Page 1

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cheetah 15K.3 FC Disc Drive

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ST373453FC

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ST336753FC

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ST318453FC

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Product Manual, Volume 1

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Page 2

Page 3

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cheetah 15K.3 FC Disc Drive

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ST373453FC

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ST336753FC

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ST318453FC

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Product Manual, Volume 1

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Page 4

© 2002, 2003 Seagate Technology LLC. All rights reserved. Printed in the USA.

March 2003

Publication number: 100148129, Rev. D

Seagate, Seagate Technology, and the Seagate logo are registered trademarks or trademarks of Seagate

Technology LLC. Cheetah, SeaFAX, SeaFONE, SeaBOARD, and SeaTDD are registered trademarks or trademarks of Seagate Technology LLC. Other product names are registered trademarks or trademarks of their

owners.

Seagate reserves the right to change, without notice, product offerings or specifications. No part of this publica-

tion may be reproduced in any form without written permission of Seagate Technology LLC.

Page 5

Revision status summary sheet

Revision Date Writer/Engineer Sheets Affected

Rev. A 05/03/2002 K. Schweiss/B. Hohn 1/1, v-vii, and 1-74.

Rev. B 07/08/2002 K. Schweiss/B. Hohn 1/1, v-vii, and 1-74.

Rev. C 11/26/2002 K. Schweiss/B. Hohn Front and back covers, and 9.

Rev. D 03/03/2003 K. Schweiss/B. Hohn 13 and 32.

Page 6

Page 7

Cheetah 15K.3 FC Product Manual, Rev. D v

Contents

1.0 Scope . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

2.0 Applicable standards and reference documentation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2.1 Standards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2.1.1 Electromagnetic compatibility . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2.1.2 Electromagnetic compliance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2.2 Reference documents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

3.0 General description. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

3.1 Standard features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

3.2 Media description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

3.3 Performance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

3.4 Reliability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3.5 Unformatted and formatted capacities . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3.6 Programmable drive capacity. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3.7 Factory-installed accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3.8 Factory-installed options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3.9 User-installed accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

