Users Guide

Savvio SCSI

ST973401LC

ST936701LC

Users Guide

Savvio SCSI

ST973401LC

ST936701LC

©2003, 2004, 2005, Seagate Technology LLC All rights reserved

Publication number: 100293075, Rev. C

June 2005

Seagate and Seagate Technology are registered trademarks of Seagate Technology LLC.

Savvio, SeaTools, SeaFONE, SeaBOARD, SeaTDD, a nd the Wave logo are either registered trademarks or trademarks of Seagate T echnology LLC. Other product names are registered trademarks or trademarks of their owners.

Seagate reserves the right to ch ange, witho ut notice, product offerings or spec ifications . No

part of this publication may be reproduc ed in any form w ithout wr itte n per mi ssio n of Seagate

Technology LLC.

Revision status summary sheet

Revision Date Sheets Affected

Rev. A 04/09/04 Initial release. Pages 1-71.

Rev. B 01/12/05

Rev. C 06/15/05 Pages 17, 34 and 63-37.

Contents

1.0 Scope. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

2.0 Applicable standards and reference documentation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2.1 Standards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2.1.1 Electromagnetic compatibility. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2.1.2 Electromagnetic susceptibility . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2.2 Electromagnetic compliance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2.3 Reference documents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

3.0 General description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3.1 Standard features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

3.2 Media characteristics. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

3.3 Performance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

3.4 Reliability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

3.5 Formatted capacities . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

3.5.1 Programmable drive capacity. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

3.6 Factory installed accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

3.7 Options (factory installed) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

3.8 Accessories (user installed). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

4.0 Performance characteristic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

4.1 Internal drive characteristics (transparent to user) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

4.2 SCSI performance characteristics (visible to user) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

4.2.1 Access time [5]. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

4.2.2 Format command execution time (minutes) [1] . . . . . . . . . . . . . . . . . . . . . . . . . 11

4.2.3 Generalized performance characteristics. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

4.3 Start/stop time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

4.4 Prefetch/multi-segmented cache control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

4.5 Cache operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

4.5.1 Caching write data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

4.5.2 Prefetch operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

4.5.3 Optimizing cache performance for desktop and server applications . . . . . . . . . 14

5.0 Reliability specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

5.1 Error rates . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

5.1.1 Environmental interference . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

5.1.2 Read errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

5.1.3 Write errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

5.1.4 Seek errors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

5.2 Reliability and service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

5.2.1 Mean time between failure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

5.2.2 Preventive maintenance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

5.2.3 Service life . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

5.2.4 Service philosophy. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

5.2.5 Service tools. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

5.2.6 Hot plugging Savvio SCSI disc drives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

5.2.7 S.M.A.R.T. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

5.2.8 Thermal monitor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

5.2.9 Drive Self Test (DST). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

5.2.10 Product warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Savvio SCSI Product Manual, Rev. C i

6.0 Physical/electrical specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

6.1 AC power requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

6.2 DC power requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

6.2.1 Conducted noise immunity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

6.2.2 Power sequencing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

6.2.3 12 V - Current profile . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

6.3 Power dissipation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

6.4 Environmental limits. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

6.4.1 Temperature. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

6.4.2 Relative humidity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

6.4.3 Effective altitude (sea level) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

6.4.4 Shock and vibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

6.4.5 Air cleanliness . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

6.4.6 Corrosive environment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

6.4.7 Acoustics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

6.4.8 Electromagnetic susceptibility . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

6.5 Mechanical specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

7.0 Defect and error management . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

7.1 Drive internal defects . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

7.2 Drive error recovery procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

7.3 SCSI systems errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 8

8.0 Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

8.1 Drive orientation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

8.2 Cooling. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

8.3 Drive mounting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

8.4 Grounding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

9.0 Interface requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

9.1 General description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

9.2 SCSI interface messages supported . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

9.3 SCSI interface commands supported . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

9.3.1 Inquiry Vital Product data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

9.3.2 Mode Sense data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

9.4 SCSI bus conditions and miscellaneous features supported. . . . . . . . . . . . . . . . . . . . . . . 51

9.5 Synchronous data transfer. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

9.5.1 Synchronous data transfer periods supported . . . . . . . . . . . . . . . . . . . . . . . . . . 52

9.5.2 REQ/ACK offset . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

9.6 Physical interface. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

9.6.1 DC cable and connector. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

9.6.2 SCSI interface physical description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

9.6.3 SCSI interface cable requirements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

9.6.4 Mating connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

9.7 Electrical description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

9.7.1 Multimode—SE and LVD alternatives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

9.8 Terminator requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

9.8.1 Terminator power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

9.9 Disc drive SCSI timing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

10.0 Seagate Technology support services . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

ii Savvio SCSI Product Manual, Rev. C

List of Figures

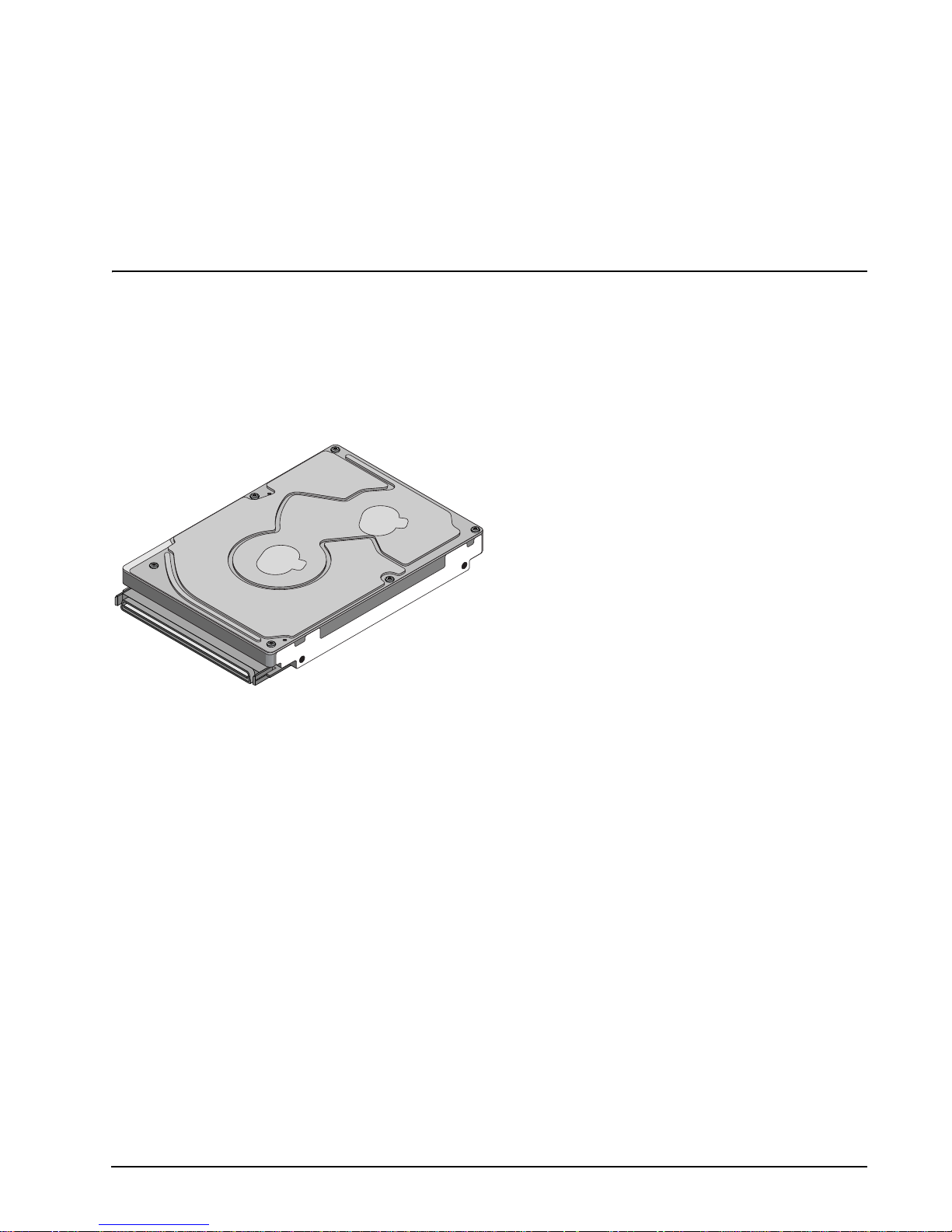

Figure 1. Savvio SCSI family drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Figure 2. Typical ST973401 drive +12 V current profile. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Figure 3. Typical ST973401 drive +5 V current profile. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Figure 4. Typical ST936701 drive +12 V current profile. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Figure 5. Typical ST936701 drive +5 V current profile. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Figure 6. ST973401 DC current and power vs. input/output operations per second (SE) . . . . . . . . . . 29

