................•.. _ 10

FIGURE 8: JJ Conneclor ....•.............. - II

FIGURE 9: HOSi/Drive Imerface and Drh-eConfiguralion 12

FIGURE 10: Daisy-Chain Configuration 13

FIGURE II: Radial Configuralion _ , ...........•... 14

FIGURE 12:Comrol Signals Drh·er/ReceiverCombinalion ...•........... 16

FIGURE 13: Read/Wrile Timing ...............•..................... 17

FIGURE 14: Buffered·Seek Timing _ 18

FIGURE IS: Slow-Step Timing _•..........•.......... 18

FIGURE 16:AUla-Truncation Timing ........••.•..................•.. 19

FIGURE 17: Drive Select .....•..................................... 20

FIGURE 18: Recovery Mode Timing ......•••..•...................... 21

FIGURE 19: Faull Detection Flow ..........•........•............... 24

FIGURE 20: Power·On Sequence Timing _ 2S

FIGURE 21: Dala Signal Driver/Receiver CombirUltion 26

FIGURE 22: Write Operation _ 26

FIGURE 23: Read Operation , .•...................... 28

FIGURE 24: Microprocessor Operation ..........................•.... 30

FIGURE 2S:Spindle MOIOIControl ...........••...............••.... 31

FIGURE 26: PC Board Removal ..........• _" _

TABLES

TABLE I: JI Host/Drive Pin Assignments ......•..................... 8

TABLE 2: J2 HOSi/Drive Pin Assignments .. _.• _.....•..........•..•.. 10

TABLE 3: Precompensalion Pallem .......•..••..................... 27

$

n

••••• '!.ut.,ICoI

•

..

J,2:1·--;i

~!f'"

"

,

I

I

,

II'

'i'

!...I

~,

I

•

,

L_~:::'J

G

·

1

;

u

!- 1

:! •

.;i

~

•••• ...11:

ilSI~~,.

3:~:!Jil

I

·r

It·

':

i G I

1!l1i ii

It 1'111

II!I~~~

<I

•

~

..

'tt(;

T,obI,OfC_tffl'

.... '~ .,.~"'

v

Page 8

...

..•.

Page 9

il II mlndator)' tilat approved £SO p"nudonl be OMen-ed during tills

proccdn". nil Indnllft and-stade wrilt-lt •• pI.

Note: Earlier revisions of this PCB. Seagale part number 20301, required

the PROM (7D) to be Iransferred

'required and the replacement board il downward compatible for all

verlions.

Parts Required: PC Board 20301-004

Tools Required: Torque driver, T-IO and T-' TOI1l.,its

I. Secure a padded anti-static work surface.

2. Remove the two fronl panel screws (or if instaileJ, the printed circuit

cable shield.)

10 Ihe replacement PCB. This il no longer

J. Orient the drive with the PCB up.

ot. Remove and retain the three PCB moundna screws. There may be

a clear insuladng washer installed at one or more of the mountin.

points. Be sure to replace at the same point(s) during reassembly.

,_ Locate and carefully free the Primed Circuit Cable. Do not crease

the cable.

6. Locale and carefully free the spindle motor and stepper motor

connections.

7. Lirt out the PCB.

8. Your replacement PCB will be shipped to you with a kit containing

two around springs.

Jr the spindle molor has a steel ball in the center of its hub, mount

a.

the spring with the graphite bUllon (I).

Jr the spindlemotor has a short post at the center of the hub, mount

b.

the bare copper sprina (2).

9. Verify thai the Ground Sprina assembly is aligned and will make

positive contact with the spindle hub. NOle thatlhe washer and hex

nUl bolh mounl on the solder side of Ihe PCB. Refer to Figur~ 17.

10. Tighten the Ground Spring mounting screw to 2.' inch/lbs. Transfer

the blue Isodamp pad to the replacement board.

II. Reconnect the Stepper and Spindle motor connections.

12. Reconnect Ihe Printed Circuit cable.

13. Torque the PCB mountina screws to 9 inch/lbs. Do not forget to

replace the clear insulating washer(s), ir Installed.

PC8

COMPONENT SIDE

WASHER

HEX NUT

ISOOAUP - ••r •

SPRING

(2)

GAOUNO/8UTTONHEAO SCREW

=

ria

I

,

I

2·\6 UNe

PC8

SOlDER SIDE

~

fl,

GAOliNO

SPRING

FIGURE 27:

Ground Spring

Assembly

~.

.-t

INTRODUCTION

The Seagate ST22S disc drive provides OEMs and system integratoi"$

with over 20 megabytes of formalled capacity in a $hock-~esisiani

half-heighi package. The ST225 is designed fOr single-user desk-lOp

systems, local storage in network or multi-user sysiems, Or

in upgrade for PCs. The low-power ST22S design is ideal for th~ lip-

plicalions in either rugged indumial or quiet office environments. The

ST225 supports the industry-siandard ST412 interface and has the

same voltage requirements for ease of integration.

High reliability is assured through the use of LSI, a single printed cir-

cuit board, mini-monolithic heads and proven oxide media. Scagate's

proprietary helical-band rotary-actuator features simplicity and ease of

manufacture with excellent thermal stability. A dedicated head ship-

ping zone assures data integrity during shipping and hllndling. The

ST225 offers

of 20,000 hours.

Our manufacturing facilities have been designed and located ex-

clusively for high volume production and testing of disc drives.

Seagate's ongoing commitment to vertical integration assures availa-

biliiy of the latest technology at the same consistent quality and lowest

possible cost. Scagate inspects every assembly at every stage of the

production process. A proprietary test system continuously verifes oUr

goals of volume production with rigorous quality control.

II low-cost, rugged and reliable disc drive with an MTBF

ST213

Oct. 29, 1985

This manual may be used to install and configure 8eagate's ST213. The 81213 is a

half-heighl, single-disc. 10 Megabyie (formatted) Winchester. It employ s the samf[1

efficient helical-band rotary-actuator as the 81225 and also supports the industry-

standard 8T412 interface.

\A)lIage requirements. interface connectors and mounting requirements are iden-

tical to the 81225. Please refer to page 40, Appendix number 3 for specifications.

lIS an add-

.u

ST11J OEM/II •••.f'

STZ1J OEM/II ••. F

vii

Page 10

9.0

FIELD SERVICE

The ST22$ doc:s nol require prcvcnlalivc mainlcnancc. The PC Board may

be eAchanicd in Ihe field. Refer below

10 Sccl;(m 9.1 for .hi! procedure.

PC BOARD REMOVAL

9.1

~

FIGURE 26:

PC Board Removal

UOUNTING SCREWS

:(>.0: COUPONENT SIDE

h. or o'

~

SPlNOlE UQTOR

CONNECTION

ST11' OEM/kt. T

'SlUEt PCC_

ISOOA•••• Ii

\UOUNT ON SOlDER SlDEI CONNECTION

STEPPER MOTOR

CONNECTION

3J

Page 11

The primary functions. listed below, are incorporated within the cus-

tom spindle motor IC (lC 48).