4.0 Performance characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

4.1 Internal drive characteristics. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

4.2 Seek performance characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

4.2.1 Access time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

4.2.2 Format command execution time for ≥ 512-byte sectors (minutes) . . . . . . . . . . . . . 9

4.2.3 General performance characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

4.3 Start/stop time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

4.4 Prefetch/multi-segmented cache control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

4.5 Cache operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

4.5.1 Caching write data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

4.5.2 Prefetch operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

4.5.3 Optimizing cache performance for desktop and server applications . . . . . . . . . . . 12

5.0 Reliability specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

5.1 Error rates . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

5.1.1 Interface errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

5.1.2 Environmental interference. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

5.1.3 Write errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

5.1.4 Seek errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

5.2 Reliability and service. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

5.2.1 Mean time between failure (MTBF) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

5.2.2 Preventive maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

5.2.3 Service life . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

5.2.4 Service philosophy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

5.2.5 Service tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

5.2.6 Hot plugging the drive. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

5.2.7 S.M.A.R.T. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

5.2.8 Thermal monitor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

5.2.9 Drive Self Test (DST) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

5.2.10 Product warranty. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

6.0 Physical/electrical specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

6.1 AC power requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

6.2 DC power requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

6.2.1 Conducted noise immunity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

6.2.2 Power sequencing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

6.2.3 Current profiles . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

6.3 Power dissipation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

6.4 Environmental limits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Page 8

vi Cheetah 15K.3 FC Product Manual, Rev. D

6.4.1 Temperature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

6.4.2 Relative humidity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

6.4.3 Effective altitude (sea level) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

6.4.4 Shock and vibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

6.4.5 Air cleanliness . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31

6.4.6 Acoustics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31

6.4.7 Electromagnetic susceptibility . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31

6.5 Mechanical specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .32

7.0 Defect and error management . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

7.1 Drive internal defects/errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

7.2 Drive error recovery procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

7.3 FC-AL system errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .34

8.0 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .35

8.1 Drive ID/option selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .35

8.2 LED connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .35

8.2.1 J6 connector requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .36

8.3 Drive orientation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .36

8.4 Cooling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .36

8.5 Drive mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .37

8.6 Grounding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .37

9.0 Interface requirements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .39

9.1 FC-AL features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .39

9.1.1 Fibre Channel link service frames . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .39

9.1.2 Fibre Channel task management functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .39

9.1.3 Fibre Channel task management responses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .39

9.1.4 Fibre Channel port login. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .40

9.1.5 Fibre Channel port login accept . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .41

9.1.6 Fibre Channel Process Login. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .41

9.1.7 Fibre Channel Process Login Accept. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .41

9.1.8 Fibre Channel fabric login . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .42

9.1.9 Fibre Channel fabric accept login . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .43

9.1.10 Fibre Channel Arbitrated Loop options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .44

9.2 Dual port support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .44

9.3 SCSI commands supported . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .45

9.3.1 Inquiry data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .49

9.3.2 Mode Sense data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .49

9.4 Miscellaneous operating features and conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .54

9.5 FC-AL physical interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .55

9.5.1 Physical characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .55

9.5.2 Connector requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .56

9.5.3 Electrical description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .57

9.5.4 Pin descriptions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .57

9.5.5 FC-AL transmitters and receivers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .58

9.5.6 Power. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .58

9.5.7 Fault LED Out . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .58

9.5.8 Active LED Out . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .58

9.5.9 Enable port bypass signals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .59

9.5.10 Motor start controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .59

9.5.11 SEL_6 through SEL_0 ID lines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .59

9.5.12 Device control codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .62

9.6 Signal characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .62

9.6.1 TTL input characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .62

9.6.2 LED driver signals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .62

9.6.3 Differential PECL output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .63

9.6.4 Differential PECL input. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .63

10.0 Seagate Technology support services. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .65

Page 9

Cheetah 15K.3 FC Product Manual, Rev. D ix

List of Figures

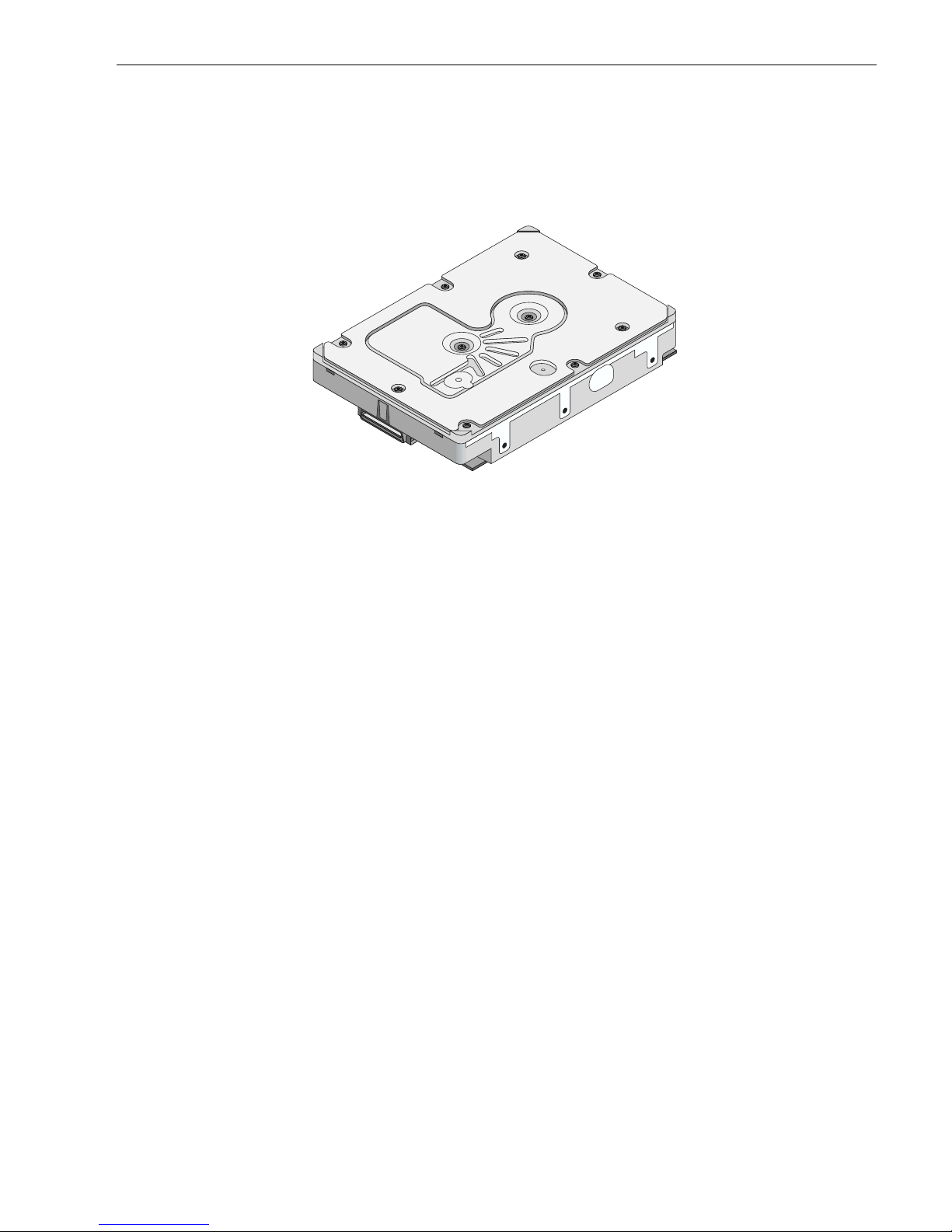

Figure 1. Cheetah 15K.3 FC family disc drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Figure 2. Typical ST373453FC drive +12V current profile . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Figure 3. Typical ST373453FC drive +5V current profile . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Figure 4. Typical ST336753FC drive +12V current profile . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Figure 5. Typical ST336753FC drive +5V current profile . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Figure 6. Typical ST318453FC drive +12V current profile . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Figure 7. Typical ST318453FC drive +5V current profile . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Figure 8. ST373453FC DC current and power vs. input/output operations per second . . . . . . . . . . . . 26

Figure 9. ST336753FC DC current and power vs. input/output operations per second . . . . . . . . . . . . 26

Figure 10. ST318453FC DC current and power vs. input/output operations per second . . . . . . . . . . . . 27

Figure 11. Locations of the HDA temperature check point . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Figure 12. Recommended mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Figure 13. Mounting configuration dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Figure 14. Physical interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Figure 15. LED indicator connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Figure 16. Air flow . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Figure 17. Physical interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Figure 18. Port bypass circuit physical interconnect . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Figure 19. FC-AL SCA device connector dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Figure 20. J6 connector dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Figure 21. FC-AL transmitters and receivers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Figure 22. Transmit eye diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Figure 23. Receive eye diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Page 10

Page 11

Cheetah 15K.3 FC Product Manual, Rev. D 1

1.0 Scope

This manual describes Seagate Technology® LLC, Cheetah® 15K.3 FC (Fibre Channel) disc drives.

Cheetah 15K.3 FC drives support the Fibre Channel Arbitrated Loop and SCSI Fibre Channel Protocol specifications to the extent described in this manual. The

describes the general Fibre Channel Arbitrated Loop characteristics of this and other Seagate Fibre Channel

drives.

Figure 1. Cheetah 15K.3 FC family disc drive

Fibre Channel Interface Manual

(part number 77767496)

Page 12

2 Cheetah 15K.3 FC Product Manual, Rev. D

Page 13

Cheetah 15K.3 FC Product Manual, Rev. D 3

2.0 Applicable standards and reference documentation

The drive has been developed as a system peripheral to the highest standards of design and construction. The

drive depends upon its host equipment to provide adequate power and environment in order to achieve optimum performance and compliance with applicable industry and governmental regulations. Special attention

must be given in the areas of safety, power distribution, shielding, audible noise control, and temperature regulation. In particular, the drive must be securely mounted in order to guarantee the specified performance characteristics. Mounting by bottom holes must meet the requirements of Section 8.5.

2.1 Standards

The Cheetah 15K.3 FC family complies with Seagate standards as noted in the appropriate sections of this

manual and the Seagate

The Cheetah 15K.3 FC disc drive is a UL recognized component per UL1950, CSA certified to CAN/CSA

C22.2 No. 950-95, and VDE certified to VDE 0805 and EN60950.

2.1.1 Electromagnetic compatibility

The drive, as delivered, is designed for system integration and installation into a suitable enclosure prior to use.

As such the drive is supplied as a subassembly and is not subject to Subpart B of Part 15 of the FCC Rules

and Regulations nor the Radio Interference Regulations of the Canadian Department of Communications.

The design characteristics of the drive serve to minimize radiation when installed in an enclosure that provides

reasonable shielding. As such, the drive is capable of meeting the Class B limits of the FCC Rules and Regulations of the Canadian Department of Communications when properly packaged. However, it is the user’s

responsibility to assure that the drive meets the appropriate EMI requirements in their system. Shielded I/O

cables may be required if the enclosure does not provide adequate shielding. If the I/O cables are external to

the enclosure, shielded cables should be used, with the shields grounded to the enclosure and to the host controller.

Fibre Channel Interface Manual

, part number 77767496.

2.1.1.1 Electromagnetic susceptibility

As a component assembly, the drive is not required to meet any susceptibility performance requirements. It is

the responsibility of those integrating the drive within their systems to perform those tests required and design

their system to ensure that equipment operating in the same system as the drive or external to the system

does not adversely affect the performance of the drive. See Section 5.1.2 and Table 2, DC power requirements.

2.1.2 Electromagnetic compliance

Seagate uses an independent laboratory to confirm compliance with the directives/standards for CE Marking

and C-Tick Marking. The drive was tested in a representative system for typical applications. The selected system represents the most popular characteristics for test platforms. The system configurations include:

• Typical current use microprocessor

• 3.5-inch floppy disc drive

• Keyboard

• Monitor/display

•Printer

• External modem

•Mouse

Although the test system with this Seagate model complies with the directives/standards, we cannot guarantee

that all systems will comply. The computer manufacturer or system integrator shall confirm EMC compliance

and provide the appropriate marking for their product.

Electromagnetic compliance for the European Union

If this model has the CE Marking it complies with the European Union requirements of the Electromagnetic

Compatibility Directive 89/336/EEC of 03 May 1989 as amended by Directive 92/31/EEC of 28 April 1992 and

Directive 93/68/EEC of 22 July 1993.

