Page 1

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Barracuda 4FC Disc Drive

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ST15150FC

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Product Manual, Volume 1

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Page 2

Page 3

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Barracuda 4FC Disc Drive

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ST15150FC

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Product Manual, Volume 1

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Page 4

© 1995 Seagate Technology, Inc. All rights reserved

September 1995

Publication number: 83329080, Rev. A

Seagate®, Seagate Technology®, and the Seagate logo are registered trademarks of Seagate

Technology, Inc. Elite

TM

, SeaFAXTM, SeaFONETM, SeaTDDTM, and SeaBOARDTM are trademarks of Seagate Technology, Inc. Other product names are registered trademarks or trademarks of their owners.

No part of this publication may be reproduced in any form without written permission from

Seagate Technology, Inc.

Printed in the United States of America

Page 5

Revision status summary sheet

Revision Date Writer/Engineer Sheets Affected

A (draft 1) 4/14/95 L. Newman/J. Coomes All

A (draft 2) 4/17/95 L. Newman/J. Coomes All

A (draft 3) 4/27/95 L. Newman/J. Coomes All

A (draft 4) 5/22/95 L. Newman/J. Coomes All

A (draft 5) 6/19/95 L. Newman/J. Coomes All

A (draft 6) 8/24/95 L. Newman/J. Coomes All

A 9/5/95 L. Newman/J. Coomes All

Page 6

Page 7

ST15150FC Product Manual, Rev. A vii

Contents

1.0 Scope . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

2.0 Applicable standards and reference documentation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2.1 Standards. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2.2 Reference documents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

3.0 General description. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

3.1 Standard features. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

3.2 Media description. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

3.3 Performance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

3.4 Reliability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

3.5 Unformatted and formatted capacities . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3.6 Factory-installed accessories. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3.7 Factory-installed options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3.8 User-installed accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

4.0 Performance characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

4.1 Internal drive characteristics. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

4.2 Seek performance characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

4.3 Thermal calibration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

4.3.1 Seek time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

4.3.2 Format command execution time for ≥ 512-byte sectors . . . . . . . . . . . . . . . . . . . . 10

4.3.3 General performance characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

4.4 Start/stop time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

4.5 Prefetch/multi-segmented cache control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

4.6 Cache operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

4.6.1 Caching write data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

4.7 Synchronized spindle operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

5.0 Reliability specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

5.1 Error rates . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

5.1.1 Environmental interference. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

5.1.2 Interface errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

5.1.3 Write errors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

5.1.4 Seek errors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

5.2 Reliability and service. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

5.2.1 Mean time between failure (MTBF) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

5.2.2 Preventive maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

5.2.3 Service life . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

5.2.4 Service philosophy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

5.2.5 Service tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

5.2.6 Product warranty. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

5.2.7 Hot plugging the drive. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

6.0 Physical/electrical specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

6.1 AC power requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

6.2 DC power requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

6.2.1 Conducted noise immunity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

6.2.2 Power sequencing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

6.2.3 12V current profile . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

6.3 Power dissipation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

6.4 Environmental limits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

6.4.1 Temperature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

6.4.2 Relative humidity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

6.4.3 Effective altitude (sea level reference) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

6.4.4 Shock and vibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

6.4.5 Air cleanliness. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Page 8

viii ST15150FC Product Manual, Rev. A

6.5 Electromagnetic susceptibility . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

6.6 Mechanical specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

7.0 Defect and error management . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

7.1 Drive internal defects/errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

8.0 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

8.1 Drive ID/option selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

8.2 LED connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

8.2.1 J20 connector requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

8.3 Drive orientation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

8.4 Cooling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

8.4.1 Air flow. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

8.5 Drive mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31

8.6 Grounding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31

9.0 Interface requirements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

9.1 General description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

9.2 FC-AL features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

9.2.1 Fibre Channel link service frames . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

9.2.2 Fibre Channel task management functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

9.2.3 Fibre Channel task management responses. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

9.2.4 Fibre Channel port login. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .34

9.2.5 Fibre Channel port login accept. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .35

9.2.6 Fibre Channel Process Login (PRLI). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .35

9.2.7 Fibre Channel Process Accept (ACC) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .35

9.2.8 Fibre Channel Arbitrated Loop options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .36

9.3 Dual port support. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .36

9.4 SCSI interface commands supported . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .36

9.4.1 Inquiry data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .38

9.4.2 Mode Sense data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .39

9.5 Miscellaneous operating features and conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .40

9.6 FC-AL physical interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .41

9.6.1 Physical characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .41

9.6.2 Connector requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .42

9.6.3 Electrical description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .42

9.6.4 Pin descriptions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .43

9.6.5 Synchronized spindles interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .44

9.7 Signal characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .48

9.7.1 TTL input characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .48

9.7.2 LED driver signals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .48

9.7.3 Low drive LED signals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .48

9.7.4 Differential PECL output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .48

9.7.5 Differential PECL input. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .49

10.0 Technical support services. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .51

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .53

Page 9

ST15150FC Product Manual, Rev. A 1

1.0 Scope

This manual describes Seagate Barracuda 4FC (Fibre Channel) disc drives.

Barracuda 4FC drives support the Fibre Ch annel Arbitrate d Loop and S CSI Fi bre Chan nel Pro tocol specif ica-

tions to the extent des cribed in th is manu al. The

77767496) describes the general Fibre Channel Arbitrated Loop characteristics of this and other Seagate Fibre

Channel drives.

Fibre Channel Arbitrated Loop Prod uct Manu al

(part number

Figure 1. Barracuda 4FC family disc drive

Page 10

Page 11

ST15150FC Product Manual, Rev. A 3

2.0 Applicable standards and reference documentation

Seagate takes all reasonable steps to insure that its produ cts are certifiable to currently a ccepted standards.

Typical applications of these disc drives include customer packaging and subsystem design.

Safety agencies conditionally certify compon ent assemblies, such as the Barracuda 4FC disc drive, based on

their final acceptability in the end-use product. The subsystem designer is responsible for meeting these conditions of acceptability in obtaining safety/reg ulatory agency compliance in their end use product and certifying

where required by law.

2.1 Standards

The Barracuda 4FC disc drive is designed to be a UL recognized compon ent per UL1950, CSA certified to

CSA C22.2 No 950-M89, and VDE certified to VDE 0805 and EN60950.

The Barracuda 4FC disc drive is supplied as a component part. It is the responsibility of the subsystem

designer to meet EMC/regulatory requirements established by the FCC, DOC, and VDE. Engineering test

characterizations of radiated emissions are available from the Seagate safety department.

2.2 Reference documents

ST15150FC Installation Guide

Seagate part number: 83329070

Fibre Channel Arbitrated Loop (FC-AL) Product Manual

Seagate part number: 77767496

SCSI Interface Product Manual

Seagate part number: 77738479

ANSI Fibre Channel Documents

X3.230-199x FC Physical and Signaling Interface (FC-PH)

X3.xxx-199x FC Arbitrated Loop (FC-AL)

X3T10-993.D Fibre Channel Protocol for SCSI (FCP)

TBD Direct Disk Attachment Profile

ANSI Small Computer System Interface (SCSI) Documents

X3T9.2/86-109 Rev. 10H (SCSI-2)

X3T10-994D (SCSI-3) Architecture Model

In case of conflict between this document and any referenced document, this document takes precedence.

Page 12

Page 13

ST15150FC Product Manual, Rev. A 5

3.0 General description

Barracuda 4FC drives are random access storage devices designed to support the Fibre Channel Arbitrated

Loop (FC-AL) and SCSI Fib re Channel Protocol as described in the ANSI specificati ons, this document, and

Fibre Channel Arbitrated Loop Product Manual

the

face characteristics of this drive.

You can view the Fibre Channel interface simply as a transport vehicle for the supported command set

(ST15150FC drives use the SCSI command set). In fact, the Fibre Channel interface is unaware of the content

or meaning of the information be ing transported. It simply packs the SCSI comma nds in packets, transports

them to the appropriate devices, and provides error checking to ensure that the information reaches its dest ination accurately. Refer to the documents referenced in Se ct ion 2.2 if you require additional information about

the Fibre Channel interface, FC-AL topology, or the SCSI fibre channel protocol.

The head and disc assembly (HDA) is environm entally sealed at the factory. Air recirculates within the HDA

through a non-replaceable filter to maintain a contamination-free HDA environment.

