Page 1

HP ProLiant DL585 Server

Maintenance and Service Guide

Part number: 358708-009

Ninth edition: May 2006

Page 2

Legal notices

© Copyright 2004–2006 Hewlett-Packard Development Company, L.P.

The information contained herein is subject to change without notice. The only warranties for HP products and services are set forth in the express

warranty statements accompanying such products and services. Nothing herein should be construed as constituting an additional warranty. HP

shall not be liable for technical or editorial errors or omissions contained herein.

Microsoft, Windows, and Windows NT are U.S. registered trademarks of Microsoft Corporation. Windows Server 2003 is a trademark of

Microsoft Corporation. Linux is a U.S. registered trademark of Linus Torvalds. AMD and Opteron are trademarks of Adavanced Micro Devices,

Inc.

Part number: 358708-009

Ninth edition: May 2006

2

Page 3

Contents

1 About this guide

Audience assumptions .............................................................................................................................. 5

Technician notes......................................................................................................................................5

Where to go for additional help ................................................................................................................ 5

Integrated Management Log................................................................................................................. 6

Telephone numbers ............................................................................................................................. 6

2 Illustrated parts catalog

Customer self-repair program .................................................................................................................... 7

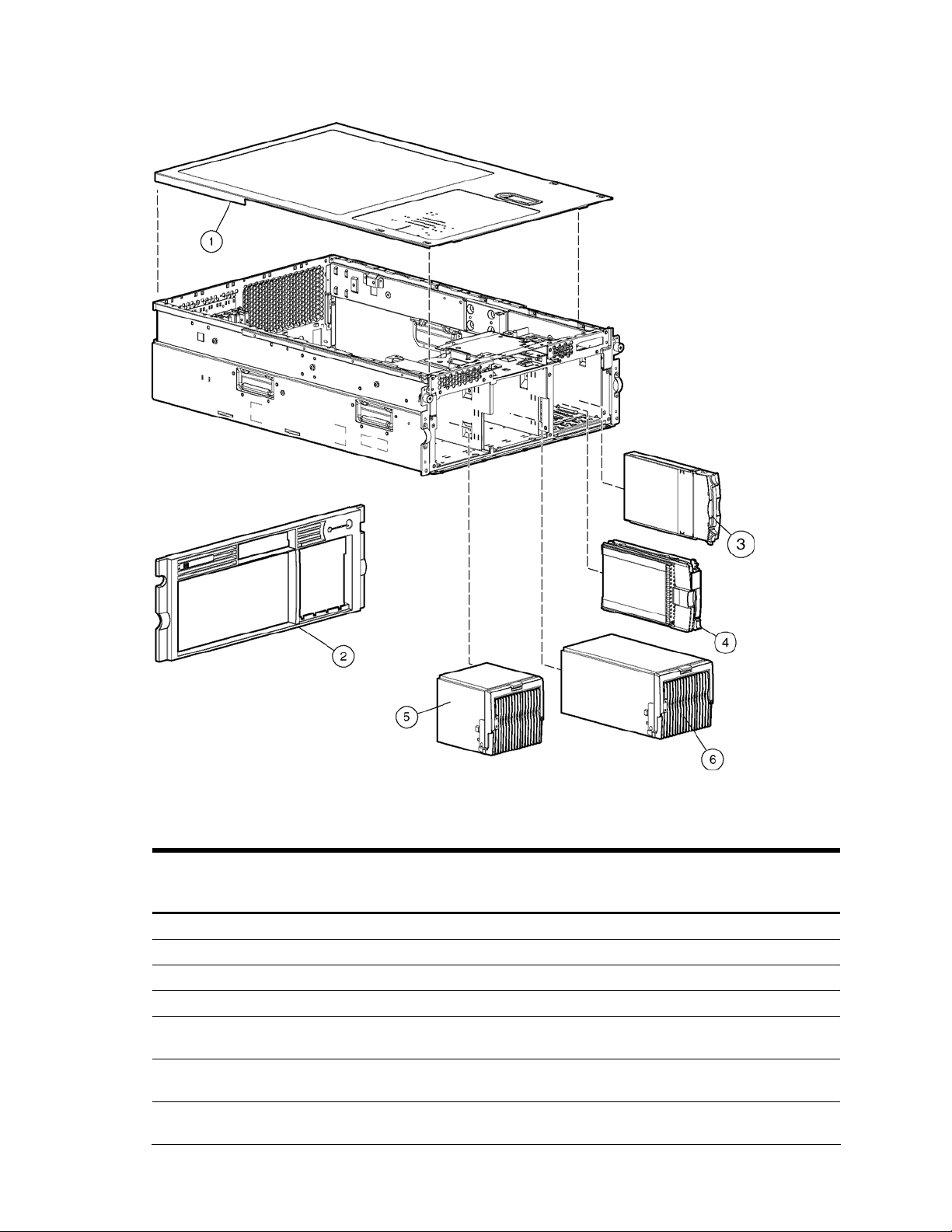

Mechanical components exploded view...................................................................................................... 8

Mechanical components spare parts list...................................................................................................... 8

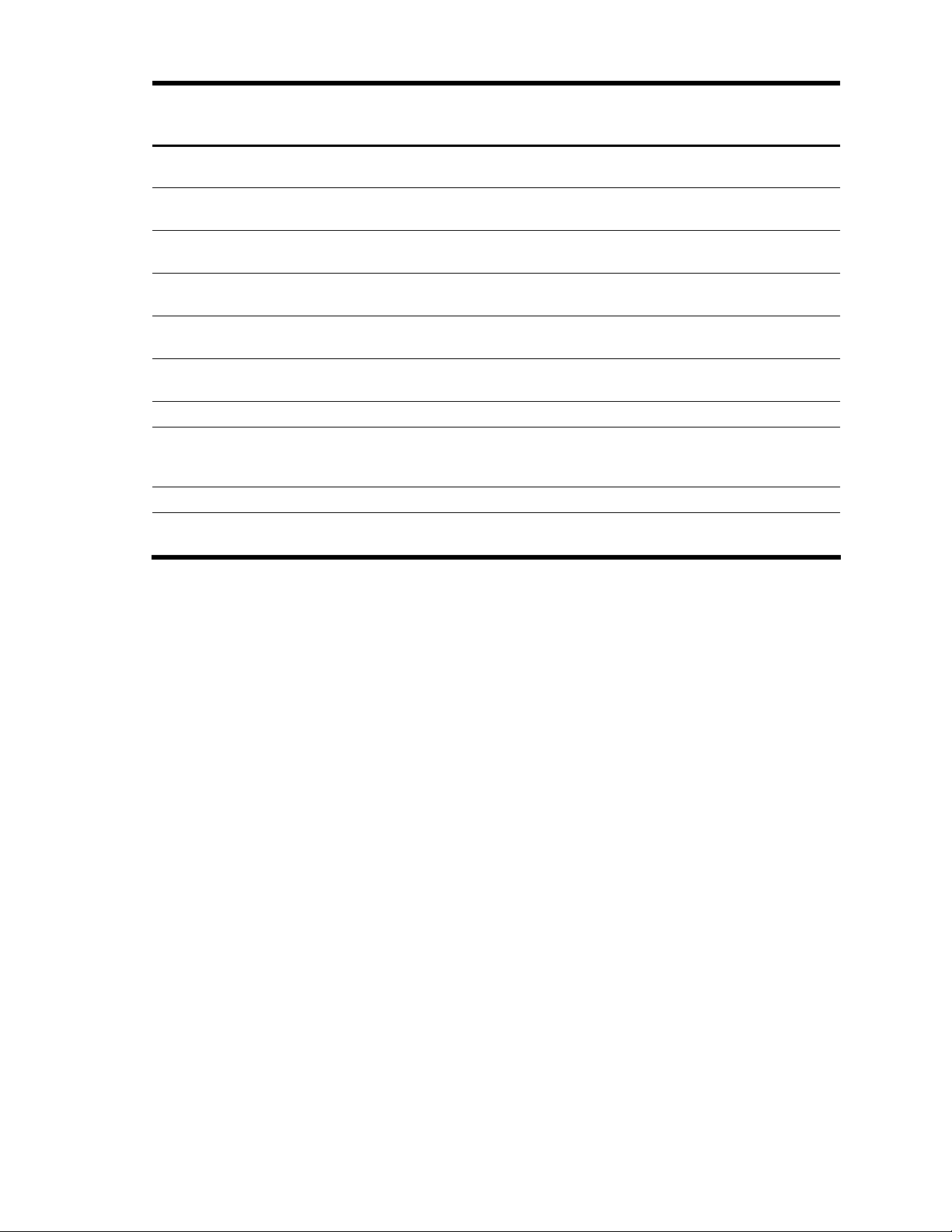

System components exploded view .......................................................................................................... 10

System components spare parts list........................................................................................................... 10

3 Removal and replacement procedures

Safety considerations.............................................................................................................................. 14

Electrostatic discharge ....................................................................................................................... 14

Server warnings and cautions............................................................................................................. 14

Preparation procedures........................................................................................................................... 14

Powering down the server.................................................................................................................. 15

Locating and removing the Torx T-15 tool............................................................................................. 16

Extending the server from the rack....................................................................................................... 16

Removing the access panel ..................................................................................................................... 18

Installing the access panel.................................................................................................................. 18

Removing the server from the rack....................................................................................................... 19

Processor memory boards ....................................................................................................................... 20

Processor memory board population guidelines ....................................................................................20

PPM ................................................................................................................................................ 21

Processor ......................................................................................................................................... 22

Memory options..................................................................................................................................... 24

Minimum memory requirements .......................................................................................................... 24

Memory population guidelines for processor memory boards with eight DIMM slots .................................. 24

Memory population guidelines for processor memory boards with four DIMM slots.................................... 24

Removing a DIMM ............................................................................................................................ 25

Hard drive blanks .................................................................................................................................. 26

Hot-plug SCSI hard drives ....................................................................................................................... 26

Drive replacement precautions............................................................................................................ 26

Hot-plug SAS or SATA hard drives ........................................................................................................... 27

SAS or SATA hard drive cage ................................................................................................................. 28

Power transfer board.............................................................................................................................. 29

Power supply blank................................................................................................................................ 31

Hot-plug power supplies ......................................................................................................................... 32

Hot-plug fans......................................................................................................................................... 33

Universal media drives ........................................................................................................................... 33

Front bezel............................................................................................................................................ 35

Power button/LED assembly ............................................................................................................... 36

Expansion boards .................................................................................................................................. 37

Performance balancing...................................................................................................................... 38

PCI-X expansion boards ..................................................................................................................... 38

SCSI cables........................................................................................................................................... 39

Front fan cage....................................................................................................................................... 40

Pass-through board ................................................................................................................................ 41

QuickFind diagnostic display board and lightpipe ..................................................................................... 42

Rear fan cage ....................................................................................................................................... 43

Contents 3

Page 4

BBWC assembly.................................................................................................................................... 44

SCSI backplane..................................................................................................................................... 45

System battery....................................................................................................................................... 46

System board ........................................................................................................................................ 48

AC filter cable assembly ......................................................................................................................... 50

Re-entering the server serial number ......................................................................................................... 53

4 Diagnostic tools

5 Server component identification

Connectors............................................................................................................................................ 56

Rear panel ....................................................................................................................................... 56

SCSI backplane................................................................................................................................ 57

DIMM slots....................................................................................................................................... 58

Processor and PPM............................................................................................................................ 58

LEDs..................................................................................................................................................... 59

Front panel....................................................................................................................................... 59

QuickFind diagnostic display.............................................................................................................. 60

Hot-plug SCSI hard drives .................................................................................................................. 61

Hot-plug SAS or SATA hard drives ......................................................................................................63

Hot-plug fans.................................................................................................................................... 65

Hot-plug power supplies..................................................................................................................... 65

NIC................................................................................................................................................. 66

BBWCE ........................................................................................................................................... 67

Internal diagnostic display.................................................................................................................. 68

System board switches............................................................................................................................ 69

System maintenance switch (SW3) ...................................................................................................... 69

System ID switch (SW4)..................................................................................................................... 70

iLO/Redundant ROM override switch (SW5) ........................................................................................ 71

Non-maskable interrupt switch ............................................................................................................ 72

Rear unit identification LED switch .......................................................................................................72

6 Troubleshooting

If the server does not start ....................................................................................................................... 74

Diagnostic steps..................................................................................................................................... 75

Problems after initial boot........................................................................................................................ 80

Troubleshooting a failed processor........................................................................................................... 82

Two-processor memory board configuration ......................................................................................... 82

Four-processor memory board configuration ......................................................................................... 82

Other information resources .................................................................................................................... 83

Specifications

Server specifications............................................................................................................................... 84

Index

Contents 4

Page 5

1 About this guide

This maintenance and service guide can be used for reference when servicing the HP ProLiant DL585 Server.

WARNING! To reduce the risk of personal injury from electric shock and hazardous energy levels, only

authorized service technicians should attempt to repair this equipment. Improper repairs can create conditions

that are hazardous.

Audience assumptions

This guide is for service technicians. HP assumes you are qualified in the servicing of computer equipment and trained

in recognizing hazard in products with hazardous energy levels and are familiar with weight and stability

precautions for rack installations.

