Page 1

ABOUT

SEMC Troubleshooting Manual

Troubleshooting Manual

C903

C903

ABOUT TROUBLESHOOTING MEASUREMENT POINTS

1228-1147 rev. 1

APPENDIXCOMPONENT OVERVIEW FUNCTIONAL OVERVIEW

1 (129)

Page 2

ABOUT

General information

The purpose of this document is to provide enhanced technical information for Sony Ericsson

repair technicians in order to assist during service, repair and troubleshooting operations on Sony

Ericsson mobile phones. It should be used as a complement to other repair instructions and tools

as notifi ed by the local Sony Ericsson representative.

To search for components throughout the entire document use the “search” function in Adobe

Acrobat Reader 7.0 (or later version) and enter the component name or other word. Use zoom to

enlarge.

For easier navigation of the document you can use the bookmarks that appear in the Bookmarks

tab on the left side of the Adobe Acrobat Reader window. Each bookmark jumps to a page in the

document.

Disclaimer

This document is Sony Ericsson confi dential and should be treated as confi dential in accordance

with the agreement with Sony Ericsson. This document is intended for use by authorized service

technicians only. Sony Ericsson is not to be held responsible for any damages or losses caused

intentionally or unintentionally due to unauthorised use of the information in this document.

Note

When disassembling and reassembling the phone the instructions and processes described in the

Mechanical Working Instructions, the Generic Repair Manual and the Repair Center Handbook

must be followed.

Revision History

Rev. Date Changes / Comments

106/19/2009Initital revision.

ABOUT Contents

ABOUT 2

Contents 2

Equipment List 3

TROUBLESHOOTING 8

Power On/Off Problems 8

USB and Software Flash Problems 8

Dead Phone Problems 9

Display Problems 10

Display Illumination Problems 11

Opto Sensor Problems 11

On-Off Key Problems 12

Numeric Keypad Problems 12

Navigation Keypad Problems 13

Volume Up and Down Button Problems 13

Camera Button Problems 14

Play & Camera Mode Button Problems 14

Navigation Keypad LED Problems 15

Numeric Keypad LED Problems 16

Camera Button LED Problems 16

Tally LED Problems 17

Trickle Charge LED Problems 17

Flash LED Problems 18

Camera Lens LED Problems 19

Camera Cover Detect Problems 19

Main Camera Problems 20

VGA/VTF Camera Problems 21

Data Communication Problems 21

Charging Problems 22

USB/VBUS Charging Problems 22

SIM Problems 23

Memory Stick Problems 23

Microphone Problems 24

Earphone Problems 24

Loudspeaker Problems 25

Handsfree Aux Earphone Problems 25

Handsfree Aux Microphone Problems 25

Handsfree Connection Problems 26

FM Radio Problems 27

FM Radio Antenna Problems 27

Bluetooth Problems 28

GSM Network Problems 28

WCDMA Problems 29

A-GPS Problems 30

Accelerometer Problems 30

Vibrator Problems 31

Real Time Clock Problems 31

Slide Sensor Problems 32

TV Out Problems 32

System Connector Protection Test 33

Current Consumption Test 33

Backup Capacitor Test 35

Charging Test 35

ASIC Revision Test 36

Measurement Points Pictures 37

MEASUREMENT POINTS

Primary Side 50

Secondary Side 51

Camera SIM FPC 52

Main Flex Assy FPC 53

Navigation Keypad FPC 54

Keypad FPC 55

Top Schematic 56

Audio Top 57

Audio Analog 58

Audio Digital 59

Audio FM Radio 60

SEMC Troubleshooting Manual

Application & System Performance Top 61

System Top 62

System Control - Clocks & Resets 63

System Memories 64

System PoP IF 65

Power Top 66

Power Regulators & Charging 67

Power Imaging 68

Power ASICs 69

Connectivity Top 70

Connectivity Top 71

Connectivity I2C & ADC 72

Connectivity Cards 73

Connectivity 74

Imaging Top 75

Imaging Display 76

Imaging Camera 77

Imaging Camera 78

Imaging LMU 79

Imaging Flash LED 80

Access Top 81

Access GSM & UMTS 82

Access Bluetooth 83

Access AGPS 84

Camera SIM FPC 85

Main Flex Assy FPC 86

Navigation Keypad FPC 87

Keypad FPC 88

COMPONENT OVERVIEW 89

Primary Side 89

Secondary Side B - C 90

Secondary Side L - Z 91

FUNCTIONAL OVERVIEW

Technical Description 92

Platform Block Diagram 103

Block Diagram Power Distribution 104

Block Diagram Clocking Concept 105

APPENDIX

Replaceable Components 106

Components - B3100, B4200, B4410 107

Components - L1200, L2200, L2261 108

Components - L2401-04 108

Components - L2406, L2408, L4102 108

Components - L4200, N1210 109

Components - N1211, N2206 109

Components - N1300, N2200, N2203 110

Components - N2210, N2288 111

Components - N2271, N2290 111

Components - N2410, N2411, N2420 112

Components - N2421, N2422, N3100 113

Components - N3101, N4201, N4240 114

Components - N4401, R2449 114

Components - S2403, V2202, V2412 115

Components - V2417, V2413, V2420-21 115

Components - 0V2430, V2470 115

Components - V4110, V4111, V4200 116

Components - V4310, V4350, V4360 116

Components - W1300, X1000, X1002-03 117

Components - X1010-11, X1030 117

Components - X1200, X1210, X2400 118

Components - X2403, X2405, X4202 119

Components - X4300, Z2400 120

Troubleshooting Software Documentation 121

Troubleshooting Fixture Setup Instructions 128

C903

ABOUT

1228-1147 rev. 1

2 (129)

Page 3

ABOUT Equipment List

SEMC Troubleshooting Manual

C903

C903 Equipment List

Troubleshooting Fixture

Location: CSPN – Repair Instructions – Mechanical – Tool Catalogue – RepairToolsCatalogue.pdf

Part number: 1225-3244

Note! Additional information about the TRS Fixture Kit can be found in the Trouble Shooting

Fixtures Setup Instructions document which is included in this TRS Manual.

Dummy Battery

Location: CSPN – Repair Instructions – Mechanical – Tool Catalogue – RepairToolsCatalogue.pdf

Part number: NTZ 112 533

Note! The resistance between GND and BDATA should be approximately 120 KOhm.

Instruments

Power Supply Channel 1 (VBATT)

Agilent 6632B or similar

Location: CSPN – Repair Instructions – Mechanical – Tool Catalogue – RepairToolsCatalogue.pdf

Instrument Settings:

Voltage: 3.8 Volt

Limiter: 2.0 A

Note! Max cable length between the Power Supply Channel 1 VBATT and the dummy battery is 1

metre. The cable must have a capacity for at least 16A.

ABOUT

Info: Additional information about the equipment used for TRS can be found in the following

location: CSPN – Repair Instructions – Mechanical – Tool Catalogue – RepairToolsCatalogue.pdf or

matris.xls – C Model Tab.

Power Supply Channel 2 (DCIO/SEPI)

Agilent 6632B or similar

Location: CSPN – Repair Instructions – Mechanical – Tool Catalogue – RepairToolsCatalogue.pdf

Instrument Settings:

Voltage: 5.0 Volt

Limiter: 2.0 A

Oscilloscope

Agilent DSO7052A or similar

Location: CSPN – Repair Instructions – Mechanical – Tool Catalogue – RepairToolsCatalogue.pdf

Digital Multimeter (DMM)

Fluke 83 or similar

Location: CSPN – Repair Instructions – Mechanical – Tool Catalogue – RepairToolsCatalogue.pdf

Note! The 0, 64 mm Test Probes is recommended by Sony Ericsson when the DMM is in use,

please see Picture 1.

Picture 1

1228-1147 rev. 1

3 (129)

Page 4

ABOUT

Equipment List

SEMC Troubleshooting Manual

C903

Spectrum Analyzer

R&S FSL 9 kHz – 3 GHz or similar

Location: CSPN – Repair Instructions – Mechanical – Tool Catalogue – RepairToolsCatalogue.pdf

RF probe

HP 85024A or similar

Location: CSPN – Repair Instructions – Mechanical – Tool Catalogue – RepairToolsCatalogue.pdf

Mobile Phone Tester

Yokogawa VC200 or similar

Location: CSPN – Repair Instructions – Mechanical – Tool Catalogue – RepairToolsCatalogue.pdf

FM Signal Generator

R&S SMC100A or similar

Location: -

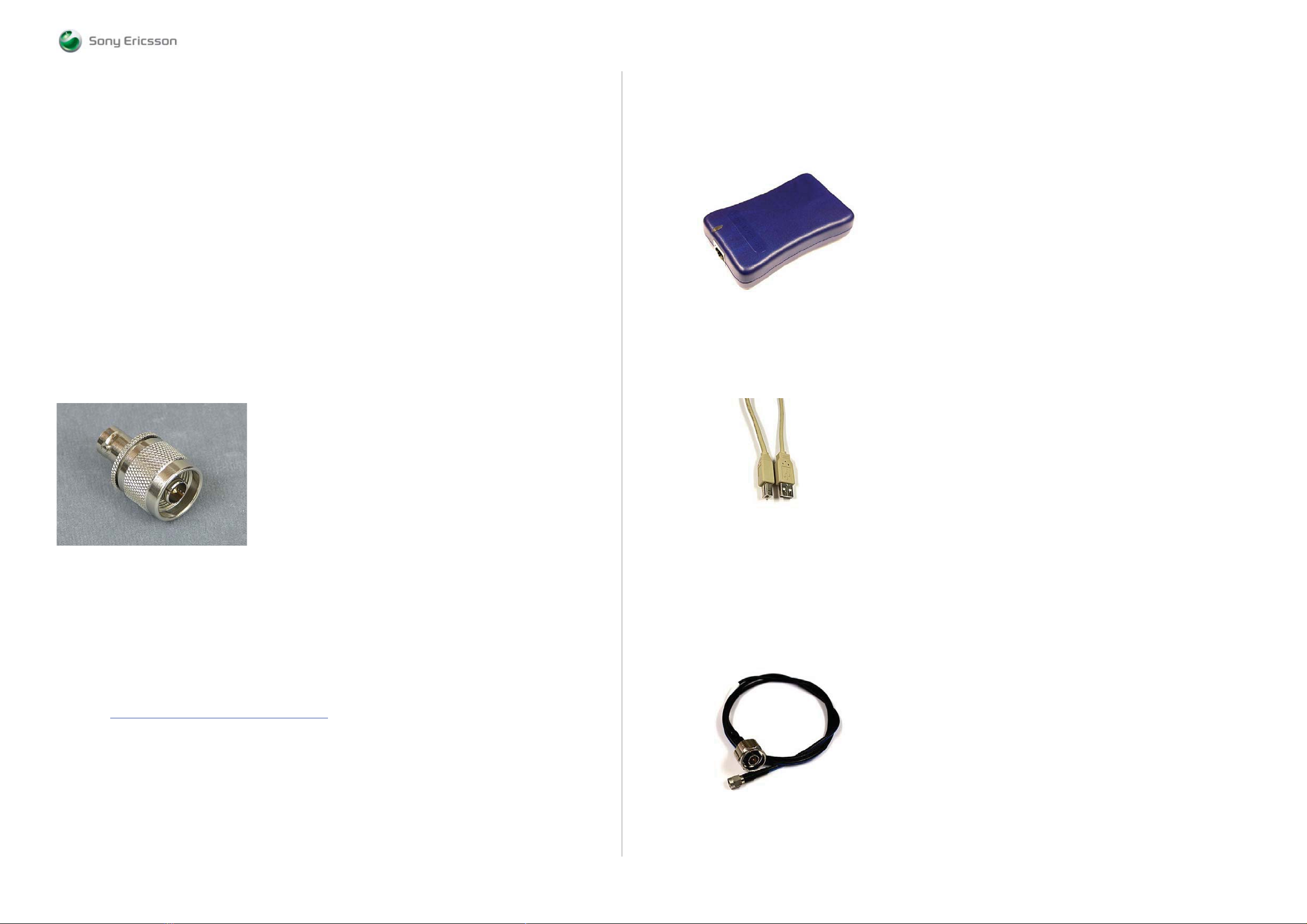

RF Adaptor

Adaptor 33 N-BNC-50-1

Adaptor to Signal Generator RF Output

See Picture 2

Location: -

Picture 2

SE Communication Interface SEPI BOX

Location: CSPN – Repair Instructions – Mechanical – Tool Catalogue – RepairToolsCatalogue.pdf

Part number: LTN 214 1484

See Picture 3.

Picture 3

Cables

USB Computer Cable

Location: CSPN – Repair Instructions – Mechanical – Tool Catalogue – RepairToolsCatalogue.pdf

See Picture 4.

Picture 4

ABOUT

PC Package & PC Software

PC Package (Computer)

Location: CSPN – Repair Instructions – Mechanical – Tool Catalogue – RepairToolsCatalogue.pdf

Urquell Fault Trace SW with project file

Location: CSPN – Repair Instructions – Electrical – C903, C903a – Trouble Shooting Application –

Project File: C903, C903a Project_R1A

Drivers

SEPI BOX Drivers

Location: http://emma.extranet.sonyericsson.com

/– Drivers – DSS / SEPI / SEMUTS

DSU-60/USB Cable

Location: CSPN – Repair Instructions – Mechanical – Tool Catalogue – RepairToolsCatalogue.pdf

Part number: KRY 101 1413

RF Test Cable Flexible

Location: CSPN – Repair Instructions – Mechanical – Tool Catalogue – RepairToolsCatalogue.pdf

Part number: RPM 119 885

See Picture 5.

Picture 5

1228-1147 rev. 1

4 (129)

Page 5

ABOUT

Equipment List

SEMC Troubleshooting Manual

C903

SEPI Interface Cable – A1

Location: CSPN – Repair Instructions – Mechanical – Tool Catalogue – RepairToolsCatalogue.pdf

Part number: KRY 101 1119/1

See Picture 6.

Picture 6

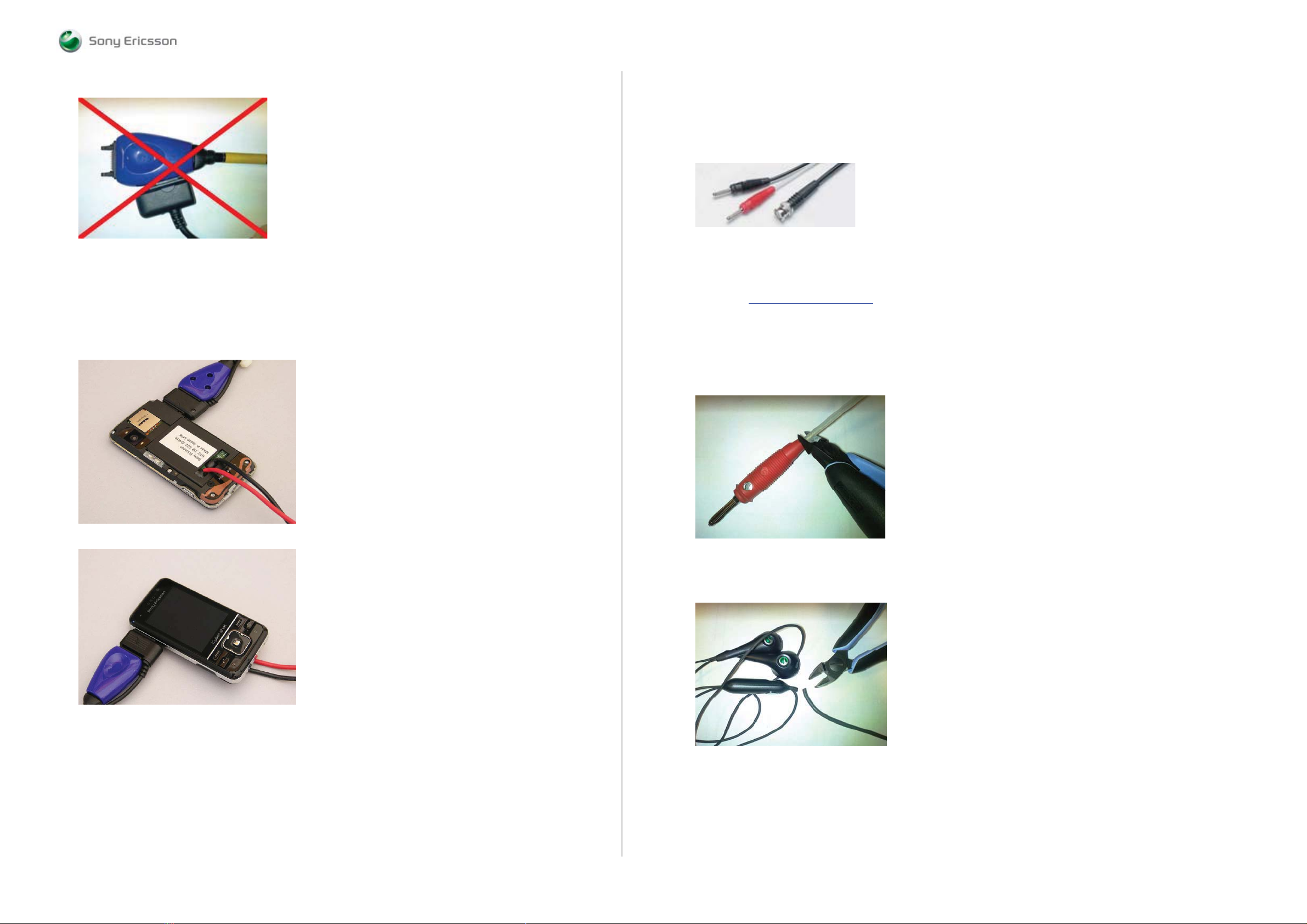

Power Cable RED to Power Supply Channel 1 (VBATT)

Maximum Length: 1m

Location: CSPN – Repair Instructions – Mechanical – Tool Catalogue – RepairToolsCatalogue.pdf

Power Cable BLACK to Power Supply Channel 1 (VBATT )

Maximum Length: 1m

Location: CSPN – Repair Instructions – Mechanical – Tool Catalogue – RepairToolsCatalogue.pdf

Step 2:

Connect the CST-75 charger Red or White wire to the Plus Output and the Black wire to the Minus

(GND) Output at backside of the Power Supply Channel 2 (DCIO/SEPI) according to Picture 8.

Picture 8

Step 3:

Cut off insulating material from back side of the charger plug according to Picture 9.

Picture 9

ABOUT

Customized Power Supply Channel 2 Cable (DCIO/SEPI)

Customize the cable according to following instructions below:

(Step 1, Step 2, Step 3 and Step 4)

Step 1:

Take the CST-75 battery charger and cut of the charger according to Picture 7.

Picture 7

Note! The Cable length must be exact 1.3 metre.

Step 4:

Connect DCIO Cable and SEPI Interface Cable – A1 according to Picture 10.

Picture 10

1228-1147 rev. 1

5 (129)

Page 6

ABOUT

Equipment List

SEMC Troubleshooting Manual

C903

Picture 11

Note! This is setup is wrong!

