Scott TC Shock,Equalizer TC Shock Owner's Manual

CONFORME AUX EXIGENCES DE SECURITE - NF R30-020

T

OWNERS MANUAL

BEDIENUNGSANLEITUNG

MANUEL D’UTILISATION

BIKE

OWNERS

MANUAL

2007

©2005 Sc

ott Sports SA – all rights r

eserv

ed

WWW.SCOTT-SPORTS.COM

Scott Sports SA

Route du Crochet 17

1762 Givisiez / Switzerland

www

.sc

ott-sports.c

om

«SAG-BOY»

The length of the grey beam shows the optimum eye-to-eye distance of the rear shocks.

Der graue Balken zeigt den optimalen Bolzenabstand des Dämpfers.

La longueur de la barre grise représente l’écart optimal entre les points de fixation

de l’amortisseur.

EQUALIZER TC SHOCK

ENGLISH

01

00

CONTENT

DEUTSCH

FRANÇAIS

> Traction Control-Functions P. 02

> Power Stabilizer P. 02

> Intelligent Rebound Valve P. 03

> Oil Transfer Shock P. 03

> Picture of the Equalizer TC Shock

and Remote Control Lever P. 04

> Basic Set-Up of the Remote

Control Equalizer TC Shock P. 05

> Mount of the remote control of P. 05

Equalizer TC Shock

> Recommended Tools for the

Shock Set-Up P. 06

> Set-Up of Positive Air Chamber

Equalizer TC Shock P. 07

> Set-Up of Negative Air Chamber

Equalizer TC Shock P. 07

> Set-Up of Rebound Equalizer TC Shock P. 08

> More Details about Shock Set-Up

Equalizer TC Shock P. 09

> Maintenance / Service Guide P. 09

> Warranty P. 12/13

CONTENT

The basic set-up of a Scott Equalizer TC Shock is easy

and can be done within a few minutes.

The Scott Equalizer TC Shock should be adjusted exactly

to the current rider for reaching maximum safety and

fun while riding.

All adjustments should be done at the local dealer

or following this manual.

ENGLISH

03

02

DEUTSCH

FRANÇAIS

The heart of the TC-System is the newly developed

and innovative Scott Equalizer TC Shock, offering three

functions which make this system possible.

By using the remote lever you can choose between following functions:

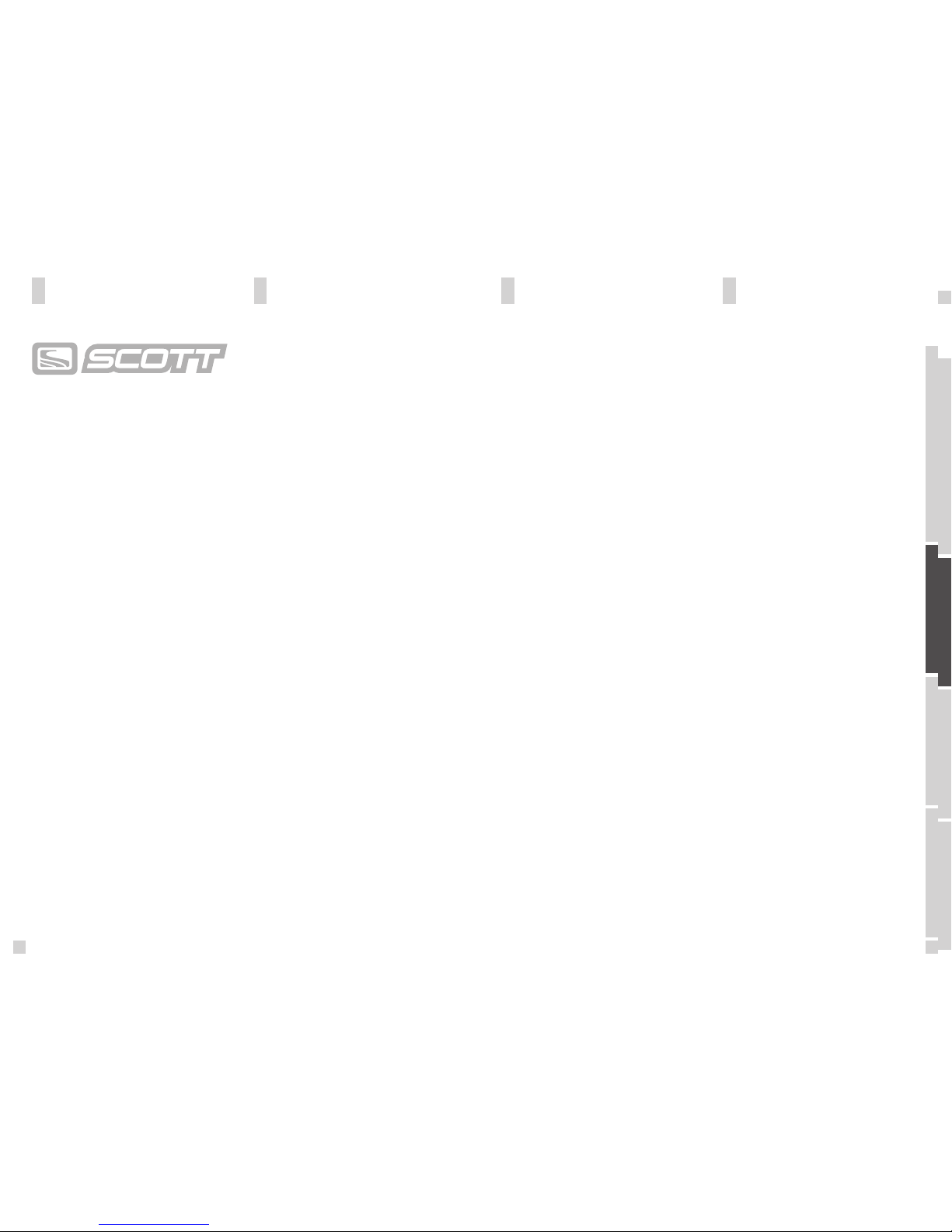

1. ALL TRAVEL MODE: full travel of 165mm

2. TRACTION MODE: by reducing the chamber volume

inside the shock the travel of the shock will be reduced

to around 60% (approx. 100mm), the characteristic of

the air spring gets harder. This results in climbing

without “bobbing” and offers still optimum traction of

the rear wheel.

3. LOCK OUT MODE: the shock is locked, climbing on

asphalt roads is now possible without any power loss.

Simultaneously a blow-off-system prevents the shock

being damaged in case the rider did not open the system while crossing obstacles.

You will find following positions on the remote lever.

[1]

TRACTION CONTROLFUNCTIONS INTELLIGENT REBOUND VALVE OIL TRANSFER SHOCK

In contrary to conventional systems which have the

piston with compression and rebound shim stack

moving in an oil bath, our new developed OTS-system pushes the oil through a fixed piston from one

oil chamber to another.

By using this fixed piston Scott was able to integrate more functions (e.g. Power Stabilizer,

Intelligent Rebound Valve) beside the standard

compression/ rebound adjustment devices.

In addition the shock works with a bigger volume

of oil which results in a bigger heat resistance

and a reduced wear and tear of the oil.

Scott found a revolutionary way to design a valve that

adjusts itself by the speed of impact on the rebound

motion.

In contrary to conventional systems our new designed

Intelligent Rebound Valve system can distinguish

if the shock should rebound fast or slow.

On small impacts the system stays fully active and

reacts with a fast rebound.

After a jump or big impacts/grooves the rebound is

slowed down automatically. Doing so, the kick back of

the saddle that results from too fast rebound, is eliminated.