Technician notes

WARNING! Only authorized technicians trained by HP should attempt to repair this equipment. All

troubleshooting and repair procedures are detailed to allow only subassembly/module-level repair. Because of

the complexity of the individual boards and subassemblies, no one should attempt to make repairs at the

component level or to make modifications to any printed wiring board. Improper repairs can create a safety

hazard.

WARNING! To reduce the risk of personal injury from electric shock and hazardous energy levels, do not

exceed the level of repairs specified in these procedures. Because of the complexity of the individual boards

and subassemblies, do not attempt to make repairs at the component level or to make modifications to any

printed wiring board. Improper repairs can create conditions that are hazardous.

WARNING! To reduce the risk of electric shock or damage to the equipment:

• Disconnect power from the system by unplugging all power cords from the power supplies.

• Do not disable the power cord grounding plug. The grounding plug is an important safety

feature.

• Plug the power cord into a grounded (earthed) electrical outlet that is easily accessible at all

times.

CAUTION: To properly ventilate the system, you must provide at least 7.6 cm (3.0 in) of clearance at the front

and back of the server.

CAUTION: The computer is designed to be electrically grounded (earthed). To ensure proper operation, plug

the AC power cord into a properly grounded AC outlet only.

NOTE: Any indications of component replacement or printed wiring board modifications may void any

warranty.

Where to go for additional help

In addition to this guide, the following information sources are available:

• User documentation

• Service Quick Reference Guide

• Service training guides

• Service advisories and bulletins

• QuickFind information services

• HP Systems Insight Manager (HP SIM) software

About this guide 5

Page 6

Integrated Management Log

The server includes an integrated, nonvolatile management log that contains fault and management information. The

contents of the Integrated Management Log (IML) can be viewed with HP SIM.

Telephone numbers

For the name of the nearest HP authorized reseller:

• In the United States, see http://www.hp.com/service_locator

• In Canada, see http://www.hp.com

For HP technical support:

• In the United States and Canada, call 1-800-HP-INVENT (1-800-474-6836).

• Outside the United States and Canada, see http://www.hp.com.

.

.

About this guide 6

Page 7

2 Illustrated parts catalog

Customer self-repair program

The HP customer self-repair program offers you the fastest service under either warranty or contract. It enables HP to

ship replacement parts directly to you so that you can replace them. Using this program, you can replace parts at

your own convenience.

Through this convenient, easy-to-use program:

• An HP support specialist will diagnose and assess whether a replacement part is required to address a system

problem. The specialist will also determine whether you can replace the part.

• Replacement parts are express-shipped. Most in-stock parts are shipped the same day you contact HP. You

might be required to send the defective part back to HP, unless otherwise instructed.

• This program is available for most HP products currently under warranty or contract. For information on the

warranty service, see the HP website at

http://h18004.www1.hp.com/products/servers/platforms/warranty/index.html

For more information about the HP customer self-repair program, contact your local service provider. For the North

American program, see the HP website at http://www.hp.com/go/selfrepair

Customer replaceable parts are identified in the following tables.

.

.

Illustrated parts catalog 7

Page 8

Mechanical components exploded view

Figure 1 Mechanical components exploded view

Mechanical components spare parts list

Table 1 Mechanical components spare parts list

Item Description Assembly

number

1 Access panel 321466-001 — 359772-001 — Yes

2 Front bezel 233588-002 — 243669-001 — Yes

3 SCSI hard drive blank 302531-002 — 122759-001 — Yes

4 Hard drives — — — — —

— 36-GB SCSI hard drive,

U320 15K*

— 72-GB SCSI hard drive,

U320 10K*

— 72-GB SCSI hard drive,

U320 15K*

271837-016‡

See requirement

271837-008‡

See requirement

271837-018‡

See requirement

Modified

assembly

number

404670-008 289241-001‡

404670-003 289042-001‡

404670-007 289243-001‡

Spare part

number

See requirement

See requirement

See requirement

Modified spare

part number

404714-001 Yes

404709-001 Yes

404713-001 Yes

Customer selfrepair (Yes/No)

Illustrated parts catalog 8

Page 9

Table 1 Mechanical components spare parts list

Item Description Assembly

number

— 146-GB SCSI hard drive,

U320 10K*

— 146-GB SCSI hard drive

U320 15K*

— 300-GB SCSI hard drive,

U320 10K*

— 36-GB SAS hard drive,

10K*

— 72-GB SAS hard drive,

10K*

— 60-GB SATA hard drive,

5.4K*

5 Power supply blank 233685-001 — 267133-001 — Yes

6 Power supply, 870 W,

hot-plug (2.6-GHz and

dual-core models)

7 Power cord retainer kit* — — 313825-001 — Yes

8 SAS/SATA hard drive

blank

271837-010‡

See requirement

281837-028‡

See requirement

271837-021‡

See requirement

375696-001

375712-001

375696-002

375712-002

390158-001 — 382264-001 — Yes

192147-002‡

See requirement

376383-001 — 392613-001 — Yes

Modified

assembly

number

404670-002 289044-001‡

404670-006 347779-001‡

404670--001 351126-001‡

— 376596-001 — Yes

— 376597-001 — Yes

192147-502 192201-002‡

Spare part

number

See requirement

See requirement

See requirement

See requirement

Modified spare

part number

404708-001 Yes

404712-001 Yes

404701-001 Yes

409781-002 Yes

Customer selfrepair (Yes/No)

* Not shown

‡REQUIREMENT:

For Customers in the EU only.

The use of the Original Spare part is regulated by RoHS legislation§.

If your unit contains a part that is labelled with the Modified Spare number, the Modified Spare must be ordered as

the replacement part in the EU.

If your unit contains a part that is labelled with the Original Spare number, please order the Original Spare as the

replacement part in the EU. In this case either the Original Spare or the Modified Spare may be shipped which will

not affect performance or functionality of the unit.

§Directive 2002/95/EC restricts the use of lead, mercury, cadmium, hexavalent chromium, PBBs and PBDEs in

electronic products.

Illustrated parts catalog 9

Page 10

System components exploded view

Figure 2 System components exploded view

System components spare parts list

Table 2 System components spare parts list

Item Description Assembly

number

— Media storage devices — — — — —

1 CD-RW drive, universal

media

2a DVD-ROM drive, 8X,

universal media

(optional)*

2b DVD-RW drive, universal

media (optional)*

— Boards — — — — —

4 SCSI backplane 010879-001‡

5 Diagnostic display board

and lightpipe

6 Pass-through board 279758--001‡

7 System board 011977-002‡

2947669D1/9D2‡ See

requirement

168003935/9D1‡ See

requirement

336084-9D1‡

See requirement

See requirement

012134-001‡

See requirement

See requirement

See requirement

Modified

assembly

number

383696-002 337273-001‡

395910-001 268795-001‡

263394-002 384070-001‡

010879-501 231128-001‡

012134-501 356784-001‡

012662-501 249106-001‡

011977-502 356782-001‡

Spare part

number

See requirement

See requirement

See requirement

See requirement

See requirement

See requirement

See requirement

Modified spare

part number

399959-001 Yes

397928-001 Yes

399396-001

412320-001 Yes

416251-001 Yes

417235-001 Yes

412318-001 No

Customer selfrepair (Yes/No)

Illustrated parts catalog 10

Page 11

Table 2 System components spare parts list

Item Description Assembly

number

8 Processor memory boards — — — — —

— Processor memory board

(PC2100/PC2700)**

— Processor memory board

(PC2100/PC2700)**

— Processor memory board

(PC3200)**

9 Processors — — — — —

— Processor, Opteron 850,

2.6 GHz

— Processor, 2.8 GHz 397805-001 — 399203-01 — Yes

— Processor, dual core, 1.8

GHz

— Processor, dual core, 2.2

GHz

— Processor, dual core, 2.4

GHz

— Processor, dual core, 2.6

GHz

10 Heatsink 321961-007 — 383420-001 — Yes

11 Processor power module

(PPM)

12 Cable kit — — 243670-001 — Yes

— U320 SCSI cable

assembly

— U320 SCSI cable

assembly

— Power cable assembly 233303-001 — — — Yes

— Hot-plug cable assembly 241793-012 — — — Yes

13 Battery, system, 3 V 166899-001 — 153099-001 — Yes

14 5i Plus cache memory

module

15 Battery-Backed Write

Cache Module (BBWC),

4.8 V

16 BBWC cache module

cable*

17 Fan assembly, hot-plug,

92 x 38 mm

18 Fan cage cable

assembly*

19 SAS backplane kit* — — 376475-001‡

— SAS backplane board * 012564-001‡

011974-002‡

See requirement

011974-003‡

See requirement

012567-001‡

See requirement

391162-001 — 382043-001 — Yes

389711-001 — 390247-001 — Yes

389711-003 — 390249-001 — Yes

389711-004 — 403836-001 — Yes

389711-005 — 410873-001 — Yes

383265-001 — 383337-001 — Yes

166298-003 — — — Yes

166298-039 — — — Yes

011665-001 — 260741-001 — Yes

011668-001 — 260740-001 — Yes

262695004/005

321520-001 — 359773-001 — Yes

321518-001 — 361442-001 — No

See requirement

Modified

assembly

number

011974-502 356783-001 — Yes

011974-503 382596-001‡

012567-501 378476-001‡

— 283033-001 — Yes

012564-501 — — Yes

Spare part

number

See requirement

See requirement

See requirement

Modified spare

part number

412319-001 Yes

412321-001 Yes

411794-001 Yes

Customer selfrepair (Yes/No)

Illustrated parts catalog 11

Page 12

Table 2 System components spare parts list

Item Description Assembly

number

— Power transfer board * 012662-001‡

See requirement

20 SAS cable kit* — — 393535-001 — Yes

— SAS data cable assembly * 361316-002 — — — Yes

— SAS power cable * 379196-001 — — — Yes

21 SAS array controller* 012335-001‡

See requirement

22 SAS array cache (with

battery)*

23 Plastics kit* — — 359768-001 — Yes

— Processor memory board

air baffle *

— Chassis air baffle, lower * 338886-001 — — — Yes

— Chassis air baffle, upper * 333359-001 — — — Yes

24 AC power cord, 15 A,

125 V*

25 AC power cord, 15 A,

125 V*

26 AC power cord, 10 A,

C14–C19 IEC*

27 Rack-mounting hardware

kit for square-hole racks*

28 Rack-mounting hardware

kit for round-hole racks*

(optional)

29 Cable kit, AC filter cable

assembly*

— Internal AC power cable

assembly

— Internal AC power cable

assembly

30 Torx screwdriver, T-15* 107473-001 — 199630-001 — Yes

31 Return kit* — — 279645-001 — Yes

— Memory — — — — —

32 512-MB, PC2700 (DDR

SDRAM)*

33 1-GB, PC2700 (DDR

SDRAM)*

34 2-GB, PC2700 (DDR

SDRAM)*

35 4-GB, PC2700 (DDR

SDRAM)*

36 512-MB, PC3200 (DDR

SDRAM)*

011773-002‡

See requirement

337992-001 — — — Yes

178968-001 — 237457-001 — Yes

178968-001 — 237458-001 — Yes

287485-003 — 311582-001 — Yes

284499-002 — 313215-001 — Yes

287528-B21 — 291895-001 — Yes

— — 243671-001 — No

233106-001 — — — No

233106-002 — — — No

331561-841‡

See requirement

331562-851‡

See requirement

331563-851‡

See requirement

331564-061‡

See requirement

373028-051‡

See requirement

Modified

assembly

number

012662-501 — — Yes

012335-501 370855-001‡

011773-502 309522-001‡

413150-841 399956-001‡

413151-851 399957-001‡

413152-851 399958-001‡

413153-861 395547-001‡

373028-851 378913-001‡

Spare part

number

See requirement

See requirement

See requirement

See requirement

See requirement

See requirement

See requirement

Modified spare

part number

417343-001 Yes

416828-001 Yes

416255-001 Yes

416256-001 Yes

416257-001 Yes

416258-001 Yes

416105-001 Yes

Customer selfrepair (Yes/No)

Illustrated parts catalog 12

Page 13

Table 2 System components spare parts list

Item Description Assembly

number

37 1-GB, PC3200 (DDR

SDRAM)*

38 2-GB, PC3200 (DDR

SDRAM)*

373029-051‡

See requirement

373030-051‡

See requirement

Modified

assembly

number

373029-851 378914-001‡

373030-851 378915-001‡

Spare part

number

See requirement

See requirement

Modified spare

part number

416106-001 Yes

416107-001 Yes

Customer selfrepair (Yes/No)

* Not shown

**Mixing processor speeds or cache sizes is not supported

‡REQUIREMENT:

For Customers in the EU only.

The use of the Original Spare part is regulated by RoHS legislation§.

If your unit contains a part that is labelled with the Modified Spare number, the Modified Spare must be ordered as

the replacement part in the EU.

If your unit contains a part that is labelled with the Original Spare number, please order the Original Spare as the

replacement part in the EU. In this case either the Original Spare or the Modified Spare may be shipped which will

not affect performance or functionality of the unit.

§Directive 2002/95/EC restricts the use of lead, mercury, cadmium, hexavalent chromium, PBBs and PBDEs in

electronic products.

Illustrated parts catalog 13

Page 14

3 Removal and replacement procedures

You need the following items for some procedures:

• Torx T-15 tool

• Flathead screwdriver

• Diagnostics Utility on the HP SmartStart CD

Safety considerations

Before performing service procedures, review the following safety information.

