Page 1

OPERA TION AND MAINTENANCE INSTRUCTIONS

SEMS™

SCOTT ELECTRONIC MANAGEMENT SYSTEM

PDA–PERSONAL DISTRESS ALARM AND

PDR–PERSONAL DISTRESS RECEIVER

USER ACCOUNTABILITY SYSTEM AND PERSONAL DISTRESS ALARM

FOR THE SCOTT AIR-PAK® 2.2 / 3.0 / 4.5 /

SELF-CONTAINED BREATHING APPARATUS

FIFTY

WARNING

THE SCOTT SEMS USER ACCOUNTABILITY SYSTEM IS INTENDED FOR USE WITH SCOTT

SELF-CONTAINED BREATHING APPARATUS (SCBA) WHICH MAY SUPPORT HUMAN LIFE

IN HAZARDOUS ATMOSPHERES. FAILURE TO CAREFULLY READ AND UNDERSTAND

THE FOLLOWING INSTRUCTIONS MAY RESULT IN SERIOUS INJURY OR DEATH TO THE

SCBA USER.

USE OF A RESPIRATOR INTEGRATED WITH THE SEMS USER ACCOUNTABILITY SYSTEM

WILL REQUIRE MODIFICATION OF THE RESPIRATOR "REGULAR OPERATIONAL

INSPECTION PROCEDURES" AND WILL REQUIRE TRAINING OF THE RESPIRATOR USER

IN THE USE OF SUCH RESPIRATORS.

THE FOLLOWING INSTRUCTIONS SUPPLEMENT BUT DO NOT REPLACE THE OPERATING

AND MAINTENANCE INSTRUCTIONS SUPPLIED WITH EACH RESPIRATOR.

1

Page 2

WARNING

READ AND UNDERSTAND THIS COMPLETE INSTRUCTION MANUAL BEFORE USING A

RESPIRATOR EQUIPPED WITH A SEMS ACCOUNTABILITY SYSTEM. FAILURE TO USE THE

SEMS ACCOUNTABILITY SYSTEM IN ACCORDANCE WITH THESE INSTRUCTIONS MAY

LEAD TO CIRCUMSTANCES WHICH COULD RESULT IN SERIOUS INJURY OR DEATH.

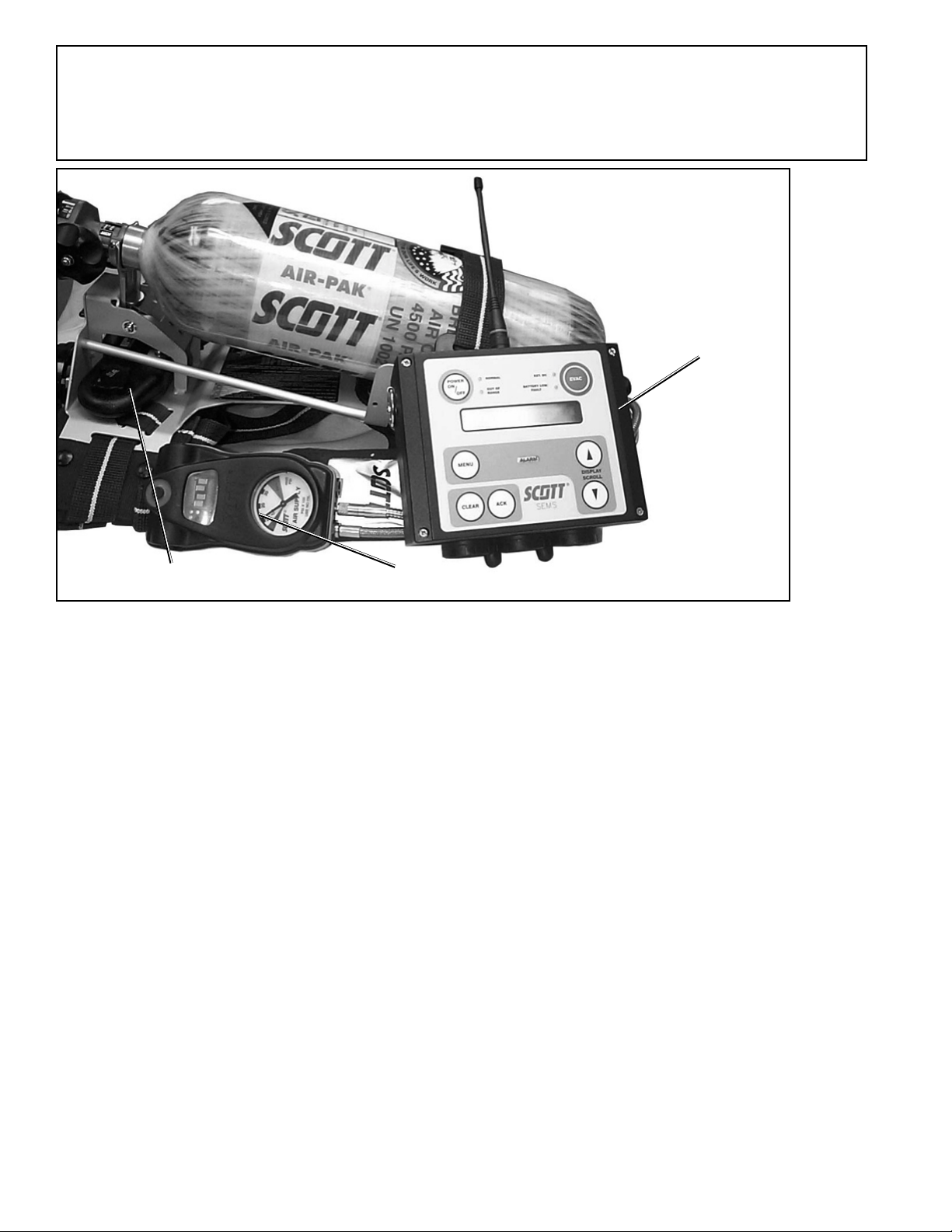

BASE

STA TION

SENSOR MODULE

PORT ABLE UNIT

FIGURE 1

DESCRIPTION

The SCOTT Electronic Management System (SEMS) provides a

method of communication between respirator users in a hazardous

area and a designated person outside of the hazardous area. The

SCOTT SEMS PDA Personal Distress Alarm is an optional accessory

which is intended to be integrated only with SCOTT AIR-PAK® 2.2 /

Fifty

3.0 / 4.5 /

self-contained breathing apparatus (SCBA). The SEMS

equipment consists of individual SEMS PDA Portable Units with Control Console attached to the SCOTT AIR-PAK self-contained breathing apparatus and a SEMS PDR Personal Distress Receiver Base

Station. The equipment can transmit and receive specific information

between the respirator users and the Base Station operator. The specific information consists of user identification and status as well as

alerts for evacuation. Complete training in the use of the SEMS equipment is required before actual use in a hazardous environment.

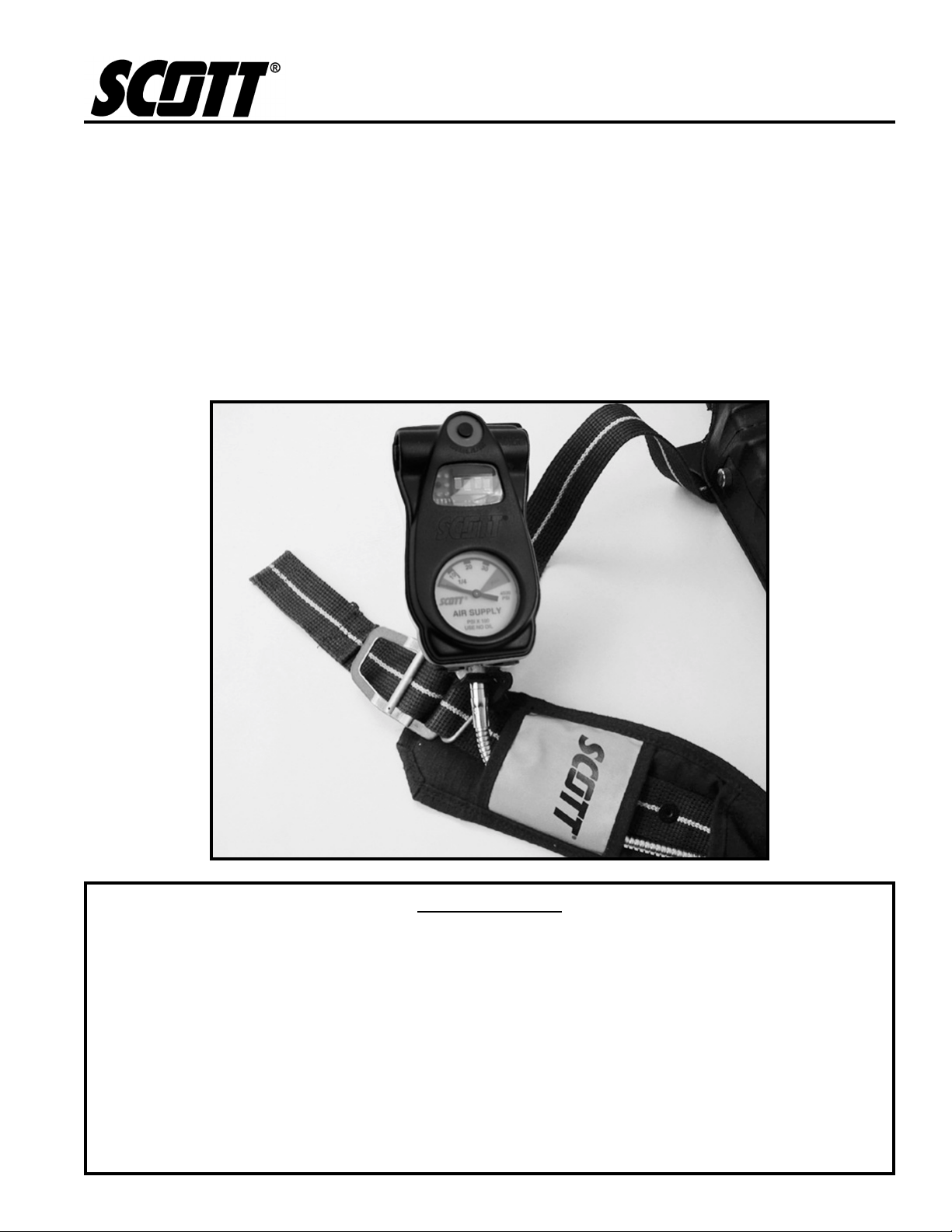

The SEMS PDA Control Console is integrated into the SCOTT AIRPAK SCBA as a part of the remote air pressure gauge which hangs

over the right shoulder of the respirator user. The Control Console

also operates the PERSONAL ALERT SAFETY SYSTEM (P ASS) distress alarm intended to assist in locating a respirator user who is incapacitated or in need of assistance. The Control Console has a set of

status lights, a four character digital display , a dial air pressure gauge,

and three control buttons which can easily be pressed with gloved

hands. Power is supplied by batteries in both the Control Console and

in the SEMS PDA distress alarm battery compartment on the SCBA

backframe.