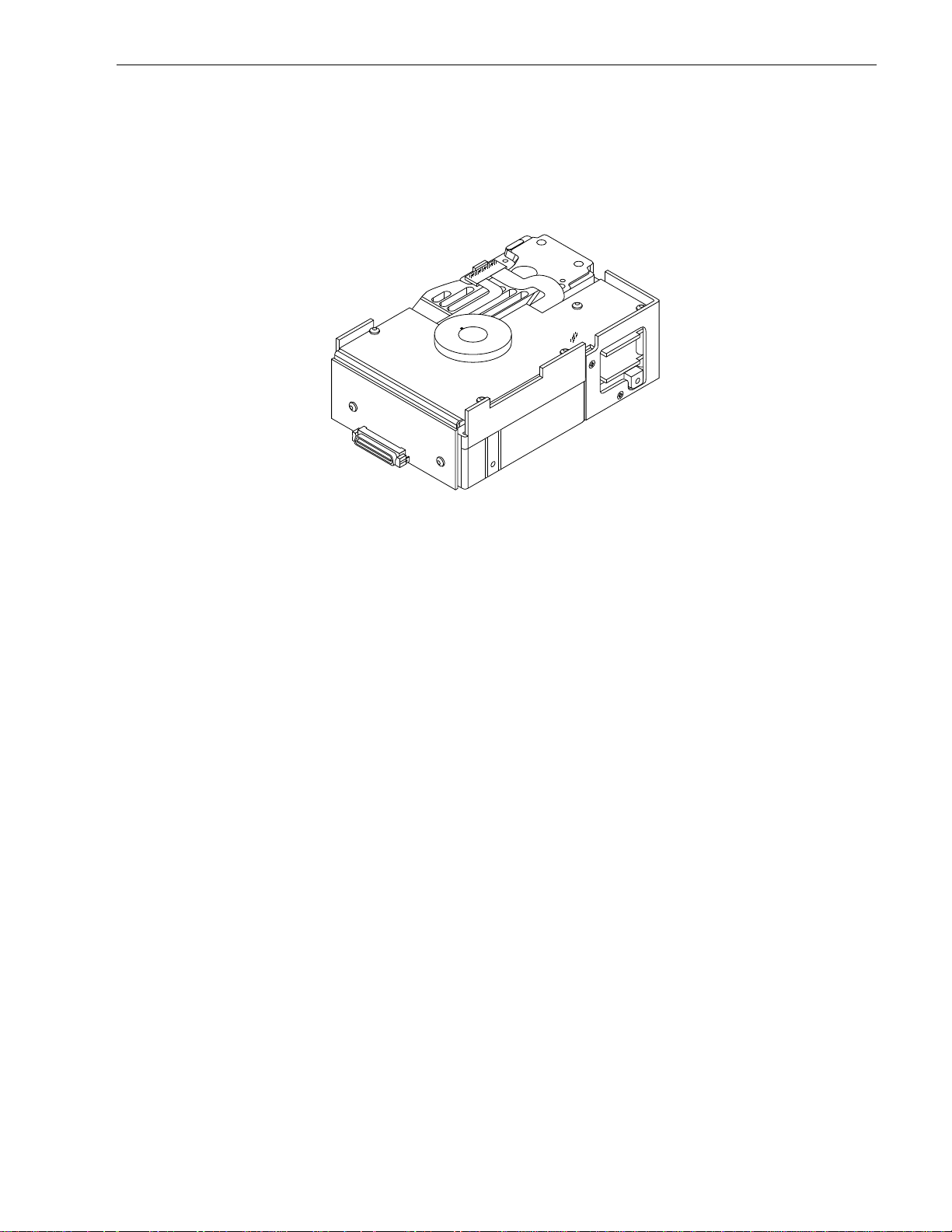

Refer to Figure 2 for an explode d view of the drive. Never disassemble the HDA . This exploded view is for

information only. Do not attempt to service items in the sealed en closure (hea ds, media, actuat or, etc.) as this

requires special facilitie s. The drive contains no p arts replaceable by the user and opening the HDA for any

reason voids your warranty.

(part number 77767496) which describes the general inter-

Figure 2. Barracuda 4FC disc drive

Barracuda 4FC drives use a dedicated landing zone at the innermo st radi us of the me dia to eli minate the pos sibility of destroying or degrading data by landing in the data zone. The head s automatical ly go to the landing

zone when power is removed from the drive.

An automatic shipping lock prevents potential damage to the heads and discs that results from movement during shipping and handling. The shippin g lock disengages and the head load process begins when power is

applied to the drive.

Barracuda 4FC drives decode track 0 locat ion data from the dedicate d servo surface to eliminate mechanical

transducer adjustments and related reliability concerns.

The drives also use a high-performance actu ator assembly design that provides excellent performance with

minimum power dissipation.

Page 14

6 ST15150FC Product Manual, Rev. A

3.1 Standard features

Barracuda 4FC drives have the following standard features:

• Integrated dual port FC-AL controller

• Support for FC-AL (Fibre Channel Arbitrated Loop)

• Differential copper FC drivers and receivers

• Downloadable firmware using the FC-AL interface

• Drive selection ID and configurati on options are set on the FC-AL backpanel , T-card, or through interface

commands. Jumpers are not required on the drive.

• FC world-wide name uniquely identifies the drive and each port

• Supports up to 16 initiators

• User-selectable logical block size (180 to 4,096 bytes)

• Reallocation of defects on command (Post Format)

• User-selectable number of spare sectors per cylinder

• Industry standard 3.5-inch full-high form factor dimensions

• Programmable sector realloca tion scheme

• Flawed sector reallocation at format time

• Programmable autowrite and read reallocation

• Reallocation of defects on command (post format)

• 96-bit Reed-Solomon error correction code

• Sealed head and disc assembly (HDA)

• No preventive maintenance or adjustments required

• Dedicated head landing zone

• Automatic shipping lock

• Automatic thermal compensation

• Embedded Grey Code track address to eliminate seek errors

• Self-diagnostics performed at power on

• 1:1 interleave

• Zone bit recording (ZBR)

• Vertical, horizontal, or top down mounting

• Dynamic spindle brake

• 998 Kbyte data buffer

3.2 Media description

The media used on the dri ve has a diameter of approximately 95 m m (approximately 3.7 inches). The alum inum substrate is coated with a thin film ma gnetic material, overcoated with a proprietary protecti ve layer for

improved durability and environmental protection.

3.3 Performance

• Programmable multi-segmentable cache buffer

• 106.3 Mbytes/sec maximum instantaneous data transfers

• 7,200 RPM spindle; average latency = 4.17 msec

• Command queuing of up to 64 commands

• Background processing of queue

• Supports start and stop commands

• Provides synchronized spindle capability

• Adaptive seek velocity; improved seek performance

3.4 Reliability

• 800,000 hour MTBF (Class A computer room environment)

• Fibre Channel (FC) interface transports SCSI protocol through CRC protected frames

• LSI circuitry

• Balanced low mass rotary voice coil actuator

Page 15

ST15150FC Product Manual, Rev. A 7

3.5 Unformatted and formatted capacities

The standard OEM models are formatted to 512 bytes per block.

ST15150FC drives have nine (9) spare sectors per cylinder and one (1) spare cylinder per unit.

Formatted Unformatted

ST15150FC 4,294 Mbytes 5,062 Mbytes

Users having the necessary equipment may modi fy the data bl ock size before issuing a format command an d

obtain different formatted capacities than those listed. User-available capacity also depends on the spare reallocation scheme you select. See the Mode Select command and the Fo rmat command in the

Arbitrated Loop Product Manual

(part number 77767496).

Fibre Channel

3.6 Factory-installed accessories

OEM standard drives are shipped with the Barracuda 4FC Installation Guide (part number 83329070).

3.7 Factory-installed options

You may order the following items which are incorporated at the manufacturing facility during production or

packaged before shipping:

• Black plastic front panel with green lens (part number 70553702).*

• Black plastic front panel with red lens (part number 70553701).*

• Single-unit shipping pack. The drive is normally shipp ed in bulk packaging to provide maximum protection

against transit damage. Units shipped individually require additional protection as provided by the single unit

shipping pack. Users planning single unit distribution should specify this option.

• ST15150FC Installation Guide, part number 83329070.

*You may order other front panel colors. Each panel has a single rectangul ar LED indicator lens that, when

glowing, indicates the drive is selected.

3.8 User-installed accessories

The following accessories are available. All kits may be installed in the field.

• Front panel kit (green lens), part number 70869751.

• Single-unit shipping pack kit.

• Adapter accessory frame kit, part number 75790701.

(adapts a 3.5-inch drive to fit in a 5.25-inch drive mounting space).

This kit contains the frame to allow a 3.5-inch drive to be mounted in a 5.25-inch drive bay. It includes mounting hardware, front panel with a green lens, an LED with cable that connects to the remote LE D connector,

and installation instructions.

• Evaluation kit, part number 70935895.

