WIRED

CONTROLLER

MINI CHILLER

USER MANUAL

KJR-120F

AIR CONDITIONING

“Originalinstructions”

Chiller wired controller

1.1 Mini chiller wired controller: KJR-120F

1.1.1Specifications

Model

Description

power adapter

230-240V~50Hz

KJR

-

120F

Touch key and backlight function

Input Voltage

10V AC

Operating environment

temperature

-15

ºC~+43ºC

Operating RH

RH 40%~RH 90%

Chiller wired controller

1.1.2 Button introduction

Item

Description

Item

Description

1

Operation icon

9

Water temperature

2

Mode area

10

ON/OFF key

3

Water temperature

11

Right, left key

4

Timer ON/OFF

12

OK key

5

Function icon

13

Function key

6

On-line unit qty. indication

14

Add, reduce key

7

Reserved

15

Cancel key

8

Clock

16

Mode key

1. Operation icon :

Indicate the ON and OFF status; when it is ON, it will display; when it is OFF, it will disappear;

2.Mode area:

Indicate the main unit operating mode;

3. Water temperature

Two status can be displayed: ;

14

13

3

1

2

4

16

11

15

5

6

7

8

9

10

11

12

(Long press 3s

for cancelling timing)

(Long press 3s

for unlocking)

MODE

FUNCTIONS

Chiller wired controller

4. Timing ON/OFF indication :

Indicate the timer information;

5. Function icon;

1) Computer

Display when connects to computer.

2) Conflict

Displays when the unit operation forced cooling mode.

3) Maintenance

Displays when the unit is needed. Press″MODE″ key for 3 seconds to cancel the icon and timing will

restart until next maintenance.

4) Cycle : The reserved icon

5) E-heating : The reserved icon.

6) Check

Display when check function is operated;

7) Anti-freezing

Displays when ambient temperature is low which means the main unit need anti-freezing action

8) Lock

Displays when no key operation for 2 minutes and all keys are locked. Press ―OK‖ key for 3 seconds

to unlock;

9) Error : Displays when error or protection occurs and means the unit need maintainence by

professionals.

Chiller wired controller

6. On-line unit qty. indication:

Under normal status display the quantity of the units connected to the wired controller; under check status

display the device serial number.

7. Water level indication: The reserved icon

8. Clock:

Under normal status display clock; during timer setting it displays the setting timing time.

9. Water temperature:

Under normal status display water temperature; during water temperature setting it displays the setting

numerical value; under spot check status display spot check parameter;

10. ON/OFF key: On and Off functions.

11. Right, Left key:

Under main page to press this key can query the setting water temperature; Press right key to shift to the

next step setting under timing setting status; Press these keys to turn over the unit parameter information

under check status.

12. OK key:

After setting the parameter then press this key to confirm. After keys locking then long press this key for 3

seconds to unlock.

Chiller wired controller

13. Function key:

Setting water temperature, timing and clock etc; Press FUNCTION key for 3 seconds to enter check

status, setting unit number and forced open water pump.

14. Add, Reduce key:

Move up or move down values of temperature, timing etc.

15. Cancel key:

During setting parameters press this key to cancel setting. After timing setting and then long press this

key 3 seconds to cancel timing.