I. Monitors the Hall signal from the spindle motor and uses the Hall

transistions to commutate the motor phases. It regulates the motor

speed by measuring the Hall period and comparing it to the oscilla·

tor clock period.

1. Employs a sense line to regulate the start current and execute a cur·

rent limit shut-orr.

3. Monitors the power supply for output driver shut-olf •. When the

power is olf. the oulput drivers become self-biases on, which brakes

the molor using back·EMF. '

4. Locked·Rolor Protection: IC 48 monitors the .ime from the first

Hall transition. If the mOlor does not spin.up. the drivers will be

disabled to avoid overheating Ihe circuil. This Hall signal is gen·

crated by a transducer located in the motor hub. Two complele

square waves are generated each comple.le revolution.

1QO

SPECIFICATION

SUMMARY

'1

PERFORMANCE SPECIFICATIONS

Capadty

Per Drive:

Pcr Surrace:

Per Track:

Per Sector:

Sectors per Track:

ACCESS TIME DEFINITION AND TIMING

Access time is defined as the time from the leading edge of the last

Step pulse received to SEEK COMPLETE (including carriage settling).

The period between Step pulses must be between s,.sec and 2O!psec.

Average access time is measured over a lOS·track seek (one·third

stroke.' The calculation assumes the following:

I. Nominaltempc:rature and power

2. The average is taken from an inward one-third stroke, plus an out·

ward one-third stroke.

Track-to- Track:

Avcrage:

Maximum Seek:

Varona'lIed

25.&1 MB

6.41 M8

10,416 Bytes

NA

NA

lO.Omsec max.

65.Omsec max. '

150.Omsec

fOrMliit<Ki

1(1.15MB 28.42 MB

5.tM MB S.JS MR

U92 Bytes g,704 Bytes

156 Bytes 512 Bytes

31 Sectors 11 Secton

mIX. '

11.11

U.1

FUNCTIONAL SPECIFICATIONS

Rotational Speed:

Latency:

Recording Density:

Aux Density:

Track Density:

Cylinders:

Tracks:

ReadfWrite Heads:

Discs:

DaUlTransfer Rate:

Recording Scheme:

(!J

PHYSICAL SPECIFICATIONS

Height:

Width:

Depth:

Weight:

3,600 RPM

8.33msec nominal

9,827 BPI (Cylinder 614)

9,827

588 TPI

615

2,460

4

2

5.0 Megabits/second

MFM

I.6J Inche$ mo:. (41.4mm)

5.75 •.: iodle$

8.00 inehei mo. {W3.2mm)

2.13 Ibs (USKII)

± 1'1(,

Fa(Cylinder 614)

U~.OS '.:' mm)

1.2

~.3

I. hft'•••••-Sft.

J1

ST11' OEM/Bn. F

ST11' OEM/An. F

Page 12

1.4

MTBF:

PM:

MTTR:

Service ufe:

Recoverable Read Errors: I per 10" bits read J

Nonrecoverable Read Errors: I per 10" bits read •

I'

Seek Errors: I per 10- sc:c:ks

RELIABILITY !jPECIFICATIONS

20,000 Power-on hours I

Not required

30 minu\c:S

S yc:an

READ ERROR RATES1.4.1

1.4.1.1

Bit jilter reduction determines the relationship between the leading

edge of READ DATA and the center of the data window.

The specified Read error rates arc: based on the following bit jilter

specification. Ihe data separator must provide at least - 40 dB of bit

jilter reductio n at 2F with an offset error of less than LSnsc:c shift

from the center of the data window.

BIT JmER

SEEKING 8.1.3

Upon rc:ceh'ing Ii S.eppulse •• he MPU pauses for :!S(\.rsc:c10 allow for

additional pulses befol'Cexecuting the seeli operalion. Every incomin.

pulse reselS the

pulse is received.

When sc:c:king.Ihe MPU counts the number of tracks to be covered.

and employs the optimum step algorithm to mlch Ihe largetlrack.

:!S~;C:C timer. The 5eek will nOI begin unlil Ihe lasl

While seeking. Ihe MPU conlrols the direction and mode of the cus-

tom stepper

tual phase commulations. Acttleralion/deceleration are delermined by

the varied frequency of the pulses and .he use of the MOlor IC Direc-

tion line. This IC provides both

~,

windings.

With READY and SEEK COMPLETE true. the MPU re.urns \0 the

Ie. Pulses are sent to the stepper chip. which does the ac-

Ii curreni source and sink iO molor

Idle mode.

SPINDLE MOTOR CONTROL

8.2

1.4.2

A medial defea is a Read error when data, which bas been correctly

wrilten, cannat be recovered within 16 retries.

A printout wimlbe provided with each drive listing the location of any

defect by head, cylinder, sector and byte. It will also specify the

number of bytles from the Index pulse. •

There: will be, no more than eight (S) defects per surface for a max-

imum total of thirty-two (32) per drive. Cylinder Zero will be free of

defects.

1.5

ENVIRONMENTAL SPECIFICATIONS

1.5.1

Operating:

Nonoperating::

1.5.2

Operating:

Nonoperating:'

1. T,rIca'_., 25'C, 8' _ ••••L Colaoto' ••• potMiL S,... H__ 111.

J. R•••••••••• wt.~1oo•• mrIn

4. N•••••••••• w. ••II~I•• 6 mrIn

to 113'F (lO'C to 4S'Q

SO'F

- 4O'F to 140'F ( - 4O'C to 6O'C)

TEMPERATURE GRADIENT

IS'F /br (lO'C/hr) max.

Below condensation

MEDIA DEFECTS

AMBIENT TEMPERATURE

5•••••••••• 31.-1", 256.,../_ •• r•••••

POWEll

NS(

IIIPOI.AA

""TOIl

""""AS

IIIOI'OlAA

""TOIl

DRIVERS

FIGURE 25:

Spindle Motor Control

'19

To insure sufficienl staning power. the spindle motor circuil is run

with a set of biploar motor drivers. Once the spindle motor has started

running, Ihe MPU switches the motor circuit from bipolar

drivers; which significantly lowers the required running currenl.

