SBE 38

Digital Thermometer

User Manual, Version 013

Sea-Bird Electronics, Inc.

13431 NE 20th Street

Bellevue, Washington 98005 USA

: 425/643-9866

Tel

Fax:425/643-9954

This page intentionally left blank.

SBE 38 DIGITAL THERMOMETER OPERATING MANUAL

Manual Generation Date....................................................................................................................................................................................................................................

1

Limited Liability Statement...............................................................................................................................................................................................................................

2

Declaration of Conformity.................................................................................................................................................................................................................................

4

SBE 38 Manual - Version 013...............................................................................................................................................................................................................................

5

SBE 38 Reference Sheet - Version 004......................................................................................................................................................................................................................

38

Calibration Certificates..................................................................................................................................................................................................................................

40

SBE 38 Specification Sheet................................................................................................................................................................................................................................

45

Appnote 42ITS-90 Temperature Scale.......................................................................................................................................................................................................................

47

Appnote 56Interfacing to RS-485 Sensors..................................................................................................................................................................................................................

48

Appnote 57Connector Care.................................................................................................................................................................................................................................

50

Appnote 68USB Ports......................................................................................................................................................................................................................................

53

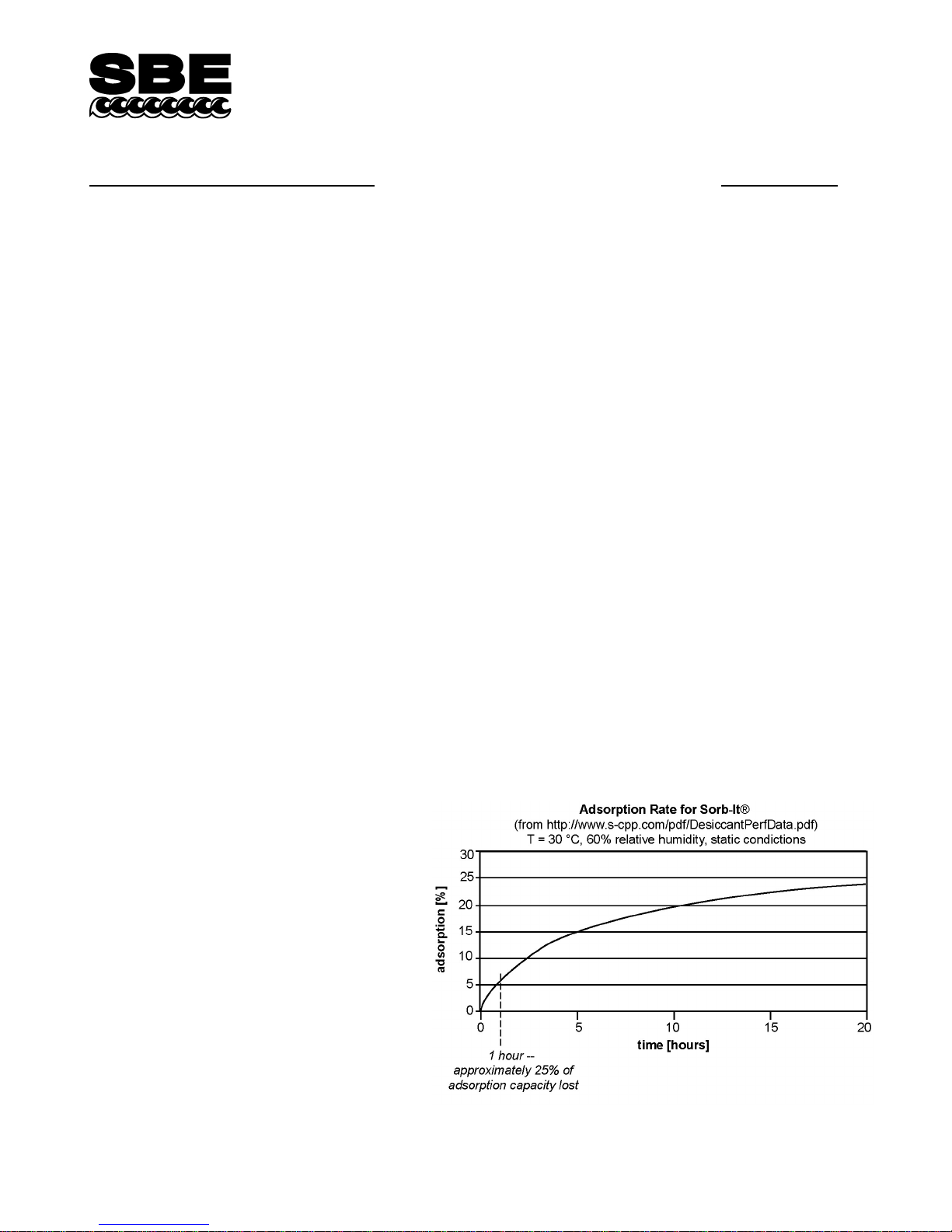

Appnote 71Desiccant Use and Regeneration.................................................................................................................................................................................................................

54

Dwg 32277ACable Assy, RMG-4FS to DB-9S with Power Leads..................................................................................................................................................................................................

60

dwg 32604B Cable Assy, RMG-4FS to DB-9S with 9V Connector...............................................................................................................................................................................................

61

Warranty..................................................................................................................................................................................................................................................

62

Service Request Form......................................................................................................................................................................................................................................

65

TABLE OF CONTENTS

SEA-BIRD ELECTRONICS, INC.

13431 NE 20th St.

Bellevue, Washington 98005 USA

Phone: (425) 643 9866

Fax: (425) 643 9954

Email: seabird@seabird.com

1

Manual Generation Date: 26 August 2011

2

L I M I T E D L I A B I L I T Y S T A T E M E N T

Extreme care should be exercised when using or servicing this equipment. It should be used or

serviced only by personnel with knowledge of and training in the use and maintenance of

oceanographic electronic equipment.

SEA-BIRD ELECTRONICS, INC. disclaims all product liability risks arising from the use or servicing of

this system. SEA-BIRD ELECTRONICS, INC. has no way of controlling the use of this equipment or of

choosing the personnel to operate it, and therefore cannot take steps to comply with laws pertaining to

product liability, including laws which impose a duty to warn the user of any dangers involved in

operating this equipment. Therefore, acceptance of this system by the customer shall be conclusively

deemed to include a covenant by the customer to defend, indemnify, and hold SEA-BIRD

ELECTRONICS, INC. harmless from all product liability claims arising from the use of servicing of this

system.

3

This page intentionally left blank.

4

5

SBE 38 Digital

Oceanographic

Thermometer

With RS-232 or optional RS-485 Interface

Note: NEW ADDRESS

as of January 2010

User’s Manual

Sea-Bird Electronics, Inc.

13431 NE 20

Bellevue, Washington 98005 USA

Telephone: +1 425-643-9866

Fax: +1 425-643-9954

E-mail: seabird@seabird.com Manual Version #013, 03-23-11

Website: www.seabird.com Firmware Version 1.4 and later

th

Street

2

6

Limited Liability Statement

Extreme care should be exercised when using or servicing this equipment. It should be used or serviced

only by personnel with knowledge of and training in the use and maintenance of oceanographic

electronic equipment.

SEA-BIRD ELECTRONICS, INC. disclaims all product liability risks arising from the use or servicing

of this system. SEA-BIRD ELECTRONICS, INC. has no way of controlling the use of this equipment

or of choosing the personnel to operate it, and therefore cannot take steps to comply with laws

pertaining to product liability, including laws which impose a duty to warn the user of any dangers

involved in operating this equipment. Therefore, acceptance of this system by the customer shall be

conclusively deemed to include a covenant by the customer to defend, indemnify, and hold SEA-BIRD

ELECTRONICS, INC. harmless from all product liability claims arising from the use or servicing of

this system.

Manual revision 013 Table of Contents SBE 38

3

Table of Contents

Section 1: Introduction ....................................................................................4

About this Manual .............................................................................................4

Quick Start .........................................................................................................4

Unpacking SBE 38 .............................................................................................5

Section 2: Description of SBE 38 ....................................................................6

System Description ............................................................................................6

Specifications .....................................................................................................7

Dimensions and End Cap Connector .................................................................8

Section 3: Preparing SBE 38 for Deployment ...............................................9

Installing Software .............................................................................................9

Power and Communications Test ......................................................................9

Test Setup ...................................................................................................9

Test ........................................................................................................... 10

Section 4: Deploying and Operating RS-232 SBE 38 .................................. 13

Sampling Modes .............................................................................................. 13

Polled Sampling ........................................................................................ 13

Continuous Sampling ................................................................................ 14

Baud Rate, Cable Length, and Power .............................................................. 15

Command Descriptions .................................................................................... 17

Data Formats .................................................................................................... 19

Deployment ...................................................................................................... 19

Recovery .......................................................................................................... 20

7

Section 5: Routine Maintenance and Calibration ....................................... 21

Corrosion Precautions ...................................................................................... 21

Connector Mating and Maintenance ................................................................ 21

Sensor Calibration ............................................................................................ 22

Glossary .......................................................................................................... 23

Appendix I: Functional Description ............................................................. 24

Sensor Interface ............................................................................................... 24

Settings ............................................................................................................ 24

Appendix II: Electronics Disassembly/Reassembly .................................... 25

Appendix III: RS-485 Interface .................................................................... 26

Operation Description ...................................................................................... 26

Command Descriptions .................................................................................... 27

RS-485 Commands ................................................................................... 27

All Other Commands ................................................................................ 28

Data Formats .................................................................................................... 28

Wiring .............................................................................................................. 29

Conversion of RS-232 to RS-485 or RS-485 to RS-232 .................................. 29

Appendix IV: RS-232 Command Summary ................................................ 30

Appendix V: Replacement Parts .................................................................. 31

Appendix VI: Manual Revision History ...................................................... 32

Index................................................................................................................ 33