16. Mode key: Power on the cooling function,heating function or water pump function.

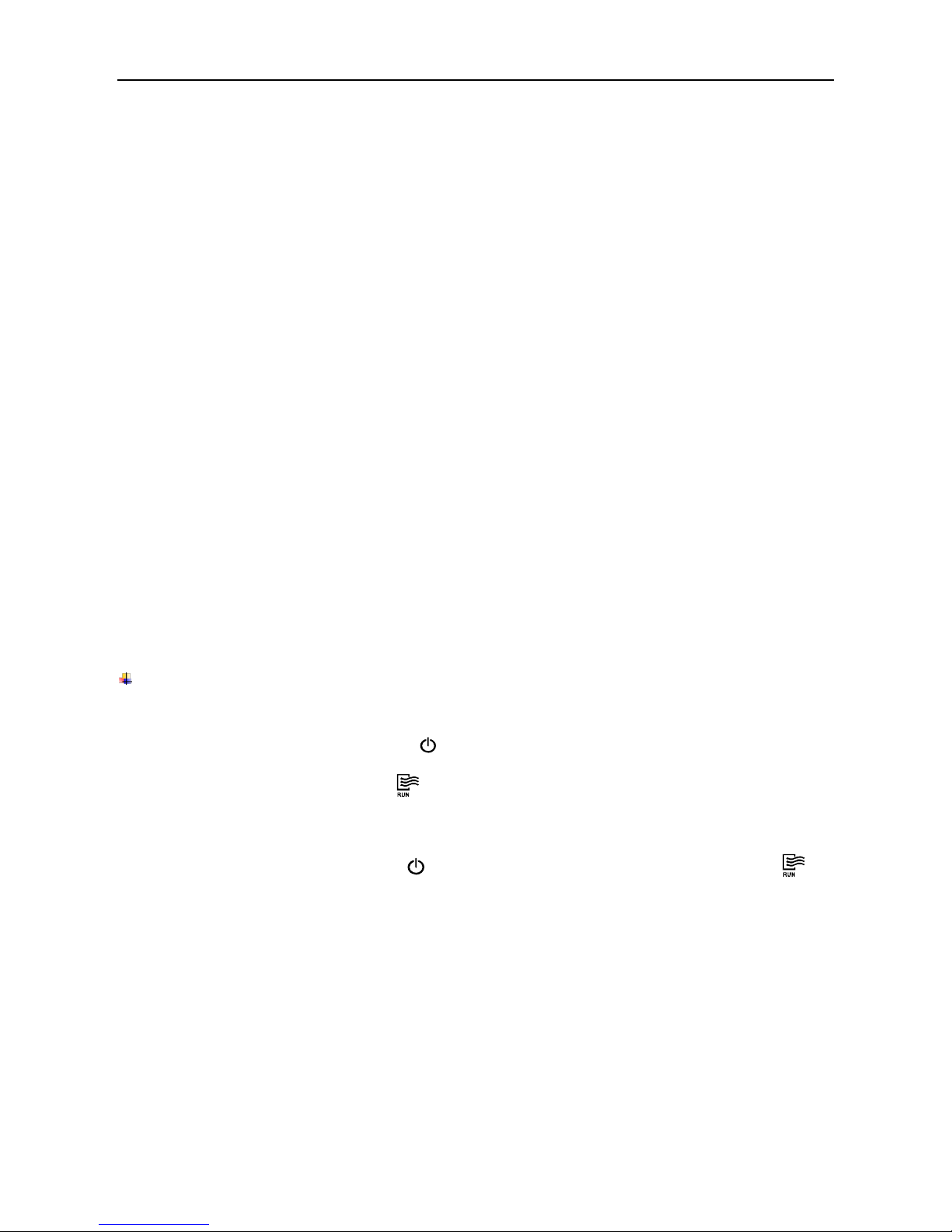

1.1.3 Operation instruction

On and Off the main unit

1) Press the On/Off key to control On and Off status of the main unit.

2) Under Off status, press the On/Off key to operate the main unit, at that time the LCD of wired

controller will display the operation icon . The main unit will be operated as the current setting of the

wired controller.

3) Under On status, press the On/Off key to off the main unit, at that time the operation icon ― on

the LCD of wired controller will disappear.

Note:

1. When outdoor unit is in restore-to-factory-default setting mode (outdoor unit displays ―OFF‖), wired

controller won‘t start the unit. Quit ―OFF‖ status through outdoor unit display operation panel.

2. If outdoor unit is forced shutdown by remote control, then the unit won‘t start by using wired controller.

Relieve the unit from shutdown status by remote control.

Chiller wired controller

Operating mode setting

Press ―MODE‖ key to choose operation mode. The setting mode will change as the following order each

time the key is pressed:

Press ―OK‖ key or wait for 7 seconds to confirm. During the setting process, pressing the ―CANCEL‖ key

to exit without saving.

→

→

Chiller wired controller

Setting water temperature:

Method 1:

Press the ▲ or ▼ to adjust the water temperature under main interface. Press OK key or wait for 7

seconds to confirm.

Method 2:

Setting water temperature in function parameter: Press FUNCTIONS key under main interface once to

enter water temperature setting interface. Press the ▲ or ▼ to adjust the water temperature .Press OK

key or wait for 7 seconds to confirm.

Water temperature setting check: To check the water temperature setting value, press the ◄ or ► key

under the main page (the page displayed after the controller is powered on).

Function parameters setting

Press FUNCTIONS key to choose operation parameters. The setting function parameters will change as

the following order each time the key is pressed:

→

→

W

ater temp. setting

T

iming

Clock

Unit NO.

→

W

ater pump forced

→

Chiller wired controller

1. Timer setting:

3 timing periods can be set on the wire controller: Timer 1, Timer 2, and Timer 3. These 3 timers can

control the main unit to be turned ON and OFF 3 times at most during a day.

