Page 1

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. . . . .

Marathon 2250

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. . . . .

Marathon 1680

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. . . . .

ATA Interface Drives

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. . . . .

Product Manual

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. . . . .

Page 2

Page 3

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. . . . .

Marathon 2250 (ST92255AG)

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. . . . .

Marathon 1680 (ST91685AG)

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. . . . .

ATA Interface Drives

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. . . . .

Product Manual

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. . . . .

Page 4

1997 Seagate Technology, Inc. All rights reserved

Publication Number: 36337-101, Rev. B, March 1997

Seagate, Seagate Technology and the Seagate logo are registered

trademarks of Seagate Technology, Inc. Marathon and SafeRite are

trademarks of Seagate Technology. Other product names are registered

trademarks or trademarks of their owners.

Seagate reserves the right t o change, without notice, produc t offerings

or specifications. No part of this publication may be reproduced in any

form without written permission from Seagate Technology, Inc.

Page 5

Marathon 2250 and Marathon 1680 Product Manual iii

Contents

Introdu c tion . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Specification summary table . . . . . . . . . . . . . . . . . . . 2

1.0 Drive specifications . . . . . . . . . . . . . . . . . . . . . . 5

1.1 Formatted capacity . . . . . . . . . . . . . . . . . . . . . 5

1.1.1 Default logical geometry . . . . . . . . . . . . . . . . 5

1.1.2 Supported CHS translation geometries . . . . . . . . 5

1.2 Physical organization . . . . . . . . . . . . . . . . . . . . 6

1.3 Recording and interface technology . . . . . . . . . . . . . 6

1.4 Physical characteristics . . . . . . . . . . . . . . . . . . . 7

1.5 Seek time . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.6 Start times . . . . . . . . . . . . . . . . . . . . . . . . . . 8

1.7 Power specifications . . . . . . . . . . . . . . . . . . . . . 8

1.7.1 Power consumption . . . . . . . . . . . . . . . . . . 8

1.7.2 Power recovery . . . . . . . . . . . . . . . . . . . . . 9

1.7.3 Conducted noise . . . . . . . . . . . . . . . . . . . . 9

1.7.4 Voltage tolerance . . . . . . . . . . . . . . . . . . . . 10

1.7.5 Power-management modes . . . . . . . . . . . . . . 10

1.8 Environ mental tolerances . . . . . . . . . . . . . . . . . . 12

1.8.1 Ambient temperature . . . . . . . . . . . . . . . . . . 12

1.8.2 Temperature gradient . . . . . . . . . . . . . . . . . 12

1.8.3 Humidity . . . . . . . . . . . . . . . . . . . . . . . . 12

1.8.4 Altitude . . . . . . . . . . . . . . . . . . . . . . . . . 12

1.8.5 Shock . . . . . . . . . . . . . . . . . . . . . . . . . . 12

1.8.6 Vibration . . . . . . . . . . . . . . . . . . . . . . . . 13

1.9 Drive acoustics . . . . . . . . . . . . . . . . . . . . . . . 14

1.10 Reliability . . . . . . . . . . . . . . . . . . . . . . . . . . 14

1.11 Agency certification . . . . . . . . . . . . . . . . . . . . 15

1.11.1 Safety certification . . . . . . . . . . . . . . . . . . 15

Page 6

iv Marathon 2250 and Marathon 1680 Product Manual

1.11.2 Electromagnetic Compatibility . . . . . . . . . . . . 15

1.11.3 FCC verification . . . . . . . . . . . . . . . . . . . . 15

2.0 Drive mounting and configuration . . . . . . . . . . . . . . 17

2.1 Handling and static-discharge precautions . . . . . . . . . 17

2.2 Jumper settings . . . . . . . . . . . . . . . . . . . . . . . 17

2.2.1 Master/slave configuration . . . . . . . . . . . . . . . 17

2.3 Remote LED configuration . . . . . . . . . . . . . . . . . 19

2.4 Drive mounting . . . . . . . . . . . . . . . . . . . . . . . 19

2.5 ATA interface connector . . . . . . . . . . . . . . . . . . . 23

3.0 ATA Attachment-3 Interface (ATA-3) . . . . . . . . . . . . . 25

3.1 ATA interface signals and connector pins . . . . . . . . . . 25

3.1.1 AT bus signal levels . . . . . . . . . . . . . . . . . . 25

3.2 ATA Interface commands . . . . . . . . . . . . . . . . . . 27

3.2.1 Supported ATA commands . . . . . . . . . . . . . . . 27

3.2.2 Identify Drive command . . . . . . . . . . . . . . . . 29

3.2.3 Set Features command . . . . . . . . . . . . . . . . 32

3.2.4 S.M.A.R.T. commands . . . . . . . . . . . . . . . . . 34

3.2.5 Drive Security commands . . . . . . . . . . . . . . . 35

Appendix. Compatibility Notes . . . . . . . . . . . . . . . . . . 37

Page 7

Marathon 2250 and Marathon 1680 Product Manual v

Figures

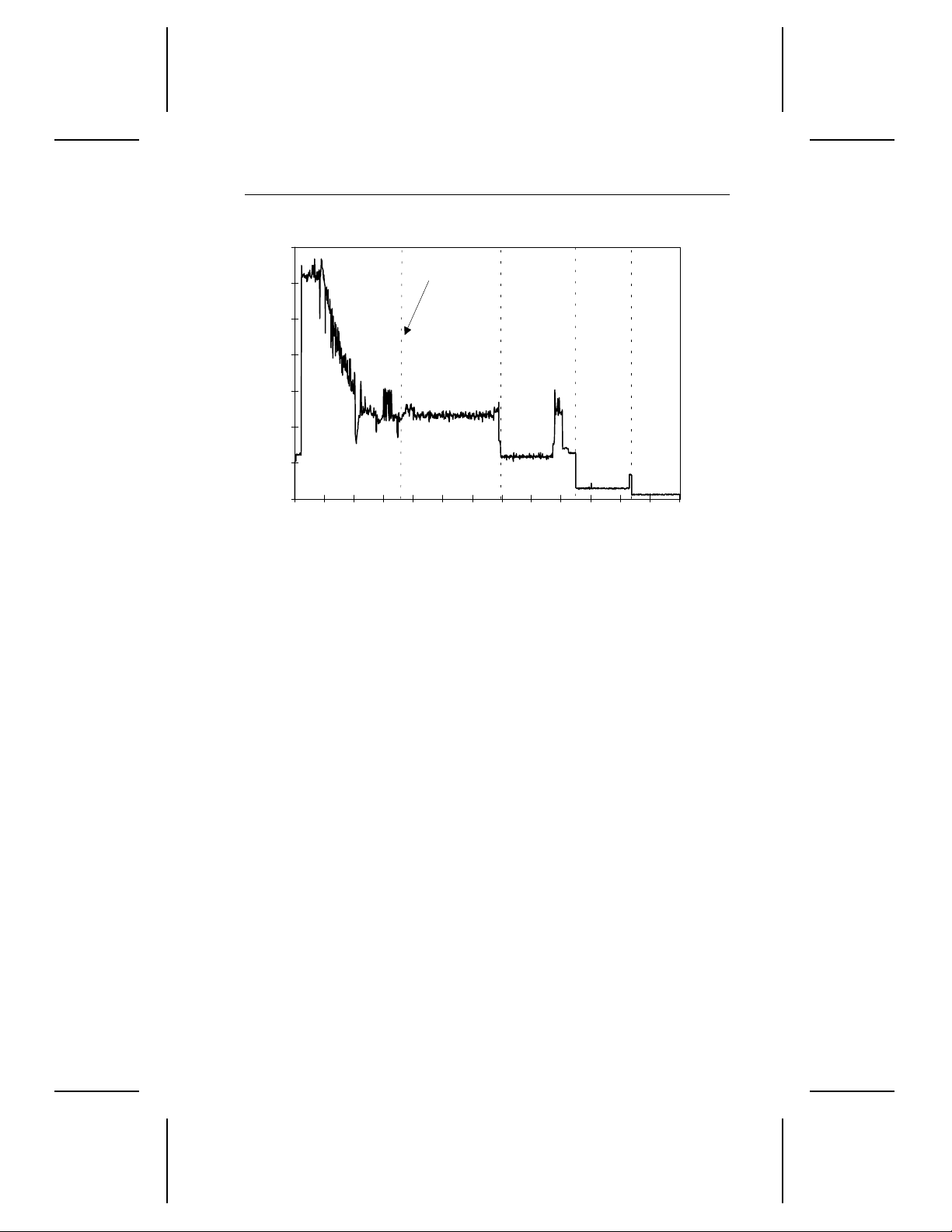

Figure 1. Typical startup and operation current profile. . . . . . . . 9

Figure 2. Connector and master/slave jumper setup . . . . . . . . 18

Figure 3. Drive mounting dimensions—side and bottom view. . . . 20

Figure 4. Drive mounting dimensions—end view . . . . . . . . . . 21

Figure 5. ATA Interface connector dimensions . . . . . . . . . . . 23

Figure 6. I/O pins and supported ATA signals . . . . . . . . . . . 26

Page 8

vi Marathon 2250 and Marathon 1680 Product Manual

Page 9

Marathon 2250 and Marathon 1680 Product Manual 1

Introduction

The Marathon 2250 (ST92255AG) and Marathon 1680 (ST91685AG)

provide very high storage capacity in a small, 17-mm hard disc drive.

