Page 1

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. . . . .

Medalist 8641, Medalist 6531

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. . . . .

Medalist 4321, Medalist 3221

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Medalist 2110

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Ultra ATA Interface Drives

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. . . . .

Product Manual

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. . . . .

Page 2

Page 3

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. . . . .

Medalist 8641, Medalist 6531

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. . . . .

Medalist 4321, Medalist 3221

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. . . . .

Medalist 2110

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. . . . .

Ultra ATA Interface Drives

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. . . . .

Product Manual

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. . . . .

Page 4

1998, 1999 Seagate Technology, Inc. All rights reserved

Publication Number: 20400075-001, Rev. B, January 1999

Seagate, Seagate Technology, the Seagate logo, Medalist and the

Medalist logo are registered trademarks of Seagate Technology, Inc.

Other product names are registered trademarks or trademarks of their

owners.

Seagate reserves the right to change, without notice, product offerings

or specifications. No part of this publication may be reproduced in any

form without written permission from Seagate Technology, Inc.

Page 5

Medalist 8641, 6531, 4321, 3221 and 2110, Rev. B iii

Contents

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Specification summary table . . . . . . . . . . . . . . . . . . . 2

1.0 Drive specifications . . . . . . . . . . . . . . . . . . . . . . 5

1.1 Formatted capacity . . . . . . . . . . . . . . . . . . . . . 5

1.1.1 Default logical geometry . . . . . . . . . . . . . . . . 5

1.1.2 Supported CHS translation geometries . . . . . . . . 6

1.2 Physical organization . . . . . . . . . . . . . . . . . . . . 6

1.3 Recording and interface technology . . . . . . . . . . . . . 6

1.4 Physical characteristics . . . . . . . . . . . . . . . . . . . 7

1.5 Seek time . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.6 Start/stop times . . . . . . . . . . . . . . . . . . . . . . . 8

1.7 Power Specifications . . . . . . . . . . . . . . . . . . . . 8

1.7.1 Power consumption . . . . . . . . . . . . . . . . . . 8

1.7.2 Conducted noise . . . . . . . . . . . . . . . . . . . . 10

1.7.3 Voltage tolerance . . . . . . . . . . . . . . . . . . . . 10

1.7.4 Power-management modes . . . . . . . . . . . . . . 11

1.8 Environmental tolerances . . . . . . . . . . . . . . . . . . 12

1.8.1 Ambient temperature . . . . . . . . . . . . . . . . . . 12

1.8.2 Temperature gradient . . . . . . . . . . . . . . . . . 12

1.8.3 Humidity . . . . . . . . . . . . . . . . . . . . . . . . 12

1.8.4 Altitude . . . . . . . . . . . . . . . . . . . . . . . . . 12

1.8.5 Shock . . . . . . . . . . . . . . . . . . . . . . . . . . 12

1.8.6 Vibration . . . . . . . . . . . . . . . . . . . . . . . . 13

1.9 Drive acoustics . . . . . . . . . . . . . . . . . . . . . . . 14

1.10 Electromagnetic susceptibility . . . . . . . . . . . . . . . 14

1.11 Reliability . . . . . . . . . . . . . . . . . . . . . . . . . . 14

1.12 Agency certification . . . . . . . . . . . . . . . . . . . . 15

1.12.1 Safety certification . . . . . . . . . . . . . . . . . . 15

Page 6

iv Medalist 8641, 6531, 4321, 3221 and 2110, Rev. B

1.12.2 Electromagnetic Compatibility . . . . . . . . . . . . 15

1.12.3 FCC verification . . . . . . . . . . . . . . . . . . . . 15

2.0 Drive mounting and configuration . . . . . . . . . . . . . . 17

2.1 Handling and static-discharge precautions . . . . . . . . . 17

2.2 Jumper settings . . . . . . . . . . . . . . . . . . . . . . . 17

2.2.1 Master/slave configuration . . . . . . . . . . . . . . . 17

2.2.2 Alternate capacity jumper . . . . . . . . . . . . . . . 17

2.3 Drive mounting . . . . . . . . . . . . . . . . . . . . . . . 18

3.0 ATA interface . . . . . . . . . . . . . . . . . . . . . . . . . 21

3.1 ATA interface signals and connector pins . . . . . . . . . . 21

3.2 ATA Interface commands . . . . . . . . . . . . . . . . . . 23

3.2.1 Supported ATA commands . . . . . . . . . . . . . . . 23

3.2.2 Identify Drive command . . . . . . . . . . . . . . . . 25

3.2.3 Set Features command . . . . . . . . . . . . . . . . 29

3.2.4 S.M.A.R.T. commands . . . . . . . . . . . . . . . . . 30

Page 7

Medalist 8641, 6531, 4321, 3221 and 2110, Rev. B v

Figures

Figure 1. Typical startup and operation current profile . . . . . . . 10

Figure 2. Alternate capacity jumper and master/slave jumpers . . 18

Figure 3. Drive mounting dimensions—top, side and end view . . . 19

Figure 4. I/O pins and supported ATA signals . . . . . . . . . . . 22

Page 8

vi Medalist 8641, 6531, 4321, 3221 and 2110, Rev. B

Page 9

Medalist 8641, 6531, 4321, 3221 and 2110, Rev. B 1

Introduction

This manual describes the functional, mechanical and i nterfac e spec ifi -

cations for the Medalist

8641 (ST38641A), Medalist 6531 (ST36531A),

Medalist 4321 (ST34321A), Medalist 3221 (ST33221A) and Medalist

2110 (ST32110A). These drives are referred to throughout this manual

by their model numbers. These drives provide the following key features:

• Low power consumption

• Quiet operation

• Support for S.M.A.R.T. drive monitoring and reporting

• High instantaneous (burst) data-transfer rates (up to 33.3 Mbytes per

second) using Ultra DMA mode 2

• Full-track multiple-sector transfer capabili ty without local processor

intervention

• 128-Kbyte cache

• State-of-the-art caching and on-the-fly error-correction algorithms

• Support for Read Multiple and Write Multiple commands

• Support for autodetection of master/slave drives that use cable select

(CSEL)