Connection Instructions for the Dummy Battery

This is correct setup when the Dummy Battery is in use.

See Pictures 12 and 13.

Picture 12

Customized FM Radio Cable

Step 1:

Use the Test lead BNC-4mm 1,5m Cable, see Picture 14.

Picture 14

Product Name: Test lead BNC-4mm 1,5m

Product Description: Test lead with 4 mm lab plugs at one end and a BNC plug at the other.

Manufacturer: PMK Germany

Location: http://www.elfa.se/en/

or other supplier.

Part number: 46-310-40

Note! This is the ELFA part number.

Step 2:

Cut the Red Lab Plug connector according to Picture 15.

Picture 15

ABOUT

Picture 13

Step 3:

Use any Hands-Free (PHF) Cable and cut it according to Picture 16.

Picture 16

Note! Cable length should be at least 40cm.

1228-1147 rev. 1

6 (129)

Page 7

ABOUT

Equipment List

SEMC Troubleshooting Manual

C903

Step 4:

Use only the Wire that is connected to PIN2 and cut off all others according to Picture 17.

Picture 17

Note! Use DMM instrument to ensure which of the wires are connected to PIN2 at Hands-Free

(PHF) system connector plug.

Step 5:

Connect the Cable from the Picture 15 and Cable from the Picture 17 according to Picture 18.

Note! Use soldering iron for this action and then use insulating material to protect the contact

point.

Picture 18

Test SIM GSM/UMTS

One Test SIM GSM/UMTS is needed to perform Current Consumption Test, see Picture 20.

Location: CSPN – Repair Instructions – Mechanical – Tool Catalogue – RepairToolsCatalogue.pdf

Note! To buy a Test SIM GSM/UMTS, please contact your supplier of test equipment.

Picture 20

Sony Memory Stick M2

Any functional Memory Stick Micro M2 Card

See Picture 21.

Picture 21

ABOUT

Test Cards

Local SIM

Any functional Local SIM Card

See Picture 19.

Picture 19

SMK RF Probe

Location: CSPN – Repair Instructions – Mechanical – Tool Catalogue – RepairToolsCatalogue.pdf

Part number: SXA 109 6356

See Picture 22.

Picture 22

1228-1147 rev. 1

7 (129)

Page 8

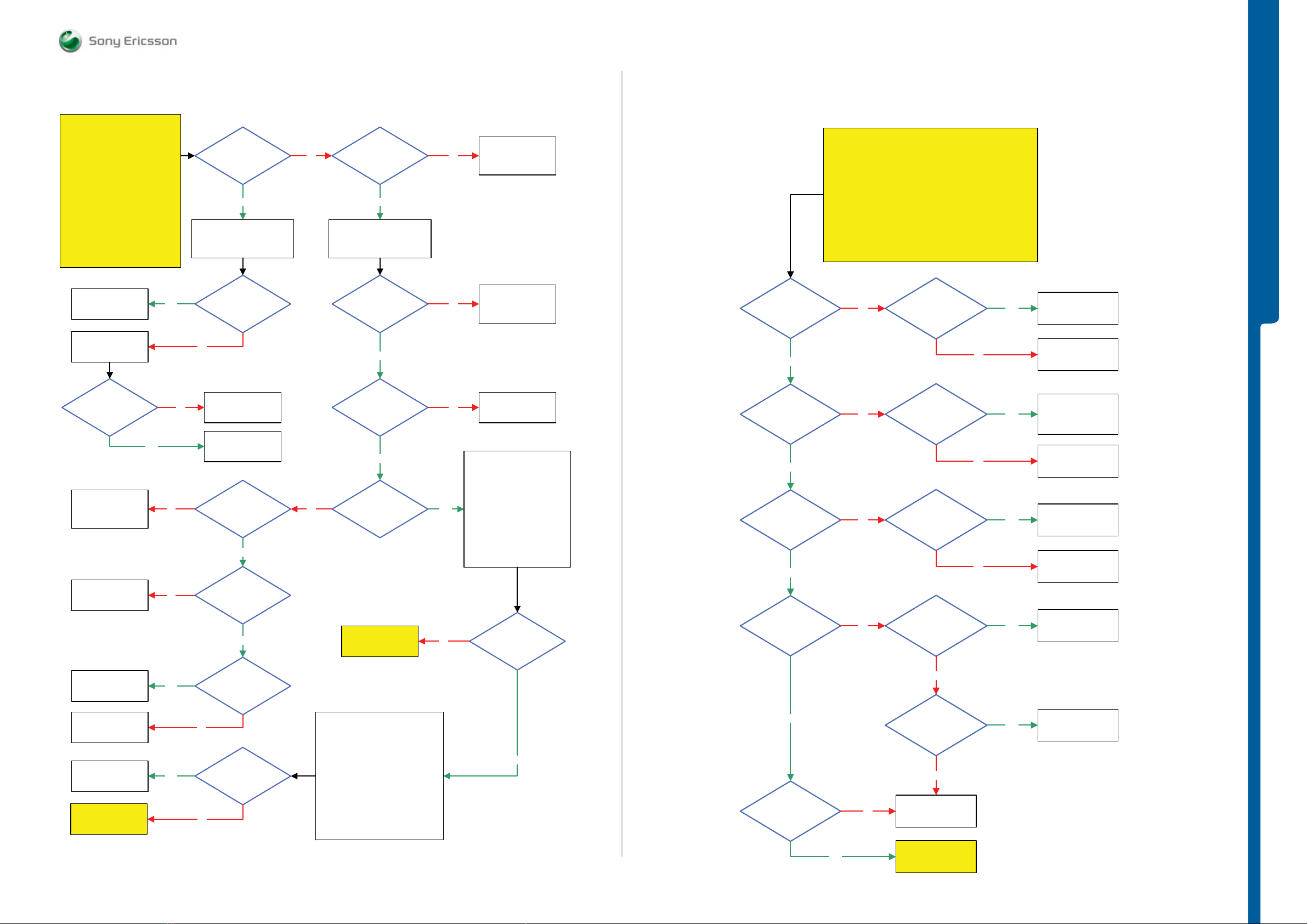

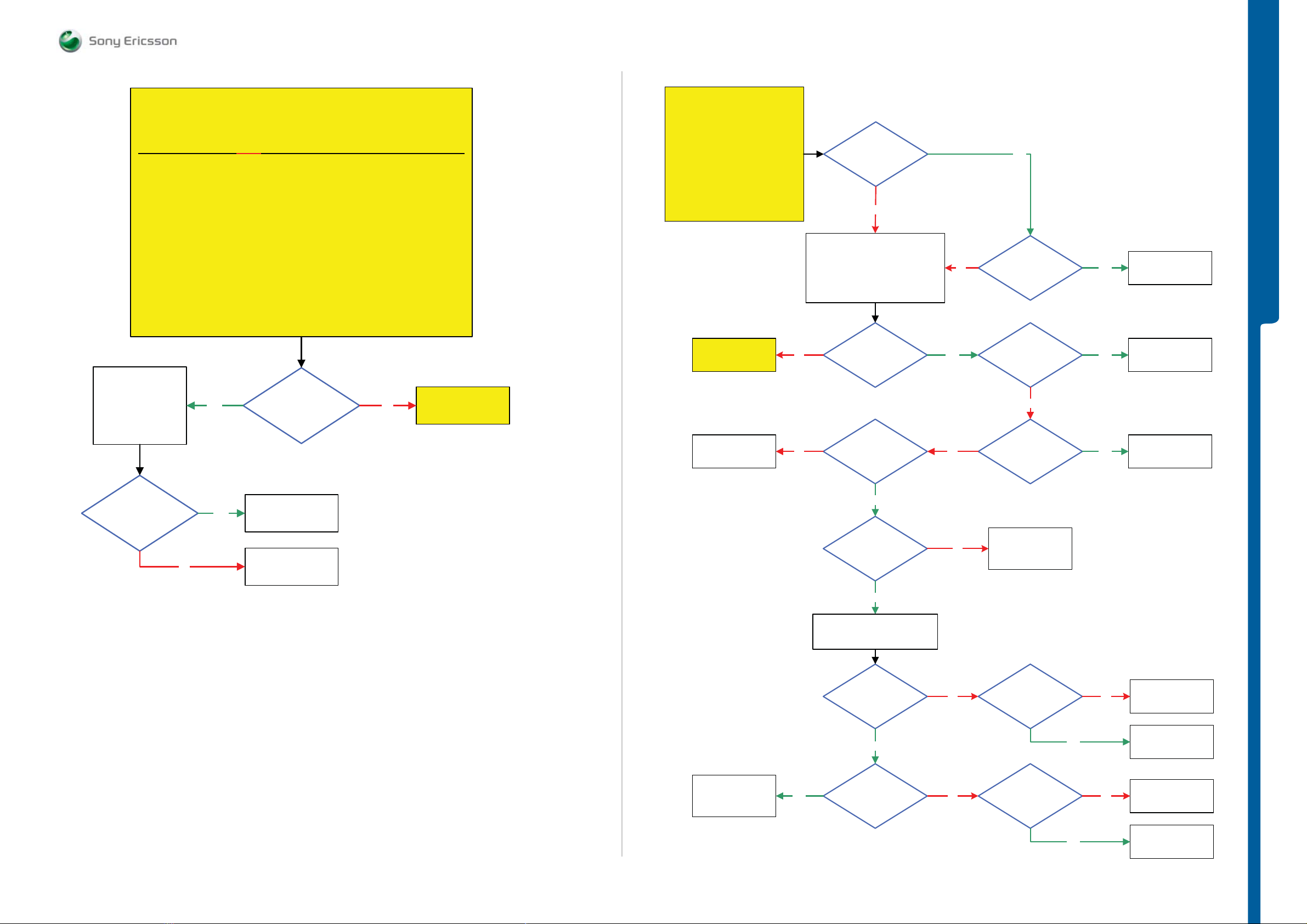

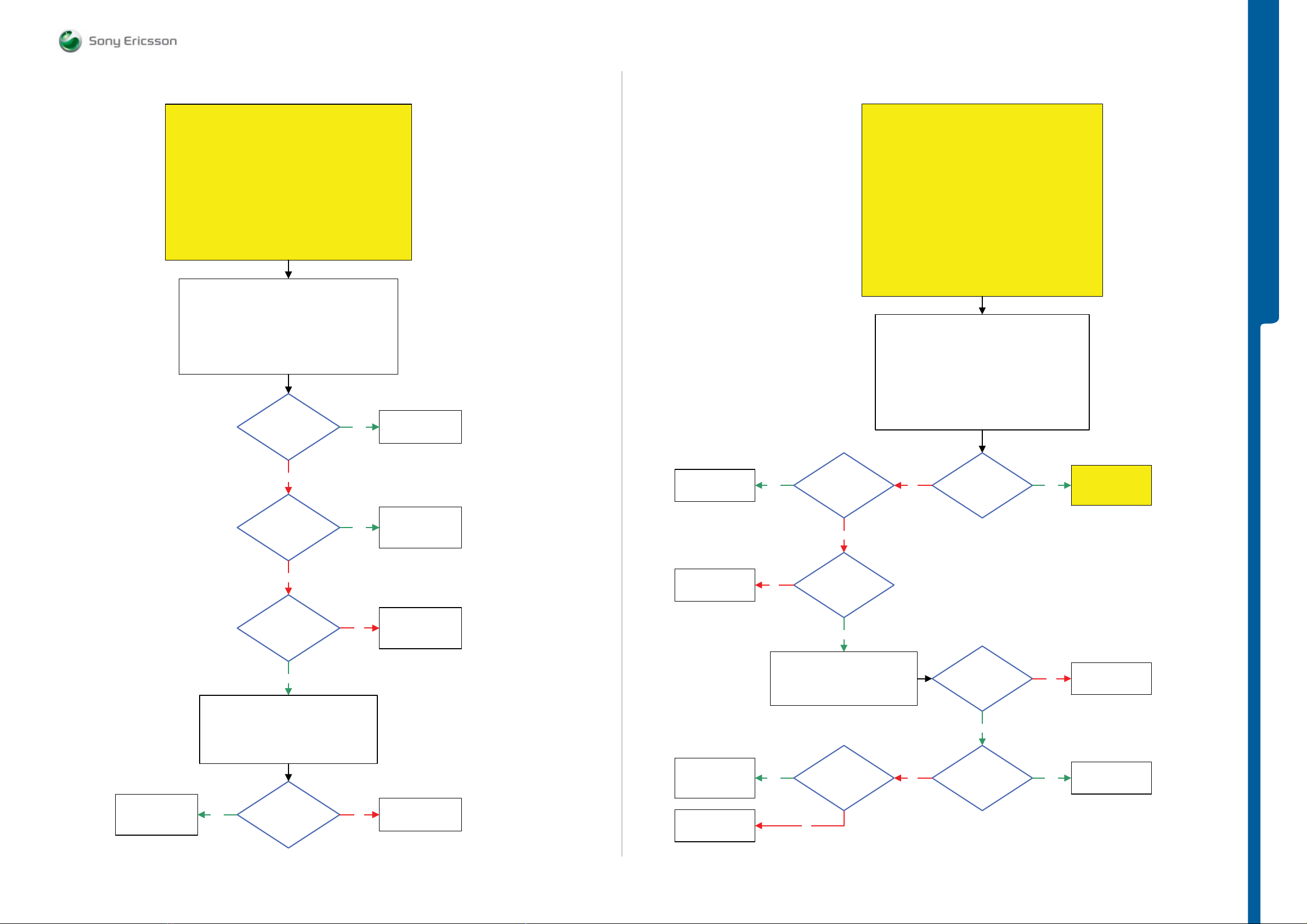

TROUBLESHOOTING Power On/Off Prob lems

- USB and Sof tware Flash Problem s

SEMC Troubleshooting Manual

C903

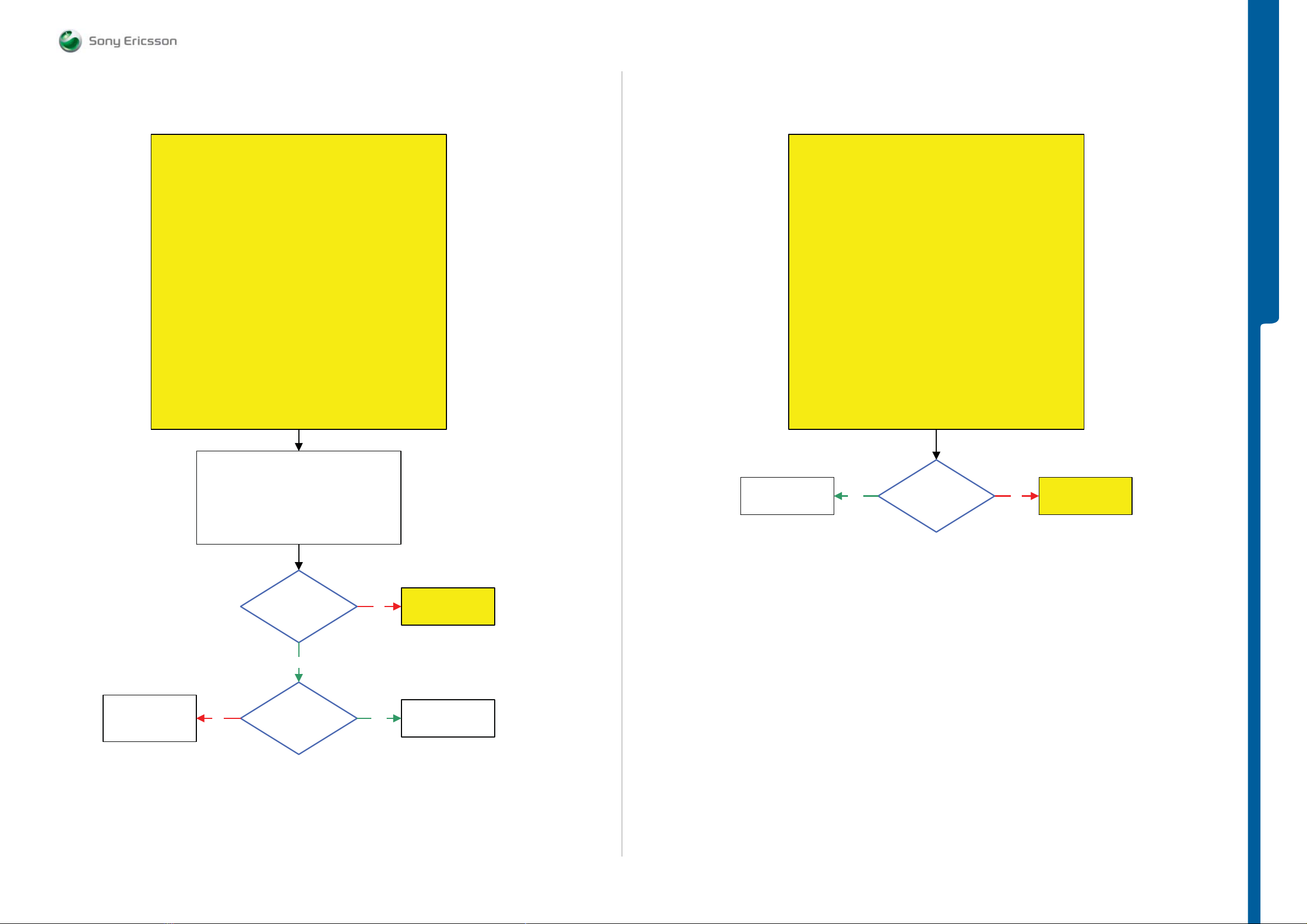

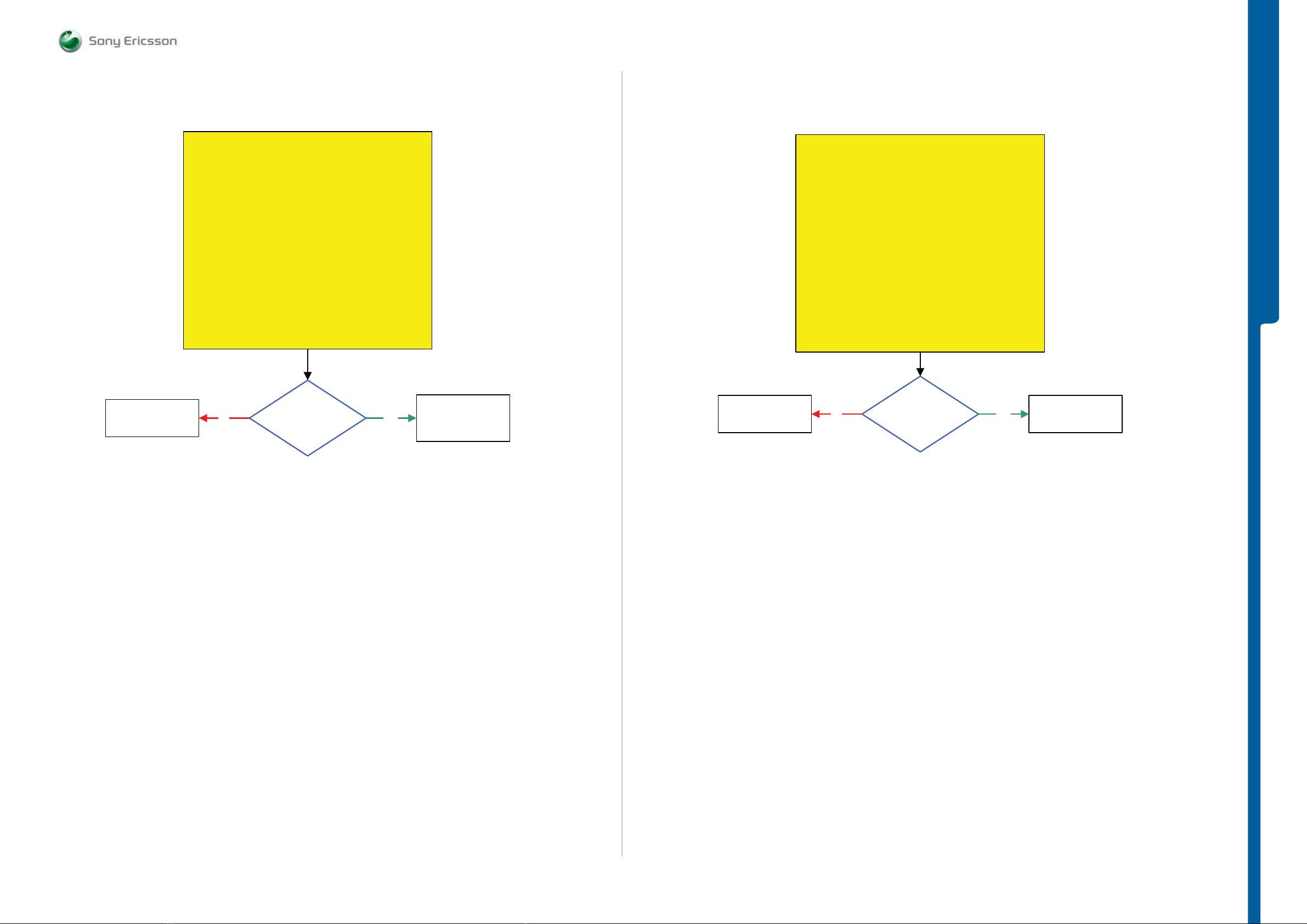

START

Use the

Dummy Battery Connected to

Power Supply Channel 1

(VBATT)