Figure 7. ST973401 DC current and power vs. input/output operations per second (LVD). . . . . . . . . . 29

Figure 8. ST936701 DC current and power vs. input/output operations per second (SE) . . . . . . . . . . 30

Figure 9. ST936701 DC current and power vs. input/output operations per second (LVD). . . . . . . . . . 30

Figure 10. Location of the HDA temperature check point . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Figure 11. Recommended mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Figure 12. Mounting configuration dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Figure 13. Air flow (suggested) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Figure 14. Physical interface (80-pin SCSI I/O connector) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Figure 15. Nonshielded 80-pin SCSI “SCA-2” connector. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Figure 16. Typical SE-LVD alternative transmitter receiver circuits. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Savvio SCSI Product Manual, Rev. C iii

1.0 Scope

This manual describes Seagate® SavvioTM disc drives.

Savvio SCSI driv es s upp ort the small computer s y st em inte r fac e (S CSI) a s des c ribed i n the ANSI SCSI SP I- 3

interface specificati ons to the extent des cribed in this manual. The S CSI Interfac e Product Man ual (part num-

ber 75789509) describes general SCSI interface characteristics of this and other families of Seagate drives.

Figure 1. Savvio SCSI family drive

Savvio SCSI Product Manual, Rev. C 1

2 Savvio SCSI Product Manual, Rev. C

2.0 Applicable standards and reference documentation

The drive has been developed as a system peripheral to the highest standards of design and construction. The

drive depends upon its host equ ipment to provide adequate power and envi ronment in order to achi eve opti-

mum performance and co mpliance with applicable indus try and governmental regulations. Special attention

must be given in the areas of safety, power distribution, shielding, audible noise control, and temperature regu-

lation. In particula r, the drive must b e s ecur el y mou nted i n o rde r to gua ra nte e th e s pe ci fie d p er formance char-

acteristics. Mounting by bottom holes must meet the requirements of Section 8.3.

2.1 Standards

The Savvio SCSI fam ily compl ies with Seag ate standard s as noted in the app ropriate s ections of this Ma nual

and the Seagate SCSI Interface Product Manual, part number 75789509.

The Savvio SCSI disc dri ve is a UL re cogni zed co mponent per UL195 0, CSA ce rtifi ed to CSA C2 2.2 No. 950-

95, and VDE certified to VDE 0805 and EN60950.

2.1.1 Electromagnetic compatibility

The drive, as delivered , is designed for system integrati on and installation into a suitable encl osure prior to

use. As such the d rive is supplied as a subassembly and is not subject to Subpart B of Part 15 of the FCC

Rules and Regulation s nor the Radio Interference Reg ulations of the Canadian Departm ent of Communica-

tions.

The design characteristics of the drive serve to minimize radiation when installed in an enclosure that provides

reasonable shielding. As such, the drive is capable of meeting the Class B limits of the FCC Rules and Regula-

tions of the Canadian Department of Communications when properly packaged. However, it is the user’s

responsibility t o assure that the drive mee ts the appropriate EMI re quirements in their system. S hielded I/O

cables may be requir ed if the en closure do es not provi de adequate shieldi ng. If the I/O cab les are exte rnal to

the enclosure, shielded cables should be used, with the shields grounded to the enclosure and to the host con-

troller.

2.1.2 Electromagnetic susceptibility

As a component a ssembly, the drive is not requ ired to meet any susc eptibi lity perfor mance requ irements. It is

the responsibilit y of those integrating the driv e wit hin their systems to pe rfo rm those tests required a nd des ig n

their system to ensure th at equipment operating in the same sy stem as the drive or external to the syste m

does not adversely affect the per formance of the drive. See Section 5.1.1 and Table 2, DC power require-

ments.

Savvio SCSI Product Manual, Rev. C 3

2.2 Electromagnetic compliance

Seagate uses an indepe ndent laboratory to co nfirm compliance to the di rectives/standard(s) for CE Marking

and C-Tick Marking. The drive was tested in a representative system for typical applications. The selected system represents the most popular characteristics for test platforms. The system configurations include:

• Typical current use microprocessor

• 3.5-inch floppy disc drive

• Keyboard

• Monitor/display

• Printer

• External modem

•Mouse

Although the test system with this Seagate model complies to the directives/standard(s), we cannot guarantee

that all systems will comply. The computer manufacturer or system integrator shall confirm EMC compliance

and provide CE Marking and C-Tick Marking for their product.

Electromagnetic compliance for the European Union

If this model has the CE Marking it co mplies with the European Union requirements of the El ectromagnetic

Compatibility Directive 89 /336/EEC of 03 May 1989 as amend ed by Dir ective 92 /31/ EEC of 28 Apri l 1992 an d

Directive 93/68/EEC of 22 July 1993.

Australian C-Tick

If this model has th e C-Tick Marking it complies with the Austr alia/New Zeal and Standard AS/NZS3548 199 5

and meets the Electromagnet ic Compatibility (EMC) Framework requi rements of Australia’s Spectrum Management Agency (SMA).

Korean MIC

If this model has the Korean Ministry of Information and Communication (MIC) logo, it complies with paragraph

1 of Article 11 of the Electromagnetic Compatibility (EMC) Control Regulation and meets the Electroma gnetic

Compatibility Framework requirements of the Radio Research Laborator y (RRL) Ministry of Information and

Communication Republic of Korea.

Taiwanese BSMI

If this model has t wo Chine se words meani ng “E MC ce rtifica tion” follo wed by an eig ht digi t identifi catio n n umber, as a Marking, it complies with Chinese National Standard (CNS) 13438 and meets the Electromagnetic

Compatibility (EMC) Fra mework requ irements of the Taiwanese Bureau of Standards, Metrology, and Inspection (BSMI).

4 Savvio SCSI Product Manual, Rev. C

2.3 Reference documents

Savvio SCSI Installa ti on Guide Seagate P/N 100293076

Safety and Regulatory Agency Specifications Seagate P/N 75789512

SCSI Interface Product Manual Seagate P/N 75789509

Applicable ANSI small computer system interface (SCSI) document numbers:

T10/1143D Enhanced SCSI Parallel Interface (EPI)

T10/1416D Primary Commands-2 (SPC-3)

T10/1417D SCSI Block Commands (SBC-2)

T10/1157D SCSI Architectural Model-2 (SAM-2)

T10/1302D SPI-3 (SCSI Parallel Interface version 3)

T10/1365D SPI-4 (SCSI Parallel Interface version 4)

SFF-8451 Specification for SCA-2 Unshielded Connections

Package Test Specification Seagate P/N 30190-001 (under 100 lb.)

Package Test Specification Seagate P/N 30191-001 (over 100 lb.)

Specification, Acoustic T est Requirements, and Procedures Seagate P/N 30553-001

In case of conflict between this document and any referenced document, this document takes precedence.

Savvio SCSI Product Manual, Rev. C 5

6 Savvio SCSI Product Manual, Rev. C

3.0 General description

Savvio SCSI drives combine giant magnetoresistive (GMR) heads, partial response/maximum likelihood

(PRML) read chann el ele ct ronic s , em bed ded se r vo techno logy, and a wide Ultra320 SCSI interface to provide

high performance, h igh c apaci ty d ata s torage for a vari ety o f systems including en gin eer ing wor k statio ns , n et-

work servers, mainframes, and supercomputers.