Key Features:

• Low power consumption

• Com pact, SFF-8200-compati ble form-fact or

• High r otat ional speed for fast internal data transfer

• Quiet operation

• S afeRite shock protection

• S upport for PIO modes 0, 1, 2, 3 and 4, as well as single-word and

multiword DMA modes 0, 1 and 2

• High instantaneous (burst) data-transfer rates (up to 16.6 Mbytes per

second) using PIO mode 4 and DMA mode 2

• 103-Kbyte adaptive multisegmented cache

• Fast caching and on-the-fly error-correction algorithms

• Fast microprocessor for low command overhead

• Support for S.M.A.R.T. drive monitoring and reporting

• S uppor t for drive password security

• Support for Read/Write Multiple commands

• S upport for autodetection of master/slave drives using cable-select

(CSEL) and DASP– signals

Page 10

2 Marathon 2250 and Marathon 1680 Product Manual

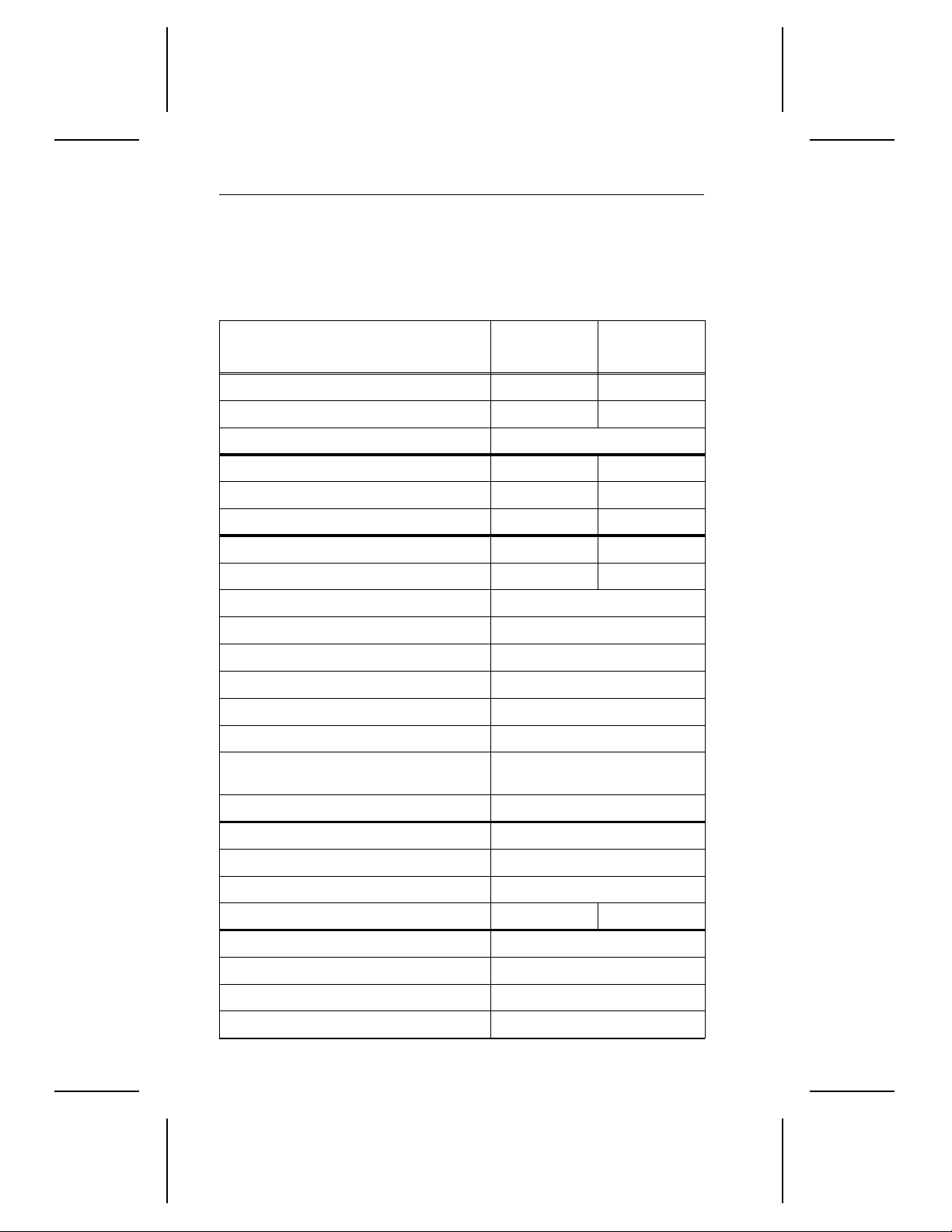

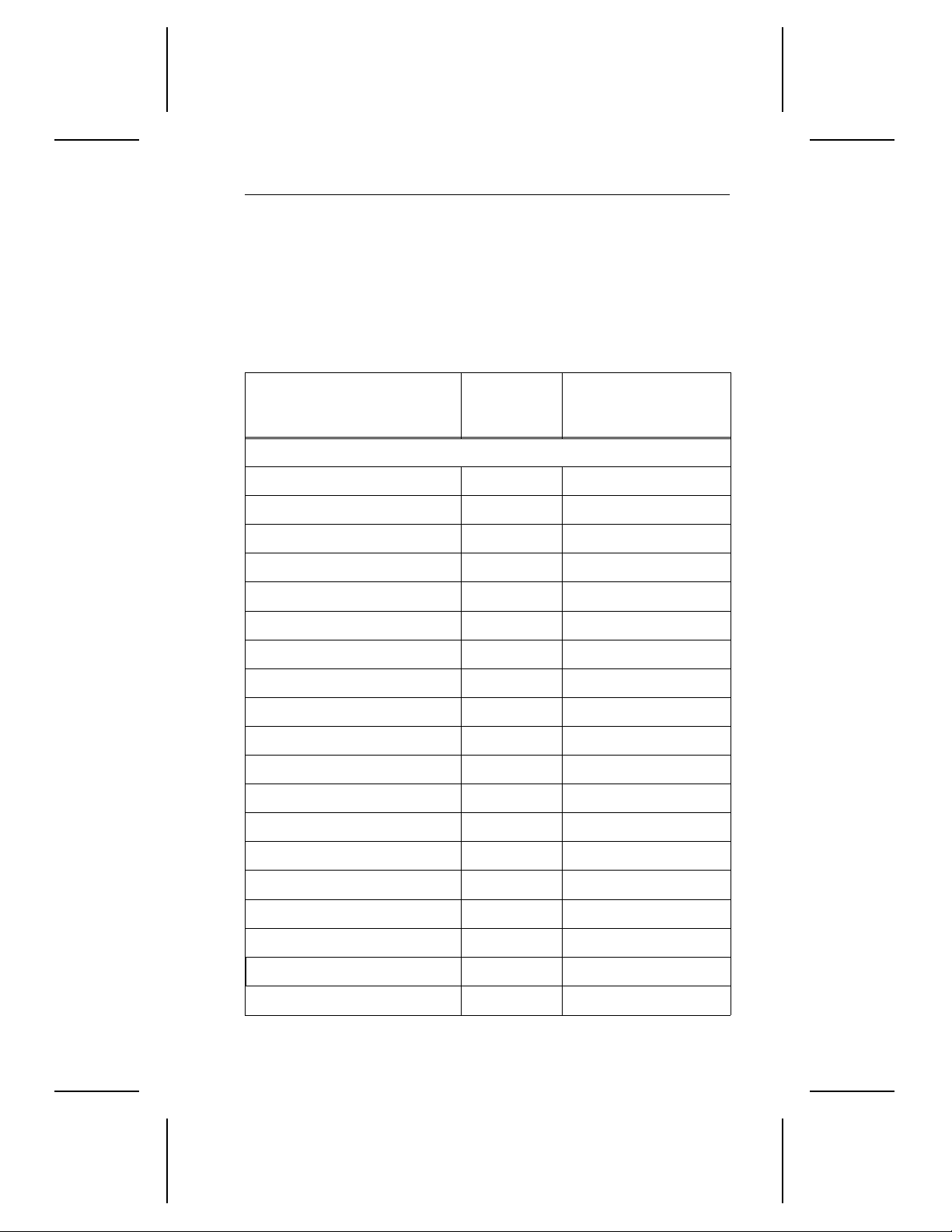

Specification summary table

The specifications listed in this table are for quick reference. For details

on a specification measurement or definition, see the appropriate section

of this manual.