Page 14

4 Cheetah 15K.3 FC Product Manual, Rev. D

Australian C-Tick

If this model has the C-Tick Marking it complies with the Australia/New Zealand Standard AS/NZS3548 1995

and meets the Electromagnetic Compatibility (EMC) Framework requirements of Australia’s Spectrum Management Agency (SMA).

Korean MIC

If this model has the Korean Ministry of Information and Communication (MIC) logo, it complies with paragraph

1 of Article 11 of the Electromagnetic Compatibility (EMC) Control Regulation and meets the Electromagnetic

Compatibility Framework requirements of the Radio Research Laboratory (RRL) Ministry of Information and

Communication Republic of Korea.

Taiwanese BSMI

If this model has two Chinese words meaning “EMC certification” followed by an eight digit identification number, as a Marking, it complies with Chinese National Standard (CNS) 13438 and meets the Electromagnetic

Compatibility (EMC) Framework requirements of the Taiwanese Bureau of Standards, Metrology, and Inspection (BSMI).

2.2 Reference documents

Cheetah 15K.3 FC Installation Guide

Seagate part number: 100148127

Fibre Channel Interface Manual

Seagate part number: 77767496

ANSI Fibre Channel Documents

X3.230-1994 FC Physical and Signaling Interface (FC-PH)

X3.297.1997 FC-PH-2 Fibre Channel Physical and Signaling Interface-2

X3.303.1998 FC-PH-3 Fibre Channel Physical and Signaling Interface-3

X3.272-1996 FC Arbitrated Loop (FC-AL)

X3.269-1996 Fibre Channel Protocol for SCSI (FCP)

NCITS TR-19 Private Loop SCSI Direct Attach (PLDA)

NCITS TR-20 Fabric Loop Attachment (FC-FLA)

SFF-8045 Specification for 40-pin SCA-2 Connector with Parallel Selection

SFF-8067 Specification for 40-pin SCA-2 Connector with Bidirectional Enclosure Services

Interface

ANSI Small Computer System Interface (SCSI) Documents

X3.131-1994 (SCSI-2)

X3.270-1996 (SCSI-3) Architecture Model

NCITS 305-199X (SCSI-3) Enclosure Services

Specification for Acoustic Test Requirement and Procedures

Seagate part number: 30553-001

Package Test Specification Seagate P/N 30190-001 (under 100 lb.)

Package Test Specification Seagate P/N 30191-001 (over 100 lb.)

In case of conflict between this document and any referenced document, this document takes precedence.

Page 15

Cheetah 15K.3 FC Product Manual, Rev. D 5

3.0 General description

Cheetah 15K.3 FC drives combine giant magnetoresistive (GMR) heads, partial response/maximum likelihood

(PRML) read channel electronics, embedded servo technology, and a Fibre Channel interface to provide high

performance, high capacity data storage for a variety of systems including engineering workstations, network

servers, mainframes, and supercomputers. Cheetah 15K.3 FC drives also support 2-Gbit Fibre Channel which

can transfer data at up to 200 Mbytes per second and 400 Mbytes per second in dual-loop configurations.

Cheetah 15K.3 FC drives are random access storage devices designed to support the Fibre Channel Arbitrated Loop (FC-AL) and SCSI Fibre Channel Protocol as described in the ANSI specifications, this document,

and the

acteristics of this drive. Cheetah 15K.3 FC drives are classified as intelligent peripherals and provide level 2

conformance (highest level) with the ANSI SCSI-1 standard.

The head and disc assembly (HDA) is sealed at the factory. Air recirculates within the HDA through a nonreplaceable filter to maintain a contamination-free HDA environment.

Never disassemble the HDA and do not attempt to service items in the sealed enclosure (heads, media, actuator, etc.) as this requires special facilities. The drive does not contain user-replaceable parts. Opening the HDA

for any reason voids your warranty.

Cheetah 15K.3 FC drives use a dedicated landing zone at the innermost radius of the media to eliminate the

possibility of destroying or degrading data by landing in the data zone. The heads automatically go to the landing zone when power is removed from the drive.

Fibre Channel Interface Manual

(part number 77767496) which describes the general interface char-

An automatic shipping lock prevents potential damage to the heads and discs that results from movement during shipping and handling. The shipping lock disengages and the head load process begins when power is

applied to the drive.

Cheetah 15K.3 FC drives decode track 0 location data from the servo data embedded on each surface to eliminate mechanical transducer adjustments and related reliability concerns.

The drives also use a high-performance actuator assembly with a low-inertia, balanced, patented, straight arm

design that provides excellent performance with minimal power dissipation.

Page 16

6 Cheetah 15K.3 FC Product Manual, Rev. D

3.1 Standard features

Cheetah 15K.3 FC drives have the following standard features:

• 2-Gbit Fibre Channel interface. For 2 gigabit operation, the block size must be divisable by 8.

• Integrated dual port FC-AL controller

• Concurrent dual port transfers

• Support for FC arbitrated loop, private and public attachment

• Differential copper FC drivers and receivers

• Downloadable firmware using the FC-AL interface

• Supports SCSI enclosure services via interface connector

• 128-deep task set (queue)

• Supports up to 32 initiators

• Drive selection ID and configuration options are set on the FC-AL backpanel or through interface commands. Jumpers are not used on the drive.

• Supports SCSI Enclosure Services through the interface connector

• Fibre Channel worldwide name uniquely identifies the drive and each port

• User-selectable logical block size (512 to 528 bytes per logical block). For 2 gigabit operation, the block size

must be divisable by 8.

• Selectable frame sizes from 256 to 2,112 bytes

• Industry standard 3.5-inch low profile form factor dimensions

• Programmable logical block reallocation scheme

• Flawed logical block reallocation at format time

• Programmable auto write and read reallocation

• Reed-Solomon error correction code

• Sealed head and disc assembly (HDA)

• No preventive maintenance or adjustments required

• Dedicated head landing zone

• Automatic shipping lock

• Embedded Grey Code track address to eliminate seek errors

• Self-diagnostics performed at power on

• 1:1 interleave

• Zone bit recording (ZBR)

• Vertical, horizontal, or top down mounting

• Dynamic spindle brake

• 8,192 Kbyte data buffer (see Section 4.5).

• Embedded servo design

• Reallocation of defects on command (Post Format)

• Fibre Channel interface transports SCSI protocol

3.2 Media description

The media used on the drive has an aluminum substrate coated with a thin film magnetic material, overcoated

with a proprietary protective layer for improved durability and environmental protection.

3.3 Performance

• Programmable multi-segmentable cache buffer

• 200 Mbytes/sec maximum instantaneous data transfers per port.

• 15k RPM spindle; average latency = 2.0 msec

• Command queuing of up to 128 commands

• Background processing of queue

• Supports start and stop commands

• Adaptive seek velocity; improved seek performance

Page 17

Cheetah 15K.3 FC Product Manual, Rev. D 7

3.4 Reliability

• 1,200,000 hour MTBF

• LSI circuitry

• Balanced low mass rotary voice coil actuator

• Self-Monitoring Analysis and Reporting Technology (S.M.A.R.T.)

• Dithering

3.5 Unformatted and formatted capacities

Formatted capacity depends on the spare reallocation sectors scheme selected, the number of data tracks per

sparing zone, and the number of alternate sectors (LBAs) per sparing zone. The following table shows the

standard OEM model capacity:

Formatted Unformatted

ST373453FC 088BB998h (73.4 Gbytes) 96.4 GB

ST336753FC 0445DCCCh (36.7 Gbytes) 48.2 GB

ST318453FC 0222EE66h (18.4 Gbytes) 24.1 GB

Standard OEM models are formatted to 512 bytes per block. You can order other capacities by requesting a different sparing scheme and logical block size.

