Scott 2.2,4.5,5.5 Operating & Maintenance Instructions

OPERATING & MAINTENANCE INSTRUCTIONS

SCOTT AIR-PAK X3 SNAP-CHANGE

Models

2.2 / 4.5 / 5.5

Pressure-Demand Self-Contained Breathing Apparatus (SCBA)

NFPA-1981 (2013 Edition) Compliant

CYLINDER AND

VALVE ASSEmBLY

REGULATOR QUICK

DISCONNECT

REGULATOR

IN REGULATOR

HOLDER

RIC-UAC

CONNECTION

PULL

HANDLE

SNAP-CHANGE

PRESSURE REDUCER

CYLINDER

LATCH

CONTROL CONSOLE

(HUD ONLY VERSION)

REmOTE

PRESSURE

GAUGE

TyPICAl AIR-PAK X3 SNAP-CHANGE WITH SNAP-CHANGE CYLINDER

Typical configuration of SCOTT SCBA shown with various optional and accessory equipment.

Appearance of respirators will vary by model. Not all respirators include all features illustrated.

IMPROPER USE OF THIS RESPIRATOR MAy RESUlT IN PERSONAl INJURy OR DEATH. IMPROPER

USE INClUDES, BUT IS NOT lIMITED TO, USE WITHOUT ADEQUATE TRAINING, DISREGARD OF THE

WARNINGS AND INSTRUCTIONS CONTAINED HEREIN, AND FAIlURE TO INSPECT AND MAINTAIN THIS

RESPIRATOR. READ AND UNDERSTAND All INSTRUCTIONS BEFORE ATTEMPTING TO OPERATE OR

SERVICE THIS EQUIPMENT.

THIS RESPIRA T OR IS INTENDED T O BE USED ONly IN CONJUNCTION WITH AN ORGANIZED RESPIRATORy

PROTECTION PROGRAM WHICH COMPlIES WITH THE REQUIREMENTS OF "PRACTICES FOR RESPIRA T ORy

PROTECTION," Z88.2 AVAIlABlE FROM AMERICAN NATIONAl STANDARDS INSTITUTE INC., 1430

BROADWAy, NEW yORK, N.y., 10018, OR THE REQUIREMENTS OF OSHA SAFETy AND HEAlTH STANDARD

29 CFR 1910 PARAGRAPH 134 AVAIlABlE FROM THE U. S. DEPARTMENT OF lABOR, OCCUPATIONAl

SAFETy AND HEAlTH ADMINISTRATION, OR OTHER PERTINENT NATIONAlly RECOGNIZED STANDARDS,

SUCH AS THOSE PROMUlGATED By THE U. S. COAST GUARD OR THE DEPARTMENT OF DEFENSE.

SCOTT, the SCOTT SAFETY Logo, Scott Health and Safety, AIR-PAK, X3, VIBRALERT, AV-3000, SNAP-CHANGE, and HT are registered

and/or unregistered marks of Scott Technologies, Inc. or its affiliates.

WARNING

© 2014 Scott Safety.

Page 1 of 48 P/N 595279-01 Rev. B 5/14

SCOTT AIR-PAK X3

Models 2.2 / 4.5 / 5.5 Pressure-Demand

Self-Contained Breathing Apparatus (SCBA)

NFPA-1981 (2013 Edition) Compliant

GENERAl DESCRIPTION

The SCOTT AIR- PAK X3 SNAP-CHANGE self-contained brea thing apparatus (SCBA) is a respirator intended to provide respiratory protection to

an individual when entering into, working in and exiting an objectionable,

an oxygen deficient, and/or an unbreathable (toxic) atmosphere. This

equipment is designed to withstand exposure to certain environmental

conditions as defined by the applicable approvals.

TRAINING IS REQUIRED BEFORE USE. The SCOTT AIR-PAK X3 SNAPCHANGE SCBA is to be used only by persons trained in the use of the

respirator and only in conjunction with an organized respiratory protection

program. The SCBA must be used and maintained properly and is not to

be used for purposes other than authorized by your respiratory protection

program. This respirator must not be used underwater.

MAJOR COMPONENTS OF THE RESPIRATOR

The basic SCOTT AIR-PAK X3 SNAP-CHANGE SCBA consists of a backframe

and harness assembly, a cylinder and valve assembly to store a supply

of breathing air under pressure, a dual path pressure reducer mounted on

the backframe, a facepiece mounted pressure demand breathing regulator,

and a SCOTT full facepiece with a head harness to secure the facepiece to

the face. All SCOTT AIR-PAK X3 SNAP-CHANGE SCBA’s described in this

instruction are equipped with at least two independent end of service time

indicators, a remote pressure gauge mounted on the shoulder strap, and

an air saver switch located on the breathing regulator. All model respirators

described by these instructions feature an aluminum backframe equipped

with shoulder straps and waist straps made of Kevlar1.

The cylinder mounts on the X3 SNAP-CHANGE with a special SnapChange direct coupling, available as 2.2 (2216 psig). 4.5 (4500) or 5.5

(5500 psig) model. All features apply to all models.

The full facepiece is available in specific models and sizes. The facepiece

must be properly fitted to the user before use. The facepiece may be readily

detached from the breathing regulator to allow for use of the best fitting

and most comfortable size facepiece for each user. Fit testing per OSHA

Standard 29 CFR Part 1910.134 Appendix A or ANSI Standard Z88.10

requires testing in the negative pressure mode using equipment such as a

Portacount

of SCOTT Fit Test Adapter P/N 804057-01 or equivalent and appropriate

negative pressure testing equipment. mask Seal Kit P/N 805655-01 may

also be required to attain a proper fit. Refer to the FACEPIECE FITTING

AND FIT TESTING section of this instruction.

2

Respirator Fit Tester. For this, SCOTT facepieces require use

THIS RESPIRATOR, IS INTENDED TO

WARNING

PROTECT THE USER ONly FROM THE

EFFECTS OF AN OXyGEN DEFICIENT

ATMOSPHERE AND/OR ATMOSPHERES

CONTAINING TOXIC OR HAZARDOUS

SUBSTANCES By PROVIDING A SUPPly

OF RESPIRABlE BREATHING AIR TO A

FACEPIECE SEAlED TO THE USER'S FACE.

SOME TOXIC OR HAZARDOUS

ATMOSPHERES CONTAIN SUBSTANCES

WHICH CAN POISON By ABSORPTION

THROUGH EXPOSED SKIN. FAIlURE TO

TAKE All NECESSARy PRECAUTIONS

WHEN ENTERING A HAZARDOUS

ATMOSPHERE MAy RESUlT IN SERIOUS

INJURy OR DEATH.

WARNING

THE INFORMATION IN THIS INSTRUCTION

IS MEANT TO SUPPlEMENT, NOT

REPlACE, THE INSTRUCTIONS, TRAINING,

SUPERVISION, MAINTENANCE, AND

OTHER ElEMENTS OF yOUR ORGANIZED

RESPIRATORy PROTECTION PROGRAM.

SEE WARNING ON SECOND PAGE OF

THIS DOCUMENT. FAIlURE TO HEED ANy

WARNINGS IN THIS INSTRUCTION MAy

RESUlT IN SERIOUS INJURy OR DEATH.

WARNING

THIS EQUIPMENT IS DESIGNED TO

WITHSTAND EXPOSURE TO CERTAIN

ENVIRONMENTAl CONDITIONS AS DEFINED

By THE APPlICABlE APPROVAlS.

REGUlARly INSPECT THIS EQUIPMENT

FOR DAMAGE AND REMOVE DAMAGED

EQUIPMENT FROM SERVICE. FAIlURE TO

DO SO MAy RESUlT IN SERIOUS INJURy

OR DEATH.

1

Kevlar is a registered trademark of E.I. du Pont de Nemours and Company,

Wilmington, DE.

Page 2 of 48P/N 595279-01 Rev. B 5/14

The AV-3000 HT Facepiece is made of heat resistant materials. When using

the AV-3000 HT Facepiece in applications where high heat may occur,

follow all training and operating procedures relating to heat exposure. To

avoid possible injury, the respirator user must understand the hazards

of heat exposure including temperature, duration and repeat exposure.

The removable pressure-demand breathing regulator mounts directly to

the facepiece and is equipped with an Air Saver/Donning Switch and a

red Purge Knob.

All models of the AIR-PAK X3 SNAP-CHANGE SCBA respirator are equipped

with the VIBRALERT alarm in the facepiece mounted regulator. The

VIBRALERT alarm serves two functions: as an end of service time indicator

and to alert the user of a malfunction in the dual path pressure reducer. In

normal operation, the VIBRALERT alarm vibrates the breathing regulator

and facepiece to warn the user by both sound and feel that approximately

33% of full cylinder pressure remains. In addition, if the primary air path of

the pressure reducer becomes blocked or should fail closed, the secondary

air path will automatically begin supplying air to the breathing regulator and

the VIBRALERT alarm will be actuated to warn the user of the malfunction.

The HEADS-UP DISPLAY is an independent end of service time indicator

alarm attached to the facepiece mounted regulator and is standard on

respirators required to have two independent redundant alarms. The

HEADS-UP DISPLAY provides a visual monitor of the air supply with

four lights that appear just below the facepiece field of vision. A separate

low battery light warns the user that the batteries must be replaced. The

HEADS-UP DISPLAY detects cylinder pressure directly and is totally

independent of the VIBRALERT.

Whenever any end of service indicator alarm or alarms actuate, the user

must leave the area requiring respiratory protection immediately.