Drive Specification

Guaranteed Mby te s (1 Mbyte=106 bytes) 2,250 1,680

Guaranteed sectors (LBA mode) 4,394,940 3,282,490

Bytes per sector 512

Default sectors per track 63 63

Default read/write heads 16 16

Default cylinders 4,360 3,256

Physical read/wr ite he ads 10 8

Discs 5 4

Recording densit y (bit s/ i nch, m a x) 120,000

Track density (tracks/inch) 5,555

2

Areal density (Mbit s/ in ch

Spindle speed (RPM) 4,508

Internal data-tra nsf er rate (Mbit s/ sec max ) 60.8

I/O data-transf er ra te (M byt es /s ec m ax) 16.6

A TA data-transf er mo des supported PIO modes 0, 1, 2, 3, 4 and

Cache buffer (Kby te s) 103

) 666

Marathon

2250

multiword DMA modes 0, 1, 2

Marathon

1680

Height (mm max) 17.2

Width (mm max) 70.1

Length (mm max) 100.45

Weight (grams typical) 204 200

Track-to-track seek time (msec typical) 4 (read), 5 (write)

Average see k time (m se c ty pi cal) 12 (read), 14 (wr ite)

Full-stroke seek t ime ( ms ec m ax) 26 (read), 28 (wr ite)

Average latency (msec) 6.65

Page 11

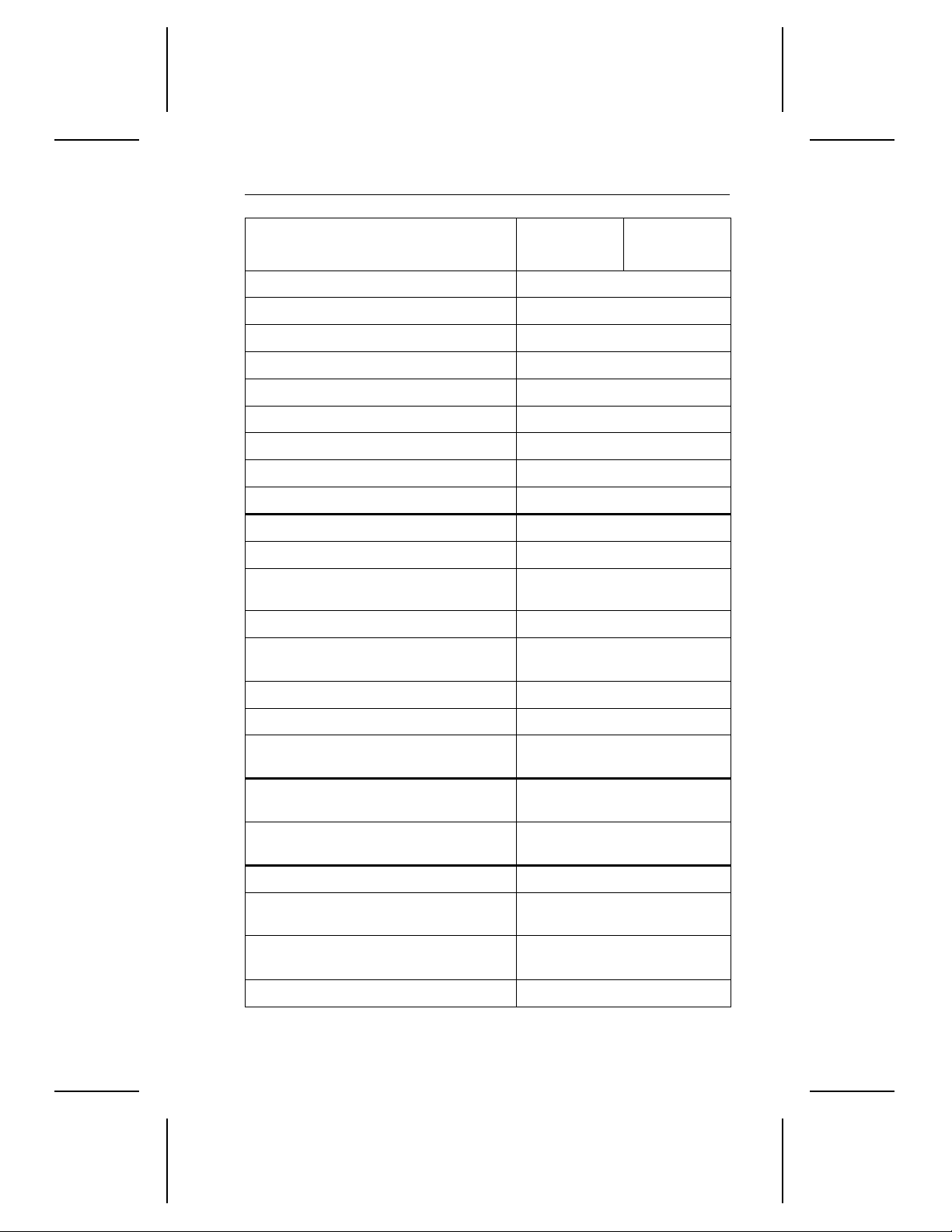

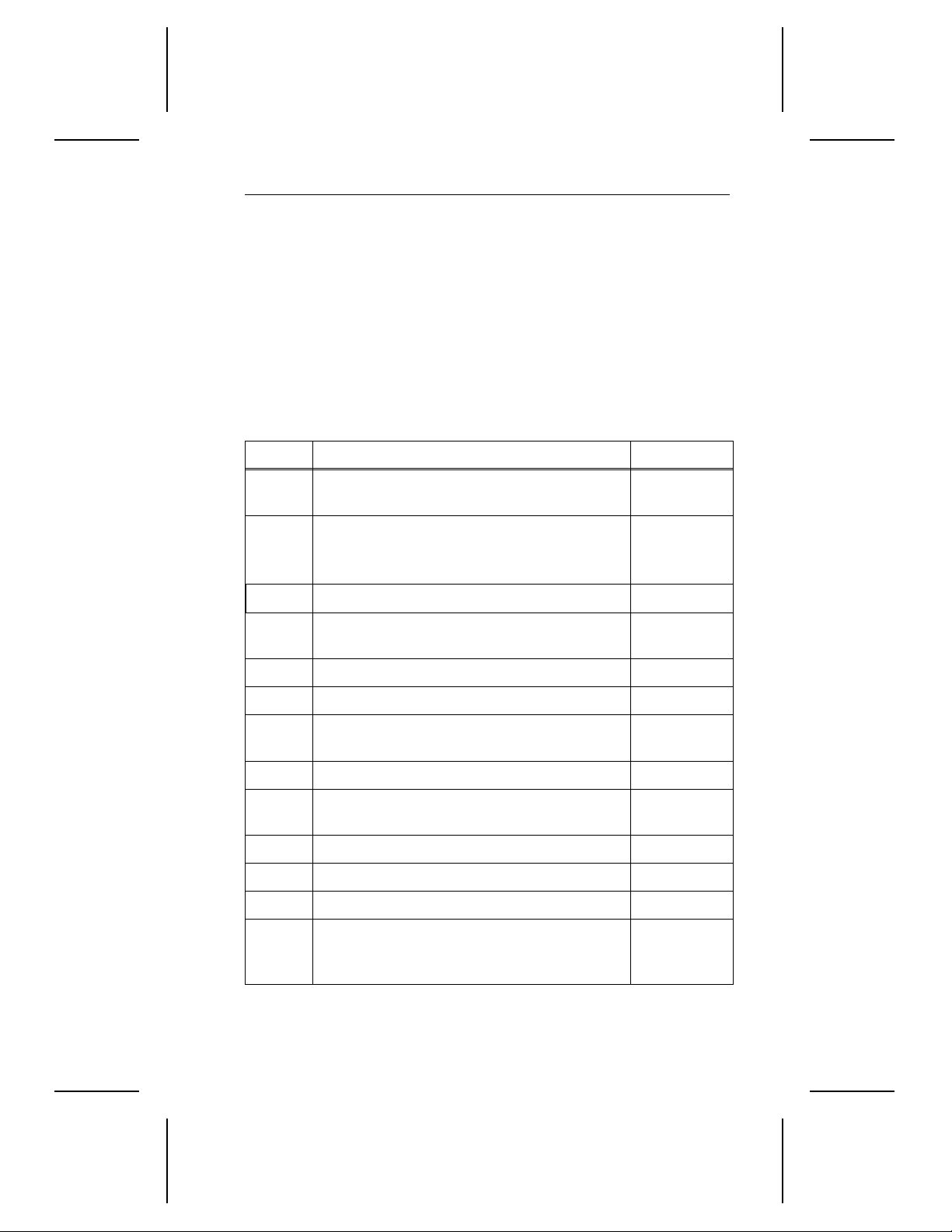

Marathon 2250 and Marathon 1680 Product Manual 3

Drive Specification

Power-on to ready (sec typical) 3.5

Standby to ready (sec typical) 2

Spinup current (pe ak) 1.3 amps

Read/Writ e power and current (typical) 2.5 watts, 0.5 am ps

Seek power and curren t (ty pical ) 2.5 watts, 0.5 am ps

Idle mode power and current (typical) 1.2 watts, 0. 24 am ps

Standby mode power and current (typical) 0.3 watts, 0. 06 am ps

Sleep mode power an d cur ren t (typi cal) 0.1 watts, 0.02 am ps

Voltage tolerance (including noise)

Ambient temperature (°C) 5 to 55 (op.), –40 to 70 (nonop.)

Temperature gradient (°C per hour max) 30

Relative humidity (ope rati ng) 8% to 80%

Wet bulb temper at ur e (°C max) 29.4 (op.), 40 (nono p. )

Altitude (meters ab ove m ean sea level,

max)

Marathon

2250

+5 volts, ± 5%

(10% per hour max grad.)

–300 to 3,040 (op. ),

–300 to 12,19 0 (no nop. )

Marathon

1680

Shock, operating (G s ma x) 125 (2 msec)

Shock, nonoperati ng (Gs max , 2 msec ) 350

Vibration (Gs max at 5– 400 H z,

without physica l da ma ge or los s of dat a)

Drive acoustics (bel s— sound power)

Idle mode (dBA—sound pressure)

Drive acoustics (bel s— sound power )

Seek mode (dBA—sound pressure)

Nonrecoverable rea d error s 1 per 10

Mean time between failures

(power-on hours)

Contact start-st op cy cl es

(40°C, ambient humidi t y)

Service life (years) 5

0.75 (op.)

4.0 (nonop.)

3.5 (typical), 3.8 (max )

24 (typical), 28 (max)

3.8 (typical), 4.1 (max )

26 (typical), 30 (max)

13

bits read

300,000

50,000

Page 12

4 Marathon 2250 and Marathon 1680 Product Manual

Page 13

Marathon 2250 and Marathon 1680 Product Manual 5

1.0 Drive specifications

Unless otherwise noted, all specific ations are measured under ambient

conditions, at 40°C, at sea level and nominal power.

