Page 1

INVERTER

Plug-in option

FR-A7AY

INSTRUCTION MANUAL

Analog output function

Digital output function

PRE-OPERATION INSTRUCTIONS

1

INSTALLATION AND WIRING

2

PARAMETER LIST

EXTENSION ANALOG OUTPUT

DIGITAL OUTPUT

3

4

5

Page 2

Thank you for choosing this Mitsubishi Inverter plug-in option.

This instruction manual gives handling information and

precautions for use of this equ ipment. Incorr ect handling might

cause an une xpected fault. Before using the equipment, please

read this manual carefully to use the equipment to its optimum.

Please forward this manual to the end user.

This section is specifically about

safety matters

Do not attempt to install, operate, maintain or inspect this

product until you have read through this instruction manual and

appended documents carefully and can use the equipment

correctly. Do not use this product until you have a full

knowledge of the equipment, safety information and

instructions.

In this instruction manual, the safety instruction levels are

classified into "WARNING" and "CAUTION".

Assumes that incorrect handling may

WARNING

CAUTION

Note that even the level may lead to a se rious

consequence according to conditions. Please follow the

instructions of both levels because they are important to

personnel safety.

cause hazardous conditions, resulting

in death or severe injury.

Assumes that incorrect handling may

cause hazardous conditions, resulting

in medium or slight injury, or may

cause physic al damage only.

CAUTION

SAFETY INSTRUCTIONS

1. Electric Shock Prevention

WARNING

• While power is on or when the inverter is running, do not

open the front cover. You may get an electric shock.

• Do not run the inver ter with the front cover or wiring cover

removed. Otherwise, you may access the exposed highvoltage terminals and charging part and get an electric shock.

• If power is off, do not remove the front cover except for wiring

or periodic inspec tion. You may access the char ged inverter

circuits and get an electric shock.

• Before starting wiring or inspection, check to make sure that

the inverter power indicator lamp is off, wait for at least 10

minutes after the power supply has been switched off, and

check that there are no residual voltage using a tester or the

like. The capacitor is charged with high voltage for some time

after power off and it is dangerous.

• Any person who is involved in the wiring or inspection of this

equipment should be fully competent to do the work.

• Always install the plug-in option before wiring. Otherwise,

you may get an electric shock or be injured.

• Do not touch t he plug-in option with wet hands. Otherwise

you may get an electric shock.

• Do not subject the cables to scratches, excessive stress,

heavy loads or pin ching. Otherwise you m ay get an electric

shock.

A-1

Page 3

2. Injury Prevention

3) Usage

CAUTION

• Apply only the voltage specified in the instruction manual to

each terminal. Otherwise, burst, damage, etc. may occur.

• Ensure that the cables are connected to the correct terminals.

Otherwise, burst, damage, etc. may occur.

• Always make sure that pol arit y is correct to prevent dam age, etc.

Otherwise, burst, damage may occur.

• While power is on or for some time after power-off, do not touch

the inverter as it is hot and you may get burnt.

3. Additional Instructions

Also note the follo wing points to prevent an accidental fail ure,

injury, electric shock, etc.

1) Transportation and mounting

CAUTION

• Do not install or o pe ra te th e plug-in opti on if it is damaged or

has parts missing.

• Do not stand or rest heavy objects on the product.

• Check that the mounting orientation is correct.

• Prevent other cond uctive bodies such as screws and metal

fragments or other flammable substance such as oil from

entering the inverter.

2) Trial run

CAUTION

• Before starting operation, confirm and adjust the parameters.

A failure to do so may cause some machines to make

unexpected motions.

WARNING

• Do not modify the equipment.

• Do not perform parts removal whic h is not instruct ed in this

manual. Doing so may lead to fault or damage of the inverter.

CAUTION

• When parameter clear or all parameter clear is performed,

reset the required parameters before starting operations.

Each parame ter returns to the initial value.

• For prevention of damage due to static electricity, touch

nearby metal before touch ing this prod uct to elimin ate static

electricity from your bo dy.

4) Maintenance, inspection and parts replacement

CAUTION

• Do not test the equipment with a megger (measure insulation

resistance).

5) Disposal

CAUTION

• Treat as industrial waste.

6) General instruction

All illustrations given in this manual may have been drawn with

covers or safety guards removed to provide in-depth

description. Before starting operation of the product, always

return the covers and guards into original positions as specified

and operate the equipment in accordance with the manual.