This kit provides an adapter card ( “T-card”) to allow cable con necti ons fo r two FC inte rfaces an d D C p ower.

T wo twin axial cables, 6-feet in length, are included for the input and output connections to the FC interfaces.

A small DC fan is included for cooling.

Page 16

Page 17

ST15150FC Product Manual, Rev. A 9

4.0 Performance characteristics

This section provides detailed information concerning performance-related characteristics and features of Barracuda 4FC drives.

4.1 Internal drive characteristics

ST15150FC

Drive capacity 5.062..................................Gbytes (unformatted)

Read/write data heads 21

Bytes per track 64,160................................Bytes (average)

Bytes per surface 232.4..................................Mbytes (unformatted)

Cylinders/tracks per surface 3,711..................................Tracks (user accessible)

Tracks per inch 4,048..................................TPI

Bits per inch 73,820................................BPI

Servo heads 1

Internal data rate 47.5 - 72.0.........................Mbytes/sec (variable with zone)

Disc rotation speed 7,200 ± 0.5%.....................rpm

Avg rotational latency 4.17....................................msec

4.2 Seek performance characteristics

All performance characteristics assume that the rmal calibration is not in process when th e SCSI command is

received. A SCSI command being executed is not interrup ted for therma l calib ratio n. If therma l calib ratio n is in

process when a SCSI command is received, the command is queu ed until the compensation for the specific

head being calibrated com pletes. When compensation completes for the spe cific head being calibrated, the

first queued SCSI command is executed.

Refer to paragraph 9.6, “FC-AL physical interface” and to the

Fibre Channel Arbitrat ed Loop Product Manual

(part number 77767496) for additional timing details.

4.3 Thermal calibration

ST15150FC drives use an automatic therma l calibrati on (TCAL) process to mai ntain a ccurate head al ignmen t

with the data cylinders. The host s ytem may choose to allow the drive to perform TCAL at th e drive’s predefined intervals or the Rezero Unit command may be issued by the host to reset the TCAL timer so that the

host knows when the TCAL will occur.

1. At power up and following a SCSI reset, the drive calibrate s al l of the he ads before any re ad or write co m-

mands are processed. All heads are also calibrated during the SCSI Rezero Unit command.

2. The drive delays 300 seconds before initiating any TCALs. No TCALs occur during this delay period.

3. A single-head TCAL is then scheduled at 7.1 second intervals.

4. After the drive TCALs all of the heads, the interval is increased to schedule a single head TCAL every 14.3

seconds.

5. The drive attempts to find an idle period of 25 to 50 milliseconds prior to performing a single head TCAL. If

this TCAL is delayed for another interval of time, the drive forces the TCAL at the next command boundary.

This guarantees that no head will remain uncalibrated for more than 600 seconds (2 * 21 heads * 14.3 seconds per head) and that no TCALs are closer together than the interval time.

Note. Any TCAL performed during the “standard” retry sequence is limited to the failing head and is disabled

if the host has selects a retry count of zero.

Page 18

10 ST15150FC Product Manual, Rev. A

4.3.1 Seek time

Including drive

controller overhead

Drive level (msec) (msec)

Read Write Read Write

Average typical

Single track typical

Full stroke typical

1. Rate measured from the start of the first sector transfer to or from the host.

2. Typical seek values are measured under nominal conditions of temperature, voltage, and horizontal orientation as measured on a representative sample of drives.

2

2

2

8.09.09.010.0

0.60.91.61.9

17 19 18.0 20.0

1

4.3.2 Format command execution time for ≥ 512-byte sectors

Maximum (with verify) 60 minutes

Maximum (without verify) 40 minutes

4.3.3 General performance characteristics

Minimum sector interleave 1 to 1

Data buffer to/from disc media (512-byte sector)

Data transfer burst rate (≤ 1 sector)

Min

Max

5.30 Mbytes/sec*

8.94 Mbytes/sec*

Data transfer sustained rate (< 1 track)

Min (divided by interleave factor)

Max (divided by interleave factor)

FC-AL interface data

Maximum instantaneous transfer rate 106.3 Mbytes/sec

Sector sizes

Default is 512-byte data blocks

Variable (180- to 4,096-bytes) in multiples of four bytes

Read/write consecutive sectors on a track Yes

Flaw reallocation performance impact (for flaws reallocated using the

spare sectors per track reallocation scheme

Flaw reallocation performance impact (for flaws reallocated using the

spare sectors per cylinder reallocation scheme)

Flaw reallocation performance impact (for flaws reallocated using the

spare tracks per volume reallocation scheme

Overhead time for head switch (512 byte sectors) 0.7 msec

Overhead time for one track cylinder switch 1.6 msec (typical)

Average rotational latency 4.17 msec

*Assumes no errors and no relocated sector s.

3.56 Mbytes/sec*

7.65 Mbytes/sec*

Negligible

Negligible

35 msec (typical)

4.4 Start/stop time

If the Motor Start optio n is disa bled, the drive b ecomes ready w ith 30 seconds after DC power i s applied. If a

recoverable error condition is detected during the start sequence, the drive executes a recovery procedure and

the time to become ready may exceed 30 seconds. During the st art sequence, the drive responds to some

commands over the FC-AL interface. Stop time is less than 30 seconds (maximum) from removal of DC power.

Page 19

ST15150FC Product Manual, Rev. A 11

If the Motor Start option is ena bl ed, the int ernal control ler accep ts the comm ands l isted in the

Product Manual

been received, the drive becomes ready for normal operations within 30 seconds (excluding the error recovery

procedure). The Motor Start command can also be used to co mmand the dri ve to stop the spindl e (see Start/

Stop command information in the

There is no power control switch on the drive.

4.5 Prefetch/multi-segmented cache control

The drive provides a prefetch/multi-segmented cache algo rithm that in many cases can enhance system performance. To sel ect t his featu re th e host sen ds th e M ode Sel ect com man d w ith the p roper val ues in the ap pl icable bytes in page 08h (see the

cache enabled.

4.6 Cache operation

Of the 1,024 Kbytes physical buffer space in the drive, 998 Kbytes can be used as a cache. The cache can be

divided into logical segments from which data is read and to which data is written.

The drive keeps track of the logical block addresses of the data stored in each segment of the cache. If the

cache is enabled (see RCD bit in the

host with a read command is retrieved f rom the cache, i f possible, befo re any disc access is initiate d. Data in

contiguous logical blocks immediately beyond that requested by the Read command can be retrieved and

stored in the cache for immediate transfer to the initiator on subsequent read commands. This is referred to as

the prefetch operation. Since data that is prefetched may replace data alrea dy in the cache segment, an in iti ator can limit the amount of prefetch data to optimize system pe rformance. The drive never prefetches more

sectors than the number specified in bytes 8 and 9 of Mode page 08h (see

Product Manual

writes, with no prefetch operation and no segmented cache operation.

less than 3 seco nds after DC power has been ap plied. After the Motor Start com mand has

Fibre Channel Arbitrated Loop Product Manual

Fibre Channel Arbitrated Loop Product Manual

Fibre Channel Arbitrated Lo op Product Manu al

).

). Default is prefetch and read

), data requested by the

Fibre Channel Arbitrated Loop

). If the cache is not enabl ed, 998 Kbytes of the buffer are used as a circular buffer for read/

FC-AL Interface

The following is a simplified description of the prefetch/cache operation:

Case A—read command is received and the first logical block is already in cache:

1. Drive transfers to the initiator the first logical block requested plus all subsequent contiguous logical blocks

that are already in the cache. This data may be in multiple segments.

2. When a requested logical bl oc k is reached t hat i s not i n any seg men t, the drive fe t ches it a nd any re mai ning requested logical block addresses from t he disc and puts them in a segment of the cache. The d rive

transfers the remaining requested logical blocks from the cache to the initiator in accordance with the

“buffer-full” ratio specification given in Mode Select Di sconnect/Re connect pa ramete rs, page 02h (see the

Fibre Channel Arbitrated Loop Product Manual

3. The drive prefetches additional logical blocks contiguo us to those transferred in step 2 above and stores

them in the segment. The drive stops filling the segment when the maximum p refetch value has been

transferred (see the

Case B—read command is received an d th e fi r st log ical block address reque ste d is not in a ny segm ent o f th e

cache.

1. The drive fetches the requested logical blocks from the d isc and transfers them into a segme nt, and the n

from there to the initiator in accordance with the “buffer-full” ratio specifi cation given in Mode Select Disconnect/Reconnect parameters, page 02h (see the

2. The drive prefetches additional logical blocks contiguous to those transferred in Case A, step 2 above and

stores them in the segment. The drive stops filling the segment when the maximum prefetch value has

been transferred.