This respirator is tted with a Rapid Intervention Crew/Company Universal Air

Connection (RIC UAC) System which permits emergency replenishment of an

approved SCBA breathing air supply cylinder from an approved air supply source

while in use. This is not a Quick Charge attachment and must not be used for routine

recharging of the cylinder, for “buddy breathing”, for transferring air from another

SCBA cylinder, or any unapproved use. The RIC UAC is for emergency use only

when the respirator user is incapacitated within the hazardous atmosphere.

Batteries are required for the proper operation of this equipment. Refer

to the BATTERY REPLACEmENT section of this instruction for details of

installation.

QUESTIONS OR CONCERNS

If you have any questions or concerns regarding use of this equipment,

contact your authorized SCOTT distributor, or contact SCOTT at 1-800247-7257 (or 704-291-8300 outside the continental United States).

For all NFPA compliant versions of this respirator, report any operational

malfunctions to the certication agency Safety Equipment Institute (SEI),

1307 Dolley madison Blvd.. Suite 3A, mcLean, VA 22101, (703) 442-5732,

Fax (703) 442-5756.

For all NIOSH compliant versions of this respirator, report any complaints of

damage, malfunction or failure of the breathing apparatus that may represent

a hazard to the user to the certication agency NIOSH/NPPTL /Respirator

Branch, P.O. box 18070, Pittsburgh, PA 15236, (412) 386-4000.

THE AV-3000 HT FACEPIECE IS MADE OF

WARNING

HEAT RESISTANT MATERIAlS. WHEN USING

THE AV-3000 HT FACEPIECE, FOllOW All

TRAINING AND OPERATING PROCEDURES

RElATING TO HEAT EXPOSURE. THE

RESPIRATOR USER MUST UNDERSTAND

THE HAZARDS OF HEAT EXPOSURE

INClUDING TEMPERATURE, DURATION,

AND REPEAT EXPOSURE. FAIlURE TO DO

SO MAy RESUlT IN SERIOUS INJURy OR

DEATH.

WARNING

USE OR MISUSE OF THIS RESPIRATOR IN

SUCH A MANNER AS TO EXPOSE THE USER

TO THE ATMOSPHERE THE RESPIRATOR

IS INTENDED TO PROTECT AGAINST MAy

RESUlT IN SERIOUS INJURy OR DEATH.

WARNING

BATTERIES ARE REQUIRED FOR PROPER

OPERATION OF THIS EQUIPMENT. FAIlURE

TO INSTAll BATTERIES AND TO PERFORM

A REGUlAR OPERATIONAl INSPECTION

MAy RESUlT IN A MAlFUNCTION OF THE

EQUIPMENT WHICH COUlD RESUlT IN SERIOUS INJURy OR DEATH.

EXPORT AND IMPORT

The international transport of this equipment and portions thereof is

regulated under United States export regulations and may be regulated

by the import regulations of other countries.

If you have any questions or concerns regarding these regulations, contact SCOTT at 1-800-247-7257 (or 704-291-8300 outside the continental

United States).

2

Portacount Plus is a registered trademark of TSI Incorporated

Page 3 of 48 P/N 595279-01 Rev. B 5/14

SPECIFIC MODEl DESCRIPTIONS

The SCOTT AIR-PAK X3 SNAP-CHANGE SCBA is available as:

• Model 2.2 SCBA (2216 psig operating pressure),

• Model 4.5 SCBA (4500 psig operating pressure),

• Model 5.5 SCBA (5500 psig operating pressure).

Each model can be identified by a large label with black printing on the

pressure reducer with the word SCOTT printed vertically and the model

number (2.2, 4.5, or 5.5) printed at the bottom. In addition, the remote

pressure gauge mounted on the shoulder harness is imprinted with the

operating pressure on the face of the gauge.

The basic AIR-PAK X3 SNAP-CHANGE SCBA models are equipped with

an aluminum backframe.

All of the SCOTT respirator models are certified by the National Institute

of Occupational Safety and Health (NIOSH) as pressure-demand selfcontained breathing apparatus. See APPROVAL AND CERTIFICATIONS

section of this instruction for additional information. Also see the NIOSH

Approval Label, SCOTT document P/N 595281-01, included with this

instruction.

SCOTT MODEl 2.2 SCBA

• Use only with cylinder and valve assemblies with a full rated

service pressure of 2216 psig

• Certified by NIOSH as a 30-minute rated respirator.

SCOTT MODEl 4.5 SCBA

• Use only with cylinder and valve assemblies with a full rated

service pressure of 4500 psig

• Certified by NIOSH (depending on the cylinder and valve assembly

installed) as a

– 30-minute rated SCBA

– 45-minute rated SCBA

– 60-minute rated SCBA

SCOTT MODEl 5.5 SCBA

• Use only with cylinder and valve assemblies with a full rated

service pressure of 5500 psig

• Certified by NIOSH (depending on the cylinder and valve assembly

installed) as a

– 30-minute rated SCBA

– 45-minute rated SCBA

– 60-minute rated SCBA

– 75-minute rated SCBA

The time duration ratings are approval agency classifications and are not

intended to indicate the actual duration a user may achieve. Please see

the SERVICE LIFE section of this instruction for additional information.

NIOSH approval and NFPA compliance are granted to respiratory protection equipment made up of specific combinations of parts or assemblies

that have been successfully tested to the performance standards established by the approval agencies.

To maintain NIOSH approval and NFPA compliance, an AV-3000 HT

Facepiece P/N 805337-34 (Small), P/N 805337-35 (medium), or P/N

805337-36 (Large) must be used only with DARK Grey Nose Cup with

INHALATION VALVES P/N 201126 (Small), P/N 201127 (medium), or P/N

201128 (Large).

If you are using an AV-3000 HT facepiece and do not have the correct

Nose Cup, contact SCOTT or your authorized SCOTT distributor. Failure

to comply with this requirement will void the approvals for your respirator.

Use of a non-compliant configuration in a hazardous atmosphere may

result in serious injury or death.

TO MAINTAIN NIOSH APPROVAl AND

WARNING

NFPA COMPlIANCE, AN AV-3000 HT

FACEPIECE P/N 805337-34 (SMAll), P/N

805337-35 (MEDIUM), OR P/N 80533736 (lARGE) MUST BE USED ONly WITH

DARK GREy NOSE CUP WITH INHAlATION

VAlVES P/N 201126 (SMAll), P/N 201127

(MEDIUM), OR P/N 201128 (lARGE). USE

OF A NON-COMPlIANT CONFIGURATION IN

A HAZARDOUS ATMOSPHERE MAy RESUlT

IN SERIOUS INJURy OR DEATH.

Page 4 of 48P/N 595279-01 Rev. B 5/14

APPROVAlS AND CERTIFICATIONS

All models of the SCOTT AIR-PAK X3 SNAP-CHANGE SCBA described

in these instructions conform to the requirements of Title 42 Part 84 of the

Code of Federal Regulations and are certified by the National Institute of

Occupational Safety and Health (NIOSH). Each respirator configuration is

approved under the appropriate approval number for the air pressure and

time duration. See the NIOSH/CBRN approval label, SCOTT document P/N

595281-01, included with these instructions. Also see the CAUTIONS AND

LImITATIONS SECTION and the SPECIFIC LImITATIONS section of these

instructions for the cautions and limitations which apply to NIOSH certified

respirators of this type.

The SCOTT AIR-PAK respirator is a modular design composed of replaceable

subassemblies and may include certain SCOTT accessories. Each major

subassembly and accessory is labeled with its SCOTT part number. In

order to maintain the NIOSH approved status of the respirator, use only

those subassemblies and/or accessories listed as applicable to a particular

NIOSH approval number.

All models of the SCOTT AIR-PAK X3 SNAP-CHANGE SCBA are certified

by NIOSH for use in ambient temperatures down to -25° F (-32° C). See

LOW TEmPERATURE OPERATION section of this instruction. To maintain

NIOSH certification, AIR-PAK X3 SNAP-CHANGE SCBA cylinders must be

refilled with compressed air which meets the requirements for Grade D or

higher compressed air as specified in the Compressed Gas Association

publication CGA G-7.1 entitled Commodity Specification for Air, available

from the Compressed Gas Association, Inc., 1725 Jefferson Davis Hwy.,

Suite 1004, Arlington, VA 22202. In addition to meeting these requirements,

the air must be dry to a dew point of -65° F (-54° C) or less. For fire

service use, the preferred air quality shall be as specified in NFPA 1989.

See SCOTT Specialist Level maintenance modules available upon request

from SCOTT for additional information on refilling SCOTT SCBA cylinders.

This SCOTT AIR-PAK X3 SNAP-CHANGE SCBA also meets the requirements

of the National Fire Protection Association (NFPA) 1981 (2013 edition)

Standard on Open-Circuit Self-Contained Breathing Apparatus for the Fire

Service when configured in accordance with the NFPA a pproval. To maintain

NFPA compliance, the SCOTT AIR-PAK X3 SNAP-CHANGE SCBA must be

used only in accordance with NFPA standard 1500, entitled Standard on

Fire Department Occupational Safety and Health Program.

This also includes Chemical, Biological, Radiological, and Nuclear (CBRN)

Approval Status under the NIOSH standard. Before using a respirator for a

CBRN application, the user must verify that the respirator is comprised of

only CBRN approved components. An approved mask mounted breathing

regulator can be identified by its orange background label. An approved

backframe assembly can be identified by a NIOSH/CBRN label. Other

components must be identified by individual part number.