Electrostatic discharge

A discharge of static electricity can damage static-sensitive devices or microcircuitry. Proper packaging and

grounding techniques are necessary precautions to prevent damage. To prevent electrostatic damage:

• Transport products in static-safe containers such as conductive tubes, bags, or boxes.

• Keep electrostatic-sensitive parts in their containers until they arrive at static-free stations.

• Cover workstations with approved static-dissipating material. Use a wrist strap connected to the work surface

and properly grounded (earthed) tools and equipment.

• Keep work area free of nonconductive materials such as ordinary plastic assembly aids and foam packing.

• Be sure that you are properly grounded (earthed) when touching a static-sensitive component or assembly.

• Avoid touching pins, leads, or circuitry.

• Use nonconductive field service tools.

Server warnings and cautions

WARNING! Do not exceed the level of repair specified in the procedures in the product documentation. All

troubleshooting and repair procedures are detailed to allow only subassembly or module-level repair. Because

of the complexity of the individual boards and subassemblies, do not attempt to make repairs at the component

level or to make modifications to any printed wiring board. Improper repairs can create a safety hazard.

WARNING! To reduce the risk of electric shock or damage to the equipment:

• Do not disable the AC power cord grounding plug. The grounding plug is an important safety

feature.

• Plug the power cord into a grounded (earthed) electrical outlet that is easily accessible at all

times.

• Unplug the power cord from each power supply to disconnect power to the equipment.

WARNING! To reduce the risk of personal injury from hot surfaces, allow the hot-plug drives and the internal

system components to cool before touching.

CAUTION: Do not operate the server for extended periods without the access panel. Operating the server

without the access panel results in improper airflow and improper cooling that can lead to thermal damage.

Preparation procedures

To access some components and perform certain service procedures, you must do one or more of the following:

• Extend the server from the rack.

Removal and replacement procedures 14

Page 15

IMPORTANT: If you are performing service procedures in an HP, Compaq branded, or third-party rack

cabinet, you can use the locking feature of the rack rails to support the server and gain access to internal

components.

For more information about telco rack solutions, see the RackSolutions.com website at

http://www.racksolutions.com/hp

• Access internal components.

If you must access internal components for removal or replacement, you can remove the access panel without

removing the server from the rack.

• Power down the server.

NOTE: Do not power down the server if you are performing a hot-plug procedure.

• Remove the server from the rack.

If the rack environment, cabling configuration, or the server location in the rack creates awkward conditions,

remove the server from the rack.

WARNING! Before lifting the server, remove all hot-plug power supplies and hard drives to reduce the weight.

Powering down the server

WARNING! To reduce the risk of personal injury, electric shock, or damage to the equipment, remove the

power cord to remove power from the server. The front panel Power on/Standby button does not completely

shut off system power. Portions of the power supply and some internal circuitry remain active until AC power is

removed.

.

IMPORTANT: If installing a hot-plug device, it is not necessary to power down the server.

1. Back up the server data.

2. Shut down the operating system as directed by the operating system documentation.

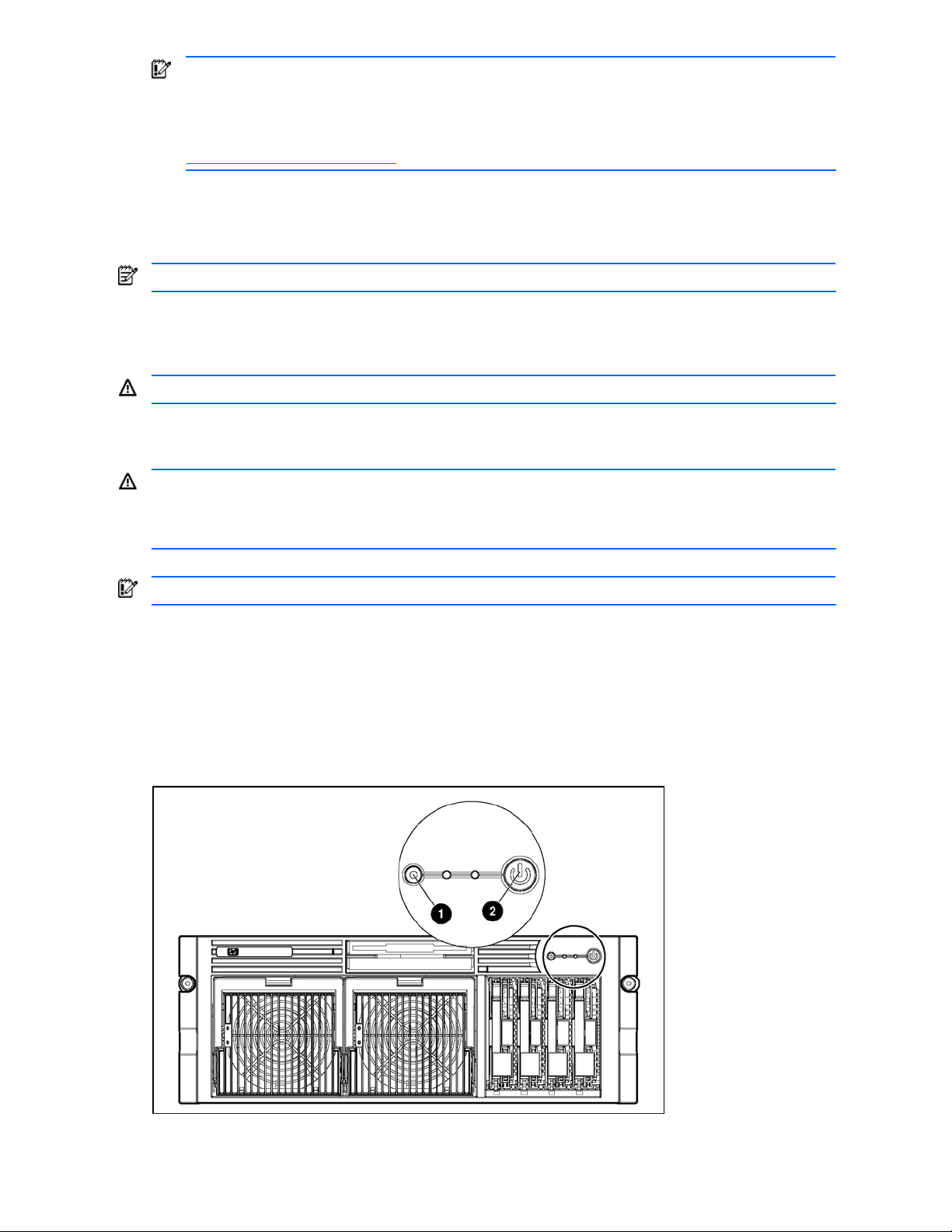

3. If the server is installed in a rack, press the UID LED button on the front panel. Blue LEDs illuminate on the front

and rear of the server.

4. Press the Power on/Standby button to place the server in standby mode. When the server activates standby

power mode, the system power LED changes to amber.

Figure 3 Identifying the UID LED (1) and Power on/Standby buttons (2)

5. If the server is installed in a rack, locate the server by identifying the illuminated rear UID LED button.

6. Disconnect the power cords.

Removal and replacement procedures 15

Page 16

The system is now without power.

Locating and removing the Torx T-15 tool

Many hardware procedures in the server are toolless, but a few require the removal of Torx T-15 screws that have

been installed for shipping or security reasons. A Torx T-15 tool ships with the server for the removal of these screws.