During a prefetch, the drive crosses a cyli nde r bou nda ry to fe tch da ta o nl y if the Disconti nui ty (DIS C) bi t is set

to 1 in bit 4 of byte 2 of the Mode Select parameters page 8h. De fault is zero for bit 4 (see the

Arbitrated Loop Product Manual

Fibre Channel Arbitrated Loop Product Manual

).

).

).

Fibre Channel Arbitrated Loop Product Manual

).

Fibre Channel

Each cache segment is actually a self-contained circul ar buffer whose length is an integer num ber of sectors.

The wrap-around capability of the individual segments greatly enhances the cache’s overall performance,

allowing a wide range of user-selectable configurations. The drive supports operation of any integer number of

Page 20

12 ST15150FC Product Manual, Rev. A

segments from 1 to 16. Divide the 998 Kbytes in the buffer by the number of segments to get the segment size.

Default is 3 segments. (See the

Fibre Channel Arbitrated Loop Product Manual.

)

4.6.1 Caching write data

Write caching is a write operation by the drive that makes use of a drive buffer storage area where the data to

be written to the medium is stored while the drive performs the Write command.

Write caching is enabled independently of read caching. The default write cache setting for ST15150FC drives

is with write caching disabled. To enable the write cache, use the Write Caching Enable (WCE) bit.

For write caching, the same buffer space and segmentatio n is used as set up for rea d fun cti ons. When a writ e

command is issued, the cache is first checked to see if any logical b locks that are to be written are already

stored in the cache from a previous read o r write command. If there are, the respective cache segments are

cleared. The new data is cached for subsequent read commands.

If a 10-byte CDB Write command (2Ah) is issued with the data page out (DPO) bit set to 1, no write data is

cached, but the cache segmen ts are still checked and cleared, if need be, for any logi cal blocks that are bein g

written (see the

Fibre Channel Arbitrated Loop Product Manual

).

If the number of write data logical blocks exceeds the size of the segment being written into when the e nd of

the segment is reached, the data is written into the beginning of the same cache segment, overwriting the data

that was written there at the beginning of the operation. However, the drive does not overwrite data that has not

yet been written to the medium.

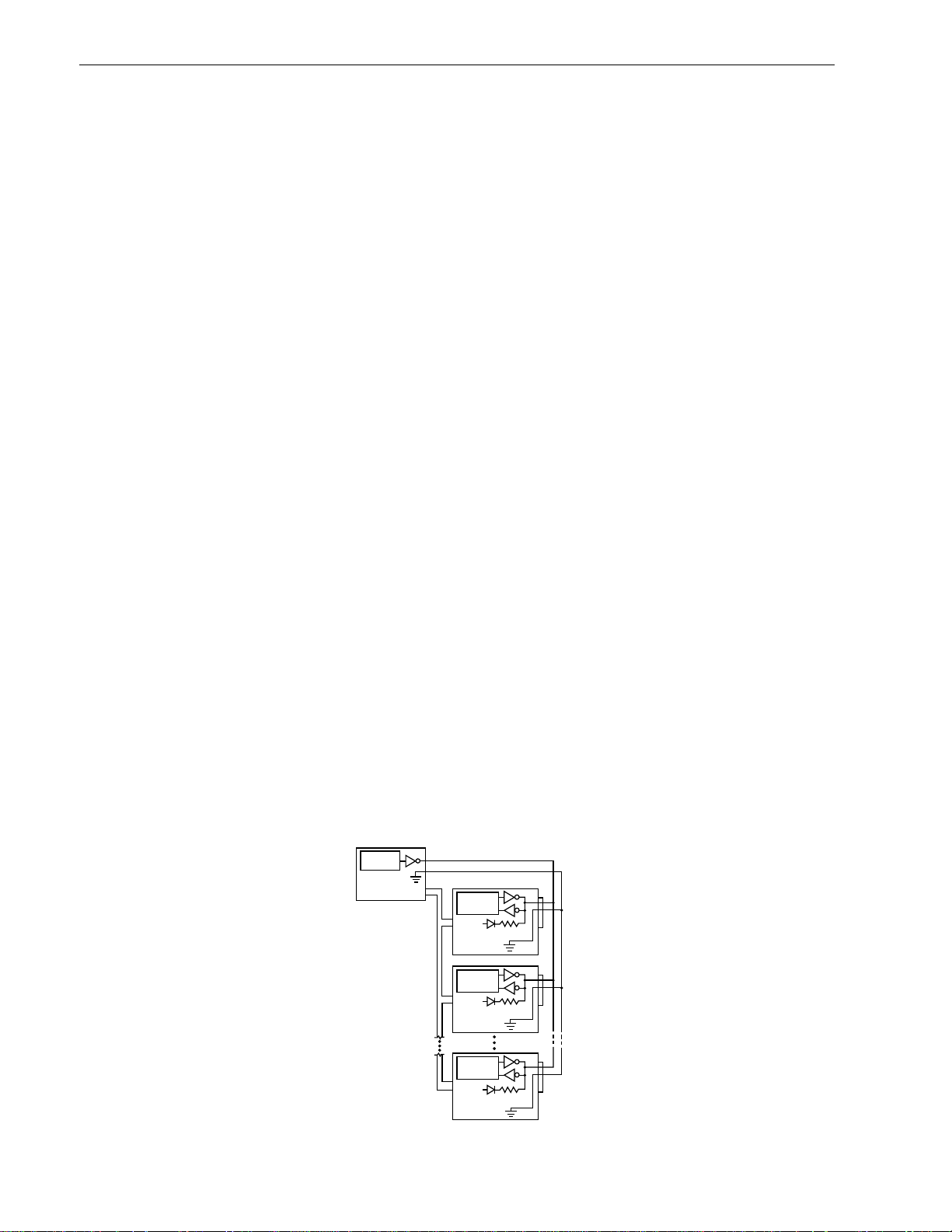

4.7 Synchronized spindle operation

Synchronized spindle operation allows several drives operating from the same host to operate their spindles at

the same synchronized rotational rate. Drives operating in a system in synchronized mode increase the system

capacity and transfer rate in a cost-effective manner.

The spindle sync signal is routed in the backpanel to connect th e dri ves in the synchroni zed s ystem as show n

in Figure 3.

Each drive in the system can be configured by the host (using a Mode Select command) to ope rate in either

the master or slave mode. Drives can be re-configured by the host any time after power-up to be master or

slave by use of the Mode Se lect command Rigid Disc Drive Ge ometry page. The master provides the reference signal to which all other drives phase-lock, including the master. There is only one master per system,

and that can be a drive or the host computer. All drives may be configured as slaves allowing the host to provide the reference signal.

Each drive can be configured for the non-synchronized mode in which it ignores any re ference signal that

might be present—this is the de fault mode as shipped from the facto ry. The connection of the synchronized

reference signal to the host is required only if the host is to provide the reference signal. If the ho st does not

provide the reference signal, the host should not be connected.

Sync Interface

Master Sync

Source

Host

(or other drive)

System

Interface

Spindle

Control

+5V

Drive 1

Spindle

Control

+5V

Drive 2

J6

8

R

T

J6

8

R

T

Figure 3. Synchronized drive interconne ct d iagram

Spindle

Control

+5V

Drive n

J6

8

R

T

Page 21

ST15150FC Product Manual, Rev. A 13

Rotational Position Locking

Note. Mode Select page 4, byte 17, bits 1 and 0.

RPL Description

00b Indicates that spindle synchronization is disabled (default val ue)

01b The target operates as a synchronized spindle slave

10b The target operates as a synchronized spindle master

11b The target operates as a synchronized spindle master control

(not supported by the disc drive)