2

NOTE

USE ONL Y IN ACCORDANCE WITH NFPA 1500,

"

STANDARD ON FIRE DEPARTMENT

OCCUPATIONAL SAFETY AND HEALTH

PROGRAM."

Page 3

The SEMS PDA

distress alarm warns the user when the air supply

cylinder has reached 50% of its full capacity and also functions as an

electronic end of service time indicator for the respirator by sounding

an alarm when the air supply cylinder has been depleted to 25% of its

full capacity. The Control Console digital display shows the approximate cylinder pressure. Details of the end of service time indicator

operation are also discussed in the Operation and Maintenance instructions provided with the respirator.

The SEMS PDR Base Station is a compact battery operated device

that can be tripod mounted or carried by a strap. A digital display

provides information about status of the respirator users who are logged

onto the Base Station. Simple dedicated function buttons control the

transmission and receipt of signals with the respirator users. The Base

Station can be easily interfaced with a computer for programming and

advanced applications.

When a respirator user opens the cylinder valve and begins use of an

AIR-PAK SCBA equipped with the SEMS PDA, the Portable Unit will

automatically begin to operate. If the SEMS PDR Base Station is

present at time of entry, the SEMS PDA must log-in with the Base

Station before entry into the hazardous area. Contact between the

SEMS PDA Portable Unit and the Base Station will continue until the

respirator user terminates use of the SCBA.

Each installation of SEMS equipment operates as a distinct set of

Portable Units and Base Station that transmit and receive on a single

frequency. If another installation of SEMS equipment is used in the

same area, the operation of each group will remain discreet and

separate between Portable Units and Base Stations. The SEMS

equipment operates between 453.0375 and 465.6375 MHz on radio

channels defined in FCC Title 47 (Telecommunications) Part 90 section 20, Limitation (27) and requirement Part 90.238. Programming

of the Portable Units and Base Station is essential and must be

performed prior to training and use. See SEMS Programming Guide,

SCOTT P/N 89506-01 for complete details of programming the SEMS

equipment.

The installation of the SCOTT SEMS PDA distress alarm is approved

by the National Institute of Occupational Safety and Health (NIOSH)

Fifty

on all models of SCOTT AIR-PAK 2.2 / 3.0 / 4.5 /

SCBA.

The SCOTT SEMS PDA distress alarm Portable Unit, when added to

a SCOTT Air-Pak respirator, as shown in FIGURE XX, consists of a

Sensor Module with battery compartment mounted to the bottom of

the respirator backframe, a pressure gauge with transducer, and a

Control Console mounted on the wearer’s right shoulder strap at the

pressure gauge location. The SEMS PDA Portable Unit requires three

(3) nine volt batteries to operate: two in the Sensor Module on the

backframe and one in the Control Console.

Installation of the SCOTT SEMS PDA distress alarm requires some

disassembly of the respirator and should only be performed by an

authorized service center. Contact SCOTT HEALTH AND SAFETY,

Monroe, NC at 1-800-247-7257 for details.

WARNING

NO PERSONAL ALERT SAFETY SYSTEM, RESPIRATOR OR COMBINATION OF PERSONAL

ALERT SAFETY SYSTEM AND RESPIRATOR,

BY THEMSELVES, CAN PROVIDE COMPLETE

PROTECTION IN FIRE SITUA TIONS. HOWEVER,

USING AN ALARM AND A RESPIRATOR IN

ACCORDANCE WITH THE REQUIREMENTS

OF AN ORGANIZED RESPIRAT OR Y PROTECTION PROGRAM IS ONE OF THE MANY

SAFETY PRECAUTIONS WHICH SHOULD BE

TAKEN TO AVOID PERSONAL INJURY OR

DEATH.

3

Page 4

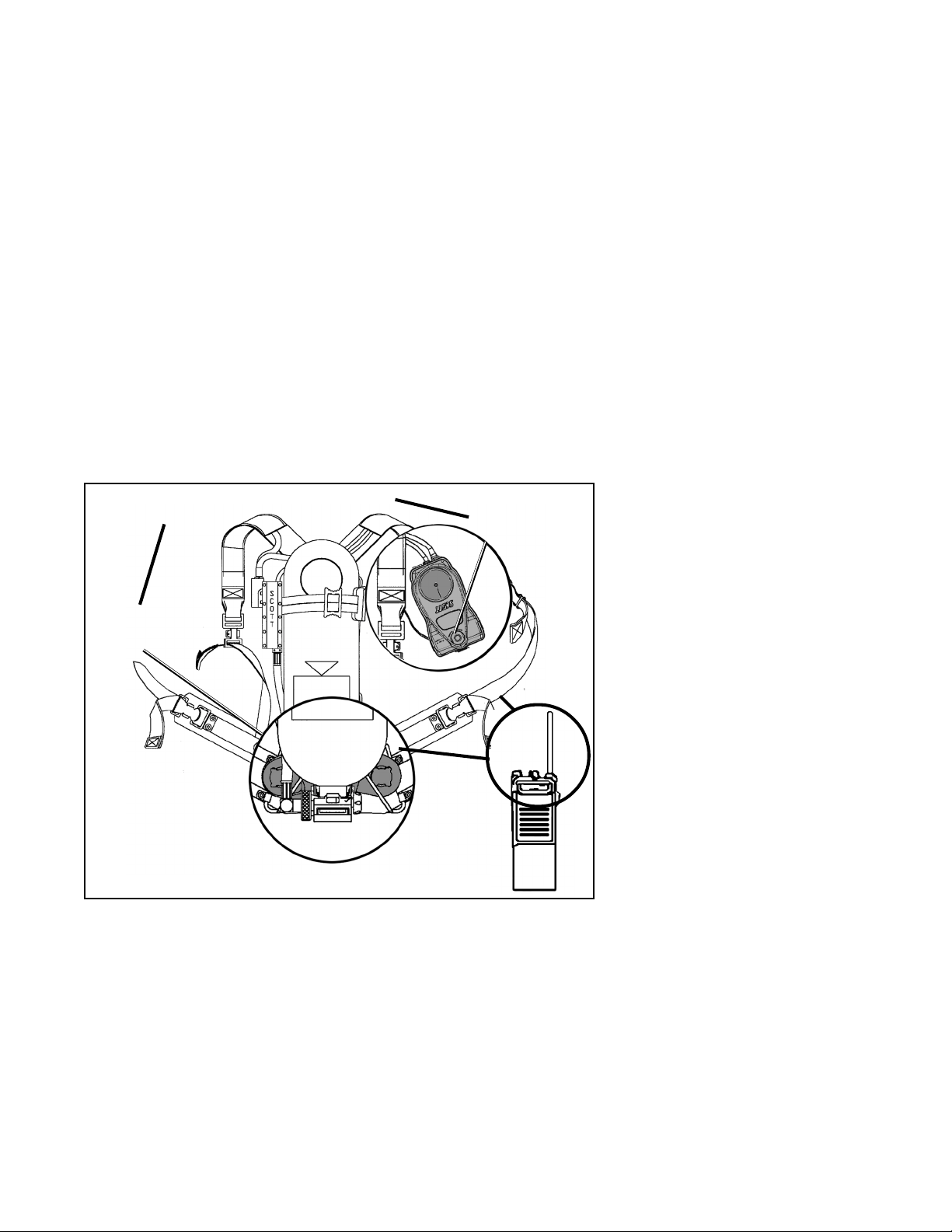

DETECTING AND A VOIDING

RADIO FREQUENCY INTERFERENCE:

When any electronic device is adversely affected by radio waves, Radio

Frequency Interference (RFI) is said to have occurred. All electronic

devices like the SEMS PDA distress alarm may be subject to the effects of RFI. Radio transmissions from the antennas of radios including those used by fire fighters, police and other public safety related

personnel may produce RFI in the SEMS PDA distress alarm. RFI

may occur while the radio is transmitting if the respirator equipped

with the SEMS PDA distress alarm is in close proximity to a base

station or high-powered vehicle mounted radio, or if the antenna of a

personal portable hand held radio is touching or within six (6) inches

of the Control Console or Sensor Module of the SEMS PDA distress

alarm (See FIGURE 4).

Be aware of the symptoms of RFI. A SEMS PDA distress alarm affected by RFI may temporarily give false indications such as the sudden sounding of the loud continuous three-tone chirp of the full alarm.

In some instances the lights on the Control Console may flash without

sounding the alarm. In rare circumstances, an alarm which was sounding may stop.

If the SEMS PDA exhibits any of the symptoms of RFI, identify the

source of the RFI and do the following:

· If the symptoms of RFI occur when standing near a base sta-

tion transmitting antenna or a truck mounted radio antenna,

move away from the antenna until the symptoms stop.

· If the symptoms of RFI occur while transmitting on a hand-

held radio, move the radio away from the SEMS PDA.

CHECK THE CONTROL CONSOLE AND BE CERT AIN THE GREEN

LIGHT IS FLASHING NORMALLY WHEN THE INTERFERENCE

STOPS, REGARDLESS OF THE SOURCE.

In normal usage with the air cylinder open, the SEMS PDA distress

alarm will typically resume normal operation after experiencing RFI.

In some circumstances after experiencing RFI, it may be necessary to

remove the unit from service. Remove and reinstall the battery to reset the unit (see BATTERY REPLACEMENT section of this instruction). Then inspect and return the unit to service.

W ARNING

KEEP THE ANTENNAS OF HAND-HELD

RADIOS AT LEAST SIX (6) INCHES AWAY

FROM THE CONTROL CONSOLE AND THE

SENSOR MODULE OF THE SEMS PDA

DISTRESS ALARM WHEN TRANSMITTING.

Close proximity of RADIO EQUIPMENT to the

SEMS PDA DISTRESS ALARM during radio

transmission may cause the unit to MALFUNCTION. FAILURE TO RECOGNIZE A MALFUNCTION OF THE SEMS PDA DISTRESS

ALARM AND TAKE THE PROPER CORRECTIVE

ACTION MAY RESULT A NONWORKING DISTRESS ALARM WHICH WILL NOT SOUND IF

THE USER STOPS MOVING AND LEAD TO SERIOUS INJURY OR DEATH.

W ARNING

USERS OF RESPIRATORS EQUIPPED WITH

THE SEMS PORTABLE UNIT MUST BE AW ARE

OF THE PROPER OPERATION OF THE

EQUIPMENT. FAILURE TO RECOGNIZE A

MALFUNCTION OF THE SEMS PORTABLE

UNIT AND TAKE PROPER CORRECTIVE ACTION

MAY RESULT IN SERIOUS INJURY OR DEATH.