The SCOTT AIR-PAK X3 SNAP-CHANGE SCBA protects ONLY the face

and the respiratory tract from airborne contaminants. When used in a

potentially CBRN environment, the organization's respiratory protection

program must provide the appropriate protective clothing and head wear

for use with this respirator and must insure that protective clothing and

head wear does not interfere with use of the respirator.

It is the responsibility of the respirator user’s respiratory protection program

to properly identify and maintain respirator equipment for CBRN applications.

• The attachment of components, accessories, or devices to the

SCOTT AIR-PAK X3 SNAP-CHANGE SCBA which are not listed

on the NIOSH/CBRN approval label may void the NIOSH/CBRN

approval and may degrade the performance of the respirator.

• The attachment of components, accessories or devices not listed on

the NIOSH/CBRN approval label, may void the NFPA certification

and may degrade respirator performance with respect to the NFPA

certification requirements.

FAIlURE TO VERIFy THAT THE RESPI-

WARNING

RATOR HAS All REQUIRED EQUIPMENT

INSTAllED AND OPERATING MAy VOID

THE NFPA APPROVAl AND MAy DEGRADE

THE PERFORMANCE OF THE RESPIRATOR

WHICH COUlD lEAD TO SERIOUS INJURy

OR DEATH.

WARNING

ONly THOSE RESPIRATOR COMPONENTS

APPROVED UNDER THE NIOSH CBRN

STANDARD MAy BE USED FOR A CBRN

APPlICATION. THE USE OF UNAUTHORIZED

AND/OR UNAPPROVED COMPONENTS OR

ACCESSORIES FOR A CBRN APPlICATION

COUlD CAUSE PARTIAl OR COMPlETE

FAIlURE OF THE RESPIRATOR WHICH MAy

RESUlT IN SERIOUS INJURy OR DEATH.

Page 5 of 48 P/N 595279-01 Rev. B 5/14

SERVICE lIFE

Each configuration of self-contained breathing apparatus (SCBA) certified by NIOSH is assigned a "service life" classification for a duration

time of each size of air supply cylinder (30 minute, 45 minute, etc.).

The service life duration time is determined by NIOSH using a breathing

machine designed to simulate an average adult user performing work at

a "moderate work rate."

Do not expect to obtain the NIOSH rated service life duration time from this

respirator on each use. The work being performed may be more or less

strenuous than that used in the NIOSH test. Where work is more strenuous,

the duration may be less than one half the NIOSH rated service life and the

time remaining after either end of service indicator alarm actuates may

be similarly reduced. The end of service indicator alarms actuate when

approximately 33% of full cylinder pressure remains in the cylinder and

valve assembly. Although all end of service indicator alarms are set to

actuate at the set point of approximately 33% of full rated service pressure, they are completely independent of each other and therefore may

not actuate at precisely the same moment. The alarms will continue to

operate until the cylinder is nearly depleted.

The duration time of the respirator will depend on such factors as:

1. the degree of physical activity of the user;

2. the physical condition of the user;

3. the degree to which the user’s breathing is affected by emotional

factors;

4. the degree of training or experience which the user has with this or

similar equipment;

5. whether or not the cylinder is fully charged at the start of the work

period;

6. the possible presence in the compressed air of carbon dioxide concentrations greater than .04% normally found in atmospheric air;

7. the atmospheric pressure; for example, if used in a pressurized tunnel or caisson at 2 atmospheres (15 psi gauge or approximately 30

psi absolute) the duration will be one-half as long as when used at

1 atmosphere; and at 3 atmospheres will be one-third as long;

8. loose or improperly fitting facepiece;

9. the condition of the respirator.

INTRINSIC SAFETy

The SCOTT AIR-PAK X3 SNAP-CHANGE SCBA respirator equipped

with a Heads-Up Display P/N 200280-SERIES and/or a PASS distress

alarm P/N 201160-SERIES is listed by SGS U.S. TESTING COmPANY

INC. as intrinsically safe per ANSI/UL Std. UL-913 for use in Class I,

II, Division 1, Groups C, D, E, F, and G Ha zardous Loc ations.

To maintain the Intrinsic Safety Listing, the respirator must be inspected

regularly per the following Regular Operational Inspection procedures.

Do not tamper with or substitute components in any manner. Use only

batteries of the type indicated in the Battery Replacement instructions.

Open the battery compartments only in an area known to be free of

flammable or explosive hazards.

SUBSTITUTION OF COMPONENTS MAy

WARNING

IMPAIR INTRINSIC SAFETy. TO REDUCE

THE RISK OF IGNITION OF A FlAMMABlE

ATMOSPHERE, BATTERIES MUST ONly

BE CHANGED IN AN AREA KNOWN TO

BE NONFlAMMABlE. TO REDUCE THE

RISK OF EXPlOSION, DO NOT MIX OlD

BATTERIES WITH UNUSED BATTERIES,

OR MIX BATTERIES FROM DIFFERENT

MANUFACTURERS.

WARNING

lOOSE OR WORN ElECTRICAl

CONDUCTORS OR INSTAllATION OF

INCORRECT BATTERIES MAy CAUSE A

HAZARDOUS SITUATION IN A FlAMMABlE

OR EXPlOSIVE AREA. FAIlURE TO

REGUlARly INSPECT THE RESPIRATOR,

INClUDING All ElECTRONIC COMPONENTS,

AS DESCRIBED IN THIS INSTRUCTION OR

FAIlURE TO CORRECT DAMAGE TO THE

ElECTRONIC COMPONENTS, MAy IMPAIR

THE INTRINSIC SAFETy OF THE UNIT. THE

INSTAllATION OF INCORRECT BATTERIES

OR SUBSTITUTION OF ANy OTHER

COMPONENTS MAy IMPAIR THE INTRINSIC

SAFETy OF THE UNIT. IF THE RESPIRATOR

IS USED IN AN EXPlOSIVE OR FlAMMABlE

ATMOSPHERE, IMPAIRING THE INTRINSIC

SAFETy OF THE UNIT MAy lEAD TO A FIRE

OR AN EXPlOSION WHICH COUlD RESUlT

IN SERIOUS INJURy OR DEATH.

Page 6 of 48P/N 595279-01 Rev. B 5/14

OPTIONS AND ACCESSORIES

The SCOTT AIR-PAK X3 SNAP-CHANGE SCBA may be equipped with one

or more accessories or options. The user of the respirator must determine

which accessories or optional components are installed on the respirator.

Become thoroughly familiar with the operation and maintenance of the

accessories and options as explained in this instruction and in all other

instructions provided with this respirator or the option or accessory. These

and other options may be added to a respirator after purchase. Refer to

the instructions provided with the accessories or optional components for

details of the operation and the required changes to the REGULAR OPERATIONAL INSPECTION.

• Spectacle corrective lens kit.

• Quick Disconnect on the mask mounted breathing regulator.

• Duration extending accessory hose to connect to a low pressure air-

line supply enabling the respirator user to breathe air from a remote

air supply.

• An alternate optional waist belt. Refer to the inspection and use in-

structions provided with the waist belt before use. Additional training

is required before use of the alternate optional waist belt.

• Various electronic telemetry and communications devices are also

available.

• PAK-ALERT distress alarm (Personal Alert Safety System) which moni-

tors the motion of a respirator user and emits an audible signal when

the user has not moved for a period of time. When the PAK-ALERT

distress alarm is installed, it also powers the Heads-Up Display end

of service time indicator.

PAK-ALERT DISTRESS ALARM DATA LOGGING FEATURE

The PAK-ALERT distress alarm includes on-board electronics which maintain a running log of event data including start-up, shut-down, and PASS

activation. The SCOTT DATA LOGGER Computer Interface is required

to access the information. Instructions for downloading the data log are

SCOTT P/N 595123-01 and are included with the computer interface.

ONly THOSE OPTIONS AND/OR

WARNING

ACCESSORIES AUTHORIZED By SCOTT AND

APPROVED By NIOSH AND NFPA MAy BE

INSTAllED IN THIS RESPIRATOR. THE USE

OF UNAUTHORIZED AND/OR UNAPPROVED

OPTIONS OR ACCESSORIES COUlD CAUSE

PARTIAl OR COMPlETE FAIlURE OF THE

RESPIRATOR WHICH MAy RESUlT IN

INJURy OR DEATH.

WARNING

THE USER OF THIS RESPIRATOR MUST

RECEIVE TRAINING IN THE OPERATION

OF THE RESPIRATOR INClUDING THE

OPERATION OF All OPTIONS AND/

OR ACCESSORIES INCORPORATED IN

THE RESPIRATOR. SEE WARNING AT

THE BEGINNING OF PAGE TWO OF THIS

INSTRUCTION.

Page 7 of 48 P/N 595279-01 Rev. B 5/14

FACEPIECE FITTING AND FIT TESTING

A respirator Quantitative Fit Test must be performed to ensure the correct

respirator facepiece size has been selected and assigned to the user. It is

the responsibility of the Respiratory Protection Program manager or Safety

Coordinator to assist the user in selecting the correct respirator size relative

to the user’s facial features and dimensions. Fit Testing must be performed

with any approved SCOTT accessories that will be used with the respirator

installed, such as a communications device installed on the facepiece.