Ultra320 SCSI uses negotiated transfer rates. These transfer rates will occur only if your host adapter supports

these data transfer rates and is compatible with the required hardware requirements of the I/O circuit type. This

drive also operates at S CSI-1 and SCSI- 2 data tran sfer rat es for backw ard compatib ility with non- Ultra/ Ultra2/

Ultra320 SCSI host adapters.

Table 1 lists the features that differentiate the Savvio SCSI models.

Table 1: Drive model number vs. differentiating features

Model number Number of heads Formatted Capacity

ST973401LC

ST936701LC

4

2

73.4 Gbytes

36.7 Gbytes

[1] See Section 9.6 for details and definitions.

The drive records and recovers data on approximately 2.5-inch (65 mm) non-removable discs.

The drive supports the Small Computer System Interface (SCSI) as described in the ANSI SCSI interface

specifications to th e e xte nt des cri bed i n th is m anu al , wh ic h d efi nes t he pr odu ct perfo rm anc e ch ar acter isti cs o f

the Savvio SCSI family of drives, and the SCSI Interface Product Manual, part number 75789509, which

describes the general interface characteristics of this and other families of Seagate SCSI drives.

The drive’s interface supports multiple initiators, disconnect/reconnect, self-configuring host software, and

automatic features that relieve the host from the necessity of knowing the physical characteristics of the targets

(logical block addressing is used).

The head and disc assembly (HDA) is sealed at the factory. Air circulates within the HDA through a non-

replaceable filter to maintain a contamination-free HDA environment.

Never disassemble the HDA a nd do not at tempt to service ite m s i n t he se aled enclosure ( hea ds, m edi a, ac tu-

ator, etc.) as this requires specia l facilities. The d rive contains no replac eable parts. Opening the HDA voids

your warranty.

Savvio SCSI drives use a dedicated landing zone at the innermost radius of the media to eliminate the possibil-

ity of destroying o r degrading data by landin g in the data zone. The drive automatically goes to the l anding

zone when power is removed.

An automatic shipping lock prevents potential damage to the heads and discs that results from movement dur-

ing shipping and handl in g. T he s hip pin g lo ck auto mat ic all y dis eng age s whe n powe r i s ap plied to the drive and

the head load process begins.

Savvio SCSI Product Manual, Rev. C 7

Savvio SCSI dr ives deco de track 0 loca tion data from the ser vo data embed ded on eac h surfa ce to eli minate

mechanical transducer adjustments and related reliability concerns.

A high-performance actuator assembly with a low-inertia, balanced, patented, straight-arm design provides

excellent performance with min im al powe r diss ipation .

3.1 Standard features

The Savvio SCSI family has the following standard features:

• Integrated Ultra320 SCSI controller

• Multimode SCSI drivers and receivers—single-ended (SE) and low voltage differential (LVD)

• 16 bit I/O data bus

• Asynchronous and synchronous data transfer protocol

• Firmware downloadable via SCSI interface

• Selectable even byte sector sizes from 512 to 528 bytes/sector

• Programmable sector reallocation scheme

• Flawed sector reallocation at format time

• Programmable auto write and read reallocation

• Reallocation of defects on command (post format)

• ECC maximum burst correction length of 320 bits

• No preventative maintenance or adjustment required

• Dedicated head landing zone

• Embedded servo design

• Self diagnostics performed when power is applied to the drive

• Zoned bit recording (ZBR)

• Vertical, horizontal, or top down mounting

• Dynamic spindle brake

• 8,192 kbytes data buffer

• Hot plug compatibility (Section 9.6.4.1 lists proper host connector needed)

• Drive Self Test (DST)

• BackGround Media Scan (BGMS)

• Data Integrity Check

•Power Save

• Supports SCSI bus fairness

3.2 Media characteristics

The media used on the drive has an alumi num sub st rat e co ated with a thin fi lm magn eti c mater ia l, over coate d

with a proprietary protective layer for improved durability and environmental protection.

3.3 Performance

• Supports industry standard Ultra320 SCSI interface

• Programmable multi-segmentable cache buffer (see Section 4.5)

• 10,000 RPM spindle. Average latency = 3.00 ms

• Command queuing of up to 64 commands

• Background processing of queue

• Supports start and stop commands (spindle stops spinning)

8 Savvio SCSI Product Manual, Rev. C

3.4 Reliability

• Mean time Between Failure (MTBF) of 1,400,000 hours

• LSI circuitry

• Balanced low mass rotary voice coil actuator

• Incorporates industry-standard Self-Monitoring, Analysis and Reporting Technology (S.M.A.R.T.)

• 5-year warranty

3.5 Formatted capacities

Standard OEM models are formatted to 512 bytes per block. The sector size is selectable at format time. Users

having the necessary equipm ent may mo dify the data block s ize before issuing a fo rmat comm and and obtain

different formatted capacities than those listed.

To provide a stable target capacity environment and at the same time provide users with flexibility if they

choose, Seagate recommends product planning in one of two modes:

1. Seagate designs specify capacity points at certain sector sizes that Seagate guarantees current and future

products will meet. We recommend custo mers use this capacity in their project pl anning, as it ensures a

stable operating point with bac kward and forwar d com patibility from gen eration to gener ation. The curren t

guaranteed operating points for this product are:

ST936701 ST973401

Sector Size

Decimal Hex Decimal Hex

512 71,687,372 445DCCC 143,374,744 88BB998

514 70,512,692 433F034 141,025,384 867E068

520 70,197,546 42F212A 140,395,092 85E4254

522 68,914,176 41B8C00 137,828,352 8371800

524 68,766,592 4194B80 137,577,184 83342E0

2. Seagate drives also may be used at the maximum available capacity at a given sector size, but the excess

capacity above the gua rantee d l ev el wi ll v ar y between other drive fami li es an d f ro m g ene ratio n to generation, depending on how eac h sector size actually forma ts out for zone frequencies and sp lits over servo

bursts. This added capaci ty potent ial may range from 0.1 to 1.3 percent above th e guarant eed capacities

listed above. Us ing th e dr ives in th is mann er gi ves the ab so lute m aximu m capacity poten tial, but the user

must determine if the extra ca pacity potential is useful, or whether their assurance of backward and forward compatibility takes precedenc e.

3.5.1 Programmable drive capacity

Using the Mode Select command, the drive can change its capacity to something less than maximum. See the

Mode Select Paramete r Lis t table in the SCS I Comman d Refer ence M anual. Re fer to t he Par ameter li st blo ck

descriptor number of blocks field. A value of zero in the number of blocks field indicates that the drive shall not

change the capacity it i s currently form atted to have. A number in t he number of bloc ks field that is less than

the maximum numbe r of LBAs changes the total driv e capacity t o the val ue in the block descripto r number o f

blocks field. A value greater than the maximum number of LBAs is rounded down to the maximum capacity.

3.6 Factory installed accessories

OEM Standard drives are shipped with the Savvio SCSI Installation Guide, part number 100293076, and the

Safety and Regulatory Agency Specifications, part number 75789512 (unless otherwise specified).

Savvio SCSI Product Manual, Rev. C 9

3.7 Options (factory installed)

All customer req uested options are inc orporated during produ ction or packaged at t he manufacturing facil ity

before shipping. Some of the options available are (not an exhaustive list of possible options):

• Other capacities can be ordered depending on sparing scheme and sector size requested.

• Single unit shipping pack. The drive is normall y shipped in bulk packagin g to provide maximum pro tection

against transit damage. Units shipped individually require additional protection as provided by the single unit

shipping pack. Users planning single unit distribution should specify this option.

• The Savvio SCSI Installation Guide , part number 100293076, i s usually include d with each standard O EM

drive shipped, but extra copies may be ordered.

• The Safety and Regulatory Agency Specifications, part nu mber 75789512, is usually included with each

standard OEM drive shipped, but extra copies may be ordered.

3.8 Accessories (user installed)

The following accessories are available. All accessories may be installed in the field.

• Single unit shipping pack.