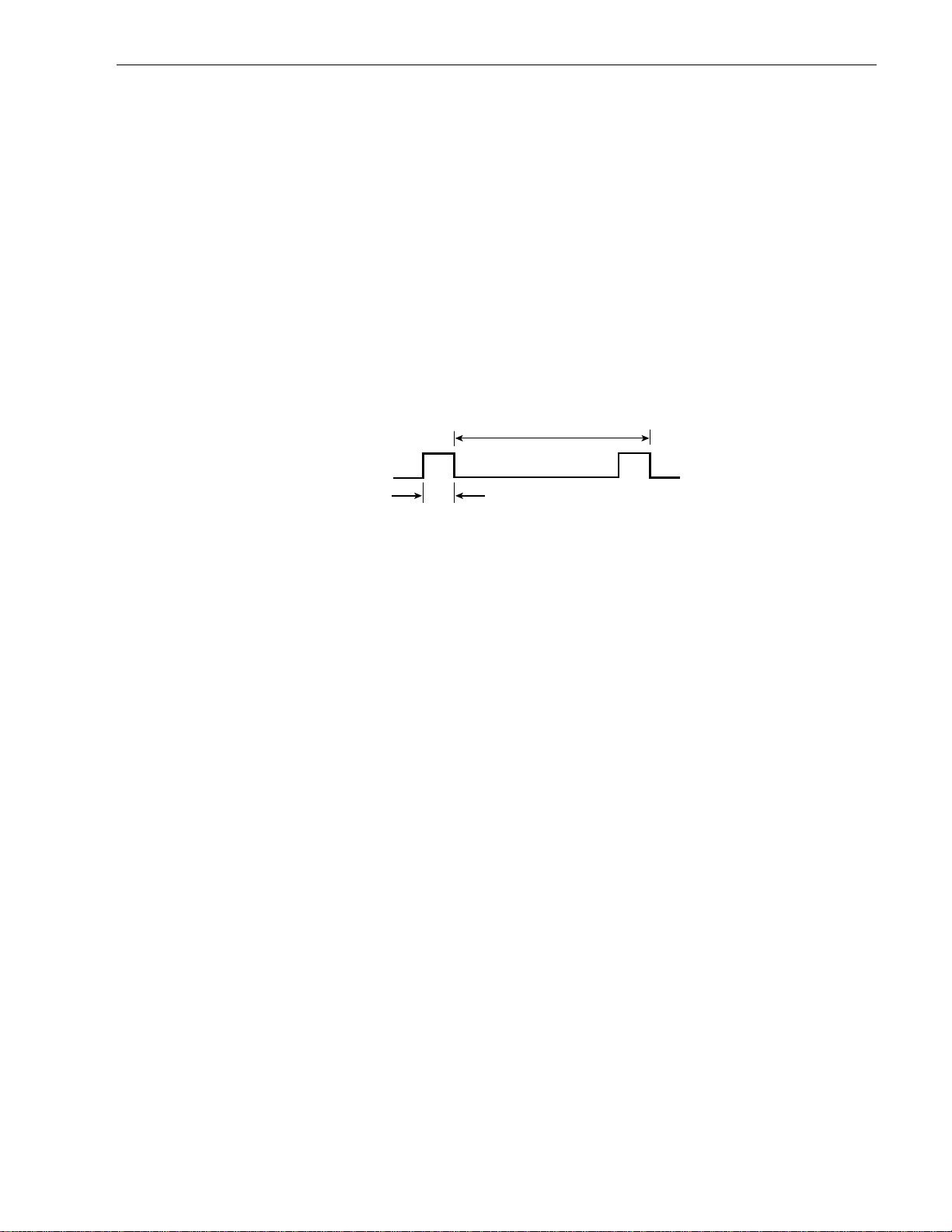

The Pike LSI on the master drive provides the reference signal (SSREF+). The index signal generates a 120

Hz signal. The signal is normally false/negated (nominal 0V) and makes a transition to the true/asserted (nominal +5V) level to indicate the re ference p ositi on d urin g the revolu tio n pe riod. The m aster and slave d rives use

the trailing (falling) edge of the reference signal to phase-lock their spindles. A maxi mum of 10 seconds is

allowed for a slave to synchronize with the reference signal.

Figure 4 shows the characteristics of the reference signal.

T

SSREF +

T = 0.0083 second (± 1.0% max); ± 10 µsec cycle to cycle variance; ± 20 µsec phase error while synchronized

1

0

1.0 µsec min.

1.37 µsec max.

Figure 4. Synchronized reference signal characteristics

SCSI factors

The Rotational Position Lockin g (RPL) field in byte 17 (bits 0 and 1) of the Rigid Disc Drive Geometry mode

parameters page (page 04h) is used for enabling and disabling spindle synchronization mode (see the

Channel Arbitrated Loop Prod uct Manual

). When the target achieves synchronizatio n, it creates a unit atten-

Fibre

tion to all initiators. The sense key is set to Unit Attention and the additiona l sense code set to Spindles Synchronized (5C01).

If subsequent to achieving synchronization the target detects a change of synchronization and:

1. If the logical unit is not executi ng an I/O process for the initiat or, the target creates a unit attention condition. The sense key is set to Unit Attention and the addi tional sense code set to Spindle Synchronized

(5C01) or Spindle Not Synchronized (5C02).

2. If the logical unit is executing an I/O process and no other error occurs, the target returns Check Condition

status. The sense key is set to Recovered Error if the target is able to complete th e I/O process or Hardware Error if the target is unable to complete the I/O process. The additional sense code is set to Spindles

Synchronized (5C01) or Spindles Not Synchronized (5C02).

The drive may be operated with a rotational skew when synchronized. The rotational skew is applied in the

retarded direction (lagging the synchronized spind le master control). A rotational offset of up to 2 55/256 of a

revolution lagging ma y be selected. The amount of offset is selecte d by using the Mode Select command,

Rigid Disc Drive Geometry page (pag e 04), byte 18 ( see the

Fibre Channel Arbitrated Loop Product Manua l

The value in byte 18 (0-FFh) is the numerator o f a fractional multiplier that has 256 a s the denominator. For

example, 40h selects 40h/FFh or 1/4 of a revolution lagging skew; 80h selects 1/2 revolution lagging skew, etc.

Since the drive supports all offset values from 0 to 255, values sent by the initiator are not rounded off. The

drive translation of the digital offset values to physical rotational offsets results in offset values wh ose phase

error lies within the ±20 µsec phase error with respect to the supplied 120 Hz reference signal.

).

The drive does not have the capability to adjust the rot atio nal offset value reque sted by the ini tiator to a physical offset in the drive that corresponds in any way to sector bound arie s or changes in ZBR zon es. Such correspondences or changes, if required, must b e formulated by the initiator for it to calculate the val ue of offset it

sends to the drive.

Page 22

Page 23

ST15150FC Product Manual, Rev. A 15

5.0 Reliability specifications

The following reliability specifi cations assume correct host and drive operational interface, includi ng all interface timings, power supply voltages, and environmental requirements.

Seek error rate: Less than 10 errors in 108 seeks

Recoverable media error rate

(using default settings):

Unrecovered media data: Less than 1 sector in 10

Miscorrected media data: Less than 1 sector in 10

Interface error rate: Less than 1 error in 1012 bits transferred with minimum receive eye. Less than 1

MTBF: 800,000 hours

Service life: 5 years

Preventive maintenance: None required

Less than 10 errors in 10

14

error in 10

ential PECL input.”

bits transferred with typical receive eye. See Section 9.7.5, “Differ-

5.1 Error rates

The error rates stated in this manual assume the following:

• The drive is operated in accordance w ith this manual using DC power as defined in pa ragraph 6.2, “DC

power requirements.”

• The drive has been formatted with the SCSI format commands.

• Errors caused by media defects or host system fai lu res are exclud ed fro m error rate comp utati on s. Refer t o

Section 3.2, “Media descriptio n.”

11

bits transferred

14

bits transferred

21

bits transferred

5.1.1 Environmental interference

When evaluating systems operation under conditions of electrom agnetic interference (EMI), the performance

of the drive within the s ystem is con sidered accepta bl e if the drive does n ot g ene rate a n un recove rabl e cond ition.

An unrecoverable error, or condition, is defined as one that:

• is not detected and corrected by the drive itself, or

• is not capable of being dete cted from the error o r faul t statu s p rovided throu gh th e dri ve or FC -AL inte rface ,

or

• is not capable of being recovered by normal drive or s ystem recovery procedures with out op erator interven-

tion.

5.1.2 Interface errors

An interface error is defined as a failure of the receiver on a port to recover the data as transmitted by the

device port connected to the receiver. The error may be detected as a running disparity error, illegal code, loss

of word sync, or CRC error. The total error rate for a loop o f devices is the sum of th e individual de vice error

rates.

5.1.3 Write errors

Write errors can occur as a result of media defects, e nvironmental interference, or equ ipment malfunction.

Therefore, write errors are not predictable as a function of the number of bits passed.

If an unrecoverable write error occurs because of an equipment malfunction in the drive, the error is classified

as a failure affecting MTBF. Unrecoverable write errors are those that cannot be corrected with in two a ttem pts

at writing the record with a read verify after each attempt (excluding media defects).

5.1.4 Seek errors

A seek error is defined as a failure of the drive to position the hea ds to the a ddressed track. There must be n o

more than one recoverable seek error in 10

7

physical seek operations. Aft er de tectin g a n initia l seek error, the

drive automatically reseeks to t he addressed track up to three time s. If a reseek is successful, the Exte nded

Sense reports a seek positioning error (15h), no seek comp lete error (02h), or track follow error (09h), and the

Page 24

16 ST15150FC Product Manual, Rev. A

sense key reports a recovered error (1h). If all three reseeks fail, a seek positioning error (15h) is reported with

a Medium (3h) or Hardware error (4h) reported in the Sense Key. This is an unrecoverable seek error. Unrecoverable seek errors are classified as failures for MTBF calculations. Refer to paragraph 5.1.1.2 of

Channel Arbitrated Loop Product Manual

5.2 Reliability and service

The reliability of Barracuda 4FC disc drives can be enhanced by ensuring that the drive receives adequate

cooling. This section provides recommended air-flow information, temperature measurements, and other information, which may be used to enhance the service life of the drive.