A-2

Page 4

CONTENTS

1 PRE-OPERATION INSTRUCTIONS 1

1.1 Unpacking and Product Confirmation .............................................................................................1

1.1.1 Packing confirmation......................................................................................................................................1

1.1.2 Parts...............................................................................................................................................................2

1.1.3 Specifications.................................................................................................................................................3

2 INSTALLATION AND WIRING 5

2.1 Pre-Installation Instructions .............................................................................................................5

2.2 Installation Procedure.......................................................................................................................6

2.3 Wiring..................................................................................................................................................7

3 PARAMETER LIST 9

4 EXTENSION ANALOG OUTPUT 11

4.1 Wiring Example................................................................................................................................11

4.2 Internal Block Diagram....................................................................................................................12

4.3 Terminals..........................................................................................................................................13

4.4 Extension Analog Output Function Parameter List......................................................................14

4.5 Adjustment Procedure ....................................................................................................................15

4.5.1 Setting of analog output signal voltage/current switchover (Pr. 309) ...........................................................15

4.5.2 Calibration of meter......................................................................................................................................16

4.5.3 Output signal setting.....................................................................................................................................18

4.5.4 Analog signal adjustment [Pr. 307, Pr. 308, Pr. 311, Pr. 312]......................................................................19

4.6 Instructions ......................................................................................................................................20

I

Page 5

5 DIGITAL OUTPUT 21

5.1 Internal Block Diagram....................................................................................................................21

5.2 Terminals..........................................................................................................................................22

5.3 Digital Output Function Parameter List.........................................................................................23

5.4 Output Signal List............................................................................................................................24

II

Page 6

1 PRE-OPERATION INSTRUCTIONS

1.1 Unpacking and Pr oduct Confirmation

Take the plug-in option out of the package, check the unit name, and confirm that the product is as you

ordered and intact.

This product is a plug-in option dedicated for the FR-F

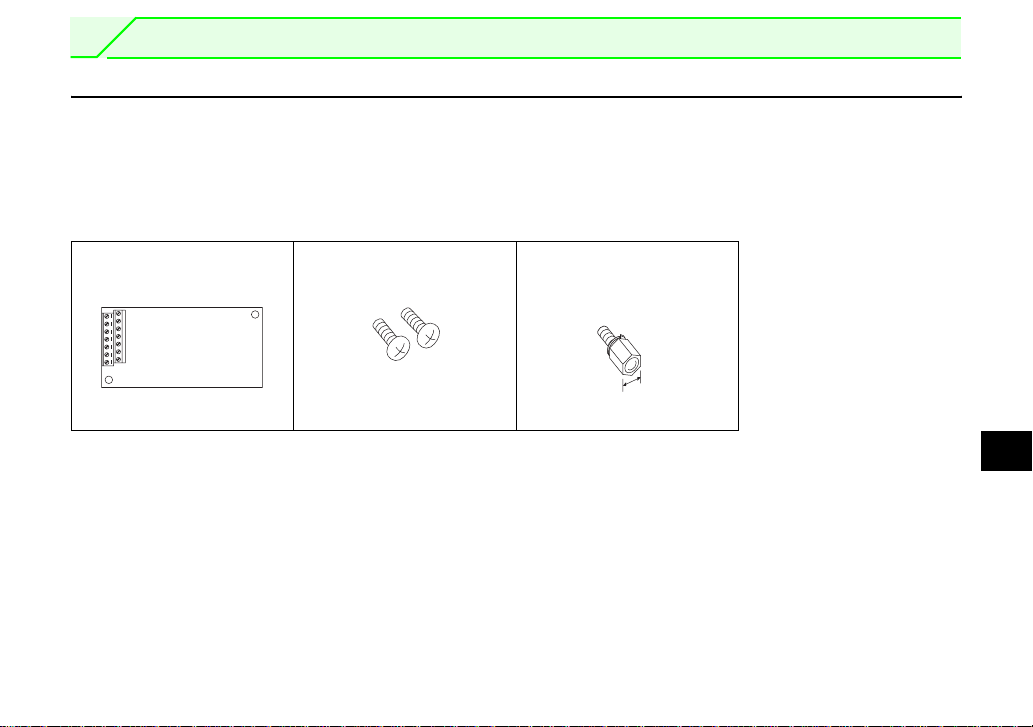

1.1.1 Packing confirmation

Check the enclosed items.

Plug-in option

.........................................1

Mounting screw (M3 × 6mm)

.............. 2 (Refer to p age 6.)

700 series.

Hex-head screw fo r o pt ion

mounting (5.5mm)

...............1 (R ef er to page 6.)