• MR recording heads and PRML technology, which provides the drives

with increased areal density

Page 10

2 Medalist 8641, 6531, 4321, 3221 and 2110, Rev. B

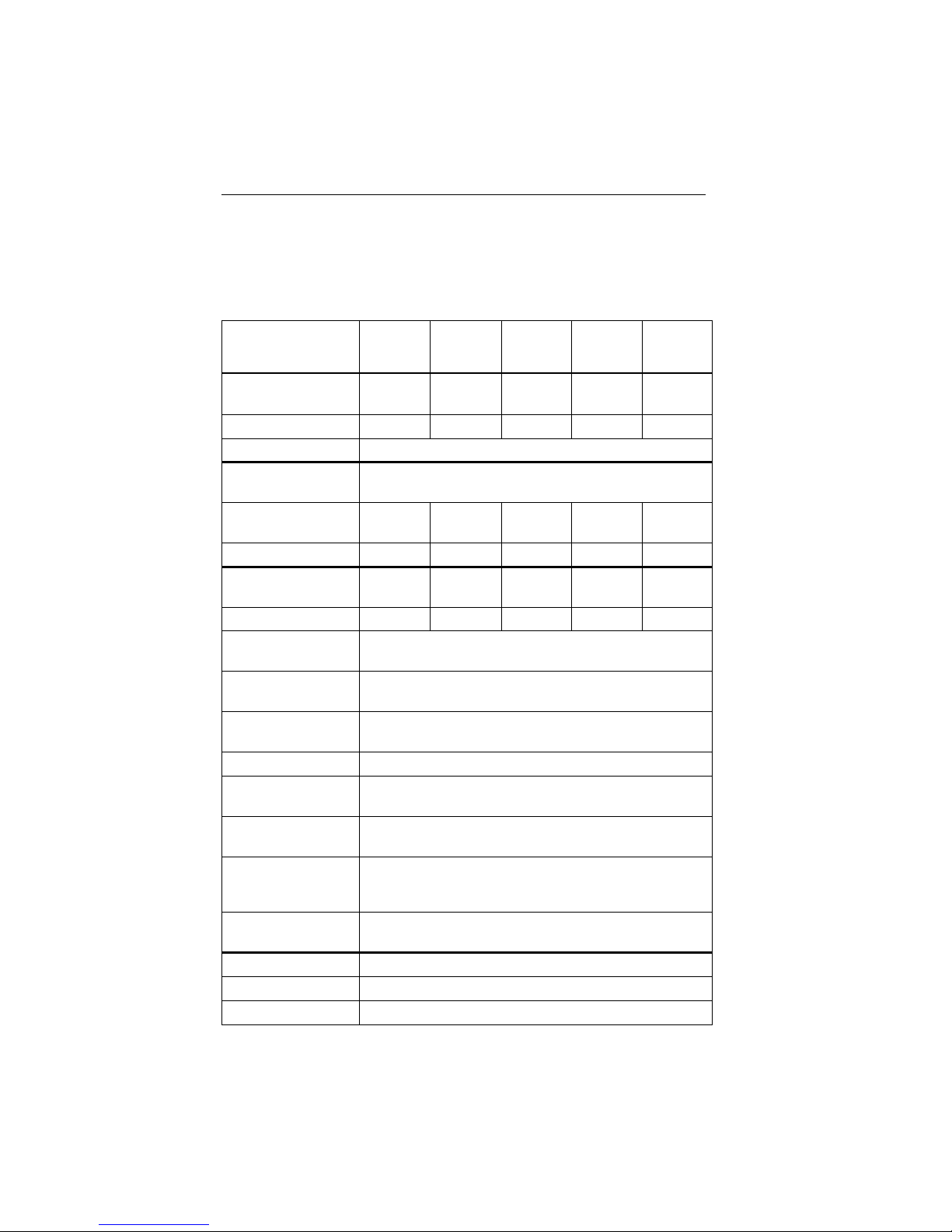

Specification summary table

The specifications listed in this table are for quick reference. For details

on specification measurement or definition, see the appropriate sec tion

of this manual.

Drive

Specification

Guaranteed Mbytes

(×106 bytes)

Guaranteed sectors

Bytes per sector 512

Default sectors per

track 63

Default read/write

heads 16 15 15 16 16

Default cylind ers 16,383 13,446 8,894 6,253 4,092

Physical read/write

heads 8 6 4 4 2

Discs 4 3 2 2 1

Recording density

(bits/inch max) 153,870

Track density

(tracks/inch) 9,190

Areal density

(Mbits/inch2 max) 1,581

Spindle speed (RPM) 5,400

Internal data-transfer

rate (Mbits/sec max) 140

I/O data-transfer rate

(Mbytes/sec max) 33.3

ATA da ta -tra ns fe r

modes supported

Cache buf fe r

(Kbytes) 128

Height (mm ma x) 2 6.10

Width (mm max) 101.85

Length (mm max) 147.0

ST38641A ST36531A ST34321A ST33221A ST32110A

8,606 6,505 4,303 3,227 2,111

16,809,660 12,706,470 8,404,830 6,303,024 4,124,736

PIO modes 0, 1, 2, 3, 4;

Multiword DMA modes 0, 1, 2;

Ultra DMA modes 0, 1, 2

Page 11

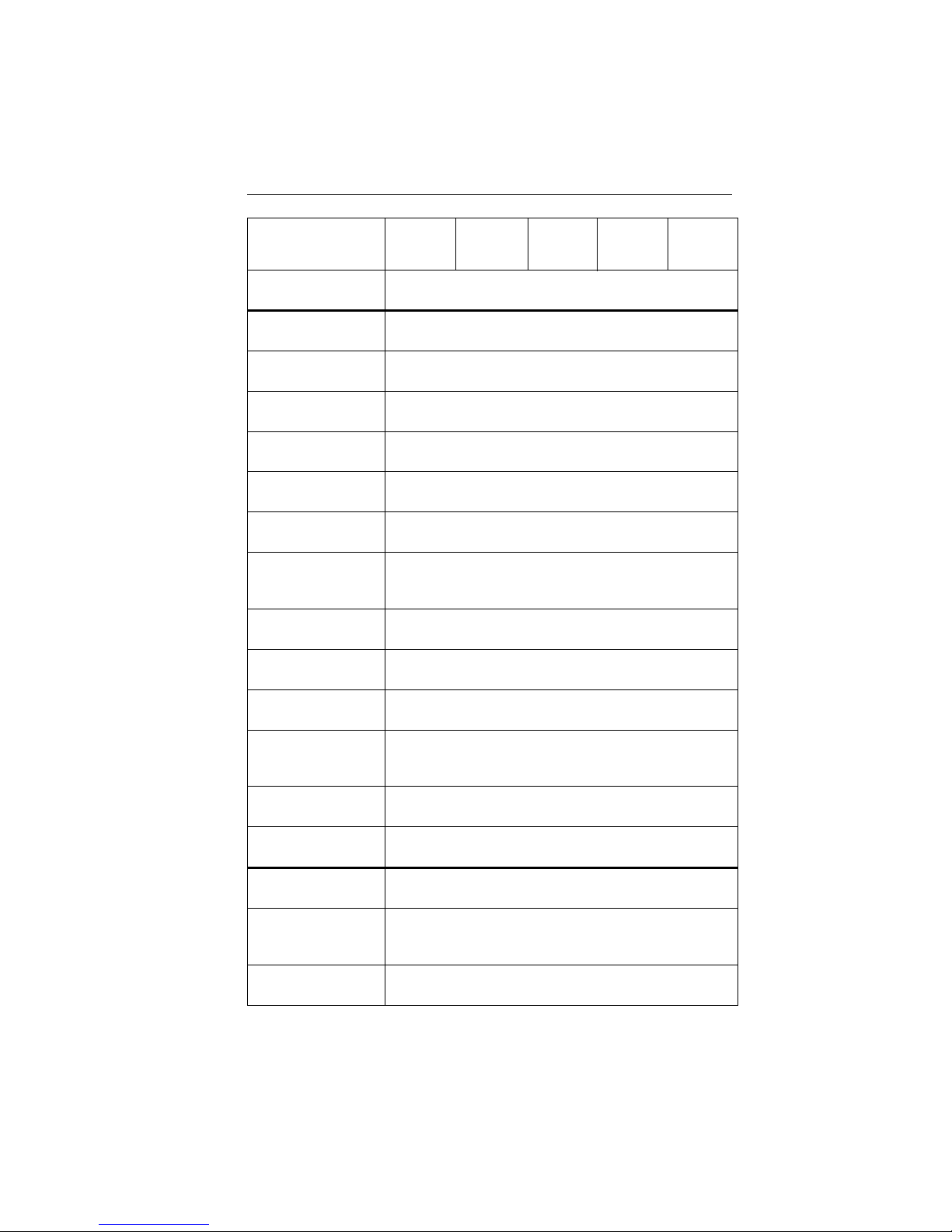

Medalist 8641, 6531, 4321, 3221 and 2110, Rev. B 3

Drive

Specification

ST38641A ST36531A ST34321A ST33221A ST32110A

Weight

(grams typical) 544

Track-t o-t rac k seek

time (msec typical) 1.3 (read), 1.7 (write)