10 Savvio SCSI Product Manual, Rev. C

4.0 Performance characteristic

4.1 Internal drive characteristics ( transparent to user)

ST973401 ST936701

Drive capacity 73.4 36.7 GBytes (formatted, rounded off values)

Read/write heads 4 2

Bytes/track 360,000 360,000 Kbytes (average, rounded off values)

Bytes/surface 18,387 18,387 Mbytes (formatted, rounded off values)

Tracks/surface (total) 51,052 51,052 Tracks (user accessible)

Tracks/inch 105 105 KTPI

Peak bits/inch 660 660 KBPI

Internal data rate 506-753 506-753 Mbits/sec (variable with zone)

Disc rotational speed 10,009 10,009 revolutions/min (RPM)

Average rotational latency 3.00 3.00 msec

4.2 SCSI performance characteristics (visible to user)

The values giv en in Section 4 .2.1 apply to a ll models of the S avvio SCSI fami ly unless otherwis e specified.

Refer to Section 9.9 and to the SCSI Interface Product Manual for additional timing details.

4.2.1 Access time [5]

Including controller overhead

(without disconnect) [1] [3]

Drive level Drive level

Not including controller overhead

(without disconnect) [1] [3]

Read Write Read Write

msec msec

Average—Typical [2] 4.70 5.10 4.50 4.90

Single Track—Typical [2] 0.65 0.95 0.45 0.75

Full Stroke—Typical [2] 8.70 9.10 8.50 8.90

4.2.2 Format command execution time (minutes)

ST973401 ST936701

[1]

Maximum (with verify) 52 26

Maximum (no verify) 26 13

Savvio SCSI Product Manual, Rev. C 11

4.2.3 Generalized performance characteristics

Minimum sector interleave 1 to 1

Data buffer transfer rate to/from disc media (one 512-byte sector):

Minimum

Maximum

[3]* 63 Mbytes/sec

[3] 94 Mbytes/sec

SCSI interface data transfer rate (asynchronous):

Maximum instantaneous one byte wide 5.0 Mbytes/sec [4]

Maximum instantaneous two bytes wide 10.0 Mbytes/sec [4]

Synchronous transfer rate Ultra320 SCSI

In low voltage differential (LVD) interface mode 5.0 to 320 Mbytes/sec

Sector Sizes:

Default 512 byte user data blocks

Variable 512 to 528 bytes per sector in even number of bytes per sector.

If n (number of bytes per sector) is odd, then n-1 will be used.

Read/write consecutive sectors on a track Yes

Flaw reallocation performance impact (for flaws reallocated at format time using

Negligible

the spare sectors per sparing zone reallocation scheme.)

Average rotational latency 3.00

msec

Notes for Section 4.2.

[1] Execution time measu red from receipt of the last by te of the Command Descriptor B lock (CDB) to the

request for a Status Byte Transfer to the Initiator (excluding connect/disconnect).

[2] Typical access times are measured u nder nom inal condi tions of te mpera ture, v oltage, and hor izontal or i-

entation as measured on a representative sample of drives.

[3] Assumes no errors and no sector has been relocated.

[4] Assumes system ability to support the rates listed and no cable loss.

[5] Access time = controller overhead + average seek time and applies to all data transfer commands.

Access to data = access time + latency time.

4.3 Start/stop time

After DC power at nomi nal vol tage has been appli ed, th e dr ive bec omes ready withi n 20 seco nds if the Mo tor

Start Option is disabled (i.e. the motor sta rts as soon as the power has be en applied). If a rec overable error

condition is detected during the start sequence, the drive executes a recovery procedure which may cause the

time to become ready to exceed 20 seco nds. During spin up to ready time the drive responds to s ome commands over the SCSI interface in less than 3 seconds after application of power. Stop time is 30 seconds from

removal of DC power.

If the Motor Start Option is enabled, the internal controller accepts the commands listed in the SCSI Command

Reference Manual less than 3 s ec ond s a fter DC power h as bee n ap pli ed . After the Moto r Start Command has

been received the dri ve becomes re ady for norma l operations withi n 20 second s typically (excluding a n error

recovery procedur e). The Motor Start Command can also be u sed to command t he drive to stop the spi ndle

(see the SCSI Command Reference Manual).

There is no power control switch on the drive.

12 Savvio SCSI Product Manual, Rev. C

4.4 Prefetch/multi-segmented cache control

The drive provides prefetch (read look-ahead) and multi-segmented cache control algorithms that in many

cases can enhance system performance. “Cache” as used herein refers to the drive buffer storage space when

it is used in cache operations. To select prefetch and cache features the host sends the Mode Select command

with the proper values in the applicable bytes in Mode Page 08h (see the SCSI Command Reference Manual).

Prefetch and cache ope ration are independent features from the standpoint that each is enabled and disabled

independently via the Mode Select command. However, in actual operation the prefetch feature overlaps

cache operation somewhat as is noted in Section 4.5.1 and 4.5.2.

All default cache and prefetch Mode paramete r values (Mode Page 08 h) for standard OEM versions of this

drive family are given in Tables 15.

4.5 Cache operation

In general, 7,100 kbytes of the physical buffer space in the drive can be used as storage space for cache operations. The buffer can be d ivided into logical segments (Mode Selec t Page 08h, byte 13) from which data is

read and to which data is written. The drive supports a maximum of 64 cache segments. The drive maintains a

table of logical block dis c medium a ddres ses of th e data stored i n eac h segm ent of the buffer. If cache operation is enabled (RCD bit = 0 in Mode P age 08h, byte 2, bit 0. See SCSI Command Referenc e Manual), data

requested by the hos t with a Read command is r etrie ved from the buffer ( if i t i s th er e) , b efo re an y di sc ac ce ss

is initiated. If c ache oper ation is no t enabl ed, the buffer (stil l se gmented with r equired num ber of s egments) is

still used, but only as circular buffer segments during disc medium read operations (disregarding Prefetch

operation for the momen t). That is, the drive does not check in the buffer segments for the requested read

data, but goes directly to the medium to retrieve it. The retrieved data merely passes through some buffer segment on the way to the h ost. On a ca che mis s, all data transfe rs to the hos t are in acc ordance wi th buffer-full

ratio rules. On a cach e hit the drive igno res the buffer-full r atio rules . See e xplanati ons assoc iated with Mode

page 02h (disconnect/reconnect control) in the SCSI Command Reference Manual.

The following is a simplified description of a read operation with cache operation enabled:

Case A - A Read command is received and the first logical block (LB) is already in cache:

1. Drive transfers to the initiator the first LB requested plus all subsequent contiguous LBs that are already in

the cache. This data may be in multiple segments.

2. When the requested LB is reached that is not in any cache segment, the drive fetches it and any remaining

requested LBs from th e disc and puts them in a segment of the cache. The dri ve transfers the re maining

requested LBs from the ca che to t he host in accorda nce with the disconn ect/r econn ect speci fication mentioned above.

3. If the prefetch feature is enabled, refer to Section 4.5.2 for operation from this point.

Case B - A Read command requests data, the first LB of which is not in any segment of the cache:

1. The drive fetches the requested LBs from the disc and transfers them into a segment, and from there to

the host in accordance with the disconnect/reconnect specification referred to in case A.

2. If the prefetch feature is enabled, refer to Section 4.5.2 for operation from this point.

Each buffer segment is act ually a self-containe d circular sto rage (wrap-arou nd occurs), the length of which is

an integer number of disc medium sectors. The wrap-around capability of the individual segments greatly

enhances the buffer’s overall performance as a cache storage, allowing a wide range of user selectable configurations, which includes their use in the prefetch operation (if enabled), even when cache operation is disabled

(see Section 4.5.2) . The number of segments is s et dynamically by t he drive and cannot be s et by the host.

The size in Kbytes of eac h segment is not reported by the Mode Sen se co mma nd page 08 h, by tes 14 and 15 .

The value 0XFFFF is always reported. If a size specification is sent by the host in a Mode Selec t command

(bytes 14 and 15) no new segment size is set up by the drive, and if the STRICT bit in Mode page 00h (byte 2,

bit 1) is set to one, the drive resp onds as it does for any attempt to chan ge unchangeable parameter s (see

SCSI Command Reference Manual).

Savvio SCSI Product Manual, Rev. C 13

4.5.1 Caching write data

Write caching is a write operation by the d rive th at makes u se of a dr ive b uffer s to rage ar ea wher e the da ta to

be written to the medium is stored in one or more segments while the drive performs the write command.