Refer to NIOSH Procedure No. RB-CET-STP-CBRN-0352, DETERMINA-

TION OF LABORATORY RESPIRATOR PROTECTION LEVEL (LRPL)

QUANTITATIVE, MEDIUM FLOW, DEEP PROBE, CORN OIL, FIT FACTOR

PERFORMANCE TEST FOR CHEMICAL, BIOLOGICAL, RADIOLOGICAL

and NUCLEAR (CBRN) FULL FACEPIECE RESPIRATORY PROTECTION

DEVICES (RPD) STANDARD TESTING PROCEDURE Attachment C, Sizing

and Test Panels for LRPL for details.

The size and style facepiece must be selected based on the user’s measured

face size. For initial fitting, carefully don the facepiece and conduct a NEGATIVE

PRESSURE LEAK TEST. Refer to the DONNING PROCEDURE section of this

instruction for the procedure. Follow the DONNING PROCEDURE CAREFUlly.

If the selected facepiece does not pass the NEGATIVE PRESSURE LEAK TEST

or does not fit securely without movement in the chin or chin cup area or the

user experiences discomfort in the chin or throat, try the next nearest size,

larger or smaller. After passing the NEGATIVE PRESSURE LEAK TEST, the

facepiece size selected must be verified by successfully passing a respirator

Quantitative Fit Test.

Respirator fit tests are explained fully in the American National Standard

Practices for Respiratory Protection, ANSI Z88.10-2001 which is published

by the American National Standards Institute (ANSI), 11 West 42nd Street,

New York, New York, 10036, and in the Occupational Safety and Health

Standards, OSHA 29 CFR 1910.134 Appendix A, which is published by the

Occupational Safety and Health Administration (OSHA), 200 Constitution

Avenue, NW, Washington DC, 20210.

Quantitative Fit Testing per OSHA Standard 29 CFR Part 1910.134 Appendix

A, or ANSI Standard Z88.10-2001 requires testing in the negative pressure

mode using equipment such as a Portacount1 Respirator Fit Tester. For Quantitative Fit Testing, SCOTT facepieces require use of the appropriate negative

pressure testing equipment such as the Portacount Respirator Fit Tester along

with the following:

• SCOTT 40mm facepiece adapter, P/N 200423-01,

• a new SCOTT CBRN CAP-1 Canister, P/N 045135 or SCOTT P100 Car-

tridge, P/N 052683**,

• SCOTT Probed Fit Test Adapter P/N 805628-01 or equivalent probed

facepieces and the full range of sizes and styles

• Mask Seal Kit, P/N 805655-01

• the appropriate SCOTT communications device and mounting bracket

properly installed on the facepiece

• the optional SCOTT AV-NBC Shroud, P/N 31000558.

Depending on whether the user is fit testing for CBRN SCBA Open Circuit

mode of operation (minimum Fit Factor equal to or greater than 500 minimum)

or CBRN APR (minimum Fit Factor equal to or greater than 2000 minimum)

appropriate negative pressure testing equipment must be used. For example,

if you are Fit Testing for CBRN SCBA Open Circuit or CBRN APR, you should

use a P100 Filter, SCOTT P/N 052683 and the SCOTT P/N 805628-01 Fit

Test Adapter. If you are using a Facepiece that has been specially modified

for a Fit Testing Program such as that described in NIOSH Procedure No.

RB-CET-STP-CBRN-0352, DETERMINATION OF LABORATORY RESPIRA-

TOR PROTECTION LEVEL (LRPL) QUANTITATIVE, MEDIUM FLOW, DEEP

PROBE, CORN OIL, FIT FACTOR PERFORMANCE TEST FOR CHEMICAL,

BIOLOGICAL, RADIOLOGICAL and NUCLEAR (CBRN) FULL FACEPIECE

RESPIRATORY PROTECTION DEVICES (RPD) STANDARD TESTING PROCEDURE, you should install the appropriate filtration element directly into

the 40 mm facepiece adapter.

THE USER MUST BE PROPERly FITTED

WARNING

USING A RESPIRATOR QUANTITATIVE FIT

TEST BEFORE USE AND FOllOW All

WARNINGS AND SPECIAl OR CRITICAl

USER’S INSTRUCTIONS SPECIFIED DURING

USE. FAIlURE TO DO SO MAy RESUlT IN

SERIOUS INJURy OR DEATH.

WARNING

FIT TESTING IN ACCORDANCE WITH OSHA

STANDARD 29 CFR PART 1910 IS REQUIRED

AS PART OF THE REQUIRED TRAINING

BEFORE USE OF THIS RESPIRATOR.

FAIlURE TO PROPERly FIT AND TRAIN

THE USER IN USE OF THE FACEPIECE AND

RESPIRATOR MAy RESUlT IN EXPOSURE

TO THE HAZARDOUS ATMOSPHERE WHICH

COUlD lEAD TO SERIOUS INJURy OR

DEATH.

WARNING

RESPIRATORS SHAll NOT BE WORN WHEN

CONDITIONS PREVENT A GO OD FACE SEAl.

SUCH CONDITIONS MAy INClUDE, BUT

ARE NOT lIMITED TO, FACIAl HAIR SUCH

AS GROWTH OF BEARD OR SIDEBURNS,

OR lOW HAIRlINE THAT CROSSES OR

INTERFERES WITH THE SEAlING SURFACE,

THICK OR PROTRUDING HAIRSTylES SUCH

AS PONy TAIlS OR BUNS THAT INTERFERE

WITH THE SMOOTH AND ClOSE FIT OF

THE HEAD HARNESS TO THE HEAD, A

SKUll CAP THAT PROJECTS UNDER

THE FACEPIECE, OR TEMPlE PIECES ON

GlASSES. AlSO, THE ABSENCE OF ONE

OR BOTH DENTURES CAN SERIOUSly

AFFECT THE FIT OF A FACEPIECE. USE OF

AN IMPROPERly FITTED FACEPIECE MAy

lEAD TO EXPOSURE TO THE HAZARDOUS

ATMOSPHERE WHICH COUlD RESUlT IN

SERIOUS INJURy OR DEATH.

**Depending on whether the user is fit testing for CBRN SCBA Open Circuit mode of

operation (minimum Fit Factor equal to or greater than 500) or CBRN APR (minimum

Fit Factor equal to or greater than 2000).

Page 8 of 48P/N 595279-01 Rev. B 5/14

When using a Portacount Respirator Fit Tester for Quantitative Fit Testing, TSI

recommends that the level of particles in the ambient air must be between

5000 and 30000 particles/cm3. Refer to the Portacount Respirator Fit Tester

user instructions for details including available Particle Generators to use

with the Portacount Respirator Fit Tester if you have difficulty achieving the

minimum level of ambient particle count required.

Test subjects must be in good health at the time of the fit testing. Smoking

or eating less than 30 minutes prior to the test is prohibited. Any and all

conditions that might interfere with a good face to facepiece seal must be

addressed and corrected before performing the fit testing. Refer to the list

of conditions in the DONNING PROCEDURES section of this instruction.

To verify the fit factor of the respirator, testing must incorporate an exercise

regimen of normal daily activities. SCOTT requires the following set of fit

test exercises, which are based on OSHA Standard 29 CFR Part 1910.134

Appendix A, and ANSI Z88.10-2001 with modifications.

Exercises are to be performed each for 60 seconds (except as noted) in a

standing position during the test:

• Normal Breathing

• Deep breathing

• Turning head side to side

• Moving head up and down (look up/look down)

• Talking (read the Rainbow Passage)

• Grimace (15 seconds)

• Bending Over (touch toes) / Reach up (toward the ceiling)

• Normal Breathing (repeat)

Fit test exercises must be performed carefully as if the respirator was being used in a hazardous atmosphere. DO NOT bump the facepiece, filter,

or adapter into the body through exaggerated motions. DO NOT talk except

when directed to by the test administrator.

SCOTT requires that users of this respirator with the AV-3000 HT, must

achieve a Fit Factor of at least 500 for CBRN SCBA (Open Circuit) use and

a Fit Factor of at least 2000 for CBRN APR use with their assigned facepiece

style and size using the fit test procedures and exercise regimen stated

above. If a Fit Factor of at least 500 for CBRN SCBA (Open Circuit) use and

a Fit Factor of at least 2000 for CBRN APR use cannot be achieved with any

facepiece size or style, the user mUST NOT use this respirator.

If the respirator user passes a NEGATIVE PRESSURE LEAK TEST but DOES

NOT pass a respirator Quantitative Fit Test, try the next nearest size, larger

or smaller and repeat the NEGATIVE PRESSURE LEAK TEST and the Quantitative Fit Test. If leakage is still detected, either per these user instructions

or the OSHA fit testing process, the use of mask Seal Kit P/N 805655-01

may be required to attain a proper fit. Refer to the INSTALLATION AND USE

INSTRUCTIONS, SCOTT P/N 89462-01, included with the mask Seal Kit.

After installing the mask Seal Kit, repeat the fit testing process to confirm a

proper fit. If leakage is still detected, do not use the respirator.

Once the proper size is selected and assigned to the user following successful Portacount Respirator Fit Tester testing to achieve minimum Fit Factors

required, the respirator user must perform and pass a NEGATIVE PRESSURE

LEAK TEST every time the facepiece is donned to ensure proper fit before

using the respirator in a hazardous atmosphere.

During NEGATIVE PRESSURE LEAK TESTING, any facepiece leakage that

is detected from other than the face to facepiece seal may indicate damaged

or defective equipment. Remove the defective equipment from service and

tag for repair by authorized personnel. Repeat the testing with equipment

known to be operating properly.