Average seek tim e

(msec typical) 11.0 (read), 11.5 (write)

Full-stroke seek time

(msec typical) 19.8 (read), 20.2 (write)

Average late nc y

(msec) 5.6

Power-on to ready

(sec typical) 10

Standby to ready

(sec typical) 10

Startup current:

12V (peak)

5V (RMS)

1.8 amps

0.6 amps

Seek power

and current (mean) 9.1 watts

Read/Write power

and current (typical) 5.5 watts

Idle mode power

and current (typical) 4.9 watts

Standby mode

power and current

0.9 watts

(typical)

Sleep mode power

and current (typical) 0.9 watts

Voltage tolerance

(including noise)

5V

5%

±

12V ± 8%

Ambient

temperature 5° to 55°C (op.), –40° to 70°C (nonop.)

Temperature

gradient (per hour

20°C

max)

Relative humi dity

(op. and nonop.)

8% to 90% (op.)

5% to 95% (nonop.)

continued

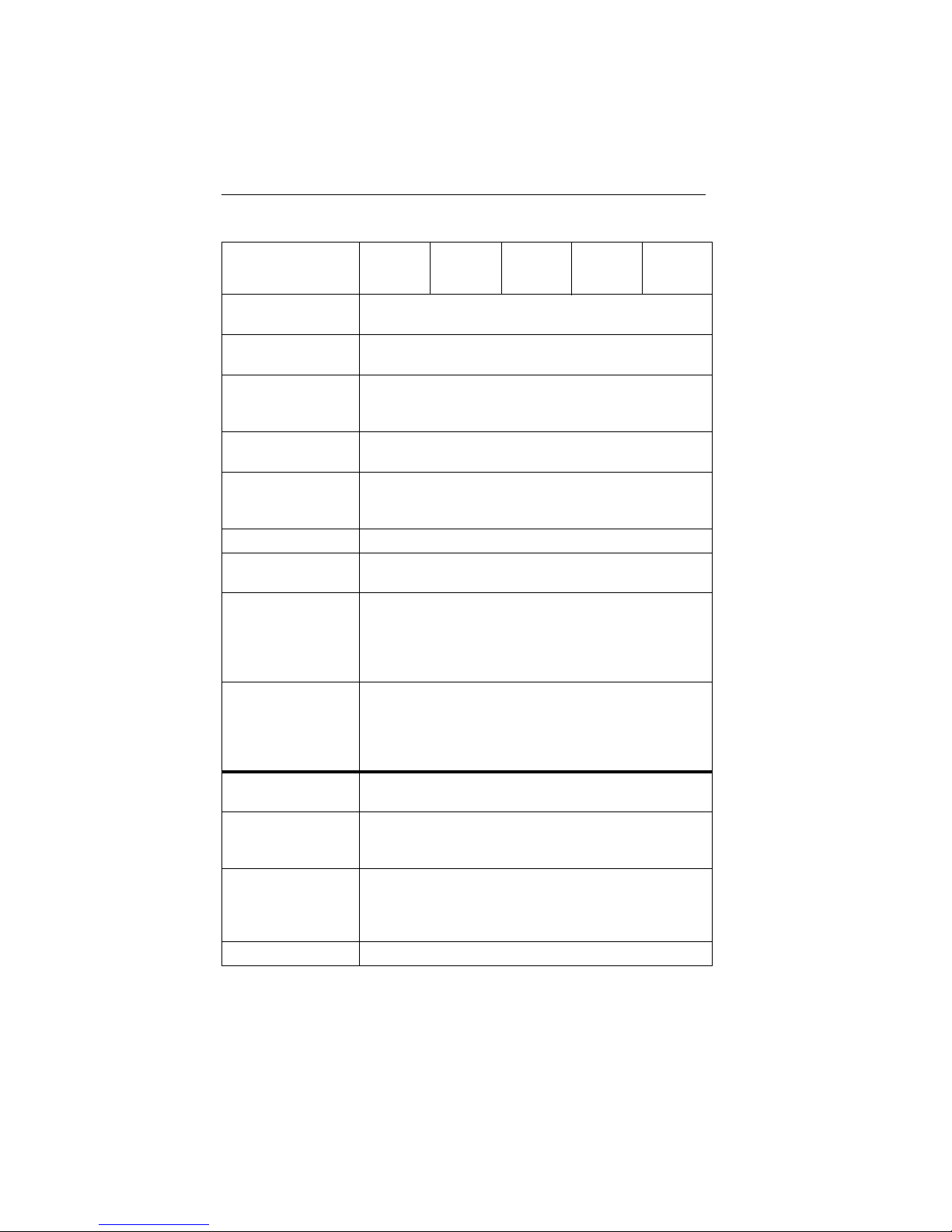

Page 12

4 Medalist 8641, 6531, 4321, 3221 and 2110, Rev. B

continued from pre vi ou s pa ge

Drive

Specification

ST38641A ST36531A ST34321A ST33221A ST32110A

Relative humi dity

gradient 10% per hour max

Wet bulb temperature (max) 29.4°C (op.), 29.4 °C (nonop. )

Altitude (meters

below mean sea

level, max)

–122 to 3,048 (op.)

–122 to 12,192 (nonop.)

Shock, operating

(Gs max at 11 msec) 15

Shock, nonoperating

(Gs max at 11 msec)

(Gs max at 2 msec)

75

200

Vibration, operating 0.50 G (0 to peak, 22–350 Hz)

Vibration,

nonoperating 5.0 Gs (0 to peak, 22–350 Hz)

Drive acoustics

(bels—sound power)

3.5 (typical), 3.9 (ma x)

Idle mode

(dBA—sound pres-

30 (typical)

sure)

Drive acoustics

(bels—sound power)

4.0 (typical), 4.3 (ma x)

Read/Write mode

(dBA—sound pres-

32 (typical)

sure)

Nonrecoverable

read errors 1 per 10

14

bits read

Mean time between

failures

400,000

(power-on hours)

Contact start -st op

cycles

40,000

(25°C, 40% relative

humidity)

Service life (years) 5

Page 13

Medalist 8641, 6531, 4321, 3221 and 2110, Rev. B 5

1.0 Drive specifications

Unless otherwise noted, all specifications are measured under ambient

conditions, at 25°C, and nominal power. For convenience, the phrases

the drive

ST38641A, ST36531A, ST34321A, ST33221A and the ST32110A.

and

this drive

1.1 Formatted capacity

are used throughout this manual to indicate the

Drive

Model

ST38641A 8,606 16,809,660 512

ST36531A 6,505 12,706,470 512

ST34321A 4,303 8,404,830 512

ST33221A 3,227 6,303,024 512

ST32110A 2,111 4,124,736 512

Note.