Note. For 2 gigabit operation sector sizes must be divisible by 8.

The sector size is selectable at format time. Users having the necessary equipment may modify the data block

size before issuing a format command and obtain different formatted capacities than those listed. Cheetah

15K.3 FC drives use a zone sparing scheme. The drive is divided into frequency zones with a variable number

of spares in each zone.

3.6 Programmable drive capacity

Using the Mode Select command, the drive can change its capacity to something less than maximum. See the

Mode Select (6) parameter list table in the

Fibre Channel Interface Manual

, part number 7767496. A value of

zero in the Number of Blocks field indicates that the drive will not change the capacity it is currently formatted

to have. A number other than zero and less than the maximum number of LBAs in the Number of Blocks field

changes the total drive capacity to the value in the Number of Blocks field. A value greater than the maximum

number of LBAs is rounded down to the maximum capacity.

3.7 Factory-installed accessories

OEM standard drives are shipped with the

Cheetah 15K.3 FC Installation Guide

(part number 100148127).

3.8 Factory-installed options

You may order the following items which are incorporated at the manufacturing facility during production or

packaged before shipping. Some of the options available are (not an exhaustive list of possible options):

• Other capacities can be ordered depending on sparing scheme and sector size requested.

• Single-unit shipping pack. The drive is normally shipped in bulk packaging to provide maximum protection

against transit damage. Units shipped individually require additional protection as provided by the single unit

shipping pack. Users planning single unit distribution should specify this option.

• The

Cheetah 15K.3 FC Installation Guide,

part number 100148127, is usually included with each standard

OEM drive shipped, but extra copies may be ordered.

• The

Safety and Regulatory Agency Specifications

, part number 75789512, is usually included with each

standard OEM drive shipped, but extra copies may be ordered.

3.9 User-installed accessories

The following accessories are available. All kits may be installed in the field.

• Evaluation kit, part number 73473641.

This kit provides an adapter card (“T-card”) to allow cable connections for two FC ports and DC power.

• Single-unit shipping pack.

Page 18

8 Cheetah 15K.3 FC Product Manual, Rev. D

Page 19

Cheetah 15K.3 FC Product Manual, Rev. D 9

4.0 Performance characteristics

This section provides detailed information concerning performance-related characteristics and features of

Cheetah 15K.3 FC drives.

4.1 Internal drive characteristics

ST373453FC ST336753FC ST336753FC

Drive capacity 73.4 36.7 18.4 Gbytes (formatted, rounded off value)

Read/write data heads 8 4 2

Bytes per track 377,770 377,770 377,770 Bytes (average, rounded off values)

Bytes per surface 12,046 12,046 12,046 Mbytes (unformatted, rounded off value)

Tracks per surface (total) 31,310 31,310 31,310 Tracks (user accessible)

Tracks per inch 64,000 64,000 64,000 TPI

Peak bits per inch 542 542 542 KBPI

Internal data rate 609-891 609-891 609-891 Mbits/sec (variable with zone)

Disc rotation speed 15k 15k 15k rpm

Avg rotational latency 2.0 2.0 2.0 msec

4.2 Seek performance characteristics

See Section 9.5, "FC-AL physical interface" on page 55 and the

Fibre Channel Interface Manual

(part number

77767496) for additional timing details.

4.2.1 Access time

Including controller overhead

(msec)

Read Write Read Write

Average Typical

Single track Typical

Full stroke Typical

1. Execution time measured from receipt of the FCP Command to the FCP Response.

2. Assumes no errors and no sector has been relocated.

3. Typical access times are measured under nominal conditions of temperature, voltage, and horizontal orientation as

measured on a representative sample of drives.

4. Access time = controller overhead + average seek time and applies to all data transfer commands.

Access to data = access time + latency time.

3,4

3,4

3,4

3.8 4.1 3.6 3.9

0.40 0.60 0.20 0.40

6.7 7.1 6.5 6.9

1, 2

Not including controller overhead

(msec)

1,2

4.2.2 Format command execution time for ≥ 512-byte sectors (minutes)

ST373453FC ST336753FC ST318453FC

Maximum (with verify)

Maximum (without verify)

90 60 30

45 30 15

Page 20

10 Cheetah 15K.3 FC Product Manual, Rev. D

4.2.3 General performance characteristics

Minimum sector interleave 1 to 1

Data buffer to/from disc media (one 512-byte logical block)*

Minimum 51.8 MBytes/sec

Maximum 86.0 MBytes/sec

Fibre Channel Interface maximum instantaneous transfer rate 200 Mbytes/sec* per

port (dual port = 400

Mbytes/sec*)

Logical block sizes

Default is 512-byte data blocks

Variable 512 to 704 bytes per sector in even number of bytes per sector. If n (number of bytes per sector) is odd, then n-1 will be used.

Read/write consecutive sectors on a track

Flaw reallocation performance impact (for flaws reallocated at format time

using the spare sectors per sparing zone reallocation scheme.)

Average rotational latency

*Assumes no errors and no relocated logical blocks. Rate measured from the start of the first logical

block transfer to or from the host.

Ye s

Negligible

2.0 msec

4.3 Start/stop time

If the Motor Start option is disabled, the drive becomes ready within 20 seconds after DC power is applied. If a

recoverable error condition is detected during the start sequence, the drive executes a recovery procedure and

the time to become ready may exceed 20 seconds. Stop time is 30 seconds (maximum) from removal of DC

power.

If the Motor Start option is enabled, the internal controller accepts the commands listed in the

Interface Manual

less than 3 seconds after DC power has been applied. After the Motor Start command has

Fibre Channel

been received, the drive becomes ready for normal operations within 20 seconds (excluding the error recovery

procedure). The Motor Start command can also be used to command the drive to stop the spindle.

There is no power control switch on the drive.

4.4 Prefetch/multi-segmented cache control

The drive provides a prefetch (read look-ahead) and multi-segmented cache control algorithms that in many

cases can enhance system performance. Cache refers to the drive buffer storage space when it is used in

cache operations. To select this feature, the host sends the Mode Select command with the proper values in

the applicable bytes in page 08h. Prefetch and cache operations are independent features from the standpoint

that each is enabled and disabled independently using the Mode Select command; however, in actual operation, the prefetch feature overlaps cache operation somewhat as described in sections 4.5.1 and 4.5.2.

All default cache and prefetch mode parameter values (Mode Page 08h) for standard OEM versions of this

drive family are given in Table 16.

4.5 Cache operation

Note. Refer to the

Fibre Channel Interface Manual

for more detail concerning the cache bits.

Page 21

Cheetah 15K.3 FC Product Manual, Rev. D 11

Of the 8,192 kbytes physical buffer space in the drive, approximately 7,500 kbytes can be used as a cache.

The buffer can be divided into logical segments (using Mode Select Page 08h, byte 13) from which data is read

and to which data is written.