IF A SATISFACTORY NEGATIVE PRESSURE LEAK TEST CANNOT BE PERFORmED, DO NOT USE THE RESPIRATOR OR ENTER THE HAZARDOUS

ATmOSPHERE.

The facepiece alone does not provide any protection against a hazardous

atmosphere without the use of the complete respirator.

A respirator Quantitative Fit Test must be routinely carried out as outlined

above for each user of this respirator to determine or confirm the amount of

protection that the respirator provides.

Periodically repeating the fit testing is required to identify any physical

changes of the user (such as those listed in the DONNING PROCEDURES)

which could effect the fit of the facepiece.

Page 9 of 48 P/N 595279-01 Rev. B 5/14

WARNING

IMPROPER USE OF A RESPIRATOR MAy RESUlT IN PERSONAl INJURy OR DEATH. IMPROPER

USE INClUDES, BUT IS NOT lIMITED TO, USE WITHOUT TRAINING, DISREGARD OF THE WARNINGS

AND INSTRUCTIONS SUPPlIED WITH THE RESPIRATOR AND ITS ACCESSORIES AND FAIlURE

TO INSPECT AND MAINTAIN THE RESPIRATOR. READ AND UNDERSTAND THE INSTRUCTION

MANUAl AND ANy APPlICABlE ACCESSORy INSTRUCTIONS AND WARNINGS BEFORE ATTEMPTING

TO USE A RESPIRATOR

CAUTIONS AND lIMITATIONS

D – AIRLINE RESPIRATORS CAN BE USED ONLY WHEN THE RESPIRATORS ARE SUPPLIED WITH RESPIRABLE

AIR mEETING THE REQUIREmENTS OF CGA G-7.1 GRADE D OR HIGHER QUALITY.

E – USE ONLY THE PRESSURE RANGES AND HOSE LENGTHS SPECIFIED IN THE USER'S INSTRUCTIONS.

I – CONTAINS ELECTRICAL PARTS WHICH HAVE NOT BEEN EVALUATED AS AN IGNITION SOURCE IN FLAm-

mABLE OR EXPLOSIVE ATmOSPHERES BY mSHA/NIOSH.

J – FAILURE TO PROPERLY USE AND mAINTAIN THIS PRODUCT COULD RESULT IN INJURY OR DEATH.

m – ALL APPROVED RESPIRATORS SHALL BE SELECTED FITTED, USED AND mAINTAINED IN ACCORDANCE

WITH mSHA, OSHA AND OTHER APPLICABLE REGULATIONS.

N – NEVER SUBSTITUTE, mODIFY, ADD OR OmIT PARTS. USE ONLY EXACT REPLACEmENT PARTS IN THE

CONFIGURATION AS SPECIFIED BY THE mANUFACTURER.

O – REFER TO USER'S INSTRUCTIONS AND/OR mAINTENANCE mANUALS FOR INFORmATION ON USE AND

mAINTENANCE OF THESE RESPIRATORS.

S – SPECIAL OR CRITICAL USER'S INSTRUCTIONS AND/OR SPECIFIC USE LImITATIONS APPLY. REFER

TO INSTRUCTION mANUAL BEFORE DONNING.

CAUTIONS AND lIMITATIONS OF USE FOR CBRN SCBA

Q – USE IN CONJUNCTION WITH PERSONAL PROTECTIVE ENSEmBLES THAT PROVIDE APPROPRIATE LEVELS

OF PROTECTION AGAINST DERmAL HAZARDS.

R – SOmE CBRN AGENTS mAY NOT PRESENT ImmEDIATE EFFECTS FROm EXPOSURE, BUT CAN RESULT

IN DELAYED ImPAIRmENT, ILLNESS, OR DEATH.

T – DIRECT CONTACT WITH CBRN AGENTS REQUIRES PROPER HANDLING OF THE SCBA AFTER EACH USE AND

BETWEEN mULTIPLE ENTRIES DURING THE SAmE USE. DECONTAmINATION AND DISPOSAL PROCEDURES

mUST BE FOLLOWED. IF CONTAmINATED WITH LIQUID CHEmICAL WARFARE AGENTS, DISPOSE OF THE

SCBA AFTER DECONTAmINATION.

U – THE RESPIRATOR SHOULD NOT BE USED BEYOND 6 HOURS AFTER INITIAL EXPOSURE TO CHEmICAL

WARFARE AGENTS TO AVOID POSSIBILITY OF AGENT PERmEATION.

EBSS - EBSS ACTIVATION OR ENGAGEmENT OF EBSS IN EITHER THE DONOR OR RECEIVER mODE CHANGES

THE SCBA USE TO ESCAPE-ONLY, APPROVED SERVICE TImE FOR EITHER THE DONOR, OR THE RECEIVER

IS NO LONGER APPLICABLE. ADDITIONAL CRITICAL CAUTIONS AND LImITATIONS APPLY. REFER TO EBSS

IN THE USERS' mANUAL.

S—SPECIAl OR CRITICAl USER’S INSTRUCTIONS

ALL mODELS ARE APPROVED ONLY WHEN COmPRESSED AIR CYLINDER IS FULLY CHARGED WITH AIR mEETING THE REQUIREmENTS OF THE COmPRESSED GAS ASSOCIATION SPECIFICATION G-7.1, GRADE D AIR OR EQUIVALENT SPECIFICATIONS, OR

mEETING CE EUROPEAN STANDARD EN 132. THE CONTAINER SHALL mEET APPLICABLE DOT SPECIFICATIONS.

AIRLINE RESPIRATORS CAN BE USED ONLY WHEN THE RESPIRATORS ARE SUPPLIED WITH RESPIRABLE AIR mEETING THE

REQUIREmENTS OF CGA G-7.1, GRADE D OR HIGHER QUALITY, OR mEETING CE EUROPEAN STANDARD EN 132.

EXCEPT AS NOTED HEREIN, ALL mODELS OF THE SCOTT 2.2, 4.5, OR 5.5 ARE APPROVED FOR RESPIRATORY PROTECTION

DURING ENTRY INTO OR ESCAPE FROm OXYGEN DEFICIENT ATmOSPHERES, GASES AND VAPORS, AT TEmPERATURES

ABOVE -25° F / -32° C.

mASK SEAL KIT P/N 805655-01 IS REQUIRED IF A USER SEAL CHECK IS UNSATISFACTORY EITHER PER THE USER INSTRUCTIONS OR THE OSHA FIT TESTING PROCESS. THE mASK SEAL KIT IS PROVIDED WITH THE FULL FACEPIECE. THIS IS A NIOSH

APPROVED COmPONENT TO ENHANCE THE FIT OF THE FACEPIECE.

EBSS, RIC/UAC, AIRLINE CONNECTION OR ANY OTHER QUICK DISCONNECT CONNECTIONS ARE NOT TO BE mADE OR BROKEN IN CBRN ENVIRONmENTS.

EBSS—SPECIAl OR CRITICAl USER’S INSTRUCTIONS

EBSS mAY NOT BE ENGAGED OR ACTIVATED IN DONOR mODE AFTER THE DONOR END-OF-SERVICE-TImE-INDICATOR (EO-

STI) HAS ACTIVATED.

USERS mUST BE FULLY TRAINED IN THE OPERATION OF EBSS IN ACCORDANCE WITH A TRAINING PROGRAm CONFORmING

TO THE REQUIREmENTS OF NFPA STAN

1500, FIRE DEPARTmENT OCCUPATIONAL SAFETY AND HEALTH PROGRAm.

SImULTANEOUS CONNECTION OF mORE THAN TWO USERS, ONE DONOR, AND ONE RECEIVER, IS NOT PER-

mITTED

DARDS 1404, FIRE SERVICE RESPIRATORY PROTECTION TRAINING AND

Page 10 of 48P/N 595279-01 Rev. B 5/14

REGUlAR OPERATIONAl INSPECTION

The following procedure shall be used when you first receive the respirator and for daily or periodic inspection of the respirator. Respirators in

regular use must be inspected at the start of each use period and during

cleaning after each use. Respirators maintained for emergency use must

be inspected as frequently as required to assure the respirator will function properly when required. The US Labor Department (OSHA), pursuant

to 29 CFR 1910.134, requires at least monthly inspection of respirators

maintained for emergency use. NFPA recommends weekly inspection for

emergency use respirators. NIOSH recommends an inspection for cylinder

pressure at least weekly. The condition of storage at your location or the

regulations which apply to your respiratory protection program may require

more frequent periodic inspections.

If the respirator is equipped with a PAK-ALERT distress alarm, the following

procedures must be modified to include inspection of the PASS Device.

Details of the REGULAR OPERATIONAL INSPECTION of the PAK-ALERT

distress alarm are included in the user instructions for the PAK-ALERT

distress alarm. The part number of the required PAK-ALERT distress alarm

user instructions appears on the label on the Sensor module.

IF ANY DISCREPANCY OR mALFUNCTION IS NOTED DURING

THE INSPECTION, DO NOT USE THE RESPIRATOR. REmOVE

THE RESPIRATOR FROm SERVICE AND TAG IT FOR REPAIR BY

AUTHORIZED PERSONNEL.

INSPECTION OF THE RESPIRATOR

If any damage is found in this inspection, remove the respirator from

service and tag for repair by authorized personnel.

1. Inspect the complete respirator for worn or damaged components.

a) Inspect hoses and rubber parts which exhibit cracking, splitting,

or brittleness.

b) Inspect harness webbing and all elastomeric components for cuts,

tears, abrasion, fraying, or indication of heat of chemical damage.

c) Check all buckles and fasteners for proper operation.

d) Check the cylinder retention system for damage and for proper

operation.

e) Verify that the respirator has been properly cleaned.

f) Look especially for evidence of damage caused by exposure to

high heat or chemicals.