No

Is the

phone consuming

any current when

powering on the

phone

Yes

Power On/Off Problems

Is the phone

consuming more than

1mA when the phone

is powered off

No

Is it possible to

power on the phone

Connect a chargerNo

Yes

Yes

Is it possible to power

off the phone

Is the phones

behavior as normal

Optimized

charging

No

Yes

No

Yes

On-Off Key Problems

Go to

Dead phone

Problems part 1

TRS guide

Go to

Current

Consumption Test

After this go to

Charging Test

Go to

TRS guide

START

Step 1:

Perform

System Connector Protection Test

If successful go to step 2.

Step 2:

Download ITP SW into the Phone

Go to

USB/VBUS

Charging Problems

USB and Software Flash Problems

Is the

Flash process

Start-up when using

EMMA SW

No

Use TRS Fixture

1: Connect: VBATT and DCIO/SEPI

2: Remove: DCIO/SEPI

3: Connect: USB Cable from the PC

Does

the Phone

Indicate charging

on the display

Yes

No

YesNo

Is the

ITP SW Flash

Successful

Is MP 14

(X2405_Pin 10)

Short circuit to

GND

No

Yes

Yes

SL 5 Replace

N2020

SL 4 Escalate

Replace

V2421

TROUBLESHOOTING

Is the current

consumption between

10mA to 70mA

Yes

Flash

the phone with

correct CDA

software

Flash

The phone with

the ETS software.

Is the ETS SW Flash

Successful

No

Go to

Data Communication

Problems

TRS guide

No

No

Flash

the phone with

correct CDA

software

CDA Software

Flash

Successful

Yes

1. Customize the phone into DPY/Z

2. Startup the phone and wait for

the configuration to take place

(takes less than a minute)

3. Customize with correct CDA

Yes

4. Activate the phone

Is the Problem

solved

No

Go to

Dead Phone

Problems part 1

TRS guide

Press ”C”

Connect USB from PC.

Update SEMC BOOT if

necessary. Run EMMA

SUCR SW. Is Phone

Flash Ok

No

Is the

Flash process

started

Yes

Yes

SL 4 Replace

N2420

SL 5 Replace

R2442

Go to

System Connector

No

NoYes

Protection Test

After this go to

Data Communication

Problems TRS guide

Is the Problem

solved

Yes

Claim for a

SW Upgrade

SL 4 Replace

N2420

SL 5 Replace

N2010

No

Yes

5 Volt DC at

MP 75 (C2433)

Yes

2.7V – 3.3V DC

at MP 68 (C2437) and

1.8V DC at MP 76

(C2435)

Yes

Remove the PBA from the

TRS Fixture

Max

2 Ohm between

MP 14 (X2405_Pin 10)

and MP 65 (Z2400_Pin 2)

Yes

Max

2 Ohm between

MP 15 (X2405_Pin 11)

and MP 66

(Z2400_Pin 3)

No

No

No

No

Is MP 15

(X2405_Pin 11)

Short circuit to

GND

SL 4 Replace

N2420

SL 5 Replace

N2010

Max

0.5 Ohm between

MP 14 (X2405_Pin 10)

and MP Z2400_Pin 1)

Max

0.5 Ohm between

MP 15 (X2405_Pin 11)

and MP 64

(Z2400_Pin 4)

Yes

Yes

Yes

No

No

Replace

V2420

Replace

X2405

Replace

Z2400

Replace

X2405

Replace

Z2400

1228-1147 rev. 1

8 (129)

Page 9

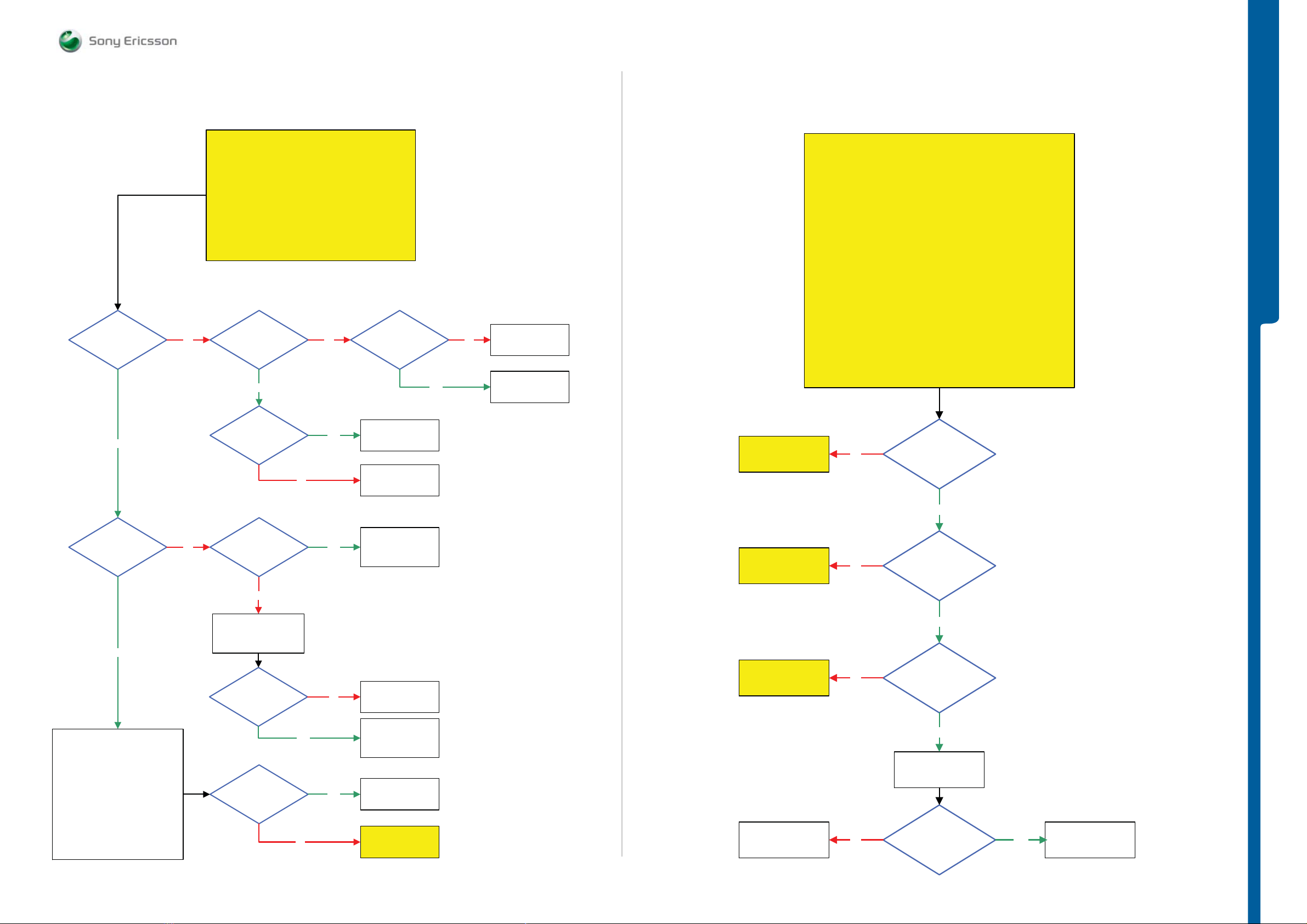

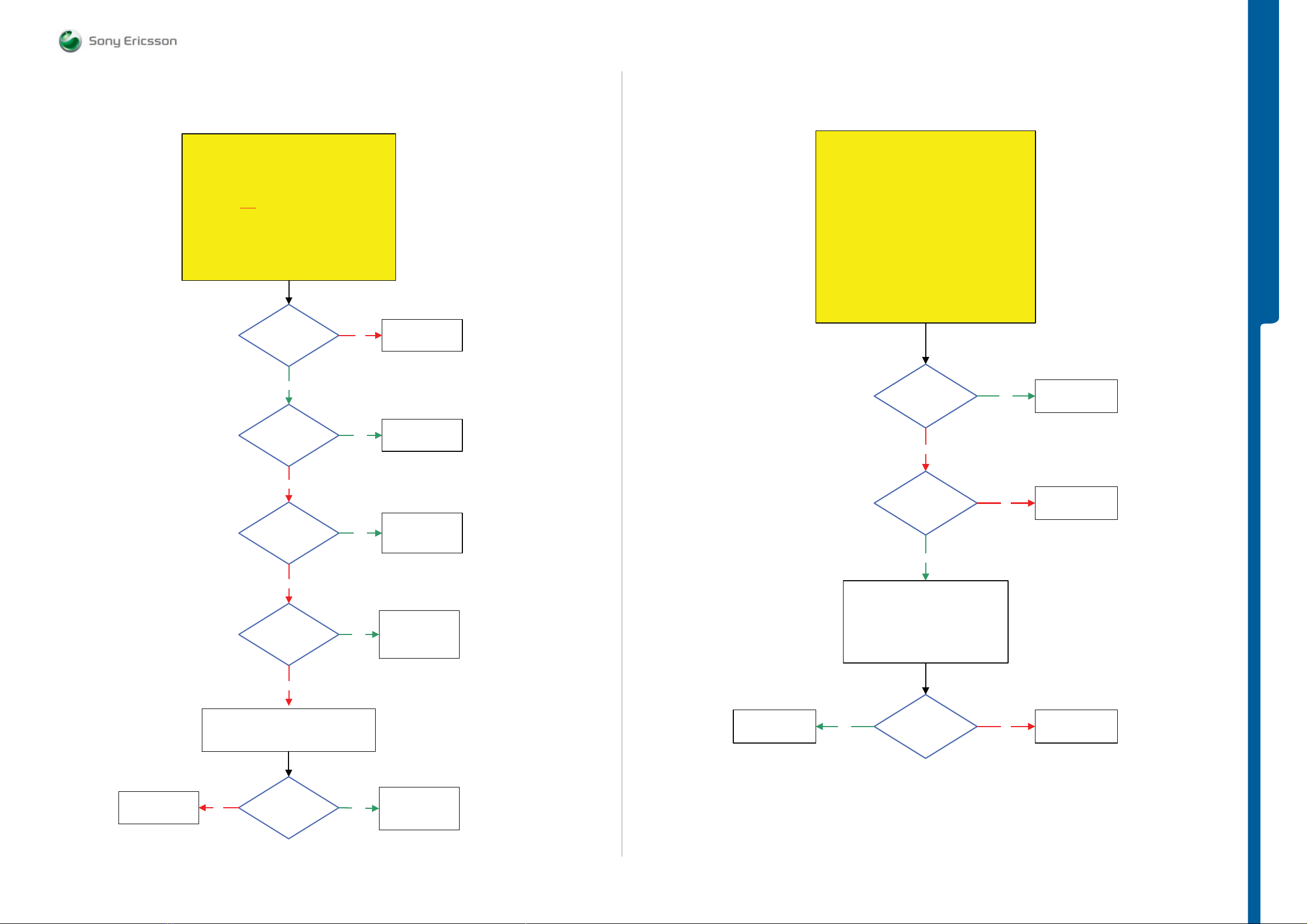

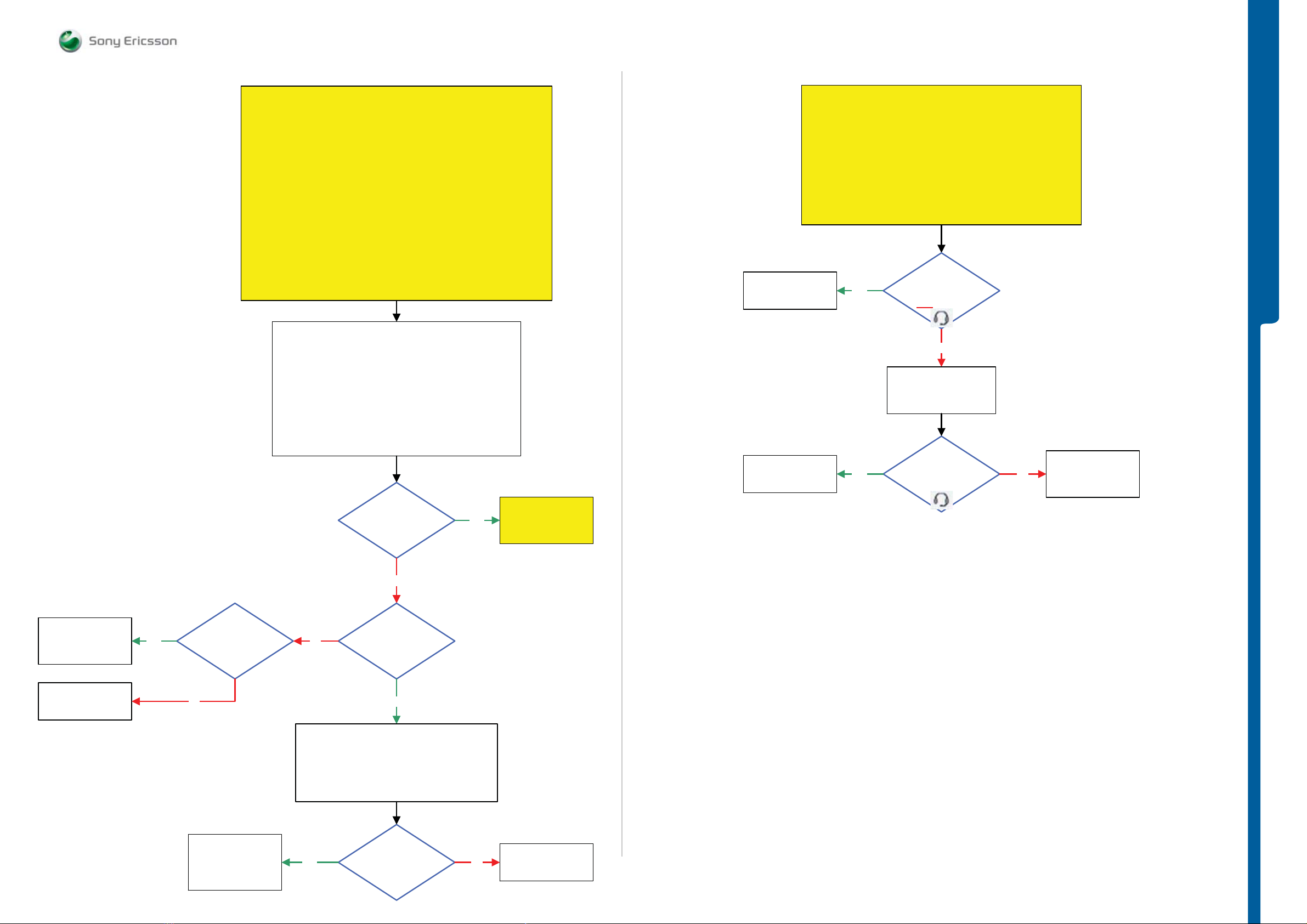

TROUBLESHOOTING Dead Phone Proble m s

SEMC Troubleshooting Manual

C903

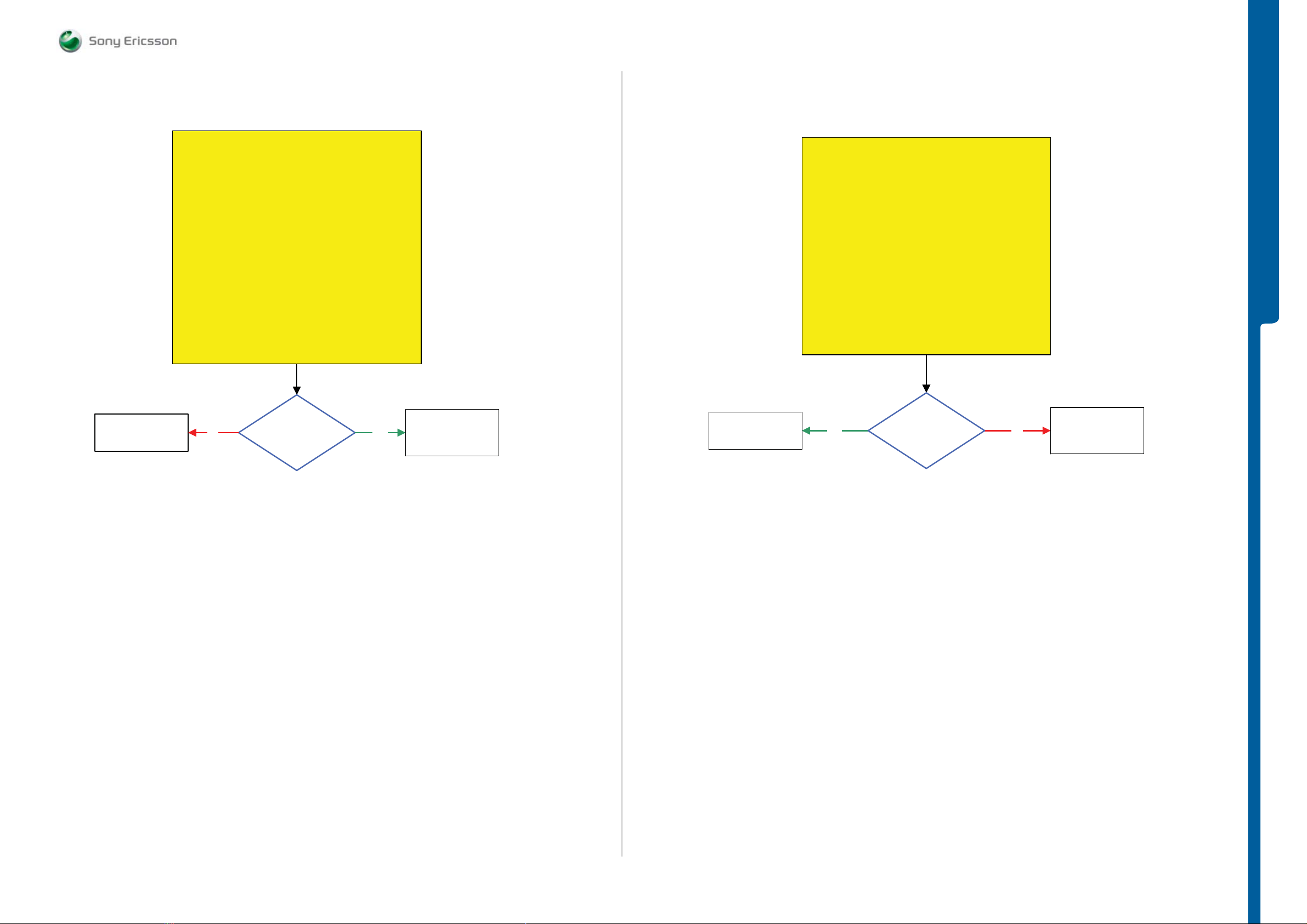

START

Try to recover the Phone by using

Connect USB Cable to the Phone

and update SEMCBOOT after this

If successful claim SW Flash

If not continue with Step 2.