If read caching is enabled (RCD=0), then data written to the medium is retained in the cache to be made available for future read cache h its. The same buffer space an d segme ntation is use d as set up for read functions .

The buffer segmentation s cheme is set up or changed independently, having nothing to do with the state of

RCD. When a write command is issued, i f RCD=0, the cache is first checke d to see if any logical blocks tha t

are to be written are a lready stored in the cache f rom a previous read or write comman d. If there are, the

respective cache segments are cleared. The new data is cached for subsequent Read commands.

If the number of write data logi cal block s exceeds th e size of the s egment being wr itten into, whe n the end of

the segment is reached, the data is written into the beginning of the same cache segment, overwriting the data

that was written there at the beginning of the operation. However, the drive does not overwrite data that has not

yet been written to the medium.

If write caching is enabled (WCE=1), then the drive may return GOOD status on a write command after the

data has been transferred into the cache, but before the data has been written to the medium. If an error

occurs while writing the data to the medium, and GOOD status has already been returned, a deferred error will

be generated.

The Synchronize Cache command may be used to force the drive to write all cached write data to the medium.

Upon completion of a Synchronize Cache command, all data received from previous write commands will have

been written to the medium.

Tables 15 show Mode default settings for the drives.

4.5.2 Prefetch operation

If the Prefetch fea ture i s ena bl ed, data in co nti guo us lo gic al b lock s on t he d is c immediately beyond tha t whi c h

was requested by a Read command can be re trieved and stored in the buffer for i mmediate transfer from the

buffer to the host on subseque nt Read com mands that request t hose logica l block s (this is tr ue even if cache

operation is disabled). Though the prefetch operation uses the buffer as a cache, finding the requested data in

the buffer is a prefetch hit, not a cache operation hit. Prefetch is enabled using Mode Select page 08h, byte 12,

bit 5 (Disable Read Ahead - DRA bit). DRA bi t = 0 enables prefetch. S ince data that is prefetc hed replaces

data already in some buffer segment(s ), the hos t can lim it the amou nt of pr efet ch data to optimi z e syst em performance. The max prefetch field (bytes 8 a nd 9) limits the amount of pref etch. The drive does not use the

Prefetch Ceiling field (bytes 10 and 11).

During a prefetch operati on, the dri ve crosses a cylinde r boundary to fetch mor e data only if th e Discontinu ity

(DISC) bit is set to one in bit 4 of byte 2 of Mode parameters page 08h.

Whenever prefetch ( re ad loo k-ah ead) is enabled ( ena ble d b y DRA = 0), i t o per at es und er th e c on tro l of A RLA

(Adaptive Read Look-Ahead). If the host uses software interleave, ARLA enables prefetch of contiguous

blocks from the disc when it senses that a prefetch hit will likely occur, even if two consecutive read operations

were not for physically con tiguou s blocks of da ta (e.g., “software i nterleave”) . ARLA disab les prefetc h when it

decides that a prefetch hit will not likely occur. If the host is not using software interleave, and if two sequential

read operations are no t for c ontiguous bloc ks of data , ARLA d isables pr efetc h, but as long as seq uentia l read

operations request contiguous blocks of data, ARLA keeps prefetch enabled.

4.5.3 Optimizing cache performance for desktop and server applications

Desktop and server applications require different drive caching operations for optimal performance. This

means it is difficult to provide a single configuration that meets both of these needs. In a desktop environment,

you want to configure the ca che to respond quic kly to repetitive acc esses of multiple sm all segments of data

without taking the time to “look ahea d” to the next conti guous segmen ts of data. In a server environ ment, you

14 Savvio SCSI Product Manual, Rev. C

want to configure the cac he to provide large volumes of seque ntial data in a non-repetitive manner. In this

case, the ability of the cache to “look ahead” to the next contiguous segmen ts of sequential data is a good

thing.

The Performance Mode (PM) bit contr ols the way the drive switches the cache buffer into different modes o f

segmentation. In “server mode” (PM bit = 0), the drive can dynamically cha nge the number of cache buffer

segments as needed to opt imize the performa nce, based on the command st ream from the hos t. In “desktop

mode” (PM bit = 1), the number of segments is maintained at the value defined in Mode Page 8, Byte 13, at all

times (unless changed by using a Mode Select command). For additional information about the PM bit, refer to

the Unit Attention Param eters page (00h) of the Mode Sense command (1Ah) in the SCSI Interfac e Product

Manual, part number 75789509.

Savvio SCSI Product Manual, Rev. C 15

16 Savvio SCSI Product Manual, Rev. C

5.0 Reliability specifications

The following reliabi lity specifications assume cor rect host/drive operational interfa ce, including all interface

timings, power supply voltages, environmental requirements and drive mounting constraints (see Section 8.3).

Seek Errors

Less than 10 in 10

Read Error Rates [1]

Recovered Data Less than 10 errors in 10

Unrecovered Data Less than 1 sector in 10

Miscorrected Data Less than 1 sector in 10

MTBF 1,400,000 hours

Service Life 5 years

Preventive Maintenance None required

Note.

[1] Error rate specified with automatic retries and data correction with ECC enabled and all flaws reallocated.

5.1 Error rates

The error rates stated in this specification assume the following:

• The drive is operated per this specification using DC power as defined in this manual (see Section 6.2).

• The drive has been formatted with the SCSI FORMA T command.

• Errors caused by me dia defects or host sy s tem fai lure s are e xc lu ded from er r or r ate c omp utations. Refer t o

Section 3.2, “Media Characteristics.”

• Assume random data.

8

seeks

12

bits transferred (OEM default settings)

15

bits transferred (OEM default settings)

21

bits transferred

5.1.1 Environmental interference

When evaluating s ystems ope ration under cond itions o f Electro magnetic Interferen ce (EMI) , the per formance

of the drive within the system sh all be consid ered acce ptable if the drive do es not gener ate an unrec overable

condition.

An unrecoverable error, or unrecoverable condition, is defined as one that:

• Is not detected and corrected by the drive itself;

• Is not capable of being detected from the error or fault status provided through the drive or SCSI interface; or

• Is not capable of being recovered by normal drive or system recovery procedures without operator intervention.

Savvio SCSI Product Manual, Rev. C 17

5.1.2 Read errors

Before determination or measurement of read error rates:

• The data that is to be used for measurement of read error rates must be verified as being written correctly on

the media.

• All media defect induced errors must be excluded from error rate calculations.

5.1.3 Write errors

Write errors can occur as a result of media defects, envi ronmental interfe rence, or equipm ent malfunction.

Therefore, write errors are not predictable as a function of the number of bits passed.

If an unrecoverable write error occurs because of an equ ipm ent malfu nctio n in the drive , the error is classi fied

as a failure affecting MTBF. Unrecoverable write errors are those which cannot be corrected within two

attempts at writing the record with a read verify after each attempt (excluding media defects).

5.1.4 Seek errors

A seek error is de fine d a s a failu re of t he d ri ve to pos it ion the heads to the addressed tra ck. T h er e shal l be n o

more than ten recoverable seek errors in 10

8

physical seek operations. After detecting an initial seek error, the

drive automatical ly perfor ms an error recovery process. If the err or recovery process fai ls, a see k positionin g

error (15h) is rep orted with a Hard ware error (4h) rep orted in the Sens e Key. This is an unrecoverable seek

error. Unrecoverable seek errors are classified as fa ilures for MTBF calculati ons. Refer to the SCSI Interfac e

Product Manual, part number 75789509, for Request Sense information.

5.2 Reliability and service

You can enhance the reliability of Savvio SCSI disc drives by ensu ring that the drive rec eives adequat e cooling. Section 6 provid es temperature measurements an d other information that may be used t o enhance the

service life of the drive. Section 8.2 provides recommended air-flow information.

5.2.1 Mean time between failure

The production disc dri ve shall achieve an MTBF of 1 ,400,000 hours when operate d in an environment that

ensures the HDA case t emperatures specified in Section 6.4 are not ex ceeded. Short-term ex cursions up to

the specificatio n limits of the ope rating en vironm ent will no t affect MTBF pe rformance. Continua l or sustaine d

operation at case temperatures above the values shown in Section 6.4.1 may degrade product reliability.