10 unipolar

2

ml' DEMIR"". F

ST11' DEMIR,., F

31

Page 13

8.1

The microprocessor monitors and controls the internal drive runClions

and the host interrace lines. The MPU has only three active modes:

Initializing. W.ltlng. or Sftklnl •..

MICROPROCESSOR

8.0

THEORY OF

OPERATIONS

RELATIVE HUMIDITY

Opei'ating:

Maximum Wet Bulb:

Nonoperating:

8 to 80% noncondensing

78.8'F (26'C) noncondensiili

5 to 95~ nOilcoildeilsing

U.3I

NCO'i'I.fIIf

~

.-!!!!-

CON'''1I11 Iot:IF~,

DIRECtION

~

'RACK •

-.

-

su., •..••

a.1.1 MPU INITIALIZING

At power-on, the MPU initializes the stepper circuit to phase minus A

and minus B, and resets all interrace lines under its control.

As the drive spins-up, the MPU switches rrom bipolar to unipolar aRer

approximately 40 revolutions. The processor will measure the period

or the index signal to assure that the drive is up-to-speed berore the re-

calibration routine is initiated.

The MPU sets phase minus A and minus B on the stepper chip (lC

80) and then executes the Seek and Discriminator routines. which re-

calibrates the Read/Write heads to Track

READY and SEEK COMPLETE. The drive is available to accept

commands 24 seconds max. aRer polAer-up.

a.1.2

When in the idle mode, the MPU loops. waiting ror Slep pulses. The

custom Read/Write LSI chip monitors the power inputs and. on tran-

sients, resets the MPU which will reinitialize the drive.

19, divides Index, and gives

MPU·IDLE

FIGURE 24:

Microprocessor

Operation

AlTITUDE LIMITS

Operating:

Nonoperating:

••

~

OPERATING SHOCK

Maximum permitted shock without incurring physical damage or de·

gradation in performance: 10 G's ."

OPERATING VIBRATION

Maximum permined vibration, at the rollowing rrequencies. without

incurring physical damage: or degradation in perrormance: '

Frequency Vibration

5 - 22 Hz .01OHdouble amplitude

22 - 300 Hz .25 G amplitude (peak)

300 - 22 Hz .25 G amplitude (peak)

22 - 5 Hz .01Owdouble: amplitude

NONOPERATING SHOCK

Maximum permitted shock without incurring physical damage or de·

gradation in performance: 40 G's -,'.'

NONOPERATING VIBRATION

Maximum permitted vibi'ation, at the rollowing rrequencies, without

incurring physical damage or degmdation in perronnancc:

IFnquenc)' Vlbratloll)

5 - 22 Hz .010' double amplitude

22 - 300 Hz .50 G amplitude (peak)

300 - 22 Hz .50 G amplitude (peak)

22 - 5 Hz .010' double amplitude

DC POWER REQUIREMENTS

The ST22S is listed in accordance with UL 478 and CSA C22.2

(O-MI982), and meets all applicable sections or IEC 380 and VDE

0806/08.81, as tc:stedby

- 1,000 ft to 10,000 ft

- 1,000 ft to 30,000 ft

TUV-Rhf!infand. North Amf!rica.

U,iJ

1.5.5

1.5.6

1.5.7

1.5.8

',I

1.(1

i. 11_ •••••.••••".,•••••••••••••

7. S.p<ot 10•••• ot , ••• rI•• _' ••••••••••• Villi _"", ••••• ,,.. ••••••••••••••

s..s.m••••1.7

•. lioMlt"",.'-"1 •• ,•••• 1,,1•• _

JO

STll' OEM/II ••. F

STllS OEMI"", F

J

Page 14

Power may be applied or removed in any sequence without

data or damage to the drive.

~=of

+U Volls DC:

Voltage Tole:rance (including ripple):

Maximum elmeR!

Typical Current

Oil Power-on:

±S%

2.2 Amp

.9 Amp

+5 Volts DC:

Voltage Tolerance (inc. ripple):

Typical Current:

Power

1.11.1

The maximllm permiued ripple is 1000V (peak-to-peak) on either

+ 12 Volts or +,Volts measured on Ihe hoSl system power supply across

the following equivalent resistive loads:

-+- 12 Volts DC 1612

1: ,1ft

.gAmp

14.8 typical'

INPUT NOISE RIPPLE

+ S Volts DC SQ

1.11.2 INPUT NOISE FREQUENCY

20MHz max. on both the + 12 and + S Volt lines

AMPS

ZERO-CROSS DETECTOR

This element detects bit positions as the slope of the Read Data signals

crosses the zero threshold. At this point analog data an: cbanged to di· .

gig).

TIME DOMAIN FILTER

When a high resolution head reads a low frequency data pallem, there

is

Itendency for the head signal to decay between bilS. If the signal de·

cays below the uro cross threshold. a spurious data bit will be generat-

ed. Such false bits are ignored by delaying the clocking bit past the p0-

tentia! point of highest drop.

""

LINE DRIVER

This element changes raw digital data to a differential data. providins

immunity to common mode noise during transmission.

1.2.ti\

7.2.1

7.2.'

26

2.0

1.0

6

t. 1\1•••••••• ....." 1M 101••••••••••••••••••••• ' •••• coMl,"'"

JS"C ••• _

s.. .....

NotnI••1.",,- .,,1'"

SpI•••••••••••••••n••III -kilt

4

r-- -- --+-MAXIMUM PEAK CURRENT

1 ~ 3 4 5 6 7 8 9 10 11 12 13 14 15 18 17 18 19 20

SECONDS $

1••.,.,.1_

I I

SEEKING

FIGURE 1:

Typical RMS +12Volt DC

Start-Up CUffent Plot

IDlE

ST11J OEM/RIO. F

ST11J OU//hY. F 29

Page 15

O~'~-..'.O£l'· .•••.·•.~ •. ~••••• "'"_ ••__ •••.• ' .•• _ •.•••.••.••..

7.2

1.2.1

The data recovered by reading a track is transmitted to the host system

via a differential pair of MFM READ DATA lines. The transition of

+MFM READ DATA line going more positive than the - MFM

the

READ DATA line. represents a nux reversal on the tfilck of the select·

ed head.

1.2.2

The binary decoder (IC 4H) selects the desired head based on the status

or the Head Select lines. If the DC vollases are too low, possibly

causing an inaccurate Read operation, the decoder (pin.J2) will select

a nonexistent head. By rererencing 0 to + 5 Volts actual ground appears

as - 5 Volls, which eliminates the necessity of a negative power source

normally required by the LSI preamp.

1.2.3

With the Head Center Tap (HCT) active. data from the selected head

will now into the preamp (9E). which amplifies the Read signal and

also acts as a high-pass filler.