5.5mm

1

1

Page 7

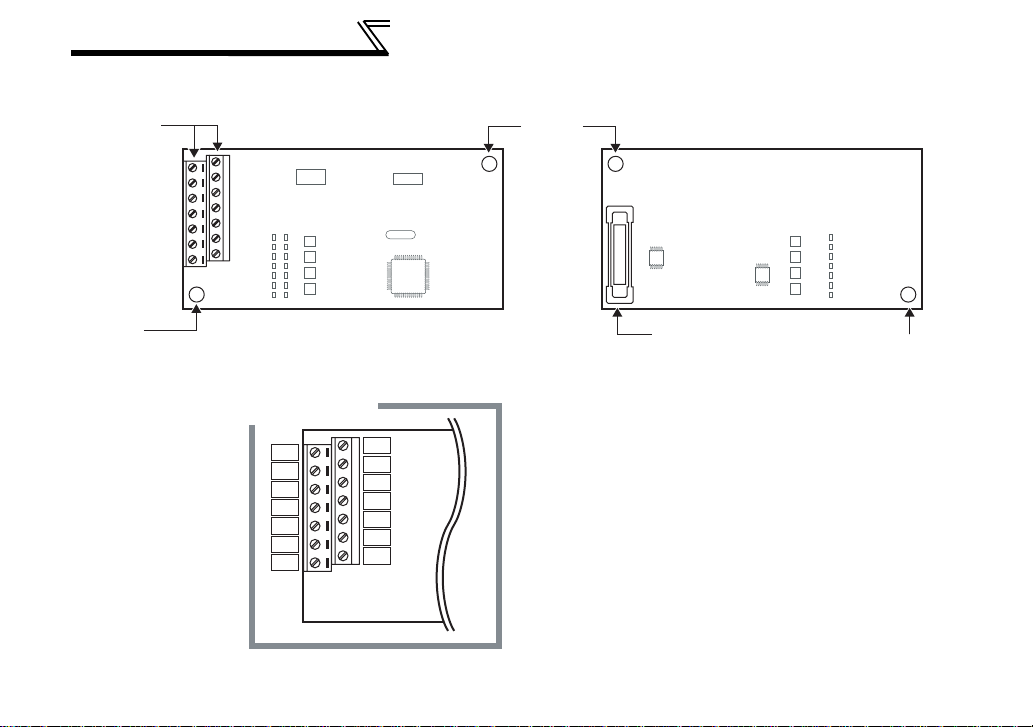

PRE-OPERATION INST RUC TI ON S

1.1.2 Parts

Terminal

block

Front view

Mounting

hole

Rear view

Mounting

hole

2

Terminal layout

AMC

NC

SE

Y3

Y4

Y5

Y6

AM0

AM1

NC

SE

Y0

Y1

Y2

Connector

Connect to the inverter

option slot

(Refer to page 6.)

Mounting hole

Page 8

1.1.3 Specifications

(1) Output signals

Voltage output (across terminals AM0-AMC) 0 to 10VMAXDC

Current output (across terminals AM1-AMC) 0 to 20mADC

(2) Output resolution

Voltage output 3mV

Current output 10

(3) Output accuracy (reference value)

±10% of the full-scale output value

Depends on the output signal type.

(4) Meters used

• Voltmeter

DC voltmeter Full-scale 10V (internal impedance 10kΩ or more)

• Ammeter

DC ammeter Full-scale 20mA (internal impedance 300Ω or less)

• Wiring length

Maximum 10m

µA

PRE-OPERATION INST RU CT ION S

1

3

Page 9

MEMO

4

Page 10

2 INSTALLATION AND WIRING

2.1 Pre-Installation Inst ructions

Make sure that the input power of the inverter is off.

CAUTION

With input power on, do not install or remove the plug-in opt ion. Otherwise, the inverter and

plug-in option may be damaged.

2

5

Page 11

INSTALLATION AND WIRING

2.2 Installation P rocedure

1) Remove the inverter front cover.

2) Mount the hex-head screw for option

1)

Screw hole for

option mounting

Inverter side

option

connector

3)

Screw hole for

option mounting

(on earth plate)

Hex-head screw

for option mounting

CAUTION

1. When the inverte r can not recognize that the option unit is mounted due to improper installation, etc.,

" " (option alarm) is displayed.

2. Note that a hex-head screw for opti on mounting or mountin g screw may drop duri ng mounting and remova l.

2)

4)

Mounting

screws

mounting into the inverter screw hole (on

earth plate). (size 5.5mm, tightening

torque 0.56N⋅m to 0.75N⋅m)

3) Securely fit the connector of the plug-in

option to the inverter connector along the

guides.

4) Securely fix the both right and left sides

of the plug-in option to the inverter with

the accessory mounting screws. If the

screw holes do not line-up, the connector

may not have been plugged snugly.