DOS systems cannot access more than 528 Mbytes on a drive

unless 1) the host system supports and is configured for LBA addressing or for extended CHS addressing, 2) the host system

contains a specialized drive controller, or 3) the host system runs

BIOS translation software. Contact your Seagate

sentative for details.

Guaranteed Mbytes

(1 Mbyte = 10

6

bytes)

Guaranteed

sectors

Bytes per

sector

®

repre-

1.1.1 Default logical geomet ry

CHS Mode Cylinders Read/Write heads Sectors per track

ST38641A 16,383 16 63

ST36531A 13,446 15 63

ST34321A 8,894 15 63

ST33221A 6,253 16 63

ST32110A 4,092 16 63

LBA Mode

When addressing either drive in LBA mode, all blocks (sectors) are

consecutively numbered from 0 to

guaranteed sectors as defined above.

n – 1,

where n is the number of

Page 14

6 Medalist 8641, 6531, 4321, 3221 and 2110, Rev. B

1.1.2 Supported CHS translation geometries

These drives support any translation geometry that sati sfies

following conditions:

• Sectors per track ≤ 63

• Cylinders ≤ 16,383 (for drives over 8.4 Gbytes)

• Heads ≤ 16

The ST38641A logical cylinders are:

Logical cylinders=16,809,660 / ( logical sectors per tr ack × logical heads)

The ST36531A logical cylinders are:

Logical cylinders=12,706,470 / ( logical sectors per tr ack × logical heads)

The ST34321A logical cylinders are:

Logical cylinders=8 ,4 0 4, 8 3 0 / (l og i ca l se ct o rs pe r tr a ck × logical heads)

The ST33221A logical cylinders are:

Logical cylinders=6,303,024 / (logical sectors per track × logical heads)

The ST32110A logical cylinders are:

Logical cylinders=4 ,1 2 4, 7 3 6 / (l og i ca l se ct o rs pe r tr a ck × logical heads)

of the

all

1.2 Physical organization

Drive Model Read/Write heads (MR) Number of discs

ST38641A 8 4

ST36531A 6 3

ST34321A 4 2

ST33221A 4 2

ST32110A 2 1

1.3 Recording and interface technology

Interface ATA

Recording method 16/17 (0,14) ZBR

Recording density (bits/inch) 153,870

Track density (tracks/inch) 9,190

Areal density (Mbits/inch

2

) 1,581

Page 15

Medalist 8641, 6531, 4321, 3221 and 2110, Rev. B 7

Spindle speed RPM ( ± 0.2%) 5,400

Internal data-transfer rate

(Mbits per second max)

I/O data-transfer rate

(Mbytes per second max)

Interleave 1:1

Cache buffer (Kbytes) 128

140

16.6 (PIO mode 4 with IORDY)

16.6 (multiword DMA mode 2)

33.3 (Ultra DMA mode 2)

1.4 Physical characteristics

Drive Specification

Maximum height (mm)

(inches)

Maximum width (mm)

(inches)

Maximum length (mm)

(inches)

Typical weight (grams)

(pounds)

ST38641A

ST36531A

ST34321A

ST33221A

26.10

1.028

101.85

4.010

147.00

5.787

544

1.2

ST32110A

1.5 Seek time

All seek times are measured using a 486 AT computer (or faster) with an

8.3 MHz I/O bus. The measurements are taken with nominal power at

25°C ambient temperature. All times are measured using drive diagnostics. The specifications in the table on page 8 are defined as follows:

• Track-to-track seek time is an average of all possible single-track

seeks in both directions.

• Average seek time is a true statistical random average of at least 5,000

measurements of seeks between random tracks, less overhead.

• Full-stroke seek time is one-half the time needed to seek from the first

data cylinder to the maximum data cylinder and back to the first data

cylinder. The full-stroke typical value is determined by averaging 100

full-stroke seeks in both directions.

Page 16

8 Medalist 8641, 6531, 4321, 3221 and 2110, Rev. B

Read

Seek type

Track-to-track 1.3 1.7

Average 11.0 11.5

Full-stroke 19.8 20.2

Average latency: 5.6 msec

Note.

These drives are designed to consistently meet the seek times

represented in this manual. Physical seeks, regardless of mode

(such as track-to-track and average) are expected to meet or exceed the noted values. Due to the manner in which these drives

are formatted, however, benchmark tests that include command

overhead or measure logical seeks may produce results that

vary from these specifications.

(msec, typ.)

Write

(msec, typ.)

1.6 Start/stop times

Power-on to Ready (sec) 10 (typical)

Standby to Ready (sec) 10 (typical)

Ready to spindle stop (sec) 12 (typical)

1.7 Power Specifications

The drive receives DC power (+5V or +12V) through a four-pin standard

drive power connector.

1.7.1 Power consumption

Power requirements for the drives are listed in the table on page 9.

Typical power measurements are based on an average of drives tested

under nominal conditions, using 5.0V input voltage at 25°C ambient

temperature.

Spinup power is measured from the time of power-on to the time that the

drive spindle reaches operating speed.

During seek mode, the read/write actuator arm moves toward a specific

position on the disc surface and does not execute a read or write

operation. Servo electronics are ac tive. Seek mode power represents

the worst case power consumption, using only random seeks with read

or write latency time. This mode is not typical and is provided for worstcase information.

Page 17

Medalist 8641, 6531, 4321, 3221 and 2110, Rev. B 9

Read/Write power and current are measured with the heads on track,

based on a 16-sector write followed by a 32-msec delay, then a 16-sector

read followed by a 32-msec delay.

Operating power and current are measured using 40 percent random

seeks, 40 percent read/write mode (1 write for each 10 reads), and 20

percent drive inactive.

Idle mode power is measured with the drive up to speed, with servo

electronics active, and with the heads in a random track location.

During Standby mode, the drive accepts commands, but the drive is not

spinning, and the servo and read/write electronics are in power-down

mode.

Mode Typical Watts RMS Typical Amps RMS

5V 12V

Spinup 0.6 1.8 (Peak)

Seeking 9.1

0.5 0.55

(Random,

no read/write)

Read/Write 5.5 0.5 0.25

Operating 5.5 0.5 0.25

Idle 4.9 0.38 0.25

Standby 0.9 0.18 —

Sleep 0.9 0.18 —

Page 18

10 Medalist 8641, 6531, 4321, 3221 and 2110, Rev. B

1.7.1.1 Typical current profile

Figure 1 shows a typical current profile

Current (Amps)

1.8

1.6

1.4

1.2

1.0

0.8

0.6

0.4

0.2

0.0

0123456789

Time (seconds)

Figure 1. Typical startup and operation current profile

1.7.2 Conducted noise

Input noise ripple is measured at the host system power supply acros s

an equivalent 80-ohm resistive load on the +12 volt line or an equivalent

15-ohm resistive load on the +5 volt line.