4

Page 5

If the SEMS PDA distress alarm is affected by RFI when the respirator

air supply is turned off or the cylinder is empty, the distress alarm

could be turned off during use. If this occurs, depress the RED Manual

Alarm Button and hold at least two seconds to activate the alarm.

IF THE SYMPTOMS OF RFI OCCUR, THE RESPIRATOR USER

MUST CHECK THE SEMS PDA DISTRESS ALARM TO VERIFY THA T

IT IS FUNCTIONING PROPERLY. IF THE GREEN LIGHT ON THE

CONTROL CONSOLE DOES NOT RESUME FLASHING IN THE

NORMAL MANNER AFTER EXPERIENCING THE SYMPTOMS OF

RFI, OR IF THE UNIT CONTINUES TO MALFUNCTION IN ANY

OTHER WAY , PROCEED T O A SAFE AREA, REMOVE THE RESPIRA TOR FROM SERVICE AND TAG FOR REPAIR BY AUTHORIZED

PERSONNEL.

Minimize or eliminate the effects of RFI by protecting the SEMS PDA

with the following steps:

• Maintain a safe distance from a base station transmitting antenna

or a truck mounted radio antenna.

• Keep the antennas of hand held radios at least six (6) inches away

from the CONTROL CONSOLE or the SENSOR MODULE (See

FIGURE 2).

KEEP RADIO ANTENNAS A T LEAST

SIX (6) INCHES FROM THESE AREAS

SENSOR

MODULE

FIGURE 2

RFI WARNING AREAS

CONTROL

CONSOLE

WARNING

BE AWARE OF THE POTENTIAL EFFECT OF

RADIO TRANSMISSIONS FROM BASE STA TION

OR TRUCK MOUNT RADIOS WHEN USING A

RESPIRATOR WITH THE SEMS PDA DISTRESS

ALARM. Close proximity of RADIO EQUIPMENT

to the SEMS PDA DISTRESS ALARM during radio transmission may cause the unit to MALFUNCTION. FAILURE TO RECOGNIZE A MALFUNCTION OF THE SEMS PDA DISTRESS

ALARM AND TAKE THE PROPER CORRECTIVE

ACTION MAY RESULT A NONWORKING DISTRESS ALARM WHICH WILL NOT SOUND IF THE

USER STOPS MOVING AND LEAD TO SERIOUS

INJURY OR DEATH.

5

Page 6

FCC NOTICE

This equipment has been tested and found to comply with the requirements of United States Federal Communications Commission,

Code of Federal Regulations, FCC title 47, part 90 Section 20, limitation (27) and requirement Part 90.238 over frequency range 453.0375

to 465.6375 MHz, as well as FCC Section 1.1310 for Occupational/

Controlled Exposure limits.

If the SEMS Base Station or Portable Unit has been damaged, DO

NOT use this equipment. Maintenance or repair of this equipment

must only be performed by an authorized SCOTT service center.

Unauthorized service may void the manufacturers warranty and may

cause damage to the equipment. Use only Scott authorized accessories, cables, and power connectors. Consult the operating and service manuals for instructions on battery replacement, battery maintenance, and use of accessory cables.

RADIO FREQUENCY INTERFERENCE (RFI)

When any electronic device is adversely affected by radio waves, Radio Frequency Interference (RFI) is said to have occurred. All electronic devices like the SEMS PDA distress alarm may be subject to the

effects of RFI, most of which are temporary in nature. Users of the

SCOTT AIR-P AK SCBA with the integrated SEMS PDA distress alarm

must be familiar with the normal operation of the distress alarm and

must also be familiar with how to identify and avoid the effects of RFI

(see DETECTING AND A VOIDING RADIO FREQUENCY INTERFERENCE on page 14). If RFI occurs to the SEMS PDA distress alarm, it

may be caused by transmissions from two-way radio base stations or

high-powered vehicle mounted radios or transmissions from hand-held

or personal radios where the radio antenna is touching or very close to

(less than 6 inches from) components of the SEMS PDA distress alarm.

INTRINSICALL Y SAFE LISTING

The SEMS PDA distress alarm, when installed on a SCOTT respirator,

is listed as intrinsically safe in Class I Division 1 Groups A, B, C and D

hazardous locations by Entela Testing Laboratories. T o maintain Intrinsic Safe Listing, the respirator with SEMS PDA distress alarm must be

inspected regularly per the following Regular Operational Inspection

procedures. SEMS PDA distress alarm components must not be tampered with in any manner. Only batteries of the type indicated on the

Sensor Module label and in the Battery Replacement instructions may

be installed. The battery compartments must only be opened in an

area known to be free of flammable or explosive hazards.

PROGRAMMING

Before SEMS equipment can be put into service, the Base Station and

each Portable Unit must be programmed to work with each other. The

amount and detail of the information programmed in will depend on the

requirements of the organization using the SEMS. At a minimum, the

equipment must be setup so that the Base Station will recognize each

Portable Unit in the group and associate an identity of the respirator

user with the Portable Unit. In this way, specific users who have entered a particular region of the hazardous area can be contacted individually to evacuate to a safe atmosphere. In addition, if a Portable Unit

transmits a DISTRESS SIGNAL, the Base Unit will display the identity

of the respirator user. See SEMS Programming Guide, SCOTT P/N

89506-01 for complete details of programming the SEMS equipment.

W ARNING

RADIO FREQUENCY INTERFERENCE (RFI)

MA Y CAUSE A MALFUNCTION OF THE SEMS

PDA DISTRESS ALARM. USERS OF RESPIRATORS EQUIPPED WITH THE SEMS PDA

DISTRESS ALARM MUST BE AW ARE OF THE

PROPER OPERATION OF THE DISTRESS

ALARM. FAILURE TO RECOGNIZE A MALFUNCTION OF THE SEMS PDA DISTRESS

ALARM AND TAKE PROPER CORRECTIVE

ACTION MAY RESULT IN SERIOUS INJURY OR DEATH.

6

Page 7

BASIC FUNCTIONS OF THE SEMS EQUIPMENT

The SEMS equipment has two primary functions:

· Personal Alert Safety System (PASS) Distress Alarm

· Evacuation Signal

1. The PASS Distress Alarm is joined to the SEMS PDA distress

alarm operation. The Portable Unit will send a signal to the Base

Station when the SEMS PDA distress alarm goes into full alarm.

Activation of the full alarm can be either by manual activation of

the user or by automatic activation from lack of user movement

for the time period set on the SEMS PDA distress alarm. Once

acknowledged by the Base Station operator, “PASS” will appear

on the Control Console display.

2. The Evacuation Signal is sent from the Base Station to the SEMS

PDA Portable Unit. It can be handled one of two ways:

a) All-Call Signal: The Base Station will send a signal to all SEMS

PDA Portable Units logged on to it. When received, the Control Console will display “EVAC” and sound an audible signal.

Every respirator user must acknowledge this signal by press-

twice

ing

will continue to read “EVAC” until user leaves hazardous area

and shuts down the respirator.

b) Selective Evacuation Alarm The Base Station will send a sig-

nal to only one individual unit logged on to it. When received,

the Control Console will display “EVAC” and sound an audible

alarm. The selected respirator user must acknowledge this signal by pressing

sole. Display will continue to read “EVAC” until user leaves

hazardous area and shuts down the respirator.

the RESET button on the Control Console. Display

twice

the RESET button on the Control Con-

Other additional functions include:

1. The Contact Signal is an automatic signal sent by the Base Sta-

tion to every Portable Unit that is logged in to the Base Station.

Any respirator user who does not return an acknowledgment to

the Contact Signal within 120 seconds will be shown on the Base

Station as “OUT OF RANGE.”

2. Air supply cylinder levels are monitored by the Portable Unit and

the Base Station. The user can press and hold the RESET button at any time for a digital display of the remaining air supply

cylinder pressure. The approximate cylinder pressure is displayed.

The user receives a “½ AIR” warning in the display with an audible alarm when the cylinder reaches one-half of full pressure.

The user also receives a “LOW AIR” warning in the display with

an audible alarm when the cylinder reaches one quarter of full

pressure. The “LOW AIR” warning is also transmitted to the Base

Station. The “LOW AIR” alarm will continue to operate until the

respirator is shut down.

3. Users can inform the Base Station that they are withdrawing from

the hazardous atmosphere by pressing and holding the “WITHDRAW” button on the Control Console for at least two seconds.

The display will read “W–D” until the user leaves the hazardous

area and shuts down the respirator.

7

Page 8

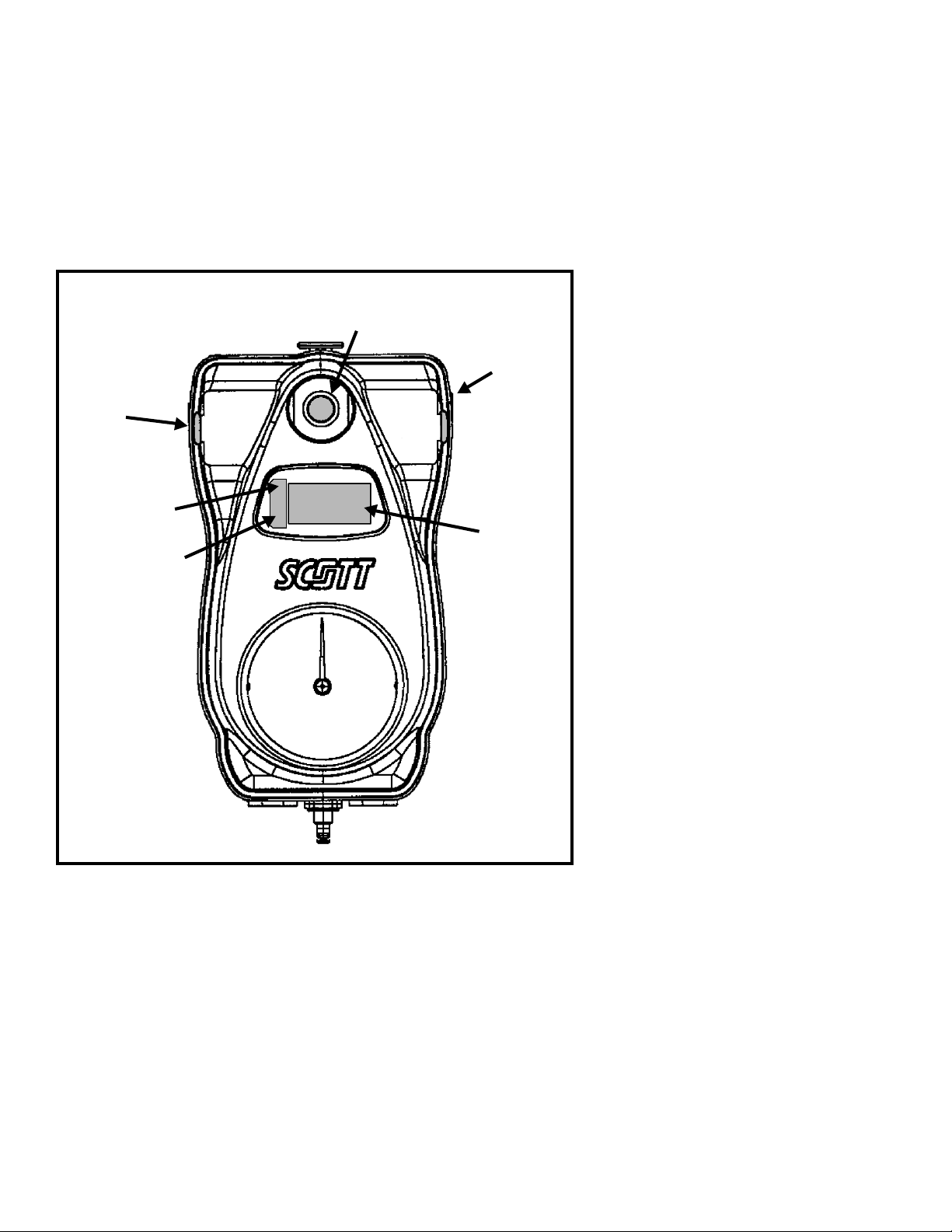

OPERA TION OF THE SEMS PDA DISTRESS ALARM

With proper batteries installed and a charged air cylinder, the SEMS

PDA distress alarm (PASS) is automatically activated when the respirator is pressurized by opening the cylinder valve of the respirator. If