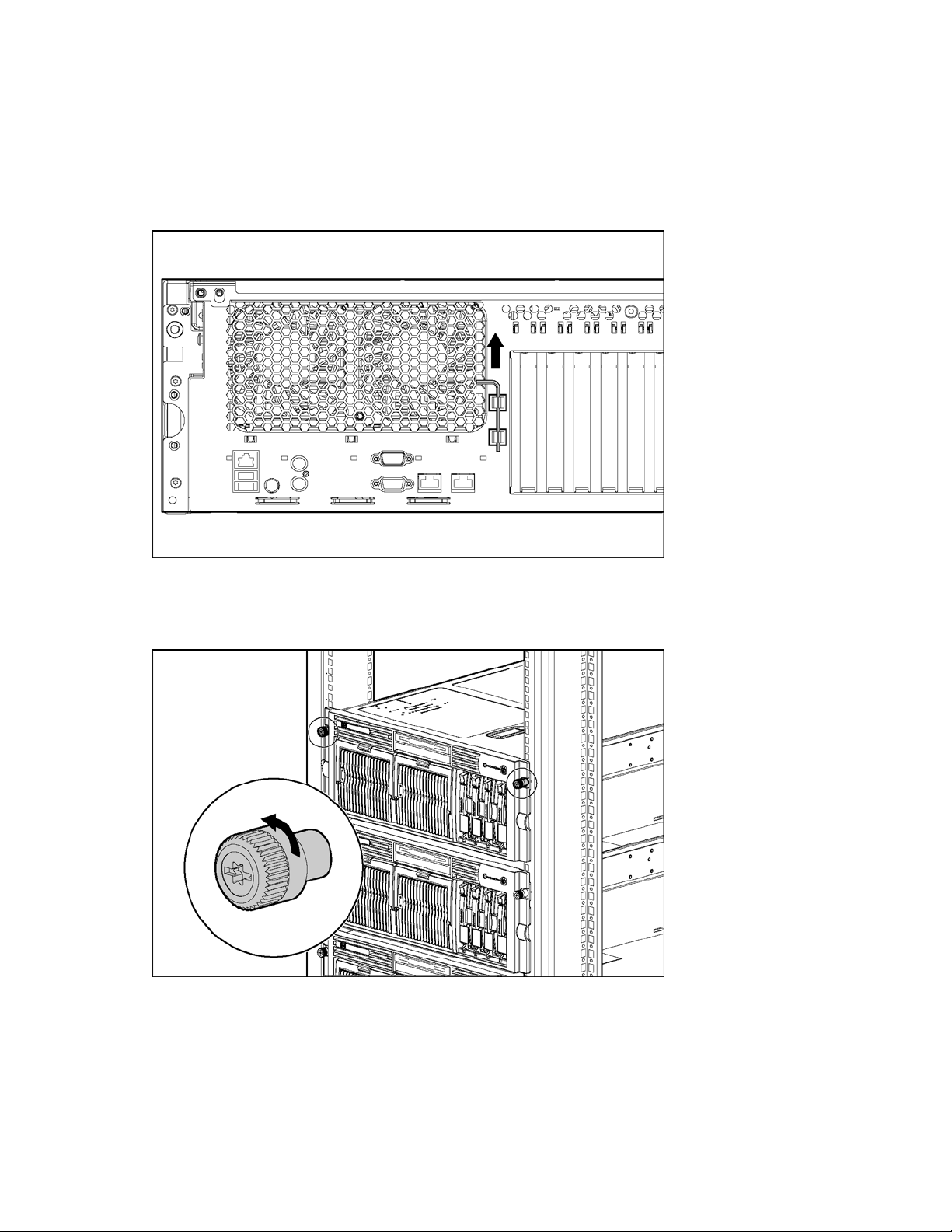

1. Locate the Torx T-15 tool on the back of the server.

2. Slide the tool upward out of the retaining clips.

Figure 4 Removing the Torx T-15 tool

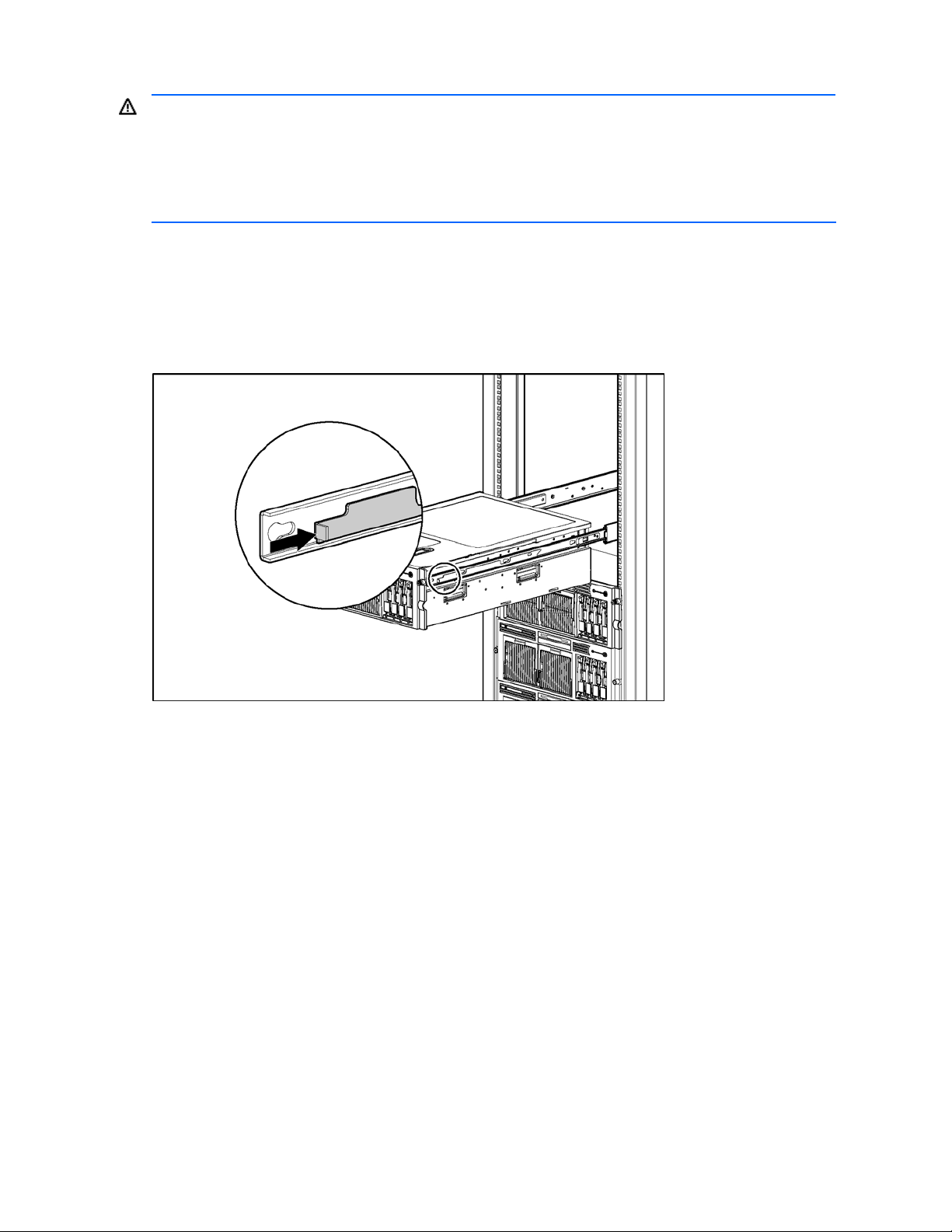

Extending the server from the rack

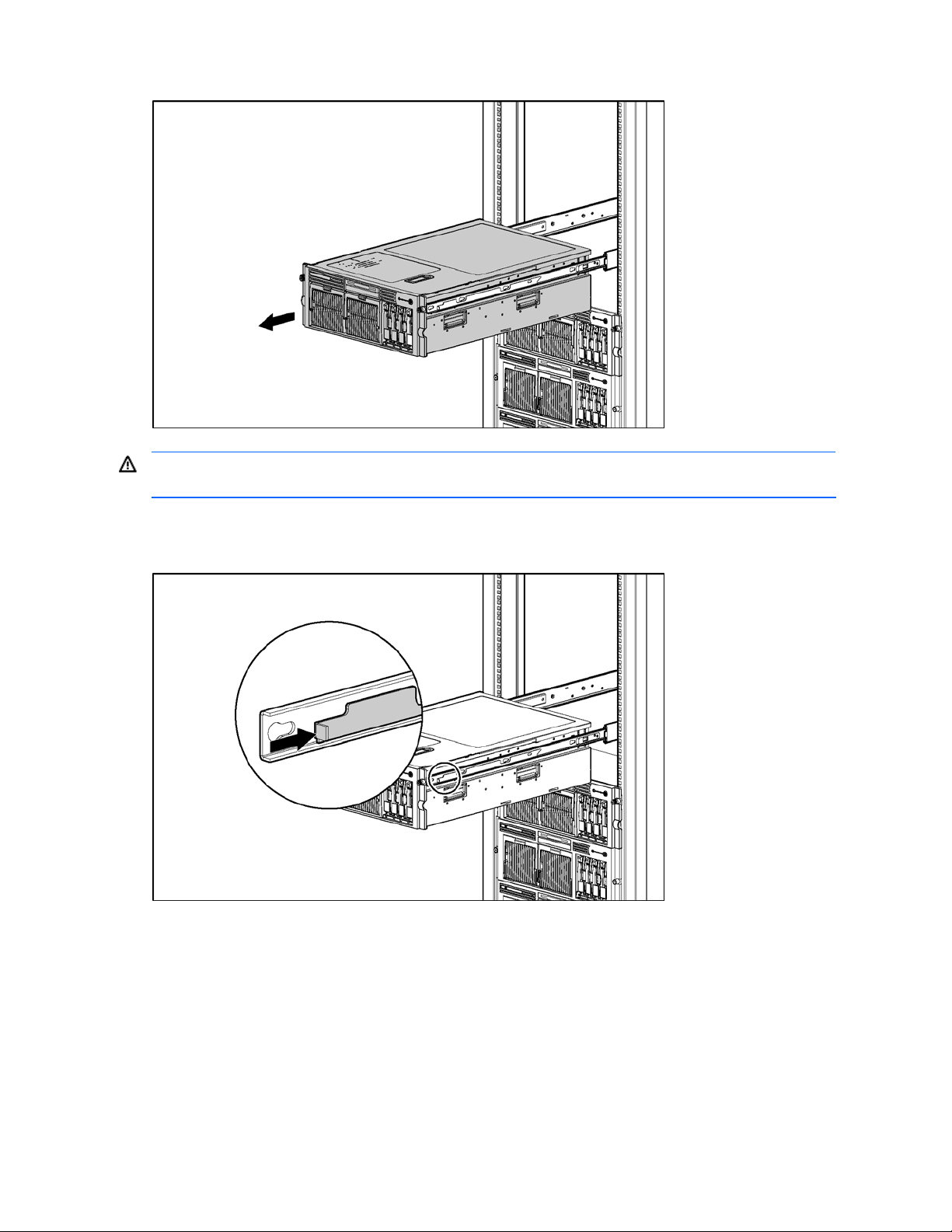

1. Loosen the thumbscrews that secure the server to the front of the rack.

Figure 5 Loosening the front panel thumbscrews

Removal and replacement procedures 16

Page 17

2. Extend the server on the rack rails until the server rail-release latches engage.

Figure 6 Extending the server from the rack

WARNING! Be careful when pressing the rail-release levers and sliding the component into or out of the rack.

The sliding rails could pinch your fingertips.

3. After performing the installation or maintenance procedure, press the rail-release levers at the front of both

server rails and slide the server into the rack.

Figure 7 Sliding the server into the rack

4. Secure the server by tightening the thumbscrews.

Removal and replacement procedures 17

Page 18

Removing the access panel

WARNING! Pressing the Power On/Standby button sets the server to the standby position, which removes

power from most areas of the server. However, portions of the power supply and some internal circuitry remain

active until the AC power cord is removed.

WARNING! To reduce the risk of personal injury from hot surfaces, allow the internal system components to

cool before touching.

CAUTION: Electrostatic discharge can damage electronic components. Properly ground yourself before

beginning any installation procedure.

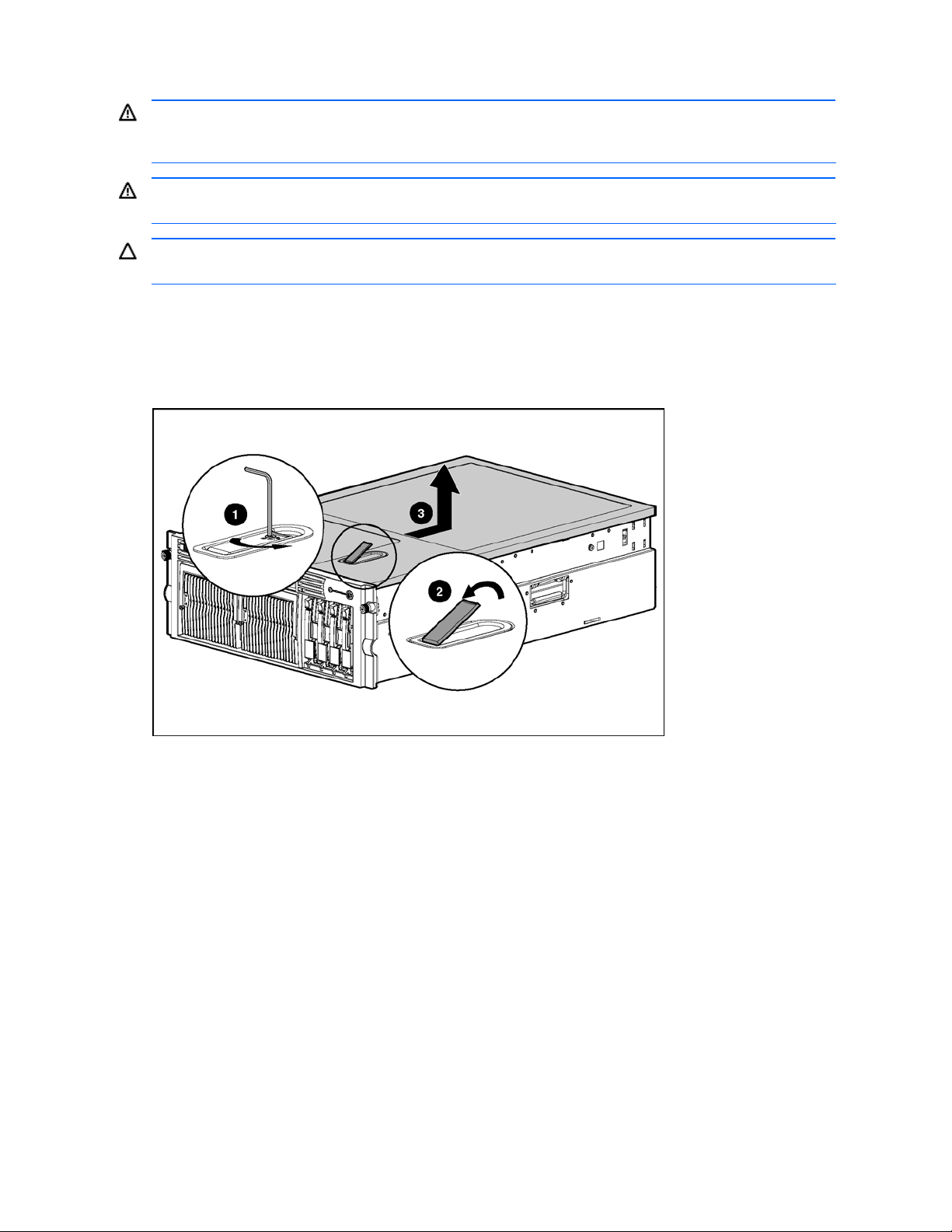

1. Power down the server. See “Powering down the server” earlier in this chapter.

2. Extend the server from the rack. See “Extending the server from the rack” earlier in this chapter.

3. Unlock the access panel latch .

4. Lift up on the latch (2), and remove the access panel .

Figure 8 Removing the access panel

Installing the access panel

1. Place the access panel on top of the server with the latch open. Allow the panel to extend past the rear of the

server approximately 1.25 cm (0.5 inches).

2. Push down on the latch. The access panel slides to a closed position.

Removal and replacement procedures 18

Page 19

Removing the server from the rack

WARNING! The server is very heavy, up to 44.5 kg (98 lb). To reduce the risk of personal injury or damage to

the equipment:

• Remove all hot-plug power supplies to reduce the weight of the server before lifting it.

• Observer local occupational health and safety requirements and guidelines for material

handling.

• Get help to lift and maneuver the server.

To remove the server from the rack:

1. Power down the server. See “Powering down the server” earlier in this chapter.

2. Extend the server from the rack. See “Extending the server from the rack” earlier in this chapter.

3. Unplug the cables from the rear of the server.

4. Press the rail-release levers on the rails, and slide the server off the rack rails.

Figure 9 Removing the server from the rack

5. Place the server on a sturdy, level surface.

Reverse steps to install the server in the rack.

Removal and replacement procedures 19

Page 20

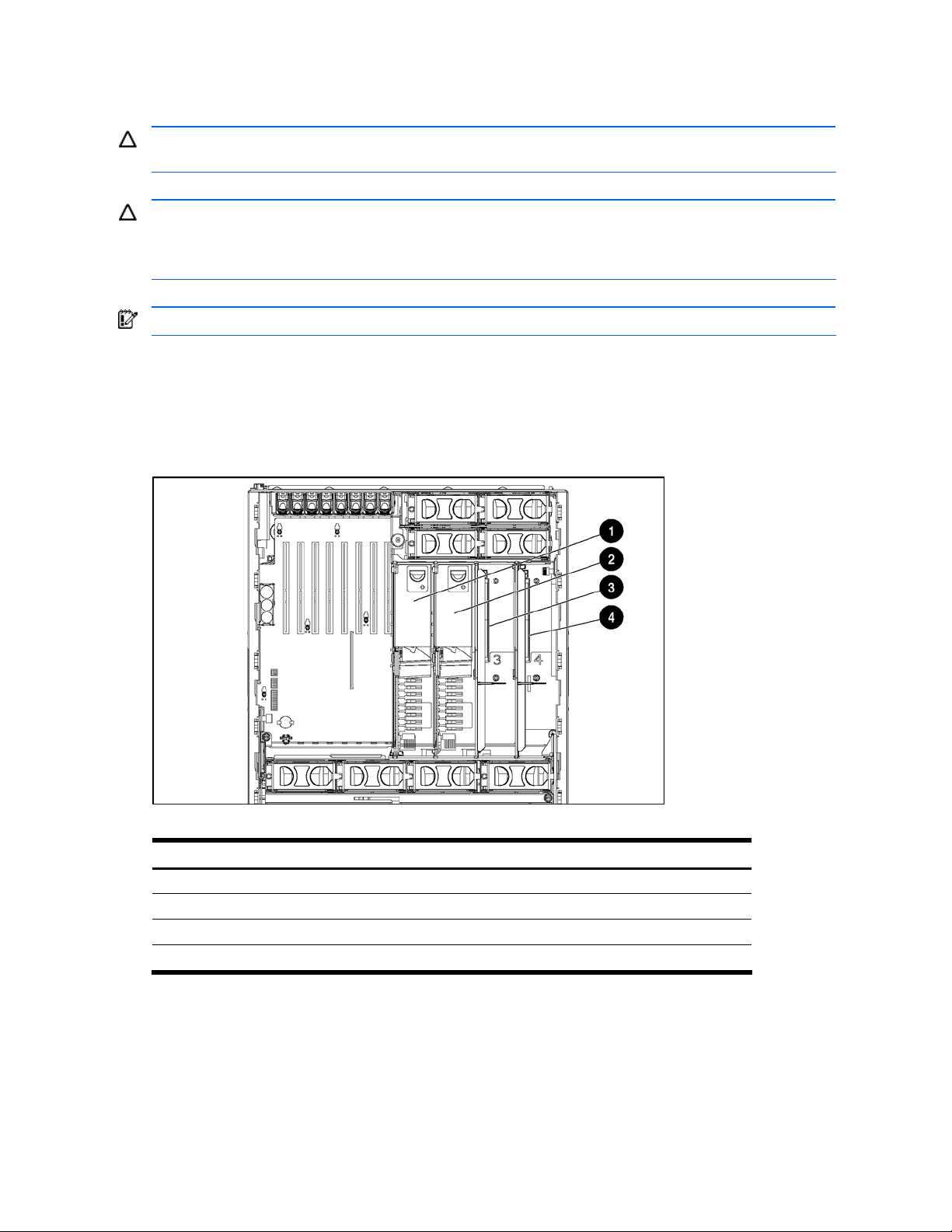

Processor memory boards

The server supports up to four processor memory boards with AMD® Opteron™ processors.