4

8

Manual revision 013 Section 1: Introduction SBE 38

Section 1: Introduction

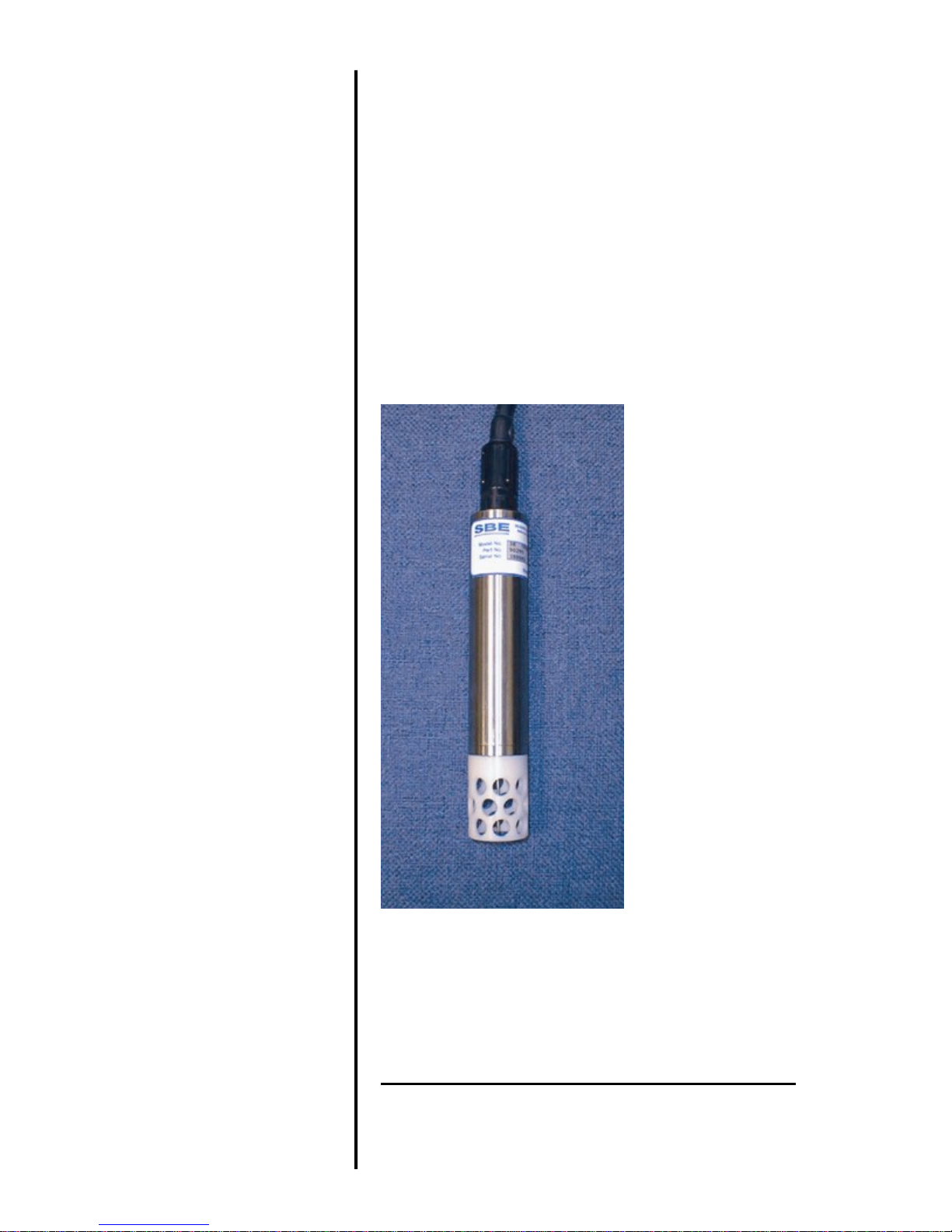

This section includes a Quick Start procedure, and photos of a standard

SBE 38 shipment.

About this Manual

This manual is to be used with the SBE 38 Digital Oceanographic

Thermometer. It is organized to guide the user from installation through

operation and data collection. We’ve included detailed specifications,

command descriptions, maintenance and calibration information, and helpful

notes throughout the manual.

Sea-Bird welcomes suggestions for new features and enhancements of our

products and/or documentation. Please contact us with any comments or

suggestions (seabird@seabird.com or 425-643-9866). Our business hours are

Monday through Friday, 0800 to 1700 Pacific Standard Time (1600 to 0100

Universal Time) in winter and 0800 to 1700 Pacific Daylight Time (1500 to

0000 Universal Time) the rest of the year.

Quick Start

Follow these steps to get a Quick Start using the SBE 38 with a standard

RS-232 interface. The manual provides step-by-step details for performing

each task:

1. Test Power and Communications (see Section 3: Preparing SBE 38

for Deployment).

2. Deploy the SBE 38 (see Section 4: Deploying and Operating RS-232 SBE 38

for a complete description of setup, or see Appendix IV: RS-232 Command

Summary):

A. Establish setup parameters.

B. Check status (DS) and calibration coefficients (DC) to verify setup.

C. Use one of the following sequences to start sampling:

• If AutoRun=N: Send Go to start sampling continuously now, or

TS or TH to take a single sample.

• If AutoRun=Y: Apply power to start sampling

continuously now.

D. Deploy SBE 38.

For an SBE 38 with optional RS-485 interface, see Appendix III: RS-485

Interface for details.

Manual revision 013 Section 1: Introduction SBE 38

5

Software, and Electronic Copies of

SBE 38

I/O Cable with 9V battery snap

User Manual

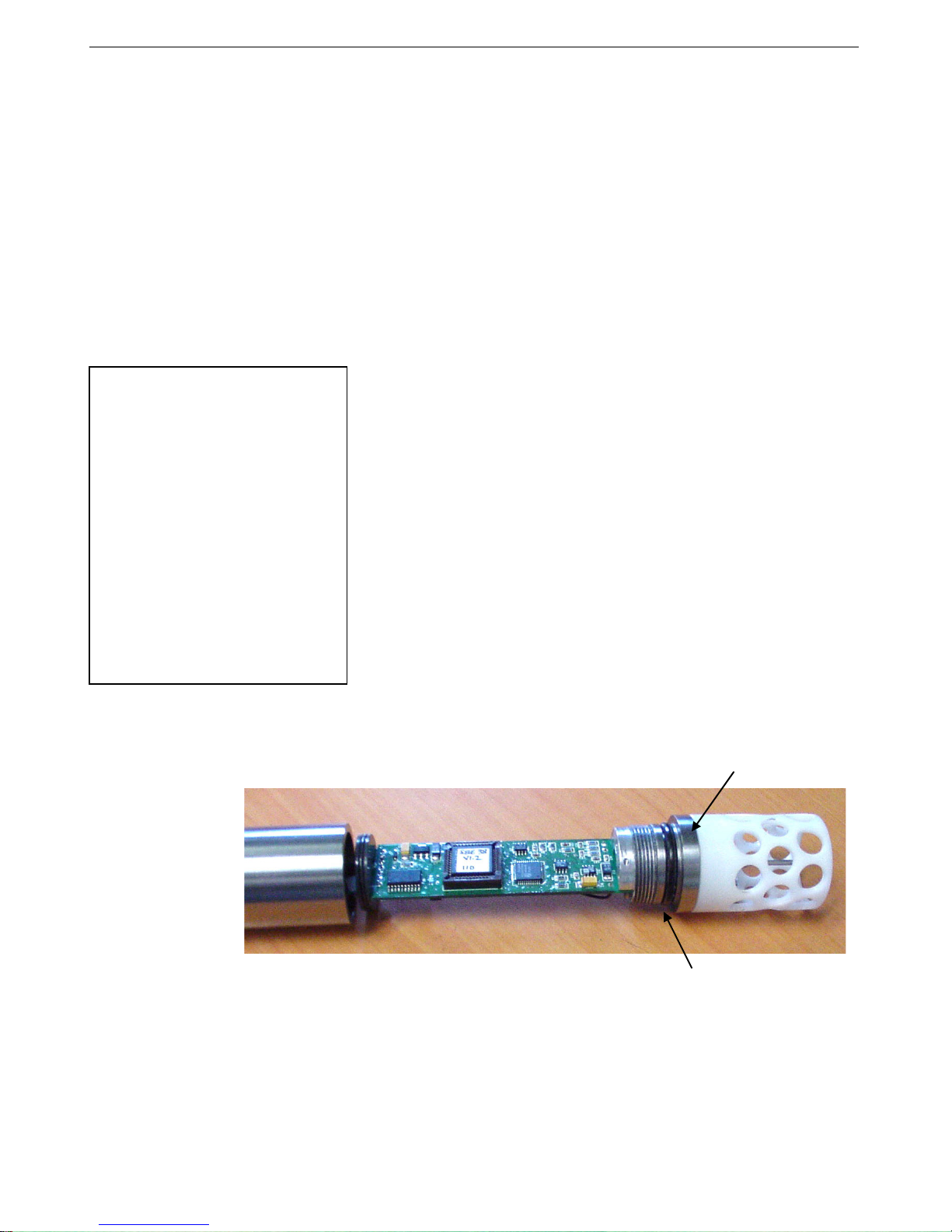

Unpacking SBE 38

Shown below is a typical SBE 38 shipment.

connector and 9V battery

SBE 38 Digital

Oceanographic

Thermometer

Software Manuals and User Manual

9

6

Notes:

10

Manual revision 013 Section 2: Description of SBE 38 SBE 38

Section 2: Description of SBE 38

This section describes the functions and features of the SBE 38, including

specifications and dimensions.

System Description

Sophisticated A/D acquisition electronics, ultra-stable thermistor, and state-ofthe-art calibration provide the standards-level performance of an expensive

AC bridge and platinum thermometer at a small fraction of the cost. The

SBE 38 is unaffected by shock and vibration, has high accuracy and stability,

and is easy to use. It has a rugged, corrosion-proof, 10,500 meter (34,400 foot)

titanium pressure housing. Real-time temperature data is transmitted in ASCII

characters (in °C or raw counts) via an RS-232 or optional RS-485 serial

interface for display or logging by PC or data logger.

The SBE 38’s measurement range is -5 to +35 °C. Absolute accuracy is better

than 0.001 °C (1 mK) and resolution is approximately 0.00025 °C (0.25 mK).

Each sensor includes certification that demonstrates drift of less than 0.001 °C

(1 mK) during a six-month period.

Applications include calibration baths, oceanographic/aquatic research, and

environmental monitoring.

The SBE 38 operates in one of three ways:

• RS-232 (full duplex) with one SBE 38 connected to the interface

• RS-485 (half duplex) with one SBE 38 connected to the interface

• RS-485 (half duplex) with several RS-485 sensors sharing one pair

of wires

On power-up, the SBE 38 reads its EEPROM, which includes calibration

coefficients and other setup information. As programmed, the SBE 38 samples

and transmits temperature continuously, or waits for a command to begin

sampling. Note that for RS-485 applications with several sensors sharing one

pair of wires, the SBE 38 cannot sample continuously.

The SBE 38 is frequently integrated as a remote temperature sensor with one

of our thermosalinograph instruments (SBE 21 Thermosalinograph or SBE 45

MicroTSG), to provide accurate sea surface temperature. See the manuals for

those instruments for integration information.

• Help files provide detailed

information on the software.

• Separate software manuals on

CD-ROM contain detailed

information on Seasave V7 and

SBE Data Processing.

• Sea-Bird supplies the current

version of our software when you

purchase an instrument. As software

revisions occur, we post the revised

software on our FTP site. See our

website (www.seabird.com) for the

latest software version number, a

description of the software changes,

and instructions for downloading the

software from the FTP site.

The SBE 38 is supplied with a powerful Win 2000/XP software package,

SEASOFT V2, which includes:

• SEATERM terminal program for easy communication.

• Seasave V7 real-time data acquisition and SBE Data Processing

post-processing programs –Seasave V7 and SBE Data Processing can be

used to view and process the entire data stream, including data from the

SBE 38, when the SBE 38 is integrated with one of the following -

- SBE 21 or 45 thermosalinograph;

- SBE 16plus, 16plus V2, or 16plus-IM V2 SEACAT C-T Recorder; or

SBE 19plus V2 SEACAT CTD Profiler.

Manual revision 013 Section 2: Description of SBE 38 SBE 38

7

°

= (0.133 * NAvg) + 0.339

Note:

Specifications

Measurement

Range

-5 to +35 °C

11

If the SBE 38 is sampling data

and the voltage is less than

6.5 volts for 10 consecutive

scans, the SBE 38 halts sampling

and displays a low battery

indication in the data.