Check for loose plugging.

REMARKS

After removing two screws on the right and left

places, remove the plu g- in opt ion.

(The plug-in option is easi l y re m oved if the

control circuit terminal bl ock is re moved before .)

6

Page 12

INSTALLATION AND WIRING

2.3 Wiring

(1) Strip off the sheath of the cable to wire.

Strip off the sheath about the size below. If the length of the sheath pealed is too long, a short circuit

may occur among neighboring wires. If the length is too short, wires might come off.

Cable stripping size

5mm

REMARKS

Information on bar terminals

Introduced products (as of October, 2003): Phoenix Contact Co.,Ltd.

Terminal Screw

Size

M2 Al 0.5-6WH A 0.5-6 0.3 to 0.5

⋅ Bar term i nal cr i m pi ng t ool: CRIMPFOX ZA3 (Phoe ni x C o ntact C o. , Ltd.)

When using th e bar t ermi na l ( wit ho ut insu la ti on sl ee ve) ,

use care so that the twisted wires do not come out.

(2) Loosen the terminal screw and insert the cable into the terminal.

Screw Size Tightening Torque Cable Size Screwdriver

M2 0.22N⋅m to 0.25N⋅m

CAUTION

Undertightening can cause cable disconnection or malfunction. Overtightening can cause a short circuit or

malfunction due to damage to the screw or unit.

Wire the stripped cable after twisting it to prevent it from becoming loose.

In addition, do not solder it.

Use a bar type terminal as required.

Bar Terminal Model

(with insulation sleeve)

Bar Terminal Model

(without insulation sleeve)

0.3mm

2

to 0.75mm

2

(Tip thickness: 0.4mm/tip width: 2.5mm )

Wire Size (mm2)

Small flat-blade screwdriver

2

7

Page 13

INSTALLATION AND WIRING

C

(3) For wiring of the 30K(00620 (EC Version)) or less, route wires between the control circuit terminal block

and front cover. If cables can not be routed between the control circuit terminal block and front cover due

to the increased number of cables, remove a hook of the front cover and use a space become available.

For wiring of the 37K(00770 (EC Version)) or more, use the space on the left side of the control circuit

terminal block.

Wiring can be also performed using a cable

groove in the inverter side surface

Cut off

with a

nipper,

etc.

Cut off a hook on the inverter

front cover side surface.

(Cut off so that no portion is left.)

Control circuit

terminal block

30K or less 37K or more

REMARKS

When wires can no t b e co nn ect ed to th e ter mi nal block due t o p a ral le l c o nn ect i on o r w il l not f it i n t he w ir i ng s p ac e due

to large gauge or the incr eased number of cables, pe rfor m wiring by using a junction te rm inal block, etc.

AUTION

Do not use empty t erminals as junction terminals because t hey are used in the o ption unit. If

they are used as the junction terminals, the option unit may be damaged.

When installing the inverter front cover, the cables to the inverter's control circuit terminals and

option unit term ina ls s ho uld b e ro uted p rop erly in th e wiring space to pr even t them f rom b eing

caught between the inverter and its cover.

After wiring, wire offcuts must not be left in the inverter. They may cause a fault, failure or

malfunction.

8

Page 14

3 PARAMETER LIST

When the FR-A7AY is mounted on the inverter, the following parameters are extended.

Parameter

Number

306 Analog output signal selection

307 Setting for zero analog output 0 to100% 0.1 0%

308 Setting for m aximum analog output 0 to100% 0.1 100%

309

310

311

312

EXTENSION ANALOG OUTPUT

323 AM0 0V ad ju st m en t 900 to1100% 1 1000%

324 AM1 0mA adjustment 900 to 1100% 1 1000%

C0(900) FM(CA) terminal calibration

C1(901) AM terminal calibration

Analog output signal voltag e/ current

switchover

Analog meter voltage output

selection

Setting for zero analog meter

voltage output

Setting for maximum analog meter

voltage output

Name Setting Range

1 to 3, 5, 6, 8,(9),

10 to14,17, 21, 24, 50,

52, 53

0, 1, 10, 11 1 0

1 to 3, 5, 6, 8, (9),

10 to14, 17, 21, 24, 50,

52, 53

0 to100% 0.1 0%

0 to100% 0.1 100%

Minimum

Increments

12

12

Initial

Value

Refer to

Page

11 and

later

3

9

Page 15

PARAMETER LIST

Parameter

Number

313 DO0 output selection

314 DO1 output selection

315 DO2 output selection

316 DO3 output selection

317 DO4 output selection

318 DO5 output selection

DIGITAL OUTPUT

319 DO6 output selection

Name Setting Range

0 to 5, (7), 8, 10 to 19,

25, 26, 45 to 47, 64, 70,

(71 to 78), 86 to 96, 98,

99, 100 to 105, (107),

108, 110 to 116, 125,

126, 145 to 147, 164,

170, 186 to 196, 198,

199, 9999

Minimum

Increments

1 9999

Initial

Value

Refer to

Page

21 and

later

10

Page 16

4 EXTENSION ANALOG OUTPUT

4.1 Wiring Example

By setting the Pr. 306 to Pr. 312 values, analog signals such as the output frequency and output current can

be output from the voltage output terminal (AM0) and current output terminal (AM1).

