Page 1

Copy No.:

Instruction Manual

Model No. : Scott 1800.................

Year of Manufacture : 2005.......

Manufactured by :..........

Document Number : S99999--1........

Issue : 1.....................

Date of Issue : July 2005..............

Page 2

ISSUE NOTE

This is Issue 1; Date of Issue: July 2005

Copyright 2005

Page 3

Table of Contents

III

Scott 1800

TABLE OF CONTENTS

1 INTRODUCTION & SAFETY 1--1...........................................................

1.1 Introduction 1--3....................................................................

1.1.1 Scott 1800 Machine Specifications & Utility Requirements 1--4..........................

1.2 General Safety Guidelines 1--5.......................................................

1.3 Safety 1--6..........................................................................

1.3.1 Main Power Switch 1--6...........................................................

1.3.2 Main Air Disconnect 1--6..........................................................

1.4 Warnings, Cautions & Notes 1--7.....................................................

1.4.1 Warnings 1--7....................................................................

1.4.2 Cautions 1--7....................................................................

1.4.3 Notes 1--7.......................................................................

1.5 On Machine Warnings 1--8...........................................................

1.5.1 Hazards 1--8....................................................................

1.6 Safety Procedures 1--9..............................................................

1.6.1 Appropriate Dress 1--9............................................................

1.6.2 Keep Area Clean 1--9.............................................................

1.6.3 Grease and Oil 1--9..............................................................

1.6.4 Manual Usage 1--9...............................................................

2 INSTALLATION 2--1......................................................................

2.1 Installation Requirements 2--3........................................................

2.1.1 Pre-Installation Requirements 2--3..................................................

2.1.2 Assembly Instructions 2--4.........................................................

2.1.3 Check Punch & Die 2--5...........................................................

2.1.4 Mount Paper Supports 2--6........................................................

2.1.5 Install Plastic Reel 2-- 6............................................................

2.1.6 Set the Plastic Stop Guide 2--8.....................................................

3 OPERATION 3--1.........................................................................

3.1 GENERAL INFORMATION 3 --3........................................................

3.1.1 Before Operating the Machine 3--3.................................................

3.2 Operator’s Controls 3--4.............................................................

3.2.1 Control Panel Layout 3--4.........................................................

3.2.2 Power On/OFF Selector Switch 3--5................................................

3.2.3 Machine Mode Selector Switch 3--5.................................................

3.2.4 Power On Indicator Lamp 3--5.....................................................

3.2.5 Foot Pedal 3--6..................................................................

3.2.6 Main Air ON/OFF 3--6.............................................................

3.2.7 Plastic Advance/Cut Switch 3--6....................................................

3.2.8 Production Sheet Counter 3--7.....................................................

3.2.9 Machine Heater Controls 3--7......................................................

3.2.10 Machine Timers

3--8..............................................................

Page 4

Table of Contents

IV

Scott 1800

3.3 Omron Timer Setting Instructions 3--9................................................

3.4 Scott 1800 Frequently Asked Questions 3--10..........................................

3.5 Tab Bank Layout (Method 1) 3--11.....................................................

3.6 Index Tab Set--Up Procedure (Method 2) 3--13..........................................

3.7 Flow Control Valve Setting 3--17.......................................................

3.7.1 Change or Clean Upper Braking 3--17................................................

3.7.2 Setting Flow Control Valves 3--19....................................................

3.7.3 Testing Flow Control Settings 3--21..................................................

4 MAINTENANCE 4--1......................................................................

4.1 Punch and Die Setting Instructions 4--3...............................................

4.1.1 Punch & Die Removal 4--3........................................................

4.1.2 Reinstallation Punch & Die 4--11....................................................

4.1.3 Setting Left Hand Die 4--15.........................................................

4.1.4 Reinstalling the Punch 4--16........................................................

4.2 Care Of Air Cylinder 4--22.............................................................

4.2.1 Lubrication 4--22..................................................................

4.3 Scott 1800 Spare Parts List 4--25......................................................

4.4 C01--1000 Series Filter -- Regulator Combination 4--26...................................

4.4.1 Installation 4--26..................................................................

4.4.2 Adjustment 4--26..................................................................

4.4.3 Maintenance & Cleaning 4--26......................................................

4.4.4 Vendor Contact Information 4--26....................................................

4.5 304-- 1000 & 2000 Series Lubricators 4--28..............................................

4.5.1 Installation 4--28..................................................................

4.5.2 Oil Adjustments 4--28..............................................................

4.5.3 Tamper Proof 4--28................................................................

4.5.4 Maintenance 4--28................................................................

4.5.5 Part Information 4--29..............................................................

4.5.6 Vendor Contact Information 4--29....................................................

5 PARTS 5-1..............................................................................

5.1 Drag Roller Assembly 5-4................................................................

5.2 Idle and Drive Feed Assembly 5-6.........................................................

5.3 Plastic Feed Air Cylinder Assembly 5-8....................................................

5.4 Punch Assembly 5-10....................................................................

5.5 Heater Press Air Cylinder Assembly 5-12....................................................

5.6 Frame Press Mounting Assembly 5-14......................................................

5.7 Die Assembly 5-16.......................................................................

5.8 Paper Guide Assembly 5-18...............................................................

5.9 Plastic Reel Holder Assembly 5-20.........................................................

5.10 Column Mounting Assembly 5-22..........................................................

5.1 1 Body Mounting Assembly 5-24............................................................

5.12 Air Valve Assembly 5-26.................................................................

5.13 Cover and Plate Assembly 5-28...........................................................

5.14 Leg Extension Assembly 5-30............................................................

5.15 Machine Mounting Rail Assembly 5-32.....................................................

5.16 Bottom Support Rail Assembly 5-34.......................................................

Page 5

Table of Contents

V

Scott 1800

5.17 Guard Assembly 5-36...................................................................

5.18 Controls Mounting Assembly 5-38.........................................................

6 SCHEMATICS 6-1........................................................................

Page 6

1 Introduction & Safety

1--1

Scott 1800 Issue 1

1 INTRODUCTION & SAFETY

Scott 1800 Issue 1

Page 7

1 Introduction & Safety

1--2

Scott 1800 Issue 1

Page 8

1 Introduction & Safety

1--3

Scott 1800 Issue 1

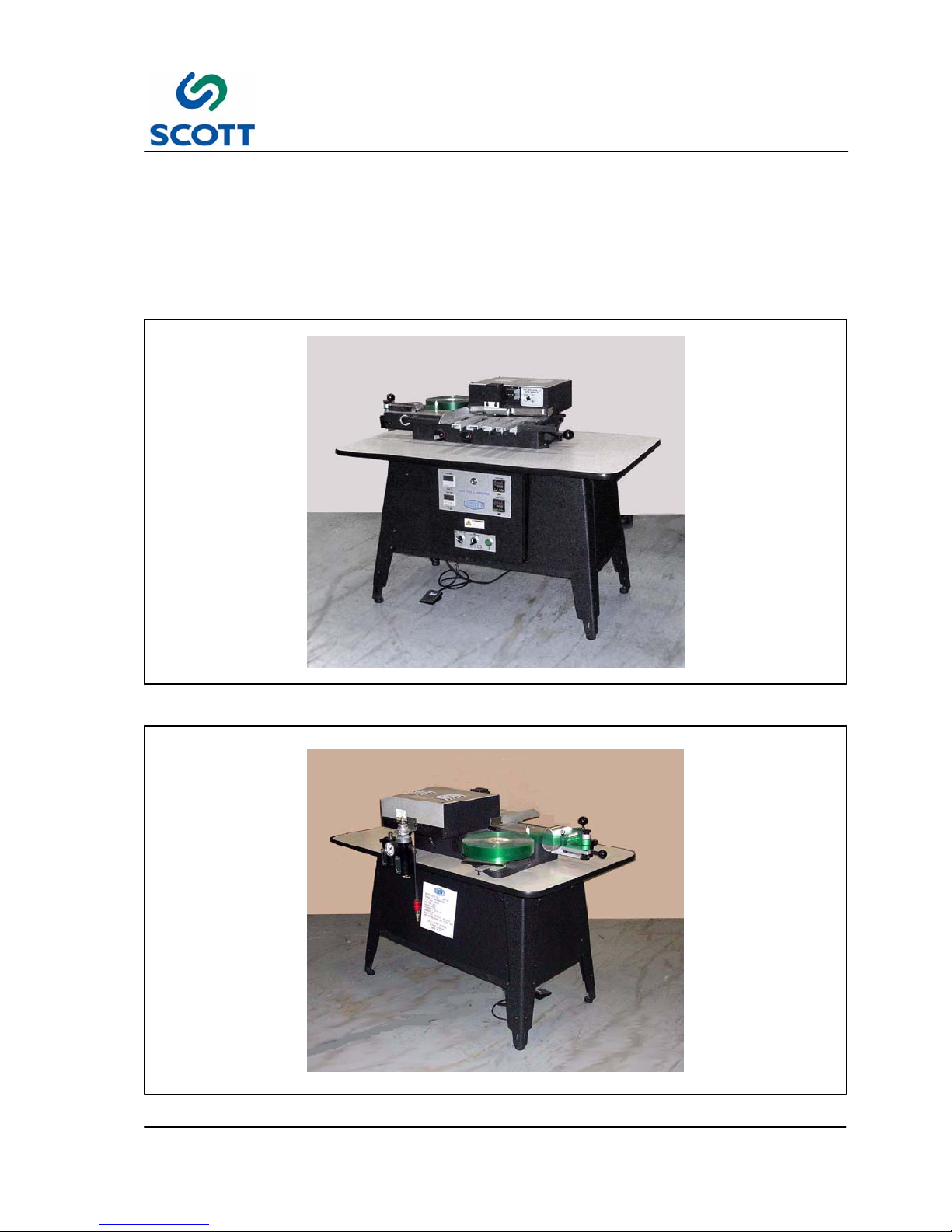

1.1 Introduction

The Scott 1800 Plastic Index Tab Machine is a semi--automatic, manually fed machine for laminating plastic

to index tabs. The plastic is coated with a heat--seal adhesive which is activated when run through the

machine under heat and pressure. The standard width of the plastic is 1--5/8 inches wide.

The Scott 1800 machine can operate at the rate of up to 4,500 sheets per hour.

Fig. 1-1. Machine Front View

Fig. 1-2. Machine Rear View

Page 9

1 Introduction & Safety

1--4

Scott 1800 Issue 1

1.1.1 Scott 1800 Machine Specifications & Utility Requirements

Model Scott 1800t

Speed

Up to 4,500 sheets per hour.

Sheet Size

MIN: 5 1/2” (140MM) LENGTH

MAX: 15” (381MM) WIDE

Plastic Size

MIN: 1” (25.4mm)

MAX: 5.5” (139.7MM)

Paper

32lb. Bond to 25pt.

Electrical Requirements

5AMP 120VAC 50 or 60hz.

Decibel Rating

70dB

Dimensions

Length: 51”

Width: 35”

Height: 38”

Shipping Weight

330lb (150kg)

Warranty

One year against defects in parts

Page 10

1 Introduction & Safety

1--5

Scott 1800 Issue 1

1.2 General Safety Guidelines

Providing a safe working environment for operating your machine is the responsibility of the user. The

suggested precautions, material safety data and other suggestions that follow do not have preference over

the user’s own plant practices, regulations or safety committee recommendations.

Personal injury and equipment damage can be avoided by the continued adherence to the safety features

provided with this machine and in keeping with the necessary governmental requirements. The guarding

and interlocking safety switches have been installed on the machine for the operator’s safety. These items

should be maintained in good working order by the user.