Initial Accuracy 1

Typical Stability

Resolution

Calibration

Response Time 2

Self-Heating

Error

RMS Noise

(at temperature

equivalent of 8.5 °C)

External Power

Materials

± 0.001 °C (1 mK)

0.001 °C (1 mK) in 6 months, certified

0.00025 °C (0.25 mK)

-1 to +32 °C

500 milliseconds

less than 200 µK

NAvg Noise (

C)

1 0.000673

2 0.000408

4 0.000191

8 0.000133

16 0.000081

32 0.000052

Note:

NAvg = number of A/D cycles per sample.

Interval between samples (seconds)

RS-232 (standard):

8 – 15 VDC at 15 milliamps average

RS-485 half-duplex (optional):

8 – 15 VDC at 10 milliamps average

Titanium pressure case rated at

10,500 meters (34,400 feet)

Weight

Notes:

1

NIST-traceable calibration applying over the entire range.

2

Time to reach 63% of final value following a step change in temperature.

In water: 0.5 kg (1.2 lbs)

In air: 0.9 kg (2.0 lbs)

8

Pin Signal

12

Manual revision 013 Section 2: Description of SBE 38 SBE 38

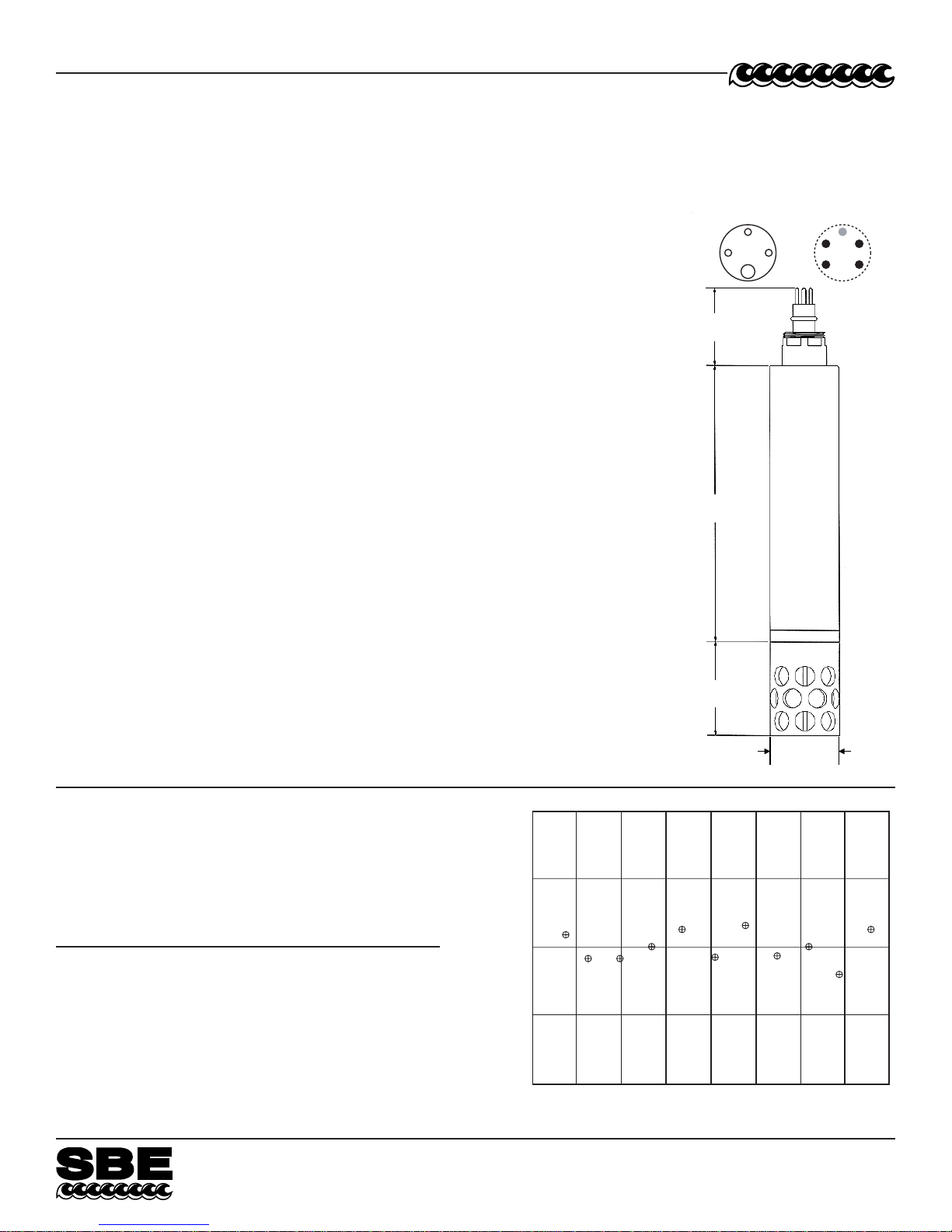

Dimensions and End Cap Connector

The SBE 38 is available with a 4-pin XSG-4-BCL-HP-SS or optional

MCBH-4MP (WB), TI (3/8” length base, ½-20 thread) (wet-pluggable)

external connector.

1 Common

2 RS-232 Receive or RS-485 A

3 RS-232 Transmit or RS-485 B

4 Power

Manual revision 013 Section 3: Preparing SBE 38 for Deployment SBE 38

9

Cable

Locking

Notes:

Section 3:

Preparing SBE 38 for Deployment

This section describes the software installation and the pre-check procedure

for preparing the SBE 38 for deployment.

Installing Software

Sea-Bird recommends the following minimum system requirements for

• Help files provide detailed

information on the software.

Separate software manuals on the

CD-ROM contain detailed

information on Seasave V7 and

SBE Data Processing.

• It is possible to use the SBE 38

without the SEATERM terminal

program by sending direct

commands from a dumb terminal or

terminal emulator, such as Windows

HyperTerminal.

• Sea-Bird supplies the current

version of our software when you

purchase an instrument. As software

revisions occur, we post the revised

software on our FTP site. See our

website (www.seabird.com) for the

latest software version number, a

description of the software changes,

and instructions for downloading the

software from the FTP site.

installing the software: Windows 2000 or later, 500 MHz processor,

256 MB RAM, and 90 MB free disk space for installation. Although

SEASOFT V2 was designed to work with a PC running Win 2000/XP;

extensive testing has not shown any compatibility problems when using the

software with a PC running Windows Vista or Windows 7 (32-bit).

If not already installed, install Sea-Bird software programs on your computer

using the supplied software CD:

1. Insert the CD in your CD drive.

2. Install software: Double click on SeasoftV2_date.exe (date is the date that

version of the software was created). Follow the dialog box directions to

install the software. The installation program allows you to install the

desired components. Install all the components, or just install SEATERM,

Seasave V7, and SBE Data Processing .

The default location for the software is c:\Program Files\Sea-Bird. Within that

folder is a sub-directory for each program.

13

Power and Communications Test

sleeve

Dummy plug

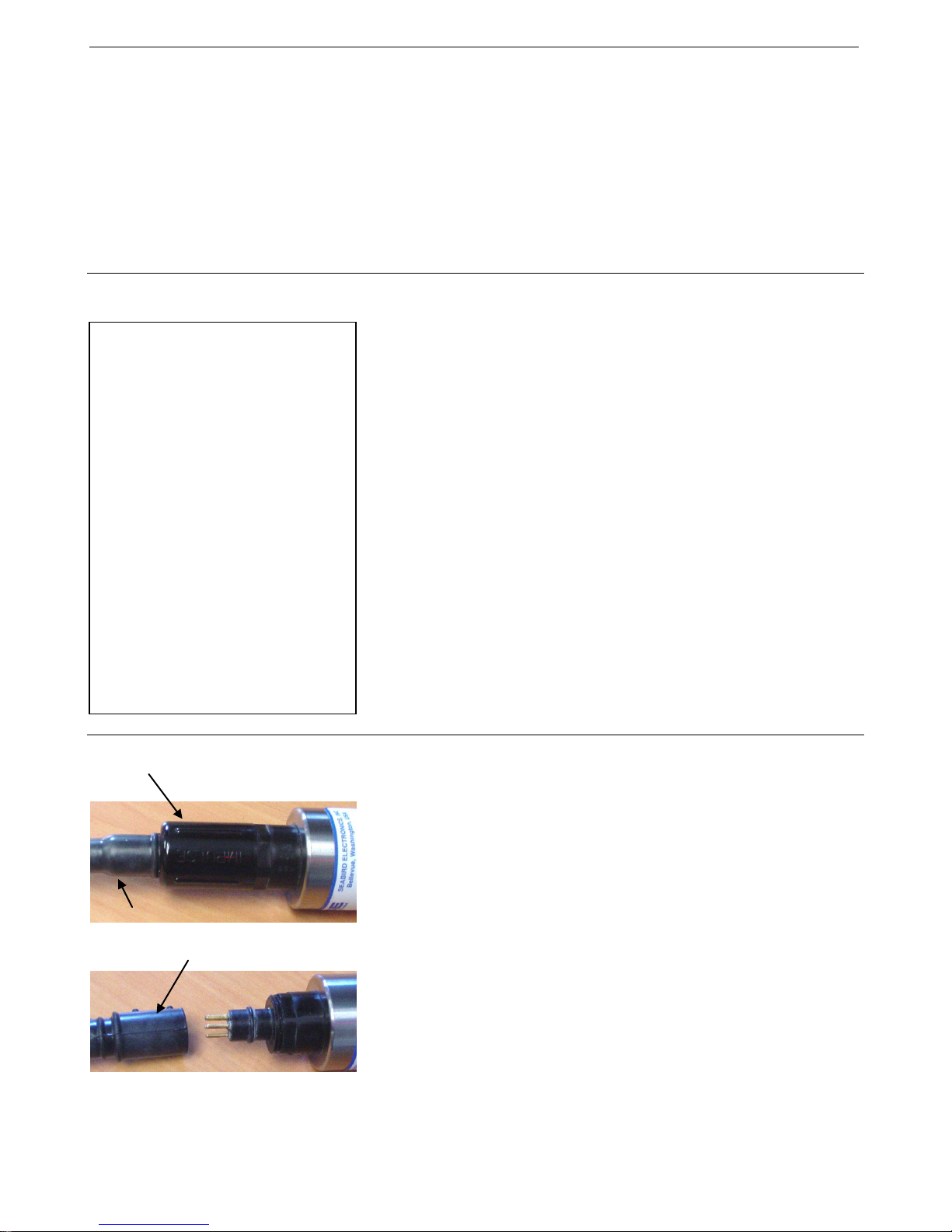

Test Setup

1. If applicable, remove locking sleeve and dummy plug from bulkhead

connector:

A. By hand, unscrew the locking sleeve from the SBE 38’s bulkhead

connector. If you must use a wrench or pliers, be careful not to

loosen the bulkhead connector instead of the locking sleeve.

B. Remove the dummy plug from the SBE 38’s bulkhead connector by

pulling the plug firmly away from the connector.