current consumption

Step 1:

EMMA SW

Press key 2 and 5

Run EMMA SUCR SW

and retest the Phone

Step 2:

Use TRS Fixture

Connect: VBATT Only

Replace

N2420 or N1200

SL 5 Remove

N2000

SL 4 Escalate

Is the

still more than

1mA

Yes

SL 4 Replace

N2420

SL 5 Replace

N2000

Replace

N1211

Yes

No

current consumption

more than 1mA

Try to trace

Faulty Component

by using Freezing Spray

N2420 or N1200

getting hot

No

No

SL 5 Replace

SL 4 Escalate

Try to trace Faulty

Component by using

Freezing Spray

At MP 86 (C2209

VDDE18) and 2.8V DC at

MP 119 (C1251

LDOA_OUT)

at MP 110 (C1253)

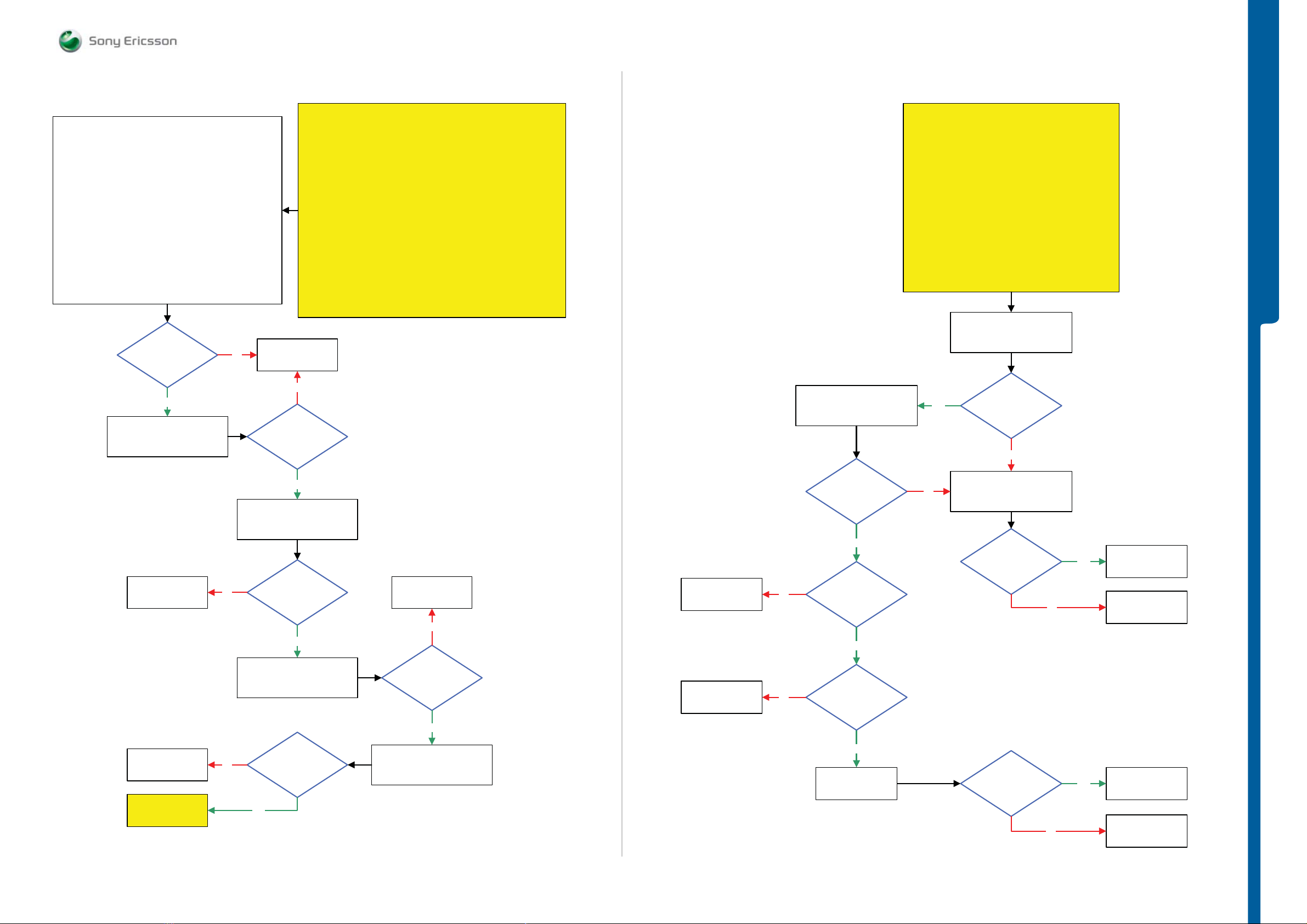

Dead Phone Problems part 1

Is the

Yes

Is

N2000

1.8V DC

Yes

2.8V DC

Yes

No

NoNo

MP 35 (X2201_Pin 4) and

DCIO/SEPI to the Phone

Is the

connection between

MP 27 (X1040 / PBA

GND) Ok

Yes

Connect:

32 kHz

at MP 79 (C2100)

Yes

32 kHz RTCCLK at

MP 106 (R1404)

Yes

26 MHz

SYSCLK1 at

MP 89 (SP2108)

Go to

Dead Phone

Problems part 2

SL 4 Escalate

No

No

No

Yes

No

SL 5 Replace

X2201 or R2200

SL 4 Escalate

SL 5 Replace

B2100 or N2000

SL 5 Replace

SL 4 Escalate

Check the following

Voltages:

2.6V MP 84 (C2402 VAUDIO26)

2.5V MP 90 (C2208 VANA25)

2.7V MP 120 (C2210 VBT27)

2.7V MP 117 (C2211 VDIG)

2.6V MP 109 (C2212 VBEAR26)

1.2V MP 61 (C2220 VCORE12)

1.8V MP 56 (L2202 VCORE18)

all Voltages

N2000

Are

Ok

Is the

VAUDIO26

Voltage

Ok

Yes

Is the

VANA25

Voltage

Ok

Yes

Is the

VBT27

Voltage

Ok

Yes

Is the

VDIG

Voltage

Ok

Dead Phone Problems part 2

START

Before following this guide the

Dead Phone Problems part 1 TRS guide

No

No Yes

No

No

NOTE !

must be finished.

Is N2422

getting hot

Is any of

N2200 or N2010

getting hot

Is N1300

getting hot

Is any of

N2411 or N1300

getting hot

Yes

No

No

Yes

No

Yes

TROUBLESHOOTING

Replace

N2422

SL 5 Replace

N2000

SL 4 Escalate

SL 4 Replace

N2200

SL 5 Replace

N2010

SL 5 Replace

N2000

SL 4 Escalate

Replace

N1300

SL 5 Replace

N2000

SL 4 Escalate

Replace

N2411 or N1300

Replace

N1200 or N1300

SL 5 Replace

N2010

SL 4 Escalate

SL 5 Replace

N2020

SL 4 Escalate

Go to Data

Communication

Problems TRS guide

Yes

Yes

1.8V DC

at MP 108 (R2115)

No

Is the

ITP SW Flash

Successful

No

Step 1:

Disconnect:

VBATT and DCIO/SEPI

Step 2:

Main Flex Assy and Navigation PBA

Press the ”C” key and Connect

USB Cable from the PC to the PBA

Flash the Phone with the ETS SW

Connect:

Assy to the PBA

Connect: VBATT Only

Step 3:

Use EMMA SW

Yes

Yes

Is the

VBEAR26

Voltage

Ok

Yes

No

No

Is X4202

damaged

No

SL 5 Replace

N2000

SL 4 Escalate

Go to

Dead Phone

Problems part 3

Yes

Replace

X4202

1228-1147 rev. 1

9 (129)