It is assumed that the user’s safety department has established a safety program that is in keeping with a

complete analysis of industrial hazards. Before installing and operating or performing maintenance and

clean--up procedures on the machine, it is suggested that the safety program be reviewed to ensure that it

covers the possible hazards that might occur with the operation of this machine.

Due consideration must be given to those hazards which arise from the presence of electrical power, high

temperature, and cleaning materials used in the operational areas of the machine. Proper installation and

care of protective devices and over--pressure protective equipment should be considered an essential part of

any safety program.

Special lock--out features are to prevent the possibility of applying power to the equipment at any time when

maintenance work is in progress.

In general, personnel should be guided by all basic rules of safety associated with the equipment and the

process. It should be further understood that information contained in this manual does not relieve operating

and maintenance personnel of the responsibility of exercising normal good judgment in operating and care of

the machine and its attendant equipment.

Page 11

1 Introduction & Safety

1--6

Scott 1800 Issue 1

1.3 Safety

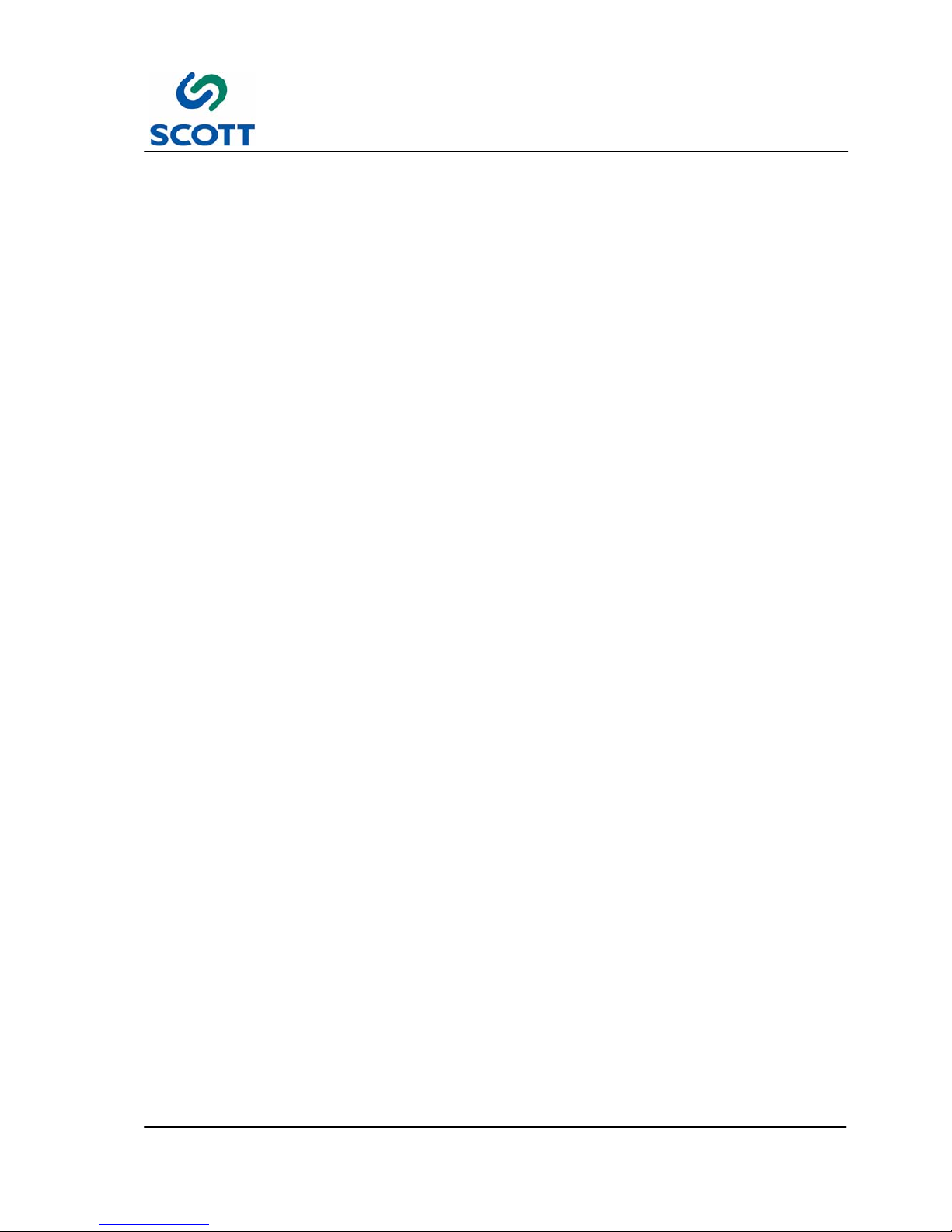

Fig. 1-3. Turn Machine Off Before Making

Adjustments

1.3.1 Main Power Switch

If machine is to be shut down for adjustments or

repairs, turn the power supply to the machine off.

Fig. 1-4. Shut Off Main Air Before Working on

Machine

1.3.2 Main Air Disconnect

Shut off main air before making any machine

adjustments.

Page 12

1 Introduction & Safety

1--7

Scott 1800 Issue 1

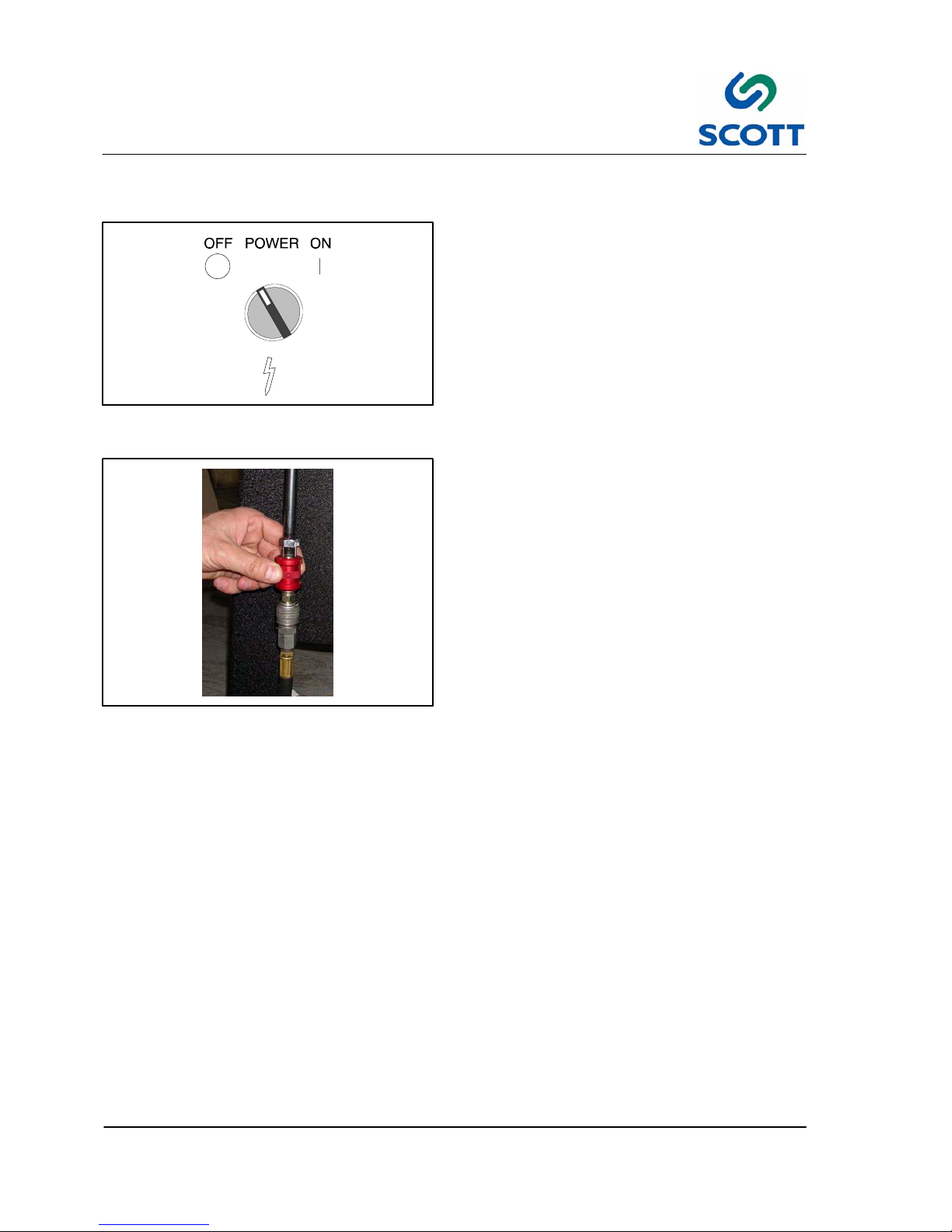

1.4 Warnings, Cautions & Notes

In order to emphasize certain areas in the interest of personal safety and a properly operated and maintained

machine, you will encounter the words WARNING, CAUTION, and NOTE throughout this manual.

WARNING!

Fig. 1-5. Warnings Indicate Personal Danger

1.4.1 Warnings

AN OPERATING PROCEDURE,

PRACTICE, ETC. WHICH IF NOT

CORRECTLY FOLLOWED, COULD

RESULT IN PERSONAL INJURY OR

LOSS OF LIFE.

WARNING!

CAUTION!

Fig. 1-6. Cautions Indicate Potential Damage to

Equipment

1.4.2 Cautions

AN OPERATING PROCEDURE,

PRACTICE, ETC. WHICH, IF NOT

STRICTLY OBSERVED, COULD RESULT

IN DAMAGE TO OR DESTRUCTION OF

EQUIPMENT.

CAUTION!

Note !

Fig. 1-7. Notes Indicate Essential Information

1.4.3 Notes

An Operating Procedure, Condition,

etc. Which is Essential To Highlight.

Note !

Page 13

1 Introduction & Safety

1--8

Scott 1800 Issue 1

1.5 On Machine Warnings

Fig. 1-8. Hot Surface Hazard

1.5.1 Hazards

Observe Hazard signs.

Fig. 1-9. Voltage Warnings

There are two hazardous voltage warnings. One is

on the main electrical cabinet above the operator’s

controls and the other is on the top cover.

Page 14

1 Introduction & Safety

1--9

Scott 1800 Issue 1

1.6 Safety Procedures

Fig. 1-10. Wear Proper Clothing

1.6.1 Appropriate Dress

Personnel working in the machine operation area

must remove jewelry and neckties. Personnel

must wear clothing appropriate for the work area.

Fig. 1-11. Keep Work Area Clean and Neat

1.6.2 Keep Area Clean

Loose materials, tools and equipment, not

essential to the operation of the machine, must be

removed from the machine work area.

Fig. 1-12. Clean Up Oil and Grease Spills

1.6.3 Grease and Oil

Clean up all oil and grease spills around the

machine work area.

Fig. 1 -13. Read Manuals First

1.6.4 Manual Usage

Read and understand the instructions in the

manual before operating, adjusting or servicing

machine.

Page 15

2 Installation

2--1

Scott 1800 Issue 1

2 INSTALLATION

Scott 1800 Issue 1

Page 16

2 Installation

2--2

Scott 1800 Issue 1

Page 17

2 Installation

2--3

Scott 1800 Issue 1

2.1 Installation Requirements

All procedures in this section provide advance planning and site preparation data for installation of the Scott

1800. Environmental requirements, unpacking instructions, electrical and physical specifications are

included. This information should be used as a reference during the development of site preparation plans

before you install your machine.

If any questions arise while performing any of the following procedures, contact:

Note ! A forklift is required to lift the machine off the shipping skid and place it on the floor.