2. Install the Sea-Bird I/O cable on the SBE 38:

• XSG Connector (shown in photos) - Align the raised bump on the

side of the connector with the large pin (pin 1 - ground) on the

SBE 38.

• MCBH Connector (optional) – Align the pins.

3. Connect the I/O cable connector to your computer’s serial port.

4. Connect the I/O cable battery terminal clip to a 9-volt battery. Note that

the 9-volt battery supplied with the SBE 38 will provide approximately

50 hours of operation.

10

Note:

Note:

Note:

Status bar

Menus

Command/Data Echo Area

Toolbar

Instrument

Computer

Instrument

Baud rate, data bits,

SBE 38

14

Manual revision 013 Section 3: Preparing SBE 38 for Deployment SBE 38

Test

See SEATERM’s help files.

1. Double click on SeaTerm.exe. If this is the first time the program is used,

the setup dialog box may appear:

Select the instrument type (SBE 38) and the computer COM port for

communication with the SBE 38. Click OK.

2. The main screen looks like this:

There is at least one way, and as

many as three ways, to enter

a command:

• Manually type a command in

Command/Data Echo Area

• Use a menu to automatically

generate a command

• Use a Toolbar button to

automatically generate

a command

Once the system is configured and

connected (Steps 3 through 5

below), to update the Status bar:

• on the Toolbar, click Status; or

• from the Utilities menu, select

Instrument Status.

SEATERM sends the status

command, which displays in the

Command/Data Echo Area, and

updates the Status bar.

Capture

to file

status –

grayed

COM port

EPROM version

stop bits, and parity

out if not

capturing

• Menus – Contains tasks and frequently executed instrument

commands.

• Toolbar – Contains buttons for frequently executed tasks and

instrument commands. All tasks and commands accessed through the

Toolbar are also available in the Menus. To display or hide the

Toolbar, select View Toolbar in the View menu. Grayed out Toolbar

buttons are not applicable.

• Command/Data Echo Area – Echoes a command executed using a

Menu or Toolbar button, as well as the instrument’s response.

Additionally, a command can be manually typed in this area, from the

available commands for the instrument. Note that the instrument must

be awake for it to respond to a command (use Connect on the Toolbar

to wake up the instrument).

• Status bar – Provides status information. To display or hide the Status

bar, select View Status bar in the View menu.

Manual revision 013 Section 3: Preparing SBE 38 for Deployment SBE 38

11

Toolbar

Button

Equivalent

Command*

Re-establish communications with SBE 38.

(press Enter

Display instrument setup and status (number of

Coefficients

Display calibration coefficients.

DC

Capture instrument responses on screen to file.

Status bar.

Free computer COM port used to communicate

another program.

and SBE 38

Interface for communication

SBE 38

Notes:

Following are the Toolbar buttons applicable to the SBE 38:

Description

15

Connect

Capture

Disconnect

*See Command Descriptions in Section 4: Deploying and Operating

RS-232 SBE 38.

3. In the Configure menu, select SBE 38. The dialog box looks

like this:

Computer COM port, baud rate,

data bits, and parity for

communication between computer

Status

Computer responds with S> prompt.

A/D cycles per sample, sampling status, etc.).

File has .cap extension. Press Capture again to

turn off capture. Capture status displays in

with SBE 38. COM port can then be used by

between computer and

key)

DS

—

—

• SEATERM’s baud rate must be the

same as the SBE 38 baud rate (set

with Baud=). Baud= is factory-set to

9600, but can be changed by the user

(see Command Descriptions in

Section 4: Deploying and Operating

RS-232 SBE 38).

• When you click OK, SEATERM saves

the Configuration Options settings to

the SeaTerm.ini file in your Windows

directory. SeaTerm.ini contains the last

saved settings for each instrument.

When you open SEATERM and select

the desired instrument (SBE 38, 39,

etc.) in the Configure menu, the

Configuration Options dialog box

shows the last saved settings for that

instrument.

Make the selections in the Configuration Options dialog box:

• COMM Port: COM 1 through COM 10, as applicable

• Baud Rate: 9600 (documented on Configuration Sheet)

• Data Bits: 8

• Parity: None

• Mode: RS-232 (Full Duplex) or RS-485 (Half Duplex)

Click OK to save the settings.

12

Note:

16

Manual revision 013 Section 3: Preparing SBE 38 for Deployment SBE 38

4. In the Communications menu, select Options / Cycle baud

when connecting.

5. Click Connect on the Toolbar. SEATERM tries to connect to the SBE 38

at the baud set in Step 3. If it cannot, it cycles through all other possible

baud rates to try to connect. When it connects, the display looks like this:

SBE 38 V 1.4 S/N 0090 (this line may not appear)

S>

This shows that correct communications between the computer and the

SBE 38 has been established.

If the system does not provide the S> prompt:

• Click Connect again.

• Verify the correct instrument was selected in the Configure menu and

the settings were entered correctly in the Configuration Options

dialog box. Note that the baud rate’s factory setting is documented on

the Configuration Sheet in this manual.

• Check cabling between the computer and the SBE 38.

6. Display SBE 38 status information by clicking Status on the Toolbar. The

display looks like this:

See Appendix III: RS-485 Interface

for details on sending commands to

an SBE 38 with optional RS-485

interface.

SBE 38 V 1.4 S/N = 0090

NAVG=1

Not sampling data

Automatically start sampling on power up

Default interface is RS-232

7. Command the SBE 38 to take a sample by typing TS and pressing the

Enter key. The display looks like this if the output format was set to

converted data (Format=C) with 4 digits to the right of the decimal place

(Digits=4):

23.7658

where 23.7658 = temperature in degrees Celsius

This number should be reasonable; i.e., room temperature.

The SBE 38 is ready for programming and deployment.

Manual revision 013 Section 4: Deploying and Operating RS-232 SBE 38 SBE 38

13

Example: (user input in bold)

S>TS

Note:

Section 4:

Deploying and Operating RS-232 SBE 38

This section includes:

See Appendix III: RS-485 Interface

for details on deploying and

operating an SBE 38 with optional

RS-485 interface.

Sampling Modes

• system operation description, including example sets of

operation commands

• baud rate, cable length, and power limitations

• detailed command descriptions

• data formats

• instructions for deploying and recovering the SBE 38

The SBE 38 has two sampling modes:

• Polled Sampling – take a single sample on command

• Continuous Sampling – sample continuously; start when power is applied

or on command, depending on the setup

Descriptions and examples follow for an SBE 38 with RS-232 Interface. Note

that the SBE 38’s response to each command is not shown in the examples.

Review the sampling modes and the commands described in Command

Descriptions before setting up your system.

Polled Sampling

The SBE 38 takes one sample of data on command. Transmission of data to

the computer is dependent on the particular command used.

17

Apply power and establish communications. Set up to average 4 measurements per sample and output converted

data with 3 digits after decimal place. Command SBE 38 to take a sample and send data to computer.

(Apply power and then click Connect on Toolbar.)

S>NAVG=4

S>FORMAT=C

S>DIGITS=3

S>DS (to verify setup)

14

Example: Continuous Sampling (user input in bold)

18

Manual revision 013 Section 4: Deploying and Operating RS-232 SBE 38 SBE 38

Example 1 AutoRun=N: Apply power and establish communications. Set up to average 4 measurements per sample and output

converted data with 3 digits after decimal place. Set up to wait for a command when power is applied. Remove power.

(Apply power and then click Connect on Toolbar.)

S>NAVG=4

S>FORMAT=C

S>DIGITS=3

S>AUTORUN=N

S>DS (to verify setup)

(Remove power.)

When ready to start sampling, apply power and establish communications. Send command to start sampling continuously,

outputting real-time data. When desired, send command to stop sampling.

(Apply power and then click Connect on Toolbar.)

S>GO

S>STOP (You may need to send Stop several times to interrupt sampling.)

Example 2 AutoRun=Y: Apply power and establish communication. Set up to average 4 measurements per sample and output

converted data with 3 digits after decimal place. Set up to automatically begin sampling when power is applied. Remove power.

(Apply power and then click Connect on Toolbar.)

S>NAVG=4

S>FORMAT=C

S>DIGITS=3

S>AUTORUN=Y

S>DS (to verify setup)

(Remove power.)

To start sampling, apply power. SBE 38 begins sampling continuously, outputting real-time data.

To stop sampling, remove power.

To change setup: apply power, and then stop sampling by command.

(Apply power)

(Press Enter key to get S> prompt)

S>STOP (You may need to send Stop several times to interrupt sampling.)

(Enter commands as desired to change setup.)

Continuous Sampling

The SBE 38 continuously samples and transmits real-time data.

Sampling is started by:

• Sending Go, or

• Setting AutoRun=Y. If AutoRun=Y, sampling automatically starts when

power is applied.

Sampling is stopped by:

• Sending Stop, or

• Removing power.

Manual revision 013 Section 4: Deploying and Operating RS-232 SBE 38 SBE 38

15

Maximum Cable Length (meters)

Maximum Baud Rate

800

1200

400

2400

200

4800

100

9600

Example 1 – For 18 gauge wire, what is maximum distance to transmit power to RS-232 SBE 38?

Note:

Baud Rate, Cable Length, and Power

On the ship, cables longer than 3 meters should be installed inside an earthed

metal conduit by a qualified electrician. This minimizes the potential for

external signals to disrupt communication and ensures that high voltage lines

(such as the sea cable) are sufficiently protected. Cables shorter than 3 meters

can be used without shielding when installing or bench testing the instrument.

Notes:

• Baud rate is set with Baud=

(see Command Descriptions in

this section).

• For RS-485, see Appendix III:

RS-485 Interface for

baud rate limitations.

Common wire resistances:

Gauge Resistance (ohms/foot)

12 0.0016

14 0.0025

16 0.0040

18 0.0064

19 0.0081

20 0.0107

22 0.0162

24 0.0257

26 0.0410

28 0.0653

Baud Rate and Cable Length

For RS-232, the length of cable that the SBE 38 can drive to transmit real-time

data is dependent on the baud rate. The allowable combinations are:

Power and Cable Length

There are two issues to consider:

• Limiting the IR loss to 1 volt; higher IR loss will prevent the

instrument from transmitting real-time data because of the difference in

ground potential.

• Supplying enough power at the power source so that sufficient power is

available at the instrument after considering IR loss.

Looking at each issue separately:

Limiting IR Loss to 1 Volt

The limit to cable length is typically reached when the maximum current times

the power common wire resistance is more than 1 volt, because the difference

in ground potential of the SBE 38 and ground controller prevents the SBE 38

from transmitting real-time data.

= 1 volt = IR

V

limit

Where

I = current required by SBE 38 (15 mA for RS-232; 10 mA for RS-485).

Maximum cable length = R

limit

/ wire resistance per foot

limit

19

Is this controlling factor for maximum cable length if wanting to transmit at 1200 baud?

R

= V

limit

For 18 gauge wire, resistance is 0.0064 ohms/foot.

Therefore, maximum cable length is 67 ohms / 0.0064 ohms/foot = 10417 feet = 3176 meters.

Note that 3176 meters > 800 meters (maximum distance SBE 38 can transmit data at 1200 baud), so IR loss is not

controlling factor for this example.

Example 2 – Same as above, but there are 4 SBE 38s powered from the same power supply.