The drive keeps track of the logical block addresses of the data stored in each segment of the buffer. If the

cache is enabled (see RCD bit in the

Fibre Channel Interface Manual

), data requested by the host with a read

command is retrieved from the buffer, if possible, before any disc access is initiated. If cache operation is not

enabled, the buffer (still segmented with the required number of segments) is still used, but only as circular

buffer segments during disc medium read operations (disregarding Prefetch operation for the moment). That is,

the drive does not check in the buffer segments for the requested read data, but goes directly to the medium to

retrieve it. The retrieved data merely passes through some buffer segment on the way to the host. On a cache

miss, all data transfers to the host are in accordance with buffer-full ratio rules. On a cache hit, the drive ignores

the buffer-full ratio rules. See the explanation provided with the information about Mode Page 02h (disconnect/

reconnect control) in the

Fibre Channel Interface Manual

.

The following is a simplified description of the prefetch/cache operation:

Case A—read command is received and the first logical block is already in the cache:

1. Drive transfers to the initiator the first logical block requested plus all subsequent contiguous logical blocks

that are already in the cache. This data may be in multiple segments.

2. When a requested logical block is reached that is not in any cache segment, the drive fetches it and any

remaining requested logical block addresses from the disc and puts them in a segment of the cache. The

drive transfers the remaining requested logical blocks from the cache to the host in accordance with the

Mode Select Disconnect/Reconnect parameters, page 02h.

3. If the prefetch feature is enabled, refer to section 4.5.2 for operation from this point.

Case B—A Read command requests data, and the first logical block is not in any segment of the cache:

1. The drive fetches the requested logical blocks from the disc and transfers them into a segment, and then

from there to the host in accordance with the Mode Select Disconnect/Reconnect parameters, page 02h.

2. If the prefetch feature is enabled, refer to section 4.5.2 for operation from this point.

During a prefetch, the drive crosses a cylinder boundary to fetch data only if the Discontinuity (DISC) bit is set

to 1 in bit 4 of byte 2 of the Mode Select parameters page 08h. Default is zero for bit 4.

Each cache segment is actually a self-contained circular buffer whose length is an integer number of logical

blocks. The wrap-around capability of the individual segments greatly enhances the cache’s overall performance, allowing a wide range of user-selectable configurations. The drive supports operation of any integer

number of segments from 1 to 16. Divide the 7,500 Kbytes in the buffer by the number of segments to get the

segment size. Default is 3 segments.

Note. The size of each segment is not reported by Mode Sense command page 08h, bytes 14 and 15. The

value 0XFFFF is always reported regardless of the actual size of the segment. Sending a size specification using the Mode Select command (bytes 14 and 15) does not set up a new segment size. If the

STRICT bit in Mode page 00h (byte 2, bit 1) is set to one, the drive responds as it does for any attempt

to change an unchangeable parameter.

4.5.1 Caching write data

Write caching is a write operation by the drive that makes use of a drive buffer storage area where the data to

be written to the medium is stored while the drive performs the Write command.

If read caching is enabled (RCD=0), then data written to the medium is retained in the cache to be made available for future read cache hits. The same buffer space and segmentation is used as set up for read functions.

The buffer segmentation scheme is set up or changed independently, having nothing to do with the state of

RCD. When a write command is issued, if RCD=0, the cache is first checked to see if any logical blocks that

are to be written are already stored in the cache from a previous read or write command. If there are, the

respective cache segments are cleared. The new data is cached for subsequent Read commands.

If the number of write data logical blocks exceed the size of the segment being written into, when the end of the

segment is reached, the data is written into the beginning of the same cache segment, overwriting the data that

Page 22

12 Cheetah 15K.3 FC Product Manual, Rev. D

was written there at the beginning of the operation; however, the drive does not overwrite data that has not yet

been written to the medium.

If write caching is enabled (WCE=1), then the drive may return Good status on a write command after the data

has been transferred into the cache, but before the data has been written to the medium. If an error occurs

while writing the data to the medium, and Good status has already been returned, a deferred error will be generated.

The Synchronize Cache command may be used to force the drive to write all cached write data to the medium.

Upon completion of a Synchronize Cache command, all data received from previous write commands will have

been written to the medium.

Table 16 shows the mode default settings for the drive.

4.5.2 Prefetch operation

If the Prefetch feature is enabled, data in contiguous logical blocks on the disc immediately beyond that which

was requested by a Read command are retrieved and stored in the buffer for immediate transfer from the buffer

to the host on subsequent Read commands that request those logical blocks (this is true even if cache operation is disabled). Though the prefetch operation uses the buffer as a cache, finding the requested data in the

buffer is a prefetch hit, not a cache operation hit.

To enable Prefetch, use Mode Select page 08h, byte 12, bit 5 (Disable Read Ahead - DRA bit). DRA bit = 0

enables prefetch.

Since data that is prefetched replaces data already in some buffer segments, the host can limit the amount of

prefetch data to optimize system performance. The Max Prefetch field (bytes 8 and 9) limits the amount of

prefetch. The drive does not use the Prefetch Ceiling field (bytes 10 and 11).

During a prefetch operation, the drive crosses a cylinder boundary to fetch more data only if Mode parameters

page 08h, byte 2, bit 4 is set to 1 (Discontinuity--DISC bit).

When prefetch (read look-ahead) is enabled (enabled by DRA = 0), it operates under the control of ARLA

(Adaptive Read Look-Ahead). If the host uses software interleave, ARLA enables prefetch of contiguous blocks

from the disc when it senses that a prefetch hit will likely occur, even if two consecutive read operations were

not for physically contiguous blocks of data (e.g. “software interleave”). ARLA disables prefetch when it decides

that a prefetch hit will not likely occur. If the host is not using software interleave, and if two sequential read

operations are not for contiguous blocks of data, ARLA disables prefetch, but as long as sequential read operations request contiguous blocks of data, ARLA keeps prefetch enabled.

4.5.3 Optimizing cache performance for desktop and server applications

Desktop and server applications require different drive caching operations for optimal performance. This

means it is difficult to provide a single configuration that meets both of these needs. In a desktop environment,

you want to configure the cache to respond quickly to repetitive accesses of multiple small segments of data

without taking the time to “look ahead” to the next contiguous segments of data. In a server environment, you

want to configure the cache to provide large volumes of sequential data in a non-repetitive manner. In this

case, the ability of the cache to “look ahead” to the next contiguous segments of sequential data is a good

thing.

The Performance Mode (PM) bit controls the way the drive switches the cache buffer into different modes of

segmentation. In “server mode” (PM bit = 0), the drive can dynamically change the number of cache buffer segments as needed to optimize the performance, based on the command stream from the host. In “desktop

mode” (PM bit = 1), the number of segments is maintained at the value defined in Mode Page 8, Byte 13, at all

times (unless changed by using a Mode Select command). For additional information about the PM bit, refer to

the Unit Attention Parameters page (00h) of the Mode Sense command (1Ah) in the

Product Manual

, part number 77767496.

Fibre Channel Interface

Page 23

Cheetah 15K.3 FC Product Manual, Rev. D 13

5.0 Reliability specifications

The following reliability specifications assume correct host and drive operational interface, including all interface timings, power supply voltages, environmental requirements and drive mounting constraints.

Seek error rate:

Read Error Rates

Recovered Data

Unrecovered Data

Miscorrected Data

Interface error rate:

1

Less than 10 errors in 10

Less than 10 errors in 10

Less than 1 sector in 10

Less than 1 sector in 10

Less than 1 error in 10

Less than 1 error in 10

See Section 9.6.4, "Differential PECL input." on page 63

MTBF: 1,200,000 hours

Preventive maintenance: None required

1. Error rate specified with automatic retries and data correction with ECC enabled and all flaws reallocated.

5.1 Error rates

The error rates stated in this manual assume the following:

• The drive is operated in accordance with this manual using DC power as defined in paragraph 6.2, "DC

power requirements."