5.2.1 Mean time between failure (MTBF)

The production disc drive achieves a n MTBF of 800,000 hours when ope rated in an average local disc drive

ambient temperature of 9 5°F (35°C) o r less. Sho rt-term excursions up to the spe cificat ion limits of the op erating environment will not affect MTBF performance.

The following expression defines MTBF:

MTBF = Estimated power-on operating hours in the period

Estimated power-on operating ho urs means the estimate d total power-on h ours for all drives in service. Drive

failure means any stoppage or substandard performance caused by drive malfunction.

(part number 77767496).

Number of drive failures in the period

Fibre

Data is calculated on a rolling-average base for a minimum period of six months.

5.2.2 Preventive maintenance

No routine scheduled preventive maintenance is required.

5.2.3 Service life

The drive has a useful service life of five years. Depot repair or rep lacem ent of m ajor parts is permitt ed d urin g

the lifetime.

5.2.4 Service philosophy

Special equipment is required to repair the drive HDA. To achieve the above service life, repairs must be performed only at a properly equi pped a nd staffed service and rep air facility. Troubleshooting and repair of PCBs

in the field is not recommended because of the extensive diagnostic equipment required for effective servicing.

Also, there are no spare parts available for this drive. The drive warranty is voided if the HDA is opened.

5.2.5 Service tools

No special tools are required for site installation or recommended for site maintenance. Refer to paragraph

5.2.2, “Preventive main tenance.” The depot repair philosophy of the drive precludes th e necessity for special

tools. Field repair of the drive is not practical because users cannot purchase individual parts for the drive.

5.2.6 Product warranty

Beginning on the date of shipme nt to the custom er and co nti nui ng fo r a period of fi ve years, Seagat e warrants

that each product (including components and subassemblies) or spare part that fails to function properly under

normal use due to defect in materials or workmanshi p or due to nonconformance to the applicab le specifications will be repaired or replaced, at Seagate’s option and at no charge to the customer, if returned by customer at customer’s expense to Seagate’s designated facility in accordance with Seagate’s warranty

procedure. Seagate will pay for transportin g th e repa ir or repl aceme nt i tem to th e custome r. For more detailed

warranty information, refer to the standard terms and conditions of purchase for Seagate products on your purchase documentation.

Page 25

ST15150FC Product Manual, Rev. A 17

Shipping

When transporting or shipping a drive, a Seaga te approved containe r must be used. Keep you r original box.

They are easily identifie d by the Seagate Approved Package label. Shipping a drive i n a non-approved container voids the drive warranty.

Seagate repair centers may refuse recei pt o f comp one nts imprope rly packaged or ob vi ousl y d ama ged in transit. Contact your auth orized Seaga te distributor to purchase additional boxes. Seagate recom mends shipp ing

by an air-ride carrier experienced in handling computer equipment.

Product repair and return information

Seagate customer service centers are the onl y facilities authorized to service Seagate drives. Seagate does

not sanction any third-party repair facilities. Any unauthorized rep air or tampering with t he factory-seal voids

the warranty.

5.2.7 Hot plugging the drive

Inserting and removing the drive o n the FC-AL will disrupt loop op eration. The disruption occurs when the

receiver of the next device in the loop must s ynchronize to a d ifferent input signal. FC e rror detection mechanisms, character sync, running disparity, word sync, and CRC are able to detect any error. Recovery is initiated

based on the type of error.

The Barracuda 4FC disc drive defaults to the FC-AL Monitorin g st ate, Pass-through state, when it is powe redon by switching the power or hot plugged. The control l ine to an optional port bypass circuit (external to the

drive), defaults to the Enable Bypass state. If the bypass circuit is present, the next device in the loop will continue to receive the output of the previous device to the newly inserted device. If the bypass circuit is not

present, loop operation is temp oraril y d isrupted unt il the n ext device sta rts receivi ng th e ou tput from th e ne wly

inserted device and regains synchronization to the new input.

The Pass-through state is disabled wh ile th e d isc perfo rms self test o f th e FC int erface. The con trol line for a n

external port bypass circuit remains in the Enable Bypass state while self test is running. If the bypass circuit is

present, loop operation may continue. If the bypass circuit is not present, loop operation will be halted while the

self test of the FC interface runs.

When the self test completes successfully, the control line to the bypass circuit is disabled and the drive enters

the FC-AL Monitoring state, Pass-though st ate. The receiver on the next device in the loop must synchronize

to output of the newly inserted drive.

If the self test fails, the control line to the bypass circuit remains in the Enable Bypass state.

Note: It is the responsibility of the s ystems integrat or to assure th at n o t emp erature, en ergy, or voltage hazard

is presented during the hot connect/disconn ect (hot plug) operation. Discharge the static electricity from th e

drive carrier prior to inserting it into the system.

Page 26

Page 27

ST15150FC Product Manual, Rev. A 19

6.0 Physical/electrical specifications

This section provides information relating to the physical and ele ctrical characteristics of Barracuda 4FC disc

drives.

6.1 AC power requirements

None.

6.2 DC power requirements

The voltage and current requi rements for a single drive are shown bel ow. Values indi cated apply at the drive

connector.

Table 1: DC power requirements

+5V

±5V

Voltage Regulation Notes [5]

Avg idle current [1] [8] 1.03 1.25

Max start current (peak DC) [3] [6] 1.44 2.42

Delayed motor start (max) [1] [4] 1.23 0.67

Operating current

Typical [1] [7] 1.28 1.42

Maximum [1] 1.32 1.49

Max (peak) 1.46 2.35

(Amps)

+12V

[2]

±5V

(Amps)

[1] Measured with average reading DC a mmeter. Instantaneous +12V current peaks will e xceed these val-

ues.

[2] A -10% tolerance is allowed during initial spindle start but must return to ±5% before reaching 7,200 RPM.

The ±5% must be maintained after the drive signifies tha t its power-up sequence has b een completed

and that the drive is able to accept selection by the host initiator.

[3] See +12V current profile in Figure 5.

[4] This condition occurs when the Motor Start option is enabled and the drive has not yet received a Start

Motor command.

[5] See paragraph 6.2.1, “Conducted noise immunity.” Specified voltage tolerance includes ripple, noise, and

transient response.

[6] At power-up the motor current regulator limits the 12V current to an average value o f less than 2.18A,

although instantaneous peaks may exceed thi s value. These peaks should measure 5 msec duratio n or

less.

[7] Operating condition means a third stroke seek at OD and Read One track. A command is issued every

0.075 seconds.

[8] All power-saving features enabled.

General DC power requirement notes.

1. Minimum current loading for each supply voltage is not less than 7% of the maximum operating current

shown.

2. The +5V and +12V supplies should employ separate ground returns.

3. Where power is provided to multiple drives from a common supply, careful consideration for individual

drive power requirements should be noted . Whe re mul tip le units are powered on sim ulta neo usly, the peak

starting current must be available to each device.

Page 28

20 ST15150FC Product Manual, Rev. A

6.2.1 Conducted noise immunity

Noise is specified as a periodic and random distribution of fre quencies covering a band fro m DC to 10 MHz.

Maximum allowed noise val ues given below are peak-to-peak measurements and apply at the d rive power

connector.

+5V +12V (with spindle motor not running)

0 to 100 kHz 150mV 150mV

100 kHz to 10 MHz 100mV 100mV

6.2.2 Power sequencing

The drive does not require power sequencing . The drive protects again st inadvertent writ ing during power-up

and down.

6.2.3 12V current profile

Figure 5 identifies the drive +12V current profile. The current during the various times is as shown:

4

3

Peak AC

Nominal (average) curve

2

+12V CURRENT (A)

1

T0

T1

0

04286101412 16 18 20

T2

TIME (S)

Minimum AC

T3

T4

T5

T6

Figure 5. Typical Barracuda 4FC drive +12V current profile

T0 Power is applied to the drive.

T1 Controller self-tests are performed.

T2 Spindle begins to accelerate under current limiting after performing internal diagnostics.

T3 The spindle is up to speed and the Head-Arm restraint is unlocked.

T4 Heads move from the landing zone to the data area.

T5 The adaptive calibration sequence is performed.

T6 Calibration is complete and the drive is ready for reading and writing.