The HCT voltages are monitored and controlled by the custom

Read/Write LSI (SH). This chip monitors the Write Gate line and sets

the appropriate level on its Voltage Center Tap (VeT) for Read or

Write mode.

1.2.4

This filter network attenuates high frequency noise. which is outside

the normal data sipal range.

1.2.5

Amplified data enters the circuit and is shined 90' so peak data, which

was detected over a fairly broad range. is now moved to

sloped accurately detectable position at the zero crossing point.

28

READ OPERATION

MFM READ DATA

HEAD SELECT

LSI PREAMP

LOW-PASS FILTER

PHASE SHIFTER

II highly

FIGURE 23:

Read Operation

ST1110EM/I'. ••.

9)

Reference Dimensions

FIGURE 2:

.-·0

"'II

Dimensions are in inche'i.

,A

A.is lor Shock speUfication

y

;»

"

MOUNTING REQUIREMENTS

The ST22S may be mounted in the following orientations:

Horizontal: Spindle motor dowo

Sides: Left or riaht

The drive should not be tilted front

thail

±5'. Refa to Figures 2 and J for reference and mounung di·

mensions.

~

for optimum performance the drive should be formatted in the Slime

orientation liS it will be mounted in the bost system.

SHOCK MOUNTING RECOMMENDATION

It is recommended that any external shock mounts between the drive

and the host frame be designed so that the composite $yslem has

venicml resonant frequency of 25Hz or lower.

A minimum clearance of 0.050 inch :shouldIx: allowed mround die cn·

ure perimetCl' of the drive for cooIiDi airflow and mo\iow during

!Mcchanicmlshock or vibration.

10 back. in any position, by more

o

G

If

1.7

1.7.1

II

.,.. .•.-..•._,-----_.~~.-----~~.--..

STl13 OEM/~rI.F

,

Page 16

U.2 HANDUNGAND STATIC-DISCHARGEPRECAUTIONS

After unpacki!1B and prior to system integration, the drive is eAposed

to potential ha ndling and ESD hazard.

De DOt touch the PCB "l~nKton, boIlEd rompoMnts or the

printed drcult. cable _Itbout obser.lnl Slatlc-dlscharae precautions.

Handle tbe drin b)' tbe (rame onl)'.

II is stronBly recommended that the drive always rest on a padded sur.

race, with the l1eads parked over the shippinB zone, until the drive is

mounted in the host system.

1.1.3 SHIPPINGZONE

The ST22S employs a shippinB lone. located rrom Cylinders 61S to

670, to preserve data integrity during shippin8ltranspon. The

Read/Write heads may be parked in the shipping zone by issuing a

seek to any cylinder between 615-670. The drive may then be

powered-down.

Upon power-up. the drive will recalibrate to Track _. Ir the heads are

parked while power is still applied. any Step pulse will cause the unit

to recaJibrate to Track ~.

1------- 100",-, - 1

UN t O~ - "3 moll

~.,'~ ,,~. _' u~ I

~i J 'm~21 .... _~--:-r

021 02 . e•• ' t .51) "t 02

,": SII I I ' 12'''' t $1.

1 ~-1. MIIl"lI'G

T f, L;II. 02 ,

• 17 t: a:z 3." t 01 '·uou:.~ .•~ tIpe.

fCSO t 5" (1125 t: 51' / '0fIII. ~ Oft ca"h udr;

"UUSC·18t1:!XI

'....,.--:r- I 1/

Oi.

o

'"I I ,

5G'S t 010

Ct., 22!: asl

,

!

,

f 550t02

rT'

o

$ 7$':

(, .••os-:!}

·

·

·

D

FIGURE 3:

Mounting Dimensions

$

MFM WRITE DATA

WRITE DATA is trans!11ined by a differential pair which defines the

transitions

aoing more: posilive than the - MFM WRITE DATA line is Iile active

Iransition. Tilis siBlIalmust be do"en to aninaclive Slale wilen in Ihe

Read mode.

WRITE GATE

A Write sequence is initiated when Write Gate is activated. which

causes the Read/Write LSlto apply

selected lead; concurrently data is sent

;'!

LINE RECEIVER

~

TABLE 3:

Precompensation Pattern

X

t

0

X

Differenlial Write flata. which is precompensated MFM. is received

rrom the controller.and changed

pulse generator. which changes pulse data to square wave data.

Pin·S. at IC SH. will be activated ir plus data is to be wrillen. Pin-9

will be activated ror minus data,

PRECOMPENSATION 7.1.4

Precompensation is recommended on Tracks 300 through 614. The

optimum amouill or precompensalion is 12nsec ror both early and late

bits. Tablt

compensated. An X denotes a "don't care state."

As the Read/Write heads travel inward. the track circumrerence or

course decreases. and the data bits are necessarily written eloser togeth.

er. The Write Current is Iherefore reduced

crowding.

The ST22S does not require the host to speciry a cylinderis) to beJin

applying reduced Write Currenl. This runction is managed internally

by the microprocessor •

10 be wriUen on Ihe disc. The + MFM WRITE DATA iille

+12 Volls 10 the center tap or the

10 the line receiver.

10 sinBie line. II is then red into the

J below indicates the bit panerns and the direction 10 be

10 preclude any pulse

NEXT

t

t t 0WRITE DATA EARLY

WRITE CLOCK LATE

WRITE ClOCK EARLY

IENOIHG

TIMING

t

0 0 0

0 0 t

0

WRITE DATA LATE

PREVIOUS

ALL OTHER PATTERNS-.u.

1.1.1

1.1.2

7.1.3

NOn:: Mountin, JCIrtWI mIlS! •••••••••• more .lIon .2' inch inside .he drive.

Donw1soons are in inches (mml.

6

STll' OEMIR,.. F

srl1' OEMIR". F

27

Page 17

Two pain of balanced sisnals are employed for data transfer: MfM

WRITE DATA and MFM READ DATA. Data lransfer lines belween

Ihe hosl syslem and Ihe drive are dilferenlial in nalure and may nol

be multiplexed. Refer above

ments and

Figr"t' 7 for a hosl/drive interconnection example.

HIGH

TRUf

FlAT CABI.£ OR TWlSTEO PAIR

10 TaM" 1 for data lransfer pin assign-

HIGH

'TRUE

1.0

DATA TRANSFER

LINES

FIGURE 21:

Data Signal

Driver/Receiver

Combination

2.0

ST225

HOST/DRIVE

INTERFACE

""

This section details Ihe physical specificalions or the host/drive inti:1l-

face mnnecto", Conneclor dimensions and iJili IIIS5isnmeniSfollow

under IUIchsection. Refer

and the interface connectors.