batteries are completely discharged or have not been installed, there

will be no light or sound indicating that the unit will not work at all.

Activation is indicated by 3 quick audible chirps from the Sensor Module. On activation, a green light located on the Control Console, shown

in FIGURE 3, will begin to flash approximately once a second. The

SEMS PDA distress alarm is now in the automatic mode.

MANUAL

WITHDRAW

BUTTON (BLUE

INDICATOR)

RED SIGNAL

LIGHT

GREEN SIGNAL

LIGHT

WITHDRAW

ALARM BUTTON

(RED INDICAT OR)

MANUAL

ALARM

RESET

RESET

BUTTON

(YELLOW

INDICATOR)

CONSOLE

DISPLAY

W ARNING

THE SEMS PDA DISTRESS ALARM IS INTENDED TO ASSIST IN LOCATING A PERSON WHO MAY BE IN A LIFE THREATENING SITUATION. FAILURE TO FOLLOW

THE INSTRUCTIONS FOR OPENING,

CHANGING ALL BATTERIES AND RE-CLOSING BOTH B ATTERY COMPARTMENTS MAY

RESULT IN DAMAGE WHICH COULD CAUSE

FAILURE OF THE PASS DURING A LIFE

THREATENING EMERGENCY OR COULD

CAUSE A FIRE OR EXPLOSION IN A FLAMMABLE OR EXPLOSIVE ATMOSPHERE POSSIBLY RESULTING IN SERIOUS INJURY OR

DEATH.

W ARNING

USERS OF RESPIRATORS EQUIPPED WITH

THE SEMS PDA DISTRESS ALARM MUST BE

AWARE OF THE PROPER OPERATION OF

THE DISTRESS ALARM. FAILURE TO RECOGNIZE A MALFUNCTION OF THE SEMS PDA DISTRESS ALARM AND TAKE PROPER CORRECTIVE ACTION MA Y RESULT IN SERIOUS INJURY OR DEATH.

FIGURE 3

THE PORTABLE UNIT

If the any of the batteries needs replacement, the SEMS PDA distress

alarm will indicate as follows:

• SENSOR MODULE – A single audible chirp from the Sensor Module once every 2 seconds and the green light on the control module will not flash.

• CONTROL CONSOLE – “BATT” will appear in the display but all

other functions will operate normally.

If any low battery condition appears at start-up, immediately change

all the batteries before use of the respirator. See the BATTERY REPLACEMENT section of this instruction. If a low battery condition appears while the respirator is in use, the SEMS PDA distress alarm will

continue to operate for a period of time greater then the longest duration cylinder available for the respirator.

8

Page 9

Once activated, the SCOTT SEMS PDA distress alarm will remain

activated until:

1. The respirator air cylinder is turned off with the residual air pres-

sure purged from the regulator

AND

2. The reset button on the control module has been pressed twice.

In the automatic mode the SCOTT SEMS PDA distress alarm con-

stantly monitors motion of the respirator backframe. The motion sensor is located in the Sensor Module along with the audible alarm. If

the Sensor Module does not sense motion of the respirator for 20

seconds the SEMS PDA distress alarm will signal a pre-alarm condition. If there is still no motion of the respirator for the next 12 seconds

the full alarm will sound.

PRE ALARM:

Once the respirator is pressurized, the SEMS PDA distress alarm will

automatically sound a pre-alarm if the respirator remains motionless

for more than 20 seconds.

When the pre-alarm occurs, the green flashing lights on the Control

Console and backframe are replaced by bright red lights which flash

approximately once a second and are accompanied by an ascending/

descending audible tone which increases in volume during the prealarm cycle.

If the user is

not incapacitated or not in need of assistance, the prealarm is normally reset by movement of the respirator. When reset,

the flashing red lights will be replaced by the flashing green lights and

the ascending/descending tone will stop.

A pre-alarm may also be reset by pressing and holding the reset button on the side of the Control Console until three (3) quick audible

chirps are heard and the red flashing lights on the Control Console

and backframe are replaced by the green flashing lights.

Remember that the motion sensor is in the Sensor Module under the

air cylinder valve and not in the Control Console so that actual movement of the respirator backframe is required for reset. Shaking the

Control Console

will not reset the SEMS PDA distress alarm .

WARNING

USERS OF RESPIRATORS EQUIPPED WITH

THE SEMS PDA DISTRESS ALARM MUST BE

AWARE OF THE PROPER OPERATION OF

THE DISTRESS ALARM. IF THE GREEN LIGHT

IS NOT FLASHING NORMALL Y, OR IF THE UNIT

EXHIBITS ANY OTHER SIGNS OF A MALFUNCTION WITHOUT THE USER TAKING PROPER

CORRECTIVE ACTION, IT MAY LEAD TO CIRCUMSTANCES THAT RESULT IN SERIOUS INJURY OR DEATH.

FULL ALARM:

If the user is incapacitated or in need of assistance and can not move,

the SEMS PDA distress alarm will go into full alarm 12 seconds after

the pre-alarm starts.

Full alarm is indicated by a loud, almost continuous 3 tone chirp from

the Sensor Module accompanied by the flashing of the red signal lights

on the Control Console and “PASS” will appear in the display . The full

alarm condition can only be cleared by manually pressing twice on the

reset button, located on the side of the Control Console, shown in

FIGURE 3.

After the full alarm has been silenced by pressing the reset button,

releasing it and pressing it again, the SEMS PDA distress alarm will

remain activated with the green lights flashing once every 2 seconds.

In the activated or “automatic” mode, it will again go into pre-alarm

followed by full alarm unless there is movement of the respirator at

least once every 20 seconds as long as the respirator is pressurized.

9

Page 10

MANUAL ALARM:

If the respirator user is in a situation where immediate assistance is

required, the SEMS PDA distress alarm provides a manual alarm button, located on the front of the Control Console on the user’s right

shoulder, shown in FIGURE 2.

The manual alarm causes the Full Alarm signal to be given. The

manual alarm may be activated at any time by pressing the manual

alarm button and holding at least two seconds, even when the respirator is not pressurized, provided a good battery is in the SEMS PDA

distress alarm. If the manual alarm button has been pressed without

the respirator pressurized, the alarm can be silenced by pressing the

reset button twice. The SEMS PDA distress alarm is now on and in

automatic mode. To turn the unit off, press the reset twice again while

the unit is not in alarm mode.

TURNING OFF THE SEMS PDA DISTRESS ALARM:

The SEMS PDA distress alarm can not be turned off if the respirator

cylinder valve is open and/or pressure remains in the respirator . Pressing the reset button when the respirator is pressurized will only reset

an alarm condition and return the SEMS PDA distress alarm to automatic mode.

When the use of the SEMS PDA distress alarm and respirator is no

longer required, first close the cylinder valve on the respirator, then

vent the residual air from the respirator system by opening the regulator purge valve. After waiting until the air flow stops, close the regulator purge valve and turn off the SEMS PDA distress alarm by pressing

the reset button twice after the flashing green light sequence. The

unit will say “OFF” in the display , sound a quick two tone chirp, and the

SEMS PDA distress alarm will be inactive. If there is no pressure in

the system when the reset button is pressed twice, there will be no

beep sequence.

If the respirator is turned off and depressurized without pressing the

reset button twice, the SEMS PDA distress alarm will continue to monitor motion in automatic mode. This means that the SEMS PDA distress alarm may be used to monitor motion after the respirator is turned

off and depressurized. Resetting the full alarm after the respirator has

been depressurized

will not turn off the SEMS PDA distress alarm.

The reset switch must be depressed twice after the flashing green

light sequence with no alarm condition to turn off the SEMS PDA distress alarm (the display will say “OFF” and two tone chirp should be

heard).

Remember, the loud audible alarm and flashing red lights can be turned

on at any time by pressing the manual alarm button and holding at

least two seconds.

W ARNING

NO PERSONAL ALERT SAFETY SYSTEM, RESPIRATOR OR COMBINATION OF PERSONAL

ALERT SAFETY SYSTEM AND RESPIRATOR,

BY THEMSELVES, CAN PROVIDE COMPLETE

PROTECTION IN FIRE SITUA TIONS. HOWEVER,

USING AN ALARM AND A RESPIRATOR IN

ACCORDANCE WITH THE REQUIREMENTS

OF AN ORGANIZED RESPIRAT OR Y PROTECTION PROGRAM IS ONE OF THE MANY

SAFETY PRECAUTIONS WHICH SHOULD BE

TAKEN TO AVOID PERSONAL INJURY OR

DEATH.

10

Page 11

OTHER OPERA TIONAL FEA TURES

END OF SERVICE TIME INDICATOR

The SEMS PDA

distress alarm also provides an electronic end of ser-

vice time indicator and cylinder pressure display as follows:

1/2 full cylinder

When the air supply cylinder has reached 1/2 full capacity, the

audible signal will sound and the display will read “1/2 AIR” for 10

seconds.

1/4 full cylinder

When the air supply cylinder has reached 1/4 full capacity, the

audible signal will sound and the display will read “LOW AIR” and

then flash the remaining cylinder air pressure in psig until the user

responds by pressing the RESET button. However, the alarm will

continue to repeat actuation until the system is shut down or until

the unit detects no movement by the user at which time the SEMS

PDA distress alarm sequence will begin with PRE ALARM and

FULL ALARM as stated above.