T7

Note. All times and currents are typical. See Table 1 for maximum current requirements.

6.3 Power dissipation

Typical seek power dissipation is 23 watts (79 BTUs per hour) of DC power average at nominal voltages. Typical power dissipation under idle conditions is 20 watts (68 BTUs per hour).

Page 29

ST15150FC Product Manual, Rev. A 21

6.4 Environmental limits

Temperature and hu midit y val ues experie nced by the drive must be such tha t co nde nsatio n doe s not occur on

any drive part. Altitude and at mospheric pressure specifications are referenced to a standard day at 58.7°F

(14.8°C). Maximum wet bulb temperature is 82°F (28°C).

6.4.1 Temperature

a. Operating

The MTBF specification for the drive (800, 000 h ours) is based on o perati ng at a l ocal amb ien t tem peratu re

of 95°F (35°C). Occasiona l excursions to drive ambi ent temperatures to 122°F (50°C) may occur without

impact to specified MTBF. The enclosure for the drive should be designed such that the case tempe ratures

at the locations specified i n Figures 11 and 12 are not exceeded. Air flow is needed to achie ve these temperature values. Continual or sustained operation at ca se temperatures above these values may degrade

MTBF.

The drive meets all specifications over a 41°F to 122°F (5°C to 50°C) drive ambient temperature range with

a maximum gradient of 36°F (20°C) pe r hour when the case temperature limits specified above are not

exceeded.

b. Non-operating

Non-operating temperature should remain between -40°F to 158°F (-40°C to 70°C) package ambient with a

maximum gradient of 36°F (20°C ) per hour. This assumes that the drive is packaged in the shipp ing container designed by Seagate.

6.4.2 Relative humidity

The values below assume that no condensation on the drive occurs.

a. Operating

5% to 95% relative humidity with a maximum gradient of 10% per hour.

b. Non-operating

5% to 95% relative humidity.

6.4.3 Effective altitude (sea level reference)

a. Operating

-1,000 to +10,000 feet (-305 to +3,048 meters)

b. Non-operating

-1,000 to +40,000 feet (-305 to +12,210 meters)

6.4.4 Shock and vibration

Shock and vibration limits specified in this document are measured directly on the drive chassis. If the drive is

installed in an enclosure to which the stated shock and /or vibrati on c riteria are appl ie d, resona nces may occur

internally to the enclosure resultin g in drive movement in excess of t he stated limits. If this si tuation is apparent, it may be necessary to modify the enclosure to minimize drive movement.

The limits of shock and vibrati on defined within this document are speci fied with the drive mounted in one of

the two methods shown in Figure 9.

6.4.4.1 Shock

a. Operating (normal)

The drive, as installed for normal ope ration, shall operate error free while sub jected to intermittent shock

not exceeding 2.0 Gs at a maximum duration of 11 msecs (half sinewave). Shock may be applied in the X,

Y, or Z axis.

Page 30

22 ST15150FC Product Manual, Rev. A

b. Operating (abnormal)

Equipment as installed for normal operat ion shall not incur physical damage whi le subjected to intermi ttent

shock not exceeding 10 Gs at a maximum duration of 11 msecs (half sinewave). Shock occurring at abnormal levels may promote degraded ope rational performance during the abnormal shock period. Speci fied

operational performance will continue when normal operati ng shock levels resume. Shock may be a pplied

in the X, Y, or Z axis. Shock is not to be repeated more than two times per second.

c. Non-operating

The limits of non-operating sho ck shall app ly to al l co nditio ns of han dling and transpo rtation. This inclu des

both isolated drives and integrated drives.

The drive subjected to non-repetit ive shock not exceedi ng 50 Gs at a maxim um durati on of 11 msecs (half

sinewave) will not exhibit device damage or performance degradation. Shock may be applied in the X, Y, or

Z axis.

d. Packaged

The drive as packaged in a single or multi ple drive pack of gross weight 20 pounds (8.95 kg) or less by

Seagate for general freight shipm ent sha ll withstand a drop test from 48 inches (1,070 m m) again st a co ncrete floor or equivalent.

6.4.4.2 Vibration

a. Operating (normal)

The drive as installed for normal ope ration shall ope rate error free while subj ected to continuous vibra tion

not exceeding:

5-400 Hz @ 0.5 G

Vibration may be applied in the X, Y, or Z axis.

b. Operating (abnormal)

Equipment as installed f or normal operation shall not incur physical dama ge while subjected to periodic

vibration not exceeding:

15 minutes of duration at major resonant frequency

5-400 Hz @ 0.75 G

Vibration occurring at these levels may degrade operating performance during the abnormal vibration

period. Specified operating performan ce will conti nue when normal operati ng vibration le vels are resumed .

This assumes system recovery routines are available. Ab normal vibration may be app lied in the X, Y or Z

axis.

c. Non-op erating

The limits of non-operating vibration shall apply to all conditions of handling and transportation. This

includes both isolated drives and integrated drives.

The drive shall not incur physical damag e or degrad ed performa nce as a resu lt of cont inuous vib ration no t

exceeding:

5-22 Hz @ 0.040 in. (1.02 mm) displacement

22-400 Hz @ 2.00 Gs

Vibration may be applied in the X, Y, or Z axis.

6.4.5 Air clea nliness

The drive is designed to operate in a typical office environment with minimal environmental control.

6.5 Electromagnetic susceptibility

As a component part, the drive is not required to meet any susceptibility performance requ irements. It is the

responsibility of the system integrator to perform tests required to ensure that equipment operating in the same

system as the drive does not adversely affect the performance of the drive. See paragraph 6 .2, “DC power

requirements.”

Page 31

ST15150FC Product Manual, Rev. A 23

6.6 Mechanical specifications

The following nominal dimension s are exclusive of the decorative front panel accessory. Refer to Figure 6 for

detailed mounting configuration dimensions for the drive. A minimum clearance of 0.050 in. (1.27 mm) must be

maintained from the PWA side of the drive.

Height 1.63 in 41.4 mm

Width 4.00 in 101.6 mm

Depth 5.97 in 151.6 mm

Weight 2.3 lb 1.04 kilogram s

M

F

.809 ref

H

B

Motherboard ref

.136

N

K

A

[2]

J

1.875 ± .005 1.875 ± .005

Figure 6. Mounting configuration dimension s

ED

Notes:

Mounting holes two on each

[1]

side, 6-32 UNC. Max screw

length into side of drive is

0.15 in. (3.81 mm).

Mounting holes four on bottom,

[2]

6-32 UNC. Max screw length

into bottom of drive is 0.15 in.

(3.81 mm).

Inches Millimeters

A

5.965

B

4.000

C

1.615

D

.620

E

4.000

F

.250

G

1.750

H

3.750

J

2.365

K

1.750

L

0.181

M

1.615

N

1.839

L

[1]

.508

151.511

101.60

41.02

15.748

101.60

6.35

44.45

95.25

60.071

44.45

4.59

41.021

46.70

±

.25

±

.86

±

.50

±

.13

±

.13

±

.25

±

.25

±

.25

±

.50

±

.381

±

.863

±

.56

±

0.020

±

0.010

±

0.034

±

0.020

±

0.005

±

0.005

±

0.010

±

0.010

±

0.010

±

0.010

±

0.015

±

0.034

±

0.022

±

Page 32

Page 33

ST15150FC Product Manual, Rev. A 25

7.0 Defect and error management

The drive, as delivered, complies wi th th is pro duct m anu al. The read error rates an d spe cifie d storag e cap acities are not dependent upon use of defect management routines by the host (initiator).

Defect and error management in the SCSI protocol involves the drive internal defect/error manageme nt and

FC-AL system error considerations (errors in communications betwe en the initiator and the drive). Tools for

use in designing a defect/error ma nagement p lan are brie fly outlined in th is section. Referen ces to other sections are provided when necessary.

7.1 Drive internal defects/errors

Identified defects are recorde d on the drive defects l ist tracks (referred to as the pri mary or ETF defect list).

These known defects are rea llocated during the initial dri ve format operation at the factory. See the Format

Unit command in the

by ECC is applied to recover data from additional flaws if they occur.

Fibre Channel Arbitrated Loop Produ ct Manu al

(part number 77767496). Data correction

Details of the SCSI comman ds supported by the drive are described in the

Product Manual

Channel Arbitrated Loop Product Manual

. Also, more information on the drive Error Recovery philosophy is presented in the

.

Fibre Channel Arbitrated Loop

Fibre

Page 34

Page 35

ST15150FC Product Manual, Rev. A 27

8.0 Installation

ST15150FC disc drive installation is a plug-and-play process. There are no jumpers, switche s, or terminators

on the drive which need to be set. Simply plug the drive into the ho st’s 40-pin Fibre Channel backpanel connector (FC-SCA)

connector.