CAUTION: Processor memory boards 1 and 2 must always be installed. The system will not boot if either

board is missing.

CAUTION: Update the ROM to be sure that the system ROM recognizes the new processor you are installing.

For the most recent ROMPaq, see the HP website, and follow the support link on the product website.

Failure to flash the ROM before installing processor memory boards can cause system failure.

IMPORTANT: Mixing processor speeds and cache sizes is not supported.

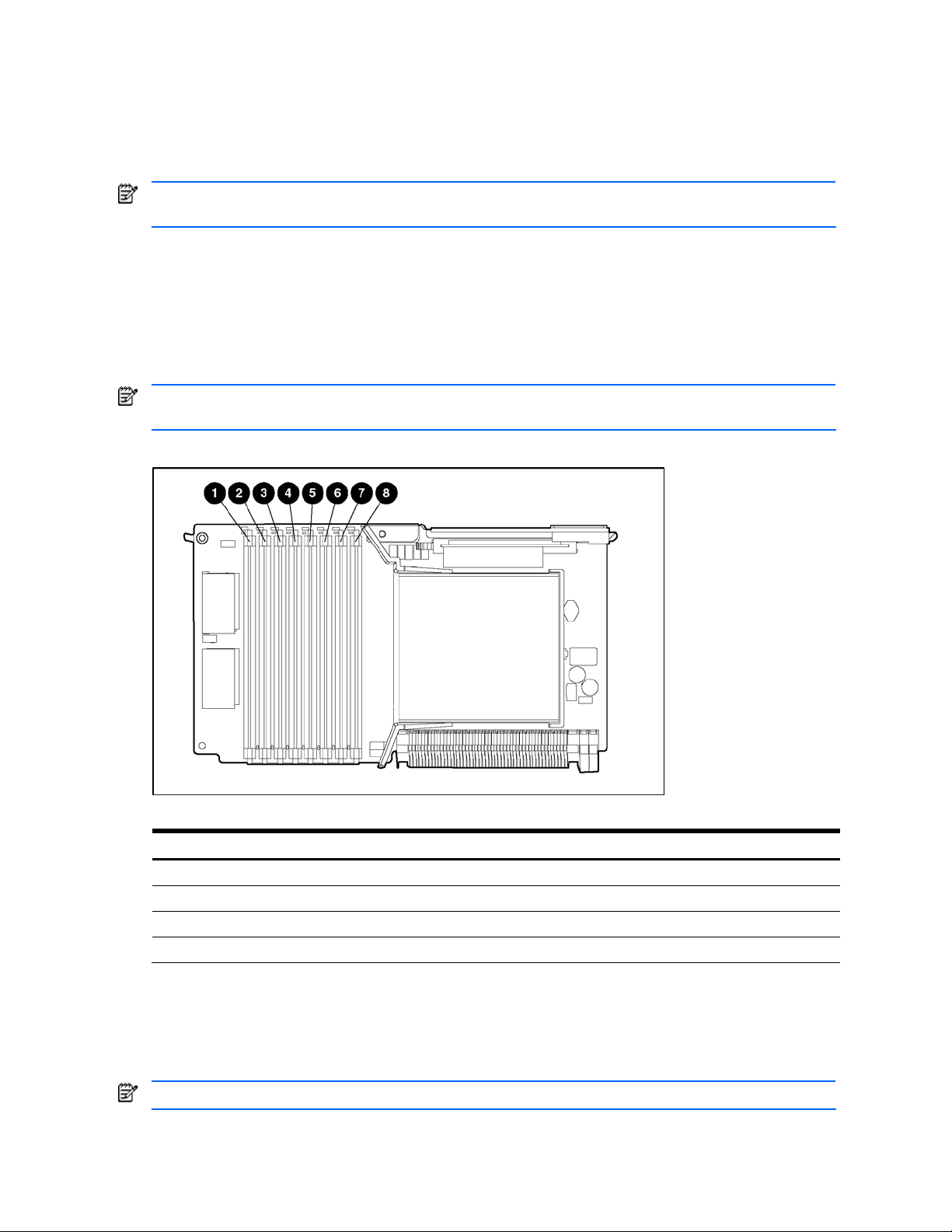

Processor memory board population guidelines

• All processors must be of the same speed and cache size.

• Processor memory boards 1 and 2 must always be installed.

• Processor memory boards 3 and 4 must be installed as a pair.

Figure 10 Locating the processor memory boards

Table 3 Processor memory boards

Item Description

1 Processor memory board slot 1 (processor)

2 Processor memory board slot 2 (boot processor)

3 Processor memory board slot 3 (air baffle)

4 Processor memory board slot 4 (air baffle)

To remove a processor memory board:

1. Power down the server. See “Powering down the server” earlier in this chapter.

2. Extend the server from the rack. See “Extending the server from the rack” earlier in this chapter.

3. Remove the access panel. See “Removing the access panel” earlier in this chapter.

Removal and replacement procedures 20

Page 21

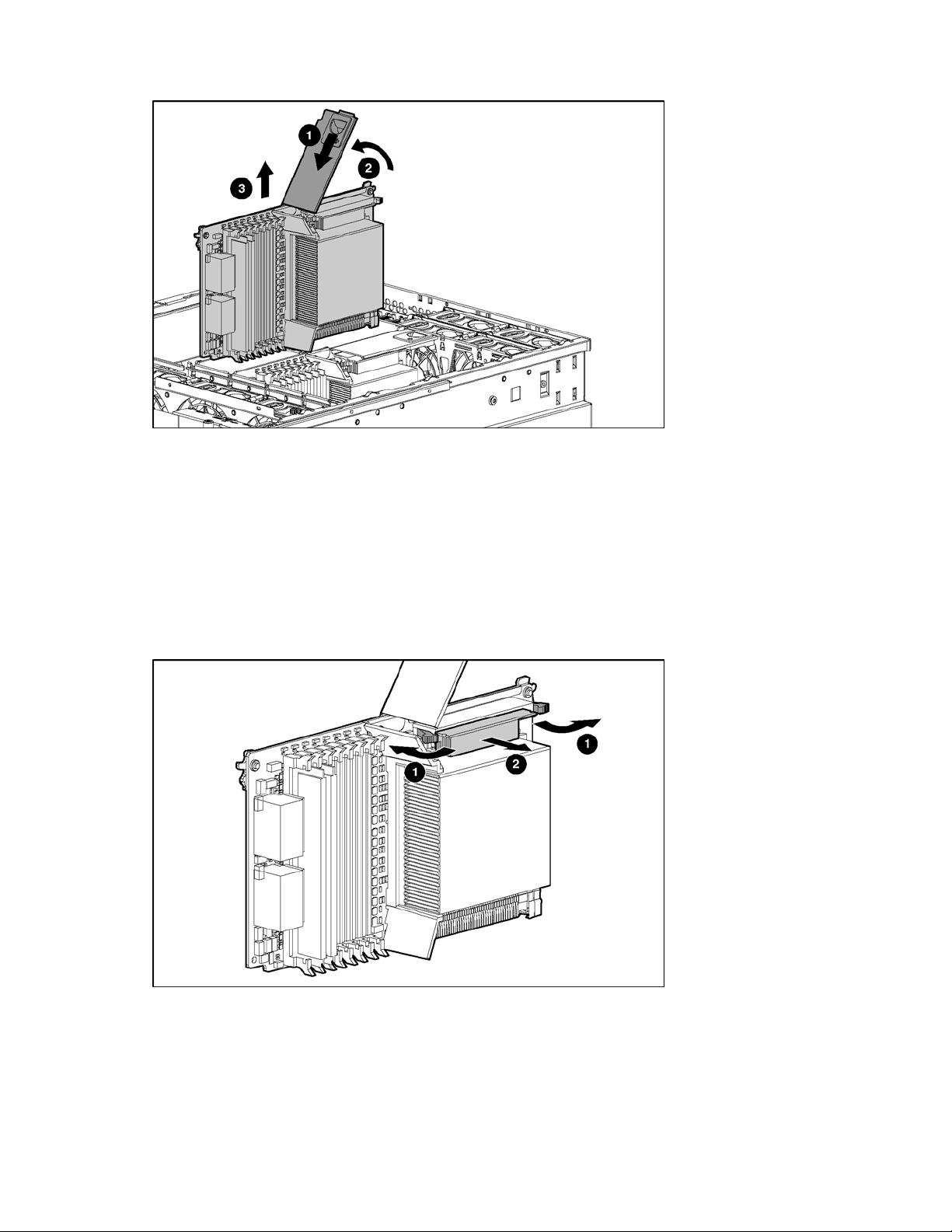

PPM

4. Remove the processor memory board.

Figure 11 Removing a processor memory board

Reverse the steps to install a processor memory board.

To remove a Power Processor Module (PPM):

1. Power down the server. See “Powering down the server” earlier in this chapter.

2. Extend the server from the rack. See “Extending the server from the rack” earlier in this chapter.

3. Remove the access panel. See “Removing the access panel” earlier in this chapter.

4. Remove the processor memory board. See “Processor memory boards” earlier in this chapter.

5. Remove the PPM from the processor memory board.

Figure 12 Removing a PPM

Reverse the steps to install a PPM.

Removal and replacement procedures 21

Page 22

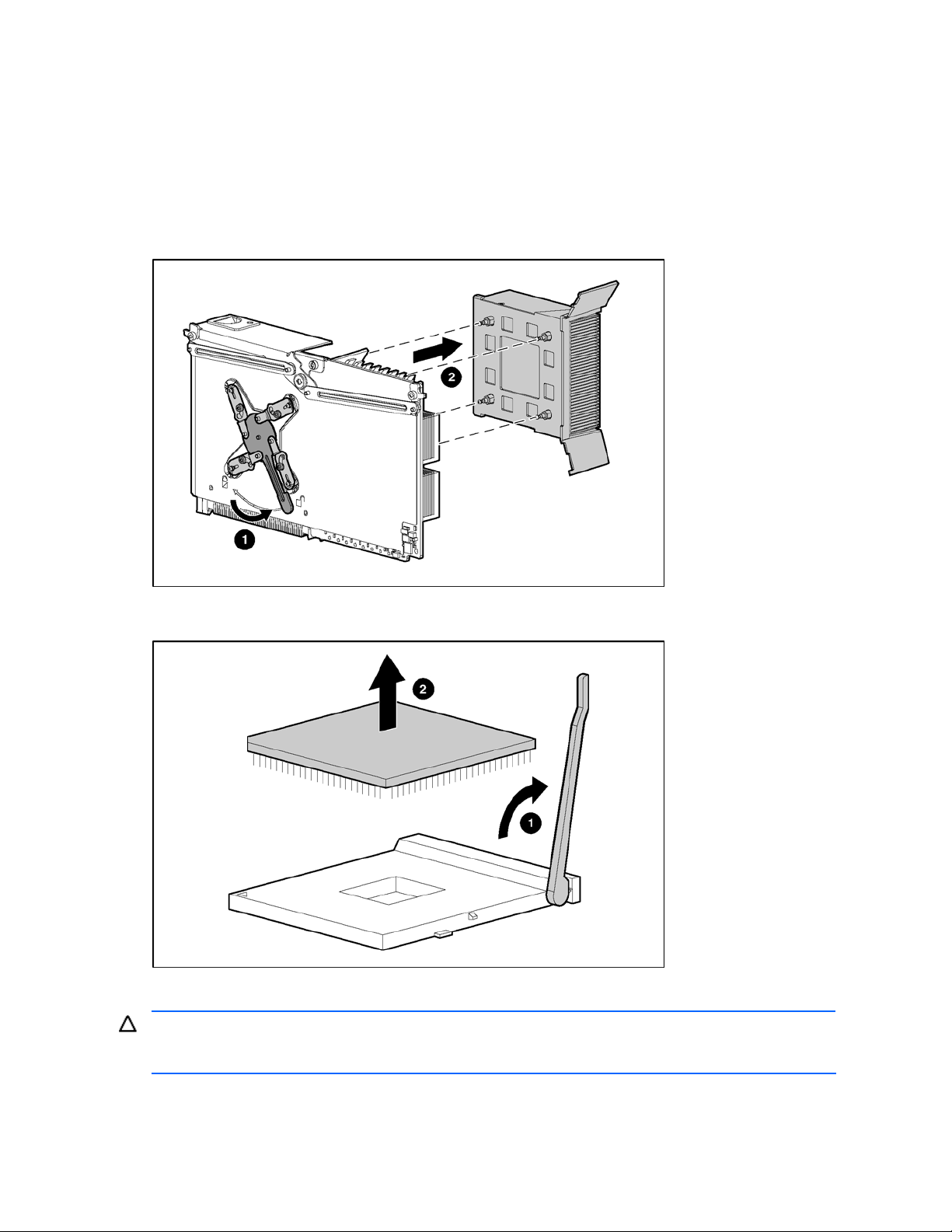

Processor

Removing a processor

1. Power down the server. See “Powering down the server” earlier in this chapter.

2. Extend the server from the rack. See “Extending the server from the rack” earlier in this chapter.

3. Remove the access panel. See “Removing the access panel” earlier in this chapter.

4. Remove the processor memory board. See “Processor memory boards” earlier in this chapter.

5. Remove the processor heatsink.

Figure 13 Removing the processor heatsink

6. Remove the processor.

Figure 14 Removing a processor

Installing a processor

CAUTION: If reusing the heatsink, clean and apply thermal grease to prevent thermal failure. The syringe in

this kit contains 1.0 gm (0.5 ml) or 0.5 gm (0.25 ml) of grease designed for use as a thermal interface

between the processor and the heatsink.