R

limit

For 18 gauge wire, resistance is 0.0064 ohms/foot.

Therefore, maximum cable length is 17 ohms / 0.0064 ohms/foot = 2604 feet = 794 meters (cable length to SBE 38

furthest from power source).

/ I = 1 volt / 0.015 Amps = 67 ohms

limit

= V

/ I = 1 volt / (0.015 Amps * 4 SBE 38s) = 17 ohms

limit

16

20

Manual revision 013 Section 4: Deploying and Operating RS-232 SBE 38 SBE 38

Supplying Enough Power to SBE 38

Another consideration in determining maximum cable length is supplying

enough power at the power source so that sufficient voltage is available, after

the IR loss in the cable, to power the SBE 38.

Example 1 – For 18 gauge wire, what is maximum distance to transmit power to RS-232 SBE 38 if using 8.5 volt power

source to supply power? Is this controlling factor for maximum cable length if wanting to transmit at 1200 baud?

SBE 38’s input power specification is 8 – 15 volts. Therefore, a 0.5 volt IR drop (8.5 volts – 8 volts) would still provide

enough power to SBE 38.

V = IR 0.5 volts = (0.015 Amps) * (0.0064 ohms/foot * cable length) Cable length = 5208 ft = 1588 meters

Note that 1588 meters > 800 meters (maximum distance SBE 38 can transmit data at 1200 baud), so IR drop in power is

not controlling factor for this example.

Example 2 – Same as above, but there are 4 SBE 38s powered from the same power supply.

V = IR 0.5 volts = (0.015 Amps * 4 SBE 38s) * (0.0064 ohms/foot * cable length)

Cable length = 1302 ft = 397 meters (cable length to SBE 38 furthest from power source).

Note that 397 meters < 800 meters (maximum distance SBE 38 can transmit data at 1200 baud), so IR drop in power is

controlling factor for this example. Using a higher voltage power supply or a different wire gauge (12 or 14 gauge) would

provide sufficient power at SBE 38 to allow 800 meter cable length.

Manual revision 013 Section 4: Deploying and Operating RS-232 SBE 38 SBE 38

17

Example: (user input in bold).

Default interface is RS-232

Note:

Note:

Note:

Go

Notes:

Command Descriptions

This section describes commands and provides sample outputs. See

Appendix IV: RS-232 Command Summary for a summarized command list.

When entering commands:

• Input commands to the SBE 38 in upper or lower case letters and register

commands by pressing the Enter key.

• The SBE 38 sends ? CMD if an invalid command is entered.

• If the system does not return an S> prompt after executing a command,

press the Enter key to get the S> prompt.

Equivalent to Status on Toolbar.

Description in example includes, where applicable,

command used to modify parameter.

If the voltage is below 6.5 volts, the

following displays in response to DS:

WARNING: LOW BATTERY VOLTAGE!!

Status Command

DS Display status and setup parameters.

21

S>DS

SBE 38 V 1.4 S/N = 0090 (firmware version, serial number)

NAVG=1 (number of A/D cycles to average for each sample [NAvg=])

Not sampling data (sampling status)

Automatically start sampling on power up (sampling start-up mode [AutoRun=])

The SBE 38’s baud (set with Baud=)

must be the same as SEATERM’s

baud rate (set in Configure menu).

• The SBE 38 transmits data after it

has completed the previous sample

and before it starts the next sample.

• For continuous sampling with an

RS-485 interface, set NAvg > 30.

See Appendix III: RS-485 Interface.

After you send AutoRun=Y, to start

sampling immediately:

• Turn power off and then on again, or

• Send

(RS-232 or RS-485 interface [Interface=])

Setup Commands

Interface=x x=232: Set interface to RS-232.

x=485: Set interface to RS-485. See Appendix III:

RS-485 Interface for all details.

Baud=x x= baud rate (1200, 2400, 4800, 9600).

Default 9600.

Format=x x=C: Output converted data (°C).

x=R: Output raw data (counts).

Digits=x x= number of digits (0 – 6) to right of decimal point

for converted temperature (°C). Applicable only if

Format=C.

NAvg=x x= number of A/D cycles to average per sample

(1 – 127).

Time between samples (seconds)

= (0.133 * NAvg) + 0.339

(Time between samples for continuous sampling;

minimum time required for each polled sample.)

AutoRun=x x=N: Wait for a command when power is applied.

x=Y: Start continuous sampling automatically when

power is applied.

.

18

Example: Display coefficients for SBE 38 (user input in bold).

Notes:

Note:

Note:

Notes:

the status to low battery.

22

Manual revision 013 Section 4: Deploying and Operating RS-232 SBE 38 SBE 38

Sampling Commands

• To capture real-time data to a file,

do this before starting sampling:

1. Click Toolbar’s Capture button.

2. Enter desired file name in

dialog box. Capture status

displays in status bar at bottom

of screen.

• If the SBE 38 is sampling data and

the voltage is less than 6.5 volts for

ten consecutive scans, the

SBE 38 halts sampling and sets

These commands are used to request data from the SBE 38.

For all sampling commands:

• Output format is determined by Format= and Digits=.

• Number of A/D cycles per sample is defined by NAvg.

Go Start sampling data continuously, and transmit data

real-time.

Time between samples (seconds)

= (0.133 * NAvg) + 0.339

Stop Stop continuous sampling. Press Enter key to get

S> prompt before entering Stop.

You may need to send Stop several

times to get the SBE 38 to respond.

TS Take 1 sample and transmit data.

TH Take 1 sample and hold data in SBE 38 buffer.

SH Transmit data that was held in SBE 38 buffer.

SL Transmit data from last sample from

SBE 38 buffer.

SLT Transmit data from last sample from SBE 38

buffer, and then take 1 new sample and hold data

in buffer.

Calibration Coefficients Commands

DC Display calibration coefficients.

• Date shown is when calibration

was performed. Calibration

coefficients are initially factory-set

and should agree with Calibration

Certificate shipped with SBE 38.

• See individual Coefficient

Commands below for definitions of

the data in the example.

S>DC

SBE 38 V 1.4 S/N = 0090

Cal Date: 08-apr-96

A0 =-9.420702e-05

A1 = 2.937924e-04

A2 =-3.739471e-06

A3 = 1.909551e-07

Slope = 1.000000

Offset = 0.0000

Equivalent to Coefficients on Toolbar.

The individual Coefficient Commands listed below modify a particular

coefficient or date:

F = floating point number

S = string with no spaces

TCalDate=S

A0=F

A1=F

A2=F

A3=F

Slope=F F=Temperature slope (default 1.0)

Offset=F F=Temperature offset (°C) (default 0.0)

S=Temperature calibration date

F=Temperature A0

F=Temperature A1

F=Temperature A2

F=Temperature A3

Manual revision 013 Section 4: Deploying and Operating RS-232 SBE 38 SBE 38

19

Notes:

CAUTION:

Locking sleeve

I/O cable

Data Formats

Converted Data (Format=C)

• Each line of output is followed by

a carriage return and line feed.

• For converted data, leading zeros

for temperature output are

suppressed, except for one zero

to the left of the decimal point

(for example, 0.1034).

• See Appendix III: RS-485

Interface for data output format

for an SBE 38 with optional

RS-485 interface.

ttt.ttt

where:

t = temperature (degrees Celsius, ITS-90)

Number of digits to right of decimal point is defined by Digits=.

Raw Data (Format=R)

nnnnnn.n

where:

n= counts

Deployment

1. Install the I/O cable:

Do not use WD-40 or other

petroleum-based lubricants, as they

will damage the connector.

A. Lightly lubricate the inside of the cable connector with silicone

grease (DC-4 or equivalent).

B. XSG Connector (shown in photo) - Install the cable connector,

aligning the raised bump on the side of the connector with the large

pin (pin 1 - ground) on the SBE 38. Remove any trapped air by

burping or gently squeezing the connector near the top and moving

your fingers toward the end cap. OR

MCBH Connector (optional) – Install the cable connector,

aligning the pins.

C. Place the locking sleeve over the connector. Tighten the locking

sleeve finger tight only. Do not overtighten the locking sleeve and

do not use a wrench or pliers.

2. Mount the SBE 38.

3. Verify that the hardware and external fittings are secure.

4. Use one of the following sequences to start sampling:

• If AutoRun=N: Send Go to start sampling continuously now, or TS

or TH to take a single sample.

• If AutoRun=Y: Apply power to start sampling continuously now.

5. Deploy the SBE 38.

23

20

WARNING!

24

Manual revision 013 Section 4: Deploying and Operating RS-232 SBE 38 SBE 38

Recovery

If the SBE 38 stops working while

underwater, is unresponsive to

commands, or shows other signs of

flooding or damage, carefully

secure it away from people until you

have determined that abnormal

internal pressure does not exist or

has been relieved. Pressure housings

may flood under pressure due to dirty

or damaged o-rings, or other failed

seals. When a sealed pressure

housing floods at great depths and is

subsequently raised to the surface,

water may be trapped at the pressure

at which it entered the housing,

presenting a danger if the housing is

opened before relieving the internal

pressure. Instances of such flooding

are rare. However, a housing that

floods at 5000 meters depth holds

an internal pressure of more than

7000 psia, and has the potential to

eject the end cap with lethal force.

A housing that floods at 50 meters

holds an internal pressure of more

then 85 psia; this force could still

cause injury.

If you suspect the SBE 38 is flooded,

point it in a safe direction away from

people, and loosen the bulkhead

connector very slowly, at least 1 turn.

This opens an o-ring seal under the

connector. Look for signs of internal

pressure (hissing or water leak). If

internal pressure is detected, let it

bleed off slowly past the connector

o-ring. Then, you can safely remove

the end cap.

1. Use one of the following sequences to stop sampling:

• Press Enter key to get S> prompt, and then send Stop to stop

sampling continuously. OR

• Remove power.

2. Rinse the SBE 38 with fresh water, and dry thoroughly.

Manual revision 013 Section 5: Routine Maintenance and Calibration SBE 38

21

CAUTION:

Note:

Section 5: Routine Maintenance

and Calibration

This section reviews corrosion precautions, connector mating and

maintenance, and sensor calibration. The SBE 38’s accuracy is sustained

by the care and calibration of the sensor and by establishing proper

handling practices.

Corrosion Precautions

All exposed materials are titanium or plastic. No corrosion precautions are

required, but direct electrical connection of the SBE 38 housing to mooring or

other dissimilar metal hardware should be avoided. Rinse the SBE 38 with

fresh water after use and prior to storage.

25

Connector Mating and Maintenance

See Application Note 57: Connector

Care and Cable Installation.

Do not use WD-40 or other

petroleum-based lubricants, as they

will damage the connector.

Clean and inspect the connectors, cable, and dummy plug before every

deployment and as part of your yearly equipment maintenance. Inspect

connectors that are unmated for signs of corrosion product around the pins,

and for cuts, nicks or other flaws that may compromise the seal.

When remating:

1. Lightly lubricate the inside of the cable connector with silicone grease

(DC-4 or equivalent).