Cylinder pressure display

Pressing and holding the RESET at any time will show the approximate cylinder pressure remaining in psig on the display.

WARNING

THE RESPIRATOR USER MUST IMMEDIATELY LEAVE THE AREA REQUIRING

RESPIRATORY PROTECTION WHEN AN

END OF SERVICE INDICATOR ALARM

ACTUATES. ACTUATION OF AN END OF

SERVICE INDICATOR ALARM WARNS

THAT APPROXIMATELY 25% OF FULL

PRESSURE REMAINS IN THE AIR SUPPLY

CYLINDER (THAT IS, APPROXIMATELY

3/4 OF THE TOTAL AIR SUPPLY HAS

BEEN USED). A DELAY IN LEAVING THE

AREA AFTER ALARM ACTUATION MAY

RESULT IN SERIOUS INJURY OR

DEATH.

BA TTERY TEST

When the SEMS PDA distress alarm is in the off condition (cylinder

valve closed with no flashing green lights, the batteries in the Sensor

Module can be checked by depressing and holding the reset button

on the console.

A green LED will illuminate on the console to indicate sufficient battery

power remaining; a red light indicates that the batteries must be replaced before the respirator is to be used again.

WARNING

FAILURE TO REPLACE THE BATTERIES AND/

OR CONTINUING WITH MULTIPLE USES OF

THE RESPIRATOR AFTER THE LOW BATTERY CONDITION HAS BEEN INDICATED BY

THE SEMS PDA DISTRESS ALARM MAY RESULT IN FAILURE OF THE SEMS PDA DISTRESS ALARM DURING USE AND POSSIBLE INJURY OR DEATH OF THE USER.

11

Page 12

USE OF THE SEMS PDA PORT ABLE UNIT

Users of SCOTT respirators equipped with the SEMS PDA Portable

Unit must be fully trained in the operation of the equipment as part of

a complete respiratory protection program before entering a hazardous environment.

1. Start-up

a) Use of the SEMS PDA Portable Unit begins when the user

opens the cylinder valve on the respirator to start respirator

usage. The unit will sound three chirps to indicate activation.

b) After a brief start-up sequence of less than ten seconds, the

green light in the Control Console and the display will show

“<<<<“ until the unit is acknowledged and logged onto a base

station. An alert tone, a “BE-doop” to indicate the system activity, is used for several functions. Whenever the alert tone

occurs, the user should look at the Portable Unit display for

information.

2. Initialization and Range

a) After the start-up sequence, the SEMS PDA Portable Unit will

send an Initialization signal to the Base Station to log in. The

Base Station will respond by showing “ACK” for the identity

assigned to that Portable Unit.

b) If the respirator user moves too far from the Base Station after

logging-in, the Control Console will begin to display “RNGE”

indicating out of range until the user moves back into the Base

Station field of operation (up to one-half mile line-of-sight).

c) If the Portable Unit is too far away from the Base Station at

start-up, or if the Base Station is not powered up, the Control

Console display will read “RNGE” right from start-up and not

be logged into the Base Station. The SEMS PDA Portable Unit

will continue trying to log-in to a Base Station until one comes

into range or is powered up.

d) Except for those functions which involve communication with

the Base Station, all other functions of the Control Console

and SEMS PDA distress alarm are still operational when the

Portable Unit is either out of range or not logged into a Base

Station.

3. Air Supply Cylinder Pressure

a) To check the air supply cylinder pressure, the user must press

and hold the RESET button on the Control Console. The approximate pressure remaining in the cylinder will be shown in

the display as PSIG.

b) When the cylinder reaches one-half of full pressure, the Con-

trol Console will display “1/2 AIR” for ten seconds.

c) When the cylinder reaches one-quarter of full pressure, the

Control Console will display “LOW AIR”. A low air signal will be

sent to the Base Station within ten seconds. The Base Station

operator must press “ACK” on the Base Station to acknowledge the user’s low air signal.

W ARNING

USERS OF RESPIRATORS EQUIPPED WITH

THE SEMS PDA DISTRESS ALARM MUST BE

AWARE OF THE PROPER OPERATION OF

THE DISTRESS ALARM. FAILURE TO RECOGNIZE A MALFUNCTION OF THE SEMS PDA DISTRESS ALARM AND TAKE PROPER CORRECTIVE ACTION MA Y RESULT IN SERIOUS INJURY OR DEATH.

12

Page 13

4. Distress Alarm

a) If the user is in distress or becomes immobile, the SEMS PDA

distress alarm will operate in conjunction with the Portable Unit.

If the distress alarm is activated, either by the user pressing

and holding the MANUAL ALARM for at least two seconds, or

from the user being immobile for the required time duration,

the Portable Unit will send a distress signal to the Base Station. The distress alarm will override all other messages and

actions of the Portable Unit.

b) When the Base Station acknowledges the user’s distress sig-

nal by pressing the “ACK” button on the Base Station, the Control Console will respond by displaying “PASS” and continuing

to sound the distress alarm on the respirator. The distress alarm

will continue until the user shuts down the respirator.

5. Evacuation

a) If the respirator users are required to leave the hazardous area,

the Base Station operator can send an evacuation message to

the Portable Units of logged-in respirator users. This message

can be sent either to all logged-in users or to selected loggedin users as chosen from the list on the Base Station.

b) The Portable Unit will emit the alert sound and “EVAC” will

appear flashing in the Control Console display.

c) When an “EVAC” message appears on the Control Console

twice

display, the respirator user must press

the RESET button on the Control Console to respond to the evacuation message. “EVAC” will continue to appear in the display of the Control Console until the user leaves the hazardous area and shuts

down the respirator.

6. Withdraw

a) The respirator user may choose to leave the hazardous area.

Pressing and holding the WITHDRAW button on the Control

Console will send that message to the Base Station.

b) When the Base Station receives a user withdrawal message,

the operator presses the “ACK” button on the Base Station to

respond.

c) When the Portable Unit receives the acknowledgment re-

sponse, the Control Console will display “W–D” until the respirator user leaves the hazardous area and shuts down the respirator.

7. Shutdown

a) After leaving the hazardous area and confirming that respira-

tor use is no longer required, doff the respirator according the

user instructions provided with the respirator.

b) Close the cylinder valve.

c) Press the RESET button twice.

d) The Control Console will sound the alert tone and flash “OFF”

in the display. The Portable Unit is now off.

8. Batteries

Battery operation is as stated in the SEMS PDA distress alarm

section of this instruction.

WARNING

IF THE LOW BATTER Y INDICA TION OCCURS A T

ANY TIME DURING USE OF THE RESPIRA T OR,

THE BATTERIES MUST BE CHANGED BEFORE

THE NEXT USE OF THE RESPIRA TOR. USE OF

A RESPIRATOR WITH DEPLETED BATTERIES

MAY LEAD TO A FAILURE OF THE RESPIRATOR WHICH COULD RESULT IN SERIOUS INJURY OR DEATH.

13

Page 14

USE OF THE SEMS BASE ST ATION

The SEMS PDR Base Station must be properly programmed before

field use. See SEMS Programming Guide SCOTT P/N 89506-01 for

complete details of SEMS programming.

The SEMS PDR Base Station requires batteries for operation. See the

BA TTER Y REPLACEMENT section of this instruction. An optional external power supply is available.

The SEMS PDR Base Station must be operated by a fully trained individual as part of a complete respiratory protection program. The Base

Station operator must have the ability to direct rescue operations as

needed.

1. Start-up

a) Press the POWER button on the Base Station to begin opera-

tion.

b) All Portable Units that were initialized before the Base Station

was powered up will be logged-in as indicated by “ACK” registered with the user’s identity.

c) Any Portable Units initialized after the Base Station is powered

up will also be logged-in as indicated by “ACK” registered with

the user’s identity.

d) The base station tracks the time for each Portable Unit from

log-in until each respirator user leaves the hazardous area and

shuts down their respirator.

W ARNING

THE SEMS BASE STATION MUST BE MONITORED BY A FULLY TRAINED INDIVIDUAL

WITH THE ABILITY TO DIRECT RESCUE OPERATIONS AT ALL TIMES WHEN LOGGED-IN

RESPIRAT OR USERS MA Y BE IN A HAZARDOUS

AREA. FAILURE TO PROVIDE A PROPERLY

TRAINED BASE STATION OPERATOR MAY

PERMIT A SITUATION TO OCCUR WHICH

COULD RESULT IN SERIOUS INJURY OR

DEATH.

POWER

BUTTON

MENU

BUTTON

EV AC

BUTTON

NORMAL

POWER EVAC

OUT OF

RANGE

DIGIT AL DISPLAY WINDOW

MENU

CLEAR

CLEAR

ACK

ACKNOWLEDGE

BUTTON

EXT

DC

LOW

BATT

ALARM

BUTTON

FIGURE 4

BASE ST A TION

ALARM

LIGHT

SCROLL

BUTTONS

14

Page 15

2. Evacuation

a) To send an evacuation message to all logged-in respirator us-

ers, the Base Station operator must press and hold the “EVAC”

button on the Base Station and then choose “ALL-CALL” from

the menu on the display. The “EVAC message will be sent to

all logged-in respirator users.

b) To send an evacuation message to only selected respirator

users, the Base Station operator uses the scroll buttons to move

up and down the list of logged-in respirator users and presses

the “EVAC” button when the selected users are highlighted in

the display.

c) The respirator users who receive the “EVAC” message must

press the RESET button on the Control Console to acknowledge the message.

d) The Base Station listing of logged-in users will display “CONF”

with each respirator user who has responded to the “EVAC”

message.

3. Air Supply Monitoring

a) When the air supply cylinder reaches one-quarter of full pres-

sure, the alert sound will occur and the Control Console will

display “LOW AIR”. A low air signal will be sent to the Base

Station within ten seconds. This end of service time indicator

(EOSTI) alarm cannot be silenced by the user until the user

leaves the hazardous area and shuts down the respirator.

b) The Base Station operator must press “ACK” on the Base Sta-

tion to acknowledge the user’s low air signal.