The MTBF target is specified as device power-on hours (POH) for all drives in service per failure.

Estimated power-on operating hours in the period = MTBF per measurement period

Number of drive failures in the period

Estimated power-on operation hours means power-up hours per disc drive times the total number of disc

drives in service. Ea ch dis c drive shall h ave accu mulate d at le ast nine months of operatio n. Data sha ll be ca lculated on a rolling average base for a minimum period of six months.

MTBF is based on the following assumptions:

• 8,760 power-on hours per year.

• 250 average on/off cycles per year.

• Operations at nominal voltages.

• Systems will prov ide adequate coolin g to ensure the case temperatures specified in Sec tion 6.4.1 are not

exceeded.

Drive failure means any stoppage or substandard performance caused by drive malfunction.

18 Savvio SCSI Product Manual, Rev. C

A S.M.A.R.T. predictive failure indic ates that the dri ve is deterior ating to an immin ent failu re and is co nside red

an MTBF hit.

5.2.2 Preventive maintenance

No routine scheduled preventive maintenance shall be required.

5.2.3 Service life

The drive shall ha ve a us eful ser vice l ife of fi ve years. Depot r epair or re place ment of m ajor parts is permitte d

during the lifetime (see Section 5.2.4).

5.2.4 Service philosophy

Special equipment is required to repair the drive HDA. In order to achieve the abo ve service lif e, repairs must

be performed only a t a pro perly e quippe d and s taffed service and repair facility. Troubleshooting and repair of

PCBs in the field is not recomm ended, because of the extensiv e diagnostic equipment req uired for effective

servicing. Also, there are no spare parts available for this drive. Drive warranty is voided if the HDA is opened.

5.2.5 Service tools

No special tools are required for site installation or recommended for site maintenance. Refer to Section 5.2.4.

The depot repair philosophy of the drive precludes the necessity for special tools. Field repair of the drive is not

practical since there are no user purchasable parts in the drive.

5.2.6 Hot plugging Savvio SCSI disc drives

The ANSI SPI-3 (T10/13 02D) document defines the physical requir ements for removal and insertion of SCSI

devices on the SCSI bus. Four cases are addressed. The cases are differentiated by the state of the SCSI bus

when the removal or insertion occurs.

Case 1 - All bus devices powered off during removal or insertion

Case 2 - RST signal asserted continuously during removal or insertion

Case 3 - Current I/O processes not allowed during insertion or removal

Case 4 - Current I/O process allowed during insertion or removal, except on the device being changed

Seagate Savvio S CSI disc d rives supp ort all four hot pluggi ng cases. Provision sh all be mad e by the s ystem

such that a device being ins erted make s power and groun d connecti ons prior to the c onnectio n of any device

signal contact to the bus. A d evice bein g remov ed sha ll ma intain powe r and gr ound c onnec tions after the di sconnection of any dev ic e sig nal c ontact f ro m th e bu s ( see S F F-8 451 Specificatio n fo r SC A-2 Uns hi eld ed C onnections).

It is the responsibility of the systems integrator to assure that no hazards from temperature, energy, voltage, or

ESD potential are presented during the hot connect/disconnect operation.

All I/O processes for th e SCSI device bein g inserted or remov ed shall be quiesc ent. All SCSI devices on the

bus shall have receivers that conform to the SPI-3 standard.

If the device being hot plugged uses single-ended (SE) drivers and the bus is currently operating in low voltage

differential (LVD) mode, then all I/O processes fo r all dev ices on the bus must be compl eted, an d the bus quiesced, before attempting to hot plug. Following the insertion of the newly installed device, the SCSI host

adapter must issue a Bus Reset, fol lowed by a sy nchronous transfer ne gotiation . Failure to per form the SCSI

Bus Reset could result in erroneous bus operations.

The SCSI bus termination and termination power source shall be external to the device being inserted or

removed.

Savvio SCSI Product Manual, Rev. C 19

End users shoul d not mix devices with high vol tage differential (HVD) driv ers and r eceivers a nd devices with

SE, LVD, or multimode drivers and receivers on the same SCSI bu s since the comm on mode vo ltages in the

HVD environment may not be controlled to safe levels for SE and LVD devices (see ANSI SPI-3).

The disc drive s pindle must come to a complete s top prior to completely removing the drive from the cabine t

chassis. Use of th e Stop Spindle command or partial withdr awal of the drive, e nou gh to b e disco nnecte d fro m

the power source, prior to removal are methods for insuring that this requirement is met. During drive insertion,

care should be taken to avoid exceeding the limits stated in Section 6.4.4, "Shock and vibration" in this manual.

5.2.7 S.M.A.R.T.

S.M.A.R.T. is an acronym for Self-Mo nitoring Ana lysis and Re porting Technology. T his technol ogy is intende d

to recognize condi tions that i ndicate a dri ve fai lure an d is d esigned to p rovide sufficie nt warn ing of a f ailure t o

allow data back-up before an actual failure occurs.

Note. The firmwa re will monitor s pecific attribute s for degradation over time but canno t predict instanta-

neous drive failures.

Each attribute has been selected to mo nit o r a s pe ci fic set o f fa il ure c ond iti ons i n th e o perati ng performance of

the drive, and the thresholds are optimized to minimize “false” and “failed” predictions.

Controlling S.M.A.R.T.

The operating mode of S.M .A.R.T. is controlled by the DEX CPT bit and the PERF bit of the “ Informational

Exceptions Control Mo de Page” (1Ch) . The DEXCPT bit i s used to enable or di sable the S .M.A.R.T. process.

Setting the DEXCPT bit will disable all S.M.A.R.T . functions. When enabled, S.M.A.R.T. will collect on-line data

as the drive performs no rmal read/wri te oper ations. W hen th e PERF bi t is set , the dr ive is c onsidered to b e in

“On-line Mode Only” and will not perform off-line functions.

The process of measuring off-line attributes and saving data can be forced by the Rezero Unit command. Forcing S.M.A.R.T. will reset the timer so that the next scheduled interrupt will be two hours.

The drive can be interrogated by the host to determine the time remaining before the next scheduled measurement and data logging process will occu r. This is accomplished by a log sense command to log page 0x3E.

The purpose is to allow the customer to control when S.M.A.R.T. interruptions occur. As described above, forcing S.M.A.R.T by the Rezero Unit command will reset the timer.

Performance impact

S.M.A.R.T . attribute data will be saved to the disc for the purpose of recreating the events that caused a predictive failure. The driv e wi ll measure and save parameter s on ce ever y tw o hou rs subj ec t to an idl e p er iod on th e

SCSI bus. The process of measu ring off-line attribute data and saving data to the disc is uninterruptable and

the maximum delay is summarized below:

Maximum processing delay

On-line only delay Fully enabled delay

DEXCPT = 0, PERF = 1 DEXCPT = 0, PERF = 0

S.M.A.R.T. delay times 60 milliseconds 370 milliseconds

Reporting control

Reporting is contr olled in the Inform ational Exceptions Control Page (1Ch). Subject to the repo rting method,

the firmware will is sue a 01-5D00 sense code to th e h ost . T he erro r co de i s pr es erve d th ro ugh bus res ets an d

power cycles.

20 Savvio SCSI Product Manual, Rev. C

Determining rate

S.M.A.R.T. monitors the rate at which error s occur and signal s a predic tive fai lure if the rate of degra ded error

rate increases to an un acce ptab le le ve l. To determine rate, error events are logged and compar ed to the number of total operations for a given attribut e. The interval define s the number of operatio ns over which to measure the rate. The counter that kee ps track of the current number of oper ations is referred to as the Interval

Counter.

S.M.A.R.T. measures error rate, hen ce for each attribute the occurrence of a n error is recorded. A counter

keeps track of the number of errors for the current interval. This counter is referred to as the Failure Counter.

Error rate is simpl y the number of errors per operation. T he algorithm t hat S.M.A. R.T. uses to reco rd rates o f

error is to set thresholds for the number of errors and the interval. If the number of errors exceeds the threshold

before the interval expires , then the error rate i s considered to be un acceptable. If the num ber of errors does

not exceed the threshol d before the interval expires, then the error rate is cons idered to be acceptable. In

either case, the interval and failure counters are reset and the process starts over.