2. XSG Connector - Install the cable connector, aligning the raised bump on

the side of the plug/cable connector with the large pin (pin 1 - ground) on

the SBE 38. Remove any trapped air by burping or gently squeezing the

connector near the top and moving your fingers toward the end cap. OR

MCBH Connector (optional) - Install the cable connector, aligning

the pins.

3. Place the locking sleeve over the cable connector. Tighten the locking

sleeve finger tight only. Do not overtighten the locking sleeve and do

not use a wrench or pliers.

Verify that a cable is installed on the SBE 38 before deployment.

22

26

Manual revision 013 Section 5: Routine Maintenance and Calibration SBE 38

Sensor Calibration

Sea-Bird sensors are calibrated by subjecting them to known physical

conditions and measuring the sensor responses. Coefficients are then

computed, which may be used with appropriate algorithms to obtain

engineering units. The temperature sensor on the SBE 38 is supplied fully

calibrated, with coefficients printed on the Calibration Certificate (see back of

manual). These coefficients have been stored in the SBE 38’s EEPROM.

We recommend that the SBE 38 be returned to Sea-Bird for calibration.

The primary source of temperature sensor calibration drift is the aging of the

thermistor element. Sensor drift is not substantially dependent upon the

environmental conditions of use, and — unlike platinum or copper elements

— the thermistor is insensitive to shock.

Sea-Bird’s Calibration Methodology

The SBE 38 is calibrated in Sea-Bird’s state-of-the-art calibration laboratory,

which maintains primary temperature standards (water triple point [TPW] and

gallium melting point [GaMP] cells), ITS-90 certified and standards-grade

platinum resistance thermometers, and a low-gradient temperature bath.

Temperature is computed using the Steinhart-Hart polynomial for thermistors

(Steinhart and Hart, 1968; Bennett, 1972), which is based on thermistor

physics. The equation characterizes the non-linear temperature versus

resistance response of the sensor. Note that thermistors require individualized

coefficients to the Steinhart-Hart equation, because the thermistor material is

an individualized mix of dopants:

t90 = 1.0 - 273.15 * Slope + Offset [°C]

a0 + a1 * [ln(n)] + a2 * [ln

2

(n)] + a3 * [ln

where

n = SBE 38 raw output (counts).

3

(n)]

Manual revision 013 Glossary SBE 38

23

Note:

Glossary

PCB – Printed Circuit Board.

SBE 38 – High-accuracy digital oceanographic thermometer.

SBE Data Processing – Sea-Bird’s Win 2000/XP data processing

All Sea-Bird software listed was

designed to work with a computer

running Windows 2000/XP. Extensive

testing has not shown any compatibility

problems when using the software with

a computer running Windows Vista or

Windows 7 (32-bit).

software, which calculates and plots measured and derived variables.

SBE Data Processing can be used to view and process the entire data stream,

including data from the SBE 38, when the SBE 38 is integrated with one of

the following:

• SBE 21 or 45 thermosalinograph,

• SBE 16plus, 16plus V2, or 16plus -IM V2 C-T Recorder

• SBE 19plus V2 CTD Profiler

Scan – One data sample.

Seasave V7 – Sea-Bird’s Win 2000/XP software used to acquire, convert,

and display real-time or archived raw data. Seasave V7 can be used to view

and process the entire data stream, including data from the SBE 38, when the

SBE 38 is integrated with one of the following:

• SBE 21 or 45 thermosalinograph,

• SBE 16plus, 16plus V2, or 16plus -IM V2 C-T Recorder

• SBE 19plus V2 CTD Profiler

SEASOFT V2 – Sea-Bird’s complete Win 2000/XP software package, which

includes software for communication, real-time data acquisition, and data

analysis and display. SEASOFT V2 includes SEATERM, SeatermAF,

SeatermV2, Seasave V7, SBE Data Processing, and Plot39.

SEATERM – Sea-Bird’s Win 95/98/NT/2000/XP terminal program used to

communicate with the SBE 38.

27

24

28

Manual revision 013 Appendix I: Functional Description SBE 38

Appendix I: Functional Description

Sensor Interface

Temperature is acquired by applying an AC excitation to a hermetically sealed

VISHAY reference resistor and an ultra-stable aged thermistor with a drift rate

of less than 0.002°C per year. A 24-bit A/D converter digitizes the outputs of

the reference resistor and thermistor. AC excitation and ratiometric

comparison using a common processing channel avoids errors caused by

parasitic thermocouples, offset voltages, leakage currents, and reference errors.

Maximum power dissipated in the thermistor is 0.5 microwatts, and

contributes less than 200 µK of overheat error.

A raw count (ratio) is related to resistance measurements:

raw counts = 1048576 * (NT) / (NR)

where

NR = output from reference resistor

NT = thermistor output

The SBE 38’s output is computed from the raw count and the calibration

coefficients that are stored in EEPROM.

The number of acquisition cycles (raw counts) averaged per measurement is

user-programmable (NAvg=; see Section 4: Deploying and Operating

RS-232 SBE 38). Increasing the number of cycles per measurement increases

the time to acquire the measurement and the interval between measurements,

while reducing the RMS temperature noise from the sensor. The interval

between measurements is:

interval [seconds] = (0.133 * NAvg) + 0.339

where

NAvg = number of acquisition cycles per measurement

The SBE 38 transmits data after it has completed the previous sample and

before it starts the next sample.

Time to transmit data = (number of characters * 10 bits/character) / baud rate

where

number of characters is dependent on the output format. Include the decimal

point when counting characters; add 2 to the number of characters output, to

account for the carriage return and line feed at the end of each scan.

Settings

Calibration coefficients and setup parameters (Baud=, NAvg=, Interface=,

etc.) are written to EEPROM and are non-volatile. These settings do not

change if power is removed.

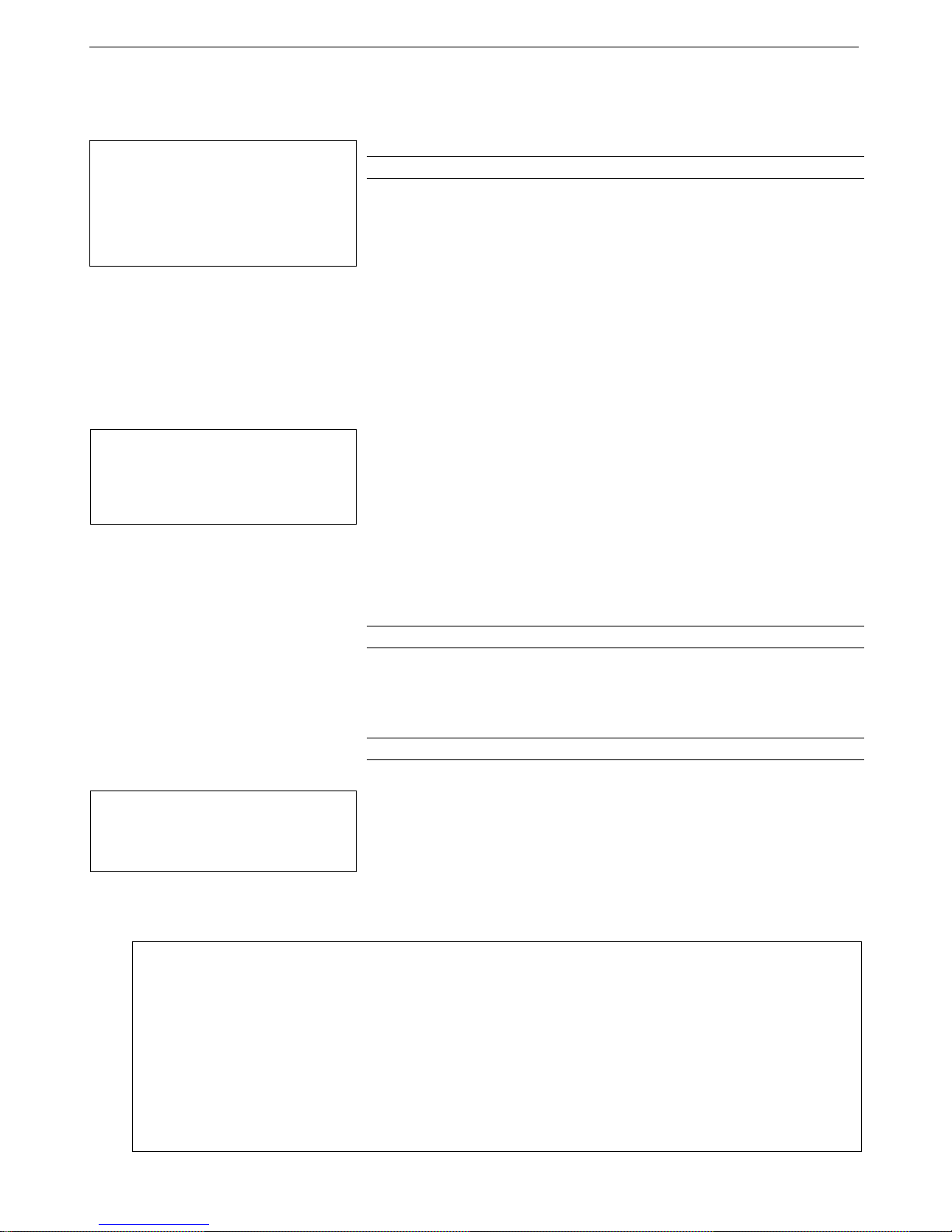

Manual revision 013 Appendix II: Electronics Disassembly/Reassembly SBE 38

25

Note:

from the chamber.

End cap

O-ring

Appendix II: Electronics

Disassembly/Reassembly

1. Remove the titanium end cap and electronics from the housing as follows:

A. Wipe the outside of the end cap and housing dry, being careful to

remove any water at the seam between them.

B. Unscrew the end cap.

C. Pull the end cap and attached electronics out of the housing. Note that

the PCB is electrically connected to the I/O connector.

D. Remove any water from the end cap O-ring and mating surfaces

Before delivery, a desiccant bag is

placed in the housing, and the

electronics chamber is filled with dry

Argon gas. These measures help

prevent condensation.

To ensure proper functioning:

1. Install a new desiccant bag

each time you open the

housing. If a new bag is not

available, see Application

Note 71: Desiccant Use and

Regeneration (drying).

2. If possible, dry gas backfill each

time you open the housing. If you

cannot, wait at least 24 hours

before redeploying, to allow the

desiccant to remove any moisture

2. Reinstall the end cap and electronics in the housing as follows:

inside the housing with a lint-free cloth or tissue.

E. Be careful to protect the O-ring from damage or contamination.

A. Remove any water from the O-ring and mating surfaces in the

housing with a lint-free cloth or tissue. Inspect the O-ring and mating

surfaces for dirt, nicks, and cuts. Clean as necessary. Apply a light

coat of O-ring lubricant (Parker Super O Lube) to O-ring and

mating surfaces.

B. Carefully fit the electronics into the housing.

C. Screw the end cap into the housing.

29

26

Example: Wake up all SBE 38s. Set up all SBE 38s to average 40 measurements per sample and output

Notes:

30

Manual revision 013 Appendix III: RS-485 Interface SBE 38

Appendix III: RS-485 Interface

Operation Description

Commands can be directed to one SBE 38 or globally to all SBE 38s. If

• IDReq=Y does not require a #ii

prefix. IDReq=N does require a #ii

prefix (#iiIDReq=N).