• The drive has been formatted with the FC-AL Format command.

• Errors caused by media defects or host system failures are excluded from error rate computations.

• Assume random data.

8

seeks

13

bits transferred (OEM default settings)

15

bits transferred

21

bits transferred

12

bits transferred with minimum receive eye.

14

bits transferred with typical receive eye.

5.1.1 Interface errors

An interface error is defined as a failure of the receiver on a port to recover the data as transmitted by the

device port connected to the receiver. The error may be detected as a running disparity error, illegal code, loss

of word sync, or CRC error. The total error rate for a loop of devices is the sum of the individual device error

rates.

5.1.2 Environmental interference

When evaluating systems operation under conditions of electromagnetic interference (EMI), the performance

of the drive within the system is considered acceptable if the drive does not generate an unrecoverable condition.

An unrecoverable error, or condition, is defined as one that:

• is not detected and corrected by the drive itself

• is not detected from the error or fault status provided through the drive or FC-AL interface

• is not recovered by normal drive or system recovery procedures without operator intervention

5.1.3 Write errors

Write errors can occur as a result of media defects, environmental interference, or equipment malfunction.

Therefore, write errors are not predictable as a function of the number of bits passed.

If an unrecoverable write error occurs because of an equipment malfunction in the drive, the error is classified

as a failure affecting MTBF. Unrecoverable write errors are those that cannot be corrected within two attempts

at writing the record with a read verify after each attempt (excluding media defects).

5.1.4 Seek errors

A seek error is defined as a failure of the drive to position the heads to the addressed track. After detecting an

initial seek error, the drive automatically performs an error recovery process. If the error recovery process fails,

a seek positioning error (15h) is reported with a Hardware error (4h) reported in the Sense Key. This is an unre-

Page 24

14 Cheetah 15K.3 FC Product Manual, Rev. D

coverable seek error. Unrecoverable seek errors are classified as failures for MTBF calculations. Refer to the

Fibre Channel Interface Manual

, part number 77767496, for Request Sense information.

5.2 Reliability and service

You can enhance the reliability of Cheetah 15K.3 FC disc drives by ensuring that the drive receives adequate

cooling. Section 6.0 provides recommended air-flow information, temperature measurements, and other information, which you can use to enhance the service life of the drive.

5.2.1 Mean time between failure (MTBF)

The production disc drive achieves an MTBF of 1,200,000 hours when operated in an environment that

ensures the case temperatures specified in Section 6.4.1 are not exceeded. Short-term excursions up to the

specification limits of the operating environment will not affect MTBF performance. Operating the drive at case

temperatures above these values will adversely affect the drive’s ability to meet specifications (see Section 6.4,

"Environmental limits").

The MTBF target is specified as device power-on hours (POH) for all drives in service per failure.

The following expression defines MTBF:

MTBF per measurement period = Estimated power-on operating hours in the period

Number of drive failures in the period

Estimated power-on operating hours means power-on hours per disc drive times the total number of disc drives

in service. Each disc drive must have accumulated at least nine months of operation. Data is calculated on a

rolling average base for a minimum period of six months.

MTBF is based on the following assumptions:

• 8,760 power-on hours per year

• 250 average on/off cycles per year

• Operating at nominal voltages

• System provides adequate cooling to ensure the case temperatures specified in Section 6.4.1 are not

exceeded.

Drive failure means any stoppage or failure to meet defined specifications caused by drive malfunction.

A S.M.A.R.T. predictive failure indicates that the drive is deteriorating to an imminent failure and is considered

an MTBF hit.

5.2.2 Preventive maintenance

No routine scheduled preventive maintenance is required.

5.2.3 Service life

Depot repair or replacement of major parts is permitted during the service lifetime.

5.2.4 Service philosophy

Special equipment is required to repair the drive HDA. Repairs must be performed only at a properly equipped

and staffed Seagate service and repair facility. Troubleshooting and repair of PCBs in the field is not recommended because of the extensive diagnostic equipment required for effective servicing. There are not spare

parts available for this drive. The drive warranty is voided if the HDA is opened.

5.2.5 Service tools

No special tools are required for site installation or recommended for site maintenance. Refer to Section 5.2.4.

The depot repair philosophy of the drive precludes the necessity for special tools. Field repair of the drive is not

practical because users cannot purchase individual parts for the drive.

5.2.6 Hot plugging the drive

Inserting and removing the drive on the FC-AL will interrupt loop operation. The interruption occurs when the

receiver of the next device in the loop must synchronize to a different input signal. FC error detection mecha-

Page 25

Cheetah 15K.3 FC Product Manual, Rev. D 15

nisms, character sync, running disparity, word sync, and CRC are able to detect any error. Recovery is initiated

based on the type of error.

The disc drive defaults to the FC-AL Monitoring state, Pass-through state, when it is powered-on by switching

the power or hot plugged. The control line to an optional port bypass circuit (external to the drive), defaults to

the Enable Bypass state. If the bypass circuit is present, the next device in the loop will continue to receive the

output of the previous device to the newly inserted device. If the bypass circuit is not present, loop operation is

temporarily disrupted until the next device starts receiving the output from the newly inserted device and

regains synchronization to the new input.

The Pass-through state is disabled while the drive performs self test of the FC interface. The control line for an

external port bypass circuit remains in the Enable Bypass state while self test is running. If the bypass circuit is

present, loop operation may continue. If the bypass circuit is not present, loop operation will be halted while the

self test of the FC interface runs.

When the self test completes successfully, the control line to the bypass circuit is disabled and the drive enters

the FC-AL Initializing state. The receiver on the next device in the loop must synchronize to output of the newly

inserted drive.

If the self-test fails, the control line to the bypass circuit remains in the Enable Bypass state.

Note. It is the responsibility of the systems integrator to assure that no temperature, energy, voltage hazard,

or ESD potential hazard is presented during the hot connect/disconnect operation. Discharge the static

electricity from the drive carrier prior to inserting it into the system.

Caution. The drive motor must come to a complete stop prior to changing the plane of operation. This time is

required to insure data integrity.

5.2.7 S.M.A.R.T.

S.M.A.R.T. is an acronym for Self-Monitoring Analysis and Reporting Technology. This technology is intended

to recognize conditions that indicate imminent drive failure and is designed to provide sufficient warning of a

failure to allow you to back up the data before an actual failure occurs.

Note. The drive’s firmware monitors specific attributes for degradation over time but can’t predict instanta-

neous drive failures.

Each monitored attribute has been selected to monitor a specific set of failure conditions in the operating performance of the drive and the thresholds are optimized to minimize “false” and “failed” predictions.

Controlling S.M.A.R.T.

The operating mode of S.M.A.R.T. is controlled by the DEXCPT and PERF bits on the Informational Exceptions

Control mode page (1Ch). Use the DEXCPT bit to enable or disable the S.M.A.R.T. feature. Setting the DEXCPT bit disables all S.M.A.R.T. functions. When enabled, S.M.A.R.T. collects on-line data as the drive performs

normal read and write operations. When the PERF bit is set, the drive is considered to be in “On-line Mode

Only” and will not perform off-line functions.

You can measure off-line attributes and force the drive to save the data by using the Rezero Unit command.