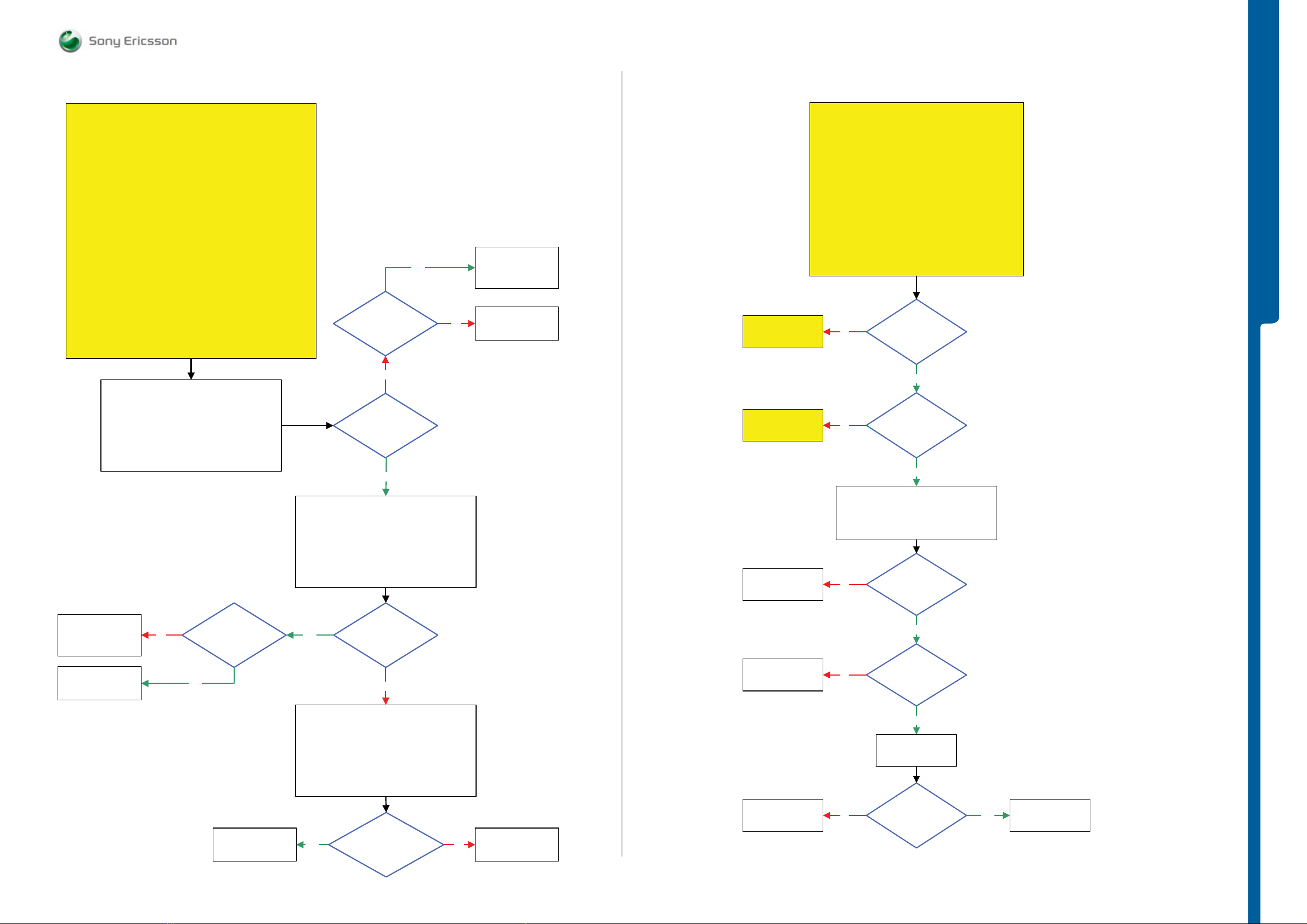

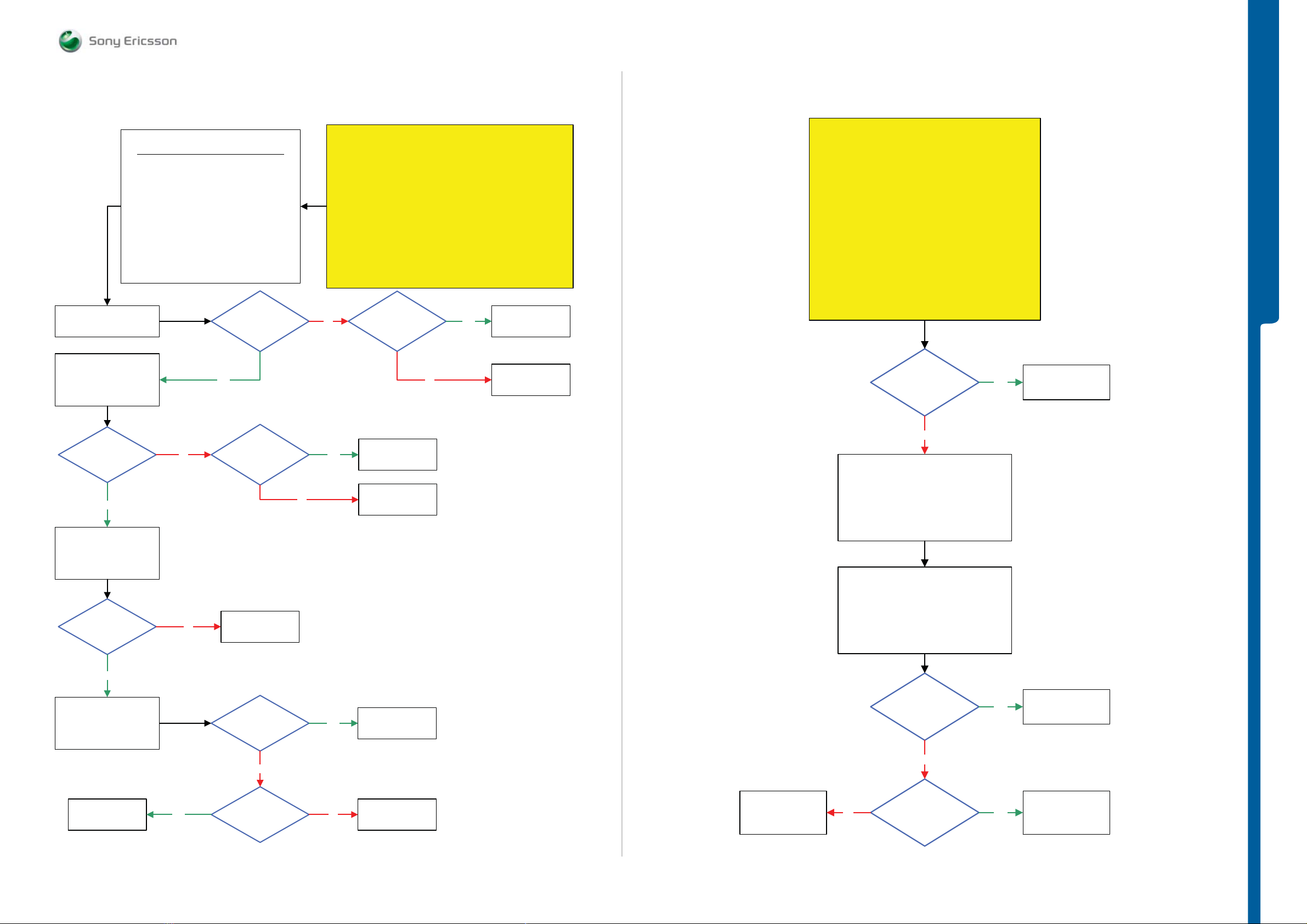

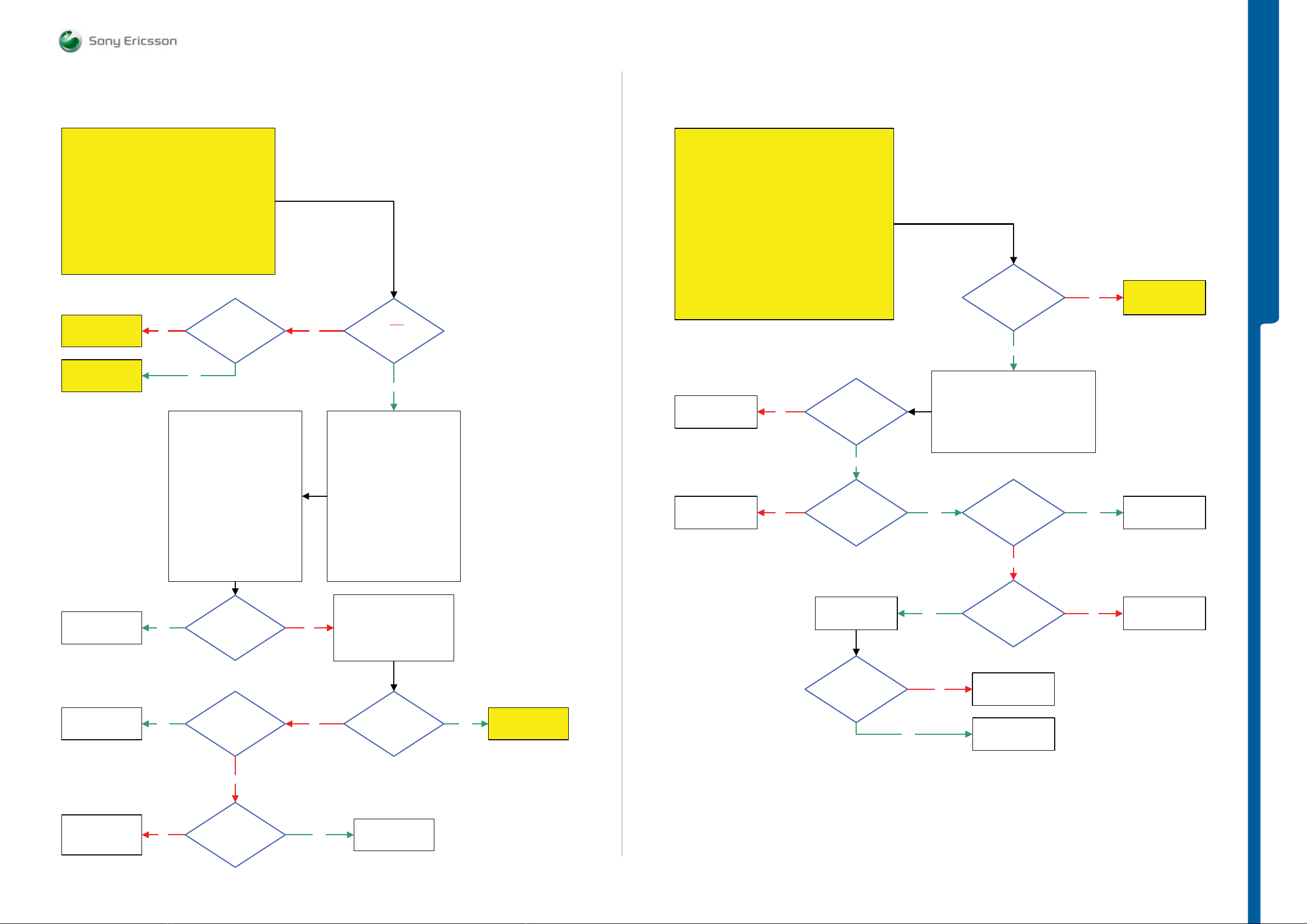

Page 10

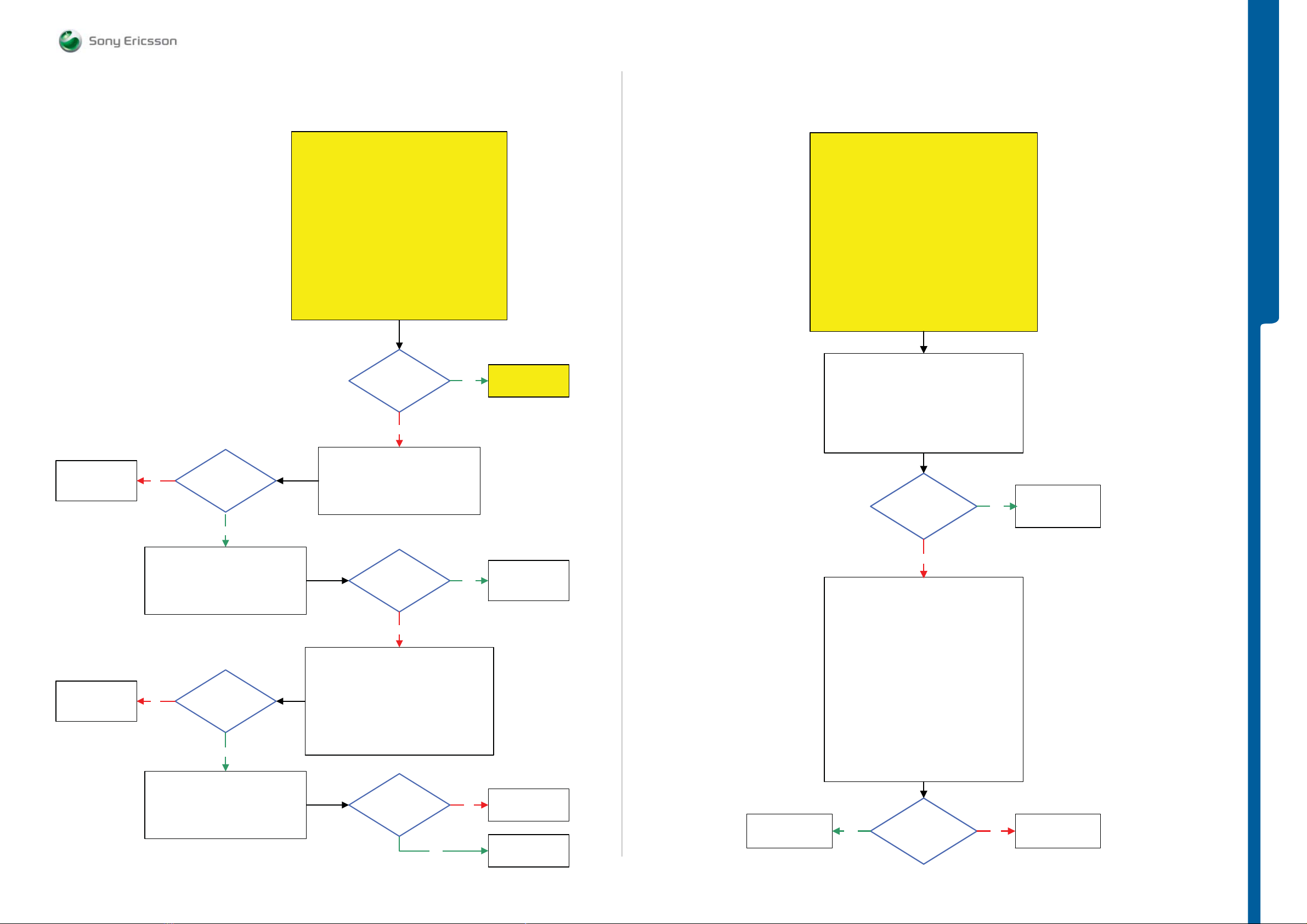

TROUBLESHOOTING

Dead Phone Proble m s - D is p l ay Proble m s

SEMC Troubleshooting Manual

C903

Is the

VCORE12

Voltage

Ok

Yes

No

Dead Phone Problems part 3

START

Before following this guide the

Dead Phone Problems part 2 TRS guide

1.1V – 1.2V DC

at MP 74

(V2201_Cathode)

Yes

1.1 – 1.2V DC

at MP 61 (C2220)

NOTE !

must be finished.

No

Yes

No

3.8 Volt DC at

MP 67 (L2201)

SL 5 Replace

N2000 or N2010

SL 4 Escalate

Replace

L2200

Yes

No

SL5 Replace

L2201

SL4 Escalate

SL 5 Replace

V2201 or N2000

SL 4 Escalate

Main Flex Assy, Navigation PBA Assy and Display to the PBA

Go to

Display illumination

Problems TRS guide

Display Problems

START

Load ETS SW into the Phone

Use TRS Fixture Display Holder and Connect:

If Display is working on the TRS Fixture then Replace

Display, Main Flex Assy or Navigation PBA Assy

If not continue with the Display Problems TRS guide

No

Use TRS Fixture

Connect: VBATT and DCIO/SEPI

Use Fault Trace SW and go to:

MMI

Misc

Init Screen Testing

Display Pattern

Activate:

TV Test Pattern

Is the

Display Backlights

Ok

TROUBLESHOOTING

Is the

VCORE18

Voltage

Ok

Yes

Step 1:

Disconnect:

VBATT and DCIO/SEPI

Step 2:

Connect:

Main Flex Assy and Navigation PBA

Assy to the PBA

Connect: VBATT Only

Step 3:

Use EMMA SW

Press the ”C” key and Connect

USB Cable from the PC to the PBA

Flash the Phone with ETS SW

No

Is MP 56 (L2202)

Short circuit to GND

No

Disconnect:

VBATT and DCIO/SEPI

Is

L2202 = Max 0.5 Ohm

Is the

ETS SW Flash

Successful

Yes

No

Yes

No

Yes

SL 4 Replace

N2200

SL 5 Replace

C2231 or N2010

SL 5 Replace

L2202

SL 4 Escalate

SL 4 Replace

N2200

SL 5 Replace

N2010

SL 5 Replace

N2020

SL 4 Escalate

Go to Data

Communication

Problems TRS guide

Go to

TV OUT Problems

TRS guide

Go to

Opto Sense

Problems TRS guide

SL 5 Replace

N2010

SL 4 Escalate

No

No

No

Yes

Is TV OUT

Ok

Yes

Is the picture

too dark or

too light

Yes

Replace

X4202

Is the Display

Problem solved

Yes

Claim Component

X4202

1228-1147 rev. 1

10 (129)

