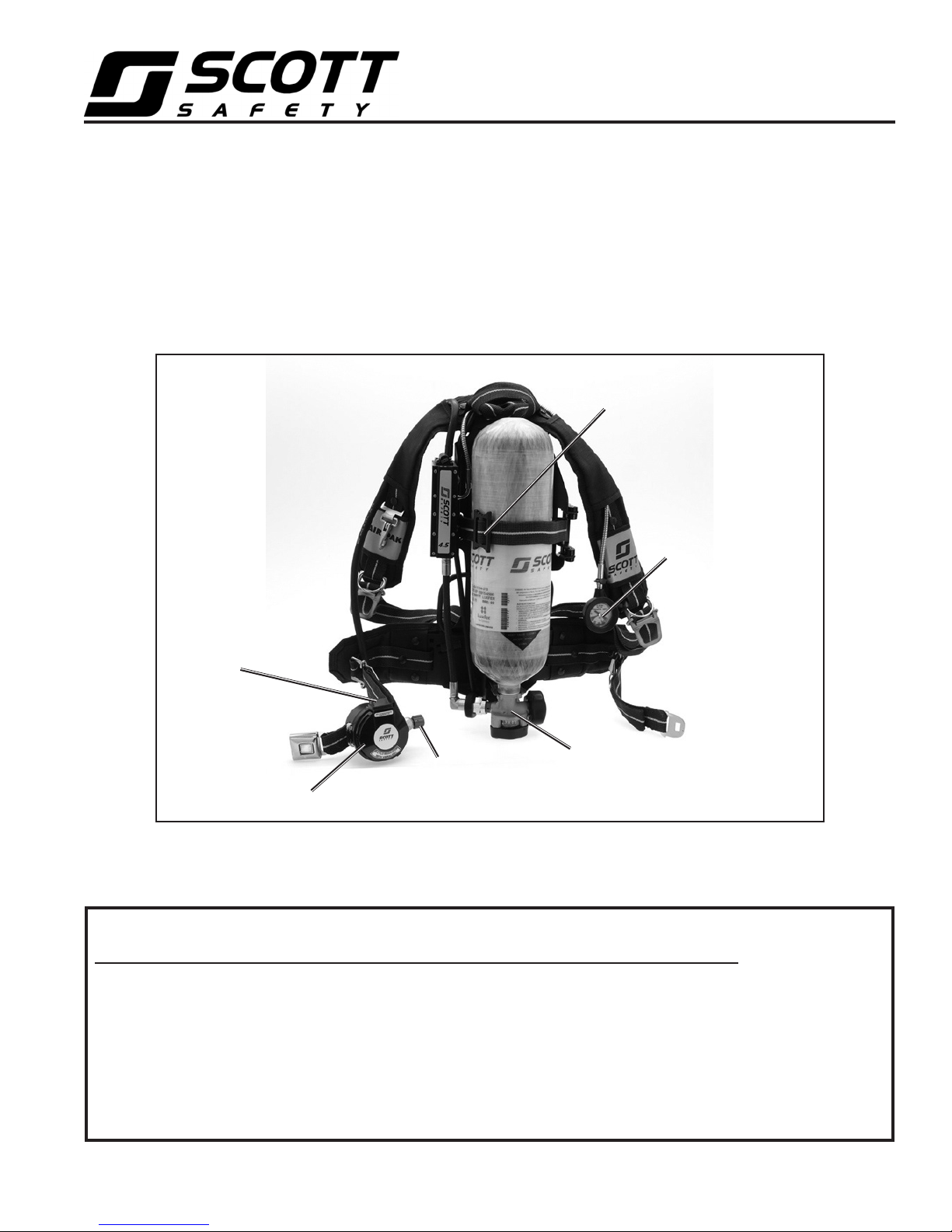

Scott AIR-PAK 75i 2.2,AIR-PAK 75i 4.5 Operating & Maintenance Instructions

OPERATING & MAINTENANCE INSTRUCTIONS

SCOTT AIR-PAK 75i

Industrial Pressure-Demand

Self Contained Breathing Apparatus (SCBA)

AIR SAVER

SWITCH

BREATHING

REGULATOR

Models

PURGE

VALV E

2.2 / 4.5

CYLINDER

VALV E

TRI-SLIDE

BUCKLE

REMOTE

PRESSURE

GAUGE

Typical configuration of SCOTT AIR-PAK 75i SCBA's shown.

Appearance of respirators may vary depending on optional and accessory equipment.

IMPROPER USE OF THIS RESPIRATOR MAY RESULT IN PERSONAL INJURY OR DEATH. IMPROPER USE INCLUDES, BUT IS NOT LIMITED TO, USE WITHOUT ADEQUATE TRAINING, DISREGARD OF THE WARNINGS AND

INSTRUCTIONS CONTAINED HEREIN, AND FAILURE TO INSPECT AND MAINTAIN THIS RESPIRATOR. READ AND

UNDERSTAND ALL INSTRUCTIONS BEFORE ATTEMPTING TO OPERATE OR SERVICE THIS EQUIPMENT.

THIS RESPIRATOR IS INTENDED TO BE USED ONLY IN CONJUNCTION WITH AN ORGANIZED RESPIRATORY

PROTECTION PROGRAM WHICH COMPLIES WITH THE REQUIREMENTS OF "PRACTICES FOR RESPIRATORY

PROTECTION," Z88.2 AVAILABLE FROM AMERICAN NATIONAL STANDARDS INSTITUTE INC., 1430 BROADWAY, NEW YORK, N.Y., 10018, OR THE REQUIREMENTS OF OSHA SAFETY AND HEALTH STANDARD 29 CFR

1910 PARAGRAPH 134 AVAILABLE FROM THE U. S. DEPARTMENT OF LABOR, OCCUPATIONAL SAFETY

AND HEALTH ADMINISTRATION, OR OTHER PERTINENT NATIONALLY RECOGNIZED STANDARDS, SUCH

AS THOSE PROMULGATED BY THE U. S. COAST GUARD OR THE DEPARTMENT OF DEFENSE.

© 2011 Scott Safety. SCOTT, the SCOTT SAFETY Logo, Scott Health and Safety, AIR-PAK, PAK-ALERT, VIBRALERT, AV-2000, AV3000, and SURESEAL are registered and/or unregistered marks of Scott Technologies, Inc. or its affiliates.

TYPICAL AIR-PAK 75i SCBA

WARNING

Page 1 of 44

P/N 595236-01 Rev. B 10/11

SCOTT AIR-PAK 75i

Industrial Pressure-Demand

Self Contained Breathing Apparatus (SCBA)

Models

2.2 / 4.5

DESCRIPTION

The SCOTT AIR-PAK 75i self contained breathing apparatus (SCBA)

is intended to provide respiratory protection to an individual when

entering into, working in, and exiting from an objectionable, oxygen

deficient, and/or unbreathable (toxic) atmosphere.

TRAINING IS REQUIRED BEFORE USE. The SCOTT AIR-PAK 75i

SCBA respirator is to be used only by persons trained in the use of

the respirator and only in conjunction with an organized respiratory

protection program. The SCBA must be used and maintained properly.

This respirator is not to be used under water, for interior structural fire

fighting or for any other purpose not authorized by the organized respiratory protection program that applies specifically to the user.

At a minimum, the SCOTT AIR-PAK 75i SCBA consists of the

following:

– a cylinder and valve assembly to store a supply of breathing air

under pressure,

– a backframe and harness assembly to support the cylinder and valve

assembly and pressure reducer on the body,

– a backframe mounted pressure reducer with a remote pressure

gauge,

– a facepiece mounted pressure demand breathing regulator with an

air saver switch,

– a SCOTT full facepiece and a head harness to secure the facepiece

to the face.

All SCOTT AIR-PAK 75i SCBA’s described in this instruction are

equipped with one end of service time indicator, a remote pressure

gauge mounted on the shoulder strap, and an air saver switch located

on the breathing regulator. All model respirators described by these

instructions are equipped with shoulder straps, waist straps and head

harnesses are made of Kevlar1.