Predictive failures

S.M.A.R.T. signals predictive failures when the dri ve is perfor ming unacc eptably for a period of time. Th e firmware keeps a running count of the number of times the error rate for each attribute is unacceptable. To accomplish this, a counter is incre mented wheneve r the error rate is unacc eptable and decremen ted (not to exceed

zero) whenever the error rate is acceptable. Should the counter continually be incremented such that it

reaches the predi ctive th resh old, a pred ictive failure is s ignal ed. This cou nter is refe rred to as the Failu re Hi story Counter. There is a separate Failure History Counter for each attribute.

5.2.8 Thermal monitor

Savvio SCSI drives implement a temperature warning system which:

1. Signals the host if the temperature exceeds a value which would threaten the drive.

2. Signals the host if the temperature exceeds a user-specified value.

3. Saves a S.M.A.R.T. data frame on the drive which exceed the threatening temperature value.

A temperature sensor monito rs the drive temperature and is sues a warning over the inte rface when the tem-

perature exceeds a s et threshol d. The tem perature is measured at power-up an d then at ten-minute intervals

after power-up.

The thermal monitor syste m generates a wa rning code of 01- 0B01 when the temp erature exceed s the specified limit in compl iance with the SCSI standard. T he drive temperature is repo rted in the FRU code field o f

mode sense data. You can use this information to determine if the warning is due to the temperature exceeding

the drive threatening temperature or the user-specified temperature.

This feature is controlled by the Enable Warning (EWasc) bit, and the reporting mechanism is controlled by the

Method of Reporting Informational Exceptions field (MRIE) on the Informational Exceptions Control (IEC)

mode page (1Ch).

The current algorithm impl ements two temperature trip points. The first trip point is set at 68°C which is the

maximum temperatur e limit a ccordi ng to th e dri ve spec ific ation. T he secon d trip point is us er-se lectable using

the Log Select com mand. The reference tempe rature parameter in the tem perature log page (see Table 11)

Savvio SCSI Product Manual, Rev. C 21

can be used to set this trip point. The default value for this drive is 68°C, however, you can set it to any va lue in

the range of 0 to 68°C. If you s pec i fy a temp erature greater than 68°C in th is fie ld, the te mpe ratur e i s rou nde d

down to

68°C. A sense code is sent to the host to indicate the rounding of the parameter field.

Table 11: Temperature Log page (0Dh)

Parameter Code Description

0000h

0001h

Primary Temperature

Reference Temperature

When the first temperature trip point is exceeded, S.M.A.R.T. data is collected and a frame is saved to the disc.

5.2.9 Drive Self Test (DST)

Drive Self Test (DST) is a technolo gy designed to recognize drive fault conditions that qualify the drive as a

failed unit. DST validates the functionality of the drive at a system level.

There are two test coverage options implemented in DST:

1. Extended test

2. Short text

The most thorough option is the extended test that performs various tests on the drive and scans every logical

block address (LBA ) of the drive. The s hort test is time-res tricted and limited i n length—it does not s can the

entire media surface, but does some fundamental tests and scans portions of the media.

If DST encounters an err or during either of these tests, it r eports a fault condition. If the drive f ails the test,

remove it from service and return it to Seagate for service.

5.2.9.1 DST Failure Definition

The drive will presen t a “diagnostic failed” con dition through the self-te sts results value of the diagnos tic log

page if a functional failur e is enco untered du ring DST. The channel and servo parameters are not mod ified to

test the drive more strin gently, and the number of retries are not redu ced. All retries and recovery proce sses

are enabled during the test. If data is recoverable, no failure condition will be reported regardless of the number

of retries required to recover the data.

The following conditions are considered DST failure conditions:

• Seek error after retries are exhausted

• Track-follow error after retries are exhausted

• Read error after retries are exhausted

• Write error after retries are exhausted

Recovered errors will not be reported as diagnostic failures.

5.2.9.2 Implementation

This section provides all of the information necessary to implement the DST function on this drive.

5.2.9.2.1 State of the drive prior to testing

The drive must be in a ready state before issuing the Send Diagno stic command . There are multipl e reasons

why a drive may not be ready, some of which are valid conditions, and not errors. For example, a drive may be

in process of doing a format, or another DST . It is the responsibility of the host application to determine the “not

ready” cause.

22 Savvio SCSI Product Manual, Rev. C

While not technically part of DST, a Not Ready condition also qualifies the drive to be returned to Seagate as a

failed drive.

A Drive Not Ready condition is reported by the drive under the following conditions:

• Motor will not spin

• Motor will not lock to speed

• Servo will not lock on track

• Drive cannot read configuration tables from the disc

In these conditions, the drive responds to a Test Unit Ready command with an 02/04/00 or 02/04/03 code.

5.2.9.2.2 Invoking DST

To in voke DST, submit the Send Diagnostic comman d with the ap propriate F unction Code (001b for the shor t

test or 010b for the extended tes t) in bytes 1, bits 5, 6, and 7. Refer to the Seagate SCSI Interface Product

Manual, part number 75789509, for additional information about invoking DST.

5.2.9.2.3 Short and extended tests

DST has two testing options:

1. short

2. extended

These testing options are described in the following two subsections.

Each test consists of th ree s egm ents: a n el ec tric al test s egm ent, a servo test segment , and a r ea d/v erify s ca n

segment.

Short test (Function Code: 001b)

The purpose of the short test is to pr ov ide a ti me-l imi ted te st that tests as much o f th e dr iv e as po ss ib le wi thi n

120 seconds. The shor t test does not scan the entire me dia surface, but does some funda mental tests and

scans portions of the media. A complete read/verify scan is not performed and only factual failures will report a

fault condition. This option provides a quick confidence test of the drive.

Extended test (Function Code: 010b)

The objective of the extended test option is to empirically test critical drive components. For example, the seek

tests and on-track operations tes t the pos it ion ing mec han ism. T he read operation tests the read head elemen t

and the media surface. The write element is tested throu gh read/write/read operations. The inte grity of the

media is checked through a r ead/verif y scan of the med ia. Motor functio nality is tested by d efault as a part of

these tests.

The anticipated length of the Extended test is reported through the Control Mode page.

5.2.9.2.4 Log page entries

When the drive begi ns DST, it creates a new entry in the Self -te st Resul ts Log page . The new entr y is c reated

by inserting a new self-test parameter block at the beginning of the self-test results log parameter section of the

log page. Existing da ta will be moved to make room f or the new param eter b lock . T he driv e r ep or ts 20 par ameter blocks in the log page. If there are more than 20 parameter blocks, the least recent parameter block will be

deleted. The new parameter block will be initialized as follows:

1. The Function Code field is set to the same value as sent in the DST command

2. The Self-Test Results Value field is set to Fh

3. The drive will store the log page to non-volatile memory

Savvio SCSI Product Manual, Rev. C 23

After a self-test is complete or has been aborted, the dri ve upda tes the Sel f-Test Results Value field in its SelfTest Results Lo g pa ge in n on- v ola til e m emo ry. The host may use Log Sense to read the resul ts from up to th e

last 20 self-tests performed by the drive. The self-test results value is a 4-bit field that reports the results of the

test. If the field i s zero, the drive pas sed with no errors detected by the DST. If the field is not zero , the test

failed for the reason reported in the field.

The drive will report th e failure condition and LBA (if applicable) in the Self-t est Results Log parameter. The

Sense key, ASC, ASCQ, and FRU are used to report the failure condition.

5.2.9.2.5 Abort

There are several ways to abort a diagnostic. You can use a SCSI Bus Reset or a Bus Device Reset message

to abort the diagnostic.

You can abort a DST executing in backgrou nd mode by using the a bort code in t he DST Functio n Code field .

This will cause a 01 ( self-test aborted b y the application cl ient) code to appear i n the self-test results v alues

log. All other abort mechanisms will be reported as a 02 (self-test routine was interrupted by a reset condition).