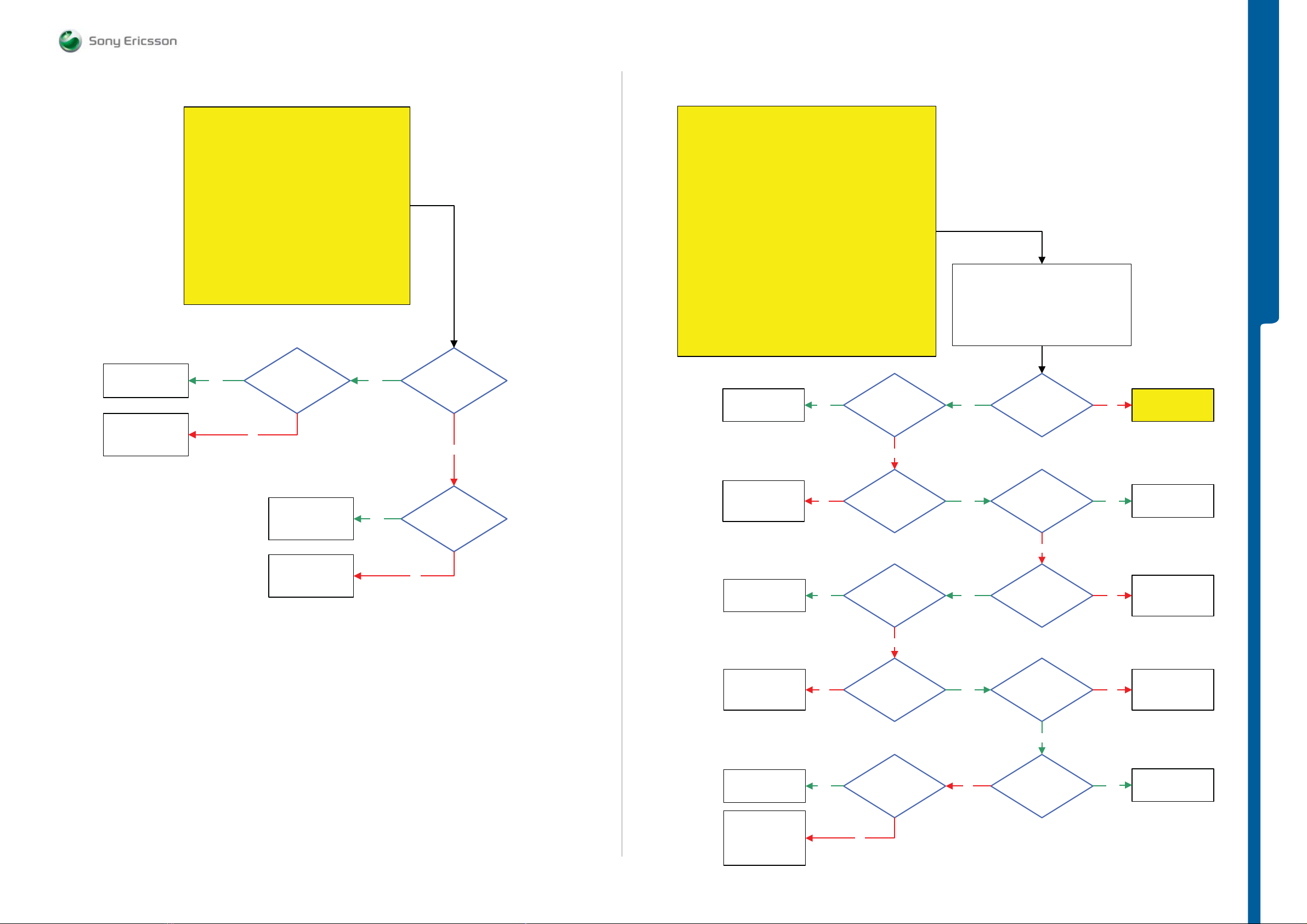

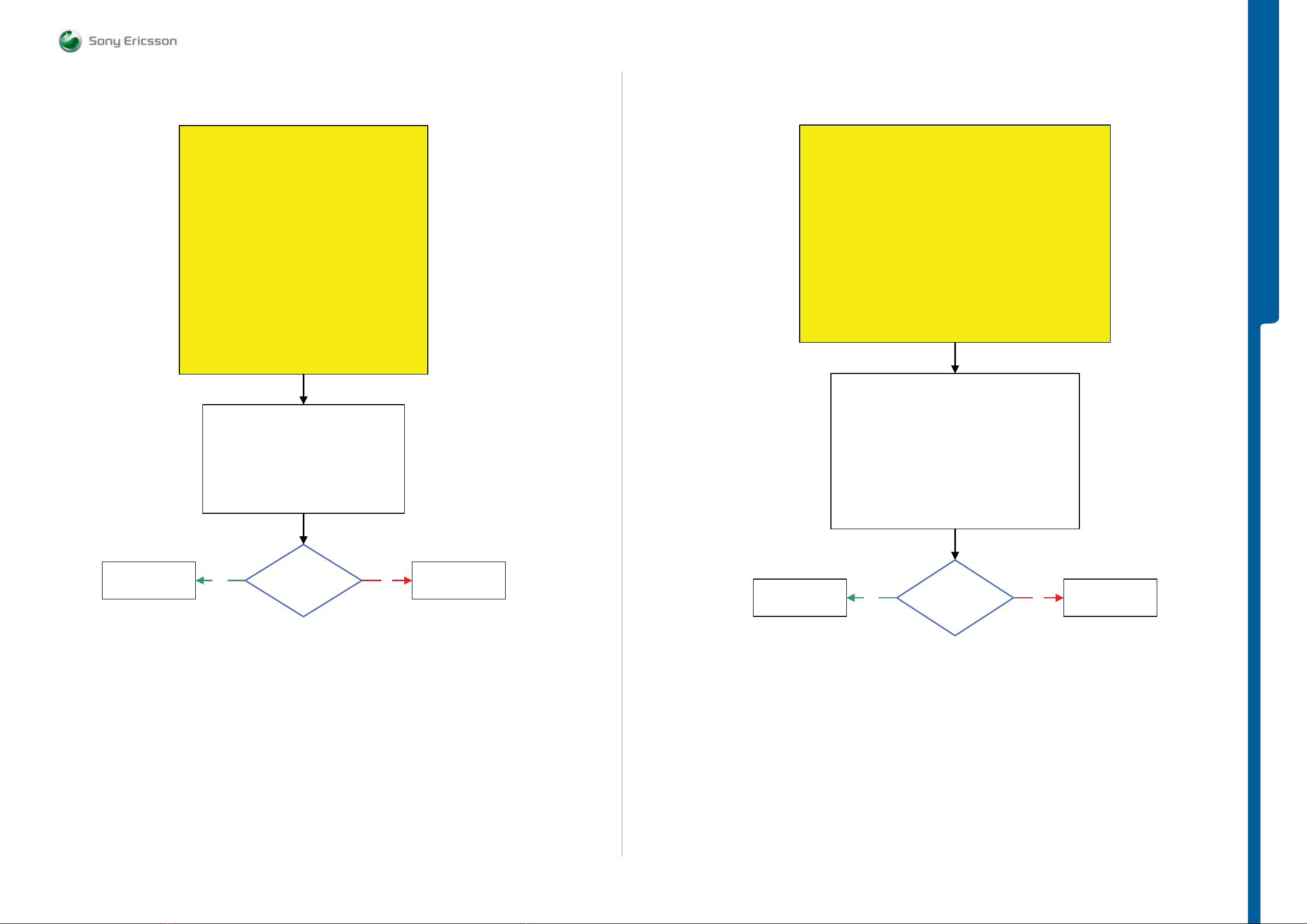

Page 11

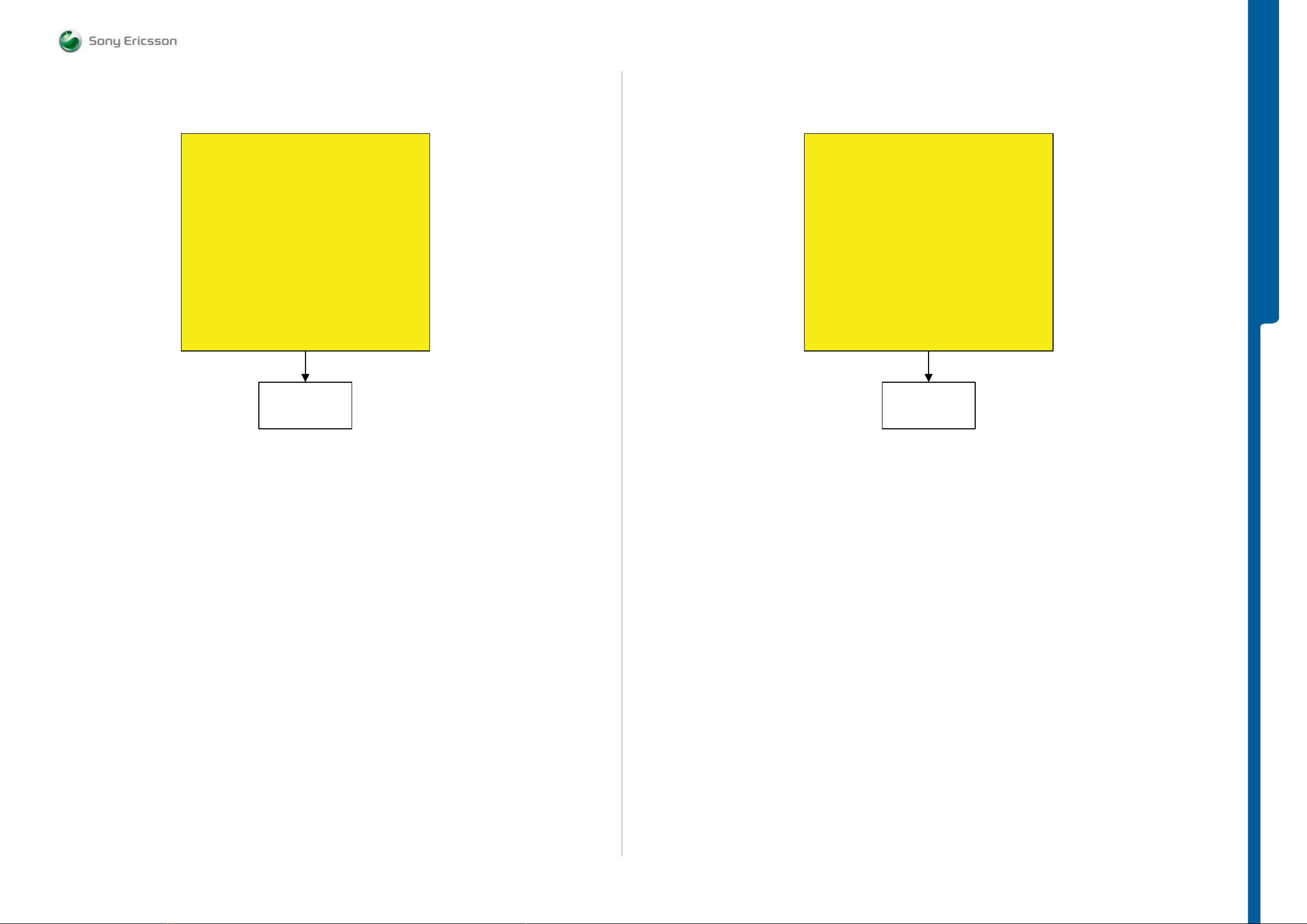

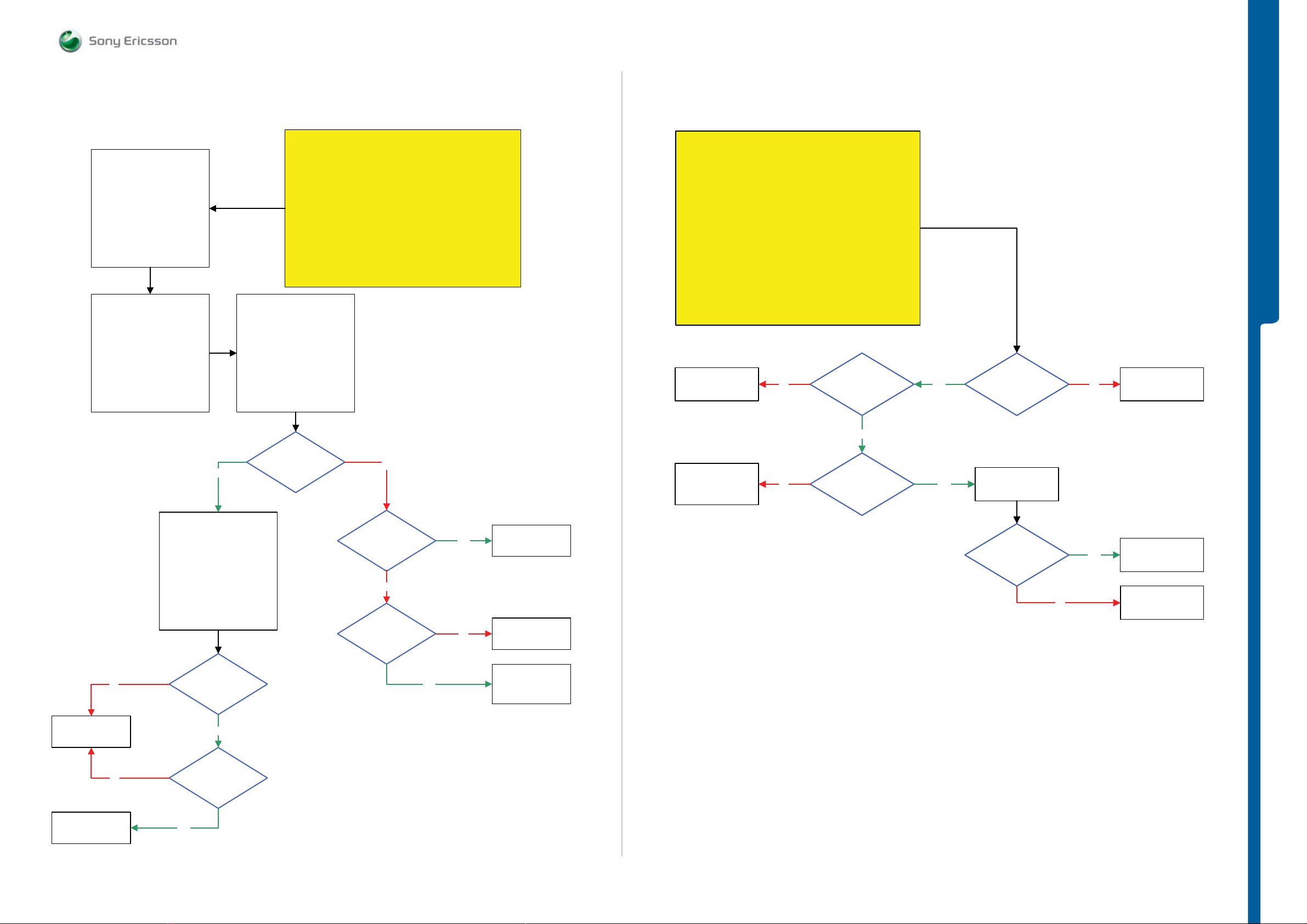

TROUBLESHOOTING Display Illumin at io n Prob le m s

- Opto Sensor Prob le m s

SEMC Troubleshooting Manual

C903

Display Illumination Problems

START

Step 1:

Flash the Phone with EMMA SUCR SW

If successful claim SW Flash

If not go to step 2.

Step 2:

Load ETS SW into the Phone

Use TRS Fixture

Use TRS Fixture Display Holder and Connect:

Main Flex Assy, Navigation PBA Assy and Display to the PBA

Connect: VBATT and DCIO/SEPI

Use Fault Trace SW and go to:

MMI

Misc

Init Screen Testing

Led and Backlight

Activate:

Display Backlight

If Display Backlight is working on the TRS Fixture then Replace

Display, Main Flex Assy or Navigation PBA Assy

If not continue with the

Display illumination Problems TRS guide

1: Use Fault trace SW and go to:

MMI

Misc

Init Screen Testing

Led and Backlight

Deactivate:

Display Backlight

2: Disconnect the Main Flex Assy and remove

the Display Holder from the TRS Fixture

Yes

3.7V - 3.8V DC at

MP 57 (N4201_Pin 3)

No

3.7V - 3.8V DC

at MP 25 (TP4200)

Yes

No

SL 4 Replace

N4201

SL 5 Replace

L4201

Replace

L4200

Go to

Display illumination

Problems TRS guide

Go to

Dispaly Problems

TRS guide

Opto Sense Problems

START

Replace Main Flex Assy and retest the Phone

If successful claim Main Flex Assy

Replace Navigation PBA Assy and retest the Phone

If successful claim Navigation PBA Assy

Replace Display and retest the Phone

If successful claim Display

Opto Sense Problems TRS guide

No

No

Step 1:

if not go to step 2.

Step 2:

If not go to step 3.

Step 3:

if not continue with the

Is the

Display

illumination (LEDs)

Ok

Yes

Can you see

any picture/image in

the Display

Yes

TROUBLESHOOTING

SL 4 Replace

V4200

SL 5 Replace

N2000

Replace

X4202

No

0 Volt DC at

MP 26 (TP4201) and

MP 20 (TP4202)

Yes

Replace

N4201

Yes

Yes

Fault trace SW

MMI

Misc

Init Screen Testing

Led and Backlight

Activate:

Display Backlight

17V - 20V

Pk-Pk Pulses

at MP 25 (TP4200)

Shortly after the Display

Backlight has been

Activated

No

Fault trace SW

MMI

Misc

Init Screen Testing

Led and Backlight

1: Deactivate:

Display Backlight

2: Activate:

Display Backlight

More

than 4 Volt Pk-Pk

Pulses at MP 58 (N4201_Pin1)

Shortly after the Display

Backlight has been

activated

No

SL 5 Replace

N2000

SL 4 Escalate

SL 5 Replace

N2000

SL 4 Escalate

Replace

N2210

SL 5 Replace

N2000

SL 4 Escalate

Use TRS Fixture

Connect: VBATT and DCIO/SEPI

1.8V – 2.3V

Pk-Pk Pulses at

No

No

No Yes

MP 107 (R2250 OPTO_EN)

Shortly after phone

Power On

Yes

3V – 3.5V

Pk-Pk Pulses at

MP 37 (TP2203 VOPTO30)

Shortly after phone

Power On

Yes

Replace

X4202

Is the

Opto Sensor Problem

solved

Claim Component

X4202

1228-1147 rev. 1

11 (129)

Page 12

TROUBLESHOOTING On-Off Key

- Numeri c Keypad Proble m s

SEMC Troubleshooting Manual

C903

Replace

V2470

SL 5 Replace

V2480, R2459, R2471

or N2010

SL 4 Escalate

On-Off Key Problems

START

Replace Navigation PBA Assy and retest the Phone

If successful claim Navigation PBA Assy

Replace Main Flex Assy and retest the Phone

If successful claim Main Flex Assy

Connect: VBATT and DCIO/SEPI

Yes

No

Step 1:

if not go to step 2.

Step 2:

if not go to step 3.

Step 3:

Use TRS Fixture

1.8 Volt DC

at MP 44

(V2470_Anode)

Yes

Is the

Problem with

Power Off

No

Numeric Keypad Problems

START

Load ETS SW into the Phone

Connect Key Flex Assy and Keyboard to the PBA

Perform Keypad Scan Test by pressing all

Keypads on the Key Flex Assy and the Camera Button (S2403)

If successful Replace Key Flex Assy

Numeric Keypad Problems TRS guide

SL 5 Replace

V2480 or N2010

SL 4 Escalate

Use TRS Fixture

Connect: VBATT and DCIO/SEPI

Use Fault Trace SW and go to:

If not then continue with the

MMI

Misc

Init Screen Testing

Activate

Keypad Scan Test

Yes

MP 50 (V2480_Pin C2)

Is

Short circuit to

GND

No

1: Disconnect the VBATT and DCIO/SEPI

Disconnect the Key Flex Assy from the PBA

2: Connect the VBATT and DCIO/SEPI again

Is the

Yes

Camera Button

S2403

Ok

No

TROUBLESHOOTING

Go to

Camera Button

Problems TRS guide

SL 4 Replace

X4202

SL 5 Replace

N2000

SL 4 Replace

V2470 or X4202

SL 5 Replace

N2000

Yes

3.7 Volt DC

at MP 46

(V2470_Cathode)

No

SL 5 Replace

R2454, R2470 or

N2010

SL 4 Escalate

SL 5 Replace

V2482 or N2010

SL 4 Escalate

SL 5 Replace

R2456, R2475 or

N2010

SL 4 Escalate

SL 5 Replace

V2476 or N2010

SL 4 Escalate

SL 4 Replace

X2400

SL 5 Replace

R2485, R2486, R2487

R2488 or R2489

No

Yes

No

Yes

1.8 Volt DC

at MP 50

(V2480_Pin C2)

Is MP 51

(V2482_Pin C1)

or MP 53 (V2482_Pin

C2) Short circuit to

GND

No

1.8 Volt DC

at MP 51

(V2482_Pin C1)

Is

MP 47 (V2476_Pin C1)

Short circuit to

GND

No

Yes

Yes

Yes

No

MP 45 (V2481_Pin C2)

Is

Short circuit to

GND

No

1.8 Volt DC

at MP 45

(V2481_Pin C2)

1.8 Volt DC

at MP 53

(V2482_Pin C2)

Yes

Is

MP 91 (V2472_Pin C2)

Short circuit to

GND

Yes

No

No

Yes

SL 5 Replace

V2481 or N2010

SL 4 Escalate

SL 5 Replace

R2493, R2472 or

N2010

SL 4 Escalate

SL 5 Replace

R2491, R2474 or

N2010

SL 4 Escalate

SL 5 Replace

V2472 or N2010

SL 4 Escalate

1228-1147 rev. 1

12 (129)

Page 13

TROUBLESHOOTING

Nav i g at i on Keypad Proble m s - Volume Up an d D own Bu t t on Prob l e m s

SEMC Troubleshooting Manual

C903

Navigation Keypad Problems

START

Step 1:

Go to Service Tests Menu and perform Keyboard Test

If successful flash the Phone with EMMA SUCR SW

if not go to step 2.

Step 2:

Load ETS SW into the Phone

Use TRS Fixture

Use TRS Fixture Display Holder and Connect:

Main Flex Assy and Navigation PBA Assy to the PBA

Connect: VBATT and DCIO/SEPI

Use Fault Trace SW and go to:

MMI

Misc

Init Screen Testing

Activate

Keypad Scan Test

Perform Keypad Scan Test by pressing all Navigation Keypads

If successful Replace Navigation PBA Assy or Main Flex Assy

If not then continue with the

Navigation Keypad Problems TRS guide

Volume + and - Button Problems

START

Step 1:

Go to Service Tests Menu and perform Keyboard Test

If successful flash the Phone with EMMA SUCR SW

if not go to step 2.

Step 2:

Load ETS SW into the Phone

Use TRS Fixture

Connect: SIM Flex Assy to the PBA

Connect: VBATT and DCIO/SEPI

Use Fault Trace SW and go to:

MMI

Misc

Init Screen Testing

Activate

Keypad Scan Test

Perform Keypad Scan Test by pressing Volume + and - Buttons

If successful replace SIM Flex Assy

If not then continue with the

Volume + and – Button Problems TRS guide

TROUBLESHOOTING

SL 4 Replace

X4202

SL 5 Replace

R2489 or N2010

1: Disconnect the VBATT and DCIO/SEPI

2: Disconnect and Remove the

Main Flex Assy and Navigation PBA Assy

No

from the TRS Fixture

Are all

Numeric Keys

Ok

Yes

Is

MP 48 (V2476_Pin C2)

Short circuit to

GND

No

Yes

Go to

Numeric Keypad

Problems TRS guide

SL 5 Replace

V2476 or N2010

SL 4 Escalate

Replace

X4300

Yes

Are all

Numeric Keys

Ok

No

Numeric Keypad

Problems TRS guide

Go to

1228-1147 rev. 1

13 (129)

Page 14

TROUBLESHOOTING Camera Butto n Prob le m s

- Play & Camera Mode Butt o n Probl e m s

SEMC Troubleshooting Manual

C903

Camera Button Problems

SL 5 Replace

V2472, V2471 or

N2010

SL 4 Escalate

START

Use TRS Fixture

Connect: VBATT and DCIO/SEPI

Is MP 93

Yes

(S2403_Pin B)

and MP 94 (S2403_Pin

C1) Short circuit

to

GND

No

Yes

1.8 Volt DC

at MP 92

(S2403_Pin A1)

Replace

Key Flex Assy

Play and Camera Mode Button Problems

START

Go to Service Tests Menu and perform Keyboard Test

If successful flash the Phone with EMMA SUCR SW

Play and Camera Mode Button Problems TRS guide

Yes

if not continue with the

Are all

Numeric Keys

Ok

No

Problems TRS guide

TROUBLESHOOTING

Go to

Numeric Keypad

SL 5 Replace

N2010

SL 4 Escalate

Replace

S2403

Yes

(S2403_Pin A1)

No

0 Volt DC

at MP 92

Press the

S2403 Camera Button

SL 5 Replace

V2481 or N2010

SL 4 Escalate

Replace

S2403

SL 5 Replace

R2492, R2473 or

N2010

SL 4 Escalate

Yes

Yes

(S2403_Pin A1)

Short circuit to

1.8 Volt DC

at MP 100

(V2481_Pin C1)

No

No

Is MP 92

GND

No

1228-1147 rev. 1

14 (129)

Page 15

TROUBLESHOOTING

N avigatio n Keypad LE D Prob le m s

SEMC Troubleshooting Manual

C903

Navigation Keypad LED Problems part 1

START

Load ETS SW into the Phone

Use TRS Fixture

Remove the Dome Foil Navi PBA and Light Block Navi

PBA from the Navigation PBA

Use the TRS Fixture Display Holder and Connect

Navigation PBA and Main Flex Assy to the PBA

Connect: VBATT and DCIO/SEPI

Use Fault Trace SW and go to:

MMI

Misc

Init Screen Testing

Led and Backlight

Activate:

Navigation Keypad

Are all

Navigation PBA

LEDs On

(except V8450)

No

Yes

Navigation Keypad

LED Problems part 2

Go to

Navigation Keypad LED Problems part 2

TROUBLESHOOTING

START

Note! Before following this guide

the Navigation Keypad Problems part 1

TRS guide must be finished.

1: Use Fault Trace SW and go to:

MMI

Misc

Init Screen Testing

Deactivate:

Navigation Keypad

2: Activate:

CleraKey BLUE LED

SL 4 Replace

X4202

SL 5 Replace

N2000

SL 4 Replace

N4240

SL 5 Replace

N2000

Are

No

No

all WHITE LEDs

Ok

Yes

Check the following BLUE LEDs:

V8431, V8434,

V8440, V8441, V8442 and V8443

3.8 Volt DC

at MP 55

(N4240_Pin 3)

Yes

Use Fault Trace SW and go to:

MMI

Misc

Init Screen Testing

Activate:

Navigation Keypad

Check the following WHITE LEDs:

V8420, V8421, V8422, V8423

V8424, V8425, V8426 and V8427

Are the

BLUE LEDs

Ok

No

1: Use Fault Trace SW and go to:

MMI

Misc

Init Screen Testing

Deactivate:

Navigation Keypad

2: Disconnect VBATT and DCIO/SEPI and

Remove the TRS Fixture Display Holder

3: Connect VBATT and DCIO/SEPI

0 Volt DC

at MP 55

(N4240_Pin 3)

Yes

No

Yes

Replace

Main Flex Assy or

Navigation PBA

Assy

Replace

N4240 or N2410

Replace

X4202

Replace

N4240 or X4202

Is V8450

”C” Key BLUE LED

Yes

Ok

No

1: Use Fault Trace SW and go to:

MMI

Misc

Init Screen Testing

Deactivate:

CleraKey BLUE LED

2: Disconnect VBATT and DCIO/SEPI and

Remove the TRS Fixture Display Holder

3: Connect VBATT and DCIO/SEPI

4: Use Fault Trace SW and go to:

MMI

Misc

Init Screen Testing

Activate:

CleraKey BLUE LED

1.8 Volt DC

Yes

at MP54

No

(N4240_Pin 1)

Replace

Main Flex Assy or

Navigation PBA

Assy

Replace

N2410

1228-1147 rev. 1

15 (129)

Page 16

TROUBLESHOOTING Numeri c Keypad LED Probl e m s

- Camera Butto n LED Problems

SEMC Troubleshooting Manual

C903

Numeric Keypad LED Problems

START

Load ETS SW into the Phone

Use TRS Fixture

Connect: Key Flex Assy to the PBA

Connect: VBATT and DCIO/SEPI

Use Fault Trace SW and go to:

MMI

Misc

Init Screen Testing

Led and Backlight

Activate:

Numeric Keypad

If Numeric Keypad LED is working on the TRS Fixture

then Replace Key Flex Assy

If not then continue with the

Numeric Keypad LED Problems TRS guide

SL 4 Replace

X2400

SL 5 Replace

V4112 or N2000

Camera Button LED Problems

TROUBLESHOOTING

START

SL 4 Replace

V4350 or V4360

SL 5 Replace

N2000

1228-1147 rev. 1

16 (129)

Page 17

TROUBLESHOOTING Tally LED Problems

- Trickle Cha rg e LED Problems

SEMC Troubleshooting Manual

C903

Replace

N2410

Tally LED Problems

START

Load ETS SW into the Phone

Connect: VBATT and DCIO/SEPI

Continue with the Tally LED Problems TRS guide

No

Use TRS Fixture

Use Fault Trace SW and go to:

MMI

Misc

Init Screen Testing

Led and Backlight

Activate:

Tally LED

1.8 Volt DC

at MP 30 (R4310)

Yes

SL 4 Replace

V4310

SL 5 Replace

V4311

SL 5 Replace

N2000

SL 4 Escalate

Trickle Charge LED Problems

START

Load ETS SW into the Phone

Connect: VBATT and DCIO/SEPI

Continue with the Trickle Charge LED Problems

No

Use TRS Fixture

Use Fault Trace SW and go to:

MMI

Misc

Init Screen Testing

Led and Backlight

Activate:

Charge LED

TRS guide

1.8 Volt DC

at MP 95

(V4350_Anode)

Yes

TROUBLESHOOTING

Replace

V4350 or V4360

1228-1147 rev. 1

17 (129)

Page 18

TROUBLESHOOTING Flash LED Problems

SEMC Troubleshooting Manual

C903

Flash LED Problems in Camera Mode

START

Step 1:

Go to Service Test and perform the Main Camera Test

If successful go to step 2, if not go to

Main Camera Problems TRS guide.