The full facepiece is available in a variety of models and sizes and

must be properly fitted to the user before use. The facepiece design

incorporates a nose cup, two inhalation valves and dual voicemitter

assemblies. The facepiece detaches from the breathing regulator to

allow for use of the best fitting and most comfortable size facepiece

for each user. Fit testing per OSHA Standard 29 CFR Part 1910 or

ANSI Standard Z88.2 requires testing in the negative pressure mode

using equipment such as a Portacount Plus2 Respirator Fit Tester.

For this, SCOTT facepieces require use of SCOTT Fit Test Adapter

P/N 804057-01 or equivalent and appropriate negative pressure testing equipment. Mask Seal Kit P/N 805655-01 may also be required to

attain a proper fit.

1

Kevlar is a registered trademark of E.I. du Pont de Nemours, Inc.

2

Portacount Plus is a registered trademark of TSI Incorporated

DO NOT OPERATE THIS EQUIPMENT WHILE

WARNING

UNDER THE INFLUENCE OF DRUGS, ALCOHOL, OR ANY MEDICATIONS OR SUBSTANCES

WHICH MAY AFFECT VISION, DEXTERITY, OR

JUDGMENT. USERS OF THIS EQUIPMENT

MUST BE IN GOOD PHYSICAL AND MENTAL

HEALTH IN ORDER TO OPERATE SAFELY.

DO NOT USE THIS EQUIPMENT WHEN FATIGUE PREVENTS SAFE OPERATION. STAY

ALERT WHEN OPERATING THIS EQUIPMENT.

INATTENTION OR CARELESSNESS WHILE

OPERATING THIS EQUIPMENT MAY RESULT

IN SERIOUS INJURY OR DEATH.

WARNING

THIS RESPIRATOR, IS INTENDED TO PROTECT THE USER ONLY FROM THE EFFECTS

OF AN OXYGEN DEFICIENT ATMOSPHERE

AND/OR ATMOSPHERES CONTAINING TOXIC

OR HAZARDOUS SUBSTANCES BY PROVIDING A SUPPLY OF RESPIRABLE BREATHING

AIR TO A FACEPIECE SEALED TO THE USER'S FACE.

WHEN PROPERLY USED, THIS RESPIRATOR

PROVIDES PROTECTION FROM AIRBORNE

TOXIC OR HAZARDOUS SUBSTANCES ONLY

TO THE EYES AND RESPIRATORY SYSTEM.

IMPROPER USE OF THIS RESPIRATOR MAY

RESULT IN SERIOUS INJURY OR DEATH.

WARNING

RESPIRATORS SHALL NOT BE WORN

WHEN CONDITIONS PREVENT A GOOD

FACE TO FACEPIECE SEAL OR A GOOD

SEAL AROUND THE NOSE CUP. SUCH

CONDITIONS MAY INCLUDE, BUT ARE NOT

LIMITED TO, GROWTH OF BEARDS, SIDEBURNS, A SKULL CAP THAT PROJECTS UNDER THE FACEPIECE, OR TEMPLE PIECES

ON GLASSES. ALSO, THE ABSENCE OF ONE

OR BOTH DENTURES CAN SERIOUSLY EFFECT THE FIT OF THE FACEPIECE. USE

OF THE RESPIRATOR WITHOUT A GOOD

FACE TO FACEPIECE SEAL OR A GOOD

SEAL AROUND THE NOSE CUP SEAL MAY

REDUCE THE DURATION OF USE AND/OR

EXPOSE THE USER TO THE ATMOSPHERE

THE RESPIRATOR IS INTENDED TO PROTECT AGAINST RESULTING IN SERIOUS

INJURY OR DEATH.

P/N 595236-01 Rev. B 10/11

Page 2 of 44

The removable pressure-demand breathing regulator mounts directly to

the facepiece. The air saver/donning switch on the breathing regulator

prevents the rapid loss of the air supply if the cylinder valve is open

and if the facepiece is removed from the face or the regulator is removed

from the facepiece. The red purge knob on the regulator allows air to

flow into the facepiece in an emergency as well as to release residual

air from the respirator after the cylinder valve is turned off.

All models of the AIR-PAK 75i SCBA respirator are equipped with the

VIBRALERT alarm in the facepiece mounted regulator. The VIBRALERT

alarm serves two functions: as an end of service time indicator, and

to alert the user of a malfunction in the dual path pressure reducer. In

normal operation, the VIBRALERT alarm vibrates the breathing regulator

and facepiece to warn the user by both sound and feel that approximately

25% of full cylinder pressure remains. In addition, the VIBRALERT alarm

will be activated to warn the user if there is a malfunction in the primary

path of the dual path pressure reducer. Air is normally supplied through

the primary air path of the pressure reducer. If the primary air path of

the pressure reducer becomes blocked or should fail closed, the secondary air path will automatically begin supplying air to the breathing

regulator and the VIBRALERT alarm will be actuated to warn the user

of the malfunction.

An optional independent end of service time indicator alarm is the

HEADS-UP DISPLAY attached to the facepiece mounted regulator. The

HEADS-UP DISPLAY is standard on respirators required to have two

independent redundant alarms. The HEADS-UP DISPLAY provides a

visual monitor of the air supply with four lights that appear just below the

facepiece field of vision. A separate low battery light warns the user that

the battery must be changed. The HEADS-UP DISPLAY lights indicate

the cylinder air supply is full to three-quarters with constant green lights,

one-half cylinder with a slowly flashing yellow light, and warns the user

that approximately one quarter or 25% of full cylinder pressure remains

with a rapidly flashing red light. The HEADS-UP DISPLAY detects cylinder pressure directly and is totally independent of the VIBRALERT.

See the HEADS-UP DISPLAY OPERATION section and the BATTERY

REPLACEMENT section of this instruction for complete details.

THE RESPIRATOR USER MUST IMMEDIATELY

WARNING

LEAVE THE AREA REQUIRING RESPIRATORY

PROTECTION WHEN THE END OF SERVICE

INDICATOR ALARM ACTUATES. ACTUATION

OF ANY END OF SERVICE INDICATOR ALARM

WARNS THAT APPROXIMATELY 25% OF

FULL PRESSURE REMAINS IN THE AIR SUPPLY CYLINDER (THAT IS, APPROXIMATELY

3/4 OF THE TOTAL AIR SUPPLY HAS BEEN

USED) OR THAT THERE IS A MALFUNCTION

IN THE RESPIRATOR. A DELAY IN LEAVING

THE AREA AFTER ALARM ACTUATION MAY

RESULT IN INJURY OR DEATH.

EXPORT AND IMPORT

The international transport of this equipment and portions thereof is

regulated under United States export regulations and may be regulated by the import regulations of other countries.

If you have any questions or concerns regarding these regulations,

contact SCOTT at 1-800-247-7257 (or 704-291-8300 outside the

continental United States).

Page 3 of 44

P/N 595236-01 Rev. B 10/11

CHOOSING THE APPROPRIATE EQUIPMENT

Respirators reduce but do not eliminate all exposure to the hazardous

atmosphere. Some facepiece/respirator combinations are more effective than others at reducing exposure depending on the nature and the

concentration of the contaminant in the hazardous atmosphere. When

choosing a respirator and facepiece, the respiratory protection program

under which this respirator is to be used must determine the appropriate

level of protection that the facepiece/respirator is expected to provide.

Use of inappropriate RESPIRATOR equipment for the work environment may result in exposure to the hazardous atmosphere which

may cause serious injury or death.

The respiratory protection program must also take into consideration the

levels of exposure which may be hazardous irrespective of respiratory

protection (e.g.: contaminants which are toxic through exposure to unprotected skin). Additional protective equipment such as apparel may be

required. However, any additional protective equipment must not interfere

with access to or operation of the respirator.

When properly donned and operated, the SCOTT ISCBA respirator provides limited protection from airborne contaminants to only the respiratory

system and part of the face of the user. The using agency must provide

the appropriate protective clothing for use with the ISCBA respirator and

must insure that protective clothing does not interfere with the operation

of the ISCBA respirator.