2.1.1 Pre-Installation Requirements

The environmental requirements of the Scott 1800 must be considered well in advance of the actual

installation. Providing a well suited operating environment will help ensure a trouble free installation process.

Consideration should be given to the following items:

● Power, location and rating of power connections.

● Floor strength

● Level floor

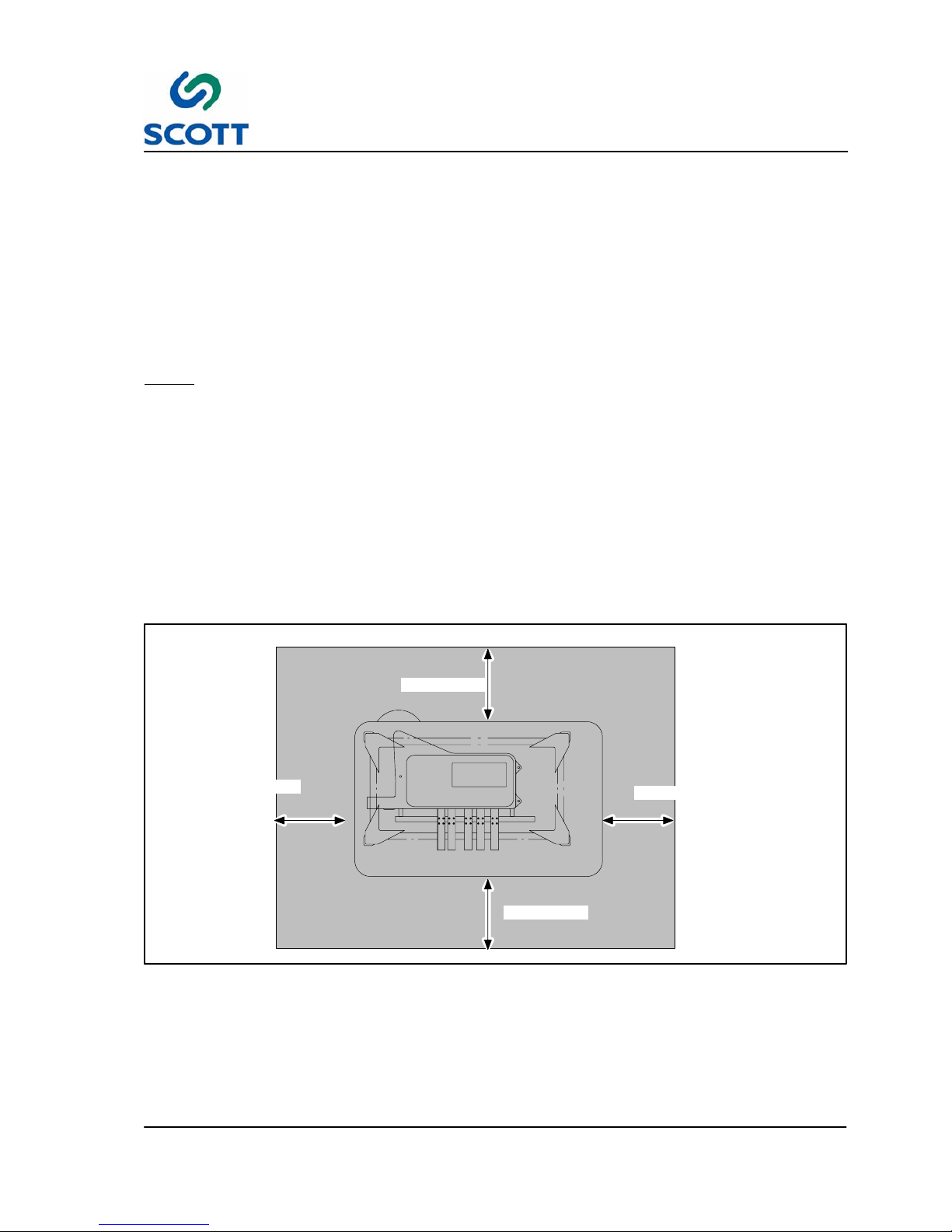

● Adequate space must be provided around all four sides of the machine to permit normal operation and

maintenance procedures. The figure shows the minimum space required.

3’ (914mm)

3’ (914mm)

3’ (914mm)

3’ (914mm)

Fig. 2-1. Scott 1800 Space Requirements

● Space should be allocated near the paper tray for a small table that can be used for small jobs, samples,

etc.

● Provide plenty of space In front of the machine so large jobs can be easily moved in and out with skids or

carts.

Page 18

2 Installation

2--4

Scott 1800 Issue 1

2.1.2 Assembly Instructions

Fig. 2 -2. Machine on Shipping Skid

The machine is shipped assembled.

Step: 1. Remove the machine from shipping skid.

Note ! Now you are ready to bring power to the machine.

DO NOT APPLY AIR PRESSURE TO THE MACHINE AT THIS TIME!!

Step: 2. Plug in the electric cord.

Step: 3. Turn the on/off switch on. The Heat light should come on and both heat controller lights will come

on if the temperature is set high enough.

Step: 4. Set both controllers to 225_F.

After the machine has reached running temperature, the lights on the heat controllers will go on

and off.

Page 19

2 Installation

2--5

Scott 1800 Issue 1

Fig. 2-3. Check Punch and Die

2.1.3 Check Punch & Die

Check the Punch and Die set of the machine. They

may or may not need to be reset, but they do need

to be checked before you start to operate the

machine for the first time, or after any time the

machine has been moved from one location to

another.

Step: 1. Follow the instructions in the

Maintenance section in this manual on

punch and die setting.

Fig. 2-4. Connect Air to Machine

Step: 2. After the dies have been checked and

properly reset if necessary, you may now

connect the air to the machine. Make

sure the pressure regulator is set to 80

P.S.I.

Page 20

2 Installation

2--6

Scott 1800 Issue 1

Fig. 2-5. Mount Paper Supports

2.1.4 Mount Paper Supports

Step: 1. Mount the paper supports, the paper side

guide and the plastic stop to the front of

the machine on the black bar locate

directly in front of the punch and die area.

Fig. 2-6. Place Plastic on Reel Holder

2.1.5 Install Plastic Reel

Step: 1. Place a reel of plastic on the plastic reel

holder on the left side of the machine.

Fold the plastic so the coating is on the

inside.

Note ! The coated side is always on the

outside of the reel.

Step: 2. Thread the machine.

Make sure the plastic goes around the

tension arm coming from the table.

Once you get the plastic started through

the tunnel, you can feed with the manual

toggle switch marked “Plastic

Advance/Plastic Cut”.

Fig. 2-7. Turn Knob for Tighter or Looser Fold

Step: 3. To adjust a tighter or looser fold, turn the

knurled pin located between the plastic

feed rollers and the drag roller.

Note ! Recommended Tension is three

Plastic Thicknesses.

Page 21

2 Installation

2--7

Scott 1800 Issue 1

A

B

Fig. 2-8. Turn Knob to Adjust Tape Tension

Step: 4. To adjust the tape tension, rotate the

black knob (A) on top of the roller with

the two rubber “0” rings.

This is the drag roller.

Adjust for slight amount of drag.

Note ! This should not need frequent

adjustment.

Step: 5. To adjust the tension between the two

feed rollers by loosening or tightening

tension arm (B) attached to upper feed

roller.

Fig. 2-9. Plastic Size Adjustment (LH Shown)

Step: 6. To adjust the size of plastic, unlock the

pinch lock on the left end of the machine

and set the scale to the desired size.

Note ! Be sure to lock the assembly.

Step: 7. Every time you set the left gauge, you

must set the gauge on the right side of

the machine to the same setting.

This centers the press on the tab you are

making.

If this is not done, you will get bad

bonding since the press will be hitting off

center.

Page 22

2 Installation

2--8

Scott 1800 Issue 1

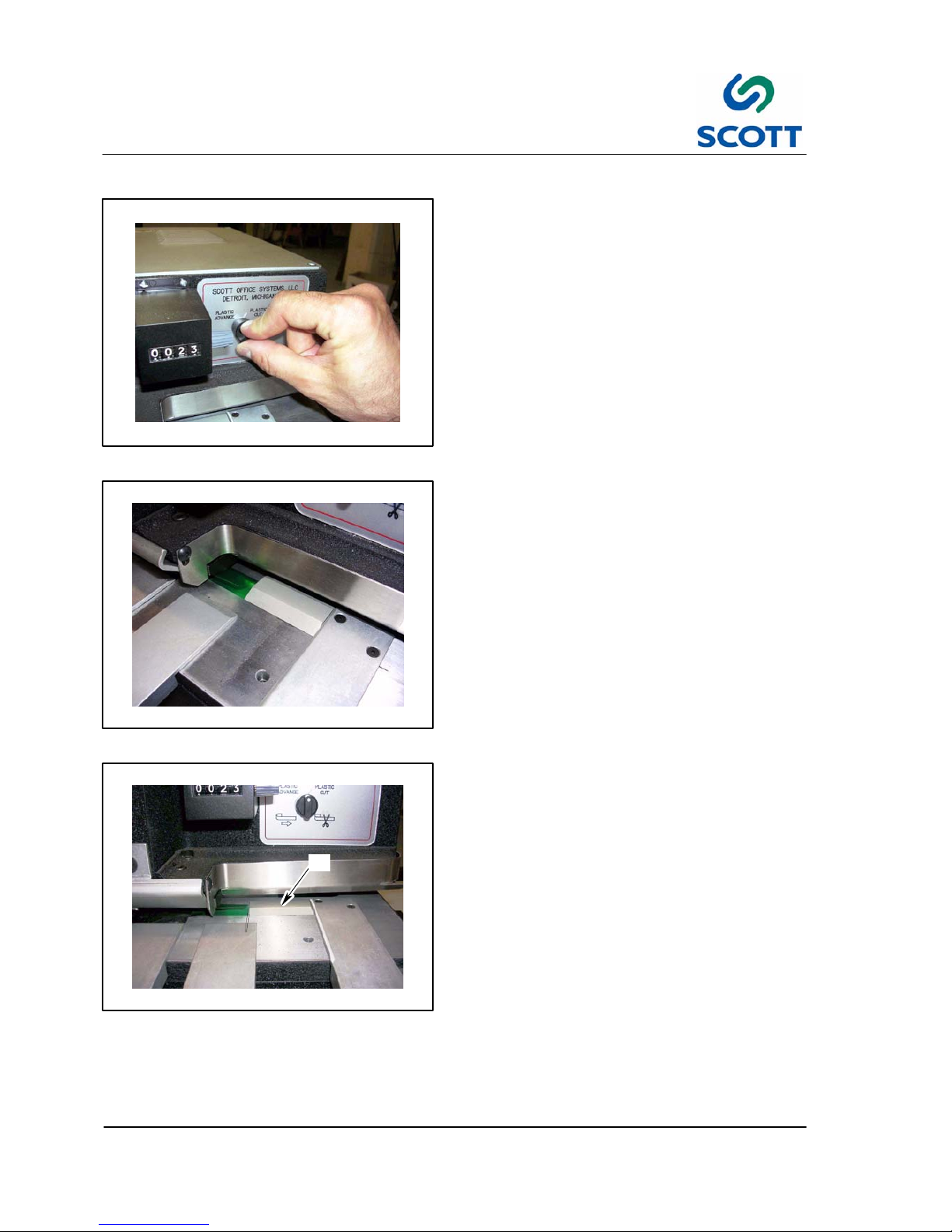

Fig. 2-10. Manually Feed and Cut Plastic

2.1.6 Set the Plastic Stop Guide

To set the Plastic Stop Guide, do the following:

Step: 1. Run tape through the machine past the

punch and die set then, cut off the plastic

with the manual switch.