Step 2:

Replace Camera 5MPixel CMOS Slim

If successful claim Camera 5MPixel CMOS Slim

if not go to step 3.

Step 3:

Replace SIM Flex Assy

If successful claim SIM Flex Assy

if not go to step 4.

Step 4:

Load ETS SW into the Phone

Use TRS Fixture

Connect the Main Camera to the PBA

Connect: VBATT and DCIO/SEPI

Use Fault Trace SW and go to:

MMI

Misc

Init Screen Testing

Led and Backlight

Activate:

Flash LED

Flash LED Problems in Torch Mode

START

Load ETS SW into the Phone

Use TRS Fixture

Connect: VBATT and DCIO/SEPI

Use Fault Trace SW and go to:

MMI

Misc

Init Screen Testing

Led and Backlight

Activate:

Flash LED

3.8 Volt DC at

MP 97 (R4115)

No

Yes

TROUBLESHOOTING

Replace

V4110, V4111

or N4401

Is the

Flash LED

Ok

Yes

1: Use Fault Trace SW and go to:

MMI

Misc

Init Screen Testing

Led and Backlight

Deactivate:

Flash LED

2: Activate

Main Camera

1.8 Volt DC at

MP 98 (R2298)

Yes

No

No

Go to Flash LED

Problems in

Torch Mode

Replace

N2410

SL 4 Replace

N4401

SL 5 Replace

N2000 or N2010

Yes

3.8 Volt DC at

MP 96 (L4102)

No

Replace

L4102

SL 4 Replace

N4401 or X4300

SL 5 Replace

N2000 or N2010

1.8 Volt DC at

MP 99 (C2298)

NoYes

Replace

N2271

1228-1147 rev. 1

18 (129)

Page 19

TROUBLESHOOTING Camera Lens LE D Prob le m s

- Camera Cover Detect Problem s

SEMC Troubleshooting Manual

C903

Replace

N2410

Camera Lens LED Problems

START

Replace SIM Flex Assy and retest the Phone

If successful claim SIM Flex Assy

Load ETS SW into the Phone

Connect: VBATT and DCIO/SEPI

Use Fault Trace SW and go to:

Continue with the Camera Lens LED Problems TRS guide

No

Step 1:

if not go to step 2.

Step 2:

Use TRS Fixture

MMI

Misc

Init Screen Testing

Led and Backlight

Activate:

Camera Lens LED

1.8 Volt DC

at MP 19 (R4320)

Yes

SL 4 Replace

X4300

SL 5 Replace

V4321

Replace

SIM Flex Assy

Camera Cover Detect Problems

START

Replace Battery Cover Assy and retest the Phone

If successful claim Battery Cover Assy

Connect SIM Flex Assy to the PBA

Connect: VBATT and DCIO/SEPI

Camera Cover Detect Problems TRS guide

NOTE! The MP is located on the SIM Flex Assy

Step 1:

If not go to step 2.

Step 2:

Use TRS Fixture

Continue with the

1.8 Volt DC

at MP 121

(B8400_Pin 1)

NoYes

TROUBLESHOOTING

SL 4 Replace

X4300

SL 5 Replace

N2010

1228-1147 rev. 1

19 (129)

Page 20

TROUBLESHOOTING Main Camera Problems

SEMC Troubleshooting Manual

C903

Main Camera Problems part 1

Use Fault Trace SW and go to:

Ignore these messages when they appear

(In the right corner of the Fault Trace SW)

Error_CommandFailed, ERR:”

”

Use Fault Trace SW and

Repeat the Main Camera Test

MMI

Misc

Init Screen Testing

Activate:

Main Camera Test

NOTE !

in the Trace window

1.8 Volt DC

at MP 87 (N2206_Pin 4)

Shortly after the Main

Camera Test has been

activated

Yes

No

Flash the Phone with EMMA SUCR SW and go to Service Tests Menu

SL 5 Replace

N2010

SL 4 Escalate

No

1.8 Volt DC

at MP 88 (R2290)

Shortly after the Main

Camera Test has been

activated

START

Step 1:

Perform: Main and VGA/VTF Camera Tests

If the Tests are successful then claim SW Flash

Replace Camera 5 Mpixel CMOS Slim and retest the Phone

If successful claim Camera 5 Mpixel CMOS Slim

Replace SIM Flex Assy and retest the Phone

if not go to step 2.

Step 2:

If not go to step 3.

Step 3:

If successful claim SIM Flex Assy

If not go to step 4.

Step 4:

Load ETS SW into the Phone

Use TRS Fixture

Connect: VBATT and DCIO/SEPI

Use Fault Trace SW

Main Camera Problems part 2

Use Fault Trace SW and

Repeat the Main Camera Test

START

Before following this guide the

Main Camera Problems part 1

TRS Guide must be finished.

Repeat the Main Camera Test

Yes

NOTE !

Use Fault Trace SW and

1.8 Volt DC

at MP 28 (TP2215)

Shortly after the Main

Camera Test has been

activated

No

TROUBLESHOOTING

Replace

N2206

Replace

N2290

Go to

Main Camera

Problems Part 2

Yes

Use Fault Trace SW and

Repeat the Main Camera Test

2.8 Volt DC

at MP 29 (TP2216)

No

Shortly after the Main

Camera Test has been

activated

Yes

Use Fault Trace SW and

Repeat the Main Camera Test

1.8 Volt DC

at MP 32 (TP2214)

No

Shortly after the Main

Camera Test has been

activated

Yes

Replace

N2290

No

2.8 Volt DC

at MP 33 (TP2213)

Shortly after the Main

Camera Test has been

activated

Yes

Use Fault Trace SW and

Repeat the Main Camera Test

SL 5 Replace

N2010

SL 4 Escalate

Replace

X1040 or X1041

No

No

1.2 Volt DC

at MP 31 (TP2217)

Shortly after the Main

Camera Test has been

activated

Yes

26 MHZ

CAMSYSCLK

at MP 52 (C2103 Shortly )

after the Main Camera

Test has been

activated

Yes

Are

MP 27 (X1040)

and X1041

connected to

GND

Yes

Replace

X4300

No

Disconnect

VBATT and DCIO/SEPI

Are

L2260 and L2261

= Max 1 Ohm

Is the

Main Camera Problem

Solved

No

No

Yes

Yes

Replace

N2203

Replace

L2260 or L2261

Claim Component

X4300

SL 5 Replace

S4300 or N2010

SL 4 Escalate

1228-1147 rev. 1

20 (129)

Page 21

TROUBLESHOOTING VGA/VTF Cam e ra Probl e m s

- Data Communi cation Problems

SEMC Troubleshooting Manual

C903

This TRS guide is valid ONLY for C903 phones with VGA/VTF Camera support.

Flash the Phone with EMMA SUCR SW and go to Service Tests Menu

If not then continue with the VGA/VTF Camera Problems TRS guide

SL 4 Replace

X4202

SL 5 Replace

N4300, N4301, N4302

N4303, N4304 or

N4305

VGA/VTF Camera Problems

START

NOTE !

Step 1:

Perform the: Main and VGA/VTF Camera Tests

If the Tests are successful then claim SW Flash

Replace the Main Flex Assy and retest the Phone

If successfull claim Main Flex Assy

Replace the Navigation PBA Assy and retest the Phone

If successfull claim Navigation PBA Assy

Yes

if not go to step 2.

Step 2:

If not go to step 3.

Step 3:

Is the

Main Camera

Ok

No

Go to

Main Camera

Problems TRS guide

START

Step 1:

Perform

System Connector Protection Test

If successful go to step 2.

Step 2:

Dowload ETS SW into the Phone

Go to

USB/VBUS

Charging Problems

SL 5 Replace

R2442

SL 4 Escalate

Data communication Problems

Is the

Flash process

Start-up when using

EMMA SW

No

1: Connect: VBATT and DCIO/SEPI

3: Connect: USB Cable from the PC

No

Use TRS Fixture

2: Remove: DCIO/SEPI

Is

the USB

Charging

Ok

5 Volt DC at

MP 75 (C2433)

Yes

TROUBLESHOOTING

No

YesNo

No

Is the

ETS SW Flash

Successful

Is

MP 14 (X2405_Pin 10)

Short circuit to GND

No

Is

MP 15 (X2405_Pin 11)

Short circuit to the

GND

Yes

Yes

Yes

SL 5 Replace

N2020

SL 4 Escalate

Replace

V2421

Replace

V2420

Is the

VGA/VTF Camera

Problem Solved

No

Yes

Claim Component

Faulty Component

SL 5 Replace

N2010

SL 4 Escalate

SL 4 Replace

N2420

SL 5 Replace

N2010

Yes

Yes

2.7V – 3.3V DC

at MP 68 (C2437) and

1.8V DC at

MP 76 (C2435)

Yes

Remove the PBA from the

TRS Fixture

Max

2 Ohm between

MP 14 (X2405_Pin 10)

and MP 65

(Z2400_Pin 2)

Yes

Max

2 Ohm between

MP 15 (X2405_Pin 11)

and MP 66

(Z2400_Pin 3)

No

No

No

SL 4 Replace

N2420

SL 5 Replace

N2010

Max

0.5 Ohm between

MP 14 (X2405_Pin 10)

and MP 63

(Z2400_Pin 1)

Max

0.5 Ohm between

MP 15 (X2405_Pin 11=

and MP 64

(Z2400_Pin 4)

Yes

No

No

SL 5 Replace

X2405

SL 4 Escalate

Replace

Z2400

SL 5 Replace

X2405

SL 4 Escalate

Yes

Replace

Z2400

1228-1147 rev. 1

21 (129)

Page 22

TROUBLESHOOTING Charging Problems

- USB/VBUS Charging Problems

SEMC Troubleshooting Manual

C903

Charging Problems

START

Step 1:

Perform Charging Test

If NOT

successful go to step 2.

Step 2:

Use TRS Fixture

Connect:

VBATT and DCIO/SEPI

Is X2201

damaged

Yes

Is MP 36 (TP2202)

Short circuit to GND

No

Yes

SL5 Replace

X2201

SL4 Escalate

SL 5 Replace

N2000

SL 4 Escalate

USB/VBUS Charging Problems

START

Perform the System Connector Protection Test

If successful go to step 2.

Use Phone with the Signalling SW (SSW)

Use TRS Fixture and connect: VBATT

Connect: USB Cable from the PC to the Phone

Step 1:

Step 2:

5V – 5.2V DC at

MP 70 (N2421_Pin 4)

No

Yes

TROUBLESHOOTING

SL 5 Replace

N2000

SL 4 Escalate

Replace

R2490 or R2449

No

No

5 Volt DC at

MP 18 (C2440)

No

Is MP 18 (C2440)

Short circuit to GND

No

Disconnect:

VBATT and DCIO/SEPI

Is the

R2490 and R2449

=Max 1 Ohm

Yes

Yes

Yes

SL 4 Replace

V2202

SL 5 Replace

N2000

SL 4 Replace

C2440, V2412 or

V2202

SL 5 Replace

C2441 or N2000

SL 4

Escalate

SL 5

Replace X2405

Replace

N2421

Yes

5V – 5.2V DC at

MP 8 (X2405_Pin 1)

Yes

Disconnect:

VBATT and USB Cable

Is L2468 = Max 1 Ohm

No

No

SL5 Replace

X2405

SL4 Escalate

Replace

L2468

1228-1147 rev. 1

22 (129)

Page 23

TROUBLESHOOTING SIM Problems

- Memory Stick Problem s

SEMC Troubleshooting Manual

C903

Activate:

SIMVCC

SIMVCC On

Activate:

SIMRSTn

Please follow instructions from 1 to 5

1: Disconnect: VBATT and DCIO/SEPI

2: Disconnect: SIM Flex Assy from the PBA

3: Restart the Fault Trace SW

4: Connect: VBATT and DCIO/SEPI

5: Use Fault Trace Sw and go to:

Logic

SIM Card Control

1.8 Volt DC at

MP C2420

Yes

SIM Problems

Flash the Phone with the EMMA SUCR SW and retest the Phone

No Yes

START

Step 1:

if successful claim SW Flash, if not go to step 2.

Load ETS SW into the Phone

Connect: SIM Flex Assy to the PBA and Insert the Test SIM

Connect: VBATT and DCIO/SEPI

Use Fault Trace SW and go to:

If the SIM Com Test is passed then Replace SIM Flex Assy

If not then continue with the SIM Problems TRS guide

Is the

C2414 Short

circuit

Step 2:

Use TRS Fixture

Logic

SIM Card Control

Activate:

SIM Com Test

No

SL 5 Replace

C2414

SL 4 Escalate

SL 5 Replace

N2000

SL 4 Escalate

Memory Stick Problems

START

Is X2403

damaged

Yes

TROUBLESHOOTING

Replace

X2403

1.8 Volt DC at

MP C2419

Yes

SIMVCC On

SIMRSTn On

Activate:

SIMCLK

1MHz and

1.8V – 2V Pk-Pk at

MP SP2407

Yes

SIMVCC On

SIMRSTn On

SIMCLK On

Activate:

SIMDAT

No

No

Is the

C2419

Short circuit

SL 5 Replace

N2010 or N2000

SL 4 Escalate

1.8 Volt DC

at MP R2416

No

Yes

Yes

SL 5 Replace

C2419

SL 4 Escalate

SL 5 Replace

N2000 or N2010

SL 4 Escalate

Replace

X4300

No

Load ETS SW into the Phone

Insert Memory M2 Card

Use TRS Fixture

Connect:

VBATT and DCIO/SEPI

Use Fault Trace SW

Fault trace SW

Logic

SIM Card control

Activate:

Memory Stick Test

Is the

Memory Stick Test

Passed

Flash the Phone with

Yes

EMMA SUCR SW

SL 5 Replace

N2000

SL 4 Escalate

Yes

No

1.8 Volt DC at

MP C2413

No

SL 5 Replace

N2010

SL 4 Escalate

SL 4 Replace

X2403

SL 5 Replace

N2000

No

No

1.8 Volt DC at

MP 43 (C2422

VMC18)

Yes

SL 4 Replace

X2403

SL 5 Replace

N2010

1228-1147 rev. 1

23 (129)

Page 24

TROUBLESHOOTING Microphone Problems

- Earphone Problems

SEMC Troubleshooting Manual

C903

Microphone Problems

START

Step 1:

Load ETS SW into the Phone

Use TRS Fixture

Connect: VBATT and DCIO/SEPI

Use Fault Trace SW

Step 2:

Continue with the

Microphone Problems TRS guide

Use Fault Trace SW and go to:

Audio and FM Radio

Audio Loop Test

Audio Input: Mic1

Loop Mode: Analog

Audio Output: Loudspeaker

Apply Audio Loop

Earphone Problems

START

Step 1:

Replace Main Flex Assy and retest the Phone

If successful claim Main Flex Assy

If not go to step 2.

Step 2:

Load ETS SW into the Phone

Use TRS Fixture

Connect: VBATT and DCIO/SEPI

Use Fault Trace SW

1: Use Fault Trace SW and go to:

Audio and FM Radio

Audio Tone

Activate:

INIT TONE TEST

Activate:

Earphone

TROUBLESHOOTING

Replace

B3100

Yes

2.2 Volt DC at

MP 115 (R3119)

No

SL 5 Replace

N2000

SL 4 Escalate

Replace

X4202

More than

400mV AC Pk-Pk

Yes No

1 kHz signal at MP 21

(TP3104) and MP 22

(TP3105)

SL 5 Replace

N2000

SL 4 Escalate

1228-1147 rev. 1

24 (129)

Page 25

TROUBLESHOOTING Loudspe aker Prob l e m s

- Handsfree Au x E a rphone Proble m s

SEMC Troubleshooting Manual

C903

Loudspeaker Problems

START

Replace Rear Cover Assy and retest the Phone

If successful claim Rear Cover Assy

Load ETS SW into the Phone

Connect: VBATT and DCIO/SEPI

Earphone Problems TRS guide

1: Use Fault Trace SW and go to:

Step 1:

If not go to step 2.

Step 2:

Use TRS Fixture

Use Fault Trace SW

Continue with the

Audio and FM Radio

Audio Tone

Activate:

INIT TONE TEST

Activate:

Loudspeaker

Can you

hear a 1 kHz tone

from the TRS Fixture

Loudspeaker

Yes

Replace

X3102

Hands-Free (PHF) Aux Earphone Problems

START

Before starting check if the Hands-Free (PHF) Connection is Ok.

System Connector Protection Test

If successful go to step 2.

Load ETS SW into the Phone

Connect: VBATT and DCIO/SEPI

Use Hands-Free (PHF) Set

Hands-Free (PHF) Aux Earphone Problems TRS guide

1: Use Fault Trace SW and go to:

2: Disconnect: DCIO/SEPI from the PBA

3: Connect the PHF set to the PBA

Note !