• Using 12-volt power, the drive is expected to operate with a maximum

of 120 mV peak-to-peak square-wave injected noise at up to 10 MHz.

• Using 5-volt power, the drive is expected to operate with a maximum

of 100 mV peak-to-peak square-wave injected noise at up to 10 MHz.

Note.

Equivalent resistance i s calculated by dividing the nominal volt-

age by the typical RMS read/write current.

1.7.3 Voltage tolerance

Voltage tolerance (including noise): 5V ± 5% and 12V ± 8%

Page 19

Medalist 8641, 6531, 4321, 3221 and 2110, Rev. B 11

1.7.4 Power-management modes

These drives provide programmable power management to provide

greater energy efficiency. In most systems, you can control power

management through the system setup program. These Seagate drives

feature several power-management modes, which are summarized in

the following table and described in more detail below:

Mode Heads Spindle Buffer

Active Tracking Rotating Enabled

Idle Tracking Rotating Enabled

Standby Parked Stopped Enabled

Sleep Parked Stopped Disabled

Active mode.

operations.

Idle mode.

commands and returns t o Active mode an y time d isc access is necessary.

Standby mode.

Standby Immediate command. If the host has set the standby timer, the

drive can also enter Standby mode automatically after the drive has been

inactive for a sp eci fi able len gth of ti me. The st an dby t ime r d ela y is est ablished using a Standby or Idle command. In Standby mode, the heads are

parked and the spindle is at rest. The drive accepts all commands and

returns to Active mode any time disc access is necessary.

Sleep mode.

command from the host. The heads are parked and the spindle is at rest.

The drive leaves Sleep mode after it receives a Hard Reset or Soft Reset

from the host. After receiving a reset, the dr ive exits Sleep mode and

enters Active mode with all current translation parameters intact.

Standby timers.

write or seek), the standby timer is reinitialized and begins counting down

from its specified delay times to ze ro. If the standby timer reach es zero before

any drive activity is required, the drive makes a transition to Standby mode. In

both Idle and Stan db y m ode, the d rive acce pt s all co mm an ds and r eturn s to

Active mode when disc access is necessary.

The drive is in Active mode during the read/write and seek

The buffer remains enabled, and the drive accepts all

The drive enter s Standb y mode when the host sen ds a

The drive enters Sleep mode after receiving a Sleep

Each time the drive performs an Active function (read,

Page 20

12 Medalist 8641, 6531, 4321, 3221 and 2110, Rev. B

1.8 Environmental tolerances

1.8.1 Ambient temperature

Operating 5° to 55°C (41° to 131°F)

Nonoperating –40° to 70°C (–40° to 158°F)

Note.

Above 1, 000 feet (305 meters), t he maximu m temperat ure is der-

ated linearly to 11 2°F (44°C ) at 10,0 00 feet (3,048 meters). Operating ambient temperature is defined as the temperature of the

environment immed iately surro undin g the drive .

1.8.2 Temperature gradient

Operating 20°C/hr (68°F/hr) max, without condensation

Nonoperating 20°C/hr (68°F/hr) max, without condensation

1.8.3 Humidity

1.8.3.1 Relative Humidity

Operating 8% to 90% noncondensing (10% per hour max)

Nonoperating 5% to 95% noncondensing (10% per hour max)

1.8.3.2 Wet bulb temperature

Operating 29.4°C (84°F) max

Nonoperating 29.4°C (84°F) max

1.8.4 Altitude

Operating –122 m to 3,048 m (–400 ft to +10,000 ft)

Nonoperating –122 m to 12,192 m (–400 ft to +40,000 ft)

1.8.5 Shock

All shock specifications assume that the drive is mounted securel y with

the input shock applied at the drive mounting screws. Shock may be

applied in the X, Y or Z axis.

Page 21

Medalist 8641, 6531, 4321, 3221 and 2110, Rev. B 13

1.8.5.1 Operating shock

These drives comply with the performance levels specified in this document when subjected to a maximum operating shock of 15.0 Gs (based

on half-sine shock pulses of 11 msec). Shocks are not to be repeated

more than two times per second.

1.8.5.2 Nonoperating shock

The nonoperating shock level that the drive can experience without

incurring physical damage or degradation in performance when subsequently put into operation is 75 Gs (based on nonrepetitive half-sine

shock pulses of 11 msec duration) or 200 Gs (based on nonrepetitive

half-sine shock pulses of 2 msec duration). Shock pulses are defined by

MIL-STD-202F.

1.8.6 Vibration

All vibration specifications as sume that the drive is mounted securely

with the input vibration applied at the drive mounting screws. Vibration

may be applied in the X, Y or Z axis.

1.8.6.1 Operating vibration

The following table lists the maximum vibration levels that the drive may

experience while meeting the performance standards specified in this

document.

5–22 Hz 0.02-inch displacement (peak to peak)

22–350 Hz 0.50 Gs acceleration (zero to peak)

1.8.6.2 Nonoperating vibration

The following table lists the maximum nonoperating vibration that the

drive may experience without incurring physical damage or degradation

in performance when put into operation.

5–22 Hz 0.08-inch displacement (peak to peak)

22–350 Hz 5.0 Gs acceleration (zero to peak)

Page 22

14 Medalist 8641, 6531, 4321, 3221 and 2110, Rev. B

1.9 Drive acoustics

Drive acoustics are measured as overall A-weighted acoustic sound

power levels (no pure tones). All measurements are generally consistent

with ISO document 7779. Sound power measurements are taken under

essentially free-field conditions over a reflecting plane. For all tests, the

drive is oriented with the cover facing upward.

For the Seek mode, the drive is placed in seek only. The number of seeks

per second is defined by the following equation:

Number of seeks per second=0.4/(average latency+average access time)

Typical sound

Mode

Idle 3.5 3.9

Read/Write 4.0 4.3

power (bels)

Maximum sound

power (bels)

1.10 E le ctroma gnet i c sus ce pt ibi lity

These drives operate without errors when subjected to the following:

Radiated noise

Electrostatic discharge*

Magnetic field strength

* Electrostatic discharge susceptibility is measured with the drive

mounted in a representative computer system (mounted to a ground

plane with earth grounding). Discharges are appl ied to the bezel or

other external surfaces on the ground plane.

≤ 3 volt/meter, 30 Hz to 500 MHz

≤ 10 KVolts

≤ 5 Gauss

1.11 Reliability

Nonrecoverable read errors 1 per 1014 bits read, max

Mean time between failures 400,000 power-on hours

(nominal power, 25°C ambient

temperature)

Contact start-stop cycles 40,000 cycles

(at nominal voltage and temperature,

with 60 cycles per hour and a 50%

duty cycle)

Page 23

Medalist 8641, 6531, 4321, 3221 and 2110, Rev. B 15

1.12 Agency certification

1.12.1 Safety certification

The drives are recognized in accordance with UL 1950 and CSA C22.2

(950) and meet all applicable sections of IEC950 and EN 60950 as tested

by TUV North America.

1.12.2 Electromagnetic Compatibility

Hard drives that display the CE marking comply with European Union

requirements specified in Electromagnetic Compatibility Directives. Testing is performed to standards EN50082-1 and EN55022-B.