Fig. 2-11. Feed Piece of Plastic

Step: 2. Feed out a piece of plastic with the

manual feed switch but DO NOT CUT the

plastic.

A

Fig. 2 -12. Bring Stop Guide to End of Plastic

and Add 1/16”, Tighten Guide

Step: 3. Bring the stop guide (A) up to the end of

the plastic and then back it away about

1/32 to 1/16th of an inch. The purpose of

the plastic stop is to help keep the plastic

registered to the same spot on the paper.

Step: 4. Tighten the guide in place.

Page 23

3 Operation

3--1

Scott 1800 Issue 1

3 OPERATION

Scott 1800 Issue 1

Page 24

3 Operation

3--2

Scott 1800 Issue 1

Page 25

3 Operation

3--3

Scott 1800 Issue 1

3.1 GENERAL INFORMATION

3.1.1 Before Operating the Machine

AVOID SERIOUS INJURY OR EQUIPMENT

DAMAGE. RESTRICT OPERATION OF THIS

MACHINE TO TRAINED, QUALIFIED

PERSONNEL ONLY.

EACH OPERATOR SHOULD KNOW THE

LOCATION AND FUNCTION OF ALL

MACHINE STOPPING CONTROLS.

REVIEW MANUAL FOR EMERGENCY

STOP BUTTON LOCATION.

Do not attempt to operate the machine before reading and understanding the manual. Pay close attention to

all WARNINGS, CAUTIONS and NOTES. Failure to do so may cause serious injury and extensive machine

damage.

Read through the inspection and pre--start procedures before starting the machine. Make these checks part

of your routine to insure efficiency and quality during the production run.

Page 26

3 Operation

3--4

Scott 1800 Issue 1

3.2 Operator’s Controls

3.2.1 Control Panel Layout

Fig. 3-1. Control Panel

Fig. 3-2. Operator’s Switches

Page 27

3 Operation

3--5

Scott 1800 Issue 1

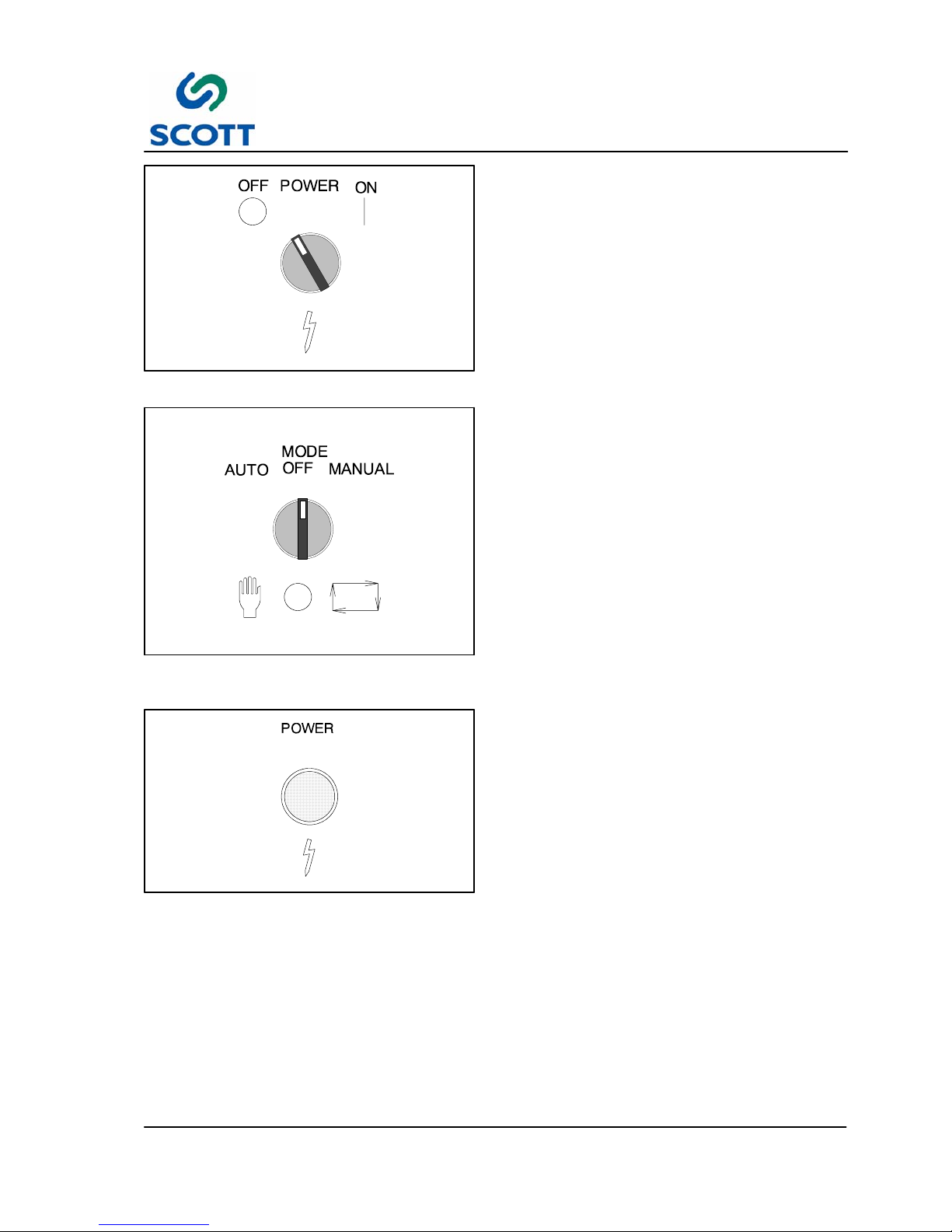

Fig. 3-3. Power On/OFF Selector Switch

3.2.2 Power On/OFF Selector Switch

OFF -- Turns Power off to the machine.

ON -- Brings Power to the machine.

Fig. 3-4. Machine Mode Selector Switch

3.2.3 Machine Mode Selector Switch

This selector switch determines the operational

mode of the machine.

AUTO -- When the selector switch is in the Auto

mode, the tab laminating function will operate

when a sheet is inserted into the platen area. By

inserting a sheet into the platen area, contact is

made with a switch which will laminate one tab.

OFF -- Tab laminating cannot be activated in this

mode. This is the standby mode.

MANUAL -- When the switch is in this position, the

switch in platen area is bypassed allowing the tab

laminating operation to be performed using the foot

pedal.

Fig. 3-5. Power On Indicator Lamp

3.2.4 Power On Indicator Lamp

Lamp is illuminated when power (power switch in

ON position) is on.

Page 28

3 Operation

3--6

Scott 1800 Issue 1

Fig. 3-6. Operator’s Foot Pedal

3.2.5 Foot Pedal

The foot pedal is used by the operator to activate

the tab laminating function.

NOTE! Machine Mode switch must be in the

Manual position to operate by foot

pedal.

Fig. 3-7. Main Air

3.2.6 Main Air ON/OFF

Slide the quick disconnect up to allow air to the

machine or down to shut it off.

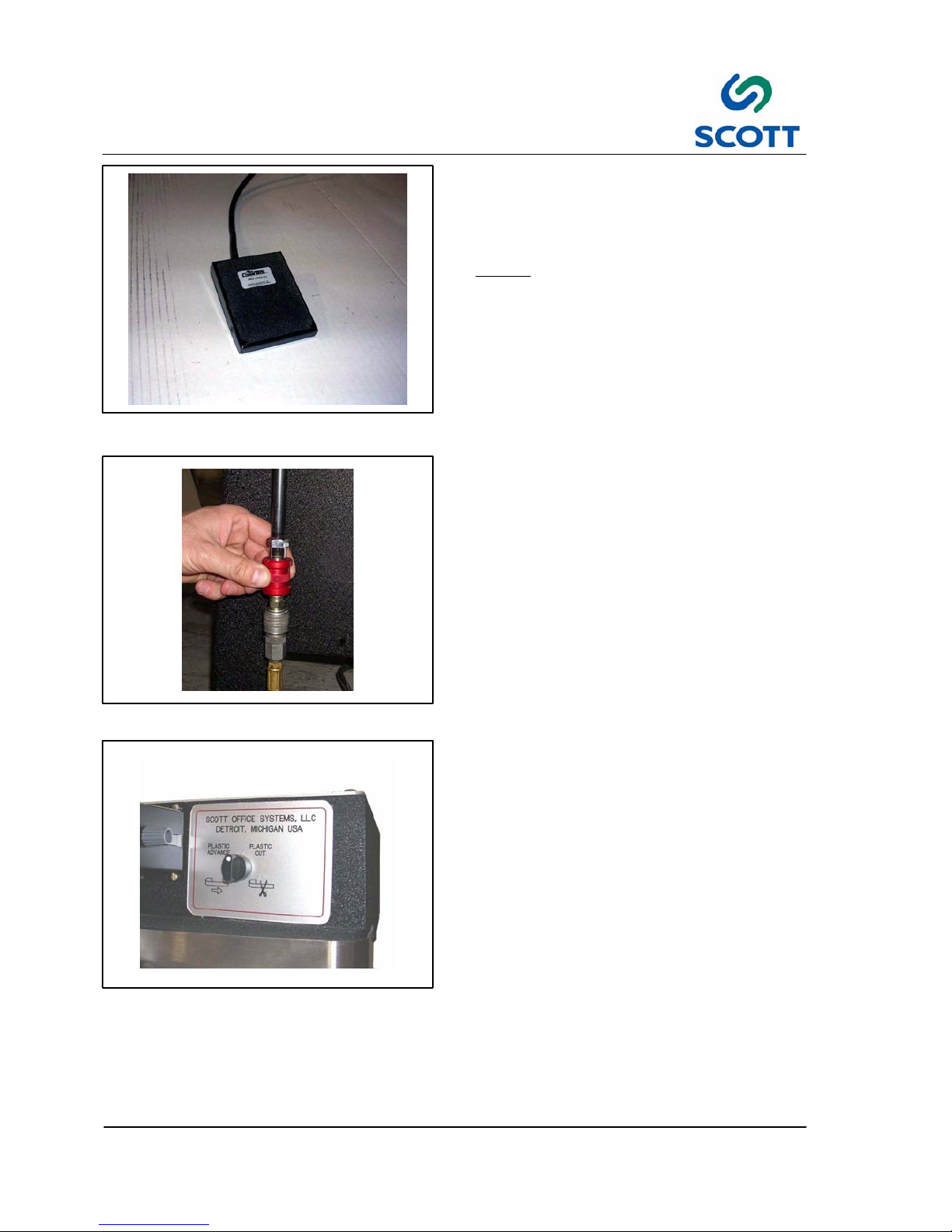

Fig. 3-8. Plastic Advance & Cut Selector Switch

3.2.7 Plastic Advance/Cut Switch

This switch allows plastic to be advanced and cut

manually.

Plastic Advance -- Manually feeds plastic into the

punch and die area.

Plastic Cut -- Activates the punch to cut the

plastic.

Page 29

3 Operation

3--7

Scott 1800 Issue 1

Fig. 3-9. Production Sheet Counter

3.2.8 Production Sheet Counter

Can be reset at any time to keep track of sheets

run.

PROCESS VALUE

SCROLL KEY

RETURN KEY

SET

VAL UE

CON:

Control

Output

ALM:

Alarm

Output

Fig. 3-10. Heater Temperature Control

3.2.9 Machine Heater Controls

Controls the upper and lower platen temperatures

by cycling power to the heaters. The setpoint

temperature is adjusted by using the buttons below

the indicator display.