1. Open the ZIF socket lever. Be sure the lever is in the fully open position.

2. Align the processor with the socket.

Removal and replacement procedures 22

Page 23

3. Set the processor into the ZIF socket, and hold it in place while closing and latching the socket lever. Verify that

the processor is fully seated in the socket.

CAUTION: Failure to fully seat and latch the processor in the ZIF socket can result in damage to the processor,

processor memory board, or both.

4. If reusing the processor and heatsink (spare part number 383420-001), clean the top of the processor and the

bottom of the heatsink using an alcohol pad (included with the thermal grease kit) or a clean dry wipe to

remove all traces of the old thermal grease. Allow the alcohol to evaporate before continuing.

CAUTION: The processor should be installed on the processor memory board before cleaning to prevent

damaging the pins.

5. Squeeze one-half of the contents if the syringe contains 1.0 gm (0.5 ml) or the entire contents if the syringe

contains 0.5 gm (0.25 ml) evenly onto the top of the processor.

6. Install the heatsink, ensuring that it is properly seated before latching it in place.

7. Install the processor memory board.

8. Replace the access panel.

9. Replace server in the rack.

10. Power up the server.

Removal and replacement procedures 23

Page 24

Memory options

Minimum memory requirements

• Two DIMMs must be installed in bank 1 on the processor memory board in slot two.

• All DIMMs on a processor memory board must have the same part number.

NOTE: Processor memory boards in slots 1, 3, and 4 can be installed without memory. Certain application

programs run more efficiently if the DIMMs are balanced across all processor memory boards.

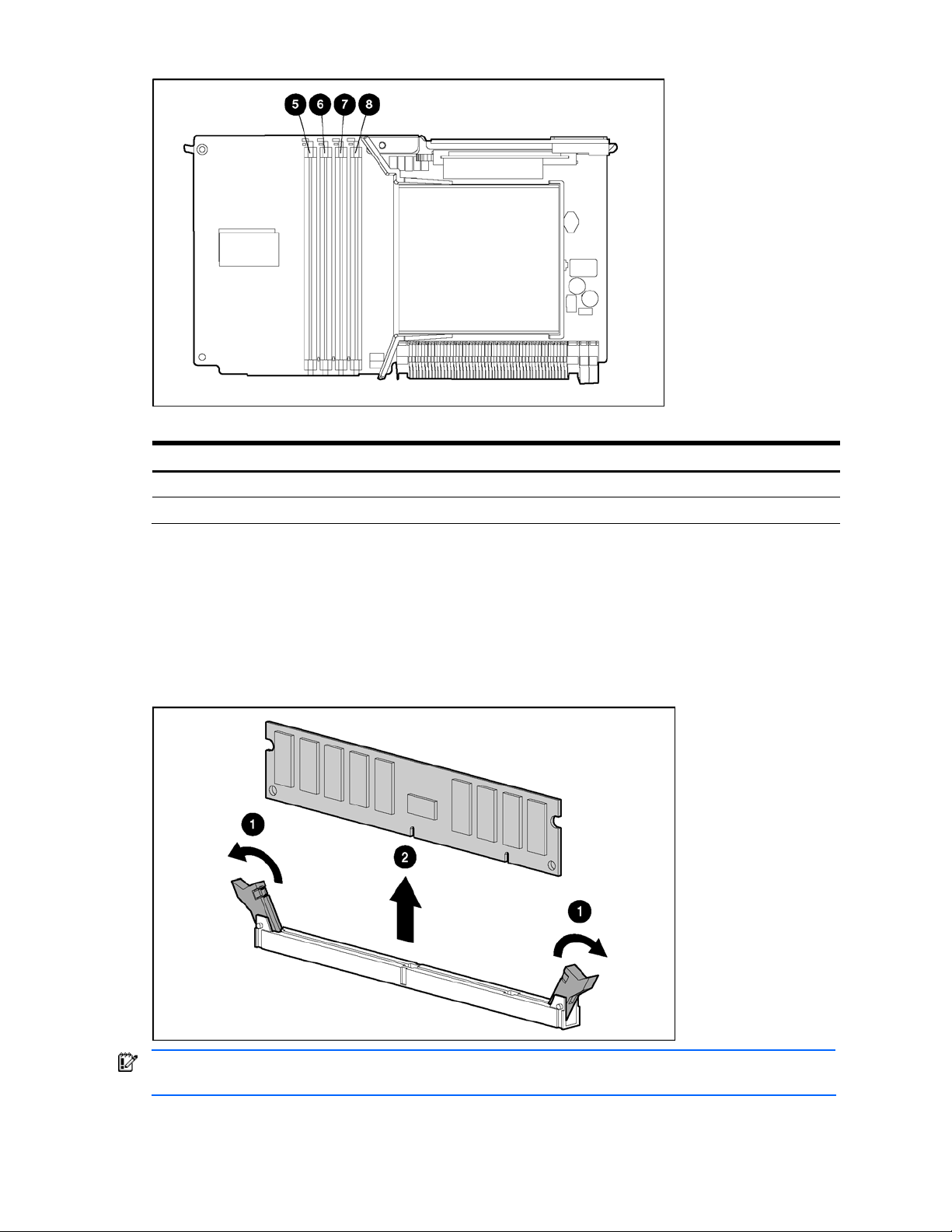

Memory population guidelines for processor memory boards with eight DIMM slots

• DIMMs on different processor memory boards can be of different sizes.

• DIMMs on the same processor memory board must be of the same size and have the same part number.

• DIMMs must be installed on a processor memory board in pairs and in bank order.

• DIMMs must populate three or fewer banks on a memory board with PC2700 DIMMs to maintain a memory

clock speed of 333 MHz.

NOTE: If all four banks (eight DIMM slots) are populated with PC2700 DIMMs, the maximum memory clock

speed will be 266 MHz.

Figure 15 DIMM slots

Table 4 Processor memory board memory banks

Slot Bank

1–2 Bank 1

3–4 Bank 2

5–6 Bank 3

7–8 Bank 4

Memory population guidelines for processor memory boards with four DIMM slots

• DIMMs on different processor memory boards can be of different sizes.

• DIMMs on the same processor memory board must be of the same size and have the same part number.

• DIMMs must be installed on a processor memory board in pairs and in bank order.

NOTE: PC3200 DIMMs are only supported by processor memory boards with four DIMM slots.

Removal and replacement procedures 24

Page 25

Figure 16 Four DIMM slots

Table 5 Processor memory board memory banks with four DIMM slots

Slot Bank

5–6 Bank 1

7–8 Bank 2

Removing a DIMM

1. Power down the server. See “Powering down the server” earlier in this chapter.

2. Extend the server from the rack. See “Extending the server from the rack” earlier in this chapter.

3. Remove the access panel. See “Removing the access panel” earlier in this chapter.

4. Remove the processor memory board. See “Processor memory boards” earlier in this chapter.

5. Remove the DIMM.

Figure 17 Removing a DIMM

IMPORTANT: Be sure all DIMM retention clips are in the closed/locked position before reinstalling processor

memory board into the system.

Reverse the removal steps to install a DIMM.

Removal and replacement procedures 25

Page 26

Hard drive blanks

To remove a hard drive blank:

1. Push the sliding release button to unlock the blank .

2. Pull the drive blank out of the drive cage .

Figure 18 Removing a drive blank

NOTE: Keep the blank for future use.

Reverse the steps to replace a drive blank.

Hot-plug SCSI hard drives

Drive replacement precautions

Be aware of the following guidelines cautioning unsafe hot-plug replacement.

• Do not remove a degraded drive if any other member of the array is offline (the online LED is off). No other

drive in the array is hot-pluggable without data loss. The exception to this is the use of RAID 1+0 as a faulttolerant configuration. In this case, drives are mirrored in pairs. More than one drive can fail and be replaced

as long as the drive or drives they are mirroring are online.

• Do not remove a degraded drive if any member of an array is missing (removed previously and not yet

replaced).

• Do not remove a degraded drive if any member of an array is being rebuilt, unless the drive being rebuilt has

been configured as an online spare. The online LED for the drive flashes green or amber, indicating that a

replaced drive is being rebuilt from the data stored on the other drives.

NOTE: An online spare drive does not activate and start rebuilding after a predictive failure alert because the

degraded drive is still online. The online spare activates only after a drive in the array has failed.

• Do not replace multiple degraded drives at the same time because the fault tolerance can be compromised.

When a drive is replaced, the controller uses data from the other drives in the array to reconstruct data on the

replacement drive. If more than one drive is removed, a complete data set is not available to reconstruct data

on the replacement drive or drives, and permanent data loss can occur.

CAUTION: Do not turn off any external unit when the server containing. A Smart Array controller is powered

up. Also, do not power up the server before powering up the drive enclosure. If these ordering rules are not

followed, the Smart Array controller might mark the drives in this enclosure as failed, resulting in permanent

data loss.

Removal and replacement procedures 26

Page 27

CAUTION: Remove or replace a hard drive only when the drive failure LED is amber. Data loss can occur if a

drive is removed when the drive online LED is green. See “Hot-plug SCSI hard drive LEDs” in Chapter 4,

“Server component identification,” for more information.

CAUTION: Remove or replace only one hard drive at a time. The controller relies on other drives to reconstruct

data on the replaced drive. Drive reconstruction is active when the drive online LED is flashing green.

To remove a hot-plug SCSI hard drive:

1. Press the release button to unlock the ejector lever on the hard drive.

2. Open the ejector lever to release the drive.

3. Slide the drive out of the cage.

Figure 19 Removing a hot-plug SCSI hard drive

IMPORTANT: Always populate hard drive bays starting with the lowest SCSI ID.

Reverse the steps to replace a hot-plug SCSI hard drive.

Hot-plug SAS or SATA hard drives

Figure 20 Hot-plug SAS or SATA hard drive ID numbers

When adding SAS hard drives to the server, observe the following general guidelines:

• The server supports eight SAS or SATA hot-plug hard drives.

Removal and replacement procedures 27

Page 28

• The system automatically sets all drive numbers.

• If only one hard drive is used, install it in the bay with the lowest number.

• Hard drives must be SFF types.

• Drives must be the same capacity to provide the greatest storage space efficiency when drives are grouped

together into the same drive array.

CAUTION: Remove or replace a hard drive only when the drive failure LED is amber. Data loss can occur if a

drive is removed when the drive Online/Activity status LED is green. See “Hot-plug SAS or SATA hard drive

LEDs” in Chapter 4, “Server component identification,” for more information.

CAUTION: Remove or replace only one hard drive at a time. The controller relies on other drives to reconstruct

data on the replaced drive. Drive reconstruction is active when the drive Online/Activity status LED is flashing

green.

1. Press the release button to unlock the ejector lever on the hard drive.

2. Open the ejector lever to release the drive.

3. Slide the drive out of the cage.

Figure 21 Removing a hot-plug SAS or SATA hard drive

IMPORTANT: Always populate hard drive bays starting with the lowest SCSI ID.

Reverse the steps to replace a hot-plug SAS or SATA hard drive.