NIOSH approval is granted to respiratory protection equipment made up

of specific combinations of parts or assemblies that have been successfully tested to the performance standards established by the approval

agencies.

To maintain NIOSH approval, an AV-3000 facepiece equipped with a SureSeal face seal P/N 31001738 (Small), P/N 31001739 (Medium), or P/N

31001740 (Large) must be used only with Grey Nose Cup P/N 31001043

(Small), P/N 31001044 (Medium), or P/N 31001045 (Large).

If you are using an AV-3000 facepiece equipped with a SureSeal face seal

and do not have a Grey Nose Cup, contact SCOTT or your authorized

SCOTT distributor. Failure to comply with this requirement will void the

approvals for your respirator. Use of a non-approved configuration in a

hazardous atmosphere may result in serious injury or death.

WARNING

THE RESPIRATORY PROTECTION PROGRAM

UNDER WHICH THIS EQUIPMENT IS TO BE

USED MUST DETERMINE THE APPROPRIATE

LEVEL OF PROTECTION THAT THE RESPIRATOR IS EXPECTED TO PROVIDE. USE OF

INAPPROPRIATE RESPIRATOR EQUIPMENT

FOR THE WORK ENVIRONMENT MAY RESULT IN EXPOSURE TO THE HAZARDOUS

ATMOSPHERE WHICH MAY CAUSE SERIOUS

INJURY OR DEATH.

WARNING

THIS RESPIRATOR PROVIDES PROTECTION ONLY TO THE USER’S RESPIRATORY

SYSTEM AND TO PART OF THE FACE. IF

THE HAZARDOUS ATMOSPHERE CONTAINS

TOXINS OR CONTAMINANTS WHICH MAY

POISON THROUGH THE SKIN, ADDITIONAL

PROTECTIVE EQUIPMENT MAY BE REQUIRED. FAILURE TO PROVIDE ADEQUATE

PROTECTIVE EQUIPMENT FOR THE HAZARDS IN THE WORKPLACE MAY RESULT

IN SERIOUS INJURY OR DEATH.

WARNING

TO MAINTAIN NIOSH APPROVAL, AN AV-3000

FACEPIECE EQUIPPED WITH A SURESEAL

FACE SEAL P/N 31001738 (SMALL), P/N

31001739 (MEDIUM), OR P/N 31001740

(LARGE) MUST BE USED ONLY WITH

GREY NOSE CUP P/N 31001043 (SMALL),

P/N 31001044 (MEDIUM), OR P/N 31001045

(LARGE). USE OF A NON-APPROVED

CONFIGURATION IN A HAZARDOUS ATMOSPHERE MAY RESULT IN SERIOUS INJURY

OR DEATH.

P/N 595236-01 Rev. B 10/11

Page 4 of 44

SERVICE LIFE

Each configuration of self-contained breathing apparatus (SCBA) certified by NIOSH is assigned a "service life" classification for a duration

time of each size of air supply cylinder (30 minute, 45 minute, etc.).

The service life duration time is determined by NIOSH using a breathing

machine designed to simulate an average adult user performing work at

a "moderate work rate."

Do not expect to obtain the NIOSH rated service life duration time from this

respirator on each use. The work being performed may be more or less

strenuous than that used in the NIOSH test. Where work is more strenuous, the duration may be less than one half the NIOSH rated service life,

and the time remaining after the end of service indicator alarm actuates

may be similarly reduced. The end of service indicator alarm actuates

when approximately 25% of full cylinder pressure remains in the cylinder

and valve assembly. The alarm will continue to operate until the cylinder

is nearly depleted.

The duration time of the respirator will depend on such factors as:

1. the degree of physical activity of the user;

2. the physical condition of the user;

3. the degree to which the user’s breathing is affected by emotional

factors;

4. the degree of training or experience which the user has with this or

similar equipment;

5. whether or not the cylinder is fully charged at the start of the work

period;

6. the possible presence in the compressed air of carbon dioxide concentrations greater than .04% normally found in atmospheric air;

7. the atmospheric pressure; for example, if used in a pressurized tunnel or caisson at 2 atmospheres (15 psi gauge or approximately 30

psi absolute) the duration will be one-half as long as when used at

1 atmosphere; and at 3 atmospheres will be one-third as long;

8. loose or improperly fitting facepiece;

9. the condition of the respirator.

WARNING

THE USER OF THIS RESPIRATOR MUST RECEIVE TRAINING IN THE OPERATION OF

THE RESPIRATOR INCLUDING THE OPERATION OF ALL OPTIONS AND/OR ACCESSORIES INCORPORATED IN THE RESPIRATOR.

SEE WARNING AT THE BEGINNING OF PAGE

TWO OF THIS INSTRUCTION.

WARNING

ONLY THOSE OPTIONS AND/OR ACCESSORIES AUTHORIZED BY SCOTT AND APPROVED BY NIOSH MAY BE INSTALLED

IN THIS RESPIRATOR. THE USE OF UNAUTHORIZED AND/OR UNAPPROVED OPTIONS

OR ACCESSORIES COULD CAUSE PARTIAL

OR COMPLETE FAILURE OF THE RESPIRATOR WHICH MAY RESULT IN INJURY OR

DEATH.

WARNING

RESPIRATORS SHALL NOT BE WORN

WHEN CONDITIONS PREVENT A GOOD

FACE TO FACEPIECE SEAL OR A GOOD

SEAL AROUND THE NOSE CUP. SUCH

CONDITIONS MAY INCLUDE, BUT ARE NOT

LIMITED TO, GROWTH OF BEARDS, SIDEBURNS, A SKULL CAP THAT PROJECTS UNDER THE FACEPIECE, OR TEMPLE PIECES

ON GLASSES. ALSO, THE ABSENCE OF ONE

OR BOTH DENTURES CAN SERIOUSLY EFFECT THE FIT OF THE FACEPIECE. USE

OF THE RESPIRATOR WITHOUT A GOOD

FACE TO FACEPIECE SEAL OR A GOOD

SEAL AROUND THE NOSE CUP SEAL MAY

REDUCE THE DURATION OF USE AND/OR

EXPOSE THE USER TO THE ATMOSPHERE

THE RESPIRATOR IS INTENDED TO PROTECT AGAINST RESULTING IN SERIOUS

INJURY OR DEATH.

Page 5 of 44

P/N 595236-01 Rev. B 10/11

SPECIFIC MODEL DESCRIPTIONS

The SCOTT AIR-PAK 75i SCBA is available as:

• Model2.2 SCBA(2216psigoperatingpressure).

• Model4.5 SCBA(4500psigoperatingpressure).

Each model can be identified by a large yellow label with black printing

on the pressure reducer with the word SCOTT printed vertically and the

model number (2.2 or 4.5) printed at the bottom. In addition, the remote

pressure gauge mounted on the shoulder harness is imprinted with the

operating pressure on the face of the gauge. The AIR-PAK 75i SCBA

models are equipped with an aluminum backframe.

All of the SCOTT respirator models are certified by the National Institute

of Occupational Safety and Health (NIOSH) as pressure-demand selfcontained breathing apparatus. See APPROVAL AND CERTIFICATIONS

section of this instruction for additional information. Also see the complete

NIOSH Approval Label, SCOTT document P/N 89347-01, included with

this instruction.

SCOTT MODEL 2.2 SCBA

• CertifiedbyNIOSH under approval number TC-13F-80 as a

30-minute rated respirator.

• Useonly with cylinder and valve assemblies with a full rated

service pressure of 2216 psig

SCOTT MODEL 4.5 SCBA

• Useonly with cylinder and valve assemblies with a full rated

service pressure of 4500 psig

• CertifiedbyNIOSH(dependingonthecylinderandvalveassembly

installed) as a

– 30-minute rated SCBA under approval number TC-13F-76

– 45-minute rated SCBA under approval number TC-13F-212

– One hour rated SCBA under approval number TC-13-96

The time duration ratings are approval agency classifications and are not

intended to indicate the actual duration a user may achieve. Please see

the SERVICE LIFE section of this instruction for additional information.