Seagate uses an independent laboratory to confirm compliance with the

EC directives specified i n the previous paragraph. Drives ar e tested in

representative end-user systems. Although CE-marked Seagate dr ives

comply with the directives when used in the test systems, we cannot

guarantee that all systems will comply with the directives. The drive is

designed for operation inside a properly designed enclosure, with properly shielded I/O cable (if necessary) and terminators on all unused I/O

ports. Computer manufacturers and system integrators should confi rm

EMC compliance and provide CE marking for their products.

Australian C-Tick

If this model has the C-Tick marking, it complies with the Australia/New

Zealand Standard AS/NZS3548 1995 and meets the Electromagnetic

Compatibility (EMC) Framework requirements of Australi a’s Spectrum

Management Agency (SMA).

1.12.3 FCC verification

These drives are intended to be contained solely within a personal

computer or similar enclosure (not attached as an external device). As

such, each drive is consi dered to be a subassembly even when it i s

individually marketed to the c ustomer. As a subassembly, no Federal

Communications Commission verification or certification of the device is

required.

Seagate Technology, Inc. has tested this device in enclosures as described above to ensure that the total assembly (enclosure, disc drive,

motherboard, power supply, etc.) does comply with the limits for a Class

B computing device, pursuant to Subpart J, Part 15 of the FCC rules.

Operation with noncertified assemblies is li kely to result in interfer ence

to radio and television reception.

Page 24

16 Medalist 8641, 6531, 4321, 3221 and 2110, Rev. B

Radio and Television Interference. This equipment generates and uses

radio frequency energy and if not installed and used in strict accordance

with the manufacturer’s instructions, may cause interference to radio and

television reception.

This equipment is designed to provide reasonable protection against

such interference in a residential installation. However, there is no

guarantee that interference will not occur in a particular installation. If this

equipment does cause interference to radio or television, which can be

determined by turning the equipment on and off, you are encouraged to

try one or more of the following corrective measures:

• Reorient the receiving antenna.

• Move the device to one side or the other of the radio or TV.

• Move the device farther away from the radio or TV.

• Plug the computer into a different outlet so that the receiver and

computer are on different branch outlets.

If necessary, you should consult your dealer or an experienced radio/television technician for additional suggestions . You may find helpful the

following booklet prepared by the Federal Communications Commission:

How to Identify and Resolve Radio-Televi sion Interference Problems

This booklet is available from the Superintendent of Documents,

U.S. Government Printing Office, Washington, DC 20402. Refer to publication number 004-000-00345-4.

.

Page 25

Medalist 8641, 6531, 4321, 3221 and 2110, Rev. B 17

2.0 Drive mounting and configuration

2.1 Handling and static-discharge precautions

After unpacking, and before installation, the drive may be exposed to

potential handling and electrostatic discharge (ESD) hazards. Observe

standard static-discharg e preca ution s. A grou nded wrist- strap is p referr ed.

Handle the drive only by the sides of the head/disc assembly. Avoid

contact with the printed circuit board, all electronic components and the

interface connector. Do not apply pressure to the top cover of the drive.

Always rest the drive on a padded antistatic surface until you mount it in

the host system.

2.2 Jumper settings

2.2.1 Master/slave conf i gurat ion

You must establish a master/slave relationship between two drives that

are attached to a single AT bus. You can configure a drive to be a master

or slave by setting the master/slave j umpers, sho wn i n F igu re 2 on

page 18.

These drives support master/slave configuration using the cable select

option. This requires a special daisy-c hain cable that grounds pin 28

(CSEL) on one of its two drive connectors. If you attach the drive to the

grounded CSEL connector, it becomes a master. If you attach the drive

to the ungrounded CSEL connector, it becomes a sl ave. To use this

option, the host system and both drives must support cable select, and

both drives must be configured for cable select. To configure this drive

for cable select, install a jumper as shown in Figure 2.

For the master drive to recognize the slave drive using the DASP– signal,

the slave drive must assert the DASP– signal at power up, and the master

drive must monitor DASP– at power up.

2.2.2 Alternate capacity jumper

Some older computers may “hang” if their BIOS detects a hard drive that

has more than 4,092 cylinders at startup. To allow these computer s to

recognize the ST38641A, the ST36531A, the ST34321 or the ST33221A,

these drives include a capacity-limiting jumper , which sets the drive’s

default translation geometry to 4,092 cylinders. This limits the drive’s

capacity to 2.1 Gbytes, unless third-party software is used.

Page 26

18 Medalist 8641, 6531, 4321, 3221 and 2110, Rev. B

ATA interface

connector

pin 1

24

8

Alternate capacity and master/slave

jumper settings

1.

The drive is shipped with a jumper on pins 7

and 8. This configures the drive for master or

single drive operation.

2. Consult your computer manual to determine

whether your computer supports cable select.

3. Use this jumper setting

not work with a jumper on pins 7 and 8.

4. Use this jumper setting if your computer fails

to boot because it cannot address drives with

more than 4,092 cylinders.

only

if the drive does

4-pin power

connector

Slave

Master or single drive

Enable cable select

Master with non-ATA

compatible slave

Limit capacity to 2.1 Gbytes

(4,092 cylinders)

1

2

3

4

135

6

7

Figure 2. Alternate capacity jumper and master/slave jumpers

2.3 Drive mounting

You can mount the drive in any orientation using four screws in the

side-mounting holes or four screws in the bottom-mounting holes. See

Figure 3 for drive mounting dimensions.

Important mounting precautions:

• Allow a minimum clearance of 0.030 inches (0.76 mm) around the

entire perimeter of the drive for cooling.

• Use only 6

• The screws sh ould be inser ted no mor e than 0. 22 inc h (5.58 mm) int o

the bottom moun ting holes and no m ore than 0.20 inch (5.0 mm) into the

side mounting holes.

• Do not overtighten the mounting screws (maximum torque: 3 inch-lb,

0.34 N.m, 3.45 kgf.cm).

• Do not use a drive interfa ce cable that is more than 18 inches (4 57 mm)

long.

32 UNC mounting screws.

-

Page 27

Medalist 8641, 6531, 4321, 3221 and 2110, Rev. B 19

Note. Dimensions are shown in mm (inches)

94.3 ± 0.8

[3.71 ± 0.03]

71.8 ± 0.8

[2.83 ± 0.03]

56.5 ± 0.8

[2.23 ± 0.03]

26.10 MAX

[1.028]

147.00 MAX

[5.787]

3X 6.35 ± 0.31

[0.250 ± 0.012]

BOTH SIDES

5.83 ± 0.38

[0.230 ± 0.015]

27.90 ± 0.27

[1.098 ± 0.011]

41.60 ± 0.33

[1.638 ± 0.013]

101.60 ± 0.33

[4.000 ± 0.013]

3X 6-32 UNC 2B

MAX INSERTION DEPTH

0.20 (5.0 mm) BOTH SIDES

PIN ONE J2

0.27

±

40.77

0.011]

[1.605 ±

44.45 ± 0.33

[1.750 ± 0.013]

4X 6-32 UNC 2B

MAX INSERTION

DEPTH 0.22 (5.6 mm)

PIN ONE J3

[0.125 ± 0.011]

PIN ONE J4

[3.750 ± 0.014]

3.18 ± 0.27

±

95.24

0.35

101.85 MAX

[4.010 MAX]

4.66 ± 0.38

[0.183 ± 0.015]

Figure 3. Mounting dimensions—top, side and end view

Page 28

20 Medalist 8641, 6531, 4321, 3221 and 2110, Rev. B

Page 29

Medalist 8641, 6531, 4321, 3221 and 2110, Rev. B 21

3.0 ATA interface

These drives use the industry-standard ATA task file interface that

supports 16-bit data transfers. It supports ATA programmed input/output

(PIO) modes 0, 1, 2, 3 and 4; multiword DMA modes 0, 1 and 2; and Ultra

DMA modes 0, 1 and 2. The drive also supports the use of the IORDY

signal to provide reliable high-speed data transfers.