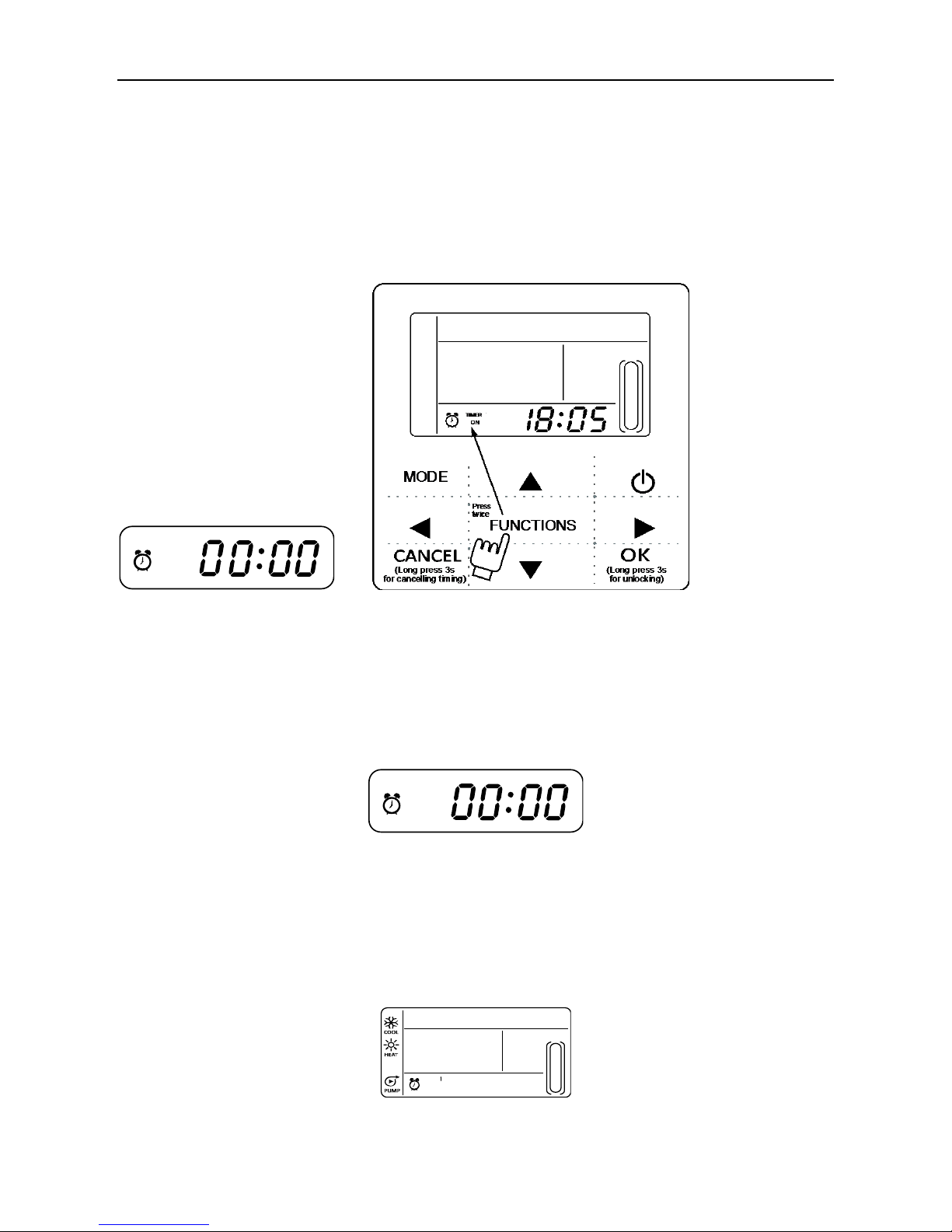

Setting method: press ―FUNCTIONS‖ key under main page twice to enter timing setting. Then the LCD

will display as the following:

2. At this time the hour of the clock will flash, which means the current setting is the hour of Timer 1 ―On‖,

press the ▲ or ▼ to adjust, press ► key when finished, and then the minute of the clock will flash,

which means the current setting is the minute of Timer 1 ―On‖, press the ▲ or ▼ to adjust, press ►

key when finished, the LCD will display as the following:

3. At this time the hour of the clock will flash, which means the current setting is the hour of Timer 1 ―Off‖,

press the ▲ or ▼ to adjust, press ► key when finished, and then the minute of the clock will flash, which

means the current setting is the minute of Timing 1 ―Off‖, press the ▲ or ▼ to adjust, press ► key when

finished, the LCD will display as the following:

1

TIMER

ON

1

TIMER

OFF

TIMER

Chiller wired controller

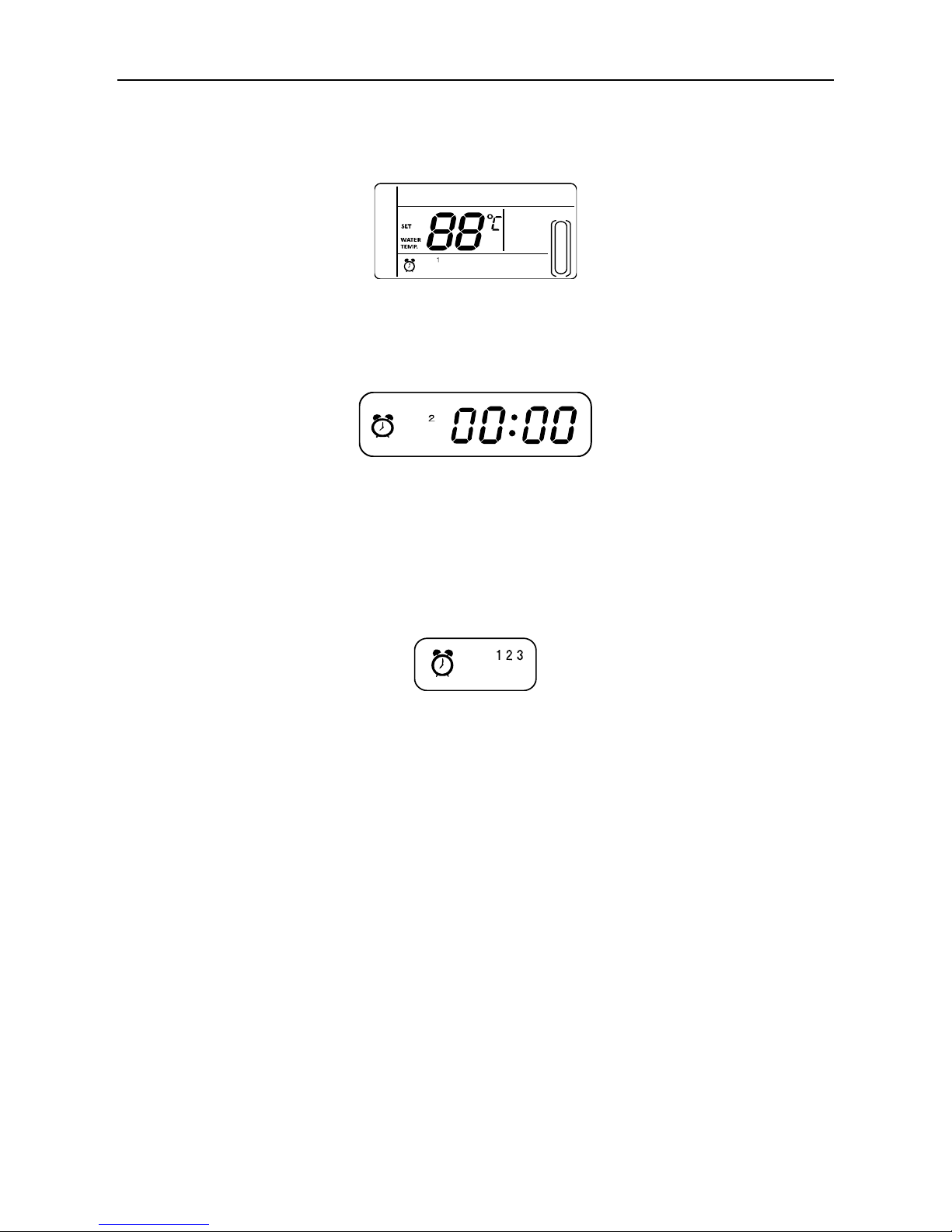

4. At this time the mode icon will flash, it means the current setting is the running mode in the Timer 1 ,

press the ▲ or ▼to adjust, press ► key when finished, the LCD will display as the following:

5. At this time the water temperature icon will flash, it means the current setting is the water temperature,

press the ▲ or ▼ to adjust, press ► key when finished, the LCD will display as the following:

6. At this time the hour of the clock will flash, it means the current setting is the hour of the Timer 2 ―On‖.

And the follow setting method will be the same as the Timer 1. Similarly, the setting of Timing 3 is the

same as this method. After setting is finished, press ―OK‖ key or wait for 7 seconds to confirm the setting,

and the LCD will display the effective timing information, as the following display:

TIMER

TIMER

ON

TIMER

Chiller wired controller

7. Example of Timing setting:

During any period of timing setting to press ―OK‖ key , the timing periods which have been set will be

effective (only if the ―On‖ and ―Off‖ of one timing period have been set, the setting is effective).

Yes

No

Yes

No

Main page

▼

Press ―FUNCTIONS‖ key twice to enter hour

setting interface of ―Timer 1 On‖

▼

▼

▼

Press ― ‖ key to enter minute setting interface of

―Timer 1 On‖, adjust the minute number to be 10

Press ― ‖ key to enter hour setting interface of ―Timer

1 Off ‖, adjust the hour number of ―Timer 1 Off‖ to be 12

Press the ―▲‖ or ―▼‖ key to set the hour

number of ―Timing 1 On‖ to be 07

Press ― ‖ key to enter minute setting interface of

―Timer 1 Off‖, adjust the minute number to be 30

The setting steps of ―Timer 2‖ and ―Timer 3‖ are the same as ―Timer 1‖, after

setting all the settings then press ―OK‖ key, the 3 timing periods will be effective.

―Timer 1‖ setting

finished, after 7

seconds, the

page shift to the

main page.

Successfully set the On time of ―Timer 1‖ to

be 07:10 and Off time of ―Timer 1 Off ‖ to be

12:30. In this time period to run heating

mode. Then back to the main page.

Finish setting the ―Timer 1‖ , then

enter the setting of ―Timer 2‖.

Whether press ―OK‖ key

Whether press ― ‖ key

▼

Press ― ‖ key to enter running mode etting,adjust

the mode to be ―HEAT‖

▼

Press ― ‖ key to enter water temp. setting , adjust

the temp. to be 45℃.

Chiller wired controller

Check timing information: to check the timing which has been set, press◄ or ► key under main page, the

―On‖ and ―Off‖ time of Timer1, Timer 2 and Timer3 will be displayed in turns.

Cancel timing:

Press ―CANCEL‖ key for 3 seconds, then all the effective timing periods will be cancelled.