APPROVALS AND CERTIFICATIONS

All models of the SCOTT AIR-PAK 75i SCBA described in these instructions

conform to the requirements of Title 42 Part 84 of the Code of Federal

Regulations and are certified by the National Institute of Occupational

Safety and Health (NIOSH). Each respirator configuration is approved

under the appropriate approval number for the air pressure and time

duration. See the complete NIOSH approval label, SCOTT document

P/N 89347-01, included with these instructions. Also see the CAUTIONS

AND LIMITATIONS SECTION and the SPECIFIC LIMITATIONS section of

these instructions for the cautions and limitations which apply to NIOSH

certified respirators of this type.

The SCOTT AIR-PAK 75i respirator is a modular design composed of

replaceable subassemblies and may include certain SCOTT accessories.

Each major subassembly and accessory is labeled with its SCOTT part

number. In order to maintain the NIOSH approved status of the respirator,

use only those subassemblies and/or accessories listed as applicable to

a particular NIOSH approval number.

All models of the SCOTT AIR-PAK 75i SCBA are certified by NIOSH

for use in ambient temperatures down to -25° F (-32° C). See LOW

TEMPERATURE OPERATION section of this instruction. To maintain

NIOSH certification, AIR-PAK 75i SCBA cylinders must be refilled with

compressed air which meets the requirements for Grade D or higher

compressed air as specified in the Compressed Gas Association publication

CGA G-7.1 entitled Commodity Specification for Air, available from the

Compressed Gas Association, Inc., 1725 Jefferson Davis Hwy., Suite

1004, Arlington, VA 22202. In addition to meeting these requirements,

the air must be dry to a dew point of -65° F (-54° C) or less. See SCOTT

Specialist Level Maintenance Modules available upon request from SCOTT

for additional information on refilling SCOTT SCBA cylinders.

THIS RESPIRATOR PROVIDES PROTEC-

WARNING

TION ONLY TO THE USER’S RESPIRATORY

SYSTEM AND TO PART OF THE FACE. IF

THE HAZARDOUS ATMOSPHERE CONTAINS

TOXINS OR CONTAMINANTS WHICH MAY

POISON THROUGH THE SKIN, ADDITIONAL

PROTECTIVE EQUIPMENT MAY BE REQUIRED. FAILURE TO PROVIDE ADEQUATE

PROTECTIVE EQUIPMENT FOR THE HAZARDS IN THE WORKPLACE MAY RESULT

IN SERIOUS INJURY OR DEATH.

P/N 595236-01 Rev. B 10/11

Page 6 of 44

HEADS-UP DISPLAY OPERATION

The optional HEADS-UP DISPLAY provides a visual monitor of the air

supply in the cylinder and valve assembly. The display is fitted to the

facepiece mounted regulator and appears across the bottom of the user's

field of view through the facepiece. The HEADS-UP DISPLAY consists

of four rectangular lights to represent the cylinder pressure at FULL,

THREE-QUARTERS, ONE-HALF, and ONE-QUARTER. A fifth round red

light indicates LOW BATTERY. The HEADS-UP DISPLAY operates as

follows:

1. When respirator use begins, the HEADS-UP DISPLAY will initialize

and illuminate all five lights for twenty (20) seconds. Operation of all

five lights must be verified every time respirator use is begun and

with every REGULAR OPERATIONAL INSPECTION.

LOW BATTERY

WARNING

1/2 YELLOW

LIGHT

(FLASHING

SLOWLY)

1/4 RED

LIGHT

(FLASHING

RAPIDLY)

3/4 GREEN

LIGHT

FULL GREEN

LIGHT

FIGURE 1

HEADS-UP DISPLAY

2. After initialization, the rectangular indicator lights will show the level

of the air supply in the cylinder as follows:

a) FULL cylinder is indicated by the two green lights glowing near

the center of the display.

b) THREE-QUARTERS cylinder is indicated by a single green light

glowing.

c) ONE-HALF cylinder is indicated by the yellow light flashing slowly

at once a second.

d) ONE-QUARTER cylinder end of service time indicator is indicated

by the red light at the far left flashing rapidly at ten times a

second. WHEN THIS WARNING LIGHT IS FLASHING RAPIDLY,

THE USER MUST LEAVE THE HAZARDOUS ATMOSPHERE IMMEDIATELY.

3. When the battery requires changing, the round LOW BATTERY indicator at the right of the display will light for twenty (20) seconds

and then begin to flash slowly at once a second. When the LOW

BATTERY indicator is actuated, the battery still has sufficient life

to operate the HEADS-UP DISPLAY longer than the longest duration cylinder installed on the respirator. However, the battery must

be changed immediately upon termination of use of the respirator,

or before reentry into a hazardous atmosphere. See the BATTERY

REPLACEMENT section of this instruction.

WARNING

THE RESPIRATOR USER MUST IMMEDIATELY LEAVE THE AREA REQUIRING RESPIRATORY PROTECTION WHEN AN END OF

SERVICE INDICATOR ALARM ACTUATES.

ACTUATION OF ANY END OF SERVICE INDICATOR ALARM WARNS THAT APPROXIMATELY 25% OF FULL PRESSURE REMAINS

IN THE AIR SUPPLY CYLINDER (THAT IS,

APPROXIMATELY 3/4 OF THE TOTAL AIR

SUPPLY HAS BEEN USED) OR THAT THERE

IS A MALFUNCTION IN THE RESPIRATOR.

A DELAY IN LEAVING THE AREA AFTER

ALARM ACTUATION MAY RESULT IN SERIOUS INJURY OR DEATH.

HEADS-UP DISPLAY QUICK GUIDE

TWO LIGHTS GLOWING

ONE LIGHT GLOWING

ONE LIGHT FLASHING SLOWLY

ONE LIGHT FLASHING RAPIDLY

WHAT THEY MEANINDICATOR LIGHTS WHAT YOU SHOULD DO

FULL CYLINDER

3/4 CYLINDER

1/2 CYLINDER

1/4 CYLINDER

Page 7 of 44

CONTINUE USING RESPIRATOR

LEAVE HAZARDOUS AREA IMMEDIATELY

P/N 595236-01 Rev. B 10/11

FACEPIECE FITTING AND FIT TESTING

A respirator Quantitative Fit Test must be performed to ensure the correct

respirator facepiece size has been selected and assigned to the user. It is

the responsibility of the Respiratory Protection Program Manager or Safety

Coordinator to assist the user in selecting the correct respirator size relative

to the user’s facial features and dimensions. Fit Testing must be performed

with any approved SCOTT accessories that will be used with the respirator

installed, such as a communications device installed on the facepiece.

Respirator fit tests are explained fully in the American National Standard

Practices for Respiratory Protection, ANSI Z88.10-2001 which is published

by the American National Standards Institute (ANSI), 11 West 42nd Street,

New York, New York, 10036, and in the Occupational Safety and Health

Standards, OSHA 29 CFR 1910.134 Appendix A, which is published by the

Occupational Safety and Health Administration (OSHA), 200 Constitution

Avenue, NW, Washington DC, 20210.

Quantitative Fit Testing per OSHA Standard 29 CFR Part 1910.134 Appendix

A, or ANSI Standard Z88.10-2001 requires testing in the negative pressure

mode using equipment such as a Portacount1 Respirator Fit Tester. For

Quantitative Fit Testing, SCOTT facepieces require use of the appropriate

negative pressure testing equipment such as the Portacount Respirator Fit

Tester along with the following:

• SCOTT40mm facepieceAdapter,P/N200423-01,

• anewSCOTTP100Cartridge, P/N052683,

• SCOTTProbedFit TestAdapterP/N805628-01or equivalent probed

facepieces and the full range of sizes and styles

• MaskSealKit,P/N805655-01

• the appropriate SCOTT communication device and mounting bracket

properly installed on the facepiece, if such an accessory will be used

with the respirator.

• anyotheroptionalhood,eyeglass,orotheraccessorythatwillbeused

with the respirator.