The controller maintains process parameters when

power is off.

Touch Keys Description Function

Scroll Key Advances the index display to the desired position.

Indexes advanced continuously and cyclically by

pressing this keypad.

Up Key Increases the parameter (Set Point or Other)

Down Key Decreases the parameter (Set Point or Other)

Return Key Resets the controller to its normal status. Also stops

auto--tuning, output percentage monitoring and

manual mode operation.

Press for 6 seconds

Long Scroll Allows more parameters to be inspected or

changed.

Press for 6 seconds

Long Return 1. Executes auto--tuning function.

2. Calibrates control when in calibration level.

Press and

Output Percentage

Monitoring

Allows the set point display to indicate the control

output value in percent.

Press and

for 6 seconds

Manual Mode Execution Allows the controller to enter the manual mode.

This can be used if the sensor fails.

Page 30

3 Operation

3--8

Scott 1800 Issue 1

Fig. 3-11. Plastic Feed and Punch Timers

3.2.10 Machine Timers

Controls the operation of the air valves which

control the operation of the Press and Plastic feed

cylinders as well as the Punch.

Page 31

3 Operation

3--9

Scott 1800 Issue 1

3.3 Omron Timer Setting Instructions

The Omron H3CA Solid--State timers in your Scott 1800 Index T ab Machine control the operation of the air

valves which in turn control the operation of the Press and Plastic feed cylinders as well as the Punch to cut

the plastic. These timers have a wide variety of settings but only a few that are useful to you in the operation

of the machine. Because of the versatility of the timers, and the wide range of time cycles that are offered,

you must make sure that the timers are set within the narrow bandwidth that is useful in the operation of your

Scott 1800.

The two timer units are located on the front of the machine above the Operator’s controls. The one on the

top, controls the Press and Plastic feed cylinders. The normal setting for this timer is as follows:

E

0 0 6 0.1/s

The letters and numbers are set by pushing on the buttons above and below each of the five windows on the

timer. By pressing the button above the window, the letter or number will decrease in value. By pressing the

button below the window, the letter or number will increase in value.

A display at the top of the timers shows what state the timer is in by indicating whether the output is on or off

and how much time is remaining left in the cycle that has been chosen. You will notice that when the

machine goes through its cycle, the display changes rapidly as the machine feeds plastic and then cuts the

piece that was just feed.

Of course, you must also make sure that the lower timer is set to the correct setting. This timer controls the

punch going down to cut the plastic and then returning to its up position. The proper setting for this timer is

as follows:

F

0 0 1 0.1/s

Any other setting than this is generally not acceptable in the operation of the machine. This is the shortest

time possible for the punch to be delayed after the paper has been removed from the machine before it

comes down to cut the plastic. The setting also indicates the amount of time that the punch will be in the

down position. What this translates to is a total time cycle of the punch of twice the indicated time setting, or

in this case, .2 seconds.

The three windows in the middle of the timer will indicate how long the timer is set for. As in the case of the

left timer, when the paper is placed into the machine, the timer will be activated for .6 seconds. During this

time the press cylinder will close the platens on the paper and seal the plastic to it. At the same time, the

feed cylinder will feed out another piece of plastic underneath the sheet that is being laminated. The time of

this timer can be increased to as great as 13/10ths of a second which compares with the original timer in the

older 1800 machines. The setting of 013 on the left timer, and 001 on the right timer will give you a machine

cycle time of 1.5 seconds total duration. This means the operating rate of the machine is 2400 sheets per

hour. With a setting of 006 and 001 (left and right timers respectively), you will have a machine operating rate

of .8 seconds per cycle or 4500 sheets per hour. You will have to decrease the time of the left timer in order

to run plastic lengths of a longer size. This is due to inconsistencies in the plastic length developed by the

faster operation of the machine. Also, the faster you run the machine, the more heat you will need in order to

get a good seal. Keep the heat as low as possible as you can though.

TIMER SETTINGS

PRESS/PLASTIC FEED TIMER PUNCH TIMER

FAST E 0 0 6 0.1/s F 0 0 1 0.1/s

SLOW E 0 1 3 0.1/s F 0 0 1 0.1/s

Page 32

3 Operation

3--10

Scott 1800 Issue 1

3.4 Scott 1800 Frequently Asked Questions

When the plastic is put through your Scott 1800, the heated platens melt the adhesive and bonds it to the

pores of the paper. The adhesive “sets”, giving it a good bond.

Q -- Are there differences in the bonding ability of various paper stocks?

Q -- Why are some papers better for bonding than others?

A-- Because of the construction and the openness of the pores varies. If the pores are closed, the bond will

be poor. If the pores are too open, such as blotter paper, they will not allow a good bond. All papers bond

differently although it is not usually noticeable. Even one side of the paper bonds better than the other since

the paper always has a different construction on each side.

Q -- What are the best bonding papers?

A -- The best are 100% sulfite stocks. A very good bonding paper is 32 lb. and 36 lb. Ledger.

Many index tab producers use this.

Q -- What papers may cause poor bonding?

● Rag content papers

● Coated paper stocks

● Some papers with overall printing

● Varnished papers

● Very close grained smooth paper stocks

● V ery coarse grained stocks

Q -- Why is bonding usually better in summer than winter?

A -- Because in the winter the humidity is low in heated plants. If the plant does not have humidity control, the

paper is dry and the pores have closed. In the summer, the paper picks up moisture and as it swells, the

pores open.

To test if there will be a bonding problem due to humidity: Slightly dampen the sheet and then laminate. Just

a very small amount of dampness is needed. Usually the difference in humidity will not affect the bond

seriously on the “good--bonding stocks” but becomes quite apparent on those which are marginal, such as

rag content paper, etc.

Q -- How to avoid problems?

A -- Always check the first few index tabs before each production run. . This is especially important for the

trade binder who gets all types of paper stocks from their printer customers.

Q -- Which way should the grain of the paper run for best bonding?

A -- For best results, the grain should be parallel to the binding edge of the sheet, on an 11 x 8--1/2” sheet,

the grain should be the 11” way. When a tab is laminated across the grain, it may warp slightly.

Page 33

3 Operation

3--11

Scott 1800 Issue 1

3.5 Tab Bank Layout (Method 1)

Choose a scale to allow you to divide the sheet into equal tab sizes. This example shows the page divided

into nine equal tabs. By changing the angle of the ruler, you can establish any number of tabs on any size

sheet of paper.

The following procedure will allow you to divide any size sheet into any number of equal size tabs.

Step: 1. First, draw two parallel lines, one at the top and one at the bottom of the paper. On an eleven inch

sheet, you will usually provide a half inch margin on both sides of the paper. These are the top and

bottom lines on the illustration attached.

Step: 2. Place a ruler across these two lines.

Step: 3. Use the lowest number on the ruler on one line and any number on the ruler which will easily divide

evenly into the number of divisions you want on the other line. The angle of the ruler is not

important.

Step: 4. Place a mark on the sheet at each division that equally divides the sheet.

For example, using an 11” sheet, if you wish to divide the sheet into 12 equal tabs, place the 0 on

one line and the 12 on the other. You use the twelve because it is a convenient unit to divide the

sheet into twelve equal parts by placing a mark at each of the inch markings.

Page 34

3 Operation

3--12

Scott 1800 Issue 1

1/2” MARGIN

1/2” MARGIN

PLASTIC

3/8”3/8”

Fig. 3-12. Method to Evenly Divide Sheet for Tabs

Above (Fig. 3-12. ) is another example.

The sheet is divided into nine equal tabs. By placing the zero on one side and the nine on the other, you are

able to make nine tabs. You will notice that this is not a standard inch ruler. Y ou may use any ruler that has

evenly divided scales that will allow you to easily divide the sheet into the number of tabs you want.

Continue the layout sheet by drawing lines up to the tab side of the sheet from the marks you made. You

may use a plastic triangle with one edge of the triangle against the edge of the sheet, or set the sheet up on

a light table or drafting table to make sure that the lines are equally spaced. The more care you take with the

layout sheet, the more accurate your tabs will be.

The lines drawn from the marks to the tab side of the paper represent the tab size. This is the space required

to make the tab, and all of the text or graphics must fit into this area. If you are plastic laminating your tab,

you will need to make the plastic size an additional 3/4” greater than the tab size. Measure the distance

between the two lines that represent the tab, and then add 3/4” for the plastic tab.

Page 35

3 Operation

3--13

Scott 1800 Issue 1

3.6 Index Tab Set--Up Procedure (Method 2)

Step: 1. Make a layout sheet of the job to be laminated. Use either the preset tab sizes or angle rule

method.

Step: 2. From your layout sheet, determine the size of the finished tab. Add an additional 3/4” for the plastic

size (3/8” on each side of the tab).

Fig. 3-13. Set Left Guide to Plastic Size

Step: 3. Set the left gauge to the plastic size you

want to produce. With the Plastic

Advance/Cut toggle switch on instrument

panel, feed one piece of plastic making

sure you hold the toggle feed switch long

enough so that it will feed a full length of

plastic.

Step: 4. Cut the piece by turning the switch

toward the Cut side.

Fig. 3-14. Compare to Layout Sheet

Step: 5. Take the piece of plastic out of the

machine and compare its size to that on

the layout sheet. Adjust the plastic size

gauge if the plastic is not exactly what

you wanted.

Page 36

3 Operation

3--14

Scott 1800 Issue 1

Fig. 3-15. Set Right Hand Guide to Same as Left

Hand Guide

Step: 6. After the correct plastic size has been

obtained, set the right hand gauge to the

same reading as the left hand gauge. For

example, if you are making a 3” piece of

plastic, both the left hand and right hand

gauges should be set at 3”. The right

hand gauge centers the press on the size

you are making and insures that it will be

properly sealed.

Fig. 3-16. Set Plastic Stop

Step: 7. Use the “Plastic Advance/Cut” switch to

manually feed one piece of plastic

without cutting the plastic at this time.

Step: 8. Take the Plastic Stop Guide and position

it on the bar by moving it so that it just

touches the edge of the uncut piece of

plastic.

Step: 9. Back the Plastic Stop Guide away from

the plastic by 1/32”. This insures that you

will have good plastic registration on your

index tab sheet.

A

B

Fig. 3-17. Align G uide with Tab Edge Mark

Step: 10.Use the “Plastic Advance/Cut” switch to

cut the plastic. Leave the cut piece of

plastic in the machine.

You will repeat the following steps as

often as necessary for each of the tab

positions.

Step: 11.Set the Paper Side Guide by using the

layout sheet or by approximating the

position you wish to apply the plastic to

the paper.

Step: 12.With your layout sheet, line up the mark

that indicates the left edge of the

laminated tab (A) with the notch (B) in the

guide that guides the paper into the

sealing area.

Step: 13.The guide height should be set just below

the punch when it is fully retracted.

Page 37

3 Operation

3--15

Scott 1800 Issue 1

B

Fig. 3-18. Move Paper Guide to Contact Edge of

Paper

Step: 14.Move the Paper Side Guide (C) into

contact with the paper’s left side.

Step: 15.Lock the Paper Side Guide on the bar.

Be sure the Paper Side Guide is locked

squarely onto the bar.

Step: 16.Attach the remaining Paper Tray

Supports to the bar between the Plastic

Stop Guide and the Paper Side Guide.

Fig. 3-19. Insert Paper In Laminating Area

Step: 17.Set the cycle switch to “Auto”.

Step: 18.Using a piece of paper the same size as

the job to be laminated, insert the paper

into the machine to apply the plastic to

the tab area.