• For customers using their own

terminal program software:

Terminate all commands with CR

only, not CRLF.

converted data with 3 digits to the right of the decimal place. Command all SBE 38s to take a sample and hold

data in buffer, and then command each SBE 38 to transmit data from buffer. Repeat sampling sequence a number

of times. (user input in bold)

(Apply power and click Connect on Toolbar to wake up all SBE 38s.)

S>IDREQ=Y (command to require ID prefix)

S>#01NAVG=40 (set number of measurements per sample to 40 for SBE 38 with ID=01)

S>#02NAVG=40 (set number of measurements per sample to 40 for SBE 38 with ID=02)

S>#01FORMAT=C (set output format to converted data for SBE 38 with ID=01)

S>#02FORMAT=C (set output format to converted data for SBE 38 with ID=02)

S>#01DIGITS=3 (set number of digits to right of decimal point to 3 for SBE 38 with ID=01)

S>#02DIGITS=3 (set number of digits to right of decimal point to 3 for SBE 38 with ID=02)

S>#01DS (verify setup with status command for SBE 38 with ID=01)

S>#02DS (verify setup with status command for SBE 38 with ID=02)

S>GDATA (global command to all SBE 38s to take sample and hold data in buffer)

S>DATA01 (get data from buffer of SBE 38 with ID=01)

S>DATA02 (get data from buffer of SBE 38 with ID=02)

(Repeat GDATA through DATA02 as desired)

IDReq=Y, a command prefix (#ii) is used to direct commands to an SBE 38

with the same ID (ii = ID). Global commands do not use a prefix, regardless of

the setting for IDReq=, and are recognized by all SBE 38s attached to the

RS-485 interface.

An example follows for a system with two SBE 38s (IDs 01 and 02)

online. Note that the SBE 38’s response to each command is not shown

in the example. Review the commands described in Command Descriptions

and the example below before setting up your system.

Manual revision 013 Appendix III: RS-485 Interface SBE 38

27

Note:

S>@@#01DS

Note:

Example 1: Multiple RS-485 instruments on 1 pair of wires (user input in bold)

S>DS

Note:

Command Descriptions

RS-485 Commands

For reliable operation, all commands

may need to be preceded with two @

characters to clear the buffers.

Example (status command for

SBE 38 with ID=01):

GData and AData perform the same

function in the SBE 38. Both are

included here to provide compatibility

with RS-485 MicroCATs.

IDReq=Y does not require a #ii prefix.

IDReq=N does require a #ii prefix

(#iiIDReq=N).

Global Commands

Global commands are recognized by all SBE 38s attached to the

RS-485 interface.

TxDelay=x x= delay after SBE 38 transmits a reply until

SBE 38 transmitter is disabled

(1 – 500 milliseconds). Default 25 milliseconds.

RxDelay=x x= delay after SBE 38 receives a command

until SBE 38 transmitter is enabled

(1 – 500 milliseconds). Default 25 milliseconds.

GData Command all SBE 38s to take 1 sample and hold

data in SBE 38 buffer until receiving:

- DATAii;

- SH, SL, or SLT (if #iiIDReq=N); or

- #iiSH, #iiSL, or #iiSLT (if IDReq=Y).

AData Command all SBE 38s to take 1 sample and hold

data in SBE 38 buffer until receiving:

- DATAii;

- SH, SL, or SLT (if #iiIDReq=N); or

- #iiSH, #iiSL, or #iiSLT (if IDReq=Y).

Get Data Command

DATAii Get data obtained with GData or AData from

SBE 38 with ID = ii (ii = 0 -99).

ID Required Command

IDReq=Y Precede commands to individual SBE 38s with #ii,

where ii= ID (ii = 0 -99). Use this setting for

systems with multiple RS-485 instruments on

1 pair of wires. Note that the use of a prefix does

not apply to Global, Get Data, or ID commands.

#iiIDReq=N Do not precede commands to individual SBE 38s

with #ii. Use this setting for systems with only

1 SBE 38.

31

S>IDREQ=Y (command to require ID prefix)

S>#01NAVG=40 (set number of A/D cycles to average for SBE 38 with ID=01)

S>#02NAVG=40 (set number of A/D cycles to average for SBE 38 with ID=02)

S>#01DS (verify setup with status command for SBE 38 with ID=01)

S>#02DS (verify setup with status command for SBE 38 with ID=02)

Example 2: Only 1 SBE 38 on 1 pair of wires, with ID=01 (user input in bold)

S>#01IDREQ=N (command to not require ID prefix; note that #ii prefix is required)

S>NAVG=40 (set number of A/D cycles to average for SBE 38, no ID required as part of command)

(verify setup with status command for SBE 38, no ID required as part of command)

28

Notes:

Note:

32

Manual revision 013 Appendix III: RS-485 Interface SBE 38

ID Commands

Only one SBE 38 can be online when sending these commands.

ID? Display SBE 38 ID (ID = ii, where ii= 0-99) and

whether ID is required as a prefix for commands to

individual SBE 38s (see IDReq=).

*ID=ii Set SBE 38 ID to ii, where ii= 0-99. *ID= must be

sent twice, because the SBE 38 requests

verification. If more than one RS-485 instrument

is online when sending this command, all

instruments online will be set to same ID.

All Other Commands

All other commands (status, setup, sampling, and coefficients) are listed

in Section 4: Deploying and Operating RS-232 SBE 38 and in

Appendix IV: RS-232 Command Summary.

Notes on use of these commands for an SBE 38 with RS-485 interface:

• Effect of IDReq=:

IDReq=Y does not require a #ii prefix.

IDReq=N does require a #ii prefix

(#iiIDReq=N).

If IDReq=Y, precede these commands with #ii (ii = 0 – 99) to direct a

command to a particular SBE 38.

If #iiIDReq=N, do not precede these commands with #ii. This setting

works only for a system with one SBE 38.

• The RS-485 interface cannot accommodate multiple instruments

transmitting real-time data at the same time. Therefore, do not set

AutoRun=Y (start sampling continuously when power is applied) for a

system with more than one RS-485 instrument on a pair of wires.

Similarly, do not attempt to send Go to multiple SBE 38s on a pair of

wires, as the system cannot transmit a command to one instrument while

another instrument is transmitting real-time data.

• If planning to sample continuously: If AutoRun=Y (sample

continuously when power is applied) or using the Go command to start

sampling continuously, set NAvg= (A/D cycles to average per sample)

to a value greater than or equal to 30.

Data Formats

• Each line of output is followed by

a carriage return and line feed.

• For converted data, leading zeros

for temperature output are

suppressed, except for one zero

to the left of the decimal point

(for example, 0.1034).

Converted Data (Format=C)

Output from continuous sampling: ttt.ttt

Output from DATAii, #iiTS, TS, #iiSH, SH, #iiSL, SL, #iiSLT, or SLT:

ii, sssss, ttt.ttt

where:

t = temperature (°C, ITS-90)

(number of digits to right of decimal point is defined by Digits=)

ii = ID (0 – 99)

sssss = SBE 38 serial number

Raw Data (Format=R)

nnnnnn.n

where:

n = counts

Manual revision 013 Appendix III: RS-485 Interface SBE 38

29

Notes:

Optional

Note:

Wiring

When configured with the RS-485 interface, the SBE 38 can transmit data over

See Power and Cable Length in

Section 4: Deploying and Operating

RS-232 SBE 38 for cable limitations

related to the supply of power.

up to 1200 meters of 26 AWG twisted pair wire cable.

The MAX1483 transceivers used in the SBE 38 are designed for bi-directional

data communications on multi-point bus transmission lines. To minimize

reflections, terminate the line at both ends in its characteristic impedance.

Also, keep stub lengths off the main line as short as possible (although the slewrate-limited MAX1483 is more tolerant of imperfect termination than standard

RS-485 ICs).

RS-485

terminating

resistor

solder

points

33

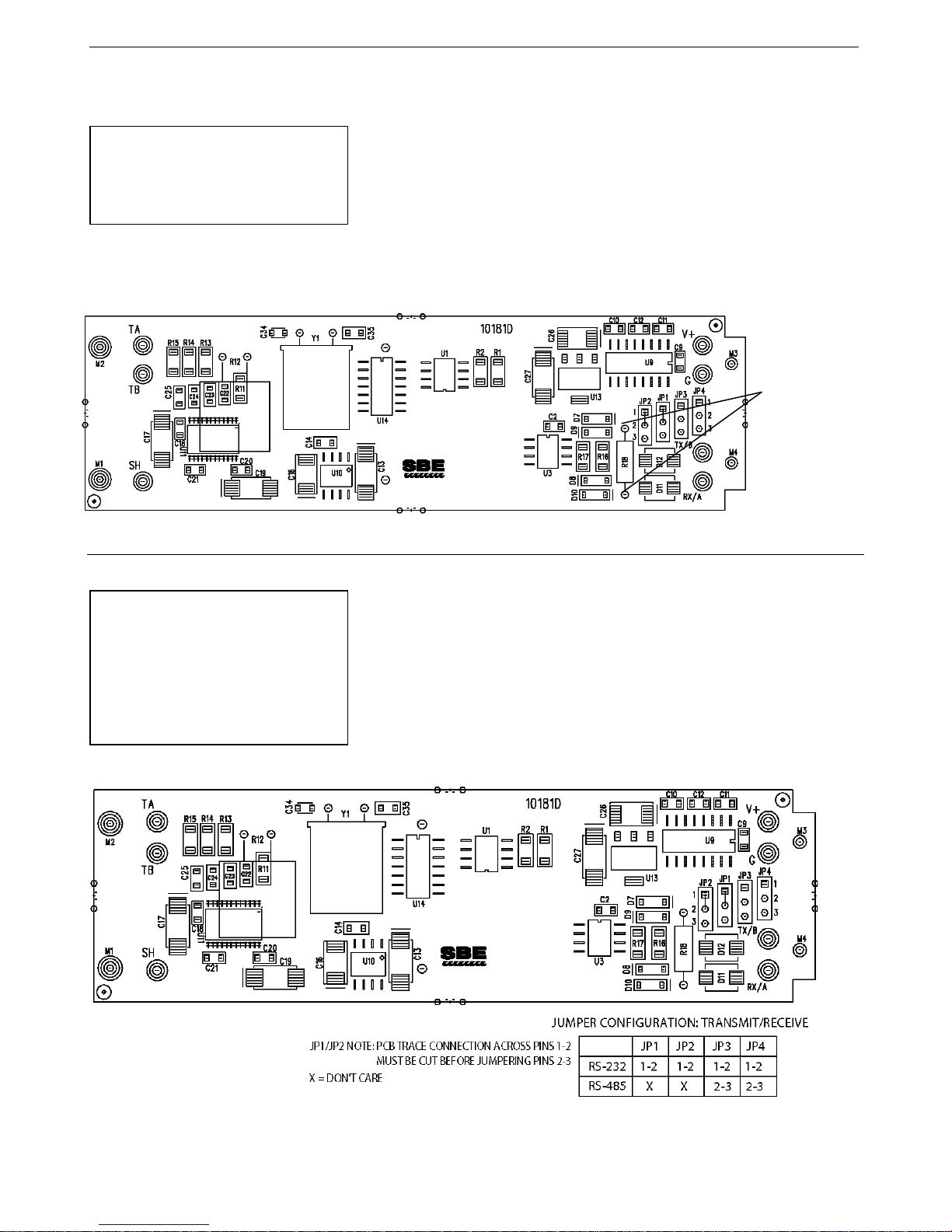

Conversion of RS-232 to RS-485 or RS-485 to RS-232

• See Appendix II: Electronics

Disassembly / Reassembly to

access the PCB.