The size and style facepiece must be selected based on the user’s measured face size. For initial fitting, carefully don the facepiece and conduct a

NEGATIVE PRESSURE LEAK TEST according to the instructions provided

with the 40mm Adapter. Refer to the DONNING PROCEDURE section of this

instruction for the procedure. Follow the DONNING PROCEDURE CARE-

FULLY. If the selected facepiece does not pass the NEGATIVE PRESSURE

LEAK TEST or does not fit securely without movement in the chin or chin

cup area or the user experiences discomfort in the chin or throat, try the

next nearest size, larger or smaller. After passing the NEGATIVE PRESSURE

LEAK TEST, the facepiece size selected must be verified by successfully

passing a respirator Quantitative Fit Test.

When fit testing for Open-Circuit, Pressure Demand Self-Contained Breathing Apparatus and/or Type C Pressure-Demand Supplied Air Respirator

mode of operation (minimum Fit Factor equal to or greater than 500

minimum) appropriate negative pressure testing equipment must be used.

You should use a P100 Filter, SCOTT P/N 052683 and the SCOTT P/N

805628-01 Fit Test Adapter.

When using a Portacount Respirator Fit Tester for Quantitative Fit Testing, TSI recommends that the level of particles in the ambient air must be

between 5000 and 30000 particles/cm3. Refer to the Portacount Respirator

Fit Tester user instructions for details including available Particle Generators to use with the Portacount Respirator Fit Tester if you have difficulty

achieving the minimum level of ambient particle count required.

Test subjects must be in good health at the time of the fit testing. Smoking

or eating less than 30 minutes prior to the test is prohibited. Any and all

conditions that might interfere with a good face to facepiece seal must be

addressed and corrected before performing the fit testing. Refer to the list

of conditions in the DONNING PROCEDURES section of this instruction.

THE USER MUST BE PROPERLY FITTED

WARNING

USING A RESPIRATOR QUANTITATIVE FIT

TEST BEFORE USE AND FOLLOW ALL

WARNINGS AND SPECIAL OR CRITICAL

USER’S INSTRUCTIONS SPECIFIED DURING USE. FAILURE TO DO SO MAY RESULT

IN SERIOUS INJURY OR DEATH.

WARNING

FIT TESTING IN ACCORDANCE WITH OSHA

STANDARD 29 CFR PART 1910 IS REQUIRED

AS PART OF THE REQUIRED TRAINING BEFORE USE OF THIS RESPIRATOR. FAILURE

TO PROPERLY FIT AND TRAIN THE USER

IN USE OF THE FACEPIECE AND RESPIRATOR MAY RESULT IN EXPOSURE TO THE

HAZARDOUS ATMOSPHERE WHICH COULD

LEAD TO SERIOUS INJURY OR DEATH.

WARNING

RESPIRATORS SHALL NOT BE WORN WHEN

CONDITIONS PREVENT A GOOD FACE SEAL.

SUCH CONDITIONS MAY INCLUDE, BUT ARE

NOT LIMITED TO, GROWTH OF BEARDS,

SIDEBURNS, FACIAL HAIR OR LOW HAIRLINE THAT CROSSES OR INTERFERES

WITH THE SEALING SURFACE, THICK OR

PROTRUDING HAIRSTYLES SUCH AS PONY

TAILS OR BUNS THAT INTERFERE WITH THE

SMOOTH AND CLOSE FIT OF THE HEAD

HARNESS TO THE HEAD, A SKULL CAP

THAT PROJECTS UNDER THE FACEPIECE,

TEMPLE PIECES ON CORRECTIVE EYE

GLASSES, EXCESSIVE USE OF COSMETICS INCLUDING MOISTURIZERS, MAKE-UP,

OR AFTER SHAVE, OR ANYTHING ELSE

WHICH INTERFERES WITH THE FACE TO

FACEPIECE SEAL. ALSO, THE ABSENCE OF

ONE OR BOTH DENTURES CAN SERIOUSLY

AFFECT THE FIT OF A FACEPIECE. USE OF

AN IMPROPERLY FITTED FACEPIECE MAY

LEAD TO EXPOSURE TO THE HAZARDOUS

ATMOSPHERE WHICH COULD RESULT IN

SERIOUS INJURY OR DEATH.

P/N 595236-01 Rev. B 10/11

Page 8 of 44

To verify the fit factor of the respirator, testing must incorporate an exercise

regimen of normal daily activities. SCOTT requires the following set of fit

test exercises, which are based on OSHA Standard 29 CFR Part 1910.134

Appendix A, and ANSI Z88.10-2001 with modifications.

Exercises are to be performed each for 60 seconds (except as noted) in

a standing position during the test:

• NormalBreathing

• Deepbreathing

• Turningheadsidetoside

• Movingheadupanddown(lookup/lookdown)

• Talking(read theRainbowPassage)

• Grimace(15seconds)

• BendingOver(touchtoes)/Reachup(toward theceiling)

• NormalBreathing(repeat)

Fit test exercises must be performed carefully as if the respirator was being

used in a hazardous atmosphere. DO NOT bump the facepiece, filter, or

adapter into the body through exaggerated motions. DO NOT talk except

when directed to by the test administrator.

SCOTT requires that users of this respirator with an approved SCOTT

facepiece, must achieve a Fit Factor of at least 500 for Type C PressureDemand Supplied Air Respirator mode of operation for use with their assigned facepiece style and size using the fit test procedures and exercise

regimen stated above. If a Fit Factor of at least 500 cannot be achieved

with any facepiece size or style, the user MUST NOT use this respirator.

If the respirator user passes a NEGATIVE PRESSURE LEAK TEST but

DOES NOT pass a respirator Quantitative Fit Test, try the next nearest

size, larger or smaller and repeat the NEGATIVE PRESSURE LEAK TEST

and the Quantitative Fit Test. If leakage is still detected, either per these

user instructions or the OSHA fit testing process, the use of Mask Seal Kit

P/N 805655-01 may be required to attain a proper fit. Refer to the INSTALLATION AND USE INSTRUCTIONS, SCOTT P/N 89462-01, included with

the Mask Seal Kit. After installing the Mask Seal Kit, repeat the fit testing

process to confirm a proper fit.

Once the proper size is selected and assigned to the user following successful Portacount Respirator Fit Tester testing to achieve minimum Fit

Factors required, the respirator user must perform and pass a NEGATIVE

PRESSURE LEAK TEST as described in these instructions every time the

facepiece is donned to ensure proper fit before using the respirator in a

hazardous atmosphere.

During NEGATIVE PRESSURE LEAK TESTING, any facepiece leakage

that is detected from other than the face to facepiece seal may indicate

damaged or defective equipment. Remove the defective equipment from

service and tag for repair by authorized personnel. Repeat the testing with

equipment known to be operating properly.

IF A SATISFACTORY NEGATIVE PRESSURE LEAK TEST CANNOT BE

PERFORMED, DO NOT USE THE RESPIRATOR OR ENTER THE HAZARDOUS ATMOSPHERE.

The facepiece alone does not provide any protection against a hazardous

atmosphere without the use of the complete respirator.

A respirator Quantitative Fit Test must be routinely carried out as outlined

above for each user of this respirator to determine or confirm the amount

of protection that the respirator provides.

Periodically repeating the fit testing is required to identify any physical

changes of the user (such as those listed in the DONNING PROCEDURES)

which could effect the fit of the facepiece.

Page 9 of 44

P/N 595236-01 Rev. B 10/11

REGULAR OPERATIONAL INSPECTION

The following procedure shall be used when you first receive the respirator and for daily or periodic inspection of the respirator. Respirators

in regular use must be inspected at the start of each use period and

during cleaning after each use. Respirators maintained for emergency

use must be inspected as frequently as required to assure the respirator

will function properly when required. The US Labor Department (OSHA),

pursuant to 29 CFR 1910.134, requires at least monthly inspection of

respirators maintained for emergency use. NIOSH recommends an

inspection for cylinder pressure at least weekly. The condition of storage at your location or the regulations which apply to your respiratory

protection program may require more frequent periodic inspections.