Connect the voltmeter or ammeter as shown below:

Power

supply

(Voltmeter)

(Ammeter)

MCCB

0 to 10VDC

+

-

+

0 to 20 mADC

-

Inverter

FR-A7AY

AM0

AM1

AMC

Motor

IM

CAUTION

The wiring length between the FR-A7AY and the voltmeter/ammeter should be 10m maximum.

4

11

Page 17

EXTENSION ANALOG OUTPUT

4.2 Internal Block Diagram

The following is the internal block diagram about the FR-A7AY analog output function.

AM0

Voltage amplifier

Connector

Controller

Current amplifier

Common to

AM0/AM1

AM1

AMC

12

Page 18

4.3 Terminals

AMC

NC

SE

Y3

Y4

Y5

Y6

AM0

AM1

NC

SE

Y0

Y1

Y2

EXTENSION ANALOG OUTPUT

Terminal Symbol Terminal Name Description

AM0

AM1

AMC

Y0 to Y6

SE

NC (empty) Do not use.

Voltage output

terminal

Current ou t put

terminal

Common

terminal

Connect a DC voltmeter (10VDC).

Connect a DC ammeter (2 0m ADC).

Common to AM0 and AM1

Used for analog output function. (Refer to page 21 )

13

4

Page 19

EXTENSION ANALOG OUTPUT

4.4 Extension Analog Output Function Parameter List

Parameter

Number

306 Analog output signal selection

307 Setting for zer o analog output 0 to 100% 0.1 0%

308 Setting for m axi m um analog output 0 to 100% 0.1 100%

309

310 Analog meter voltage output

311

312

323 AM0 0V adjustment 900 to 1100% 1 1000%

324 AM1 0mA adj u st m ent 900 to 1100% 1 1000%

C0(900) FM terminal calibration

C1(901) AM terminal calibration

Analog output signal voltag e/ cur r ent

switchover

Setting for zero analog mete r

voltage output

Setting for maximum analog meter

voltage output

Name Setting Range

1 to 3, 5, 6, 8,

(9), 10 to 14, 17,

21, 24, 50, 52, 53

0, 1, 10, 11 1 0

1 to 3 , 5, 6, 8,

(9), 10 to 14, 17,

21, 24, 50, 52, 53

0 to 100% 0.1 0%

0 to 100% 0.1 100%

Minimum

Increments

12

12

Initial

Value

REMARKS

For Pr. 306 and Pr. 310, write is enabled even when "0" is set in Pr. 77.

14

Page 20

EXTENSION ANALOG OUTPUT

4.5 Adjustment Proc edure

4.5.1 Setting of analog output signal voltage/current switchover (Pr. 309)

Use Pr. 309 Analog output sign al voltage/current switcho ver to select whether to output the same signal or

different signals from terminal AM0 (voltage output) and terminal AM1(current output).

Pr. 309

Setting

0

(initial

value)

10

1

11

Description

Same select signals are output

from the voltage output terminal

(AM0) and current output

terminal (AM1). The signal set in

Pr. 306 Analog output signal

selection is made valid. (The

setting of Pr. 310 is made i nvalid.)

Different select signals are

output from voltage output

terminal (AM0) and current

output terminal (AM1).

Terminal

AM0

Pr. 306 : Select the output signal.

Pr. 307 : Output signal value for zero analog output

AM1

Pr. 308 : Output signal value for maximum analog output

Pr. 306 : Select the output signal.

AM0

Pr. 307 : Analog output value for zero output signal

AM1

Pr. 308 : Analog output value for maximum output signal

Pr. 310 : Select the output signal.

Pr. 311 : Output signal value for zero analog output

AM0

Pr. 312 : Output signal value for maximum analog output

Pr. 306 : Select the output signal.

AM1

Pr. 307 : Output signal value for zero analog output

Pr. 308 : Output signal value for maximum analog output

Pr. 310 : Select the output signal.