Fig. 3-20. Compare Tab with Layout Sheet

Step: 19.Compare this with your layout. Adjust the

Paper Side Guide as necessary.

Page 38

3 Operation

3--16

Scott 1800 Issue 1

Fig. 3-21. Laminate Sheets

Step: 20.After the desired position has been

obtained, laminate all the sheets for this

position of your job.

Step: 21.Repeat steps 10 to 16 until finished.

Page 39

3 Operation

3--17

Scott 1800 Issue 1

Fig. 3-22. Flow Control Valves

3.7 Flow Control Valve Setting

The Scott 1800 has incorporated two flow control

valves to help regulate the plastic piece size

consistency. These two valves adjust the stroke

speed of the plastic feed cylinder to assure an

even stroke in and out to give you consistent

plastic piece size with a variance of no greater than

1/32nd of an inch.

There are two main reasons for the plastic pieces

not to be of uniform length. The first reason is that

the flow control valves are improperly adjusted.

The second reason is an inadequate amount of

brake pressure being applied to the upper feed

roller.

When the flow control valves are improperly

adjusted, the plastic piece size tends to be shorter

than the desired length. When the breaking

pressure on the upper plastic feed roller is

inadequate, the plastic pieces tend to be longer

than the desired length.

Fig. 3-23. Upper Brake is Located Under Gear

Guard

3.7.1 Change or Clean Upper Braking

To correct plastic size that is too long:

It is necessary to change or clean the upper feed

roller braking fiber and the surface that the brake

rides against.

The following are the steps for cleaning and/or

changing the braking fiber on the upper plastic

feed roller.

Page 40

3 Operation

3--18

Scott 1800 Issue 1

Fig. 3-24. Remove Guard

Step: 1. Remove the gear guard.

Fig. 3-25. Remove Screw on Shaft

Step: 2. Remove the screw on the end of the

shaft.

Step: 3. Remove the washer, spring, and the

second washer if there is one on your

assembly.

Fig. 3 -26. Remove Fiber Brake

Step: 4. Remove the fiber brake assembly.

Step: 5. Inspect the brake assembly.

If there is oil or grease on the brake fiber,

remove it with sand paper. Wait for about

five minutes to see if any more oil will

reappear on the surface of the fiber.

Sand again if more does.

If the oil persists, the replacement of the

brake is necessary.

Page 41

3 Operation

3--19

Scott 1800 Issue 1

Fig. 3-27. Clean Surface of Roller

Step: 6. Inspect and clean the surface of the

upper plastic feed roller that the brake

rides against.

Step: 7. Remove all grease and oil that may be

on this surface.

Step: 8. Reassemble the brake assembly to the

plastic feed roller by reversing steps 1, 2,

and 3.

Step: 9. Make sure that the upper feed roller has

resistance when turned after it has been

reassembled.

NOTE! If the roller turns too freely, you may

need to add on additional washer to

increase the brake pressure.

A B

Fig. 3-28. Flow Control Valves

3.7.2 Setting Flow Control Valves

Next are the steps to set the flow control valves. It

is important that you are able to hear the cylinder

as it goes outward and hits the stop which gives

you the plastic length (the left hand adjustment for

the plastic piece size).

The stroke of the cylinder should be set as slow as

possible so that it will go out to the stop, then stop

at the stop, and return to its rest position within the

cycle time of the machine. The return stroke will be

set a little faster than the out going stroke, but both

should be set as slow as possible yet fast enough

for them to complete their job.

The flow control valves are located underneath the

lower casting, on the press cylinder. The flow

control valve (A) on the left, controls the outgoing

stroke speed. The flow control valve (B) on the

right controls the return stroke speed. These

valves may differ on different machines but all of

them operate on the same principal. The speed of

the stroke is made faster by turning the valve

counter--clockwise and slowed down by turning the

valve clockwise.

Different valves lock the adjustments in different

ways. Be sure to lock the adjustment in place after

you are satisfied with the results.

Page 42

3 Operation

3--20

Scott 1800 Issue 1

Fig. 3-29. Set Plastic Piece Size to 5--1/2 Inches

Step: 1. Set the plastic piece size to 5--1/2 inches.

Step: 2. Remove the plastic from the machine.

Step: 3. Cycle the machine through one time

while watching and listening to the stroke

of the cylinder.

A

Fig. 3-30. Adjust Stroke Valve

Step: 4. Adjust the left (A) flow control valve to

where you can just hear the cylinder hit

the stop on its outgoing stroke.

Step: 5. Cycle the machine through a few times in

a row. Listen for the cylinder hitting the

stop on the outgoing stroke. If it sounds

as if it is hitting harder on the second and

third stroke, open the valve about 1/4

turn.

Step: 6. Cycle the machine through again and

watch the return stroke of the cylinder.

B

Fig. 3-31. Adjust Return Valve

Step: 7. Adjust the right (B) flow control valve so

that the cylinder comes back and seats

itself against the stop before you can

begin the next cycle. Its return speed

should be a little faster than the outgoing

stroke speed.

Page 43

3 Operation

3--21

Scott 1800 Issue 1

3.7.3 Testing Flow Control Settings

Step: 1. Thread plastic into the machine and manually feed it forward.

Step: 2. Cycle the machine through three or four times and compare the plastic pieces. Keep the pieces in

order as you cycled them through.

a. If all the pieces are the same size except the first piece, and the first piece is shorter, open the left

flow control valve by a slight amount. Repeat as necessary.

b. If each succeeding piece is longer than the preceding piece, open up the right flow control valve 1/8

turn and try again.

c. If each succeeding piece is still longer after you have executed setting above , make sure that the

cylinder is hitting the stop on the outgoing stroke (open left valve to increase speed of the outgoing

stroke).

d. If the plastic sizes seem to vary randomly in length, check the upper plastic feed roller brake

assembly and start over from Step 1.

If the above steps cannot help you after repeating them a couple of times, there may be further problems.

Contact

Page 44

4 Maintenance

4--1

Scott 1800 Issue 1

4 MAINTENANCE

Scott 1800 Issue 1

Page 45

4 Maintenance

4--2

Scott 1800 Issue 1

Page 46

4 Maintenance

4--3

Scott 1800 Issue 1

Fig. 4-1. Punch and Die Assembly

4.1 Punch and Die Setting

Instructions

The Punch and Die set is the heart of the machine

and will need to be sharpened on occasion.

This will necessitate the removal of various

components in order to remove the Punch and Die

set for sharpening. It is also necessary that the

Punch and Die set be reinstalled properly so that

you will decrease your down time and reduce your

sharpening cost.

Note !Preheat the machine for 2 hours prior to

setting the punch and die to allow for

proper operating clearances.

Note !If you have just received your machine,

or have just moved it from one

location to another, it will be

necessary to check the Punch and Die

set to make sure that they are cutting

correctly and are not hitting each

other.

Fig. 4-2. Remove Paper Trays

4.1.1 Punch & Die Removal

The following is the procedure for the removal and

reinstallation of the Punch and Die set.

Note !Make sure that Main Air Supply is off

before making adjustments the

machine.

Step: 1. Turn off the air supply to the machine.

Step: 2. Remove the Paper Trays.

Page 47

4 Maintenance

4--4

Scott 1800 Issue 1

Fig. 4-3. Remove the Cylinder Guard

Step: 3. Remove the Cylinder Guard.

Fig. 4-4. Remove the Chip Chute Deflector

Step: 4. Remove the Chip Chute Deflector.

Fig. 4-5. Remove the Punch Assembly Guards

Step: 5. Remove the three Punch Assembly

Guards.

Page 48

4 Maintenance

4--5

Scott 1800 Issue 1

Fig. 4-6. Remove the Tunnel Cover

Step: 6. Remove the Tunnel Cover.

Fig. 4-7. Remove the Guide Spring

Step: 7. Remove the Guide Spring.

Page 49

4 Maintenance

4--6

Scott 1800 Issue 1

Fig. 4-8. Remove Plastic Guide -- Keep Shims

with Guide

Step: 8. Remove the plastic opener springs.

Step: 9. Reattach hardware to opener and shim

stack to keep shim with opener.

Note !There may or may not be shims that

were used in the set up of this part.

Keep shim stack with particular

opener spring. (ie. Keep RH shim

stack with RH opener)

Fig. 4-9. Remove Punch Cap

Step: 10.To remove the punch cap, remove two of

the screws diagonally opposing each

other.

Step: 11.Remove the remaining two screws

keeping the end cap level as you remove

the screws.

Page 50

4 Maintenance

4--7

Scott 1800 Issue 1

Fig. 4-10. Remove Punch Springs

Step: 12.Remove the long spring from inside the

Punch. There is an additional shorter

spring inside the Punch which you may

or may not want to remove.

Fig. 4-11. Remove Punch

Step: 13.Insert a finger into the hole of the Punch

and pull the punch straight up and out of

the cylinder.

CAUTION

! Do not use anything metallic in

helping to remove the Punch. If you

are unable to remove the Punch by

pulling it straight up, try applying

about 20 P.S.I. of air pressure to the

machine. This will help you to pull the

punch out of the cylinder. If you still

can’t remove the punch proceed to

Step: 16. and then repeat this step.

Page 51

4 Maintenance

4--8

Scott 1800 Issue 1

A

B

Fig. 4-12. Remove Piston Packing and O --Ring

Step: 14.Remove Piston Packing (A) and O Ring

(B).

You may need a small thin blade screw

driver to assist you in their removal.

Fig. 4-13. Remove the Plastic Guide In Front of

the Dies

Step: 15.Remove the plastic guide that is in front

of the dies.

Note !Be careful not to loose the small

springs in the guide.

Page 52

4 Maintenance

4--9

Scott 1800 Issue 1

C

D

Fig. 4-14. Remove the Dies

Step: 16.Remove the four screws (C) holding the

two dies (D) to the lower casting. The

screws are located underneath the lower

casting.

Step: 17.Remove the two dies.

Fig. 4-15. Inspect the Punch and Dies

Step: 18.Inspect the Punch and Dies to make sure

that the cutting edges are not nicked,

scratched, or rounded off.

If so, they will need to be sharpened

before they are reinstalled into your

machine.

If you will also examine the Punch you will notice

that the cutting edge of the punch is angled. The

back edge away from the radius is higher. This is

important in the setting of the proper height of the

punch when you go to set the dies.

Page 53

4 Maintenance

4--10

Scott 1800 Issue 1

F

E

Fig. 4-16. Differences Between Left and Right

Guide

You will notice if you lay both of the dies next to

each other that there is a difference between the

left (E) and right (F) die. The obvious difference is

in the appearance of the dies themselves. The left

die is the one that has the beveled edge on the

one side.

You will also notice that the right die is shorter than

the left die by about .025 inch. This is to allow the

plastic to flow from the left die to the right die

without jamming.

Page 54

4 Maintenance

4--11

Scott 1800 Issue 1

4.1.2 Reinstallation Punch & Die

The following is the procedure to reinstall the Punch and Die set. There are four main steps in the setting of

the Punch and Dies. The first one is to make sure that the punch, dies, and the die pocket are free from any

oil, plastic, or any other foreign matter. Number two is to set the side guide against the punch so that it will

not have any radial (twisting) motion as it goes into the dies. The last two steps are to set the right die first

and the left die last.

A

B

Fig. 4-17. Loosen Screws and Set Punch Guide

4.1.2.1 Setting Punch Side Guide

Step: 1. Make sure the die pocket, the punch and

dies, and all the relating parts are clean.

Step: 2. To adjust the guide, loosen the two

screws (A) and push the guide sideways

into the punch (B) and tighten the two

screws.