If the respirator is equipped with a PASS device distress alarm, the following procedures must be modified to include inspection of the PASS device.

Details of the REGULAR OPERATIONAL INSPECTION of the PASS device

are included in the user instructions for the PASS device. The part number

of the required PASS user instructions appears on the label on the battery

cover of the PASS device Sensor Module.

IF ANY DISCREPANCY OR MALFUNCTION IS NOTED DURING

THE INSPECTION, DO NOT USE THE RESPIRATOR. REMOVE

THE RESPIRATOR FROM SERVICE AND TAG IT FOR REPAIR BY

AUTHORIZED PERSONNEL.

INSPECTION OF THE BREATHING AIR CYLINDER

1. Visually inspect breathing air cylinder and valve assembly for physical

damage such as dents or gouges in metal or in composite wrapping.

Cylinders which show physical damage or exposure to high heat or

flame, such as paint turned brown or black, decals charred or missing, pressure gauge lens melted or elastomeric bumper distorted,

and cylinders which show evidence of exposure to chemicals such

as discoloration, cracks in the cylinder or the composite wrapping,

peeling of the outer layers of the composite wrapping and/or bulging

of the cylinder wall, shall be removed from service and emptied of

compressed air. Publications on compressed gas cylinder inspection

procedures are available from Compressed Gas Association Inc.,

1725 Jefferson Davis Hwy., Suite 1004, Arlington, VA 22202 (703412-0900).

2. Check the latest cylinder hydrostatic test date to ensure it is current.

The date of manufacture marked on the cylinder is also the date of

the first hydrostatic test. All breathing air cylinders used with SCOTT

AIR-PAK 75i SCBA’s must be visually inspected regularly and hy-

drostatically tested at the required intervals by a licensed cylinder

re-tester. Intervals for hydrostatic testing are established in the appropriate US Department of Transportation (DOT) specification or

applicable DOT exemption, or in the appropriate Transport Canada

(TC) Permit of Equivalent Level of Safety. Refer to the current revision

of Safety Precautions for AIR-PAK Cylinders, SCOTT P/N 89080-01,

available on request from SCOTT Safety. Composite fiber overwrapped cylinders must be tested up to their maximum life which, at

the time of the publication of this instruction, is 15 years from the date

of manufacture. It is the responsibility of your organized respiratory

protection program to arrange for visual inspection and hydrostatic

testing of cylinders by a licensed re-tester.

3. Check for damage of the cylinder valve hand wheel and the threads

on the cylinder valve outlet.

4. Check the relief valve (burst disc) for damage or dirt.

5. Check the cylinder pressure gauge for “FULL” indication. If cylinder pressure is less than “FULL,” replace with a fully charged

cylinder.

THE INFORMATION IN THIS INSTRUC-

WARNING

TION IS MEANT TO SUPPLEMENT, NOT

REPLACE, THE INSTRUCTIONS, TRAINING, SUPERVISION, MAINTENANCE, AND

OTHER ELEMENTS OF YOUR ORGANIZED

RESPIRATORY PROTECTION PROGRAM.

SEE WARNING ON SECOND PAGE OF THIS

DOCUMENT. FAILURE TO HEED ANY WARNINGS IN THIS INSTRUCTION MAY RESULT IN

SERIOUS INJURY OR DEATH.

WARNING

FOLLOW THE REGULAR OPERATIONAL

INSPECTION PROCEDURE EXACTLY. IF

THE END OF SERVICE INDICATOR ALARM

DOES NOT ACTUATE AS DESCRIBED IN

THIS INSTRUCTION, THE PURGE DOES NOT

ACTUATE AS DESCRIBED IN THIS INSTRUCTION OR ANY OTHER OPERATIONAL MALFUNCTION IS NOTED, DO NOT USE THE

RESPIRATOR. REMOVE THE RESPIRATOR

FROM SERVICE AND TAG IT FOR REPAIR

BY AUTHORIZED PERSONNEL. FAILURE

TO PROPERLY IDENTIFY MALFUNCTIONS

MAY RESULT IN SERIOUS INJURY OR

DEATH.

WARNING

IF THE RESPIRATOR IS EQUIPPED WITH

A PASS DEVICE DISTRESS ALARM AND

IT FAILS TO FUNCTION IN ACCORDANCE

WITH THE INSTRUCTIONS CONCERNING

REGULAR OPERATIONAL INSPECTION SUPPLIED WITH THE DISTRESS ALARM, DO NOT

USE THE RESPIRATOR. REMOVE IT FROM

SERVICE AND TAG FOR REPAIR BY AUTHORIZED PERSONNEL. FAILURE TO PROPERLY

IDENTIFY MALFUNCTIONS MAY RESULT IN

SERIOUS INJURY OR DEATH.

WARNING

DAMAGED CYLINDERS MAY SUDDENLY

LEAK OR RUPTURE IF LEFT CHARGED WITH

COMPRESSED AIR. FAILURE TO INSPECT

FOR DAMAGE AND TO EMPTY THE AIR

FROM DAMAGED CYLINDERS MAY RESULT

IN SERIOUS INJURY OR DEATH.

P/N 595236-01 Rev. B 10/11

Page 10 of 44

INSPECTION OF THE RESPIRATOR

If any damage is found in this inspection, remove the respirator from

service and tag for repair by authorized personnel.

1. Inspect the complete respirator for worn or damaged compo-

nents.

a) Inspect hoses and rubber parts which exhibit cracking, splitting,

or brittleness.

b) Inspect harness webbing for cuts, tears, abrasion, fraying, or

indication of heat or chemical damage.

c) Check all buckles and fasteners for proper operation.

d) Check the cylinder retention system for damage and for proper

operation.

e) Verify that the respirator has been properly cleaned.

2. Remove the breathing regulator from the facepiece by pulling back

on the regulator retaining latch and rotating the regulator ¼ turn.

Inspect the gasket on the breathing regulator that seals against the

facepiece for rips or damage that may break the seal.

3. Inspect the breathing regulator for damaged or missing components.

a) Verify that the regulator gasket is not damaged and is in place

around the outlet port of the regulator.

b) Verify that the purge valve (red knob) is not damaged and turns

smoothly one-half turn from stop to stop.

FACEPIECE INSPECTION

Examine the facepiece assembly for damaged or worn components. The

facepiece must be complete and in serviceable condition with no worn,

loose, or damaged components. Inspect the facepiece as follows:

1. Inspect the facepiece seal and other rubber components for deforma-

tion, wear, damage, or cracks.

2. Inspect the lens for cracks, gouges, scratches, or any condition that

could impair the operation of the facepiece or the user’s vision.

3. Inspect the lens frame or bezel for damage such as cracks or distor-

tion.

4. Check that all lens frame retainers or bezel screws are present and

installed correctly.

5. Check that all harness anchors are present and operating properly.

6. Inspect the head harness for correct installation with all straps oriented

correctly.

7. Inspect the head harness for damage or worn components.

8. Inspect the voicemitters for dents or damage. Verify that the voicemit-

ters are properly installed and secure in the voicemitter ducts.

RESPIRATORS MUST BE CLEANED AND

WARNING

INSPECTED BEFORE STORAGE FOR

REUSE. RESPIRATORS WITH WORN OR

DAMAGED COMPONENTS SHALL NOT BE

STORED FOR REUSE. REPLACE WORN

OR DAMAGED COMPONENTS DURING INSPECTION OR REMOVE THE RESPIRATOR

FROM SERVICE AND TAG IT FOR REPAIR

BY AUTHORIZED PERSONNEL. USE OF A

RESPIRATOR WITH WORN OR DAMAGED

COMPONENTS MAY RESULT IN SERIOUS

INJURY OR DEATH.