1.1 Formatted capacity

Marathon 2250 Marathon 1680

Guaranteed Kbytes 2,250,209 1,680,634

Guaranteed sectors

(LBA mode)

Bytes per sector 512 512

DOS systems are not able to access m ore than 528 M bytes unless:

Note.

1) the host system supp orts and is conf igured for LBA addressi ng

or for extended CHS addressing , or 2) the host system contains a

specialized drive controller, or 3) the host system runs BIOS translation software. In addition, older BIOSs cannot address more than

2.1 Gbytes ( m ore than 4,096 cylinders) on a single partition. If you

encounte r this probl em with t he ST92255A G, divide the drive int o

two partitions or u pgrade your BI OS. Please cont ac t your Seagat e

representative for additional information.

4,394,940 3,282,490

1.1.1 Default logical geometry

CHS Mode

Sectors per trac k 63 63

Read/write heads 16 16

Cylinders 4,360 3,256

LBA Mode

When addressing either drive in LBA mode, all blocks (sectors) are

consecutively numbered from 0 to

Marathon 2250 Marathon 1680

– 1.

n

1.1.2 Supported CHS translation geometr ies

The Marathon 2250 supports any translation geometry that satisfies

of the following conditions:

• Sectors per track ≤ 63

• Read/write heads ≤ 16

• (Sectors per track) ×

(read/write heads) × (cylinders)

≤ 4,394,880

all

Page 14

6 Marathon 2250 and Marathon 1680 Product Manual

The Marathon 1680 supports any translation geometry that satisfies

of the following conditions:

• Sectors per track ≤ 63

• Read/write heads ≤ 16

• (Sectors per track) ×

(read/write heads)

× (cylinders) ≤ 3,282,048

1.2 Physical organization

Marathon 2250 Marathon 1680

Read/Write heads 10 8

Discs 5 4

1.3 Recordin g and inte rf ace tec hn ology

Interface ATA

Recording method 8/9

Recording density (bits/inch) 120,000

Track density (tracks/inch) 5,555

2

Areal density (Mbits/inch

Spindle speed (RPM)

( ± 0.5%)

) 666

4,508

all

Internal data-transfer rate

(Mbits per sec max—ZBR)

I/O data-transfer rate

(Mbytes per sec max)

Interleave 1:1

Cache buffer (Kbytes) 103

60.8

16.6 (PIO mode 4 with IORDY)

16.6 (multiword DMA mode 2)

Page 15

Marathon 2250 and Marathon 1680 Product Manual 7

1.4 Physical characteristics

Marathon 2250 Marathon 1680

Maximum height (inches)

(mm)

Maximum width (inches)

(mm)

Maximum length (inches)

(mm)

Typical weight (ounces)

(grams)

Note.

Maximum length excludes I/O connector pins that may extend up

to 0.015 inches beyond the edge of the head/disc assembly, per

SFF 8004 specification.

0.676

(17.2)

2.76

(70.1)

3.955

(100.45)

7.19

(204)

0.676

(17.2)

2.76

(70.1)

3.955

(100.45)

7.05

(200)

1.5 Seek time

All seek times are measured using a 25 MHz 486 AT computer (or faster)

with a 8.3 MHz I/O bus. The measurements are taken with nominal power

at sea level and 40°C ambient temperature. The specifications in the

table below are defined as follows:

• Track-to-track seek time is an average of all possible single-track

seeks in both directions.

• Average seek time is a true statistical random average of at least 5,000

measurements of seeks between random tracks, less overhead.

• Full-stroke seek time is one-half the time needed to seek from the first

data cylinder to the maximum data cylinder and back to the first data

cylinder. The full-stroke typical value is determined by averaging 100

full-stroke seeks in both directions.

Seek type Typical read

(msec)

Track-to-track 4 5

Average 12 14

Full-stroke 26 28

Average latency: 6.65 msec

Typical write

(msec)

Page 16

8 Marathon 2250 and Marathon 1680 Product Manual

1.6 Start times

Power-on to Ready (sec) 3.5 typical, 7 max

Standby to Ready (sec) 2 typical, 3 max

Idle to Ready (sec) 0.4 max

1.7 Power specif icat io ns

The drive receives DC power (+5V) through pin 41 and pin 42 of the AT

interface connector.

1.7.1 Power consumption

Power requirements for the drive are listed in the table below. Typical power

measurement s are based o n an average of dri ves tested unde r nominal

conditi ons, us ing 5.0V input volt age at 4 0°C ambi ent tempe rature a t sea

level. Active mode current and power ar e mea s ur ed with a 32-msec delay

between each operation and the drive in default logical geometry. Seeking

power and currents ar e measured during one - third-strok e buffered seeks.

Read/write power and current are measured with the heads on track, based

on a 16-sec tor w rite fol lowed by a 32-ms ec dela y, then a 16-sect or read

followed by a 32-msec delay. Spinup power is measured from time of

power-on t o time of drive-read y for normal operation. T he average peak

represents peak power that is drawn from the battery.

Watts

Mode

Spinup

Peak (see Figure 1)

Average

Active

Read/Write

Seeking

Idle 1.2 1.3 0.24 0.26

Standby 0.3 0.36 0.06 0. 072

Sleep 0.1 0.1 0.02 0.02

(at nominal voltage)

Typical

—

4.0

2.5

2.5

Max

—

—0.8

2.6

2.6

Amps

(at nominal voltage)

Typical

0.5

0.5

Max

1.3

—

0.52

0.52

Page 17

(

)

Marathon 2250 and Marathon 1680 Product Manual 9

Current (mA)

1,400

1,200

Drive ready

1,000

800

600

400

200

0

Uploa d code

Active

mode

Spinup

01234556789101112

Time

seconds

Idle

mode

Standby

mode

Sleep

mode

Figure 1. Typical startup and operation current profi le

1.7. 1.1 Typical current profile

Figure 1 shows a projected drive startup and operation current profile for

the Marathon 2250 and the Marathon 1680.

The peaks in Figure 1 are the result of inductive kickback from

Note.

the commutation of the spindle motor and, therefore, do not draw

power from the battery.

1.7.2 Power recovery

Except during execut ion of a write command or writi ng cached data, the

drive’s power can be interru pted without adverse ly affecting the drive or

previously written data. If power is removed while the drive is performing a

write operation, the integrity of the data being written cannot be guaranteed.

Do not remove power from the drive while t he interface signals are ac -

Note.

tive (at low impedance) because power may enter th e input buffer s.

1.7.3 Conducted noise

The drive is expected to operate with a maximum of:

• 150 mV peak-to-peak triangular-wave injected noise at the power

connector. The frequency is 10 Hz to 100 KHz with equivalent resistive

loads.

Page 18

10 Marathon 2250 and Marathon 1680 Product Manual

• 100 mV peak-to-peak triangular-wave injected noise at the power

connector. The frequency is 100 KHz to 10 MHz with equivalent

resistive loads.

Equi valent resistance (9.26 ohms) is calculated by dividing the

Note.

nominal voltage (5V) by the typical RMS read/write current (0.54

amps).

1.7.4 Voltage to lerance

Voltage tolerance (including noise): +5 volts, ± 5%

1.7.5 Power-management modes

Seagate’s Marathon drives provide programmable power management

to enhance battery life and to provide greater energy efficiency. In most

computers, you can control power management through the system

setup program. These drives feature several power-management

modes, which are summarized in the following table and are described

in more detail below:

Mode Heads Spindle Buffer

Active

Idle

Standby

Sleep

Active mode.

operations.

Idle mode.

after 5 seconds of inactivity. The drive remains in Idle mode with heads

flying over the media for 15 minutes; then the drive makes the transition

to Active mode and seeks to the last-known logical block address, where

it remains for 5 minutes. The drive then seeks to a new, unspecified

location two more ti mes, for 5 minutes each, after which i t makes the

transition to Standby mode. In Idle mode, the spindle remains up to

speed, the buffer remains enabled, and the drive accepts all commands

and returns to Active mode whenever a disc access command is received.

The drive enters Idle mode when an Idle or Idle Immediate command is

received. The Idle or I dle Immediate command overrides the algorit hm

described above. The drive remains in Idle mode until a disc access

command is received or the standby timer expires, whichever occurs first.

At power-on, the drive sets the Idle Timer to enter Idle mode

Moving Rotating Enabled

Varies Rotating Enabled

Parked S topped Enabled

Parked S topped Disabled

The drive is in Active mode during the read/write and seek

Page 19

Marathon 2250 and Marathon 1680 Product Manual 11

When the standby timer expires, t he drive makes the transition t o the

Standby mode. The drive requires approximately 100–200 msec to return

to Active mode from Idle mode.

Standby mode.

Standby or Standby Immediate command. If the standby command has set

the standby timer, the drive enters S tandby mode automatic ally after the

drive has be en inac tive f or t he speci fied leng th of ti me. In Standby m ode,

the buffer remains enabled, the heads are parked and the spindle is at rest.

The drive accepts all commands and returns to Active mode any time a disc

access command is received. The drive requires approximately 3 seconds

to return to Active mode from Standby mode.

Sleep mode.

command from the host. The heads are parked and the spindle is at rest.