2. Refer to the user instructions provided with an approved Voice

Amplifier or other communications device for details of operation and

maintenance. Always verify that the device has fresh batteries before

use.

3. Remove the breathing regulator from the facepiece by pulling back

on the regulator retaining latch and rotating the regulator ¼ turn.

RESPIRATORS MUST BE ClEANED AND

WARNING

INSPECTED BEFORE STORAGE FOR REUSE.

RESPIRATORS WITH WORN OR DAMAGED

COMPONENTS SHAll NOT BE STORED FOR

REUSE. REPlACE WORN OR DAMAGED

COMPONENTS DURING INSPECTION OR

REMOVE THE RESPIRATOR FROM SERVICE

AND TAG IT FOR REPAIR By AUTHORIZED

PERSONNEl. USE OF A RESPIRATOR WITH

WORN OR DAMAGED COMPONENTS MAy

RESUlT IN SERIOUS INJURy OR DEATH.

INSPECTION OF THE BREATHING AIR CYLINDER

1. Visually inspect breathing air cylinder and valve assembly for physical

damage such as dents or gouges in metal or in composite wrapping.

Cylinders which show physical damage or exposure to high heat or

flame, such as paint turned brown or black, decals charred or missing, pressure gauge lens melted or elastomeric bumper distorted, and

cylinders which show evidence of exposure to chemicals such as discoloration, cracks in the cylinder or the composite wrapping, peeling

of the outer layers of the composite wrapping and/or bulging of the

cylinder wall, shall be removed from service and emptied of compressed

air. Publications on compressed gas cylinder inspection procedures

are available from Compressed Gas Association Inc., 1725 Jefferson

Davis Hwy., Suite 1004, Arlington, VA 22202 (703-412-0900).

FOllOW THE REGUlAR OPERATIONAl

WARNING

INSPECTION PROCEDURE EXACTly. IF

THE END OF SERVICE INDICATOR AlARMS

DO NOT ACTUATE AS DESCRIBED IN

THIS INSTRUCTION, THE PURGE DOES

NOT ACTUATE AS DESCRIBED IN THIS

INSTRUCTION OR ANy OTHER OPERATIONAl

MAlFUNCTION IS NOTED, DO NOT USE THE

RESPIRATOR. REMOVE THE RESPIRATOR

FROM SERVICE AND TAG IT FOR REPAIR

By AUTHORIZED PERSONNEl. FAIlURE TO

PROPERly IDENTIFy MAlFUNCTIONS MAy

RESUlT IN SERIOUS INJURy OR DEATH.

REGUlAR OPERATIONAl INSPECTION

CONTINUED ON NEXT PAGE...

Page 11 of 48 P/N 595279-01 Rev. B 5/14

REGUlAR OPERATIONAl INSPECTION CONTINUED...

2. Check the latest cylinder hydrostatic test date to ensure it is current.

The date of manufacture marked on the cylinder is also the date of

the first hydrostatic test. All breathing air cylinders used with SCOTT

AIR-PAK X3 SNAP -CH AN GE SCB A’s must be visually inspected regularly and hydrostatically tested at the required intervals by a licensed

cylinder retester. Intervals for hydrostatic testing are established in

the appropriate US Department of Transportation (DOT) specification

or applicable DOT exemption, or in the appropriate Transport Canada

(TC) Permit of Equivalent Level of Safety. Refer to the current revision

of Safety Precautions for AIR-PAK Cylinders, SCOTT P/N 89080-01,

available on request from SCOTT Safety. Composite fiber overwrapped cylinders must be tested up to their maximum life which, at

the time of the publication of this instruction, is 15 years from the date

of manufacture. It is the responsibility of your organized respiratory

protection program to arrange for visual inspection and hydrostatic

testing of cylinders by a licensed retester.

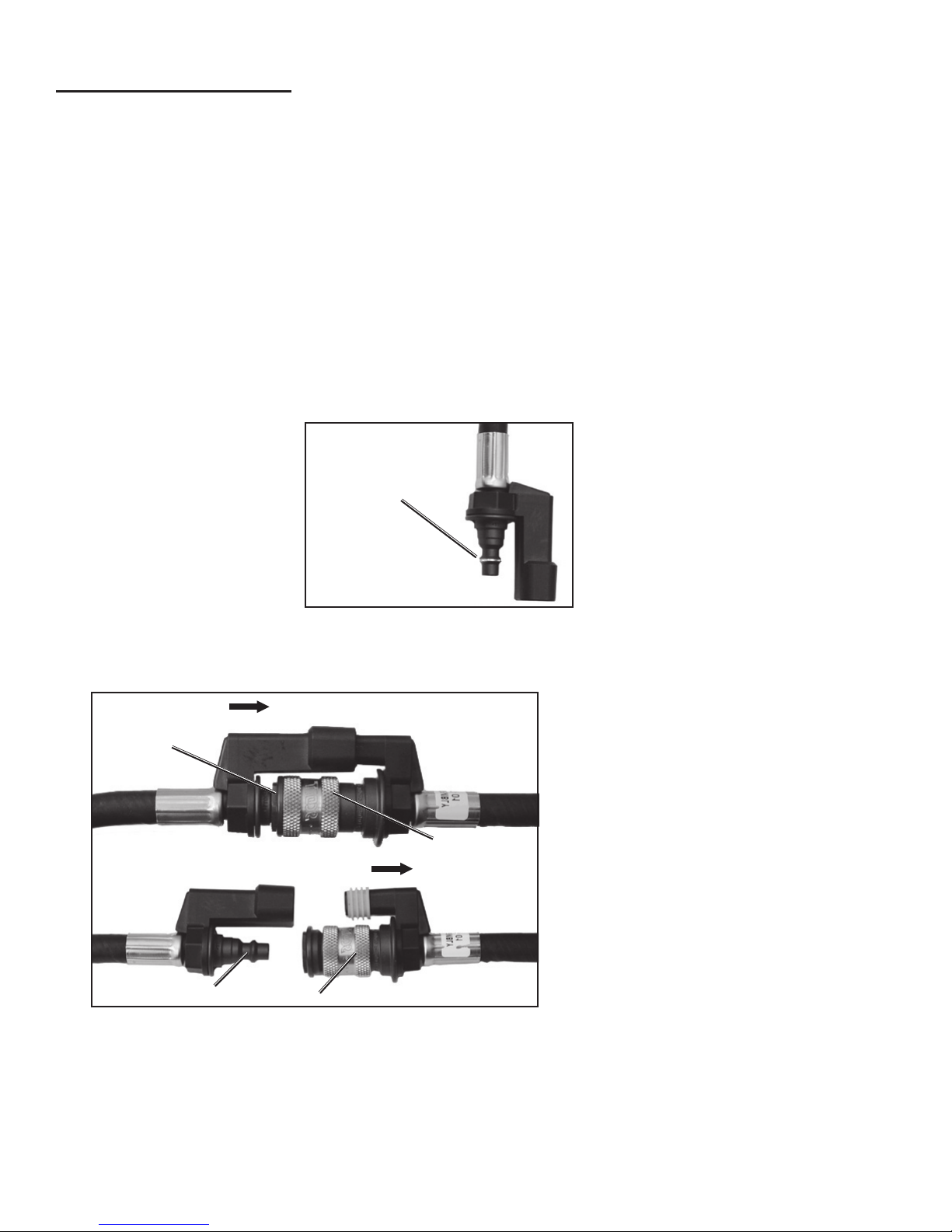

3. Inspect the cylinder valve as follows:

a) Check for damage of the cylinder valve hand wheel.

b) Inspect the cylinder valve outlet for damage. Verify that the SNAP-

CHANGE connector on the cylinder valve outlet is undamaged

and clean and free of dirt and debris.

c). Check the relief valve (burst disc) for damage or dirt.

VERIFy THAT THE

CylINDER CONNECTOR

IS ClEAN AND FREE

OF DIRT OR DEBRIS

DAMAGED CylINDERS MAy SUDDENly

WARNING

lEAK OR RUPTURE IF lEFT CHARGED WITH

COMPRESSED AIR. FAIlURE TO INSPECT

FOR DAMAGE AND TO EMPTy THE AIR

FROM DAMAGED CylINDERS MAy RESUlT

IN SERIOUS INJURy OR DEATH.

PROTECTIVE

CAP ON CGA

FIll FITTING

CylINDER VAlVE

WITH SNAP-CHANGE

ATTACHMENT

FIGURE 1

CylINDER VAlVE

4. Check the cylinder pressure gauge for “FULL” indication. If cylinder pressure is less than “FULL,” replace with a fully charged

cylinder.

RIC UAC CONNECTION INSPECTION

Inspect the RIC-UAC Connection as follows:

1. Remove the dust cap from the RIC UAC coupling on the respirator.

2. Visually inspect the coupling for dirt or damage. Remove any dirt or

contamination from the coupling.

3. If the RIC UAC coupling on the respirator appears damaged, remove

the respirator from service and tag for repair by authorized personnel.

4. If no damage is found, replace the dust cap.

Page 12 of 48P/N 595279-01 Rev. B 5/14

FACEPIECE INSPECTION

Examine the facepiece assembly for damaged or worn components. The

facepiece must be complete and in serviceable condition with no worn,

loose, or damaged components. If any damage is found or if there is

any suspicion that the facepiece may have been exposed to conditions

that may have caused damage, remove the facepiece from service and

replace.