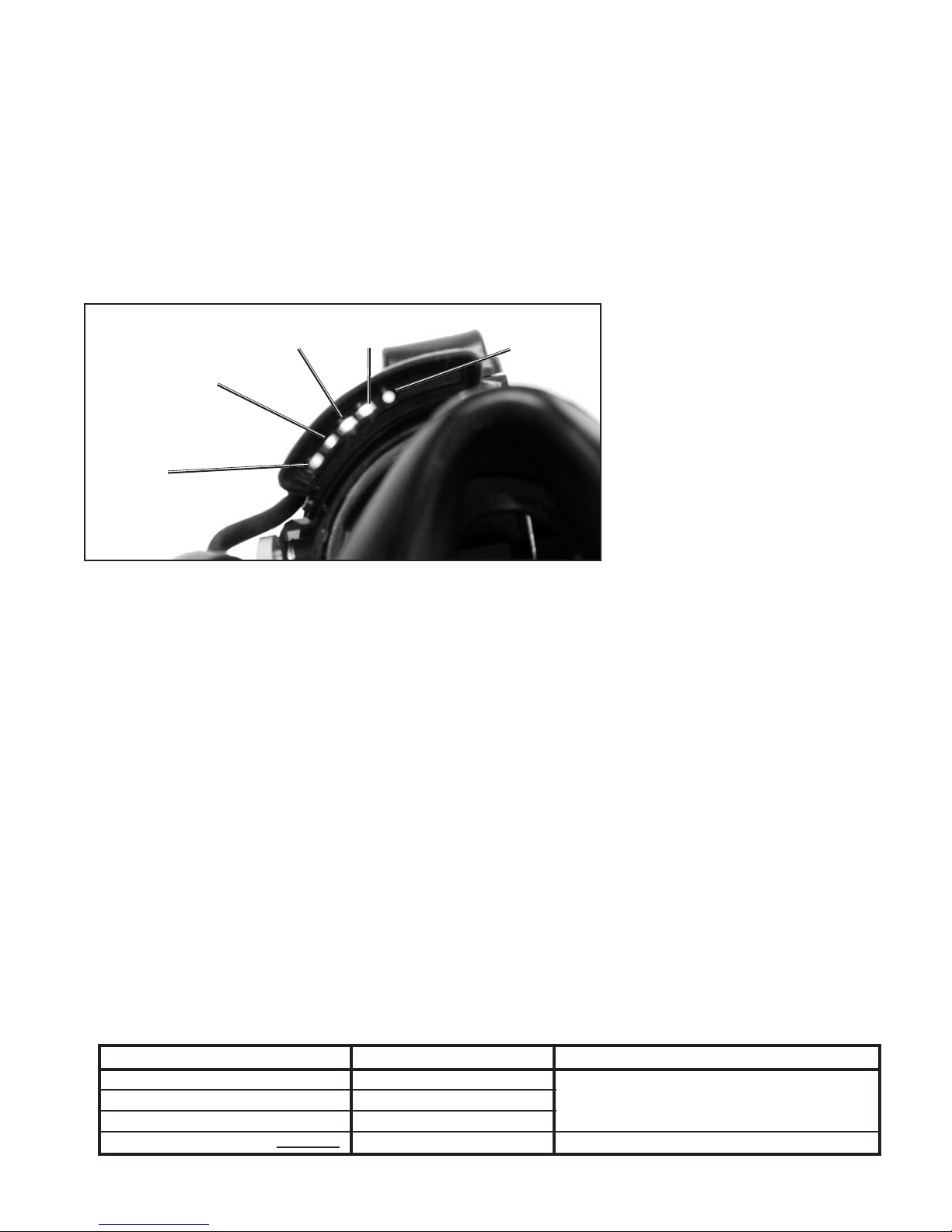

FIGURE 1

Checking Voicemitter Ducts

9. Inspect the nose cup for cuts or damage. Also look for any signs of

damage to the facepiece port side of the nose cup where the regulator attaches.

Check that the nose cup is properly seated between the flanges of

the voicemitter ducts. See FIGURE 1.

Page 11 of 44

REGULAR OPERATIONAL INSPECTION

CONTINUED ON NEXT PAGE...

P/N 595236-01 Rev. B 10/11

REGULAR OPERATIONAL INSPECTION CONTINUED...

10. Verify that the facepiece is clean.

11. Adjust the head straps to the full outward position.

12. All SCOTT facepieces used with this respirator may be fitted with a

nose cup. Verify that the Nose Cup is properly installed for the model

of facepiece being used. A Nose Cup is standard on the SCOTT AV2000 and AV-3000 full facepieces and optional on the SCOTT-O-VISTA

full facepiece.

a) SCOTT AV-3000 Facepieces are available with two different styles

of nose cup: a BLACK Nose Cup which fits behind the face seal,

and a GRAY Nose Cup which fits in front of the face seal. The

BLACK Nose cup must be fitted BEHIND the Face Seal as shown

in FIGURE 2. The GRAY Nose Cup must be fitted IN FRONT OF

the Face Seal as shown in FIGURE 3.

AV-3000 FACEPIECES ONLY

GRAY

IN FRONT

OF FACE

SEAL

BLACK

BEHIND

FACE

SEAL

FIGURE 2

BLACK Nose Cup

BEHIND Face Seal

b) The AV-2000 Nose Cup always goes BEHIND the face seal RE-

GARDLESS of the color of the nose cup. See FIGURE 4.

IN FRONT OF Face Seal

FIGURE 3

GRAY Nose Cup

IF THE NOSE CUP IS REMOVED FOR INSPEC-

CAUTION

TION, MAKE CERTAIN IT IS REASSEMBLED

CORRECTLY FOR THE MODEL FACEPIECE

AND STYLE OF NOSE CUP.

CAUTION

DO NOT USE TOOLS TO OPEN OR CLOSE

THE PURGE VALVE. OPEN OR CLOSE BY

USING FINGER-PRESSURE ONLY. ROTATION

OR THE PURGE VALVE IS LIMITED TO 1/2

TURN. USE OF TOOLS TO OPEN OR CLOSE

PURGE VALVE MAY RESULT IN DAMAGE TO

THE PURGE VALVE.