Notes:

1. To avoid timing error, each period of timing should not be crossed. E.g.:

2. Once timer on works, the unit will run as the timer on set mode and set water temperature.

3. When timing on and timing off work at the same time, wire control execution timing off.

Clock setting

Press the FUNCTIONS key 3 times to enter clock setting. The hour of the clock will flash, which means

the current setting is the hour of the clock, press the ▲ or ▼ to adjust, press ► key when finished, and

then the minute of the clock will flash, it means the current setting is the minute of the clock, press the

▲or ▼ to adjust, press OK key when finished or wait for 7 seconds to confirm. During the setting process,

pressing the CANCEL key to exit without saving.

Note:

To get the correct timing On and timing Off time, please correctly set the clock!

5:00

8:00

10:00 12:00

18:00

22:00

8:00

7:00

12:00

Correct:

Wrong:

TIMER 1

TIMER 2TIMER 1

TIMER 2

TIMER 3

Chiller wired controller

Unit number setting

Press the FUNCTIONS key 4 times to enter the unit number setting. Press ▲ or ▼ to adjust the unit

number. Press OK key when finished or wait for 7 seconds to confirm. During the setting process,

pressing the CANCEL key to exit without saving. The setting value is 0-19.

Forced open water pump

Press the FUNCTIONS key 5 times to force open the water pump. The water pump icon will flash.

Press OK key to confirm. During the setting process pressing the CANCEL key to return to the main

interface, and log off the forced water pump mode.

Notes:

a. Forcing water pump function is only limited to stand-by mode, others modes not response.

b. Under forcing water pump function, other settings will not responsible, except stopping

c. When communication disconnects, it will show E2 error in 2 minutes, the wired controller will

automatically cancel the forcing water pump function; while connected, the wired controller keeps

Chiller wired controller

synchronizing with the unit( If forcing water pump function is still on-going, the controller keeping showing

its status).

d. The outdoor unit does not response after activating the forcing water pump function,

(e.g.: forcing water pump function cannot be activated under forcing heating in stand-by mode), the

function will be automatically stopped if it is not activated within 5 minutes.