Forcing S.M.A.R.T. resets the timer so that the next scheduled interrupt is in two hours.

You can interrogate the drive through the host to determine the time remaining before the next scheduled measurement and data logging process occurs. To accomplish this, issue a Log Sense command to log page 0x3E.

This allows you to control when S.M.A.R.T. interruptions occur. Forcing S.M.A.R.T. with the RTZ command

resets the timer.

Performance impact

S.M.A.R.T. attribute data is saved to the disc so that the events that caused a predictive failure can be recreated. The drive measures and saves parameters once every two hours subject to an idle period on the FC-AL

Page 26

16 Cheetah 15K.3 FC Product Manual, Rev. D

bus. The process of measuring off-line attribute data and saving data to the disc is uninterruptable. The maximum on-line only processing delay is summarized below:

Maximum processing delay

S.M.A.R.T. delay times

On-line only delay

DEXCPT = 0, PERF = 1

50 milliseconds

Fully-enabled delay

DEXCPT = 0, PERF = 0

300 milliseconds

Reporting control

Reporting is controlled by the MRIE bits in the Informational Exceptions Control mode page (1Ch). Subject to

the reporting method, the firmware will issue to the host an 01-5Dxx sense code. The error code is preserved

through bus resets and power cycles.

Determining rate

S.M.A.R.T. monitors the rate at which errors occur and signals a predictive failure if the rate of degraded errors

increases to an unacceptable level. To determine rate, error events are logged and compared to the number of

total operations for a given attribute. The interval defines the number of operations over which to measure the

rate. The counter that keeps track of the current number of operations is referred to as the Interval Counter.

S.M.A.R.T. measures error rates. All errors for each monitored attribute are recorded. A counter keeps track of

the number of errors for the current interval. This counter is referred to as the Failure Counter.

Error rate is the number of errors per operation. The algorithm that S.M.A.R.T. uses to record rates of error is to

set thresholds for the number of errors and their interval. If the number of errors exceeds the threshold before

the interval expires, the error rate is considered to be unacceptable. If the number of errors does not exceed

the threshold before the interval expires, the error rate is considered to be acceptable. In either case, the interval and failure counters are reset and the process starts over.

Predictive failures

S.M.A.R.T. signals predictive failures when the drive is performing unacceptably for a period of time. The firmware keeps a running count of the number of times the error rate for each attribute is unacceptable. To accomplish this, a counter is incremented each time the error rate is unacceptable and decremented (not to exceed

zero) whenever the error rate is acceptable. If the counter continually increments such that it reaches the predictive threshold, a predictive failure is signaled. This counter is referred to as the Failure History Counter.

There is a separate Failure History Counter for each attribute.

5.2.8 Thermal monitor

Cheetah 15K.3 FC drives implement a temperature warning system which:

1. Signals the host if the temperature exceeds a value which would threaten the drive.

2. Signals the host if the temperature exceeds a user-specified value.

3. Saves a S.M.A.R.T. data frame on the drive which exceeds the threatening temperature value.

A temperature sensor monitors the drive temperature and issues a warning over the interface when the temperature exceeds a set threshold. The temperature is measured at power-up and then at ten-minute intervals

after power-up.

The thermal monitor system generates a warning code of 01-0B01 when the temperature exceeds the specified limit in compliance with the SCSI standard. The drive temperature is reported in the FRU code field of

mode sense data. You can use this information to determine if the warning is due to the temperature exceeding

the drive threatening temperature or the user-specified temperature.

This feature is controlled by the Enable Warning (EWasc) bit, and the reporting mechanism is controlled by the

Method of Reporting Informational Exceptions field (MRIE) on the Informational Exceptions Control (IEC)

mode page (1Ch).

The current algorithm implements two temperature trip points. The first trip point is set at 65°C which is the

maximum temperature limit according to the drive specification. The second trip point is user-selectable using

Page 27

Cheetah 15K.3 FC Product Manual, Rev. D 17

the Log Select command. The reference temperature parameter in the temperature log page (see Table 1) can

be used to set this trip point. The default value for this drive is 65°C, however, you can set it to any value in the

range of 0 to 65°C. If you specify a temperature greater than 65°C in this field, the temperature is rounded

down to 65°C. A sense code is sent to the host to indicate the rounding of the parameter field.

Table 1: Temperature Log Page (0Dh)

Parameter Code Description

0000h

0001h

Primary Temperature

Reference Temperature

5.2.9 Drive Self Test (DST)

Drive Self Test (DST) is a technology designed to recognize drive fault conditions that qualify the drive as a

failed unit. DST validates the functionality of the drive at a system level.

There are two test coverage options implemented in DST:

1. Extended test

2. Short text

The most thorough option is the extended test that performs various tests on the drive and scans every logical

block address (LBA) of the drive. The short test is time-restricted and limited in length—it does not scan the

entire media surface, but does some fundamental tests and scans portions of the media.

If DST encounters an error during either of these tests, it reports a fault condition. If the drive fails the test,

remove it from service and return it to Seagate for service.

5.2.9.1 DST failure definition

The drive will present a “diagnostic failed” condition through the self-tests results value of the diagnostic log

page if a functional failure is encountered during DST. The channel and servo parameters are not modified to

test the drive more stringently, and the number of retries are not reduced. All retries and recovery processes

are enabled during the test. If data is recoverable, no failure condition will be reported regardless of the number

of retries required to recover the data.

The following conditions are considered DST failure conditions:

• Seek error after retries are exhausted

• Track-follow error after retries are exhausted

• Read error after retries are exhausted

• Write error after retries are exhausted

Recovered errors will not be reported as diagnostic failures.

5.2.9.2 Implementation

This section provides all of the information necessary to implement the DST function on this drive.

5.2.9.2.1 State of the drive prior to testing

The drive must be in a ready state before issuing the Send Diagnostic command. There are multiple reasons

why a drive may not be ready, some of which are valid conditions, and not errors. For example, a drive may be

in process of doing a format, or another DST. It is the responsibility of the host application to determine the “not

ready” cause.

While not technically part of DST, a Not Ready condition also qualifies the drive to be returned to Seagate as a

failed drive.

A Drive Not Ready condition is reported by the drive under the following conditions:

• Motor will not spin

• Motor will not lock to speed

• Servo will not lock on track

• Drive cannot read configuration tables from the disc

Page 28

18 Cheetah 15K.3 FC Product Manual, Rev. D

In these conditions, the drive responds to a Test Unit Ready command with an 02/04/00 or 02/04/03 code.

5.2.9.2.2 Invoking DST

To invoke DST, submit the Send Diagnostic command with the appropriate Function Code (001b for the short

test or 010b for the extended test) in bytes 1, bits 5, 6, and 7.

5.2.9.2.3 Short and extended tests

DST has two testing options:

1. short

2. extended

These testing options are described in the following two subsections.

Each test consists of three segments: an electrical test segment, a servo test segment, and a read/verify scan

segment.

Short test (Function Code: 001b)

The purpose of the short test is to provide a time-limited test that tests as much of the drive as possible within

120 seconds. The short test does not scan the entire media surface, but does some fundamental tests and

scans portions of the media. A complete read/verify scan is not performed and only factual failures will report a

fault condition. This option provides a quick confidence test of the drive.