The ROM and RAM codes are valid; however, the cache is flushed before

going to sleep. The drive leaves Sleep mode when either a Hard Reset

interface signal or a Soft Reset signal ( Device Control register=04) is

received from the host. After receiving a Soft Reset, the drive exits Sleep

mode and enters Standby mode, with all current emulation and translation parameters intact. After receiving a Hard Reset signal, the drive exits

Sleep mode and enters Active m ode. The drive is reinitialized to the

default parameters. This is the same procedure as initial power-on and

requires approximately 7 seconds to complete.

Idle and standby timers.

timer at pow er- on t o 5 seco nds. If the i dle t imer r each es ze ro b efor e any

drive ac tivity i s requ ired, the drive makes a tr ansition to Idle m ode. Eac h

time the drive performs an Active function (read, write or seek), the idle and

standby timers are reinitialized and begin counting down from their specified

delay times to zero. If the standby timer has been set and no additional drive

activit y oc c ur s , the drive remains i n Idle mode for the time spec ified in t he

standby timer, then enters Standby mode.

The dri ve enter s Standb y mode when the h ost send s a

The drive enters Sleep mode only after receiving a Sleep

The drive sets the default time delay for the idle

If the host has not set the st andby timer and no ad ditional drive activity

occurs, the drive remains in Idle mode for 30 minutes, then enters standby

mode. In both Idle and Standby mode, the drive accepts all commands and

returns to Active mode when disc access is necessary.

Page 20

12 Marathon 2250 and Marathon 1680 Product Manual

1.8 Environmental tolerances

1.8.1 Ambient temperature

Operating 5° to 55°C (41° to 131°F)

Nonoperating –40° to 70°C (–40° to 158°F)

Caution.

This drive needs sufficient airflow so that the maximum surface

temperatu re at the cen ter of the top c ov er of the drive does not

exceed 62 degrees C (144 degrees F).

1.8.2 Temperature gradient

Operating 30°C/hr (86°F/hr) max, without condensation

Nonoperating 30°C/hr (86°F/hr) max, without condensation

1.8.3 Humidity

1.8.3.1 Relati ve humidity

Operating 8% to 80% noncondensing (10% per hour max)

Storage 8% to 90% noncondensing (10% per hour max)

Transit 5% to 95% noncondensing (10% per hour max)

1.8.3.2 Wet bulb temperature

Operating 29.4°C (85°F) max

Nonoperating 40°C (104°F) max

1.8.4 Altitude

Operating –300 m to 3,040 m (–1,000 ft to 10,000 ft)

Nonoperating –300 m to 12,190 m (–1,000 ft to 40,000 ft)

1.8.5 Shock

For shock specifications, it is assumed that the drive is mounted securely

with the input levels at the drive mounting screws. For nonoperating

specifications, it is as sumed t hat t he r ead/write heads are positioned in

the shipping zone.

Page 21

Marathon 2250 and Marathon 1680 Product Manual 13

At power-down, the read/write heads automatically move to the

Note.

shipping zone. The head and slider assembly park ins ide of the

maximum data cylinder. When power is applied, the heads recalibrate to Track 0.

1.8.5.1 Operating shock

The Marathon 2250 and the Marathon 1680 incorporate SafeRite shock

protection and can withstand a maximum operating shock of 125 Gs

without nonrecoverable data errors (based on half-sine shock pulses of

2 msec).

1.8.5.2 Nonoperating shock

The nonoperating shock l evel that the Marathon 2250 and Marathon

1680 can tolerate without i ncurring physical damage or degr adation in

performance is 350 Gs (based on half-sine shock pulses of 2 msec

duration) or 150 Gs (based on half-sine shock pulses of 11 msec

duration). Shock pul ses are defi ned by MIL-S TD-202 F wit h the amplitude tolerance controlled to ± 5%.

1.8.6 Vibration

For vibration specifications, it is assumed that the drive is mounted in an

approved orientation with the input levels at the drive mounting screws.

For the nonoperating specificat ions, it is assumed that the read/write

heads are positioned in the shipping zone.

1.8.6.1 Operating vibration

The following table lists the maximum vibration levels that the drive may

experience without incurring physical damage, data loss or performance

degradation.

5–22 Hz 0.02-inch displacement (peak-to-peak)

22–400 Hz 0.75 Gs acceleration (0 to peak)

400–22 Hz 0.75 Gs acceleration (0 to peak)

22–5 Hz 0.02-inch displacement (peak-to-peak)

Page 22

14 Marathon 2250 and Marathon 1680 Product Manual

1.8.6.2 Nonoperating vibration

The following table lists the maximum nonoperating vibration that the

drive may experience without incurring physical damage or degradation

in performance.

5–22 Hz 0.2-inch displacement (peak-to-peak)

22–400 Hz 4 Gs acceleration (0 to peak)

400–22 Hz 4 Gs acceleration (0 to peak)

22–5 Hz 0.2-inch displacement (peak-to-peak)

1.9 Drive acoustics

Drive ac ous tics are measured as sound power, using techniques that are

generally c onsistent wit h ISO document 7779. Measurements are ta ken

under ess entially free-fie ld conditions over a r eflecting plane, using a total

of nine microphones that measure in the 250–4,000 Hz band. This methodology determines broad-band and narrow-band noise, and discrete frequency components. For all tests, the drive is oriented with the cover facing

upward.

Mode Typical Maximum

Idle (sound power-bels) 3.5 3.8

Seek (sound power-bels) 3.8 4.1

Idle (sound pressure-dBA) 24 28

Seek (sound pressure-dBA) 26 30

1.10 Reliability

Nonrecoverable read errors 1 per 1013 bits read

Mean time between failures

(MTBF)

Contact start-stop cycles

(CSS)

Preventive maintenance None required

Service life 5 years

300,000 power-on hours

(nominal power, at sea level and

40°C ambient tem per atu re)

50,000 cycles

(at nominal voltage and 40°C , wi th 60

cycles per hour and a 50% duty cycle)

Page 23

Marathon 2250 and Marathon 1680 Product Manual 15

1.11 Agency certification

1.11.1 Safety certification

The drive is recognized in ac cordance with UL 1950 and CSA C22.2

(950-M89) and meets all applicable sections of IEC 380, IEC 435,

IEC 950, VDE 0806/08.81 and E N 60950 as tested by TUV-Rheinland,

North America.

1.11.2 Electr omag net ic Compat ibilit y

Hard drives that display the CE marking comply with European Union

requirements specified in Electromagnetic Compatibility Directive

89/336/EEC as amended by Directive 92/ 31/EEC of 28 April 1992 and

Directive 93/68/EEC of 22 July 1993.

Seagate uses an independent laboratory to confirm compliance with the

EC directives specified in the previous paragraph. Drives are tested in

representative end-user systems using 80486, Pentium and PowerPC

microprocessors. Although CE-marked Seagate drives comply with the

directives when used in t he test systems, we cannot guarant ee that all

systems will comply with the directives. The drive is designed for operation inside a properly designed enclosure, with properly shielded I/O

cable (if necessary) and terminators on all unused I/O ports. The computer manufacturer or system integrator should confirm EMC compliance

and provide CE marking for their products.

1.11.3 FCC verification

These drives are intended to be contained solely within a personal

computer or similar enclosure, not attached as an external devi ce. As

such, each drive is considered to be a subassembly even when it is sold

individually to the customer. As a subassembly, no Federal Communications Commission verification or certification of the device is required.

Seagate Technology, Inc . has tested this devic e in enclosures as described above to ensure that the total assembly (enclosure, disc drive,

motherboard, power supply, etc.) complies with the limits for a Class B

computing device, pursuant to Subpart J, Part 15 of the FCC rules.

Operation with noncertified assemblies is likely t o result in interference

with radio and television reception.

Radio and Television Interference.

uses radio frequency energy and, if not installed and used in strict

accordance with the manufacturer’s instructions, may cause interference

with radio and television reception.

This equipment generates and

Page 24

16 Marathon 2250 and Marathon 1680 Product Manual

This equipment is designed to provide reasonable protection against

such interference in a residential installation. However, there is no

guarantee that interference will not occur in a particular installation. If this

equipment does cause interference with radio or television reception

(which can be determined by turning the equipment on and off), try one

or more of the following corrective measures:

• Reorient the receiving antenna.

• Move the device to one side or the other of the radio or TV.

• Move the device farther away from the radio or TV.

• Plug the computer into a different outlet so that the receiver and

computer are on different branch outlets.

If necessary, you should consult your dealer or an experienced radio or

television technician for additional suggestions. You may find the following booklet from the Federal Communications Commission helpful:

to Identify and Resolve Radi o-Television Interference Problems

booklet is available from the Superintendent of Documents, U.S. Government Printing Offic e, Washington, DC 20402. Refer to publication

number 004-000-00345-4.

How

. This

Page 25

Marathon 2250 and Marathon 1680 Product Manual 17

2.0 Drive mounting and configuration

2.1 Handling and sta tic -d isch ar ge pr ecau ti on s

After unpacking, but before install ation, the drive may be exposed to

potential handling and ESD hazards. You must observe standard staticdischarge precautions. A grounded wrist-strap is recommended.

Handle the drive only by the sides of the head/disc assembly. Avoid

contact with the printed circuit board, all electronic components and the

interface connector. Do not apply pressure to the top cover. Always rest

the drive on a padded antistatic surface until you mount it in the host

system.

2.2 Jumper settings

2.2.1 Master/slave configuration

You must establish a master/slave relationship between two drives that are

attached to a single AT bus. You can configure a drive to become a master

or slave by setting the master/slave jumpers, as described below and shown

in Figure 2 on page 18.

Alternatively, you can configure the drive as a master or slave using the

cable-select option. This requires a special daisy-chain cable that

grounds pin 28 (CSEL) on one of its two drive connectors. If you attach

the drive to the grounded CSEL c onnec tor, it becomes a master. If you

attach the drive to the ungrounded CSEL connector, it becomes a slave.