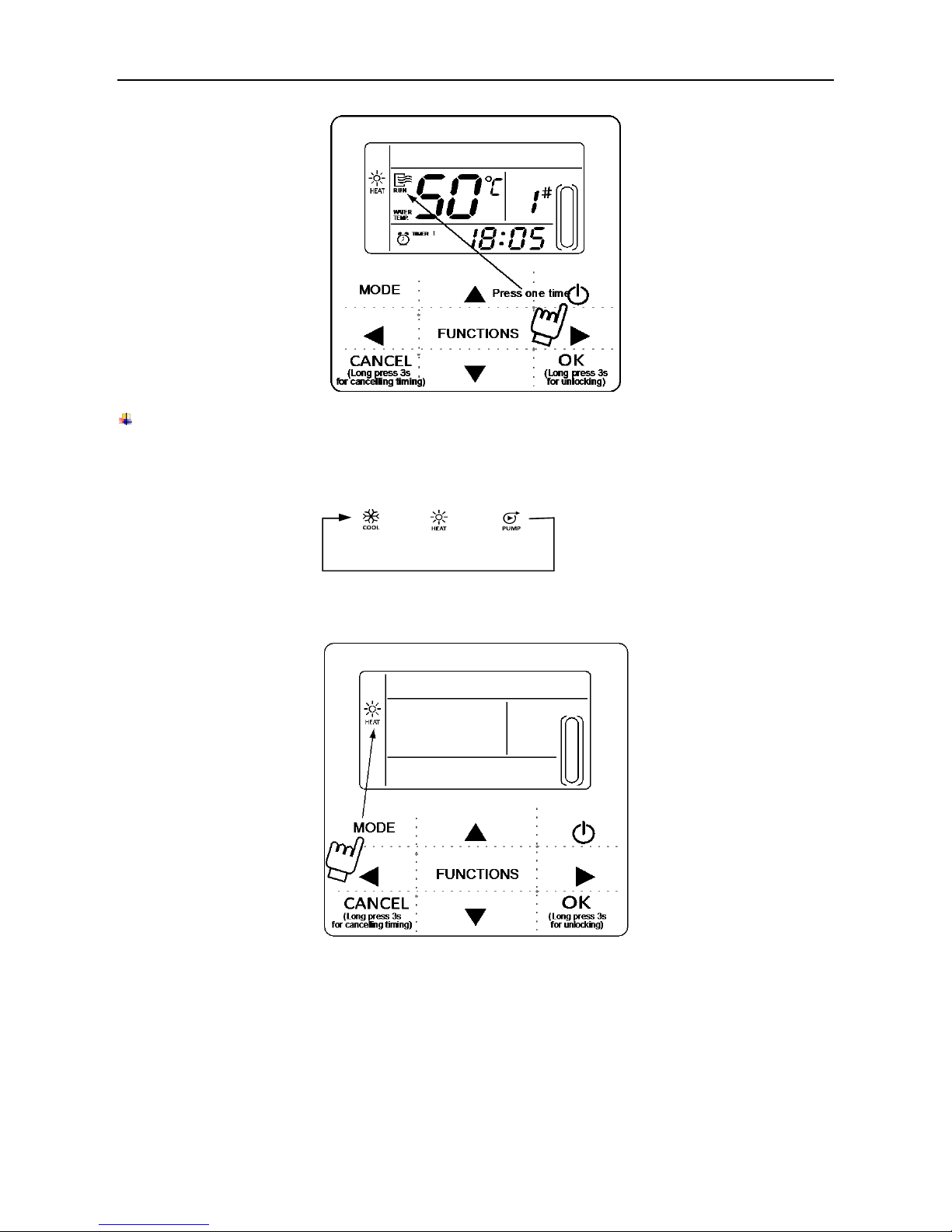

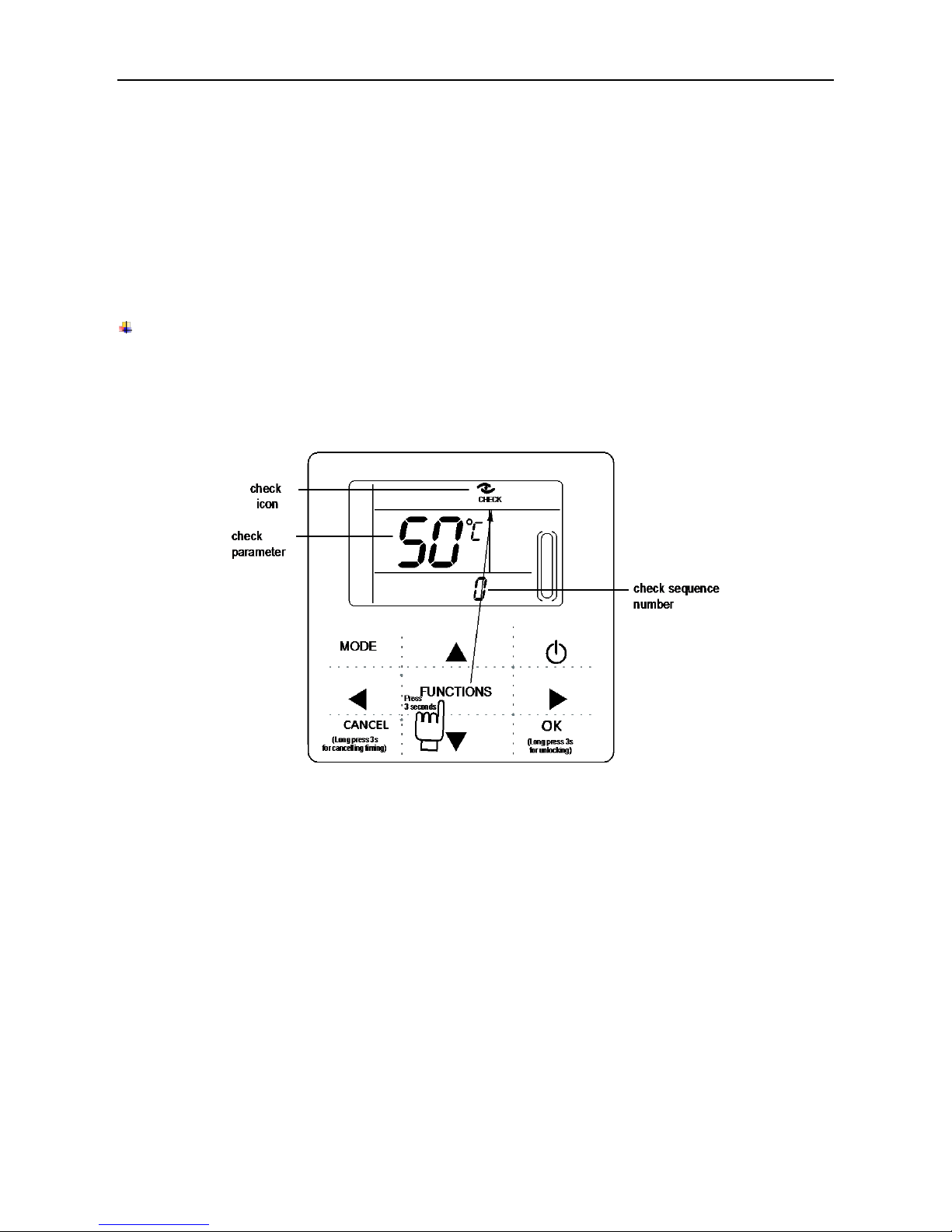

Check function

1) Check function allows the user to check all the operating parameters, error and protection information

of the unit.

2) Enter method: press FUNCTIONS key for 3 seconds to enter check interface, as the figure display:

3) Press

◄ or ►

key to check all the status information of the unit.

Chiller wired controller

Check content

NO.

Description

0

When in standby mode, water pump mode, displays water inlet temperature.

In cooling and heating mode, displays the operating frequency.

When defrosting, displays dF; When anti-freezing, displays Pb.

When oil returning, displays d0; When remote controlling displays d8.

1

Running model: 0-shutdown, 1-Pump mode, 2-Cooling, 3-Heating, 4-Forced cooling,

5-Forced heating.