CONTROllST ATUS SIGNALS

PCB EDGE-CONNECTOR, J1

Do IICri tOiiCh the PCB edge-coniiedon, board componeob or the

printed circuit albie, wllhout o~IDI !ltadc-dlscharae precaudoliS.

"melle the drive by the frame

Control and status signals belween the host and the drive are

lransmined through a 34-pin PCB edg«onneclor, J,I.

cales connector dimensions and Table I list! Ihe pin assignments. A

hosl/drive interconnection is illustrated in

With the drive resting on a padded surface, orienled wilh the PC

Board up and Ihe edge-coonectors toward you, J I is 10 your lefland

J2 is on the right Refer to Figure 9 for position and other interface

option connectors.

11 pins are numbered I through 34 with the even pins located on the

solder side of the PCB. All odd pins are ground. A key slOI is provided

belween pins 4 and 6. Pin 2 is labeled. The recommended mating

connector for JI is AMP ribbon connector, part number 88373-3.

10 Figure 9 for all overall view of the drive

2.1

001)'.

Figurt <Iindi-

Figure 5.

i'

7.1

In order to Wrile, Ihe following condilions must be lrue:

I. DRIVE SELECT active 4. Wrile Gale active

2. READY active 5. WRITE FAULT inactive

3. SEEK COMPLETE active 6. RECOVERY MODE inactive

26 STl1j DEM/R,.,. F

WRITE OPERAnON

FIGURE 22:

Write Operation

Wi'

ST113 O';:;I/R,.,. F

FIGURE 4:

Jl Connector

Dimensions

.017

I

~

t-

-i

18 EO. SP." .100- 1.800

IIOA~O THICXNII!U:0.082 ~ 0.007

TOUluua: 0 xxx :>: 0.005

__ -.ell

II:'~

"i

I,n5

7

Page 18

IITN;PIH

tSTATUSENABLED WITH DRIVE SELECT

GAOOIINO

HOST

I

J.I

- HEAD SELECT 2'

----

- WRITE FAUlT- HEAD SELECT

TRACK'

2<RECOVERY t.AOOE

SIGNAL

PINSlGNALNAMf

2

•-HEAD SELECT2'

a

.INDEX

14·HEAD SELECT

·STEP

28

30

34·DIRECTION IN

·HEAD SELECT 2'

·WRITE GATE

at·SEEK COMPlETE

10

12t·WRITE FAUt. T

18·HEAD SELECT 2'

18·RECOVERY MODE

·READY

24

.lJRIVE SELECT I

28·ORIVE SELECT 2

·DRIVE SELECT 3

32·DRIVE SELECT 4

lOt

22t

•TRACK _

ZO

•S•

11

20222.

17..•

3

1T221

J1 Host/Drive Pin

Assignments

FIGURE 5:

ControVStatus Signals

6.0

POWER-ON

SEQUENCE

'",

FIGURE 20:

Power-On

Sequence Timing

The application of DC power inititates a sequence ihai star1Sihe llpin-

die motor, regulates its speed, $Ieps the Read/Write heads

and i55UesREADY IInd SEEK COMPLETE !lCQuentially

the sequence.

READY and SEEK COMPLETE are i55Ued

drive il available

available 10 accept commands 24 seconds max. after 'he power supply

voltages maintain the specified

DC ON rf----4

SPEED REGUlATED

ROTATIONAl. Y

1660 ••••••••• 'od)

- TRACK' I: -t ....I-

- READY

10 accept tommands. Upon power-up the drive i$

± SI!(, vol. tolerancei.

-/ 17••• typo I-

1

1~1

~-:-----

f----4-t~ l-

10 the interface when ibe

10 Tm:k _

iO terminate

"{ABLE: 9

II

FRAME GNO

Q TWJSTEO PAtA6 111 GA '" "'90'1

FR.w£ GNO

l

J

-SEEK COMPLETE J--2- -.--1

I '11 _

I I I

~2'''' __ I

i/J

J3

mlJ OEM/II". F

mlJ OEM/II".'

25

Page 19

U1

HEAD SELECT

COMPARA TOR

WAeTE QA Tt:.

SEEK COMPl£TE. READY

5.8.1

A OC-Unsafe condition will cause a microprocessor reset. This will

prohibit writing. but will not directly cause a WRITE FAULT. If Write

Gate remains true, while the MPU resets from a OC-Unsafe condition,

a WRITE FAULT will be triggered through the loss of READY and

SEEK COMPLETE.

5.8.1.1

The Read/Write LSI (IC SH) continually monitors the +Sand + 12

VOC lines for low voltage conditions. If

+ 12 Volts is > 20% low, Write Current will be disabled and the

MPU will be reset.

5.8.2

During normal operations a single head will be selected. and the Vol·

\age Center Tap

If multiple heads are selected, the voltage will increase at Voltage Head

Safe (VHS. IC SH. pin-26) forcing its output low. Lesr than one head

selected will decrease the voltage at pin-4. forcing its ol.tputlow. Write

Current will then be disabled and the MPU will reset•

(vcr) will be high (lC SH, pin-27).

FAULT DETECTION!

DC·UNSAFE SIGNAL

VOLTAGE COMPARATOR

+S Volts is > IS% low or

HEAD SELECT COMPARATORS

FIGURE 19:

Fault Detection Flow

e

FIGURE 6:

J2 Connector

Dimensions

DATA SIGNALS

PCB EDGE-CONN~CTOR, J2

Do not touch the P'-B ~1I~nnectln, Itoani components IIIi' ftbe

printed dmilt alble without observlne ltatlc-dlscharge precautions..

Handle the drl.e by thl2frame only.

ReadfWrite data signals are received ud transmitted over a 20-pin

PCB edge-connector. 12.

sions and Table 2 lists the pin assignmCIIIs. A host/drive interconnec>-

tion is iUustrated in

With the driw resting on :I padded surface, oriented with the PC

Board up and the edge-conilectors toward you. J2 is to your right arid

J I is on the left. Refer below to

J2 pins are numbered I through 20 with the even pins located on the

solder side of the PCB. A key slot is provided between pins 4

Pin 2 is labeled. The recommeilded mating COilnectar for J2 is AMP

ribbon oonilector, part ilumber 88373-6.

Figurlf 6 below indicates connector dimen-

Figure 7.

Figure 9.

-1L

.CI31UIIII

III· -I~-050

mt:-T II~

; I n t+

2.2

Ilnd 6.