Pr. 311 : Analog output value for zero output signal

AM0

Pr. 312 : Analog output value for maximum output signal

Pr. 306 : Select the output signal.

Pr. 307 : Analog output value for zero output signal

AM1

Pr. 308 : Analog output value for maximum output signal

Parameters for Setting

Parameters

for

Adjustment

Pr. 323

Pr. 324

C1 (Pr. 901)

Pr. 323

C0 (Pr. 900)

Pr. 324

C1 (Pr. 901)

Pr. 323

C0 (Pr. 900)

Pr. 324

C1 (Pr. 901)

REMARKS

Analog output means voltage (0 to 10 V) and current (0 to 20m A) out put from terminal AM0 and AM1, and output

signal means t he monitor signal (refer to page 18) set in Pr. 306 and Pr. 310.

4

15

Page 21

EXTENSION ANALOG OUTPUT

4.5.2 Calibration of meter

(1) Outputting the same select signals from terminals AM0 and AM1 (Pr. 309 = 0 or 10)

START

Connect a DC voltmeter (or DC ammeter) across

terminals AM0 (or terminal AM1) and AMC.

Use Pr. 323 (Pr. 324) to calibrate the meter

when the voltage (current) input is 0.

Set "21" (reference voltage output) in Pr. 306.

Run the inverter

Use Pr. 901 to perform adjustment, then set.

END

In Pr. 306, set the types of the signals to be output.

(Refer to page 18.)

At this time, check that the polarity is correct

If the meter needle does not point to 0 when voltage or current input is 0,

use Pr. 323 AM0 0V adjustment or Pr. 324 AM1 0mA adjustment to

calibrate the meter

At this time, the following analog signal is actually output and deflects the meter.

<across terminals AM0-AMC>

Maximum output voltage set previously (factory setting: 10VDC)

<across terminals AM1-AMC>

Maximum output current set previously (factory setting: 20mADC)

press to set.

CAUTION

1. If calibration is made without "21" (reference voltage output) set in Pr. 306, Terminals FM/AM of the inve rt e r

is calibrated. To calibrate the extension analog output, always set "21" in Pr. 306.

2. When the plug-in opt ion used was remoun ted on other i nverter, use Pr. 323 and Pr. 324 to calibrate again.

16

Page 22

EXTENSION ANALOG OUTPUT

(2) Outputting different select signals from terminals AM0 and AM1 (Pr. 309 = 1 or 11)

START

Connect a DC voltmeter (or DC ammeter)

across terminals AM0 (or terminal AM1)

and AMC.

Use Pr. 323 (or Pr. 324) to calibrate the

meter when the voltage (current) input is 0.

Set "21" (reference voltage output) in Pr.

306 and Pr. 310.

Run the inverter

Terminal AM0 Terminal AM1

Use Pr. 900 to set

In Pr. 306 and Pr. 310, set the types of the signals to be output.

(Refer to page 18.)

Use Pr. 901 to set

END

At this time, check that the polarity is correct

If the meter needle does not point to 0 when voltage or current input is 0,

use Pr. 323 AM0 0V adjustment or Pr. 324 AM1 0mA adjustment to

calibrate the meter

At this time, the following analog signal is actually output and deflects the meter.

<across terminals AM0-AMC>

Maximum output voltage set previously (factory setting: 10VDC)

<across terminals AM1-AMC>

Maximum output current set previously (factory setting: 20mADC)

The inverter may be run in either the PU or external operation mode.

press to set.

CAUTION

1. If calibrat i on i s m ade wit hout "21" (reference voltage output ) se t in Pr. 306 or Pr. 310, terminals FM/AM of

the invert er is calibrated. To calibrate the exten sion analog ou t p ut, always set "21" in Pr. 306.

2. When the plug-in option used was remounted on other inverter, use Pr. 323 and Pr. 324 to calibrate again.

4

17

Page 23

EXTENSION ANALOG OUTPUT

4.5.3 Output signal setting

Set the output signals to be monitored. Set Pr. 306 to output the same signal from terminals AM0 and AM1

and Pr. 306 and Pr. 310 to output different signals. For details of signal definitions, refer to Pr. 54 and Pr. 158

of the inverter manual (applied).