Inspect the facepiece as follows:

1. Inspect the facepiece seal and other rubber components for deforma-

tion, wear, damage, or cracks.

2. Inspect the lens and lens frame as follows:

a) Inspect the lens for scratches, gouges, cracks, crazing, distortion,

melting, or any other damage or condition that could impair the

user’s vision or the operation of the facepiece.

b) Inspect the lens frame for damage such as cracks or distortion.

c) Verify that the lens frame screws are present and installed cor-

rectly.

3. Inspect the head harness as follows:

a) Check that all harness anchors are present and operating properly.

b) Inspect the head harness for correct installation with all straps

oriented correctly.

c) Inspect the head harness for damage or worn components.

4. Inspect the voicemitter ducts as follows:

a) Verify that the voicemitter ducts are properly installed through the

facepiece lens.

b) Verify that each voicemitter duct has an outer grill installed and

that the grills are not damaged.

c) Inspect the voicemitters for damage and verify that the voicemit-

ters are properly installed and secure in the voicemitter ducts.

5. Inspect the nose cup as follows:

a) Inspect the nose cup for cuts or damage. Look for any signs of

damage to the facepiece port side of the nose cup where the

regulator attaches.

b) Verify that both inhalation valves in the nose cup are present and

properly installed.

c) Verify that the Nose Cup is properly installed. Check that the nose

cup is properly seated between the flanges of the voicemitter

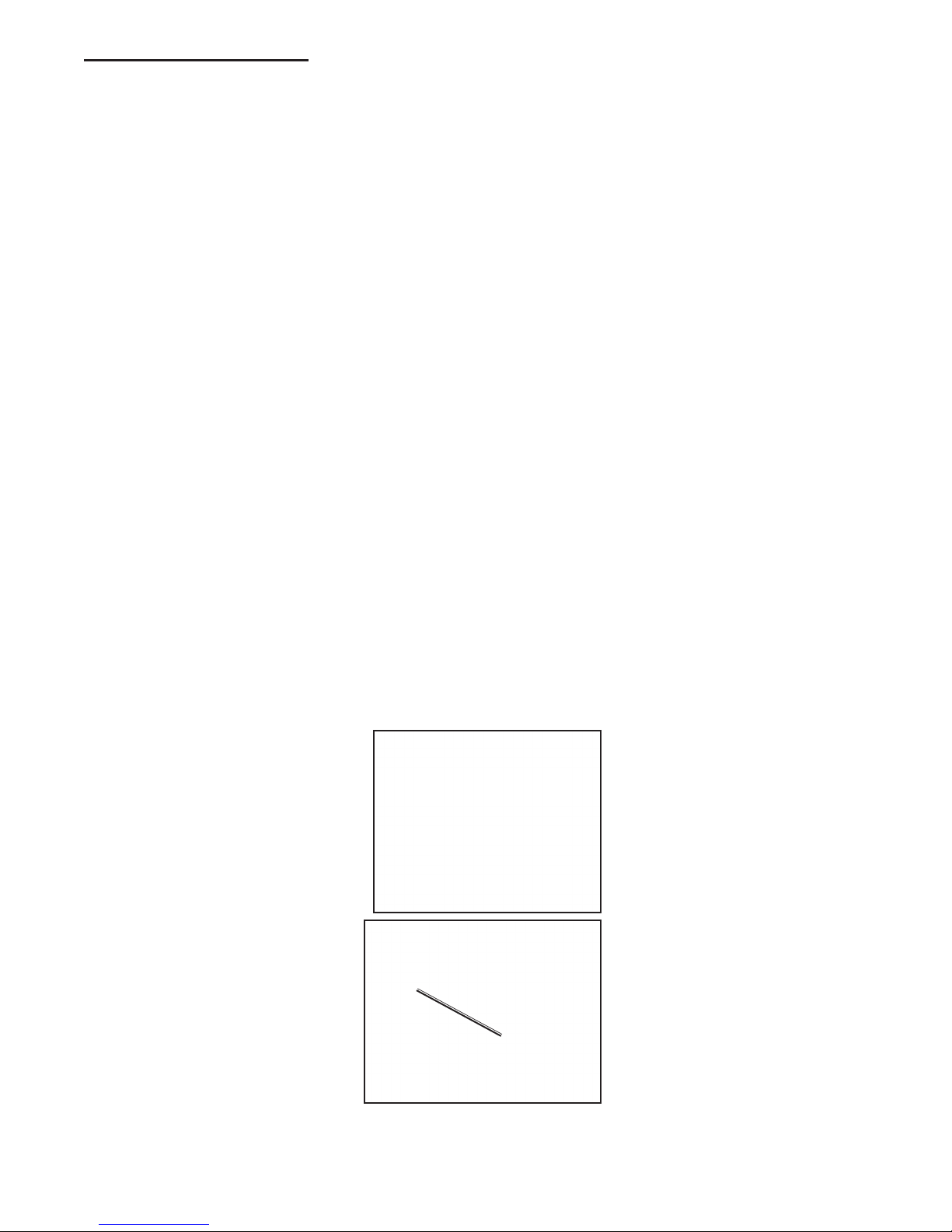

ducts. See FIGURE 2.

IF ANy FACEPIECE DAMAGE IS FOUND OR

WARNING

IF THERE IS ANy SUSPICION THAT THE

FACEPIECE MAy HAVE BEEN EXPOSED

TO CONDITIONS THAT MAy HAVE CAUSED

DAMAGE, REMOVE THE FACEPIECE FROM

SERVICE AND REPlACE. FAIlURE TO OBEy

THIS WARNING MAy RESUlT IN SERIOUS

INJURy OR DEATH.

FIGURE 2

CHECKING VOICEMITTER

DUCTS

d) The Nose Cup must be fitted

IN FRONT OF the Face Seal

as shown in FIGURE 3.

FIGURE 3

NOSE CUP IN FRONT

OF FACE SEAl

6. Verify that the facepiece is clean in accordance with the CLEANING

THE FACEPIECE section of these instructions.

7. Adjust the head straps to the full outward position.

IN FRONT

OF FACE

SEAl

CAUTION

IF THE NOSE CUP IS REMOVED FOR

INSPECTION, MAKE CERTAIN IT IS

REASSEMBlED CORRECTly.

REGUlAR OPERATIONAl INSPECTION

CONTINUED ON NEXT PAGE...

Page 13 of 48 P/N 595279-01 Rev. B 5/14

REGUlAR OPERATIONAl INSPECTION CONTINUED...

REGULATOR INSPECTION

Inspect the breathing regulator for damaged or missing components.

1. Verify that the regulator gasket is not damaged and is in place around

the outlet port of the regulator.

2. Verify that the purge valve (red knob) is not damaged and turns

smoothly one-half turn from stop to stop.

3. Inspect the Heads-Up Display for damage. Verify that the rubber

guard is in place and is not torn or damaged.

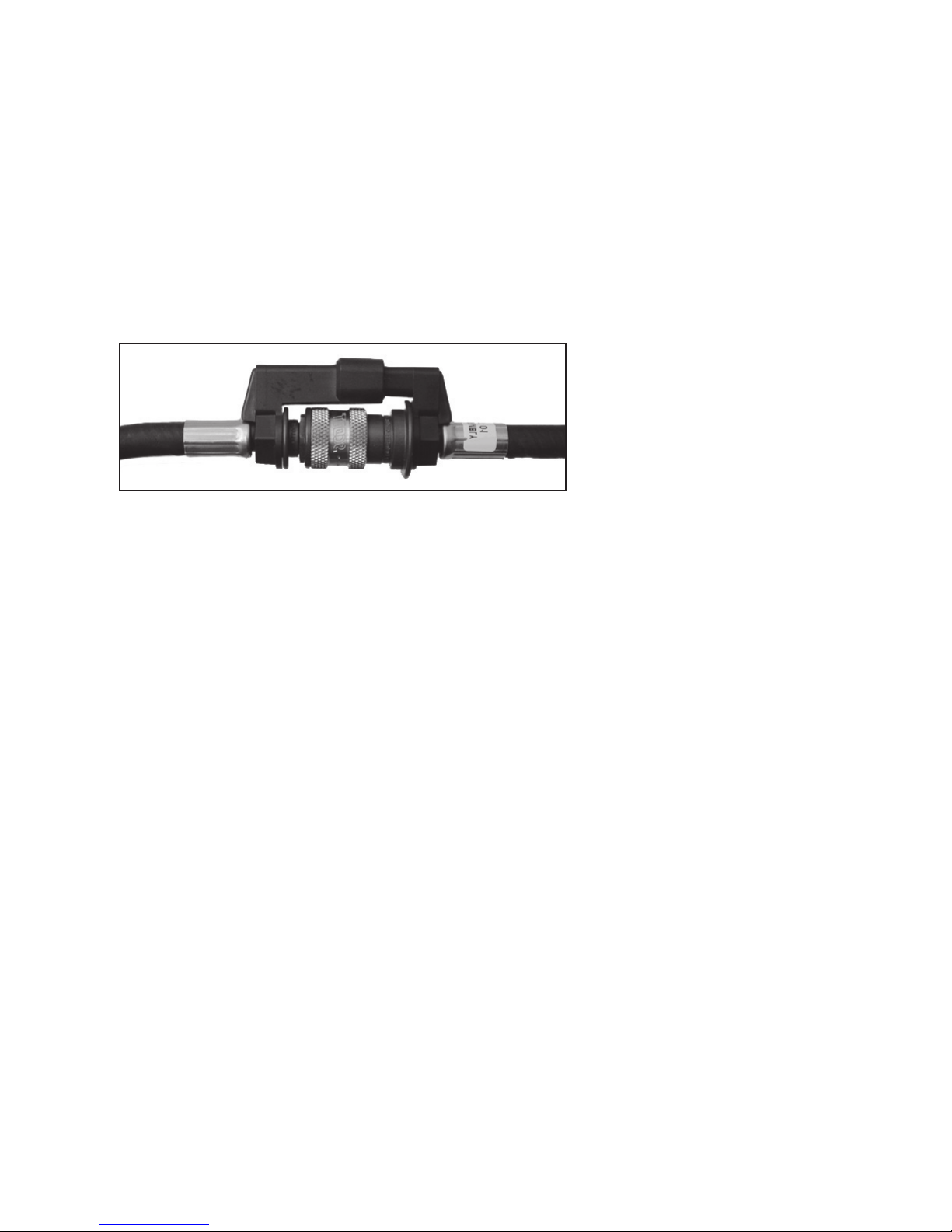

4. If the hose to the breathing regulator is equipped with a quick disconnect, inspect both the male and female quick disconnects. Pay