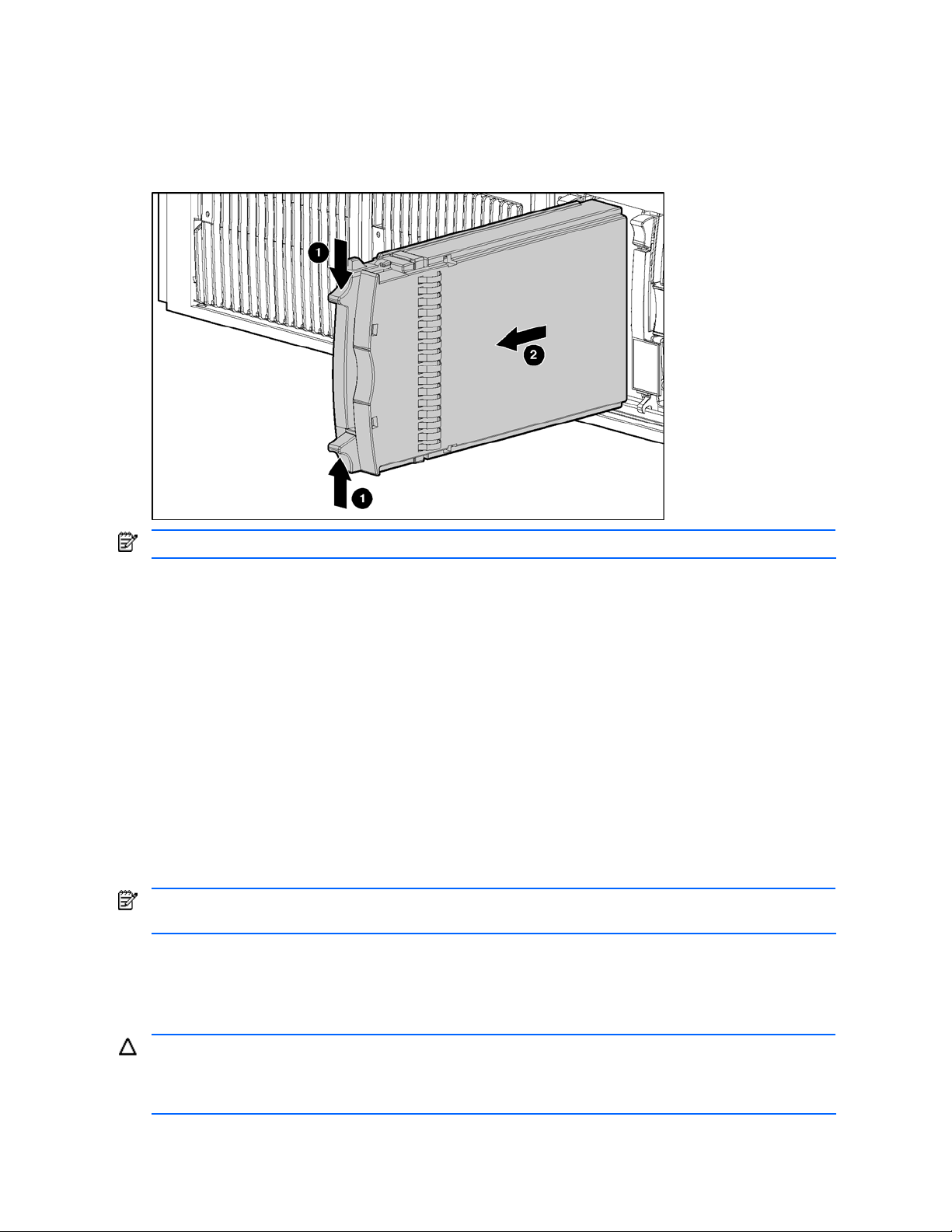

SAS or SATA hard drive cage

1. Power down the server. See “Powering down the server” earlier in this chapter.

2. Extend the server from the rack. See “Extending the server from the rack” earlier in this chapter.

3. Remove the access panel. See “Removing the access panel” earlier in this chapter.

4. Remove all hard drives and hard drive blanks. See “Hard drive blanks” and “Hot-plug SAS or SATA hard

drives” in this chapter.

Removal and replacement procedures 28

Page 29

5. Remove the screws securing the hard drive cage.

Figure 22 Removing the hard drive cage screws

6. Slowly pull the SAS hard drive cage out of the server until there is enough room to reach behind the SAS hard

drive cage.

7. Disconnect all cables from the back of the SAS hard drive cage, and slide the hard drive cage out of the server.

Reverse the steps to replace the SAS-SATA hard drive cage.

Power transfer board

1. Power down the server. See “Powering down the server” earlier in this chapter.

2. Extend the server from the rack. See “Extending the server from the rack” earlier in this chapter.

3. Remove the access panel. See “Removing the access panel” earlier in this chapter.

4. Remove all hard drives and hard drive blanks. See “Hard drive blanks” and “Hot-plug SAS or SATA hard

drives” in this chapter.

5. Remove the screws securing the hard drive cage.

Figure 23 Removing the hard drive cage screws

6. Slowly pull the SAS hard drive cage out of the server until there is enough room to reach behind the SAS hard

drive cage.

7. Disconnect all cables from the back of the SAS hard drive cage, and slide the hard drive cage out of the server.

8. Disconnect the power cable from the power transfer board, and remove the cable.

9. Loosen the thumbscrew, and remove the power transfer board.

Removal and replacement procedures 29

Page 30

Figure 24 Removing the power transfer board

Reverse the steps to replace the power transfer board.

Removal and replacement procedures 30

Page 31

Power supply blank

To remove a power supply blank:

1. Press the lever-release button on the handle of the power supply blanks .

2. Pull on the lever to release the blank .

3. Remove the power supply blank from the server .

Figure 25 Removing a power supply blank

NOTE: Keep the power supply blank for future use.

Reverse the steps to replace the power supply blank.

Removal and replacement procedures 31

Page 32

Hot-plug power supplies

For information on power supply diagnosis, see “Hot-plug power supply LEDs” in Chapter 4, “Server component

identification.”

CAUTION: Do not remove a hot-plug power supply unless two power supplies are installed. If a second power

supply is not installed, the system must be powered down to remove the power supply.

CAUTION: Hot-plug power supplies for the server are keyed to be sure that only 800-W hot-plug power

supplies can be installed in the server. The handles on 800-W power supplies are black to distinguish them

from other power supplies.

To remove a hot-plug power supply:

1. Remove the power supply shipping screw from the bottom of the server, if installed.

2. Press the lever-release button on the handle of the power supply.

3. Pull on the lever to release the power supply.

4. Remove the power supply from the server.

Figure 26 Removing a hot-plug power supply

Reverse the steps to replace the hot-plug power supply.

Removal and replacement procedures 32

Page 33

Hot-plug fans

The server supports redundant hot-plug fans in a 7+1 configuration.

To replace a hot-plug fan:

1. Extend the server from the rack. See “Extending the server from the rack” earlier in this chapter.

2. Remove the access panel. See “Removing the access panel” earlier in this chapter.

3. Identify the nonfunctioning fan by looking for an amber LED on the QuickFind diagnostic display or on the

failed fan.

4. Remove the nonfunctioning fan.

Figure 27 Removing a hot-plug fan

5. Install the fan.

6. Be sure that the LED on the fan is green.

7. Reinstall the access panel.

8. Restore the server to its operating position in the rack.

CAUTION: Do not operate the server for extended periods without the access panel installed. Operating the

server without the access panel results in improper airflow that can lead to thermal damage.

For information on hot-plug fan diagnosis, see “Hot-plug fans” in Chapter 4, “Server component identification.”

Universal media drives

To remove a universal media drive:

1. Power down the server. See “Powering down the server” earlier in this chapter.

2. Use the Torx T-15 tool to press the appropriate ejection button, and pull the universal media drive out of the

universal media bay. See “Locating and removing the Torx T-15 tool” earlier in this chapter.

Removal and replacement procedures 33

Page 34

Figure 28 Removing a drive from bay 1

Figure 29 Removing a drive from bay 2

To replace a universal media drive, slide the drive into the slot until it engages the connector.

IMPORTANT: For the diskette drive to be bootable, it must be installed in the top universal media drive bay.

For the CD-ROM or DVD-ROM drive to be bootable, it must be installed in the bottom universal media drive

bay.

Removal and replacement procedures 34

Page 35

Front bezel

To remove the front bezel:

1. Power down the server. See “Powering down the server” earlier in this chapter.

2. Extend the server from the rack. See “Extending the server from the rack” earlier in this chapter.

3. Remove the access panel. See “Removing the access panel” earlier in this chapter.

4. Using the T-15 Torx tool, remove the six screws on the exterior of the chassis and the two screws on the interior

of the chassis next to the universal media drive bays.

Figure 30 Removing the exterior and interior chassis screws

5. Using a flathead screwdriver, disengage the locking tabs on the bezel from under the chassis.

6. Remove the front bezel.

Figure 31 Disengaging the locking tabs and removing the front bezel

Reverse the steps to replace the front bezel.

Removal and replacement procedures 35

Page 36

Power button/LED assembly

To remove the power button/LED assembly:

1. Power down the server. See “Powering down the server” earlier in this chapter.

2. Extend the server from the rack. See “Extending the server from the rack” earlier in this chapter.

3. Remove the access panel. See “Removing the access panel” earlier in this chapter.

4. Unplug the cable from the diagnostic display board.

5. Push the locking tab until the opposite side comes out.

Figure 32 Removing the power button/LED assembly

Reverse the steps to replace the power button/LED assembly.

Removal and replacement procedures 36

Page 37

Expansion boards

The server supports the installation of PCI and PCI-X expansion boards.

• PCI 33 MHz and 66 MHz

• PCI-X 66 MHz, 100 MHz, and 133 MHz

Figure 33 PCI-X expansion slots and buses

Table 6 PCI-X expansion slots and buses

Item Slot Bus Description

1 Slot 1 Fifth bus 133 MHz

2 Slot 2 Sixth bus 133 MHz

3 Slot 3 Seventh bus 100 MHz

4 Slot 4 Seventh bus 100 MHz

5 Slot 5 Eighth bus 100 MHz

6 Slot 6 Eighth bus 100 MHz

7 Slot 7 Third bus 100 MHz

8 Slot 8 Third bus 100 MHz

NOTE: All PCI-X slots are 64-bit, 3.3-V keyed.

Removal and replacement procedures 37

Page 38

Performance balancing

Balancing is the paired arrangement of expansion boards for optimal performance based on the bus architecture of

the expansion slots. Properly balancing the boards across buses can improve performance. To balance expansion

boards:

• Populate slots 1 and 2 with 133-MHz PCI-X boards.

• Populate slots 3 through 8 with 100-MHz PCI-X boards.

• Populate slots across different buses before populating two slots on the same bus.

For more information about PCI-X bus architecture and numbering, see the white paper, PCI Bus Numbering in a

Windows NT Environment, on the HP website at http://www.hp.com

PCI-X expansion boards

To remove a PCI-X expansion board:

1. Power down the server. See “Powering down the server” earlier in this chapter.

2. Extend the server from the rack. See “Extending the server from the rack” earlier in this chapter.

3. Remove the access panel. See “Removing the access panel” earlier in this chapter.

4. Disconnect any cables connected to the expansion boards.

5. Press the PCI-X retaining clip toward the front of the server to lock it in the open position.

6. Press down on the expansion slot latch to release it.

7. Open the latch.

8. Remove the board from the slot.

Figure 34 Removing an expansion board

.

Reverse the steps to replace an expansion board.

Removal and replacement procedures 38

Page 39

SCSI cables

To remove the SCSI cables:

1. Power down the server. See “Powering down the server” earlier in this chapter.

2. Extend the server from the rack. See “Extending the server from the rack” earlier in this chapter.

3. Remove the access panel. See “Removing the access panel” earlier in this chapter.

4. Disconnect the SCSI cables from the SCSI backplane.

5. Disconnect the SCSI cables from the PCI-X expansion boards.

Figure 35 Disconnecting the SCSI cables

Reverse the steps to replace or install the SCSI cables.

Removal and replacement procedures 39

Page 40

Front fan cage

To remove the front fan cage:

1. Power down the server. See “Powering down the server” earlier in this chapter.

2. Extend the server from the rack. See “Extending the server from the rack” earlier in this chapter.

3. Remove the access panel. See “Removing the access panel” earlier in this chapter.

4. Remove the processor memory boards. See “Processor memory boards” earlier in this chapter.

5. Remove the PCI-X expansion boards. See “PCI-X expansion boards” earlier in this chapter.

6. Remove the SCSI cables. See “SCSI cables” earlier in this chapter.

7. Loosen the three thumbscrews that secure the front fan cage to the chassis .

NOTE: It is not necessary to remove the fans before removing the fan cage. The fan cage can be removed with

the fans installed.

8. Remove the hot-plug fans in the front fan cage. See “Hot-plug fans” earlier in this chapter.

9. Lift the front fan cage from the chassis .

Figure 36 Removing the front fan cage

Reverse the steps to replace the front fan cage.

Removal and replacement procedures 40

Page 41

Pass-through board

To remove the pass-through board:

1. Power down the server. See “Powering down the server” earlier in this chapter.

2. Extend the server from the rack. See “Extending the server from the rack” earlier in this chapter.

3. Remove the access panel. See “Removing the access panel” earlier in this chapter.

4. Remove the processor memory boards. See “Processor memory boards” earlier in this chapter.

5. Remove the PCI-X expansion boards. See “PCI-X expansion boards” earlier in this chapter.

6. Remove the SCSI cables. See “SCSI cables” earlier in this chapter.

7. Remove the front fan cage. See “Front fan cage” earlier in this chapter.

8. Loosen the two thumbscrews that secure the pass-through board to the diagnostic display board and the side

chassis wall . You might need to use a Torx T-15 screwdriver.