Pr. 306/Pr. 310

Setting

1 Output frequency 0.01Hz Pr. 55

2 Output current 0.01A/0.1A *2 Pr. 56

3 Output voltage 0.1V 800V

5 Frequency setting 0.01Hz Pr. 55

6 Running speed 1(r/min) The val u e c on v ert e d w i th th e Pr. 37 value from Pr . 55 .

8 Converter output voltage 0.1V 800V

9 *1 Regenerative brake duty 0.1% Pr. 70

10

11 Output current peak value 0.01A/0.1A *2 Pr. 56

12

13 Input power 0.01kW/0.1kW *2 Rated inverter power × 2

14 Output power 0.01kW/0.1kW *2 Rated inverter power × 2

17 Load meter 0.1% Pr. 56

21 Reference voltage output

24 Motor load factor 0.1% 200%

50 Power saving effect

52 PID set point 0.1% 100%

53 PID process value 0.1% 100%

*1 Setting can be made only for the 7 5K( 01800-EC, S75K-CH) or more.

*2 The setting depends on capac ities . ( 55K (01160-EC, 55K-CH) or less/75K (01800-EC, S75K-C H ) o r mor e. )

Types of Monitor Increments Full-Scale Value

Electronic thermal relay

function load factor

Converter output voltage

peak value

Var iable according to parameters

0.1% Electronic thermal relay function operation level

0.1V 800V

Inverter capacity

18

Page 24

EXTENSION ANALOG OUTPUT

4.5.4 Analog signal adjustment [Pr. 307, Pr. 308, Pr. 311, Pr. 312]

Use Pr. 307 or Pr. 311 to set for zero analog output (meter points 0).

In addition, use Pr. 308 or Pr. 312 to set for maximum analog output (full-scale).

Use Pr. 307 to set the value for zero analog output and Pr. 308 for maximum analog output when outputting

the same signal from terminals AM0 and AM1.

Use Pr. 307(AM1) and Pr. 311(AM0) to set the value for zero analog output and Pr. 308(AM1) and Pr.

312(AM0) for maximum analog output when outputting different signals from terminals AM0 and AM1. (Refer

to page 15.)

When Pr. 309 = 0, 1 When Pr. 309 = 10, 11

Analog output

Voltage

Current

20mA

(AM1)

0

(AM0)

10V

Output signal value (Pr. 308 or

Pr. 312) for maximum analog output

Output signal

value

Output signal value (Pr. 307 or

Pr. 311) for zero analog output

REMARKS

When Pr. 307 ≥ Pr. 308, Pr. 311 ≥ Pr. 312, the output

values at terminals AM0 and AM1 are alway s zero.

Analog output

Voltage

Current

20mA

(AM1)

0

(AM0)

10V

Output signal value (Pr. 307 or

Pr. 311) for zero output signal

Analog output

value (Pr. 308 or

Pr. 312) for

maximum

output signal

Output signal

value

REMARKS

When Pr. 307 = Pr. 308, Pr. 311 = Pr. 312, the output

values at terminals AM0 and AM 1 are values set in

parameters always.

4

19

Page 25

EXTENSION ANALOG OUTPUT

C

4.6 Instructions

(1) A voltmeter having smaller internal impedance (or an ammeter having larger internal impedance) than

the value indicated in the Specifications may not deflect to full-scale and may not be calibrated.

(2) When calibrating a meter which has a small full-scale value, set the output of terminal AM0 (or AM1) to

the minimum without the meter connected. Then, connect the meter and make calibration.

AUTION

This option unit is factory-set to provide the full-scale output of 10VDC and 20mADC. Hence, a

voltmeter (7VDC or less) or an ammeter (14mADC or less) with a small full-scale value may be

damaged accidentally during calibration. This should be fully noted.

(3) Set

(4) When an option error occurs, all outputs are tuned off.

"0%" in Pr. 307 (Pr . 31 1) and "100%" in Pr. 308 ( Pr. 312) when calibrating Pr . 323, Pr. 324, C0 (Pr. 900),

C1 (Pr. 901) when Pr. 309 =

"10 or 11 " to prevent calibration value deviation.

20

Page 26

5 DIGITAL OUTPUT

5.1 Internal Block Diagram

The following is the internal block diagram about the FR-A7AY digital output function

Y0

Connector

Controller

Common to Y0-T6

Y6

SE

5

21

Page 27

DIGITAL OUTPUT

5.2 Terminals

By setting the Pr. 313 to Pr. 319 values, output signals available with an inverter as standard can be output

from the open collector terminals.

(1) Open collector output specifications: Permissible load 24V, 0.1ADC

(2) The circuit logic is the same as that of the inverter.

For details of changing the control logic, refer to the inverter manual (basic).

Terminal Symbol Terminal Name Description

AMC

NC

SE

Y3

Y4

Y5

Y6

AM0

AM1

NC

SE

Y0

Y1

Y2

Y0

Y1 Use Pr. 314 to assign functions.

Y2 Use Pr. 315 to assign functions.

Y3 Use Pr. 316 to assign functions.

Y4 Use Pr. 317 to assign functions.