special attention to the following:

a) Inspect the operation of the locking sleeve on the female quick

disconnect. If any damage is noted, remove it from service and

tag for repair.

b) Inspect the condition of the male quick disconnect for signs of

wear. Particularly look for wear on the locking ridge as shown in

FIGURE 4. If the coating is worn through and bare metal is showing, do not use the regulator assembly. Remove it from service

and tag for replacement.

lOOK FOR WEAR

FIGURE 4

Inspecting Male

Quick Disconnect

ON lOCKING

RIDGE

DO NOT USE TOOlS TO OPEN OR ClOSE

CAUTION

THE PURGE VAlVE. OPEN OR ClOSE By

USING FINGER-PRESSURE ONly. ROTATION

OR THE PURGE VAlVE IS lIMITED TO 1/2

TURN. USE OF TOOlS TO OPEN OR ClOSE

PURGE VAlVE MAy RESUlT IN DAMAGE TO

THE PURGE VAlVE.

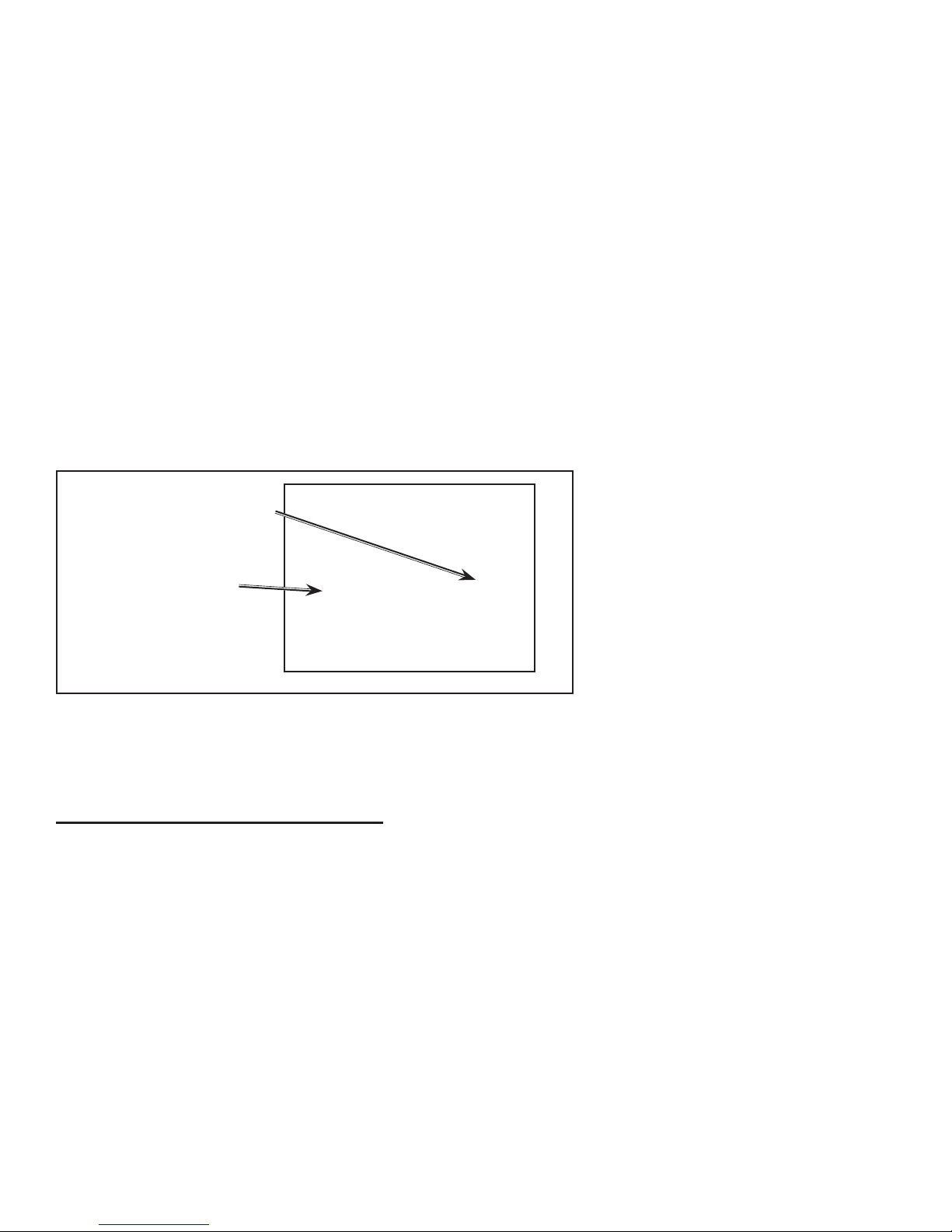

5. Verify that the quick disconnect operates properly. Breathing regulators equipped with a quick disconnect use a Pull-back Sleeve

Coupling. See FIGURE 5. Refer to the following instructions and

illustrations:

PUSH PlUG IN

D

PUll SlEEVE

BACK

E

D E

IF THE COATING IS WORN THROUGH AND

WARNING

BARE METAl IS SHOWING ON THE MAlE

QUICK DISCONNECT lOCKING RIDGE,

REMOVE THE REGUlAT OR ASSEMBly FROM

SERVICE AND TAG FOR REPlACEMENT.

USE OF A WORN QUICK DISCONNECT MAy

RESUlT IN A MAlFUNCTION lEADING TO

A lOSS OF BREATHING AIR WHICH COUlD

RESUlT IN SERIOUS INJURy OR DEATH.

FIGURE 5

Pull-back Sleeve Quick Disconnect

a) While pushing the plug “D” into the socket, pull the locking sleeve

“E” back toward the guard. The plug “D” will separate.

b) To reconnect, align the HEADS-UP DISPLAY plug with the mating

connector. A collar on the female coupling prevents misalign-

ment of the connectors. Push plug “D” into the socket until the

locking sleeve “E” pops forward. Test for proper engagement by

tugging on the coupling.

FAIlURE TO CHECK ENGAGEMENT OF

WARNING

THE COUPlING AS DESCRIBED MAy lEAD

TO HOSE SEPARATION AND lOSS OF

BREATHING AIR RESUlTING IN SERIOUS

INJURy OR DEATH.

Page 14 of 48P/N 595279-01 Rev. B 5/14

6. If the regulator is not attached to the facepiece, proceed as fol-

lows:

a) Align the two flats of the regulator outlet port with the correspond-

ing flats in the facepiece port (the red purge valve on the regulator will be in the 12 o’clock position). Insert the regulator into the

facepiece port.

b) Rotate the regulator counterclockwise (as viewed from inside of

facepiece) until the red purge valve knob is on the left side of the

facepiece. The lock tab on the regulator will lock into the facepiece

retainer with a “click.” When the lock tab is properly engaged, the

regulator will not rotate.

7. If the hose to the breathing regulator is equipped with a quick

disconnect, check that the quick disconnect is engaged properly

by tugging on the coupling and that the HEADS-UP DISPLAY

plug is properly aligned and fitted into the mating socket. See

FIGURE 6.

FAIlURE TO CHECK ENGAGEMENT OF THE

WARNING

REGUlATOR lOCK TAB TO THE FACEPIECE

AS DESCRIBED MAy RESUlT IN ROTATION

OF THE REGUlATOR. IF THE REGUlATOR

ROTATES AND FAllS OUT, THE lOSS OF

BREATHING AIR MAy RESUlT IN SERIOUS

INJURy OR DEATH.

FIGURE 6

Pull-back Sleeve Quick Disconnect

with Heads-Up Display connection

8. Verify that a FULL cylinder is properly installed in the backframe

and that the reducer hose coupling is hand tightened to the cylinder valve outlet.

If no damage is found, proceed to the OPERATIONAl TESTING.

REGUlAR OPERATIONAl INSPECTION

WRENCHES SHAll NOT BE USED TO

CAUTION

TIGHTEN THE HOSE COUPlING. OVER

TIGHTENING THE HOSE COUPlING MAy

DAMAGE THE GASKET SEAl.

CONTINUED ON NEXT PAGE...

Page 15 of 48 P/N 595279-01 Rev. B 5/14

Loading...

Loading...