To use this option, the host system and both drives must support cableselect and both drives must be configured for cable-select. To configure

Marathon drives for cable-select, install both master/slave jumpers.

For the host to recognize the slave drive using the DASP– signal, the

slave drive must assert the DASP– signal at power-up, and the master

drive must monitor DASP– at power-up.

Page 26

18 Marathon 2250 and Marathon 1680 Product Manual

Note. Drive is shown with

circuit board up.

Master/slave

configuration jumpers

Pin 1

Pin 20 removed for keying

B D

A C

Drive is master; slave may be detected using DASP– signal

Drive is master; Seagate slave drive present

Drive is slave; Seagate master drive present

Use CSEL pin grounding to differentiate master from slave

Circuit board

Figure 2. Connector and master/slave jumper setup

Jumper

for pins

A and B

Jumper

for pins

C and D Config ur a tion

Off Off Drive is master; slave drive may be detected

using DASP– signal. CSEL is ignored.

Off On Drive is master; slave drive is present. CSEL

is ignored. DASP– is ignored.

On Off Drive is slave (a master drive should be

present also). CSEL is ignored.

On On Differentiate master and slave drives using

cable-select: If a drive is attached to a

connector in which pin 28 is grounded, then it

becomes a master. If a drive is attached to a

connector in which pin 28 is ungrounded,

then it becomes a slave.

Page 27

Marathon 2250 and Marathon 1680 Product Manual 19

2.3 Remote LED configuration

The drive indicates activity to the host through the DASP– line (pin 39)

on the ATA interface. This line may be connected to a drive status

indicator driving an LED at 5V. The line has a 30 mA nominal current

limit; however, most external LEDs are sufficiently bright at 15 mA.

Because the LED drops 1.7 volts, we recommend that you place a

200-ohm resistor in series with the LED to limit the current to 15 mA.

2.4 Drive mountin g

You can mount the drive in any orientation using four screws in the four

side-mounting or four bottom-mounting holes. Allow a mi nimum clearance of 0.030 inches (0.76 mm) f or cooling around the entire perimeter

of the drive. The drive conforms to the industry-standard SFF-8200

mounting specifications and requires the use of SFF-8200-c ompatible

connectors in direct-mounting applications. See Figures 3 and 4 on

pages 20 and 21 for drive mounting dimensions.

. Per SFF 8004 specif ic ations, the I/O connector pins may extend

Note

up to 0.015 inches beyond the edge of the head/disc assembly.

Caution

Caution

. This drive needs sufficient airflow so that the maximum surface

temperature at the c enter of t he top cover of the drive does

not exceed 62°C (144°F).

. To avoid damaging the drive, use M3X0.5 metric mounting

screws only. Do not insert mounting screws more than

0.150 inches (3.81 mm) into the mounting holes. Do not overtighten the screws (maximum torque: 3 inch-lb).

Page 28

20 Marathon 2250 and Marathon 1680 Product Manual

A40

A39

A1 +A2 –A3

A23

Z

A4 ± A5

(width at

mounting

holes)

(to tips of I/O connector pins)

A37

X2

A26 thread, 4PLC

min A38 full thread

center within A27 of

position specified

A37

Z2

A32 thread, 4PLC

min A41 full thread

center within A33 of

position specified

A37

Z4

S1

A6

(to end of HDA)

A25

A31

A37

X1

A21 ± A22

A37

Z1

A37

Z3

A24

A30

A7

Y

A28

X

A29

A8

Figure 3. Drive mounting dimensions—side and bot tom vi ew

(for dimension speci ficat ions, see table on pages 21 and 22).

zxy

Page 29

Marathon 2250 and Marathon 1680 Product Manual 21

Pin 44

Pin 20 removed

for keying

Pin 1

A34

Z

A35

A36

X

A13

A12

Detail

A9

A11

Z

A10

A10.1

±

X

Figure 4. Drive mounting dimensions—end view

(for dimension speci ficat ions, see table below).

± A14

± A18

A19

A20

A17

+A2 –A3

M

zx

M

A1

A15

A16

M

zx

M

Mounting dime nsion speci fications

Dim. Description inches mm

A1 Drive height 0.668 16.97

A2 + tolerance on drive he ig ht 0.008 0.20

A3 – tolerance on drive he ig ht 0.008 0.20

A4 Drive width at mounti ng ho le s 2.750 69.85

A5 + and – toleranc e on drive wid th a t m ounting holes 0.009 0.23

A6 Maximum dr iv e lengt h (no t inclu d i n g I/O pins) 3.95 5 100.45

A7 Front-to-back connector location 0.403 10.2

A8 Allowable range, f ron t-t o-b ack co nnector location 0.039 1.00

A9 Top-to-b ot to m co nnec to r locati on, pin center line 0.157 3.99

A10 Side-to-side connector loca tion, pin center line 0.399 10.14

A10.1 + and – tolerance, side-to-side connector location 0.015 0.38

A1 1 Top- t o-b otto m pin spacing 0.079 2.00

A12 Side-to-side pin spacing 0.079 2.00

A13 Pin side-to-side dimension 0.020 0.50

A14 + and – tolerance on pin side-to-side di me nsion 0.002 0.05

A15 Allowable range, side-to-side connector location 0.030 0.75

continued on foll owi ng page

Page 30

22 Marathon 2250 and Marathon 1680 Product Manual

continued from pr evious page

Mounting dime nsion speci fications

Dim. Description inches mm

A16 Allowable range, side-to-side, pins within connector 0.003 0.08

A17 Pin top-to-bottom dimension 0.020 0.50

A18 + and – tolerance on pin top-to-bottom dim ensi on 0.002 0.05

A19 Allowable range, top-to-bottom connector location 0.020 0.50

A20 Allowable range, top-to-bottom , pins i n conn ect or 0.003 0.08

A21 Connector pin length 0.152 3.86

A22 + and – tolerance on pin length 0.008 0.20

A23 Side mounting hole height 0.118 3.00

A24 Front-to-back location of side m ounti ng holes 0.551 14.0

A25 Front-to-back distance be tw een side mounting

holes

A26 Thread description, side mount ing hol es n/a M3

A27 Diam. of cylinder into which hole center must fall 0.020 0.50

A28 Distance between side of drive and center of

nearest bottom m ount ing holes (on pin-44 side)

A29 Side-to-side distance between bot t om mo unt ing

holes

A30 Front-to-back location of bott om mou ntin g hol es 0.551 14.0

A31 Front-to-back distance be tw een bottom mounting

holes

A32 Thread description, bot to m mounting holes n/a M3

A33 Diam. of cylinder into which hole center must fall 0.020 0.50

A34 Min. vertical clearance for ma ting connector 0.039 1.00

A35 Max. side-to-side distance f ro m pin- 44 ed ge of

HDA near I/O connector to st art of clear ance for

mating connect or

A36 Min. side-to-side clearance fr om pi n-4 4 edge of

I/O connecto r to any object interruptin g

clearance of mating connector

A37 Diam. of datum targets and refere nce ar eas 0.315 8.00

A38 Min. thread depth, side mounting hol es 0.1 18 3.00

A39 Min. pin centerline to chamfer abov e connector 0.049 1.25

A40 Min. chamfer above connect or 0.010 0.25

A41 Min. thread depth, bottom moun ting holes 0.098 2.50

S1 Maximum drive length to tips of I/O pins

(Non-SFF dimensi on— f or ref ere nce only)

3.016 76.6

0.160 4.06

2.430 61.72

3.016 76.6

0.315 8.00

2.370 60.20

3.970 100.84

Page 31

Marathon 2250 and Marathon 1680 Product Manual 23

2.5 ATA interface connector

The drive connector is a 44-conductor connector with 2 rows of 22 male

pins on 0.079-inch (2 mm) centers (see Figure 4 on page 21 and Figure

5). The mating cable connector is a 44-conductor, nonshielded connector

with 2 rows of 22 female contacts on 0.079-inch (2 mm) centers. The

connectors should provide strain relief and should be keyed with a plug

in place of pin 20.

These drives are designed to support the industry-standard SFF-8200

mounting specifications. When installing these drives in fixed mounting

applications, use only S FF-compatible connectors such as Molex part

number 87368-442

printed circuit cables (P CCs), use Molex part number 87259-4413 or

equivalent to connect the drive to the system. Select a connector that

provides adequate clearance for the master/slave configuration jumpers

if the applicat ion requires the use of s uch jumpers. The ATA i nterface

cable should be no more than 18 inches long.

Per SFF 8004 specifications, the I/O connector pins may extend

Note.

up to 0.015 inches beyond the edge of the head/disc assembly.

. For applications that involve flexible cables or

x

Master/slave jumpers

1.654 (42.01)

0.158 ± 0.003 (4.00 ± 0.08)

Dimensions are in inches (mm)

Figure 5. ATA Interface connector dimensions (non -SFF dimen si on, for

reference only)

Page 32

24 Marathon 2250 and Marathon 1680 Product Manual

Page 33

Marathon 2250 and Marathon 1680 Product Manual 25

3.0 ATA Attachment-3 Interface (ATA-3)

The drives in this manual comply with the ATA-3 Standard, proposed by

the X3T10 committee, a Technical Committee of Accredited Standards

Committee X3, of the American National Standards Institute (ANSI).