You can use a daisy-chain cable to connect two drives to a single AT

host bus. For detailed information regarding the ATA interface, r efer to

the draft of

4), NCITS T13 1153D,

Standard

3.1 ATA interface signals and connector pins

Figure 4 on page 22 summarizes the signals on the ATA interface

connector that the drive supports. For a detailed description of these

signals, refer to the

AT Attachment with Packet Interface Extension (ATA/ATAPI-

subsequently referred to as the

.

Draft ATA-4 Standard.

Draft ATA-4

Page 30

22 Medalist 8641, 6531, 4321, 3221 and 2110, Rev. B

Drive pin #

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

Signal name

–

1

2

3

4

5

6

7

8

9

Reset

Ground

DD7

DD8

DD6

DD9

DD5

DD10

DD4

DD11

DD3

DD12

DD2

DD13

DD1

DD14

DD0

DD15

Ground

(removed)

DMARQ

Ground

DIOW–:

STOP

Ground

DIOR–:

HDMARDY–:

HSTROBE

Ground

IORDY:

DDMARDY–:

DSTROBE

CSEL

–

DMACK

Ground

INTRQ

–

IOCS16

DA1

–

PDIAG

DA0

DA2

–

CS0

–

CS1

–

DASP

Ground

Host pin # and signal description

1

Hardware Reset

2

Ground

3

Host Data Bus Bit 7

4

Host Data Bus Bit 8

5

Host Data Bus Bit 6

6

Host Data Bus Bit 9

7

Host Data Bus Bit 5

8

Host Data Bus Bit 10

9

Host Data Bus Bit 4

10

Host Data Bus Bit 11

11

Host Data Bus Bit 3

12

Host Data Bus Bit 12

13

Host Data Bus Bit 2

14

Host Data Bus Bit 13

15

Host Data Bus Bit 1

16

Host Data Bus Bit 14

17

Host Data Bus Bit 0

18

Device Data (15:0)

19

Ground

(No Pin)

20

21

DMA Request

22

Ground

23

Device I/O Write:

Stop Ultra DMA Burst

24

Ground

25

Device I/O Read:

Host Ultra DMA Ready:

Host Ultra DMA Data Strobe

26

Ground

27

I/O Channel Ready

Device Ultra DMA Ready

Device Ulta DMA Data Strobe

28

Cable Select

29

DMA Acknowledge

30

Ground

31

Device Interrupt

32

Reserved

33

Host Address Bus Bit 1

34

Passed Diagnostics

35

Device Address (2:0)

36

Device Address (2:0)

37

Chip Select (1:0)

38

Chip Select (1:0)

39

Drive Active / Slave Present

40

Ground

Pins 28, 34 and 39 are used for master-slave communication (details shown below).

28

34

39

Figure 4. I/O pins and supported ATA signals

Drive 0 (master)Drive 1 (slave)

28

34

39

CSEL

PDIAG

DASP–

–

Host

28

34

39

Page 31

Medalist 8641, 6531, 4321, 3221 and 2110, Rev. B 23

3.2 ATA Interface commands

3.2.1 Supported ATA commands

The following table lists ATA-standard commands that the drive supports.

For a detailed description of the ATA commands, refer to the

Standard.

See Section 3.2.4 on page 30 for details and subcommands

used in the S.M.A.R.T. implementation.

Supported by

Command name

Command

code

ST38641A, ST36531A,

ST34321A, ST33221A,

ATA-standard commands

Draft AT A-4

ST32110A

Download Microcode 92

Execute Device Diagnostic 90

Flush Cache E7

Format Track 50

Identify Device EC

Initialize Device Parameters 91

Read Buffer E4

Read DMA C8

H, C9H

Read Multiple C4

Read Sectors 20

Read Verify Sectors 40

H, 21H

H, 41H

Recalibrate 10

Seek 70

Set Features EF

Set Multiple Mode C6

S.M.A.R.T. B0

H

H

H

H

H

H

H

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

H

Yes

Yes

Yes

H

H

H

H

H

Yes

Yes

Yes

Yes

Yes

continued

Page 32

24 Medalist 8641, 6531, 4321, 3221 and 2110, Rev. B

continued from pre vi ou s pa ge

Supported by

Command name

Command

code

ST38641A, ST36531A,

ST34321A, ST33221A,

ST32110A

Write Buffer E8

Write DMA CA

H, CBH

Write Multiple C5

Write Sectors 30

H, 31H

ATA-standard power-management commands

Check Power Mode 98

Idle 97

Idle Immediate 95

Sleep 99

Standby 96

Standby Immediate 94

or E5

H

or E3

H

or E1

H

or E6

H

or E2

H

or E0

H

H

Yes

Yes

H

Yes

Yes

H

H

H

H

H

H

Yes

Yes

Yes

Yes

Yes

Yes

Page 33

Medalist 8641, 6531, 4321, 3221 and 2110, Rev. B 25

The following commands contain drive-specific features that may not be

described in the

Draft ATA-4 Standard

.

3.2.2 Identify Drive command

The Identify Drive command (command code ECH) transfers information

about the drive to the host following power up. The data is organized as

a single 512-byte block of data, whose c ontents are shown in the table

below. All reserved bits or words should be set to zero. Parameters listed

with an “x” are drive-specific or vary with the state of the drive. See

Section 1 of this manual for default parameter settings.

Note.

If the alternate capacity jumper is installed on these drives, the drive

capacity is reduced in word 1 to 4,09 2 cylinder s.