Digital output

terminals

Y5 Use Pr. 318 to assign functions.

Y6 Use Pr. 319 to assign functions.

SE

Common

terminal

AM0

Used for analog output function. (Refer to page 11) AM1

AMC

NC (empty) Do not use.

Use Pr. 31 3 to assign functions.

This is a common terminal (for sink and

source).

22

Page 28

DIGITAL OUTPUT

5.3 Digital Output Function Parameter List

Parameter Number Name Initial Valu e Setting Range

313 DO0 output selection 9999

314 DO1 output selection 9999

315 DO2 output selection 9999

316 DO3 output selection 9999

317 DO4 output selection 9999

318 DO5 output selection 9999

319 DO6 output selection 9999

REMARKS

⋅ For Pr. 313 to Pr. 319, write is disabled dur i ng operatio n even when "2" is set in Pr. 77 Parameter write disable

selection. When changing the parameter setting, stop the operation.

⋅ With th is fu nct i on , ou tp ut si gnals can be set redundantly.

0 to 5, (7), 8, 10 to 19, 25, 26,

45 to 47, 64, 70, (71 to 78), 86

to 96, 98, 99,

100 to 105, (107), 108, 110 to

116, 125, 126, 145 to 147, 164,

170, 186 to 196, 198, 199,

9999

23

5

Page 29

DIGITAL OUTPUT

5.4 Output Signal List

For details of signal definitions, refer to Pr. 190 to Pr. 196 Output terminal functio n selection of the inverte r

manual (applied).

Setting

Positive

Logic

Negative

Logic

0 100 RUN Inverter running 15 115 FUP PID upper limit

1 101 SU Up to frequency 16 116 RL

2 102 IPF

3 103 OL Overload alarm 18 MC2

4 104 FU Output frequency detection 19 MC3

5 105 FU2

7 107 RBP Regenerative brake prealarm *1 26 126 F IN Heatsink overheat pre-alarm

8 108 THP

10 110 PU PU operation mode 46 146 Y46

11 111 RY Inverter operation ready 47 147 PID During PID control activated

12 112 Y12 Output current detection 64 164 Y64 During retry

13 113 Y13 Zero current detection 70 170

14 114 FDN PID lower limit 71 RO1

Signal

Name

Instantaneous power failure/

undervoltage

Second output frequency

detection

Electronic thermal relay function

prealarm

Function

Setting

Positive

Logic

Negative

Logic

17 MC1

25 125 FAN Fan fault output

45 145 RUN3

Signal

Name

PID forward/reverse rotation output

Commercial power-supply

switchover MC1

Commercial power-supply

switchover MC2

Commercial power-supply

switchover MC3

During inverter running and

start command is on

During deceleration due to

instantaneous power failure

(retained until release)

SLEEP

During PID output suspension

Commercial-power supply side

motor 1 connection RO1

Function

24

*2

Page 30

DIGITAL OUTPUT

Setting

Positive

Logic

Negative

Logic

72 RO2

73 RO3

74 RO4

75 RIO1

76 RIO2

77 RIO3

78 RIO4

Signal

Name

Function

Commercial-power supply side

motor 2 connection RO2

Commercial-power supply side

motor 3 connection RO3

Commercial-power supply side

motor 4 connection RO4

Inverter side motor 1

connection RIO1

Inverter side motor 2

connection RIO2

Inverter side motor 3

connection RIO3

Inverter side motor 4

connection RIO4

*2

*2

*2

*2

*2

*2

*2

Setting

Positive

Logic

Negative

Logic

Signal

Name

90 190 Y90 Life alarm

91 191 Y91 Input MC shut off signal

92 192 Y92

Energy saving average value

updated timing

93 193 Y93 Current average monitor signal

94 194 ALM2 Alarm output 2

95 195 Y95 Maintenance timer signal

96 196 REM Remote output

86 186 Y86 Control circuit capacitor life *3 98 198 LF Minor fault output

87 187 Y87 Main circuit capacitor life *3 99 199 ALM Alarm output

88 188 Y88 Cooling fan life *3 9999 No function

89 189 Y89 Inrush current limit circuit life *3

*1 Setting can be made only for the 75K (01800-EC, S75K-CH) or m or e.

*2 Setting can be made only for EC and CH version.

*3 Y86 to Y89 can not be set from the i nv erter.

REMARKS

When an option error occ ur s, all outputs are tuned off.

Function

25

5

Page 31

REVISIONS

*The manual numbe r i s given on the bottom left of the back cover.

Print Date *Manual Number Revision

May, 2004 IB(NA)-0600165ENG - A First edition

Loading...

Loading...