9. Lift the pass-through board straight up and out of the chassis .

Figure 37 Removing the pass-through board

Reverse the steps to replace the pass-through board.

NOTE: Align the board with connectors on both ends and press simultaneously when installing.

Removal and replacement procedures 41

Page 42

QuickFind diagnostic display board and lightpipe

To remove the QuickFind diagnostic display board and lightpipe:

1. Power down the server. See “Powering down the server” earlier in this chapter.

2. Extend the server from the rack. See “Extending the server from the rack” earlier in this chapter.

3. Remove the access panel. See “Removing the access panel” earlier in this chapter.

4. Remove the processor memory boards. See “Processor memory boards” earlier in this chapter.

5. Remove the PCI-X expansion boards. See “PCI-X expansion boards” earlier in this chapter.

6. Remove the SCSI cables. See “SCSI cables” earlier in this chapter.

7. Remove the front fan cage. See “Front fan cage” earlier in this chapter.

8. Remove the pass-through board. See “Pass-through board” earlier in this chapter.

9. Eject all devices from the universal media drive bays. See “Universal media drives” earlier in this chapter.

10. Unplug the Power button/LED cable. See “Power button/LED assembly” earlier in this chapter.

11. Loosen the two thumbscrews holding the diagnostic display board.

12. Slide the board to the rear of the unit until it stops, and then lift it up.

Figure 38 Removing the QuickFind diagnostic display board and lightpipe

13. Lift the board out gently, being careful of the universal media drive bay connector.

Reverse the steps to replace the diagnostic display board and lightpipe.

Removal and replacement procedures 42

Page 43

Rear fan cage

To remove the rear fan cage:

1. Power down the server. See “Powering down the server” earlier in this chapter.

2. Extend the server from the rack. See “Extending the server from the rack” earlier in this chapter.

3. Remove the access panel. See “Removing the access panel” earlier in this chapter.

4. Remove the processor memory boards. See “Processor memory boards” earlier in this chapter.

NOTE: It is not necessary to remove the fans before removing the fan cage. The fan cage can be removed with

the fans installed.

5. Loosen the two thumbscrews that secure the rear fan cage to the chassis .

6. Remove the rear fan cage from the chassis .

Figure 39 Removing the rear fan cage

Reverse the steps to replace the rear fan cage.

Removal and replacement procedures 43

Page 44

BBWC assembly

IMPORTANT: The Battery-Backed Write Cache Enabler (BBWCE) and the 5i Plus BBWC Module must be

removed together with the cable connected to save the data in the cache. Unplugging the cable deletes all the

data in the cache.

To remove the BBWC assembly:

1. Power down the server. See “Powering down the server” earlier in this chapter.

2. Extend the server from the rack. See “Extending the server from the rack” earlier in this chapter.

3. Remove the access panel. See “Removing the access panel” earlier in this chapter.

4. Remove the processor memory boards. See “Processor memory boards” earlier in this chapter.

5. Remove the SCSI cables. See “SCSI cables” earlier in this chapter.

6. Remove the PCI-X expansion boards. See “PCI-X expansion boards” earlier in this chapter.

7. Remove the front fan cage. See “Front fan cage” earlier in this chapter.

8. Remove the 5i Plus BBWC Module.

CAUTION: Do not disconnect the cable connecting the BBWCE and the 5i Plus BBWC Module. Unplugging

the cable deletes all the data in the cache.

9. Remove the BBWCE.

Figure 40 Removing the BBWCE and 5i Plus BBWC Module

Reverse the steps to replace the BBWCE and 5i Plus BBWC Module.

Removal and replacement procedures 44

Page 45

SCSI backplane

To remove the SCSI backplane:

1. Extend the server from the rack. See “Extending the server from the rack” earlier in this chapter.

2. Power down the server. See “Powering down the server” earlier in this chapter.

3. Unseat all the hot-plug SCSI hard drives, and pull them away from the SCSI backplane. See “Hot-plug SCSI

hard drives” earlier in this chapter.

NOTE: If you plan to take the hard drives out of the drive cage, label them so that they will be installed in the

same slot.

4. Remove the access panel. See “Removing the access panel” earlier in this chapter.

5. Disconnect any SCSI cables from the SCSI backplane. See “SCSI cables” earlier in this chapter.

6. Loosen the thumbscrew.

7. Remove the SCSI backplane from the chassis.

Figure 41 Removing the SCSI backplane

Reverse the steps to replace the SCSI backplane.

Removal and replacement procedures 45

Page 46

System battery

WARNING! This server contains an internal lithium manganese dioxide or vanadium pentoxide battery. A risk

of fire and burns exists if the battery is not handled properly. To reduce the risk of personal injury:

• Do not attempt to recharge the battery.

• Do not expose to temperatures higher than 60°C (140°F)

CAUTION: Do not dispose of batteries, battery packs, and accumulators with the general household waste. To

forward them to recycling or proper disposal, use the public collection system or return them to either HP or an

authorized service provider.

To remove the battery:

1. Power down the server. See “Powering down the server” earlier in this chapter.

2. Extend the server from the rack. See “Extending the server from the rack” earlier in this chapter.

3. Remove the access panel. See “Removing the access panel” earlier in this chapter.

4. Locate the battery on the system board.

NOTE: It might be necessary to remove some PCI-X expansion boards to gain access to the battery.

Figure 42 Locating the battery on the system board

Removal and replacement procedures 46

Page 47

5. Remove the existing battery.

Figure 43 Removing the battery from the system board

6. Install the new battery.

7. Install the access panel.

8. Restore the server to its operating position in the rack.

9. Run RBSU to reconfigure the system if the settings were lost.

Removal and replacement procedures 47

Page 48

System board

To remove the system board:

1. Power down the server. See “Powering down the server” earlier in this chapter.

2. Remove all power supplies. See “Hot-plug power supply” earlier in this chapter.

NOTE: Label the individual hard drives before pulling them out.

3. Remove all the hot-plug SCSI hard drives. See “Hot-plug SCSI hard drives” earlier in this chapter.

4. Extend the server from the rack. See “Extending the server from the rack” earlier in this chapter. Although not

required, HP recommends removing the server from the rack for best performance. See “Removing the server

from the rack” earlier in this chapter.

5. Remove the access panel. See “Removing the access panel” earlier in this chapter.

6. Remove the processor memory boards. See “Processor memory boards” earlier in this chapter.

7. Remove the SCSI cables. See “SCSI cables” earlier in this chapter.

8. Remove the PCI-X expansion boards. See “PCI-X expansion boards” earlier in this chapter.

9. Remove the front fan cage. See “Front fan cage” earlier in this chapter.

10. Remove the rear fan cage. See “Rear fan cage” earlier in this chapter.

11. Remove the pass-through board. See “Pass-through board” earlier in this chapter.

12. Remove the SCSI backplane. See “SCSI backplane” earlier in this chapter.

13. Remove the BBWC assembly. See “Battery-Backed Write Cache assembly” earlier in this chapter.

Removal and replacement procedures 48

Page 49

14. Remove the lower foam air baffle.

15. Unscrew the system board thumbscrews. It might be necessary to use the Torx tool located on the back of the

server.

16. Slide the system board toward the front of the unit.

Figure 44 Unscrewing the thumbscrews and sliding the system board

IMPORTANT: When handling the system board, place your hands on the two handles only.

17. Grasping the two handles, lift the side with the processor memory board slots first, tilting the board to a 45°

angle .

18. Lift the entire system board out of the chassis .

19. Compare the switch settings on the old board against the settings in Chapter 4 to be sure that they are in the

correct positions.

Figure 45 Removing the system board from the chassis

Reverse the steps to replace the system board.

IMPORTANT: The server serial number must be re-entered through RBSU after replacing the system board. See

the “Re-entering the server serial number” section in this chapter.

Removal and replacement procedures 49

Page 50

AC filter cable assembly

The AC filter cable assembly consists of two cables leading from separate power supply input connectors near the

front of the chassis and ending in an AC filter and inlets at the rear of the chassis.

To remove the AC filter cable:

1. Power down the server. See “Powering down the server” earlier in this chapter.

2. Remove all power supplies. See “Hot-plug power supply” earlier in this chapter.

NOTE: Label the individual hard drives before pulling them out.

3. Remove all the hot-plug SCSI hard drives. See “Hot-plug SCSI hard drives” earlier in this chapter.

4. Extend the server from the rack. See “Extending the server from the rack” earlier in this chapter. Although not

required, HP recommends removing the server from the rack for best performance. See “Removing the server

from the rack” earlier in this chapter.

5. Remove the access panel. See “Removing the access panel” earlier in this chapter.

6. Remove the processor memory boards. See “Processor memory boards” earlier in this chapter.

7. Remove the SCSI cables. See “SCSI cables” earlier in this chapter.

8. Remove the PCI-X expansion boards. See “PCI-X expansion boards” earlier in this chapter.

9. Remove the front fan cage. See “Front fan cage” earlier in this chapter.

10. Remove the rear fan cage. See “Rear fan cage” earlier in this chapter.

11. Remove the pass-through board. See “Pass-through board” earlier in this chapter.

12. Remove the SCSI backplane. See “SCSI backplane” earlier in this chapter.

13. Remove the BBWC assembly. See “Battery-Backed Write Cache assembly” earlier in this chapter.

14. Remove the system board. See “System board” located earlier in this chapter.

15. Cut the four tie-wraps securing the AC filter cable to the chassis.

Figure 46 Cutting the cable tie-wraps

Removal and replacement procedures 50

Page 51

16. Remove the seven cable clips:

a. Lift to disengage the cable clip.

b. Slide the clip forward, and lift it off the chassis.

Figure 47 Removing the cable clips

17. Use the Torx T-15 tool or screwdriver to remove the eight screws that secure the power supply connectors to the

chassis bottom .

18. Remove the cords from the connectors .

19. Remove the connectors from the server .

Figure 48 Removing the power supply connectors

20. Use the Torx T-15 tool or a screwdriver to remove the four screws that secure the AC filter cable assembly to the

rear chassis wall.

Removal and replacement procedures 51

Page 52

21. Slide the assembly into the chassis, and then lift the assembly out of the chassis .

Figure 49 Removing the AC filters

Reverse the steps to replace the AC filter cable assembly.

Removal and replacement procedures 52

Page 53

Re-entering the server serial number

After replacing the system board or clearing the NVRAM, re-enter the server serial number.

1. To access RBSU, press the F9 key when prompted during POST.

2. Select the System Options menu.

3. Select Serial Number. The following warning appears:

WARNING! WARNING! WARNING! The serial number is loaded into the system during the

manufacturing process and should NOT be modified. This option should ONLY be used

by qualified service personnel. This value should always match the serial number

sticker located on the chassis.

Press the Enter key to clear the warning.

4. Enter the serial number, and press the Enter key.

5. Press the Escape key to close the menu.

6. Press the Escape key to exit RBSU.

7. Press the F10 key to confirm exiting RBSU. The server automatically reboots.

Removal and replacement procedures 53

Page 54

4 Diagnostic tools

Table 7 Diagnostic tools

Tool Description How to run the tool

Array Diagnostics Utility (ADU) ADU is designed to run on all ProLiant

systems that support HP array controllers.

ADU collects information about the array

controllers in the system and generates a

list of detected problems.

Automatic Server Recovery-2 (ASR-2) ASR-2 automatically restarts the server

after a catastrophic operating system

failure.

With ASR-2, you have two recovery

options:

• Available Recovery provides

software error recovery and

environmental recovery.

• Unattended Recovery logs the error

information to the IML, resets the

server, and tries to restart the

operating system.

Diagnostics Diagnostics tests and verifies operation

of HP hardware. If Diagnostics finds a

hardware failure, it isolates the

replaceable part, if possible.

Integrated Lights-Out (iLO) iLO is a remote management port that

can be accessed through a dedicated

Lights-Out port on the rear panel of the

server. Accessed through a standard

browser from anywhere, the iLO

capabilities will not require any unique

software applications to use.

Survey utility The survey utility gathers critical

hardware and software information on

servers running Microsoft® Windows®,

or Linux operating systems.

If a significant change occurs between

data-gathering intervals, the survey utility

marks the previous information and

overwrites the survey text files to reflect

the latest changes in the configuration.

Integrated Management Log (IML) The IML is a log of system events such as

system failures or nonfatal error

conditions. View events in the IML from

within:

• Insight Manager 7

• Survey utility

• Operating system-specific IML

utilities

For a list of HP servers that support ADU,

follow the support link on product

website at http://www.hp.com

For a complete list of ADU error

messages, see the HP Servers

Troubleshooting Guide.

Run RBSU and set ASR-2 to enable this

tool.

Access Diagnostics when POST detects a

system configuration error. For a

complete list of POST error messages,

see the HP Servers Troubleshooting

Guide. Diagnostics can be run from the

SmartStart CD or downloaded by

following the support link on the product

website at http://www.hp.com

For more information on iLO, see the

Integrated Lights-Out user guide on the

Documentation CD.

Install the survey utility from the

SmartStart CD, the Integration

Maintenance Utility, or the Management

CD.

The IML requires HP operating system

management drivers. See the

SmartStart CD for instructions on

installing the appropriate drivers.

.

.

Diagnostic tools 54

Page 55

Table 7 Diagnostic tools

Tool Description How to run the tool

ROM-Based Setup Utility (RBSU) RBSU configures the hardware installed

in or connected to the server.