I

I

.050~ ~

I

.087

I I

I

1---.Ea. SI' .•• ICII~ .100--1

1.1175

IIOA~O YHICKIIESSo 0.082:t 0.007

TOU~AHCI: 0.111111:t 0.005

(

..•..•--

24

mlJ OEM/Itn. F

STllJ OEM/II,.. ,.

9

Page 20

RTN I'IM

13

17

14

18

GROUNO

SIGNAL

PIN SIGNAl. NAME

3

19

I

RESERVED

II

9

+MfM

+ MFM

-DRIVE SELECTED

5RESERVED

7

RESERVED

GROUND

WRITE DATA

- MFMWAITE DATA

15GROUND

READ DATA

-MfM READ DATA

GROUND

RESERVED

TABLE: 2

J2 Host/Drive Pin

Assignments

READY

This sianal, when true loaelher wilh SEEK COMPLETE. indicalell thai

the drive is ready 10 Read, Wrile or Slep and lhal all conlrol inpul sill- •

nals are valid. When Ihis line is Ilia/!, all radinl. wrilinl and !teppinl

are inhibiled. The maximum lime after power-on ror READY 10 be

lrue is 24 seconds.I'

Durinllhe power-up sequence, READY remains raise unlil:

I. The recaJibralioD 10Track" is complete

2. Spindle speed is slable within

3. Drive inilialwliion roulincs arc complciC

4. DC vollagcs are wilhin lolerance

± I'" or nominal

$.5

Data Signals

10

l'

11

17

I

-

---

---

TWISTED PAIR 20 FT.•••• X

RESERVED

RESERVED

"

12

•

I J~

J..

I

II (t

-DR~2RESERVED

,,1

IS

I

13

•

II

I

IT22S

FIGURE 7:

<.

SEEK COMPLETE

This signal IOCS 10 • low level (Irue) on Ihe interrace when the

ReadfWrile heads have seuled on Ihe 6na11rack at Ihe end or

Seeking. readil.o or wriling should nOI be altempled when SEEK

COMPLETE

cascs:

I. When a recalibralion sequence is inilialed (by drive 101ic) al

power-on

2. IOOnsectypical after Ihe leading edge or a Slep pulse

3. Ir eilher

4. At the beginning and end of a RECOVERY MODE operalion

WRITE FAULT

This signal nOli6es Ihe hosl syslem Ihat • condilion exists which, ir nol

correcled, may cause an incorrecl Wrile operalion.

WRITE FAULT SIGNAL GENERATION 5.7.1

With DRIVE SELECT active. and anyone orlhe following condilions

true, the WRITE FAULT signal will be issued to Ihe inlerface and

Wrile Currenl will be inhibiled.

:s false. SEEK COMPLETE will go raise in the rollowinl

+S Volls or +12 Volts are detected as unsafe

5.6

IIseck.

5.7

i.Wrile Gale lrue wilh no Wrile Current to Ihe heads

2. Wrile Currenllo Ihe heads willi no Write Gale

3. An altempllO Wrile willi RECOVERY MODE active

4. SEEK COMPLETE false

S. A Slep pulse is received

WRITE fAULT remains lrue unlillhe condition which lriggered the

raull is correcled and Ihe resel is completed.

WRITE CURRENT INTERRUPTION

Anyone of IIIe followin. condilions will cause Wrile Currenllo be in·

hibited when Wrile Gale is lrue:

I. Mulliple hcaduelected

2. No head selected

3. READY false

U.1.1

III. no 24 •••• _ .1_ 1 h n~ r••• ,•••""'" I•••••••••••••• ,..

10

ml' OEMIR".F

sril' OEAlI~".,.

_ ••••••••• ,,1, ••• iIII•••••••••••• 11iri :!: "" ""- ~

23

Page 21

The control output signals are pted to the interface when sel\:Cted. The

control output signals are DRJVE SELECTED. INDEX. TRACK _.

READY, SEEK COMPLETE and WRJTE FAULT.

5.1

DRIVE SELECTED is a status signal transmilled over J2. which in·

forms the host system of the selection status of the drive. The signal is

driven by a TIL open collector. as illustrated in F;gur~ 11. The signal

goes low (true) on the interrace only when the device is configured as

described in Section

activated by the host system.

J.1. and the appropriate DRJVE SELECT line is

5.2

This signal is provided by the drive once each revolution (16.67msec

nominal) to indicate the beginning of a track. Normally this signal is at

a high level and makes the transition to low to indicate INDEX. Only

the transition from high to low. or the leading edge. is valid.

DRIVE SELECTED

INDEX

5wO

CONTROL

OUTPUT

SIGNALS

DC POWER CONNECTOR, J3

IIOi t01iC1itlte I'(Jj ed~necton, board romponmt. 011' the

Dei

printed drcult able without obsenlna siatlc:-dlsc:lwtle precautions.

Handle the tin.it

DC POWl:ris transmilted from the host to the drive villithe power con·

nector

JJ. JJ Ii• 4-pin AMP "Male-N-Lock" connector, AMP pan

number 35021 i·l.

component side of the PCB. The recommended mating connector is

AMP pari number i-480424.o.

...

(.

Applications using cable lengths less than live feet may use JIII8AWG

wire and AMP 61314-4 strip pins.

For applications requiring cable lengths grealer than five feel,

JIII4AWGwire is recommended using AMP 61117-4 strip pins.

lily tM frame only.

JJ is directly to the left of Ji and mounted on the

~.S

FIGURE 8:

J3 Connector

5.3

This signal is active (true) ooly wheo the Read/Write beads are posi.

tioned at Cylinder Zero.

Track ~ is the ooly cylinder that provides interrace recognition. The

drive is designed to recalibrate to Track ~ during power-on aod Auto-

Truncation operations.

Track _ may also be accessed via cooventional Buffered-Seek and

Slow-Step modes. After Track ~ is true, no action may be Iaken by the

controller until SEEK COMPLETE is also true.

5.4

The ST22S does oot use eilher an Index or Track" sensor. The drive

accesses the Index Iracks on power-up for reference information. When

the drive has reached proper speed. the stepper motor IC is set to phase

minus A and minus B. The MPU then seeks in multiplrs of eight Iracks

until it finds Track 617 and Track minus I. These He the reference

tracks that are wriuen on all four surfaces.

The MPU uses these Iracks to set hs inlernaltrack counler. The drive

then sleps in one track from Irack minus I and sets the Track" signal

on the interface. The MPU will mainlain Ihe track count until a recalibra-

tion or Auto-Truncation triggers the set-up routine.