2

Fan speed: 0-Shutdown, 1~7-Fan speed.

3

Total capacity requirements.

4

The revised capacity requirements.

5

Cooling/heating temperature setting.

6

Condenser temp. Value.(T3)

7

Outdoor ambient temp. Value.(T4)

8

Comp. Discharge temp. Value.(Tp)

9

Inlet water temp. Value.(Tin)

10

Outlet water temp. Value.(Tout)

11

Plate heat exchanger anti-freezing temp. Value 1.(Tb1 )

12

Plate heat exchanger anti-freezing temp. Value 2.(Tb2 )

13

T6 temp. Value(Reserved )

14

Outdoor unit current

15

Power supply voltage AD value

16

Electronic expansion valve opening steps

17

The unit model

18

The program version number

19

The last error record

20

The second error record

21

The first error record

22

─ ─

Chiller wired controller

When the unit has error or protection, icon will flash. If the ―error‖ icon is on, it means the

corresponding unit has error or protection at that time. The last 3 error or protection codes of the unit can

be checked. The error icon will disappear if the error or protection is cleared.

Code

Description

Code

Description

EE

EEPROM error code(Wired controller)

CP

Anti-idling protection of water pump

E9

EEPROM malfunction

F7

Tb1 temperature sensor malfunction

EA

Fan error in A region last for more than 5

minutes in heating mode

F8

Tb2 temperature sensor malfunction

Eb

Two times of E6 protection in 10 minutes

P1

High pressure protection

E4

T3&T4 temperature sensor malfunction

P2

Low pressure protection

E5

Voltage protection

P3

Outdoor units current protection

E6

DC fan motor malfunction

P4

Compressor discharge temp. Protection

H0

Communication malfunction between the

main control chip and IPDU

P5

Condenser high temperature protection

C0

Tin temperature sensor malfunction

P6

IPM mode protection

C1

Tout temperature sensor malfunction

P8

Typhoon protection

C8

Flow switch malfunction

Pb

Outdoor units anti-freezing protection

CH

High temperature protection in heating

mode

PL

Radiator high temperature protection

CL

Low temperature protection in heating

mode

PH

Water inlet and outlet temp. difference

too large protection

Error handling

Chiller wired controller

1.1.4 Installation instruction

Circuit of wired controller is the low voltage circuit. Never connect it with a standard 220V/380V circuit

or put it into a same Wiring Tube with the circuit.

The shield cable must be connected stable to the ground, or transmission may fail.

Do not attempt to extend the shield cable by cutting, if it is necessary, use Terminal Connection Block

to connect.

After finishing connection, do not use Megger to have the insulation check to the signal wire.