Extended test (Function Code: 010b)

The objective of the extended test option is to empirically test critical drive components. For example, the seek

tests and on-track operations test the positioning mechanism. The read operation tests the read head element

and the media surface. The write element is tested through read/write/read operations. The integrity of the

media is checked through a read/verify scan of the media. Motor functionality is tested by default as a part of

these tests.

The anticipated length of the Extended test is reported through the Control Mode page.

5.2.9.2.4 Log page entries

When the drive begins DST, it creates a new entry in the Self-test Results Log page. The new entry is created

by inserting a new self-test parameter block at the beginning of the self-test results log parameter section of the

log page. Existing data will be moved to make room for the new parameter block. The drive reports 20 parameter blocks in the log page. If there are more than 20 parameter blocks, the least recent parameter block will be

deleted. The new parameter block will be initialized as follows:

1. The Function Code field is set to the same value as sent in the DST command

2. The Self-Test Results Value field is set to Fh

3. The drive will store the log page to non-volatile memory

After a self-test is complete or has been aborted, the drive updates the Self-Test Results Value field in its SelfTest Results Log page in non-volatile memory. The host may use Log Sense to read the results from up to the

last 20 self-tests performed by the drive. The self-test results value is a 4-bit field that reports the results of the

test. If the field is set to zero, the drive passed with no errors detected by the DST. If the field is not set to zero,

the test failed for the reason reported in the field.

The drive will report the failure condition and LBA (if applicable) in the Self-test Results Log parameter. The

Sense key, ASC, ASCQ, and FRU are used to report the failure condition.

5.2.9.2.5 Abort

There are several ways to abort a diagnostic. You can use a SCSI Bus Reset or a Bus Device Reset message

to abort the diagnostic.

You can abort a DST executing in background mode by using the abort code in the DST Function Code field.

This will cause a 01 (self-test aborted by the application client) code to appear in the self-test results values

log. All other abort mechanisms will be reported as a 02 (self-test routine was interrupted by a reset condition).

Page 29

Cheetah 15K.3 FC Product Manual, Rev. D 19

5.2.10 Product warranty

Beginning on the date of shipment to the customer and continuing for the period specified in your purchase

contract, Seagate warrants that each product (including components and subassemblies) that fails to function

properly under normal use due to defect in materials or workmanship or due to nonconformance to the applicable specifications will be repaired or replaced, at Seagate’s option and at no charge to the customer, if returned

by customer at customer’s expense to Seagate’s designated facility in accordance with Seagate’s warranty procedure. Seagate will pay for transporting the repair or replacement item to the customer. For more detailed

warranty information, refer to the standard terms and conditions of purchase for Seagate products on your purchase documentation.

The remaining warranty for a particular drive can be determined by calling Seagate Customer Service at

1-800-468-3472. You can also determine remaining warranty using the Seagate web site (www.seagate.com).

The drive serial number is required to determine remaining warranty information.

Shipping

When transporting or shipping a drive, use only a Seagate-approved container. Keep your original box.

Seagate approved containers are easily identified by the Seagate Approved Package label. Shipping a drive in

a non-approved container voids the drive warranty.

Seagate repair centers may refuse receipt of components improperly packaged or obviously damaged in transit. Contact your authorized Seagate distributor to purchase additional boxes. Seagate recommends shipping

by an air-ride carrier experienced in handling computer equipment.

Product repair and return information

Seagate customer service centers are the only facilities authorized to service Seagate drives. Seagate does

not sanction any third-party repair facilities. Any unauthorized repair or tampering with the factory seal voids

the warranty.

Page 30

20 Cheetah 15K.3 FC Product Manual, Rev. D

Page 31

Cheetah 15K.3 FC Product Manual, Rev. D 21

6.0 Physical/electrical specifications

This section provides information relating to the physical and electrical characteristics of the drive.

6.1 AC power requirements

None.

6.2 DC power requirements

The voltage and current requirements for a single drive are shown below. Values indicated apply at the drive

connector.

Table 2: DC power requirements for operation at 1Gb mode

ST373453FC ST336753FC ST336753FC

Notes

Voltage +5V +12V [2] +5V +12V [2] +5V +12V [2]

Regulation [5] ±5% ±5% [2] ±5% ±5% [2] ±5% ±5% [2]

Avg idle current DCX

Maximum starting current

(peak DC) DC 3σ [3] 1.14 1.88 1.04 1.54 1.03 1.43

(peak AC) AC 3σ [3] 1.44 2.82 1.44 2.62 1.36 2.38

Delayed motor start (max) DC 3σ [1] [4] 0.73 0.04 0.73 0.04 0.73 0.04

Peak operating current:

Typical DCX

Maximum DC 3σ [1] 1.07 1.19 1.03 1.03 1.03 0.90

Maximum (peak) DC 3s 1.77 2.40 1.70 2.28 1.70 2.04

[1] [7] 0.95 0.66 0.93 0.53 0.93 0.41

[1] [6] 1.05 1.15 1.02 0.97 1.02 0.86

(Amps) (Amps) (Amps) (Amps) (Amps) (Amps)

[1] Measured with average reading DC ammeter. Instantaneous +12V current peaks will exceed these val-

ues. Power supply at nominal voltage. N (number of drives tested) = 6, 35 Degrees C ambient.

[2] For +12 V, a –10% tolerance is allowed during initial spindle start but must return to ±5% before reaching

14,904 RPM. The ±5% must be maintained after the drive signifies that its power-up sequence has been

completed and that the drive is able to accept selection by the host initiator.

[3] See +12V current profile in Figure 2.

[4] This condition occurs when the Motor Start option is enabled and the drive has not yet received a Start

Motor command.

[5] See paragraph 6.2.1, "Conducted noise immunity." Specified voltage tolerance includes ripple, noise, and

transient response.

[6] Operating condition is defined as random 8 block reads (ST373453 at 295, ST336753 at 306 and

ST318453 at 299) I/Os per second. Current and power specified at nominal voltages. Decreasing +5 volt

supply by 5% increases 5 volt current by 3.2%. Decreasing +12 volt supply by 5% increases 12 volt current by 2.1% (2% for ST336753 and ST318453 models).

[7] During idle, the drive heads are relocated every 60 seconds to a random location within the band from

three-quarters to maximum track.

General DC power requirement notes.

1. Minimum current loading for each supply voltage is not less than 1.7% of the maximum operating current

shown.

2. The +5V and +12V supplies should employ separate ground returns.

3. Where power is provided to multiple drives from a common supply, careful consideration for individual drive

power requirements should be noted. Where multiple units are powered on simultaneously, the peak starting current must be available to each device.

4. Parameters, other than spindle start, are measured after a 10-minute warm up.

5. No terminator power.

Page 32

22 Cheetah 15K.3 FC Product Manual, Rev. D

6.2.1 Conducted noise immunity

Noise is specified as a periodic and random distribution of frequencies covering a band from DC to 10 MHz.

Maximum allowed noise values given below are peak-to-peak measurements and apply at the drive power

connector.

+5V +12V

0 to 100 kHz 150mV 150mV

100 kHz to 10 MHz 100mV 100mV

6.2.2 Power sequencing

The drive does not require power sequencing. The drive protects against inadvertent writing during power-up

and down.

6.2.3 Current profiles

The +12V and +5V current profiles for the ST373453FC, ST336753FC, and ST318453FC models are shown

below in the following figures.

T0 Power is applied to the drive.

T1 Controller self-tests are performed.

T2 Spindle begins to accelerate under current limiting after performing internal diagnostics.