Note !There should be enough resistance

from the guide into the punch that the

punch cannot fall to the bottom of the

cylinder under its own weight.

The guide should be set tight enough so that you

cannot twist the punch sideways, yet loose enough

so that you are able to move the punch up and

down in the cylinder.

If pushing the guide in and tightening down the

screws does not allow the guide to get close

enough to the punch to keep it from twisting, then

you will have to leave the screws tight and lightly

tap on the right edge of the guide to bring it closer

to the punch to keep it from turning. The screws

are left tight so that the guide will not bounce away

from the punch. If the guide is too tight, start again.

Caution ! It is very important that the punch not have any radial movement when it enters the dies.

Severe damage may result to the punch and/or the dies. Make sure when you are setting the

side guide that the radius of the punch is facing toward you as you face the machine.

Page 55

4 Maintenance

4--12

Scott 1800 Issue 1

Fig. 4-18. Place the RH Die in the Pocket

4.1.2.2 Setting Right Hand Die

After the side guide is properly set, the next step is

to set the right side die. You will need a screwdriver

with a small blade and about a six inch or longer

shank. You will also need a 3/16th Allen wrench

and some Mylar to check the cutting.

Step: 1. Remove the punch from the Punch

Cylinder to give you room to put the die

into the pocket.

Step: 2. Place the right die in the die pocket on

the right side with the radius of the die

toward you on the left hand side.

Step: 3. Put the washers over the screws and put

the screws into the die from underneath

the lower casting. Do not tighten the

screws at this time.

Step: 4. Push the die toward the back right corner

of the die pocket.

The die may be maneuvered by using your left

hand to move the screws underneath the casting

and by placing the blade of the screwdriver into the

screw hole of the die with your right hand and

moving them both simultaneously.

CAUTION

! Be careful not to let the screwdriver

come into contact with the cutting

edge of the punch or the die. Severe

damage could result.

Fig. 4-19. Insert Punch Into the Cylinder

Step: 5. Insert the punch into the cylinder and

position it so that the radius is facing

toward you.

Step: 6. Push the punch down so that it appears

out of the bottom of the cylinder. Be sure

that the punch does not hit the die as it

comes out of the cylinder.

Page 56

4 Maintenance

4--13

Scott 1800 Issue 1

Fig. 4-20. Punch Height Should Be Slightly

Above Edge of Die (Shown Out of Place)

Step: 7. Position the height of the punch so that

the back cutting edge is just below the

top of the die. This is know as the “Punch

setting position”.

Note !Punch and Die shown removed from

punch cylinder for clarity.

Fig. 4-21. Set Die to Punch (Shown Out of

Place)

Step: 8. Set the die to the punch. This is

accomplished by positioning the die so

that the edges of both the punch and die

are up against each other.

Page 57

4 Maintenance

4--14

Scott 1800 Issue 1

Fig. 4-22. Use a Screw Driver to Hold Die in

Position

Step: 9. Carefully place the flat part of the

screwdriver blade onto the center of the

die between the two screw holes. Place

the shank of the screwdriver up against

the bottom part of the upper casting. Use

the screwdriver to hold the die down

against the bottom of the lower casting at

all times during the tightening of the

screws. If the die moves when you place

the screwdriver on top of the die, go back

to step eight and then continue.

Step: 10.Hand tighten the two screws that hold the

dieinplace.

Step: 11.While keeping the die clamped down,

carefully begin tightening the screws with

the Allen wrench. Y ou should work back

and forth between the two screws

keeping the torque as even as possible.

Note !To over tighten one screw more than the

other can cause the die to twist and

will either make the punch hit the die,

or keep it from cutting.

Step: 12.After the screws are tight, remove the

screwdriver.

Fig. 4 -23. Carefully Lift and Slowly Lower

Punch

Step: 13.Carefully lift the punch up above the die

and bring it SLOWLY back down to the

bottom of its stroke. If the punch hits or

rubs against the die, you will need to

reset the die again. This means going

backtostep8.

As long as the punch is not hitting the die on the

downward stroke, you are now ready to see if it will

cut the Mylar.

Page 58

4 Maintenance

4--15

Scott 1800 Issue 1

Fig. 4-24. Test Punch to See if will Cut Mylar

Step: 1. Place a piece of Mylar film over the top of

the die. Make sure that the plastic is not

folded in half.

Step: 2. With the Mylar over the die, bring the

punch down to see if it will cut the Mylar.

The punch should pass through the Mylar

with little or no difficulty.

If it is hard to push the punch through the

plastic, you will need to reset the die. Go

to step eight above.

Fig. 4-25. Tighten Mounting Screws If Cut is

Clean

Step: 3. If the plastic is cut cleanly, you should

make sure that the die is clamped down

tight so that it will not move in normal

operation.

Step: 4. After you have checked the die to make

sure the screws are tight, recheck the

cutting ability of the die and make sure

that the punch doesn’t hit the die.

Fig. 4-26. Set Left Hand Die

4.1.3 Setting Left Hand Die

After you have made sure that the right die is

cutting properly, it is time to set the left die. The

procedure is the same as the right die except in

this case you may use your hand to clamp the die

in place as it is being tightened down instead of

using a screwdriver. Make sure that you are

keeping the die clamped down at all times as you

are tightening the screws.

Note !Lift the Punch clear of the cutting area

before setting the left die.

After both dies are set and are properly cutting, it is

time to reassemble all of the parts removed.

Basically you will reverse the order of the first

sixteen steps in these instructions.

Page 59

4 Maintenance

4--16

Scott 1800 Issue 1

Fig. 4-27. Remove Punch From Cylinder

4.1.4 Reinstalling the Punch

Make sure that the piston packing and the 0--ring

are lubricated as well as the upper cylinder that the

punch fits into.

The following is the reinstallation procedure:

Step: 1. Remove the punch from the cylinder.

A

Fig. 4-28. Reinstall the Plastic Guide

Step: 2. Install the plastic guide (A) in front of the

dies. To replace this piece, position the

guide so that the springs are at the

bottom of the guide. Angle the left side of

the guide toward the inside of the

casting, and the right side going toward

the right die. Compress the spring and

slide the guide pocket. Slide the left side

of the guide between the left die and the

front part of the pocket. Make sure that

when the punch is brought down, the

cutout is equally centered on each side of

the punch.

Page 60

4 Maintenance

4--17

Scott 1800 Issue 1

A

B

B

A

Fig. 4-29. Mylar Openers Must Not Be In the

Cutting Area

Step: 3. Place the left and right Mylar opener

springs in their respective locations.

Note !Make sure that the openers do not

extend past the cutting edges of the

dies. By looking through the top of the

punch cylinder, you can observe the

position of the openers in relation to

the dies. They should follow the

contour of the d ies as close as

possible, but not go past the cutting

edge at any time.

Fig. 4-30. Replace the Plastic Guide Spring

Step: 4. Replace the plastic guide spring in the

plastic feed tunnel. With a piece of plastic

folded in half, make sure that the spring

just touches the folded edge of the

plastic.

Page 61

4 Maintenance

4--18

Scott 1800 Issue 1

Fig. 4-31. Replace O--Ring and Piston Packing

onto the Punch

Step: 5. Replace the o--ring and the piston

packing onto the punch. Make sure that

the veins of the packing are pointing

toward the o--ring which is installed near

the cutting edge of the punch.

Step: 6. Apply oil to the packing and the o--ring.

Fig. 4 -32. Apply Oil to Punch Cylinder

Step: 7. Apply oil to the upper punch cylinder

area.

Step: 8. Insert the punch into the cylinder. Use a

thin blade screwdriver to start the piston

packing into the cylinder.

Step: 9. Push the punch to the bottom of its

stroke.

Step: 10.Apply a small amount of oil to the upper

cylinder bushing.

Page 62

4 Maintenance

4--19

Scott 1800 Issue 1

Fig. 4-33. Reinstall the Springs into the Punch

Step: 11.Reinstall the two springs into the punch,

the short spring first.

Fig. 4-34. Reinstall End Cap

Step: 12.Reinstall the end cap with the four

screws.

Page 63

4 Maintenance

4--20

Scott 1800 Issue 1

Fig. 4-35. Reinstall Tunnel Cover

Step: 13.Reinstall the tunnel cover.

Fig. 4-36. Reinstall Paper Guide

Step: 14.Reinstall the paper guide.

Fig. 4-37. Reinstall Chip Chute Deflector

Step: 15.Reinstall the Chip Chute Deflector

Page 64

4 Maintenance

4--21

Scott 1800 Issue 1

Fig. 4-38. Reinstall Lower Casting Guard

Step: 16.Replace the guard underneath the lower

casting.

Fig. 4 -39. Turn Main Air Supply On

Step: 17.Turn the air supply back on.

This completes the punch and die setting routine. If

there are any problems, contact a service

representative at Scott Office Systems

Page 65

4 Maintenance

4--22

Scott 1800 Issue 1

A

Fig. 4-40. Air Regulator and Lubricator

4.2 Care Of Air Cylinder

4.2.1 Lubrication

The lubricator atomizes oil into the air for the air

cylinders.

There are two air cylinders. One actuates the

Press Platen and other actuates the Plastic Feed

Punch.

There is very little that can go wrong with the air

cylinders if they are lubricated properly by the

lubricator (A).

The following will help you to determine if your

machine is being properly lubricated:

B

Fig. 4-41. Look for Slight Oil Accumulation on

Underside of Valve Muffler

● There should be a slight oil accumulation on the

exhaust valve’s muffler (B) This assembly is

located inside the cover.

C

Fig. 4-42. Lubricator

Note !Use Mobil “DTE - 24” oil o r equivalent

Light Weight Non- detergent Oil Only.

Use machine oil, spindle oil or mineral

oil only.

CAUTION

! DO NOT USE AUTOMOBILE OR

DETERGENT OILS.

With the oil feed clearly seen through the sight

dome (C) in the lubricator, it is possible to adjust

the oil feed to the proper amount of lubrication.

The principle of oil “misting” in conjunction with the

integral automatic by--pass valve, eliminates the

possibility of flooding the equipment.

Page 66

4 Maintenance

4--23

Scott 1800 Issue 1

D

Fig. 4-43. Adjustment Screw

The Oil Adjustment Screw (D) in the top head of

the lubricator unit may be opened for full flow

(counter--clockwise) or closed completely

(clockwise).

The adjustment screw is held captive by the

hold--down ring on the sight dome, preventing the

screw from being backed out all the way.

E

Fig. 4-44. Drain Air Regulator Reservoir

Regularly

4.2.1.1 Drain Air Regulator

Operation is entirely automatic and no adjustments

are necessary. To get effective performance, drain

reservoir (E) regularly.

CAUTION

! If Moisture Fills Reservoir Above

Lower Baffle, It May Be Carried Over

Into The Air Line.

Step: 1. To drain reservoir open drain valve on

filter base.

Page 67

4 Maintenance

4--24

Scott 1800 Issue 1

Fig. 4-45. Clean Air Cylinder Filter Regularly

4.2.1.2 Regulator Cleaning

CAUTION

! TURN OFF AIR BEFORE

DISASSEMBLING.

Step: 1. Unscrew filter base and lower baffle

assembly to remove reservoir and filter

element.

Step: 2. Rinse in petroleum solvent such as

kerosene.

CAUTION

! DO NOT USE ACETONE,

ETHYL- ACETATE, TOLUENE, ETC.

CAUTION

! NEVER EXPOSE PLASTIC BOWL

FILTERS OR LUBRICATORS TO

LUBRICATING OILS OR

COMPRESSOR LUBRICANTS

CONTAINING PHOSPHATE ESTERS.