15

Page 16

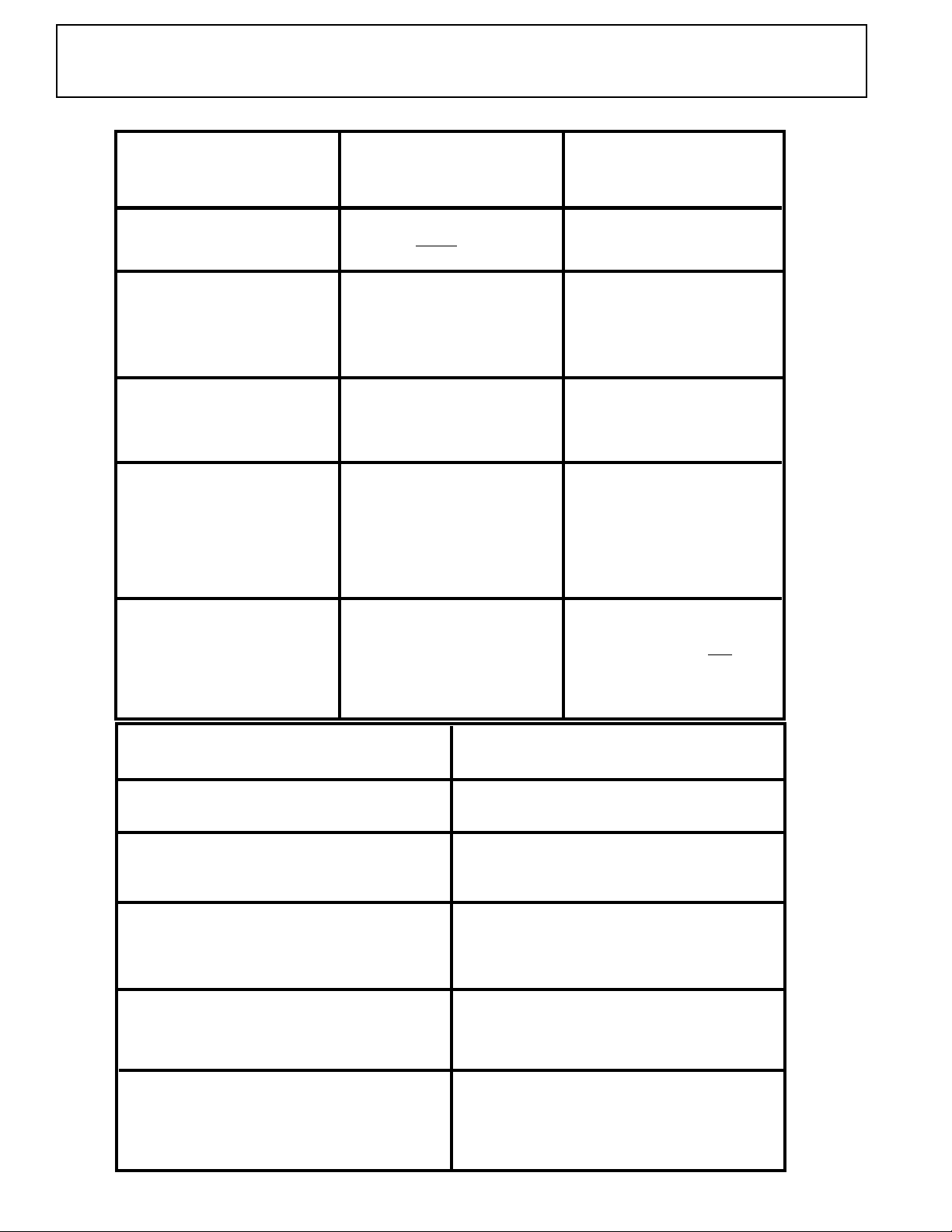

EVENT LOG

Software within the Base Station maintains a data record or EVENT

LOG of each communication to or from the Base Station from the time

it is powered for use unitl it is powered down. To acces and use the

EVENT LOG, proceed as follows:

BASE UNIT INTERF ACE SETUP

Plug the Base Unit Interface Cable into a COM port as instructed in

the COMPUTER SETUP section the SEMS Programming Instructions SCOTT P/N 89506-01.

1. Plug the other end of the Base Unit Interface Cable into the connector on the side of the Base Unit.

2. Run the SEMS Fire Department Software and select the tab labeled

“EVENT LOG.” See FIGURE 5.

FIGURE 5

EVENT LOG SCREEN

3. On the Base Unit, press and hold the EVAC button while turning

on the unit by pressing the POWER ON/OF button. Continue holding the EV AC button until the screen displays, “COMMAND MODE:

CS =0X2A58”. (NOTE: CS number may vary depending on version of Base Unit.)

4. Choose either “SAVE” or “SAVE & PURGE” to save the information in the EVENT LOG. The data will be saved as a text (.txt) file

to a folder called “Event Logs” in the same folder where the SEMS

Fire Department Software resides on your computer

[e.g.:(drive)\Program Files\SEMS Service Center\Event

Logs\(folder)].

a) “SAVE” will save the EVENT LOG file to the Event Logs folder

but leaves the EVENT LOG information on the Base Unit.

b) “SAVE & PURGE” will save the EVENT LOG file to the Event

Logs folder and then erase the EVENT LOG information from the

Base Unit.

16

Page 17

5. The EVENT LOG file is a text (.txt) which may be viewed in either

Microsoft Excel or Microsoft Word. The data is in columns separated (delimited) by commas. It may require some manipulation

of the columns to facilitate reading as shown in FIGURE 6. The

columns contain information as follows:

Column 1 Event number Identification

Column 2 Date of Event

Column 3 Time of Event

Column 4 Fire Company (blank if the PDA and the Base Unit have

the same name.)

Column 5 Truck Number

Column 6 Seat Number or Position

Column 7 Event (LOGON, PASS, ACK, etc.)

Column 8 Cylinder Pressure at time of Event

Column 9 Total time the AIR-P AK respirator had been on at time

of Event

FIGURE 6

SAMPLE EVENT LOG

Columns 4, 5, and 6 identify a particular AIR-PAK respirator

equipped with the SEMS PDA that has logged on to the Base Unit

in the course of the incident. The events include LOGON, PASS

activation, Withdrawal, Acknowledgement (ACK) of of messages,

etc.

17

Page 18

REGULAR OPERA TIONAL INSPECTION

When installed on a SCOTT SCBA, inspection and test of the SCOTT

SEMS PDA distress alarm is to be conducted along with inspection

and test of the respirator before each use. To do this, the REGULAR

OPERATIONAL INSPECTION procedures in your respirator instructions will require modification. The instructions below are to be added

to the instructions for REGULAR OPERA TIONAL INSPECTION of your

respirator. If, during the inspection, any malfunction of the respirator

or the SEMS PDA distress alarm is noted remove the respirator from

service and tag for repair by authorized personnel.

REGULAR OPERA TIONAL INSPECTION of the SEMS PDA Portable

unit installed on a SCOTT SCBA requires inspection of both the Distress Alarm (P ASS) functionality and the Portable Unit interaction with

the SEMS PDR Base Station.

Before REGULAR OPERA TIONAL INSPECTION, verify that the batteries are fresh and properly installed. Batteries are located in two

locations on the SEMS PDA distress alarm Portable Unit. Each location notifies separately when the batteries require replacement:

• As the batteries in the Sensor Module begin to approach the end

of their useful life, the Sensor Module will sound a chirp approximately every two seconds, the green lights on the control module

will go out.

• When the battery in the Control Console requires changing, “BATT”

will appear in the display .

In either condition the SEMS PDA distress alarm will continue to operate normally, going into pre-alarm after 20 seconds with no motion

and full alarm after 12 more seconds of no motion.

While in a low battery condition, the SEMS PDA distress alarm will

continue to operate for a period of time greater then the longest duration cylinder available for the respirator. However, the batteries must

be replaced before the respirator is used again. See BATTERY REPLACEMENT section of these instructions.

BA TTERY TEST

When the SEMS PDA distress alarm is in the off condition (cylinder

valve closed with no flashing green lights, the batteries in the Sensor

Module can be checked by depressing and holding the reset button

on the console.

A green LED will illuminate on the console to indicate sufficient battery

power remaining; a red light indicates that the batteries must be replaced before the respirator is to be used again.

W ARNING

FOLLOW REGULAR OPERATIONAL INSPECTION PROCEDURE EXACTLY. IF THE SEMS

PDA DISTRESS ALARM DOES NOT ACTUATE, OR DOES NOT OPERATE AS DESCRIBED OR IF ANY OTHER OPERATIONAL

MALFUNCTION IS NOTED, DO NOT USE THE

RESPIRATOR.

W ARNING

FAILURE TO REPLACE THE BATTERIES AND/

OR CONTINUING WITH MULTIPLE USES OF

THE SEMS EQUIPMENT AFTER THE LOW

BATTERY CONDITION HAS BEEN INDICATED MAY RESULT IN FAILURE OF THE

SEMS ACCOUNTABILITY SYSTEM DURING

USE WHICH COULD LEAD TO SERIOUS INJURY OR DEATH.

W ARNING

IN SEVERAL OF THE INSPECTION PROCEDURES DESCRIBED A FULL ALARM WILL

BE OBSERVED. THE FULL ALARM CONDITION INCLUDES AN AUDIBLE TONE THAT

CAN EXCEED 95 dBA AT 3 METERS (9.9 FT.).

IN ORDER TO PREVENT POSSIBLE HEARING DAMAGE DURING TEST, THE ALARM

SHOULD BE RESET IMMEDIATELY ON VERIFICATION THAT

ERLY. HEARING PROTECTION SHOULD BE

WORN IF PROLONGED EXPOSURE TO A

FULL ALARM CONDITION IS ANTICIPATED.

EMS

IS FUNCTIONING PROP-

CAUTION

THE PERFORMANCE PROPERTIES OF THE

SEMS PDA DISTRESS ALARM CANNOT BE

PROPERLY TESTED IN THE FIELD.

NOTE

IF THIS INSPECTION IS DONE IN DIRECT SUNLIGHT IT MAY BE HELPFUL TO SHADE THE

LENS ON THE CONTROL MODULE WITH YOUR

HAND TO BE SURE THE GREEN LIGHT IS

FLASHING.

18

Page 19

INSPECTION OF SEMS PDA DISTRESS ALARM

1. While performing the visual inspection of the respirator visually

inspect all SEMS PDA distress alarm enclosures, lenses, and wire

conduits for cracks, wear or other damage. If damage is noted,

remove respirator from service and tag respirator for repair by

qualified personnel.

2. Before pressurizing the respirator by opening the cylinder valve,

check the SEMS PDA distress alarm manual alarm feature by

pressing the manual alarm button, located on the front of the Control Console. Press and hold the manual alarm button at least two

seconds. The manual alarm shall begin sounding a loud almost

continuous 3 tone chirp accompanied by flashing of the red signal

light on the Control Console and backframe. Reset the manual

alarm by pressing twice on the reset button located on the side of

the Control Console (fully depress reset button, release and

press again). Unit will sound three chirps and green light will flash.

Turn the unit off by pressing the reset button twice again. Unit will

sound a two tone chirp and green lights will go out.

3. Open the cylinder valve to pressurize the system. The SEMS PDA

distress alarm shall sound 3 quick chirps and the lights on the Control Console and backframe shall begin flashing green about once

a second. The 3 chirps will sound approximately the same time the

VIBRALERT® in the mask mounted regulator actuates briefly.