The X3T10 committee has been renamed to X3T13 to reflect its current

standards work. For more information about the committee and the

standards, see the committee’s Internet FTP site:

ftp://fission.dt.wdc.com/pub/standards/X3T13T

3.1 ATA interface signals and connector pins

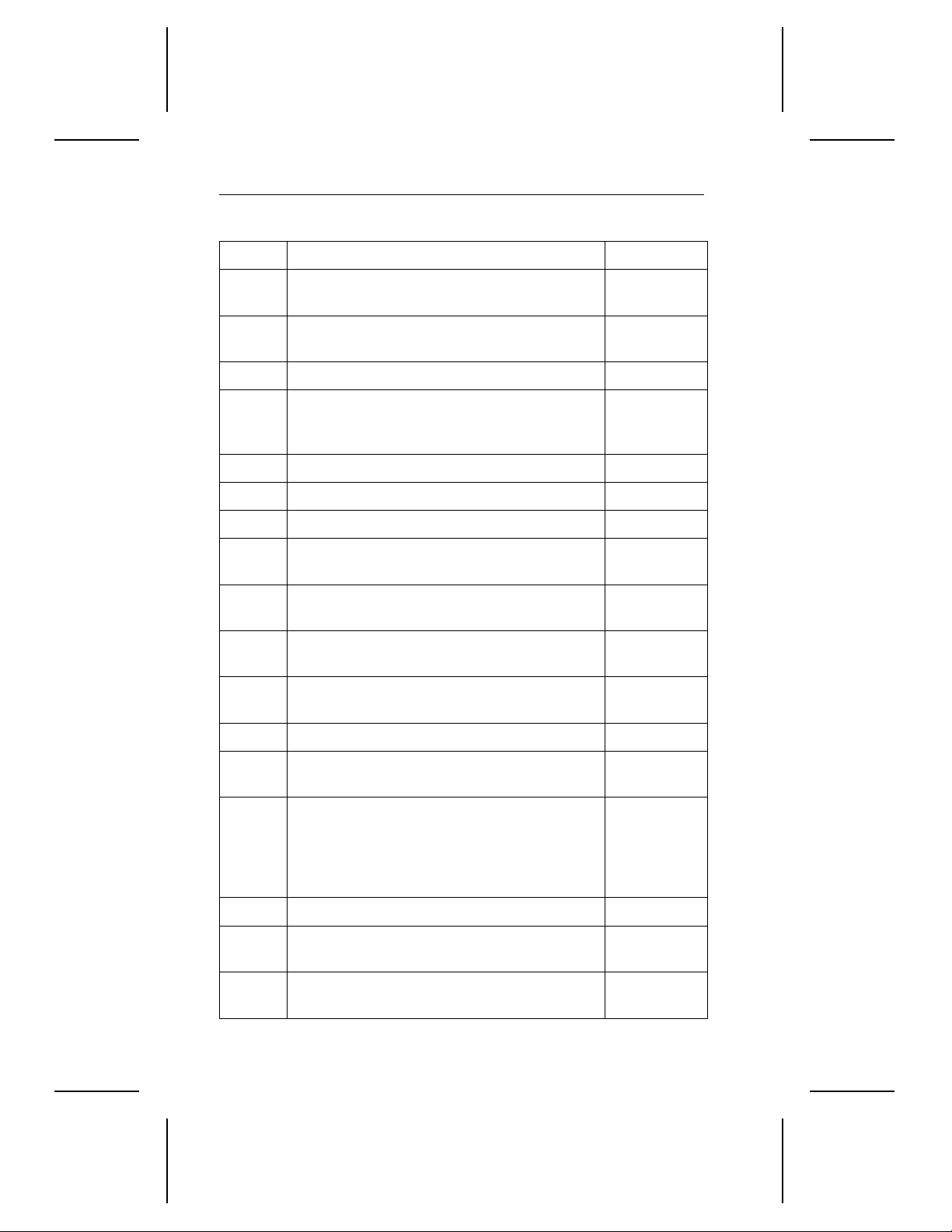

Figure 6 on page 26 summarizes the signals on the ATA interface

connector that the drive supports. For a detailed description of these

signals, refer t o the

Standard X3T10/2008D Revision 6, Information Technology AT Attachment-3 Interf ace (ATA-3),

ATA-3 Standard.

3.1.1 AT bus signal levels

Signals that the drive sends have the following output characteristics at

the drive connector:

Working Draft of the Proposed American National

subsequently referred to as the

Draft Proposed

Logic Low 0.0V to 0.4V

Logic High 2.5V to 5.25V

Signals that the drive receives must have t he following input characteristics, measured at the drive connector:

Logic Low 0.0V to 0.8V

Logic High 2.0V to 5.25V

Page 34

26 Marathon 2250 and Marathon 1680 Product Manual

Drive pin #

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

Pins 28, 34 and 39 are used for master-slave communication (details shown below).

28

34

39

Signal name

–

Reset

Ground

DD7

DD8

DD6

DD9

DD5

DD10

DD4

DD11

DD3

DD12

DD2

DD13

DD1

DD14

DD0

DD15

Ground

(removed)

DMARQ

Ground

–

DIOW

Ground

–

DIOR

Ground

IORDY

CSEL

–

DMACK

Ground

INTRQ

–

IOCS16

DA1

–

PDIAG

DA0

DA2

–

CS1FX

–

CS3FX

–

DASP

Ground

Power

Power

Ground

Reserved

Drive 0 (master)Drive 1 (slave)

28

34

39

Host pin # and signal description

1

Host Reset

2

Ground

3

Host Data Bus Bit 7

4

Host Data Bus Bit 8

5

Host Data Bus Bit 6

6

Host Data Bus Bit 9

7

Host Data Bus Bit 5

8

Host Data Bus Bit 10

9

Host Data Bus Bit 4

10

Host Data Bus Bit 11

11

Host Data Bus Bit 3

12

Host Data Bus Bit 12

13

Host Data Bus Bit 2

14

Host Data Bus Bit 13

15

Host Data Bus Bit 1

16

Host Data Bus Bit 14

17

Host Data Bus Bit 0

18

Host Data Bus Bit 15

19

Ground

(No Pin)

20

21

DMA Request

22

Ground

23

Host I/O Write

24

Ground

25

Host I/O Read

26

Ground

27

I/O Channel Ready

28

Cable Select pin

29

DMA Acknowledge

30

Ground

31

Host Interrupt Request

32

Host 16 Bit I/O

33

Host Address Bus Bit 1

34

Passed Diagnostics

35

Host Address Bus Bit 0

36

Host Address Bus Bit 2

37

Host Chip Select 0

38

Host Chip Select 1

39

Drive Active / Slave Present

40

Ground

41

+5 volts DC (logic)

42

+5 volts DC (motor)

43

Ground for power pins

44

Reserved

Host

CSEL

PDIAG

DASP–

–

28

34

39

Figure 6. I/O pins and supported ATA signals

Page 35

Marathon 2250 and Marathon 1680 Product Manual 27

3.2 ATA Interface commands

3.2.1 Supported ATA commands

The following table lists supported ATA-standard and Seagate-specific

drive commands. For a detailed description of the ATA commands, refer

to the

Draft Proposed ATA-3 Standard.

details and subcommands used in the S.M.A.R.T. implementation.

See Section 3.2.4 on page 33 for

Command

Command name

code

ATA-standard commands

Execute Drive Diagnostics 90

Format Track 50

Identify Drive EC

Initialize Drive Parameters 91

NOP 00

Read Buffer E4

Read DMA (w/retry) C8

Read DMA (no retry) C9

Read Long (w/retry) 22

Read Long (no retry) 23

Read Multiple C4

Read Sectors (w/retry) 20

Read Sectors (no retry) 21

Supporte d by

Marathon 2250

and Marathon 1680

H

H

H

H

H

H

H

H

H

H

H

H

H

Yes

Yes

Yes

Yes

No

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Read Verify Sectors (w/retry) 40

Read Verify Sectors (no retry) 41

Recalibrate 10

Seek 70

Set Features EF

Set Multiple Mode C6

continued on foll owi ng page

H

H

H

H

H

H

Yes

Yes

Yes

Yes

Yes

Yes

Page 36

28 Marathon 2250 and Marathon 1680 Product Manual

continued from pr evious page

Command

Command name

code

Execute S.M.A.R .T C ommand B0

Write Buffer E8

Write DMA (w/retry) CA

Write DMA (no retry) CB

Write Long (w/retry) 32

Write Long (no retry) 33

Write Multiple C5

Write Same E9

Write Sectors (w/retry) 30

Write Sectors (no retry) 31

Write Verify 3C

H

H

H

H

H

H

H

H

H

H

H

Supporte d by

Marathon 2250

and Marathon 1680

Yes

Yes

Yes

Yes

Yes

Yes

Yes

No

Yes

Yes

No

Drive Security Commands

Security Set Password F1H Yes

Security Unlock F2

H

Yes

Security Erase Prepare F3

Security Erase Unit F4

Security Freeze Lock F5

Security Disable Password F6

ATA-standard power-management commands

Check Power Mode 98

Idle 97

Idle Immediate 95

Sleep 99

Standby 96

Standby Immediate 94

or E5

H

or E3

H

or E1

H

or E6

H

or E2

H

or E0

H

H

H

H

H

H

H

H

H

H

H

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Page 37

Marathon 2250 and Marathon 1680 Product Manual 29

The following commands contain drive-specific features that may not be

described in the

Draft Proposed ATA-3 Standard

.

3.2.2 Identify Drive comman d

The Identify Drive command (command code ECH) transfers information

about the drive to the host following power-up. The data is organized as

a single 512-byte block of data, the contents of which are shown in the

table below. All reserved bits or words should be set to zero. Parameters

listed with an “

Section 1 of this manual for default parameter settings for the Marathon

2250 and the Marathon 1680.