AV-2000 FACEPIECES ONLY

FIGURE 4

AV-2000 Nose Cup

Always BEHIND the Face Seal

P/N 595236-01 Rev. B 10/11

Page 12 of 44

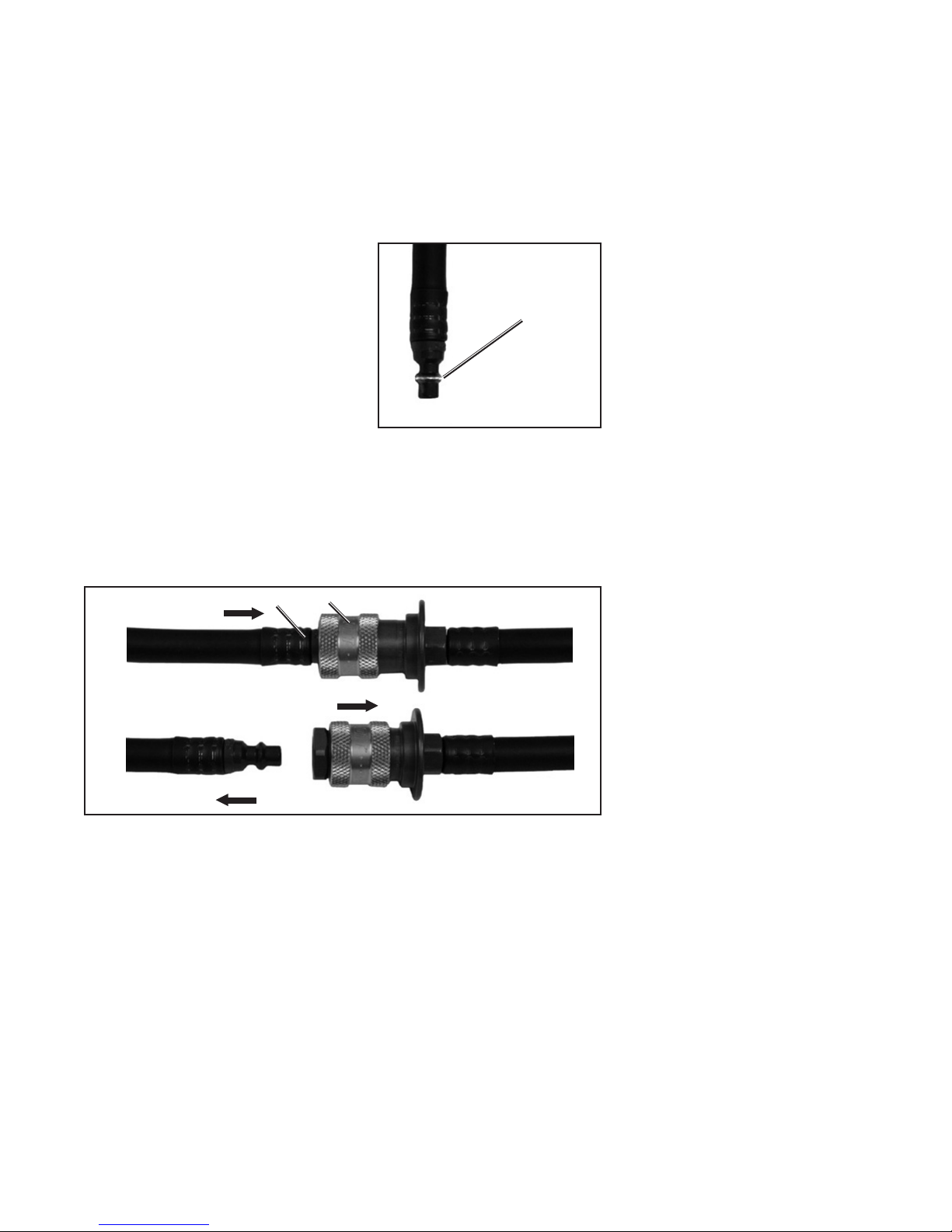

5. If the hose to the breathing regulator is equipped with a quick dis-

connect, inspect both the male and female quick disconnects. Pay

special attention to the following:

a) Inspect the operation of the locking sleeve on the female quick

disconnect. If any damage is noted, remove it from service and

tag for repair.

b) Inspect the condition of the male quick disconnect for signs of

wear. Particularly look for wear on the locking ridge as shown in

FIGURE 5. If the coating is worn through and bare metal is showing, do not use the regulator assembly. Remove it from service

and tag for replacement.

LOOK FOR WEAR

ON LOCKING

RIDGE

FIGURE 5

Inspecting Male

Quick Disconnects

6. Verify that the quick disconnect operates properly. Breathing regu-

lators equipped with a quick disconnect use a Pull-back Sleeve

Coupling. See FIGURE 6. To separate, push the plug “D” into the

socket while pulling the locking sleeve “E” back toward the guard.

The plug “D” will separate. To connect, push the plug "D" into the

socket until it engages with a "click."

7. If the regulator is not attached to the facepiece, proceed as

follows:

PUSH PLUG IN

D

E

WARNING

IF THE COATING IS WORN THROUGH AND

BARE METAL IS SHOWING ON THE MALE

QUICK DISCONNECT LOCKING RIDGE, REMOVE THE REGULATOR ASSEMBLY FROM

SERVICE AND TAG FOR REPLACEMENT.

USE OF A WORN QUICK DISCONNECT MAY

RESULT IN A MALFUNCTION LEADING TO

A LOSS OF BREATHING AIR WHICH COULD

RESULT IN SERIOUS INJURY OR DEATH.

WARNING

FAILURE TO CHECK ENGAGEMENT OF THE

COUPLING AS DESCRIBED MAY LEAD TO

HOSE SEPARATION AND LOSS OF BREATHING AIR RESULTING IN SERIOUS INJURY

OR DEATH.

PULL SLEEVE

BACK

PULL PLUG OUT

FIGURE 6

Pull-back Sleeve Quick Disconnect

a) Align the two flats of the regulator outlet port with the correspond-

ing flats in the facepiece port (the red purge valve on the regulator will be in the 12 o’clock position). Insert the regulator into the

facepiece port.

b) Rotate the regulator counterclockwise (as viewed from inside of

facepiece) until the red purge valve knob is on the left side of the

facepiece. The lock tab on the regulator will lock into the facepiece

retainer with a “click.” When the lock tab is properly engaged, the

regulator will not rotate.

8. If the hose to the breathing regulator is equipped with a quick

disconnect, check that the quick disconnect is engaged properly

by tugging on the coupling.

9. Verify that a FULL cylinder is properly installed in the backframe

and that the reducer hose coupling is hand tightened to the cylinder valve outlet.

If no damage is found, proceed to the OPERATIONAL TESTING.

Page 13 of 44

WRENCHES SHALL NOT BE USED TO TIGHT-

CAUTION

EN THE HOSE COUPLING. OVER TIGHTENING THE HOSE COUPLING MAY DAMAGE

THE GASKET SEAL.

REGULAR OPERATIONAL

INSPECTION CONTINUED

ON NEXT PAGE...

P/N 595236-01 Rev. B 10/11

REGULAR OPERATIONAL INSPECTION CONTINUED...

OPERATIONAL TESTING

1. Check that the breathing regulator purge valve (red knob on regulator) is closed (full clockwise and pointer on knob upward).

2. Fully depress the center of the air saver/donning switch on the top

of the regulator and release.

3. Slowly open the cylinder valve by fully rotating the knob counterclockwise.

a) VIBRALERT alarm shall actuate and then stop.

b) The optional HEADS-UP DISPLAY will initialize with all five lights

on for twenty seconds followed by display of cylinder supply level.

If the LOW BATTERY light at the far right of the display remains lit

or begins to flash, replace the batteries according to the BATTERY

REPLACEMENT section of this instruction before proceeding.

c) If the respirator is equipped with the PASS device distress alarm,

the distress alarm will be actuated when the cylinder valve is

opened. Refer to Operating and Maintenance instructions of the

PASS device distress alarm for the regular operational inspection

of the PASS device distress alarm.

4. Check that the remote pressure gauge is operating properly and that

it reads within 10% of the value on the cylinder pressure gauge.

5. Don the facepiece or hold the facepiece to the face to affect a good

seal. Inhale sharply to automatically start the flow of air. Breathe

normally from the facepiece to ensure proper operation.

6. Removefacepiecefromface.Airshallfreelyowfromthefacepiece.

7. Fully depress the air saver/donning switch on the top of regulator

and release. The flow of air from the facepiece shall stop. Examine

the complete respirator for air leaks. There shall be no leakage of

air from any part of the respirator.

8. Check the purge valve:

a) Rotate purge valve 1/2 turn counterclockwise (pointer on knob

downward). Air shall freely flow from the regulator.

b) Rotate purge valve 1/2 turn clockwise to full closed position (pointer

on knob upward). Air flow from regulator shall stop.

WARNING

IF THE END OF SERVICE INDICATOR ALARM

DOES NOT ACTUATE AS DESCRIBED IN

THIS INSTRUCTION, DO NOT USE THE

RESPIRATOR. REMOVE THE RESPIRATOR

FROM SERVICE AND TAG IT FOR REPAIR

BY AUTHORIZED PERSONNEL. USE OF AN

IMPROPERLY OPERATING END OF SERVICE INDICATOR MAY RESULT IN SERIOUS INJURY OR DEATH.

WARNING

IF THE RESPIRATOR IS EQUIPPED WITH

A PASS DEVICE DISTRESS ALARM AND

IT FAILS TO FUNCTION IN ACCORDANCE

WITH THE INSTRUCTIONS CONCERNING

REGULAR OPERATIONAL INSPECTION SUPPLIED WITH THE DISTRESS ALARM, DO NOT

USE THE RESPIRATOR. REMOVE IT FROM

SERVICE AND TAG FOR REPAIR BY AUTHORIZED PERSONNEL. FAILURE TO PROPERLY

IDENTIFY MALFUNCTIONS MAY RESULT IN

SERIOUS INJURY OR DEATH.

P/N 595236-01 Rev. B 10/11

Page 14 of 44

Loading...

Loading...