4. Check pre-alarm: With respirator pressurized but with air flow

stopped (with switch depressed on “donning switch” or “E-Z FLO™”

regulators or with facepiece held to face on standard models),

leave respirator motionless for 20 seconds. The green flashing

lights shall be replaced by red flashing lights. An ascending/descending tone will sound increasing in volume.

5. Check pre-alarm reset: With respirator pressurized but with air

flow stopped (see step 4 above) leave respirator motionless until

pre-alarm condition occurs. Within 12 seconds, move the respirator to activate the Sensor Module. SEMS PDA distress alarm shall

reset. The red flashing lights shall be replaced by green flashing

lights and the ascending/descending tone shall stop.

Continue with regular operational inspection of respirator as directed by respirator instructions or your approved respiratory protection plan procedure. During the inspection the respirator must

be moved or turned every 30 seconds or less to prevent the sounding of the full alarm.

Perform the following checks after completion of all respirator checks and before turning off cylinder valve:

6. Check manual reset of pre-alarm: With respirator pressurized but

with air flow stopped (see step 4 above) leave respirator motionless until pre-alarm condition occurs. Within 12 seconds press

and hold reset button. Three (3) chirps shall sound, then release

button. The SEMS PDA distress alarm shall reset to the automatic

mode and the flashing red lights will be replaced by a flashing

green lights.

7. Check full alarm: Again, as in step 6 above, leave respirator mo-

tionless until pre-alarm condition occurs. Do not reset. Within 12

seconds a loud, almost continuous 3 tone chirping shall begin,

accompanied by the flashing of the red lights on the Control Console and backframe. Display will read “PASS.”

19

WARNING

IF THE LOW BATTERY INDICATION (ONE

STEADY CHIRP EVERY TWO SECONDS

WITH NO FLASHING LIGHTS) OCCURS AT

ANY TIME DURING REGULAR OPERATIONAL

INSPECTION, DO NOT USE THE RESPIRAT OR.

CHANGE THE BATTERY IN THE BATTERY

COMPARTMENT IMMEDIATELY AND REPEAT THE REGULAR OPERATIONAL TEST

OR T AKE THE RESPIRA T OR OUT OF SERVICE

UNTIL THE BATTERY IS CHANGED AND THE

REGULAR OPERATIONAL TEST IS SUCCESSFULLY PERFORMED.

WARNING

IF THE SEMS PDA DISTRESS ALARM IS

USED IN AN AREA OF EXPLOSIVE OR

FLAMMABLE HAZARDS, FAILURE T O REGULARLY INSPECT AS INSTRUCTED, FAILURE

TO CORRECT DAMAGE BEFORE USE OR

THE INSTALLATION OF INCORRECT BATTERY MAY LEAD TO A FIRE OR EXPLOSION

WHICH MA Y RESULT IN PERSONAL INJURY

OR DEATH.

REGULAR OPERATIONAL INSPECTION

CONTINUED ON NEXT PAGE...

Page 20

8. Check alarm reset: While in full alarm, fully depress reset button,

release, and depress again. The SEMS PDA distress alarm shall

reset to the automatic mode. The loud alarm shall stop and the

red flashing lights shall be replaced by green flashing lights.

9. Check continuing operation of the SEMS PDA distress alarm:

After finishing all respirator checks involving air flow, turn of f cylinder valve (push in and turn clockwise), purge all residual pressure

in respirator (open purge valve and wait for air flow to stop, close

purge valve). The SEMS PDA distress alarm shall remain active

with green light flashing. Do not move respirator, pre-alarm shall

occur with 20 seconds. Move respirator slightly, pre-alarm shall

reset, green lights shall start flashing again.

10. Check operation of end of service time indicator:

a) Open cylinder valve again to charge system, then push in and

rotate cylinder valve knob clockwise to close.

b) When cylinder valve is fully closed, open purge valve slightly

to vent residual air pressure from system.

c) As the residual air pressure vents from the system, the remote

pressure gauge needle will swing from “FULL” and move towards “EMPTY.” Close the purge valve when the gauge needle

crosses the “¼” mark but before the beginning of the red

“EMPTY” band. The end of service indicator alarms shall actuate along with the SEMS PDA electronic end of service time

indicator.

d) After verifying that all alarms are functioning (the SEMS PDA

electronic end of service time indicator will flash in the display

“LOW AIR”) open the purge valve slightly to vent the remaining residual air pressure from the system. All alarms shall cease

operation when the system pressure drops to zero except the

electronic end of service time indicator.

e) To terminate the electronic end of service time indicator, press

the Reset button on the Control Console twice after the flashing green light sequence. When air flow stops completely, return purge valve to the fully closed position (pointer on knob

upward).

11. Turn SEMS PDA distress alarm off: With cylinder valve closed

and all residual air purged from respirator (see step 9 above) depress reset button twice (press, release and press again) and then

twice again after the flashing green light sequence. The display

will say “OFF,” the unit will sound a quick two tone chirp and the

SEMS PDA distress alarm will be inactive. The SEMS PDA distress alarm is now in the “OFF” condition.

NOTE

IF THERE IS STILL RESIDUAL PRESSURE IN THE SYSTEM, THE

UNIT WILL REMAIN “ON” IN AUTOMATIC MODE.

W ARNING

IF THE LOW BATTER Y INDICA TION OCCURS A T

ANY TIME DURING REGULAR OPERATIONAL

INSPECTION, DO NOT USE THE RESPIRA TOR.

CHANGE ALL BATTERIES IMMEDIATELY AND

REPEAT THE REGULAR OPERATIONAL TEST

OR TAKE THE RESPIRATOR OUT OF SERVICE

UNTIL THE BATTERIES ARE CHANGED AND

THE REGULAR OPERATIONAL TEST IS SUCCESSFULLY PERFORMED. USE OF A RESPIRATOR WITH DEPLETED BATTERIES MAY

LEAD TO A FAILURE OF THE RESPIRATOR

WHICH COULD RESULT IN SERIOUS INJURY

OR DEATH.

INSPECTION OF SEMS PDA PORT ABLE UNIT

When installed on a SCOTT SCBA, inspection and test of the SCOTT

SEMS PDA Portable Unit is to be conducted along with inspection

and test of the respirator and the SEMS PDA distress alarm before

each use. To do this, the REGULAR OPERATIONAL INSPECTION

procedures in your respirator instructions will require modification. The

instructions below are to be

added to the instructions for REGULAR

20

Page 21

MANUAL

ALARM BUTTON

(RED INDICA TOR)

WITHDRAW

BUTTON (BLUE

INDICATOR)

RED SIGNAL

LIGHT CONSOLE

GREEN SIGNAL

LIGHT

WITHDRAW

M

A

N

U

AL

ALARM

PUSH 2X

TO RESET

FIGURE 5

THE CONTROL CONSOLE

RESET

BUTTON

(YELLOW

INDICATOR)

DISPLAY

OPERA TIONAL INSPECTION of your respirator . If, during the inspection any malfunction of the respirator or the SEMS PDA Portable Unit

is noted, remove the respirator from service and tag for repair by authorized personnel.

1. While performing the visual inspection of the respirator inspect all

SEMS PDA Portable Unit enclosures, lenses, and wire conduits

for cracks, wear or other damage. If damage is noted, remove

respirator from service and tag respirator for repair by qualified

personnel.

2. Check the operation of the SEMS PDA distress alarm in accor-

dance with the REGULAR OPERATIONAL INSPECTION section

of this instruction for the SEMS PDA distress alarm installed on

your SCBA.

3. With an operating Base Station, verify that the SEMS PDA Por-

table Unit initializes and logs-in to the Base Station. When testing

the SEMS PDA alarms, verify that the Portable Unit and Base

Station are communicating with each other properly.

4. Verify that the batteries are properly installed and that there is no

“BATT” indication on the display.

5. Send an “EVAC’ signal to the SEMS PDA Portable Unit and check

the response. Verify that both the ALL-CALL and the Selective

Evacuation signals are properly received by the Portable Unit.

6. When testing the “LOW AIR” alarm operation, verify that the proper

signal is transmitted to the Base Station.

On a regular basis established by your respiratory protection program,

each SEMS Base Station must be inspected and tested for proper

operation. Each of the functions defined in the USE OF THE SEMS

BASE STATION section of this instruction must be checked and verified to be operating properly. If any malfunction is found, remove the

Base Station from service and tag for repair by authorized personnel.

21

WARNING

FOLLOW REGULAR OPERA TIONAL INSPECTION PROCEDURE EXACTLY. IF THE SEMS

PORTABLE UNIT OR BASE STATION DOES

NOT OPERATE AS DESCRIBED OR IF ANY

OTHER OPERATIONAL MALFUNCTION IS

NOTED, DO NOT USE THE RESPIRATOR.

USE OF A MALFUNCTIONING RESPIRATOR

MAY RESULT IN SERIOUS INJURY OR

DEATH.

Page 22

BA TTERY REPLACEMENT

SEMS PDA DISTRESS ALARM PORT ABLE UNIT

Three batteries are required to operate the SEMS PDA Distress Alarm

Portable unit: two in the Sensor Module assembly and one in the Control Console. It is recommended to replace ALL batteries at the

same time. To change batteries, place the respirator in a clean, nonhazardous area. Close respirator cylinder valve, open regulator purge

valve letting out all the trapped air, close regulator purge valve, press

the reset button twice and twice again after the flashing green light

sequence. Display will say “OFF”, unit will sound a two tone chirp and

green light will go out.

NOTE

ALWAYS BE SURE THAT CYLINDER VALVE IS OFF AND SEMS

PDA DISTRESS ALARM IS COMPLETELY INACTIVE BEFORE

CHANGING BATTERY. NEVER REMOVE OR REPLACE BATTERY

WITH SYSTEM PRESSURIZED OR DAMAGE MAY OCCUR TO

ELECTRONIC COMPONENTS.

BACKFRAME BA TTERIES

1. When replacing batteries on respirators equipped with Backframe,

P/N 804415-XX, remove the cylinder and position the respirator

with the Sensor Module facing upward as shown in FIGURE 6.

DEPRESS

REMOVE

CAUTION

SYSTEM MUST NOT BE PRESSURIZED

WHEN BATTERIES ARE INSTALLED.

DAMAGE TO THE ELECTRONIC COMPONENTS MAY RESULT IF BATTERIES ARE INSTALLED WITH SYSTEM PRESSURIZED.

W ARNING

THE SEMS PDA DISTRESS ALARM IS INTENDED TO ASSIST IN LOCATING A PERSON WHO MAY BE IN A LIFE THREATENING SITUATION. FAILURE TO FOLLOW

THE INSTRUCTIONS FOR OPENING,

CHANGING ALL BATTERIES AND RE-CLOSING BOTH B ATTERY COMPARTMENTS MAY

RESULT IN DAMAGE WHICH COULD CAUSE

FAILURE OF THE PASS DURING A LIFE

THREATENING EMERGENCY OR COULD

CAUSE A FIRE OR EXPLOSION IN A FLAMMABLE OR EXPLOSIVE ATMOSPHERE POSSIBLY RESULTING IN SERIOUS INJURY OR

DEATH.