Step 1:

Perform the

Step 2:

Use TRS Fixture

Use Fault Trace SW

Continue with the

Audio and FM Radio

Audio Tone

Activate:

INIT TONE TEST

Activate:

PHF Earphone

TROUBLESHOOTING

SL 4 Replace

N3100

SL 5 Replace

N2000

No

Is

any of MP 24

(TP3102) or MP 23

(TP3103) Short Circuit to

GND (Measure on the TRS

Fixture)

No

1.8 Volt DC

at MP 49 (R3153)

Yes

Disconnect:

VBATT and DCIO/SEPI

Remove the PBA from the TRS Fixture

Are

L3110 and L3111

= Max 1 Ohm

Yes

No

NoYes

SL 4 Replace

N3100

SL 5 Replace

C3107 or C3108

SL 4 Replace

N2410

SL 5 Replace

N2010

SL 5 Replace

L3110 or L3111

SL 4 Escalate

SL 5 Replace

X2405

SL 4 Escalate

SL 5 Replace

N2000 or N2010

SL 4 Escalate

SL 4 Replace

N3101

SL 5 Replace

N2000 or N2010

Replace

L2406

More than

300mV AC Pk-Pk

Yes

No

Yes

1 kHz signal at MP 12

(L2403) and

MP 13 (L2404)

No

More than

400mV AC Pk-Pk

1 kHz signal at MP 82

(C3149) and

MP 81 (C3150)

Yes

Disconnect VBATT and PHF Set and

Remove PBA from the TRS Fixture

Is L2406

= Max 1 Ohm

No

Can you

hear the 1 kHz tone

In the PHF

Earphone

Are

L2403, L2404,

= Max 2 Ohm

Yes

No Yes

Is any of

C2447 or C2448

Short Circuit

YesNo

No

Go to

Hands-Free (PHF)

Aux Microphone

Problems TRS guide

Replace

L2403 or L2404,

SL 5 Replace

C2447 or C2448

SL 4 Escalate

1228-1147 rev. 1

25 (129)

Page 26

TROUBLESHOOTING Handsfree Au x Mi cro p h o ne Prob l e m s

- Connecti o n Probl e m s

SEMC Troubleshooting Manual

C903

Hands-Free (PHF) Aux Microphone Problems

START

Note !

Before starting check if the Hands-Free (PHF) Connection is Ok.

Step 1:

Perform the

System Connector Protection Test

If successful go to step 2.

Step 2:

Load ETS SW into the Phone

Use TRS Fixture

Connect: VBATT and DCIO/SEPI

Use Fault Trace SW

Use Hands-Free (PHF) Set

Continue with the

Hands-Free (PHF) Aux Microphone Problems TRS guide

1: Use Fault Trace SW and go to:

Audio and FM Radio

Audio Loop Test

Audio Input: AUX1

Loop Mode: Analog

Audio Output: Loudspeaker

Apply Audio Loop

Replace

N2422

Hands-Free (PHF) Connection Problems

START

Step 1:

System Connector Protection Test

Hands-Free (PHF) Connection Problems TRS guide

Yes

Perform the

If successful go to step 2.

Step 2:

Power On the Phone

Use Hands-Free (PHF) Set

Continue with the

Can You

see the PHF icon

in the Phone Display

when the PHF set is

attached

NOT

No

Connect:

Hands-Free (PHF) Set

to the Phone

TROUBLESHOOTING

SL 4 Replace

N3101

SL 5 Replace

C3158 or N2000

SL 5 Replace

R3156 or N2000

SL 4 Escalate

Yes

MP 69 (C3158)

Short Circuit

to the GND

No

2: Disconnect: DCIO/SEPI from the PBA

3: Connect the PHF set to the PBA

Can You

Flash the Phone with

EMMA SUCR SW

Can you

hear any sound

from the TRS Fixture

Loudspeaker when

blowing into the

PHF Mic

No

Is

No

2V - 2.2V DC

at MP 69 (C3158)

Yes

Yes

Go to

Hands-Free (PHF)

Aux Earphone

Problems TRS guide

Yes No

see the PHF

icon in the Phone

Display

SL 4 Replace

N2422

SL 5 Replace

X2405 or N2010

SL 4 Replace

N3101

SL 5 Replace

X2405, C2462 or

C2463

VBATT and Hands-Free (PHF) Set

Remove the PBA from the TRS Fixture

Yes

Disconnect:

Are

L2401 and L2402

= Max 2 Ohm

No

Replace

L2401 or L2402

1228-1147 rev. 1

26 (129)

Page 27

TROUBLESHOOTING FM Radio Problems

- FM Radio Anten na Prob l e m s

SEMC Troubleshooting Manual

C903

Go to

Loudspeaker

Problems TRS guide

Go to

Hands-Free (PHF)

Problems TRS guide

START

No

Yes

Is the

Loudspeaker

Ok

FM Radio Problems

No

FM Radio

Is not

working both with

Loudspeaker and

PHF set

Yes

Replace

L2408

START

No

FM Radio Antenna Problems

Is L2408

= Max 1 Ohm

Is the

FM Radio Problems

TRS guide

done?

Yes

Use the

Digital Multimeter Instrument (DMM)

for these measurements

No

TROUBLESHOOTING

Go to

FM Radio Problems

TRS guide

SL 5 Replace

N2000

SL 4 Escalate

SL 5 Replace

C3145 or C3146

SL 4 Escalate

1: Remove the DCIO/SEPI Cable

Frequency: 103 MHz

Amplitude/Level: 50 μV

FM Dev: +/-22.5 kHz

FM Rate: 1 kHz

Yes

2: Connect:

Customized FM Radio Cable

Black Lab Plug to

TRS Fixture GND Input and

PHF Connector to the

Phone System Connector

Signal Generator

Instrument Settings:

More than

40 mV AC Pk-Pk

1 KHz signal at MP 7

(C3145) and MP 6

(C3146)

Is any of

C3145 or C3146

Short circuit

1: Load ETS SW into the Phone

2: Use TRS Fixture

Connect:

VBATT and DCIO/SEPI

3: Use Fault Trace SW and go to:

Audio and FM Radio

FM Radio

Audio Output: Loudspeaker

Frequency: 103 MHz

Set Fm Radio

Signal Generator

NoYes

No

Instrument Settings:

Change Amplitude/Level to:

800 μV

Is there

any signal on

MP 7 (C3145) and

MP 6 (C3146)

Yes

Problems TRS guide

Go to

FM Radio Antenna

SL 5 Replace

L3300

SL 4 Escalate

No

Yes

Is L3300

= Max 1.5 Ohm

Replace

N1300

Is the

Signal

Ok

Yes

Yes

Yes

No

Is C3306

Short Circuit

No

Is MP 9

(X2405_Pin 2)

Connected to

GND

Replace

V2413

Claim Component

N1300

Yes

No

SL 5 Replace

C3306

SL 4 Escalate

SL 5 Replace

X2405

SL 4 Escalate

SL 4 Replace

N1300

SL 5 Replace

N2010

No

1.8 Volt DC

No Yes

at MP 10 (R3302

FM_INT)

Replace

N1300

1228-1147 rev. 1

27 (129)

Page 28

TROUBLESHOOTING Bluetooth Probl e m s

- GSM Networ k Prob l e m s

SEMC Troubleshooting Manual

C903

1: Load ETS SW into the Phone

2: Use TRS Fixture

Connect:

VBATT and DCIO/SEPI

3: Use Fault Trace SW

4: Use RF Probe connected to

the Spectrum Analyzer

Instrument

NOTE! Do not use 10:1 Divider

Spectrum Analyzer

Instrument Settings:

Frequency: 2402 MHz

Span: 10 MHz

Amplitude: 10 dBm

Use Peak Search (MKR)

Yes

Bluetooth Problems

Flash the Phone with EMMA SUCR SW and retest the Phone

Fault trace SW Settings:

TX and RX

Bluetooth

Channel 0

Set MaxPwr MOD 0

NOTE!

MODE 0 Frequency should be

2401.84 MHz

(±0.05 MHz)

3 dBm at

MP 4 (X1300_Pin 1)

Blt MaxPwr MOD 0

(±3 dBm)

START

Step 1:

If successful claim SW Flash

If not go to step 2.

Step 2:

Continue with the

Bluetooth Problems TRS guide

No

START

Replace Rear Cover Assy and retest the Phone

If successful claim Rear Cover Assy

Load ITP SW into the Phone

Perform SERP Calibration and retest the Phone

If successful claim SERP Calibration

Disassembly the Phone and continue with the

GSM Network Problems TRS guide

Replace

Faulty Component

SL 5 Replace

R1204, R1206 or

C1209

SL 4 Escalate

Step 1:

If not go to step 2.

Step 2:

If not go to step 3.

Step 3:

No

No

GSM Network Problems

Are

X1000, X1002

X1003,X1010,X1011,

X1030 and X1210

connected to

GND

Yes

Max 1 Ohm

between MP 42

(ST1200) and MP 41

(X1200_Pin 2)

Yes

Yes

Max 0.5

Ohm between

MP 40 (X1200_Pin 1) and

MP 41

(X1200_Pin 2)

Replace

N1200

No

TROUBLESHOOTING

Replace

X1200

Replace

N1300

Replace

BT_Antenna

or N1300

No

No

Fault trace SW Settings:

TX and RX

Bluetooth

Channel 0

Turn Off

(This must be done before

the next step)

Set MaxPwr MOD 1

NOTE!

MODE 1 Frequency is

2402.16 MHZ

(±0.05 MHz)

3 dBm at

MP 4 (X1300_Pin 1)

Blt MaxPwr MOD 1

(±3 dBm)

Yes

Is

MOD 1 Freq.

at least 230 KHz

higher than

MOD 0 Freq.

Yes

-1 dBm

at MP 3

(W1300_Pin 5) and

MP 5 (W1300_Pin 7)

(±5 dBm)

No

2.7 Volt DC at

MP 120 (C2210

VBT27)

Yes

Yes

No

Replace

W1300 or X1300

SL 5 Replace

N2000

SL 4 Escalate

SL 4 Replace

N1300 or N2410

SL 5 Replace

N2010

Is the

GSM Network

Problem

solved

No

Yes

Claim Component

N1200

SL 5 Replace

N2010 or N2000

SL 4 Escalate

1228-1147 rev. 1

28 (129)

Page 29

TROUBLESHOOTING WCDMA Problems

SEMC Troubleshooting Manual

C903

This TRS guide can be used ONLY for C903 phones with WCDMA BAND I, II or V

Go to

GSM Network

Problems TRS guide

Replace

N1200

WCDMA BAND I,II,V Network Problems

START

NOTE !

Perform SERP Calibration and retest the Phone

Load ETS SW into the Phone

If successful claim SERP Calibration

Connect: VBATT and DCIO/SEPI

No

No

Step 1:

If not go to step 2.

Step 2:

Use TRS Fixture

Use Fault Trace SW

Is the

GSM Network

Ok

Yes

Is the

Problem with

WCDMA TX

Yes

Fault Trace SW

TX and RX WCDMA

Radio Settings:

Select Band: BAND I

Fast select channels:

Set Low Channel

Ch LOW

Modes: Max Pwr 23dBm

WCDMA BAND VIII Network Problems

START

This TRS guide can be used ONLY for C903 phones with WCDMA BAND VIII support

Perform SERP Calibration and retest the Phone

Go to

GSM Network

Problems TRS guide

Replace

N1200

Go to

SERP Calibration

Load ETS SW into the Phone

If successful claim SERP Calibration

Connect: VBATT and DCIO/SEPI

No

No

NOTE !

Step 1:

If not go to step 2.

Step 2:

Use TRS Fixture

Use Fault Trace SW

Is the

GSM Network

Ok

Yes

Is the

Problem with

WCDMA TX

Yes

TROUBLESHOOTING

Fault Trace SW

TX and RX WCDMA

Radio Settings:

Select Band: BAND VIII

Fast select channels:

Set Low Channel:

Ch LOW

Modes: Max Pwr 23dBm

Replace

N1200

Replace

N1210

Replace

L1200

Replace

N1210

Is the

WCDMA TX

Problem solved

Yes

No

2.5V – 3V DC at

MP 114 (C1215

No

VBATT and DCIO/SEPI

= Max 0.5 Ohm

Yes

No

N2000 or N2010

WPA_A_EN)

Disconnect:

Is L1200

SL 5 Replace

SL 4 Escalate

Yes

Yes

3V – 3.8V DC at

MP 113 (C1206

VCC_WPA)

No

1.8 Volt DC at

MP 111 (R1220

WPA0_EN)

No

SL 5 Replace

N2010

SL 4 Escalate

Replace

N1200

Replace

N1210

Replace

L1200

Replace

N1210

Is the

WCDMA TX

Problem solved

Yes

No

2.5V – 3V DC at

No

VBATT and DCIO/SEPI

Yes

No

N2000 or N2010

MP 116 (C1214

WPA_C_EN)

Disconnect:

Is L1200

= Max 0.5 Ohm

SL 5 Replace

SL 4 Escalate

Yes

Yes

3V – 3.8V DC at

MP 113 (C1206

VCC_WPA)

No

1.8 Volt DC at

MP 112 (R1222

WPA2_EN)

No

SL 5 Replace

N2010

SL 4 Escalate

Yes

Claim Component

N1210

Yes

Claim Component

N1210

1228-1147 rev. 1

29 (129)

Page 30

TROUBLESHOOTING A- G PS Probl e m s

- Accelerometer Probl e ms

SEMC Troubleshooting Manual

C903

Replace

N2410

No

No

1.8 Volt DC

At MP 102 (R1402

AGPS_LDO_EN)

Yes

1.8 Volt DC

At MP 105 (R1401

AGPS_PWRON)

Yes

A-GPS Problems

Go to Service Tests Menu and perform the GPS System Test

START

Step 1:

If successful Flash the Phone with EMMA SUCR SW

if not go to step 2.

Step 2:

Replace A-GPS Antenna and retest the Phone

If successful claim A-GPS Antenna

if not go to step 3.

Step 3:

Replace A-GPS PBA and retest the Phone

If successful claim A-GPS PBA

if not go to step 4.

Step 4:

Replace Main Flex Assy and retest the Phone

If successful claim Main Flex Assy

if not go to step 5.

Step 5:

Load ETS SW into the Phone

Use TRS Fixture

Connect: VBATT and DCIO/SEPI

Accelerometer Problems

START

Go to Service Tests Menu and perform the Accelerometer Test

If successful Flash the Phone with EMMA SUCR SW

Use Dummy Battery connected to Power Supply Channel 1 (VBATT)

Load ETS SW into the Phone

Step 1:

if not go to step 2.

Step 2:

Connect: DCIO/SEPI

Use Fault Trace SW

Fault Trace SW

General

Asic Revisions

Read All

TROUBLESHOOTING

26 MHz at

MP 103 (R2117

AGPS_CLK)

Yes

1: Disconnect:

VBATT and DCIO/SEPI

2: Connect:

VBATT and DCIO/SEPI

SL 5 Replace

N2010

SL 4 Escalate

No

No

1.8V Pk-Pk Pulses

at MP 104 (C1407)

Shortly after phone

1: Disconnect:

VBATT and DCIO/SEPI

VBATT and DCIO/SEPI

1.8V Pk-Pk Pulses

at MP 101 (C1406)

Shortly after phone

SL 4 Replace

N2410

SL 5 Replace

N2102

More than

Power On

Yes

2: Connect:

More than

Power On

No

Yes

SL 5 Replace

N2010

SL 4 Escalate

Replace

X4202

Is

Accelerometer

(N2411)

Asic Revision

0x3b

Yes

Fault Trace SW

MMI

Misc

Init Screen Testing

Activate:

Accelerometer Test

NOTE! Read X, Y, Z information in

the Info Box.

Flash the Phone with

EMMA SUCR SW

Replace

N2411

No

NOTE! Read X, Y and Z information

NOTE! Repeat this Test Sequence

Yes

No

Replace

N2411

Move the Phone and

Activate

Accelerometer Test again

in the Info Box.

10 Times

Can

you see

that X, Y and Z

information are

changing in the

info box

SL 5 Replace

N2010

SL 4 Escalate

No

Is the

Accelerometer

Problem solved

Yes

Claim Component

N2411

1228-1147 rev. 1

30 (129)

Page 31

TROUBLESHOOTING Vibrator Proble m s

- Real Time Clock Problem s

SEMC Troubleshooting Manual

C903

Replace

B4200

Vibrator Problems

START

Load ETS SW into the Phone

Connect: VBATT and DCIO/SEPI

Use Fault Trace SW and go to:

Yes

Step 1:

Step 2:

Use TRS Fixture

MMI

Misc

Init Screen Testing

Activate:

Vibrator Test

2.7V – 3.5V

Pk-Pk Pulses DC at

MP 85 (C4208)

START

Does

the phone

gain or lose

time

Real Time Clock Problems

Yes

Perform:

SERP Calibration

TROUBLESHOOTING

SL 5 Replace

C4208

SL 4 Escalate

Yes

No

Is C4208

Short circuit

No

SL 5 Replace

N2000

SL 4 Escalate

No

Perform:

Backup Capacitor

Test

Is the

Test Passed

No

Yes

Is there

still problems with

gaining or losing

time

Flash the Phone with

EMMA SUCR SW

SL 5 Replace

N2000 or C2214

SL 4 Escalate

Yes

No

Claim

SERP Calibration

SL 5 Replace

B2100

SL 4 Escalate

1228-1147 rev. 1

31 (129)

Page 32

TROUBLESHOOTING Slide Sens or Prob l e m s

- TV Out Prob lems

SEMC Troubleshooting Manual

C903

Slide Sensor Problems

START

Step 1:

Replace Rear Assy Slider and retest the Phone

If successful claim Rear Assy Slider

If not go to step 2.

Step 2:

Continue with the

Slide Sensor Problems TRS guide

SL 4 Replace

B4410

SL 5 Replace

N2010

TV OUT Problems

START

around the N2700 and N2102 components to prevent component

Be careful when cutting the Shield Can Fence

Flash the Phone with EMMA SUCR SW

If successful claim SW Flash

Load ETS SW into the Phone

Use Fault Trace SW and go to:

SL 5 Replace

N2010

SL 4 Escalate

NOTE !

damage.

Step 1:

If not go to step 2.

Step 2:

Use TRS Fixture

Connect:

VBATT and DCIO/SEPI

MMI

Misc

Init Screen Testing

Display Pattern

Activate:

TV Test Pattern

No

1.8 Volt DC at

MP 71 (R2281)

No

Is the

Display Backlights

Ok

Yes

Is the

Display

Ok

Yes

Is MP 11

(X2405_Pin 7)

Short circuit to PBA

GND

No

No

Yes

TROUBLESHOOTING

Go to

Display illumination

Problems TRS guide

Go to

Display Problems

TRS guide

Replace

V2430

SL 5 Replace

N2296

SL 4 Escalate

Replace

N2410

SL 5 Replace

N2700 or N2102

SL 4 Escalate

No

No

No

Yes

1.5 Volt DC at

MP 72 (C2297

VTV15)

1.8 Volt DC at

MP 17 (R1301)

Yes

26 MHz at

MP 118 (R2130

TV_CLK)

Yes

Yes

Yes

1.8 Volt DC at

MP 77 (R2288

VTV30_EN)

Yes

3 Volt DC at

MP 78 (C2289

VTV30)

0.9V – 1V

Pk-Pk Pulses at

MP 73 (L2405)

Yes

No

No

No

SL 5 Replace

N2700

SL 4 Escalate

SL 5 Replace

N2288

SL 4 Escalate

SL 5 Replace

N2700

SL 4 Escalate

SL 5 Replace