5.2.10 Product warr anty

Beginning on the date of shipment to customer and continuing for a period of five years, Seagate warrants that

each product (including components and subassemblies) or spare part that fails to function properly under normal use due to defect in mate rials on workm anship or due to no nconfo rmance to the appl icable s pecif ications

will be repaired or rep laced, at Seagate’s optio n an d a t no ch ar ge to c ustomer, if returned by customer at cu stomer’s expens e to Seagate’s designated faci lity in accordance wit h Seagate’s warranty procedur e. Seagate

will pay for transporting the repair or replacement item to custom er. F or more detailed warranty informat ion

refer to the Standard terms and conditions of Purchase for Seagate products.

Shipping

When transporting or shipping a dr ive, a Seagate approved container mus t be used. Keep your original box.

They are easily identified by the Seagate-approved package label . Shipping a drive in a non-approved container voids the drive warranty.

Seagate repair center s may refuse rece ipt of co mpo nen ts imp ro per l y packa ged or o bv iou sly da mag ed in transit. Contact your Autho r iz ed Se agat e Di s tribu tor to pu rc ha se add iti on al box es . Se a gate re comm ends shipping

by an air-ride carrier experienced in handling computer equipment.

Product repair and return information

Seagate customer se rvice centers are th e only facilities au thorized to service Sea gate drives. Seagate d oes

not sanction any third- party repair facilities. Any unau thorized repair or tampering with the fact ory-seal voids

the warranty.

24 Savvio SCSI Product Manual, Rev. C

6.0 Physical/electrical spe cifications

This section provides information relating to the physical and electrical characteristics of the Savvio SCSI

drive.

6.1 AC power requirements

None.

6.2 DC power requirements

The voltage and current requirements for a single drive are shown in the following table. Values indicated apply

at the drive power connector. The table shows current values in Amperes.

Table 2: DC power requirements

Notes

Voltage +5V +12 V +5V +12 V +5V +12 V +5V +12 V

Regulation [5] +10%/

Average idle current DC X

Maximum starting current

(peak DC) DC 3σ

(peak AC) AC 3σ

Delayed motor start (max) DC 3σ [1][4] 0.49 0.05 0.48 0.05 0.49 0.05 0.49 0.05

Peak operating current

DC X

Maximum DC 3σ

Maximum (peak) DC 3σ

[1][7] 0.51 0.21 0.50 0.21 0.51 0.19 0.50 0.19

[3]

[3] 0.68

[1][6]

[1] 0.73

SE mode LVD mode SE mode LVD mode

-7.5%

1.01

0.75

1.12

ST973401 ST936701

+10%/

-7.5%[2]

1.68

2.70

0.40

0.46

1.50

+10%/

-7.5%

0.72

1.14

0.74

0.75

1.32

+10%/

-7.5%[2]

1.68

2.65

0.43

0.49

1.54

+10%/

-7.5%

0.70

1.00

0.74

0.76

1.14

+10%/

-7.5%[2]

1.58

2.68

0.46

0.49

1.48

+10%/

-7.5%

0.65

1.03

0.69

0.74

1.30

+10%/

-7.5%[2]

1.58

2.66

0.47

0.49

1.48

[1] Measured with avera ge re adi ng D C am mete r or equ iv alent s am pl ing sc op e. I nstan taneou s c urr ent pea ks

will exceed these value s. Power supply at nom inal voltage. Number of driv es tested = 6, 35

De grees C

ambient.

[2] For +12 V, a –10% tolerance is permissible during in itial start of spindle , and must return t o ±5% before

10,000 rpm is rea ched. The ±5% must b e main tained after the dri ve sign ifies th at its power-up se quence

has been completed and that the drive is able to accept selection by the host initiator.

[3] See +12 V current profile in Figure 2.

[4] This condition occu rs when the Motor Start Option is ena bled and the drive has not yet receiv ed a Start

Motor command.

[5] See Section 6.2.1 “Con ducted Noise Immunity.” Specified voltage tolerance is inclusive of r ipple, noise,

and transient response.

Savvio SCSI Product Manual, Rev. C 25

[6] Operating condition is defined as random 8 block reads at:

259

I/Os per second (ST973401LC)

259

I/Os per second (ST936701LC)

[7] During idle, the d rive heads are reloca ted every 60 seconds to a random location within the band from

three-quarters to maximum track.

General Notes from Table 2:

1. Minimum current l oading fo r each sup ply voltage is not les s than 1. 2% of the ma ximum o perating current

shown.

2. The +5 and +12 volt supplies shall employ separate ground returns.

3. Where power is provided to multiple drives from a common supply, careful consideration for individual

drive power requirem ents s hou ld b e no ted. Whe re mul ti ple uni ts are pow er ed o n s imu ltaneou sl y, the peak

starting current must be available to each device.

4. Parameters, other than spindle start, are measured after a 10-minute warm up.

5. No terminator power.

6.2.1 Conducted noise immunity

Noise is specified a s a periodic an d random distri bution of frequenc ies covering a band from DC to 10 MHz.

Maximum allowed noise values given below are peak to peak measurements and apply at the drive power connector.

+5 V = 250 mV pp from 100 hz to 20 Mhz.

+12 V = 800 mV pp from 100 hz to 8 Khz;

450 mV pp from 8 Khz to 20 Khz;

250 mV pp from 20 Khz to 5 Mhz.

6.2.2 Power sequencing

The drive does not require power sequenci ng. The drive prote cts against inadver tent writing dur ing power-up

and down. Daisy-chain oper ation requires that power be maintained on the SCSI bus termi nator to ensure

proper termination of the peripheral I/O cables. T o automatically delay motor start based on the target ID (SCSI

ID) enable the Delay Motor Start option and disable the E nable Motor Start option on the backplane. To delay

the motor until the dr ive rece ives a Start Unit command, en able the Enable Re mote Motor Start option on the

backplane.

6.2.3 12 V - Current profile

Figure 2 and 4 identify the drive +12 V curr ent pr ofiles and fi gures 3 and 5 iden tify the dr ive +5 V c urrent profiles. The current during the various times is as shown:

T0 - Power is applied to the drive.

T1 - Controller self tests are performed.

T2 - Spindle begins to accelerate under current limiting after performing drive internal

diagnostics. See Note 1 of Table 2.

T3 - The spindle is up to speed and the head-arm restraint is unlocked.

T4 - The adaptive servo calibration sequence is performed.

T5 - Calibration is complete and drive is ready for reading and writing.

Note. All times and currents are typical. See Table 2 for maximum current requirements.

26 Savvio SCSI Product Manual, Rev. C

Figure 2. Typical ST973401 drive +12 V current profile

Figure 3. Typical ST973401 drive +5 V current profile

Savvio SCSI Product Manual, Rev. C 27

Figure 4. Typical ST936701 drive +12 V current profile

Figure 5. Typical ST936701 drive +5 V current profile

28 Savvio SCSI Product Manual, Rev. C

6.3 Power dissipation

ST973401

For drives using single-ended interface circuits, typical power di ssipation under idle con ditions is 5.07 watts

(17.3 BTUs per hour).

For drives using low voltage differential interface circuits, typical power dissipation under idle conditions is 5.02

watts (17.1 BTUs per hour).

To ob tain operating power for typ ical random read oper ations, refer to the foll owing two I/O rate curv es (see

Figures 6 and 7). Loc ate th e typical I/O rate for a drive in your s yst em on the horizontal axis and r ea d th e cor responding +5 volt curr ent, +12 volt current, and to tal watts on the vertical axis. To calculate BTUs per hour,

multiply watts by 3.4123.

ST 973401L C DC CURRENT/POWE R vs THRO UGHPUT (Single Ended)

1.400

1.200

R an dom 8 Bl ock Reads

14 .0 0

12 .0 0

5Volt A

12 V o l t A

Watts

1.000

0.800

0.600

Amperes

0.400

0.200

0.000

0.0 50.0 100.0 150.0 200.0 250.0 300.0

10 .0 0

8.00

6.00

4.00

2.00

0.00

Power (watts)

I/Os per Second

Figure 6. ST973401 DC current and power vs. input/output operations per second (SE)

ST973401LC DC CURRENT/POWER vs THROUGHPUT (Low Voltage Differential)

1.4 0 0

1.2 0 0

1.0 0 0

0.800