Word Description Contents

0

1

2 ATA-reserved 0000

3

” are drive-specific or vary with the state of the drive. See

x

Configuration information:

Bit 6: fixed drive

Number of fixed cylinders (default logical

emulation): 4,360 (ST92255AG);

3,256 (ST91685AG)

(ST92255AG)

(ST91685AG)

Number of heads (default logical emulation):

16

0040

1108H

0CB8

0010

H

H

H

H

4 ATA-obsolete 0000

5 ATA-obsolete 0000

Number of sectors per track

6

(default logical emulation): 63

7–9 Not used by this drive 0000

10–19

Serial number:

(20 ASCII characters, 0000

= none)

H

20 ATA-obsolete 0000

21 ATA-obsolete 0000

22 Number of ECC bytes available (16) 0010

Firmware revision (8 ASCII character string):

23–26

continued on foll owi ng page

= ROM version, ss = RAM version,

xx

RAM version

tt=

003F

ASCII

xx.ss.tt

H

H

H

H

H

H

H

Page 38

30 Marathon 2250 and Marathon 1680 Product Manual

continued from pr evious page

Word Description Contents

27–46

47

Drive model number: (40 ASCII characters,

padded with blanks to end of string)

Maximum sectors per interrupt on read/write

multiple

ST92255AG or

ST91685AG

0010

H

48 Double word I/O (not supported) 0000

Standby timer values supported per ATA

49

standard, IORDY supported, IORDY can

be disabled

50 ATA-reserved 0000

51 PIO data-transfer cycle timing mode 0200

52 DMA transfer cycle timing mode (not used) 0000

Validity of words 54–58 and words 64–70

53

(words may be valid)

Number of cylinders

54

(current emulation mode)

Number of heads

55

(current emulation mode)

Number of sectors per track

56

(current emulation mode)

57–58 Number of sectors (current emulation mode)

Number of sectors transferred during a Read

59

Multiple or Write Multiple command

(ST92255AG)

0FBC 0043H

60–61 LBA sectors available

(ST91685AG)

017FC 0032H

2C00

0003

xxxx

xxxx

xxxx

xxxx

01

xx

H

H

H

H

H

H

H

H

H

H

H

62 ATA obsolete 0000

Multiword DMA active/modes supported

63

(see note following)

Advanced PIO modes supported (modes 3

64

and 4 supported)

07

0

x

0003

H

H

H

Page 39

Marathon 2250 and Marathon 1680 Product Manual 31

Word Description Contents

Minimum multiword DMA transfer cycle time

65

per word (120 nsec)

Recommended multiword DMA transfer

66

cycle time per word (180 nsec)

Minimum PIO cycle time without IORDY flow

67

control (363 nsec)

Minimum PIO cycle time with IORDY flow

68

control (120 nsec)

0078

0078

016B

0078

H

H

H

H

69–127 ATA-reserved 0000

128–159 Seagate-reserved

xxxx

160–255 ATA-reserved 0000

The f ollowing DMA mode settings are used in word 63 of the

Note.

Identify Drive command:

Word Bit Description (if bit is set to 1)

63 0 Multiword DMA mode 0 available

63 1 Multiword DMA mode 1 available

63 2 Multiword DMA mode 2 available

63 8 Multiword DMA mode 0 currently active

63 9 Multiword DMA mode 1 currently active

63 10 M ultiword DMA mode 2 currently active

H

H

H

Page 40

32 Marathon 2250 and Marathon 1680 Product Manual

3.2.3 Set Features command

This command controls the implementation of various features that the

drive supports. When the drive receives this command, it sets BSY,

checks the contents of the Features regist er, clears BSY and generates

an interrupt. If the value in the register does not represent a feature that

the drive supports, the command is aborted. Power-on default has the

read look-ahead and write caching features enabled and 4 bytes of ECC.

The acceptable values for the Features register are defined as follows:

01

02

03

04

33

44

54

55

66

77

81

82

84

88

Obsolete

H

Enable write cache

H

Set transfer mode (based on value in Sector Count register)

H

(default)

Sector Count register values:

Set PIO mode to default (PIO mode 2), enable IORDY

00

H

Set PIO mode to default (PIO mode 2), disable IORDY

01

H

PIO Mode 0

08

H

PIO Mode 1

09

H

PIO Mode 2

0A

H

(default)

0BH PIO Mode 3

PIO Mode 4

0C

H

Obsolete

10

H

Obsolete

11

H

Obsolete

12

H

Multiword DMA Mode 0

20

H

Multiword DMA Mode 1

21

H

Multiword DMA Mode 2

22

H

Enable auto-read reassignment

H

Not implemented

H

Sixteen bytes of ECC apply on read long and write long

H

(default)

commands

Not implemented

H

Disable read look-ahead (read cache) feature

H

Disable reverting to power-on defaults

H

Not implemented

H

Obsolete

H

Disable write cache

H

Not implemented

H

Not implemented

H

Page 41

Marathon 2250 and Marathon 1680 Product Manual 33

99

9A

AA

AB

BB

Not implemented

H

Not implemented

H

Enable read look-ahead (read cache) feature

H

Not implemented

H

4 bytes of ECC apply on read long and write long commands

H

(default)

(default)

CC

Enable reverting to power-on defaults

H

(default)

At power-on or after a hardware reset, the default values of the features

are as indicated above. A software reset also changes the features to

default values unless a 66

command has been received.

H

Page 42

34 Marathon 2250 and Marathon 1680 Product Manual

3.2.4 S.M.A.R.T. commands

Self-Monitoring, Analysis and Reporting Technology (S.M.A .R.T.) is an

emerging technology that provides near-term failure predicti on for disc

drives. When S.M.A.R.T. is enabled, the Seagate drive monitors predetermined drive attributes that are susceptible to degradation over time. If

self-monitoring determines t hat a failure is likely, S.M.A.R.T. makes a

status report available s o that the host can prompt t he user to back up

data on the drive. Not all failures are predictable. S.M.A.R.T. predictability

is limited to only those attributes the drive can monitor. For more

information on S.M.A.R.T. commands and implementation, see the

Working Draft of the Proposed American National Standard X3T10/2008D

Revision 6, Information Technology AT Attachment-3

Interface (ATA-3)

This drive is shipped with S.M.A.R.T. features disabled. You must have

a recent BIOS or software package that supports S.M.A.R.T. to enable

the feature. The table below shows the S.M.A.R.T. command codes that

these drives use.

.

Before executing a S.M.A.R.T. command by writing B0

to the Command

H

Register, the host must do the following:

• Write the value 4F

• Write the value C2

to the Cylinder_Low register.

H

to the Cylinder_High register.

H

• Writ e the appropriate S.M.A.R.T. code to the Features register, as

shown in the table below:

Code in

Features

Register S.M.A.R.T. Command

D8

H

D9

H

DA

H

If an appropriate code is not written to the Features Register, the

Note.

Enable S.M.A.R.T. Operations Yes

Disable S.M.A.R.T. Operations Yes

Return S.M.A.R.T. Status Yes

command will be aborted and 0

x

Supported by

Marathon 2250 and

Marathon 1680

04 (abort) will be wr itten to the

Error register.

Page 43

Marathon 2250 and Marathon 1680 Product Manual 35

3.2.5 Drive-Securi ty com ma nd s

The drive-security commands provide a password-based security system to prevent unauthorized access to a disc drive.

During manufacturing, the master password, SEAGATE, is set for the

drive, and the lock function is disabled. The system manufacturer or

dealer may set a new master password using the Security Set Password

command (F1

password is entered, the drive rejects all security commands except

Security Set Pass wo rd.

When the user s ets a passwor d, the drive automatically enter s lock mode

(lock mode is enabled) the next time it is p ower ed on. When lo c k mod e is

enabled, the drive rejects all media-access commands until the user enters

the correct user password, completing a Security U nlock comma nd.

The drive supports two l evels of security: high sec urity and maximum

security. In high-security mode, if you forget your password, you can still

access the data by entering the master password. In maximum-security

mode, if you forget your password, you cannot access the data. However,

in maximum-security mode, you can erase all data on the drive and

reinitialize the drive using the Erase Unit command (F4

the master password to complete an Erase Unit command.

), without enabling the lock function. Before a user

H

). You must enter

H

The Freeze Lock command (F5H) prevents you from changing security

features. If, during normal drive operation, the Freeze Lock command is

executed, all normal drive commands are implemented, but the security

commands Disable Password, Erase Unit, Set Password and Unlock

cannot be completed.

See the ATA-3 specification (Document X3T10/2008D) for additional

details about the Drive Security Commands.

Page 44

36 Marathon 2250 and Marathon 1680 Product Manual

Page 45

Marathon 2250 and Marathon 1680 Product Manual 37

Appendix. Compatibility notes

ECC testing

When a Marathon 2250 or Marathon 1680 perf orms hardware-based

ECC error correction on-the-fly, the drive does not report an ECC error.

This allows ECC correction without degrading drive performance. Some

older drive diagnostic programs test ECC features by creating small data

errors and then checking to see if they are reported. Such tests, when

run on these drives, may incorrectly report an ECC detection failure

because the drive hardware corrects the data automatically, avoiding the

error rather than reporting it. Such a report does not indicate a drive

malfunction.

Page 46

Page 47

Page 48

Seagate Technology, Inc.

920 Disc Drive, Scotts Valley, California 95066, USA

Publication Number : 36337-101, Rev. B, P rinted in USA

Loading...

Loading...