Step: 3. Clean the plastic bowl units with

household soaps or detergents only.

(See service manual’s enclosed)

Step: 4. Blow out filter element with air hose.

CAUTION

! Use the proper oil in the machine. On the bowl you will see a label stating that you must

use Mobil “DTE- 24” oil or equivalent.

NEVER USE MOTOR OIL THIS WILL RUIN YOUR AIR CYLINDERS AND VALVES.

Fig. 4-46. Drain the Air Filter Bowl

Always drain the water from the air filter bowl.

CAUTION

! If you do not drain air filter bowl,

water and dirt will get into your

machine and ruin the cylinders and

valves.

CAUTION

! Never let the water get over the

baffle in the bowl. Do not let the oil get

below the intake in the bowl. For

adjustment of the oil flow, see the

instructions on the lubricator unit.

Page 68

4 Maintenance

4--25

Scott 1800 Issue 1

4.3 Scott 1800 Spare Parts List

The following are perishable parts. To avoid down--time Scott Office Systems recommend that you keep

them in stock in the quantities shown:

This is a list of all parts on the machine

Part Numbers Part Description Qty.

S--0150 Trip Switch 1

S--0030--SA Punch and Die Set 1

HW--80025 Tension Arm Spring 1

Page 69

4 Maintenance

4--26

Scott 1800 Issue 1

4.4 C01--1000 Series Filter -- Regulator Combination

4.4.1 Installation

Blow out line to remove foreign matter. Install unit with air flow entering port marked ”IN” or direction of flow

shown on head of unit. Mount in vertical position as close to equipment to be protected as possible. Unit has

dry seal pipe threads, use dope or tape sparingly on male threads only. WARNING: For use in industrial

compressed air systems only. Do not exceed recommended temperature and pressure. Polycarbonate bowl

units can be damaged and burst if exposed to solvents, strong alkalies, fire resistant and synthetic

compressor oils. Use metal bowl in all applications where a plastic bowl could come in contact internally or

externally with chemicals or lubricants incompatible with polycarbonate.

OPERATING SPECIFICATIONS BOWLS

MAX. RECOMMENDED PLASTIC METAL

TEMPERATURE 120_ F 200_ F

PRESSURE 150 PSI 250 PSI

4.4.2 Adjustment

Turning adjustment tee or knob clockwise increases secondary pressure. Adjust secondary pressure with

typical flow conditions (static setting will be slightly higher) and tighten lock nut. Regulator may have a slight

bleed out of bonnet relief hole. This will not affect operation.

4.4.3 Maintenance & Cleaning

A Repair Kit Should be on Hand Unit may be disassembled without removal from airline. SHUT OFF

AIRLINE. Bleed off airline until pressure gauge reads zero. Back off adjustment knob or screw until

compression spring is fully relieved. Refer to drawing as a guide in disassembly. Clean valve seat and

poppet, inspect for pitting, scoring, and roughness. Replace worn or doubtful parts. Filter bowl can be

cleaned with mild soap and water or kerosene. DO NOT USE ANY SOLVENTS. In reassembly, use drawing

as a guide. Do not over--tighten base nut as it shoulders on stud (50--60 lbs.).

ORDER PARTS FROM YOUR LOCAL MONNIER DISTRIBUTOR.

IF ANODIZED, PLEASE INDICATE COLOR.

4.4.4 Vendor Contact Information

Page 70

4 Maintenance

4--27

Scott 1800 Issue 1

Fig. 4-47. C01--1000 Series Filter--Regulator Combination

Page 71

4 Maintenance

4--28

Scott 1800 Issue 1

4.5 304--1000 & 2000 Series Lubricators

4.5.1 Installation

WARNING: For use in industrial compressed air systems only. Do not exceed recommended temperature

and pressure. Polycarbonate bowl units can be damaged and burst if exposed to solvents, strong alkalies,

fire resistant and synthetic compressor oils. Use metal bowl in all applications where a plastic bowl could

come in contact internally or externally with chemicals or lubricants incompatible with polycarbonate.

OPERATING SPECIFICATIONS BOWLS

MAX. RECOMMENDED PLASTIC METAL

TEMPERATURE 120_ F 200_ F

PRESSURE 150 PSI 250 PSI

Reservoir can be filled without turning off inlet supply pressure. Remove self--venting fill plug. Fill with good

grade of petroleum lubricating oil approximately 80 to 150 SSU at 100 F (SAE *5 or *10) to within 1/4” of top

of bowl. Unless temperature extremes are present, lighter oils may not wet out and heavier oils could cause

sluggish operation. Replace fill plug hand tight only.

4.5.2 Oil Adjustments

● Clockwise -- Decrease

● Counterclockwise -- Increase

Close oil needle adjustment by turning clockwise. With air flowing through unit, open oil needle adjustment

until you see approximately 2 drops of oil per minute in sight tube for each 20 SCFM. This will vary with air

flow, line pressure, devices lubricated and oil viscosity.

4.5.3 Tamper Proof

After final oil adjustment, unit can be made tamper proof by pressing tamper proof ball in top of sight dome.

TO REMOVE TAMPER PROOF BALL SHUT OFF AIR LINE and bleed off air by removing fill plug. Remove

sight dome assembly. Separate the inner and outer dome. Push tamperproof ball completely out of outer

dome from the inside. Reassemble dome assembly making sure oil adjust needle and small ”0” ring on

needle are assembled into inner dome. Push inner and outer domes together. Make sure ”0” ring, bottom of

inner dome and ”0” ring under hex of outer dome are in position. Reassemble dome assembly and fill plug.

Turn on air supply and follow oil adjustment instructions.

ORDER PARTS FROM YOUR LOCAL MONNIER DISTRIBUTOR. IF ANODIZED, PLEASE INDICATE

COLOR.

4.5.4 Maintenance

SHUT OFF AIR SUPPLY. Loosen oil fill plug to vent bowl. Bowl can now be removed by removing base nut

for cleaning with mild soap and water or kerosene. Do not use solvents, thinners or carbon tetrachloride. If

bowl seal remains in head, remove, inspect and replace if necessary. Open adjustment needle full

(counterclockwise). Use blow gun to blow air through oil pickup tube and sight dome assembly . To

reassemble unit make sure bowl seal is into head groove or on top of bowl. Position bowl in place and install

base nut with ”0” ring. Turn bowl slightly to make sure bowl centers into head groove. Do not attempt to over

tighten base nut as it shoulders on stud. Follow procedure for filling reservoir and oil adjustment.

Page 72

4 Maintenance

4--29

Scott 1800 Issue 1

Fig. 4-48. 304--1000 & 2000 Lubricators

4.5.5 Part Information

Bowl Kit Series

21557 1000

21558 1200

21559 P or T 1300

22520 P or T 2200

22521 P or T 2300

Suffix P--Polycarbonate

T--Trogamid

Seal Kit 21555

4.5.6 Vendor Contact Information

Page 73

5Parts

5-1

S99999-- 1Scott 1800 07/2005 Issue 1

5 PARTS

Scott 1800

S99999--1

07/2005 Issue 1

Page 74

5-2

5Parts

S99999-- 1Scott 1800 07/2005 Issue 1

SCOTT OFFICE SYSTEMS PARTS ORDERING INFORMATION

1. When corresponding or ordering parts from Scott Office Systems include complete Business Name, Street Ad-

dress, City, State, Country, Zip Code and Machine Serial Number.

2. Order by part number and description as shown in the manual.

3. Specify how shipments are to be made -- Freight, Parcel Post, or Express. If routing is not specified, we will use

our own judgement and not be responsible for the additional costs or delays.

4. Always confirm fax or phone orders by clearly marking “Confirmation”.

5. Address all correspondence to:

Page 75

5Parts

5-3

S99999-- 1Scott 1800 07/2005 Issue 1

PARTS RETURN

To enable us to handle credit efficiently and promptly, and to save our Customers unnecessary expense and delay, the

following procedures have been established.

1. Customers are requested not to return parts of any kind without first communicating by letter or telephone with the

Parts Service Department. We will advise what procedures to follow to expedite the issue of credit and the applicable

restocking charge. A Return Material Code Number indicating the authorization to return parts will be issued. NOTE:

Proof of purchase must be established before credit can be approved.

2. All shipments returned MUST contain a copy of the Invoice Number or Packing List that parts were received on and

the reason for return noted. Shipments may be refused if the above procedure is not followed.

3. No parts are to be returned without a Return Authorization Number issued by Parts Service.

4. Requests for credit of returned parts must contain Invoice Number and Date of Purchase.

5. Parts are to be returned “Prepaid”.

6. Parts shipped out over one (1) year cannot be accepted. Any parts for which an invoice (proof of purchase) cannot

be found, will not be accepted.

7. Return all Parts to:

8. Restocking charge is $25.00 or 10% whichever is greater.

9. Warranty Part Shipments -- Shipment of parts under warranty will be handled by U.P.S. Ground. Customer will incur

all shipping expenses by other than U.P.S. Ground.

Page 76

A

A

SECTION A -- A

5-4

5Parts

S99999-- 1Scott 1800 07/2005 Issue 1

5.1 Drag Roller Assembly

Page 77

5Parts

5.1 Drag Roller Assembly

5-5

S99999-- 1Scott 1800 07/2005 Issue 1

ITEM # PART # DESCRIPTION #REQ ITEM # PART # DESCRIPTION #REQ

1 S--0001 BODY 1

2 HW--81060 HANDLE, BALL 1

3 HW--52230 SCREW, SET, 1

4 HW--60080 NUT, HEX, 1

5 HW--79100 SPRING, COMPRESSION, 1

6 S--0060 BAR, TENSION 1

7

HW--51420 SCREW, SOC HD, 1

HW--49160 WASHER, FLAT 1

8 S--0051 SLEEVE, PIVOT 1

9 HW--60060 NUT, HEX, 1

10 HW--61220 GRIP RING, 1

11 S--0056 PLATE, PLASTIC FEED MTG. 1

12 HW--54090 SCREW, FLAT HD, 6

13 S--0058 FINGER, FOLDING 1

14 S--0054 PIN 1

15 S--0055 FINGER, FOLDING 1

16 HW--81070 KNOB, 2

17 HW--52150 SCREW, SET, 1

18 HW--79140 SPRING, COMPRESSION, 1

19 S--0053 SHAFT 1

20 HW--49060 WASHER, FLAT 2

21 HW--74060 ORING, 2

22 S--0059 ROLLER, DRAG 1

23 HW--67040 BEARING, NEEDLE, 2

24 HW--49090 WASHER, FLAT HARDEN, 2

25 S--0057 BAR 1

26 HW--52170 SCREW, SET, 1

Page 78

A

A

3

2

RCB--081214 JH--812

SECTION A -- A

5-6

5Parts

S99999-- 1Scott 1800 07/2005 Issue 1

5.2 Idle and Drive Feed Assembly

Page 79

5Parts

5.2 Idle and Drive Feed Assembly

5-7

S99999-- 1Scott 1800 07/2005 Issue 1

ITEM # PART # DESCRIPTION #REQ ITEM # PART # DESCRIPTION #REQ

1 HW--98030 COLLAR, 1

2 HW--66110 BEARING, BALL, 2

3 S--0305 SHAFT, PLASTIC FEED DRIVE 1

4 S--0124 SPUR GEAR 1

5 HW--57030 PIN, SPRING, 1

6 HW--67090 BEARING, NEEDLE, 1

7 S--0304 GEAR, ROLLER DRIVE FEED 1

8 HW--72020 BEARING, CLUTCH, 1

9 HW--61040 RING, RETAINING, 2

10 HW--52020 SCREW, SET, 1