1

remote lever

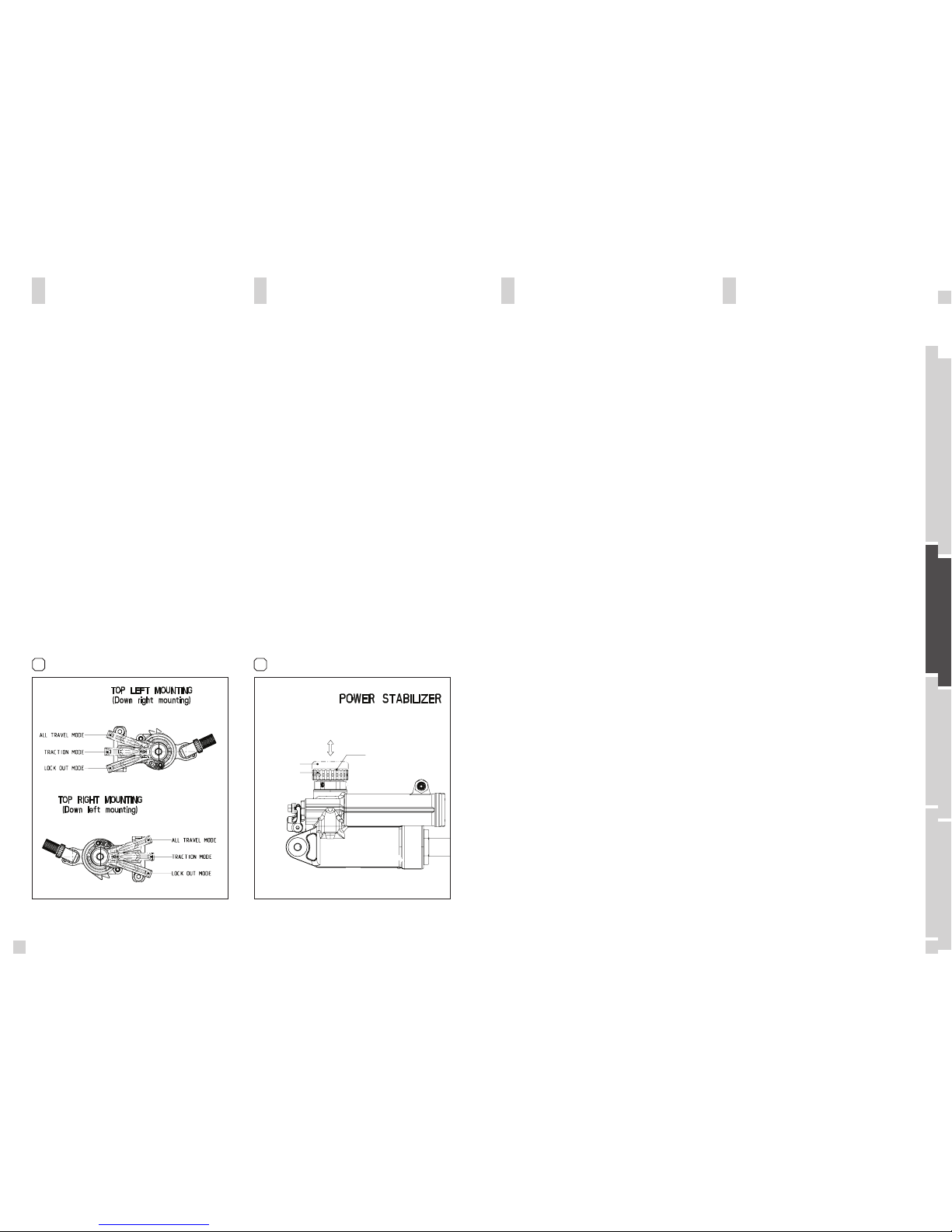

The Power Stabilizer is a option to ride with or

without Pedal Platform by just tapping one button on

the shock.

By pulling the rebound adjuster knob upward you

switch off the pedal platform for a supple break

away.

By pushing the rebound adjuster knob downward you

switch on the pedal platform for a better climbing

without bobbing when standing on the pedals. [2]

2

PowerSt abilizer OFF

PowerSt abilizer ON

PUSH / PULL

ADJUSTER KNOB

rebound knob/ps knob

ENGLISH

05

04

DEUTSCH

FRANÇAIS

In the drawing of the shock and remote lever, shown

below, you will see the parts indicated with numbers

which will be used in the manual for the adjustment

and set-up.

EQUALIZER TC SHOCK AND

REMOTE CONTROL LEVER

BASIC SET-UP OF THE REMOTE

CONTROL OF EQUALIZER

TC SHOCK

1. Put the remote lever (L1) to position “lock-out”

2. Fix the remote control cable (L2) with the cable fixation screw (S9) using a 3mm allen key (tightening

torque: 3 Nm) on the Mode Lever (S12)

3. Put the remote lever now to position “Traction Mode”

The Lock Out Pin (S11) should be pulled out approx.

1mm.

4. When putting now the remote lever to position “All

Travel” the cable will pull the Mode Lever (S12) including the Traction Mode Pin (S10) and the shock will

offer now the full travel.

5. Check now the set-up for perfect function of remote

lever and shock

6. In case you want to fine-tune the brake-away power

of the remote lever, you can do this by using a 2mm

allen key and by turning the allen screw (L4). In case

you want to readjust the tension of the remote control

cable you can do this by using the tension screw (L3).

[1]

S1 Upper Shock Bolt

S2 Lower Shock Bolt

S3 Left Piggy-Back

S4 Right Piggy-Back

S5 Shock Piston

S6 Rebound Adjuster/Power Stabilizer Knob

S7 Positive Chamber Valve

S8

Negative Chamber V

alve

S9 Remote Cable Fixation Screw

S10 Traction Mode Pin

S11 Lock Out Pin

S12 Mode Lever

L1 Remote Lever

L2 Remote Control Cable

L3 Tension Screw

L4 Allen Screw

L5

Allen Screw

L6 Cable Guide Hanger

1

MOUNT OF THE

REMOTE CONTROL

OF EQUALIZER TC SHOCK

To switch the TC2 Lever from one side of the bar to the

other one, please proceed as explained below:

[2] [3]

1. Remove the inner cable from the system as shown

in the Equalizer TC manual

2. Unscrew the clamp fixing screw on the bar clamp

with a 3 mm Allen key

3. Unscrew screw L1 by using a 3mm Allen key

4. Take the cable guide assembly (L2 + L3 + L4) away

5. Unscrew screw L5 with a 2 mm allen key

6. Unscrew the main screw L8 with a 4 mm allen key

7. Lift parts L8, L9 (2x) and L10 . Take the spri ng L6

and the ball L7 out of the assembly. Pay attention not

to loose them.

8. Remove screw L12 with 1.5mm allen key

9. Loosen base plate fixing screw L11 with a 3 mm

allen key

10. Turn index plate L13 to the position of your choice

(turn it of 180° for left or right position ), see detail

pictures.

2

Loading...

Loading...