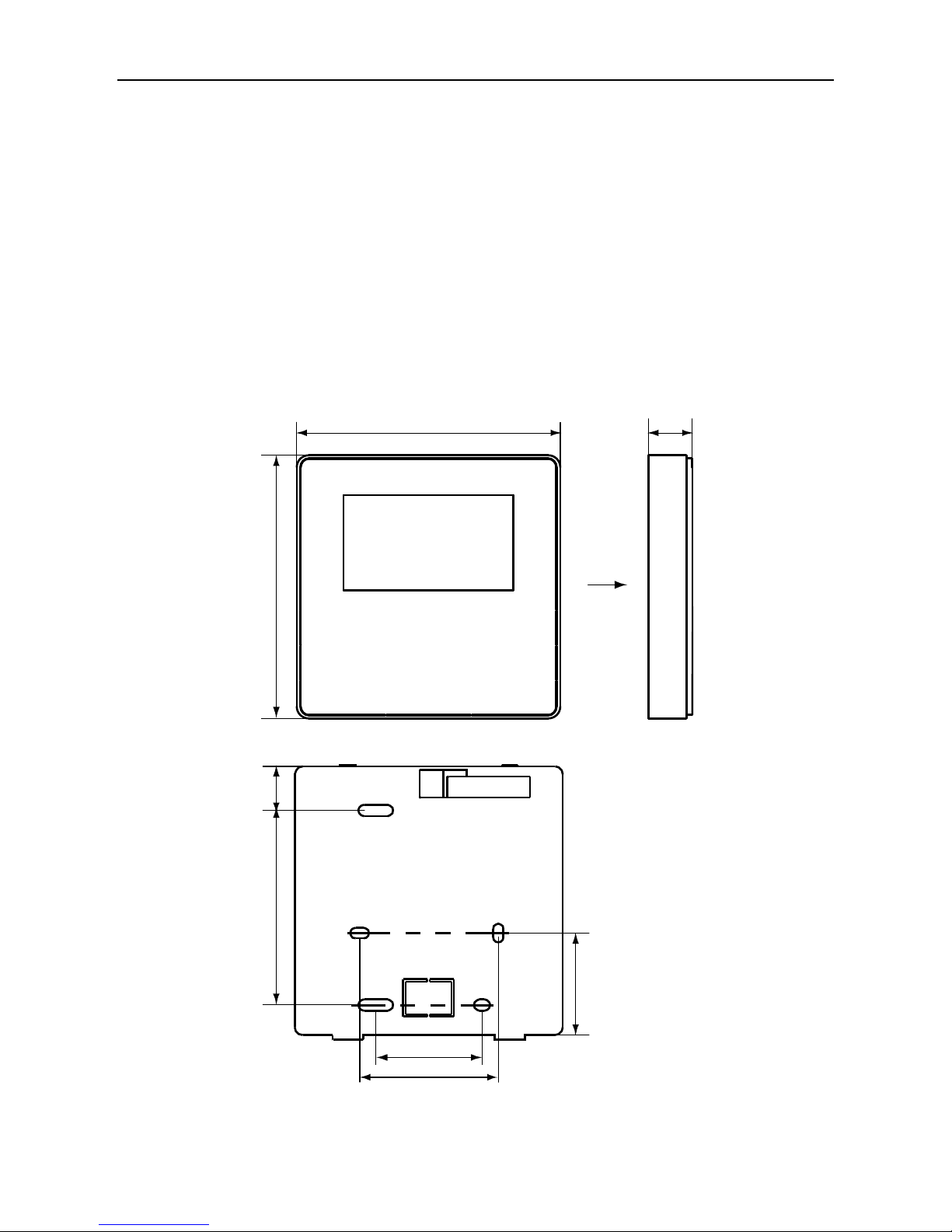

1. Structure size: 120*120*20mm

19mm84mm

44mm

46mm

60mm

120mm 20mm

120mm

Figure A

Chiller wired controller

2. Wiring sketch

3. Wiring figure

1) During installation, make sure correctly wiring the 5 wiring terminals of the wire controller: A, B

connect to output terminal of adapter; P, Q, E should connect to the P, Q, E terminals of the wiring socket

in the electric control box through 3-core shielded wire.

2) The tightening torque range of screw is: 0.8~1.2N • m (8~12 kgf • cm).

3-core shielding wire

AC22OV

Chiller wired controller

4. Back cover installation

1) Use straight head screwdriver to insert into the buckling position in the bottom of wire controller, and

spin the screwdriver to take down the back cover. (Pay attention to spinning direction, otherwise will

damage the back cover!)

2) Use three GB950-86 M4X20 screws to directly install the back cover on the wall.

3) Use two M4X25 GB823-88screws to install the back cover on the 86 electrician box, and use one

GB950-86 M4X20 screws for fixing on the wall.

Buckling

position

Back cover

Straight head

screwdriver

Front cover

Screw hole installed on the wall,use

three GB950-86 M4X20

Screw hole installed on 86

Electrician box, use two

M4X25 GB823-88

Screw hole fixed on the wall,use

one GB950-86 M4X20

Chiller wired controller

4) Adjust the length of two plastic screw bars in the accessory to be standard length from the electrical

box screw bar to the wall. Make sure when install the screw bar to the electrical box screw bar, make it as

flat as the wall.

5) Use cross head screws to fix the wire controller bottom cover in the electric control box through the

screw bar. Make sure the wire controller bottom cover is on the same level after installation, and then

install the wire controller back to the bottom cover.

6) Over fasten the screw will lead to deformation of back cover.

5. Wiring

1) Wiring, three out letting positions

86

Electrician

box

Back cover

Signal switching

wires

Cutting place of left

down side wire outlet

Chiller wired controller

When under installation, reserve certain length of the connecting wire for convenient to take down the

wired controller while during maintenance.

2) Embedded 86 electrician box wiring

3) Shielded wiring

Left down

side wire

outlet

Chiller wired controller

Avoid the water enter into the wired remote controller, use trap and putty to seal the connectors of wires

during wiring installation.

5. Front cover installation

After adjusting the front cover and then buckle the front cover; avoid clamping the communication

switching wire during installation.

Correct install the back cover and firmly buckle the front cover and back cover, otherwise will make the

front cover drop off.

NOTE CONCERNING PROTECTION OF

ENVIRONMENT

This product must not be disposed of via normal household waste after its service life, but must be

taken to a collection station for the recycling of electrical and electronic devices. The symbol on the

product, the operating instructions or the packaging indicate such disposal procedures. The materials

are recyclable in accordance with their respective symbols. By means of re-use, material recycling or

any other form of recycling old appliances you are making an important contribution to the protection

of our environment. Please ask your local council where your nearest disposal station is located.

-

In case of quality problem or other please contact your local supplier or authorized service center.

Emergency number: 112

PRODUCER

SINCLAIR CORPORATION Ltd.

1-4 Argyll St.

London W1F 7LD

Great Britain

www.sinclair-world.com

This product was manufactured in China (Made in China).

REPRESENTATIVE

SINCLAIR EUROPE spol. s r.o.

Purkynova 45

612 00 Brno

Czech Republic

TECHNICAL SUPPORT

NEPA spol. s r.o.

Purkynova 45

612 00 Brno

Czech Republic

Tel.: +420 800 100 285

Fax: +420 541 590 124

www.sinclair-solutions.com

info@sinclair solutions.com

Loading...

Loading...