The Index tracks, wriuen on Cylinder 617 and Cylinder minus I. are

wriuen wilh a unique data pauern which generates the IndexlTrack

" interface signals. The drive has a simple dala discriminator which

the MPU samples durlns inilializalion. By discriminating Ihe unique

dala paUern on Ihe IndexlTrack '" reference Iracks. Ihe MPU can set

a divide by two circuil. This circuil allows reliable Index from Ihe spin-

dle molor Han sisnal.

INDEX AND TRACK '" SENSING

TRACK _

rr0000il

POWER

+5 VOLTS

+ 12 VOLTS

+ t2 VOLTS RETURN

+ 5 VOLTS RETURN

4

2

3

1

~

~

PIN

22

ST11' OEM/It,.,. F

ST11' OEM/II,.,. F

II

Page 22

OPTIONAoI. GROUNDING POINT

(PIe •••• no,. the pcM"," 0111Io ••• 'OIIed

••••••• ,ong; ••aShefI

I

FIGURE 9:

Host/Drive Interface and

Drive Configuration

FIGURE 18:

Recovery Mode Timing

RECOVERY MODE

The RECOVERY MODE line provides a micropositionin; option

that may be used after the controller bas completed its retry options

on a Read error. StctiOli

- RECOVERY MODE

J.6 above details this option.

-f~1-

4.1&

..J

'~-1

(i:

-SfV'

~I-

• RESISTOR TERMINA nON PACK

J2-2D PIN

CONNECTOR

.-/,

J7-16 PIN CONNECTOR

(Dove conligural","'

Shown WI'h drIv. con/igured as OS-I

\

00000008

~~ITlll:r

un

fES'

4'

-SUI(

COMPI.ETi:

I _ .•..

-II-I_~.

-i--+- ~~.

i2

21

Page 23

.4.5

The DRIVE SELECT line is acUvated by the controller to selccl and

Iddress the drive.

DRIVE SELECT

FIGURE 17:

Drive Select

3mO

DRIVE

CONFIGURATION

The ST22~ may be confiaured

S«tions 3./throuah 3.6 detail the options.

DRIVE CONFIGURATION SHUNT, J7

17 is Ii 16-pin ri&hl angle shunl located midway betw«n JI and J2.

Use the provided shoning blocks

and the desired oplions. Figure 9 illustrates 17 and indicates Pin I•

10 specific iI~ iysiem ll'Cquirem<=llI\l$.

3.1

10 enable Ihe DRiVE SELECT lines

'I

ORIY!: SELECT 1

ORIVE SELECT 2

ORIVE SELECT 3

ORIVE SELECT.

FROM INTERFACE

.~

(b

DRIVE SELECT CONFIGURA TIOH

3.2

The DRIVE SELECT line enables the controller 10 select and address

the drive. Control cablc interfacc options use either a Dais)'-Chain or

Radial configuation.

Pins 15-16 shoned enables DRIVE SELECT I

Pins 13-14 shoned enables DRIVE SELECT 2

Pins

i1-12 shorted enables DRIVE SELECT 3

Pins 9-10 shorted enables DRIVE SELECT 4

DAISY·CHAIN

:U.1

Each drivc in thc chain must be configured a!i either DRIVE 1,2,] or

4, so that onl)' one DRIVE SELECT line activales

drivc in the chain must havc

installed on the PCB. Refer

lion.

;II 22013JOQ resistor termination pack

10 Figur~ 9 abovc for resistor pack locz- .

II device, The last

FIGURE 10:

Daisy-Chain

Configuration

COHTROLJ

STATUS

SECYlQfO

CONTROl BUS

DIIIVE 1

.11 ~TOR PACK

~

J2

ORM! 2

n_ATOR PACK

(........"

..

OWM!J

TER ••••••• TOR PACK

~

DATA

HANDLINCI

SECTION

20

S171J

OEU/~". F

!i1"11.IOEM/It ••. F

OlIN!! •

Ji TERMINATOR PACK

.--

J2 --

JJ

Page 24

3.3

The Radial option is enabled by shoning pins I and 2 at the J7 shunt.

Drives configured to this option are always selected and respond to all

control signals issued on the attached control cable:. The 220/330Q

resistor temnination pack must remam installed on each radially-

connected drive.

tion.

CONTROI..I

STATUS

SECTION

DATA

HANOUNCJ

SECTIOHI

F;gu'~/ / iUustrates a host/drive: Radial interconnec-

JI TEll•••••••••TOR PACK

J2

JI TEllMINATOR PACK

TER•••••• TOR PACK

JI TEII•••••••••TOR PACK

DIIIVI 1

r-

..-

DIIIVI 2

~

..-

DIIIVI S

r-

..-

DIIIVI 4

In-

..-

RADIAL

FIGURE 11:

Radial Configuration

4.:UAUTO- mUNCATION

The:drive: will enter the Aut()oTruncation mode if the controller issUe:!

an excessive number of Step pulses, which would place the

Read/Write heads outward beyond Track

Cylinder 670.

With Aut()oTruncation active. the drive will ignore additional pulses,

take control of the stepper motor and n:caIibrate the heads to Track ,.

Refer below to

OunON: If the controller is stiU issuina Slow-Step pulses after the

51225 issues SEEK COMPLETE from Aut()oTruncation mode:. the

drive will either rc:c:nterAuto-Truncation mode with DIRECTION IN

false, or step the remaining cylinders witb DIRECTION IN true.

~

Auto· Truneation Timing

FIGURE 16:

-TRACK': /1 1 _

F;gu'~/6 ..

r--UCESSIV£ STEP PULSES AfCOGHIZ£II

II or inward beyond.

~I / -J~~

I I_

I--'1- I

3.4 WRITE FAULT

The WRITE FAULT signal may be inlemailylatched.This latch may

be cleared wben DRIVE SELECT gocs false (if pins 5 and 6 are shon-

ed at J7). The standard configuration. with the shoning block re-

moved, cause:s WRITE FAULT to go false when WRITE GATE goes

false. Refer to

FAULT .

See/ion 5.7 for a detailed- di!.;:ussion of WRITE

3.5 UFE TEST

This function is used during the manufacturinl process and is not

recommended for Deld use. When pins 7 and 8 are shoned. the stepper

motor will continuously seek between Track _ and the maximum

cylinder. Whc:onin this mode the drive will ignore control signals sent

via the interface.

II)

m1J OEM/It,.,. F

CJ

. t1'

DIRECTION IN

DIRECTION IN. defines the direction the ReadfWrite: heads will

move when the STEP line is pulsed. With DIRECTION IN true, each

pulse causes the heads to move one cylinder inward toward the lipiD-

die..

When DIRECTION IN is false, each pulse causes the heads to move

one cyr :I<:routward toward Track _.

4.4

•

..