RET AINING SPRING

FIGURE 6

2. Depress the SEMS PDA distress alarm retaining spring and slide

the Sensor Module from Backframe as shown in FIGURE 6.

COVER SCREW (4 PLACES)

FIGURE 7

BA TTERY COVER

3. Turn Sensor Module over to expose the battery cover, shown in

FIGURE 7 and replace batteries as instructed in paragraphs 5

through 9 of this section.

22

Page 23

4. When replacing batteries on respirators equipped with Harness

and Backframe, P/N 804173-XX, position respirator with the cylinder down exposing the battery cover on the back of the Sensor

Module, as shown in FIGURE 8.

COVER SCREW

(4 PLACES)

FIGURE 8

BA TTERY COVER

5. To remove battery cover, first loosen all 4 cover screws 1 or 2

turns each, then fully loosen the screws so the cover can be removed. Carefully remove cover and set aside.

6. Remove used batteries from battery compartment by lifting edge

of batteries at contact end, using a finger or the flat blade of a

screw driver, being careful not to damage battery contacts or sealing rib around battery compartment.

7. Install two (2) fresh new batteries. Always replace both batter-

ies at the same time. Use only pairs of the following: Eveready

Alkaline No. 522 or EN22, Duracell Alkaline No. PC1604 or

MN1604, or for increased service life use Ultralife Lithium Battery

No. U9VL. Be sure batteries are installed with the terminals positioned as indicated by symbols molded in bottom of battery compartment.

8. The battery cover must be installed so that it is water tight after

replacement. Clean the sealing rib around battery compartment

and sealing face of the cover, shown in FIGURE 9, by wiping with

a clean damp cloth to remove any dirt or foreign matter which

might prevent a proper seal. Check cover gasket for tears or

cuts. If damage is found, remove respirator from service and tag

for repair by authorized personnel.

SEALING RIBSEALING AREA

FIGURE 9

BATTERY COMPARTMENT AND COVER SEAL

9. Install battery cover and evenly tighten 4 cover screws by moving

around the cover in a clockwise direction, turning each screw 1 or

2 turns at a time until cover is fully seated. On Backframe, P/N

804415-XX, reinstall the Sensor Module by sliding in backframe

until retaining spring snaps into place as shown in FIGURE 6.

BA TTER Y REPLACEMENT CONTINUED ON NEXT PAGE...

23

CHECK YOUR WORK!

BEFORE ASSEMBLY OF BATTERY COVER,

CHECK TO SEE BATTERY IS A FRESH, NEW

BATTERY OF THE TYPE INDICATED AND THAT

EMS HAS BEEN INSTALLED PROPERLY.

Page 24

CONTROL CONSOLE BATTERY

1. To replace the battery in the Control Console, position the respirator so the Control Console battery cover is accessible as shown in

FIGURE 10.

CONTROL CONSOLE

BATTERY COVER

FIGURE 10

2. To remove battery cover, first loosen all 4 cover screws 1 or 2

turns each, then fully loosen the screws so the cover can be removed. Carefully remove cover and set aside.

3. Remove used battery from battery compartment by lifting bottom

of battery, using a finger or the flat blade of a screw driver, being

careful not to damage battery contacts or sealing rib around battery compartment.

4. Install one (1) fresh new battery. Use only one of the following:

Eveready Alkaline No. 522 or EN22, Duracell Alkaline No. PC1604

or MN1604, or for increased service life use Ultralife Lithium Battery

No. U9VL. Be sure battery is installed with the terminals positioned

as indicated by symbols on label in bottom of battery compartment.

5. The battery cover must be installed so that it is water tight after

replacement. Clean the sealing rib around battery compartment

and sealing face of the cover, shown in FIGURE 1 1, by wiping with

a clean damp cloth to remove any dirt or foreign matter which

might prevent a proper seal. Check cover seal for tears or cuts. If

damage is found, remove respirator from service and tag for repair by authorized personnel.

COVER

SEAL

CLEAN RIB AROUND

BATTERY COMPARTMENT

FIGURE 11

BATTERY COMPARTMENT AND COVER SEAL

6. Install battery cover and evenly tighten 4 cover screws by moving around the cover in a clockwise direction, turning each

screw 1 or 2 turns at a time until cover is fully seated. AFTER

REPLACEMENT OF BATTERIES, PERFORM A REGULAR

OPERATIONAL INSPECTION BEFORE RETURNING RESPIRATOR TO SERVICE.

24

CHECK YOUR WORK!

BEFORE ASSEMBLY OF BATTERY COVER,

CHECK TO SEE BATTERY IS A FRESH, NEW

BATTERY OF THE TYPE INDICATED AND THAT

EMS HAS BEEN INSTALLED PROPERLY.

Page 25

SEMS PDR BASE STA TION

Battery replacement for the SEMS PDR Base Station is as follows:

1. Place the Base Station in a clean, non-hazardous area. Verify

that the unit is not in use and is OFF.

2. Set the Base Station with the control panel face up and the bot-

tom of the unit accessible.

3. Remove the three (3) battery caps from the battery compartments

BA TTERY ORIENT A TION

AS SHOWN

BATTERY

CAPS (3)

FIGURE 12

BA TTERY COMPARTMENTS ON BASE STATION

by unthreading them counterclockwise. See FIGURE 12.

4. Remove the six (6) depleted batteries.

5. Install six (6) fresh new “C” cell batteries, two in each battery

compartment. Use six (6) of the following: Duracell MN1400, or

Eveready Alkaline No. E93 or EN93. Insert batteries with the bottom “–” end first and with the top “+” end toward the battery cap.

Be sure orientation of batteries is as noted.

6. Replace the three (3) battery caps by threading them on clock-

wise until snug.

7. Power up the Base Station and perform the REGULAR OPERA-

TIONAL INSPECTION as defined in this instruction.

MAINTENANCE

Except for programming and battery changing, there are no service

operations or user serviceable parts available to the user.

CHECK YOUR WORK!

BEFORE ASSEMBLY OF BATTERY COVER,

CHECK TO SEE BATTERY IS A FRESH, NEW

BATTERY OF THE TYPE INDICATED AND THAT

EMS HAS BEEN INSTALLED PROPERLY.

25

Page 26

WARNING

READ AND UNDERSTAND THE COMPLETE INSTRUCTION MANUAL BEFORE USING A RESPIRATOR WITH A SEMS PDA DISTRESS ALARM INSTALLED.

QUICK REFERENCE GUIDE TO USE OF THE SEMS PDA DISTRESS ALARM:

WHEN YOU WANT TO: YOU DO: THE SEMS PDA

DISTRESS ALARM

DOES:

Turn it on. Open cylinder valve

(cylinder must have air

in it).

Reset pre-alarm

Reset full alarm

Turn it off (finished

with use)

Turn on the

manual alarm.

Move so that the respirator

moves or press reset

button once.

Press reset button on

control console twice

(push, release, push again).

Close cylinder valve, open

regulator purge valve letting

out all the trapped air, close

regulator purge valve, press

reset button twice after

flashing green light sequence.

Press alarm button on

control console (works

whether the SEMS PDA

distress alarm is on or off).

3 quick audible chirps,

green flashing light on

control console.

Red flashing light changes

to green, ascending/descending tone stops (3

quick audible chirps if

button was pressed).

Loud 3 tone chirp stops,

3 quick chirps, then red

flashing light changes to

green flashing light.

The flashing light goes out

and display will say OFF.

Unit will sound a two tone

chirp at turn off.

Goes into full alarm, loud 3

tone chirps from sensor

module and bright red

flashing light from control

console.

WHEN THE SEMS PDA

DISTRESS ALARM IS:

Quiet. No lights or sound

Flashing the green light

Flashing the red light and sounding an

ascending/descending tone.

Flashing the red light and sounding a

loud continuous 3 tone chirp

Chirping once every 2 seconds with no

light flashing

IT INDICA TES THA T:

The SEMS PDA distress alarm is off or the

batteries are used up or removed.

The SEMS PDA distress alarm is on, in

automatic mode, and monitoring your

motion.

You have not moved in the last 20 seconds, SEMS PDA distress alarm will go

into full alarm in 12 seconds or less if you

do not move.

Full alarm: Y ou have not moved in the last

30 seconds or more or you pushed the

manual alarm button and held at least two

seconds.

The backframe batteries are low. You must

replace all batteries before using the SEMS

PDA distress alarm again (it will work in

low battery condition long enough to let

you finish the cylinder of air you are on).

26

Page 27

PERFORMANCE SPECIFICA TIONS

Sound Levels:

Pre-Alarm....................... 70 to 105 dBA incrementally at left ear

Full-Alarm....................... 95 to 100 dBA @ 9.9 Ft (3m)

Frequency Range .......... 1.5 KHz to 4 KHz

Battery Life (fresh battery)

Alkaline Battery:

Automatic (green flashing light, no sound) .....Approx. 60 hours

Full Alarm (red flashing light, 95 dBA sound).......Approx. 8 hours

Lithium Battery:

Automatic (green flashing light, no sound) ............. > 120 hours

Full alarm (red flashing light, 95 dBA sound) ......... 8-16 hours

Compliance

The Scott SEMS PDA distress alarm is a NIOSH approved accessory for use on only the following Scott AIR-PAK and AIR-PAK

FIFTY respirators:

(NIOSH approval numbers have been included for identification):

Scott 2.2 Air-Pak (30 min.) TC-13F-80

Scott 3.0 Air-Pak (30 min.) TC-13F-366

Scott 4.5 Air-Pak (30 min.) TC-13F-76

Scott 4.5 Air-Pak (45 min.) TC-13F-212

Scott 4.5 Air-Pak (60 min.) TC-13F-96

NOTE

DO NOT USE A FIBERGLASS WRAPPED ONE HOUR CYLINDER ON A MODEL 4.5 AIR PAK EQUIPPED WITH A SEMS PDA

DISTRESS ALARM AS THE WEIGHT WILL EXCEED THE 35 LBS

APPROVAL LIMIT FOR SCBA’s ESTABLISHED BY NIOSH.

Report any operational malfunctions to the certification agency Safety

Equipment Institute (SEI), 1307 Dolley Madison Blvd. Suite 3A,

McLean, VA 22101, (703) 442-5732, FAX (703) 442-5756.

27

Page 28

NOTICE:

THESE USER INSTRUCTIONS

ARE TO BE REMOVED ONLY

BY THE END USER.

Health & Safety Products

Monroe Corporate Center

PO Box 569

Monroe, NC 281 11

T elephone 1-800-247-7257

FAX (704) 291-8330

www.scotthealthsafety.com

89502-01 Rev A 6/03 Printed in USA

28

Loading...

Loading...