Word Description Contents

Configuration information:

•

Bit 15: 0 = ATA; 1 = ATAPI

•

0

Bit 7: removable media

•

Bit 6: removable controller

•

Bit 0: reserved

Number of logical cylinders:

16,383 (ST38641A)

1

13,446 (ST36531A)

8,894 (ST34321A)

6,253 (ST33221A)

4,092 (ST32110A)

0C5A

H

3FFF

H

(ST38641A)

3486

H

(ST36531A)

22BE

H

(ST34321A)

186D

H

(ST33221A)

0FFC

H

(ST32110A)

2 ATA-reserved 0000

3

4 Retired 0000

continued

Number of logical heads:

15 (ST36531A, ST34321A)

16 (ST38641A, ST33221A,

ST32110A)

H

000F

H

(ST36531A)

(ST34321A)

0010

H

(ST38641A)

(ST33221A)

(ST32110A)

H

Page 34

26 Medalist 8641, 6531, 4321, 3221 and 2110, Rev. B

Word Description Contents

5 Retired 0000

Number of logical sectors per logical

6

track: 63

003F

7–9 Retired 0000

10–19

Serial number:

(20 ASCII characters, 0000

= none)

H

ASCII

20 Retired 0000

21 Retired 0100

22 Obsolete 0000

Firmware revision (8 ASCII character

23–26

string, padded with blanks to end of

string)

ST38641A

27–46

Drive model number: (40 ASCII

characters, padded with blanks to end

of string)

ST36531A

ST34321A

ST33221A

ST32110A

(Bits 7–0) Maximum sectors per

47

interrupt on Read Multiple and Write

8020

Multiple (64)

H

H

H

H

H

H

x.xx

H

48 Reserved 0000

49

Standard Standby timer, IORDY

supported and may be disabled

50 ATA-reserved 0000

51 PIO data-transfer cycle timing mode 0200

52 Retired 0200

53 Words 54–58, 64–70 and 88 are valid 0007

54 Number of current logical cylinders

55 Number of current logical heads

56

Number of current logical sectors per

logical track

57–58 Current capacity in sectors

2F00

xxxx

xxxx

xxxx

xxxx

H

H

H

H

H

H

H

H

H

H

Page 35

Medalist 8641, 6531, 4321, 3221 and 2110, Rev. B 27

Word Description Contents

59

Number of sectors transferred during a

Read Multiple or Write Mu ltip le com mand

7EBC

60–61

Total number of user-addressable

LBA sectors available:

16,809,660 (ST38641A)

12,706,470 (ST36531A)

8,404,830 (ST34321A)

6,303,024 (ST33221A)

4,124,736 (ST32110A)

(ST38641A)

E2A6H 00C1

(ST36531A)

3F5EH 0080

(ST34321A)

2D30H 0060

(ST33221A)

F040H 003E

(ST32110A)

62 Retired 0000

63

64

65

66

67

Multiword DMA active and modes

supported (see note following this table)

Advanced PIO modes supported

(modes 3 and 4 supported)

Minimum multiword DMA transfer cycle

time per word (120 nsec)

Recommended multiword DMA transfer

cycle time per word (120 nsec)

Minimum PIO cycle time without

IORDY flow control (240 nsec)

xxxx

H

07

xx

0003

0078

0078

00F0

H

0100

H

H

H

H

H

H

H

H

H

H

H

68

Minimum PIO cycle time with IORDY

flow control (120 nsec)

69–74 ATA-reserved 0000

75 Queue depth 0000

76–79 ATA-reserved 0000

80 Major version number 001E

81 Minor version number 0000

82 Command sets supported 3069

83 Command sets supported 4001

continued

0078

H

H

H

H

H

H

H

H

Page 36

28 Medalist 8641, 6531, 4321, 3221 and 2110, Rev. B

Word Description Contents

84 Command sets support extension 4000

85 Command sets enabled 30

86 Command sets enabled 0001

87 Command sets enable extension 4000

88 Ultra DMA support and current mode 0x07

89 Security erase time 0000

90 Enhanced security erase time 0000

91–127 ATA-reserved 0000

128 Security status 0000

129–159 Seagate-reserved

xxxx

160–255 ATA-reserved 0000

Note.

The following Multiword DMA and Ultra DMA mode settings are

used in words 63 and 88, respectively, of the Identify Drive data:

Description (if bit is set to 1)

Bit Word 63

0 Multiword DMA mode 0 is supported.

1 Multiword DMA mode 1 is supported.

xx

H

H

H

H

H

H

H

H

H

H

H

2 Multiword DMA mode 2 is supported.

8 Multiword DMA mode 0 is currently active.

9 Multiword DMA mode 1 is currently active.

10 Multiword DMA mode 2 is currently active.

Bit Word 88

0 Ultra DMA mode 0 is supported.

1 Ultra DMA mode 1 is supported.

2 Ultra DMA mode 2 is supported.

8 Ultra DMA mode 0 is currently active.

9 Ultra DMA mode 1 is currently active.

10 Ultra DMA mode 2 is currently active.

Page 37

Medalist 8641, 6531, 4321, 3221 and 2110, Rev. B 29

3.2.3 Set Features command

This command controls the implementation of var ious features that the

drive supports. When the drive receives this command, it sets BSY,

checks the contents of the Features register, clears BSY and generates

an interrupt. If the value in the register does not represent a feature that

the drive supports, the command is aborted. Power-on default has the

read look-ahead and write caching features enabled. The acceptable

values for the Features register are defined as follows:

Enable write cache

02

H

03HSet transfer mode (based on value in Sector Count register)

Sector Count register values:

Set PIO mode to default (PIO mode 2)

00

H

Set PIO mode t o defa ult a nd d isable IORDY (P IO mode 2)

01

H

08

PIO mode 0

H

PIO mode 1

09

H

PIO mode 2

0A

H

0BHPIO mode 3

PIO mode 4

0C

H

Multiword DMA mode 0

20

H

Multiword DMA mode 1

21

H

Multiword DMA mode 2

22

H

Ultra DMA mode 0

40

H

Ultra DMA mode 1

41

H

Ultra DMA mode 2

42

H

Disable read look-ahead (read cache) feature

55

H

Disable write cache

82

H

Enable read look-ahead (read cache) feature

AA

H

F1HReport full capacity available

(default)

(default)

(default)

At power-on, or after a hardware reset, the default values of the features

are as indicated above. A software reset also changes the features to

the default values.

Page 38

30 Medalist 8641, 6531, 4321, 3221 and 2110, Rev. B

3.2.4 S.M.A.R.T. commands

S.M.A.R.T. provides near-term failure prediction for disc drives. When

S.M.A.R.T. is enabled, the drive monitors predetermined drive attributes

that are susceptible to degradation over time. If self- monitoring determines that a failure is likely, S.M.A.R.T. makes a status report available

to the host. Not all failures are predictable. S.M.A.R.T. predictability is

limited to the attributes the drive can monitor. For more information on

S.M.A.R.T. commands and implementation, see the

These drives are shipped with S.M.A.R.T. features disabled. You must

have a recent BIOS or software package that supports S.M.A.R.T. to

enable the feature. The table below shows the S.M.A.R.T. command

codes that these drives use.

Code in

Features

Register S.M.A.R.T. Command

Draft ATA-4 Standard.

Supported by

ST38641A

ST36531A

ST34321A

ST33221A

ST32110A

D0

H

D1

H

D2

H

D3

H

D4

H

D7

H

D8

H

D9

H

DA

H

Note.

S.M.A.R.T. Read Data Yes

Vendor-specific Yes

S.M.A.R.T. Enable/Disable Attribute

Autosave

Yes

S.M.A.R.T. Save Attribute Values Yes

S.M.A.R.T. Execute Off-line Immediate Yes

Vendor-specific Yes

S.M.A.R.T. Enable Operations Yes

S.M.A.R.T. Disable Operations Yes

S.M.A.R.T. Return Status Yes

If an appropriate code is not written to the Features Register, the

command is aborted and 0

04 (abort) is written to the Error reg-

x

ister.

Page 39

Page 40

Seagate Technology, Inc.

920 Disc Drive, Scotts Valley, California 95066, USA

Publication Number: 20400075-001, Rev. B, Printed in USA

Loading...

Loading...