ST11J OEAl/Itrt. F

19

Page 25

~.:!I.~

To minimize access time. pubes may be issued at an accelerated rate

and buffered in a counter. Initiation of a seek starts immediately after

the lint pulse is m:aved. Head motion occun durinS pulse accumula-

tion. and \he seek is completed followina r=:ipt of all pulses.

- DIRECTIONIN

i1UFFERED SEEK

I~'!~E//A STABLE V///t~nCARF,I////

1__ -11- -I ~ -11-1__

~1J

1_1yp.-:-l~r--I I-~':..

-SEEK COMPlETE Ib- L

---DA-ove-SEl£-CT-1 . I

"Tme II !rom ~ 01 heed _ 10 SEEK COMPlETE.

4.3.2 SLOW-STEP(Treck-to-Treck)

In single-track Slow-Step mode. the Read/Write heads move at the

rate of the incomina Step pulses. The minimum pulse period is

3mscc. The stepper motor is sellied and SEEK COMPLETE is issued

20mscc max. after the leadina edge of the last pulse.

1__ -""9·1

--f . ----1 .__ .-1

FIGURE 14:

Buffered-Seek Timing

RECOVERY MODE 3J.i'!J

The ST22S mlY be configured \(j the RECOVERY MODE oplion by

shorting pill! ] IInd ~ II J1. This oplion enables Ihe ReJlcI/W~ilelIeacis

to mierostep. This ~epositionini oplion mlY be used lifter Ihe conlroller

has completed ill retry oplions on a read error.

RECOVERY MODE is initialed by the controller assenini die

RECOVERY MODE line low (Irue) at Ihe interface. This changes the

STEP line to

now cause SEEK COMPLETE to go false IOOnsec after the drive

ceives the pulse. The drive then microsteJl' olf-tl1lck using the op-

timum algorithm. dlowing 8mSIeCfor the heads to settle, and then

~

,J)

t.

takes the SEEK COMPLETE line true.

The controller may then allempt to read data. If data is not read

com:ctly, the coniroller malYissue Iin additionall Step pulse. Up to

eight scparIte micros\ep algorithms may be: accessed before the se-

quence is repeated.

When data is read correctly, the controller exits RECOVERY MODE

by taking the RECOVERY MODE line false ai the interface. The

drive then returns the heads to the nominal position

COMPLETE false. waiting 8mscc for the heads to settle and reassert-

ing SEEK COMPLETE.

Note:

irUc.

II microslep function aRev iOOnsec. A Step pulse will

by taking SEEK

AU writing is inhibited while the RECOVERY MODE signal is

Il'e-

- DAN! SEl£1 ,

-Ir'_...·-11-'__ .

- DIRECTIONINI

~OON'T:cAAEi'A V/////////tOON'T ~REI/////////

-STEI' -11-'__ :-:11-'-_.

~1J I'

._,.-I-t-':~~~----l

- SEEK COMPlETE I L-

18

FIGURE 15:

Slow-Step Timing

t.

Q"••

ST11' OEMIR,.. i'

$111' OEM/« ••. F IS

Page 26

The control sienals are of two types: those to be multiplexed ina multiple

drive systenn and those intended to do the multiplexine.

The signals co be multiplexed are WRITE GATE. HEAD SELECT 2·,

HEAD SELECT 2', HEAD SELECT 2', HEAD SELECT 2', DIREC-

TION IN. RECOVERY MODE and STEP. These lines are terminated

with a removable

The multiple,ung signals arc DRIVE SELECT I, DRIVE SELECT 2,

DRIVE SELECT J. and DRIVE SELECT 4. These lines arc tenninat-

ed in a sinsl~ fixed 220/JJOQ resistor pair.

Control sigmals are transmitted across the driver/receiver combination

iUustrated below in Figure 12. Control input signals arc activated in

accordance with the following specifications:

True: 0.0 Volts DC to 0.4 Volts DC at I - - 48mA max.

False:

2.S Volts DC to S.2S Volts DC at 1- +2S~A (open collector)

Tenninatlol1O: A 220133012 resistor pack

22O/JJoQ resistor pair.

480

CONTROL

INPUT SIGNALS

FIGURE 13:

ReadfWrite Timing

'I

.-

-_SELECT

~ j-,---

- HEADSEL£CT

--, f -f ---

•..---t:---I -11--_.

~ SwIIdIongI

+MFMVAUD ~

REAODATA -I 1-- -11-"'-'--'

FLAT CABlE OR TWISTED PAIR

4.1

These signals allow the selection of each ReadfV'rite head in a binary

code sequence. The heads are numbered 0 throu)J J. HEAD SELECT

2° is the least significant line. When aU HEAD ~.ELECT lines are high

on the interface. head 0 is selected. Refer below to Figure 1J below

for HEAD SELECT timing.

Note that bolh HEAD SELECT 2' and

ST22S. These lines art present on the interface, but are tenninated.

The drive will not respond to these input signals.

4.2

The active state of this signal. or low level, enables data to be written

to the disc and inhibits carriage motion if WRITE FAULT is active

on the receipt of the first Step pulse. When inactive, Dr high, this sig-

nal enables data to be transferred from the drive and enables Step

pulses to mo"e the heads.

HEAD SELECT 20, 21, 22, 2J

25 arc invalid signals for the

WRITE GATE

FIGURE 12:

Control Signals

DriverjReceiver

Combination

l

of'

"j>

o/j

,,'

~I

-WRITE GATE l1YP.bIIL ~ i=

---.-H ~I-5G-J-

+ W'M WRITE DATA nJlfl------

_led J2rM«I _ I I-

NOTE: HudlIIIIY not be awItched _ WRITE GATE .-.

STEP

The STEP signal is a SOOnsec(minimum width) pulse that intitiates

Read/Write head motion. The number of pulses issued detennines

distance traveled. Pulses are edge-detec:tedon the leadins edge of the

pulse.

The rate of Step pulses determines the access method. If the period

between pulses is from 5,isec to 2~. the access method will be

Buffcred-Seek. Slow-Step is employed if the period between pulses is

greater than or equal to Jmsec.

DIRECTION IN must be stable

the first step pulse and remain stable for iOOnsecal\er the last pulse in

a string of Step pulses. Step pulses issued between 2()(4isecand 3msec

may be lost.

If excessive Step pl:ises are issued which would cause

beyond Cylinder 670 or outward beyoDdCylinder Zero, the drive will

enter the Auto-Tru1cation mode. Refer

11YP.11I••••-,

4.3

1000sec before the leading edge of

II seek inward

10 Section 4.J.J.

16

ml' OEM/Rn. F

m1' OEM/Mn. F

17

Loading...

Loading...