• Send Interface=232 or

Interface=485 to program

the SBE 38 to match the

wired configuration.

Sea-Bird supplies the SBE 38 with the correct jumper settings on the Printed

Circuit Board (PCB) for your ordered configuration (standard RS-232 or

optional RS-485). If desired, you can modify the jumper settings to change the

configuration:

Wiring: connect -

• Pin 2 (black) to RS-232 RX / RS-485 ‘A’

• Pin 3 (green) to RS-232 TX / RS-485 ’B’

30

Status

DS

Display status and setup parameters.

x=232: RS-232 interface.

x=485: RS-485 interface.

x= baud rate (1200, 2400, 4800, 9600).

x=C: Output converted data (°C).

x=R: Output raw data (counts).

x= number of digits (0 – 6) to right of

x= A/D cycles to average per sample

(1 – 127).

x=N: Wait for a command when

Go

Start continuous sampling now.

Stop continuous sampling.

before entering Stop.

TS

Take 1 sample and transmit data.

TH

Take 1 sample and hold data in buffer.

SH

Transmit data that was held in buffer.

Transmit data from last sample

Transmit data from last sample from

Display calibration coefficients; all

CalDate=S

S=Temperature calibration date.

A0=F

F=Temperature A0.

A1=F

F=Temperature A1.

A2=F

F=Temperature A2.

A3=F

F=Temperature A3.

Slope=F

F=Temperature slope (default 1.0).

Offset=F

F=Temperature offset (default 0.0).

Notes:

34

Manual revision 013 Appendix IV: RS-232 Command Summary SBE 38

Appendix IV: RS-232 Command Summary

CATEGORY COMMAND DESCRIPTION

• See Command Descriptions

in Section 4: Deploying and

Operating RS-232 SBE 38 for

detailed information and

examples.

• See Appendix III: RS-485

Interface for details on

deploying and operating

an SBE 38 with optional

RS-485 interface.

Setup

Sampling

Interface=x

Baud=x

Format=x

Digits=x

NAvg=x

AutoRun=x

Stop

SL

Default 9600.

decimal point for converted

temperature (°C). Applicable only if

Format=C

power applied.

x=Y: Start continuous sampling

automatically when power applied.

Press Enter key to get S> prompt

from buffer.

SLT

buffer, and then take 1 new sample and

hold data in buffer.

Coefficients

(F=floating point

number; S=string

with no spaces)

Date shown is

when calibration

was performed.

Calibration

coefficients are

initially factory-set

and should agree

with Calibration

Certificate shipped

with SBE 38.

DC

coefficients and dates listed below are

included. Use individual commands

below to modify a particular

coefficient or date.

Manual revision 013 Appendix V: Replacement Parts SBE 38

31

Appendix V: Replacement Parts

Part

Number

231361

30931

801376

801263

171888

17046.1

171398.1

Plastic temperature

sensor guard

O-ring,

Parker 2-214 N674-70

4-pin RMG-4FS to

9-pin DB-9S I/O cable

with battery snap,

2.4 m (8 ft) long

4-pin MCIL-4FS to

9-pin DB-9S I/O cable

with battery snap,

2.4 m (8 ft) long

25-pin DB-25S to 9-pin

DB-9P cable adapter

4-pin RMG-4SD-LP

dummy plug with

locking sleeve

4-pin MCIL-4FS dummy

plug with locking sleeve

Part Application Description

Screws to end cap to protect

temperature sensor

Placed in end cap groove for

watertight seal

From SBE 38 (XSG) to computer 1

From SBE 38 (wet-pluggable) to

computer

For use with computer with

DB-25 connector

For SBE 38 (XSG) connector 1

For SBE 38 (wet-pluggable)

connector

Quantity in

SBE 38

1

1

1

1

1

35

32

Manual

Version

006

03/03

Major rewrite: Remove DOS terminal program information and replace with SEATERM, add wet-

calibration equation information.

007

03/04

• Correct available bauds in command summary (remove 19200 & 3840).

Update Seaterm screens.

008

01/05

009

05/06

Add more information to Recovery Warning.

010

01/09

• PCB changed, connections and jumpers changed for conversion between RS-232 & RS-485.

011

04/09

Change spec for current to 15 mA for RS-232 version. Also change current for RS-485 to 10 mA.

012

01/10

date

013

03/11

36

Manual revision 013 Index SBE 38

Appendix VI: Manual Revision History

Date Description

pluggable connector option, correct calibration range to -1 to +32 (from -1 to +35 in old manual), correct

• Add power vs cable length information.

• Update cable list to 9-pin cable.

•

• Firmware 1.3 added 3 commands: slope= (default 1.0), offset=(default 0).

• Temperature calculation has slope & offset included in equation:

t = t * slope + offset

• Remove high range temperature calibration option (removed from price list).

• Update wet-pluggable connector information.

•

• Update for V2 Seacats –integration with 16plus V2, 16plus-IM V2, 19plus V2.

• Add information about compatibility with Vista.

• Remove information about DOS software.

• Update connector maintenance information for consistency with application note 57.

•

• Change Seasoft-Win32 to Seasoft V2, update file name to SeasoftV2_

• Add information required for CE certification, and add CE mark.

• Update SBE address.

• Add more information on RS-485 operation:

- Set NAvg > 30 for continuous sampling (using Go to start sampling, or if AutoRun=Y).

- IdReq=Y does not require #ii prefix, but IDReq=N does require #ii prefix (#iiIDReq=N).

- For customers using their own terminal program: terminate commands with CR (not CRLF)

Add information about compatibility with Windows 7

•

.exe.

Manual revision 013 Index SBE 38

33

Index

37

B

Baud rate · 15, 17

C

Cable length · 15

Calibration · 22

Calibration coefficients · 18

Command summary · 30

Commands

baud · 17

calibration coefficients · 18

data format · 17

descriptions · 17

get data · 27

global · 27

ID · 27, 28

ID required · 27

RS-485 · 27

sampling · 18

setup · 17

status · 17

Communication defaults · 11

Connector · 8, 21

Continuous sampling · 14

Corrosion precautions · 21

D

Data acquisition · 9

Data format · 17, 19, 28

Data processing · 9

Deployment

installation · 19

preparing for · 9

Description · 6

Desiccant · 25

Dimensions · 8

Disassembly / reassembly · 25

E

Electronics · 25

F

Flooded instrument · 20

Format · 17

data · 19, 28

Functional description · 24

G

Get data · 27

Global commands · 27

Glossary · 23

I

ID commands · 27, 28

M

Maintenance · 21

Manual revision history · 32

Modes · See Sampling modes

O

Operation description · 26

P

Parts

replacement · 31

Polled sampling · 13

Power · 15

Q

Quick start · 4

R

Real-time data acquisition · 9

Recovery · 20

Replacement parts · 31

Revision history · 32

RS-232 · 13, 17

conversion to RS-485 · 29

RS-485 · 17, 26

conversion to RS-232 · 29

wiring · 29

RS-485 commands · 27

S

Sampling · 18

Sampling modes · 13

continuous · 14

polled · 13

SBE Data Processing · 6, 9

Seasave · 6, 9

SEASOFT · 6, 9

SEATERM · 6, 9, 10

main screen · 10

toolbar buttons · 11

Sensor · 7

Serial interface · 17, 26

Settings · 24

Setup commands · 17

Software · 6

installation · 9

Specifications · 7

Status commands · 17

System description · 6

T

Terminal program · 9

Testing · 9

Thermistor · 24

L

Limited liability statement · 2

U

Unpacking SBE 38 · 5

V

Versions · 32

1

38

SBE 38 Digital Oceanographic Thermometer Reference Sheet

(see SBE 38 User’s Manual for complete details)

Interface

• RS-232 (standard) – one SBE 38 connected to the interface.

• RS-485 (optional) – one or more SBE 38s sharing one pair of wires.

Sampling Modes

• Polled sampling – SBE 38 takes one sample and transmits data.

• Continuous sampling – SBE 38 continuously samples and transmits data. As programmed, SBE 38 begins sampling

on power-up or waits for a command to begin sampling. Note that for RS-485 applications with several sensors

sharing one pair of wires, the SBE 38 cannot sample continuously.

For both polled and continuous sampling, the SBE 38 averages NAvg A/D cycles per sample. It outputs converted (°C) or

raw (counts) data, depending on Format=. For converted data, number of digits after the decimal place is defined

by Digits=.

Communication Setup Parameters

1. Double click on seaterm.exe.

2. Once main screen appears, in Configure menu select SBE 38. Input in dialog box:

• Serial Port: COM1 through COM10 are available

• Baud Rate: 9600 (or other if applicable)

• Data Bits: 8

• Parity: No Parity

• Mode: RS-232 (Full Duplex) or RS-485 (Half Duplex)

Deployment

1. Install I/O cable and locking sleeve.

2. Program SBE 38 for intended deployment (see other side of this sheet for Command Instructions and List):

A. Establish setup parameters.

B. Use one of following sequences to start sampling:

• If AutoRun=N: Go to start sampling continuously now, or TS or TH to take a single sample.

• If AutoRun=Y: Apply power to start sampling continuously now.

3. Mount SBE 38.

Reference Sheet Version #004, 03-23-11; Firmware Version 1.4 and later

2

Command Instructions and List

Status

DS

Display status.

x=232: RS-232 interface.

Baud=x

x= baud rate (1200, 2400, 4800, 9600). Default 9600.

x=C: Output converted data (°C).

Digits=x

x= digits (0 – 6) to right of decimal point for converted temperature (°C).

NAvg=x

x= A/D cycles to average per sample (1 – 127).

x=N: Wait for a command when power applied.

Go

Start continuous sampling now.

Stop

TS

Take 1 sample and transmit data.

TH

Take 1 sample and hold data in buffer.

SH

Transmit data that was held in buffer.

SL

Transmit data from last sample from buffer.

SLT

Transmit data from last sample from buffer, and then take 1 new sample and hold data in buffer.

DC

Display calibration coefficients.

CalDate=S

S=Temperature calibration date.

A0=F

F=Temperature A0.

A1=F

F=Temperature A1.

A2=F

F=Temperature A2.

A3=F

F=Temperature A3.

Slope=F

F=Temperature slope (default = 1.0).

Offset=F

F=Temperature offset (°C) (default = 0.0).

x= delay after SBE 38 transmits a reply until SBE 38 transmitter is disabled

(1 – 500 milliseconds). Default 25 milliseconds.

x= delay after SBE 38 receives a command until SBE 38 transmitter is enabled

GData or

AData

Command all SBE 38s to take 1 sample and hold data in SBE 38 buffer until receiving:

Get Data

DATAii

Get data obtained with GDATA or ADATA from SBE 38 with ID = ii (ii = 0 -99).

IDReq=Y