The FC-AL interface is used to select drive ID and all option configurations for devices on the loop.

If multiple devices are on the same FC-AL and physical addresses are used, set the device selection IDs (SEL

IDs) on the backpanel so that no two devices have the same selection ID. This is called the hard assigned arbitrated loop physical address (AL_PA). There are 125 AL_PAs available (see Table 18 on page 47). If you set

the AL-P A on the backpanel to any value other than 0, the device plugged into the backpanel’s SCA connector

inherits this AL_PA. In the event you don’t successfully assign un ique hard addresses (and therefore have

duplicate selection IDs assigned to two or more devices), the FC-AL genera tes a message indi catin g this co ndition. If you set the AL-PA on the backpanel to a value of 0, the system issues a unique soft-assigned physical

address automatically.

Loop initialization is the process used to verify or obtain an address. The loop initialization process is performed when power is ap plied to th e drive, when a device is added or removed from the FC l oop, or when a

device times out attempting to win arbitration.

• Set all option selecti ons in the connector prior to applying power to the drive. If you change options after

applying power to the drive, recycle the drive power to activate the new settings.

• It is not necessary to low level format th is drive. The d rive is shippe d from the factory low le vel formatte d in

512-byte sectors. You need to reformat the drive onl y if you want to select a different sector size or if you

select a different spare sector allocation scheme.

–no cables are required. Refe r to Secti on 9.6 on pag e 41 fo r addi tion al info rm ati on ab out th is

8.1 Drive ID/option selection

All ST15150FC drive options are made through the interface connector (J6). Table 15 on page 43 provides the

pin descriptions for the 40-pin FC single connector (J6).

8.2 LED connections

A connector, J20, is provided on the LYJX board to provide port bypass, drive active, and drive fault LED connections (see Figure 8). Refer to Section 9.6.5.3 for a description of the Port Bypass LED function. Refer to

Section 9.6.5.2 for a description of the Active LE D function. Refer to Section 9. 6.4.3 for a description of th e

Fault LED function.

Note. The LYJX-0 board does not have the J20 connector.

J20

J6

Figure 7. Barracuda 4FC drive physical interface

Page 36

28 ST15150FC Product Manual, Rev. A

Pin 1J20

Pin 2

J20

Port A Bypass LED*

Port B Bypass LED*

Active LED*

Fault LED*

Ground

+5V

Figure 8. Barracuda 4FC LED indicator connector

Pin 1

Pin 2

* Low power LED required. See Table 22. The drive

has a 2.26 K resistor in series with this LED driver.

Connect the LED from +5V to the appropriate LED

output pin.

8.2.1 J20 connector requirements

Recommended mating connector part number: Berg receptacle, 6-position, part number 690-006.

Page 37

ST15150FC Product Manual, Rev. A 29

8.3 Drive orientation

The drive may be mounted in an y orientation. All drive performance charact erizations, however, have been

done with the drive in horizontal (discs level) and vertical (drive on its side) orientations, which are the two preferred mounting orientations.

Figure 9. Recommended mounting

8.4 Cooling

Cabinet cooling must be d esigned by th e customer so that the ambi ent temperat ure immediatel y surrounding

the drive will not exceed temperature condit ions specified in Section 6.4.1, “Temperature.” Specific consideration should be given to make sure adequate air circulation is present around the printed circuit board (PCB) to

meet the requirements of Section 6.4.1, “Temperature.”

8.4.1 Air flow

The rack, cabinet, or drawer environment for the Barracuda 4FC drive must provide cooling of the electronics

and head and disc assembly (HDA). You should confirm that adequate cooling is provided using the temperature measurement guidelines described below.

The drive should be oriented, or air flo w directed, so that the least amount of air flow resistance i s created

while providing air flow to the electron ics and HDA. Also, the shortest possib le path between the air inlet an d

exit should be chosen to minimize the travel length of air heated by the drive and other heat sources within the

rack, cabinet, or drawer environment.

Possible air flow patterns are shown in Figure 10. The air flow patterns are created by one or more fans, either

forcing or drawing air as shown in the illustrations. Other air flow patterns are acceptab le as long as the temperature measurement guidelines are met.

Page 38

30 ST15150FC Product Manual, Rev. A

Above unit

Note. Air flows in the direction shown (back to front)

or in reverse direction (front to back)

Note. Air flows in the direction shown or

in reverse direction (side to side)

Under unit

Above unit

Under unit

Figure 10. Air flow

To confirm that the required cooling for the electronics and HDA is provided, place the drive in its final mechanical configuration, perform random write/read operations and, after t he temperatures stabilize, measure th e

case temperature of the components listed below.

Air flow cooling

MTBF

800k hours

Card Component Reference

case temperature (°C)

LYJX Transmitter 1 76

LYJX Writer 2 62

LYJX Memory 3 51

LYJX Aurora 4 73

LYJX Driver 5 55

To obtain the maximum temperature for each of the reference components listed, add 15°C to the 800K MTBF

case temperatures. Operation of the drive at the maximum case temperature is intended for short time periods

only. Continuous operation at the elevated temperatures will reduce product reliability.

The air-flow pattern with which the tem peratu re gui del ines above were ge nerate d is sh own i n Figure 10. Local

average air velocities were 1.2 m/sec (23 0 lfp m) an d inlet air te mpe rature to the drive wa s 30 °C (86 °F), pl us a

5°C temperature rise in the test enclosure (35°C ambient local to the drive).

The maximum allowable HDA case temperature is 60°C (see Figure 12)

Page 39

ST15150FC Product Manual, Rev. A 31

1

Figure 1 1. LYJX temperature measurement locations

2

4

53

1.00

.50

Figure 12. HDA case temperature measurement loca tion

8.5 Drive mounting

Mount the drive using the bottom or side mounting holes. If you mount the drive using the bottom holes, ensure

that you do not physically distort the drive by attempting to mount it on a stiff, non-flat surface.

The allowable mounting surface stiffness is 80 lb/in (14.0 N/mm). The following equation and paragraph define

the allowable mounting surface stiffness:

80 lb

F

k = = or

x

in

14.0 N

mm

where k is the mounting surface stiffness (units in po unds or ne wton ) and x is th e out -of-pla ne d istorti on (un its

in inches or millimeters). The out-of-plane distortion (x) is determi ned by def ining a plane with three of the four

mounting points fixe d and evaluating the out-of-plane defection of the fourth mounting point when a known

force (F) is applied to the fourth point.

8.6 Grounding

Signal ground (PCB) and HDA ground a re connecte d togethe r in the Barracuda 4 family drives—d o not sep arate this connection. Maximizing the condu ctive contact area between HDA ground and system ground may

reduce radiated emissions. A bracket shield with tapped holes is availab le to system integrators. This shield

makes it easier to attach a braid or similar high-frequency grounding de vice. If you do not want the s ystem

chassis to be connecte d to the HDA/PCB ground, you must pro vide a nonconductive (electrically isolatin g)

method of mounting the drive in the host equipment; however, this may increase radiated emissions and is the

system designer’s responsibility.

Page 40

Page 41

ST15150FC Product Manual, Rev. A 33

9.0 Interface requirements

This section partially describes the interface requ irements as implemented on ST1515 0FC drives. Additional

information is provided in the

77738479).

9.1 General description

Fibre Channel Arbitrated Loop Interface Product Manual

(part number

The major portion of the interface requirements/implementation is described in the Seagate

Arbitrated Loop Interface Product Ma nual

. This section provides info rmation about ST15150FC drive imple-

mentation of the FC-AL standard.

9.2 FC-AL features

This section lists the Fibre Channel-specific features supported by ST15150FC drives.

9.2.1 Fibre Channel link service frames

Table 2 lists the link services supported by ST15150FC drives.

Table 2: Link services supported

Type of frame Link service

Basic link service frames Abort Sequence (ABTS)

Basic link service reply frames Basic_Accept (BA_ACC)

Basic_Reject (BA_RJT)

Extended link service frames N_Port Login (PLOGI)

Logout (LOGO)

Process Login (PRLI)

Process Logout (PRLO)

Read Link Status (RLS)

Port Discovery (PDISC)

Extended link service reply frames Accept (ACC)

Link Service Reject (LS_RJT)

Fibre Channel

9.2.2 Fibre Channel task management functions

Table 3 lists the FC SCSI FCP task management functions supported.

Table 3: Fibre Channel SCSI FCP task management functions

Task name Supported

Terminate task No

Clear ACA Yes

Target reset Yes

Clear task set Yes

Abort task set Yes

9.2.3 Fibre Channel task management responses

Table 4 lists the Fibre Channel SCSI FCP response codes returned for task management functions supported.