Copy No.:

Instruction Manual

Model No. : Scott 10,000.................

Year of Manufacture : 2004.......

Manufactured by :..........

Document Number : C9999--2........

Issue : 1.....................

Date of Issue : August 2004..............

ISSUE NOTE

This is Issue 1; Date of Issue: August 2004

Copyright 2004

Table of Contents

III

C9999--2 Issue 1

TABLE OF CONTENTS

1 INTRODUCTION & SAFETY 1--1...........................................................

1.1 Introduction 1--3....................................................................

1.1.1 Scott 10,000 Machine Specifications and Utility Requirements 1--5......................

1.2 General Safety Guidelines 1--6.......................................................

1.3 Safety Features 1--7.................................................................

1.3.1 Emergency Stop 1--7.............................................................

1.3.2 Stop and Safe 1--7...............................................................

1.3.3 Main Power Switch 1--8...........................................................

1.3.4 Guards and Covers 1--8...........................................................

1.3.5 Safety Switches 1--8..............................................................

1.4 Warnings, Cautions & Notes 1--9.....................................................

1.4.1 Warnings 1--9....................................................................

1.4.2 Cautions 1--9....................................................................

1.4.3 Notes 1--9.......................................................................

1.5 On Machine Warnings 1--10...........................................................

1.5.1 Heat Hazards 1--10................................................................

1.5.2 Electrical Shock Hazards 1--10......................................................

1.6 Safety Procedures 1--11..............................................................

1.6.1 Safety Devices 1--11...............................................................

1.6.2 Appropriate Dress 1--11............................................................

1.6.3 Keep Area Clean 1--11.............................................................

1.6.4 Grease and Oil 1--11..............................................................

1.6.5 Manual Usage 1--11...............................................................

2 INSTALLATION 2--1......................................................................

2.1 Installation Requirements 2--3........................................................

2.2 Pre-Installation Requirements 2--4....................................................

2.3 Uncrating & Placement 2--5..........................................................

2.3.1 Crate 1 -- Main Machine 2--5.......................................................

2.3.2 Crate 2 -- Additional Assemblies 2--6................................................

2.3.3 Install Tab Cutter Unit 2--6.........................................................

2.3.4 Leveling the Machine 2--8.........................................................

2.3.5 Continue Assembling Machine 2--10.................................................

2.3.6 Install Cross Conveyor 2--15........................................................

2.3.7 Install Steel Balls 2--16.............................................................

2.3.8 Connect Vacuum Canister 2--17.....................................................

2.3.9 Install Vacuum Valve 2--17..........................................................

2.3.10 Install Paper Supports on Pile Feeder 2--18...........................................

2.4 Utility Connections 2--22..............................................................

2.4.1 Electrical Connections 2--22........................................................

Table of Contents

IV

C9999--2 Issue 1

3 OPERATION 3--1.........................................................................

3.1 GENERAL INFORMATION 3--3........................................................

3.1.1 Before Operating the Machine 3--3.................................................

3.2 Operating Controls and Indicators Descriptions 3--4...................................

3.2.1 Operator’s Control Panel Layout 3--4................................................

3.2.2 Machine Stopping Device 3--4.....................................................

3.2.3 Main Operator’s Panel Control Descriptions 3--5......................................

3.2.4 Telemecanique PLC Control 3--10...................................................

3.3 Preliminary Inspection and Start-Up Procedure 3--11....................................

3.3.1 Preliminary Set-Up 3--11...........................................................

3.3.2 Pile Feeder 3--13..................................................................

3.3.3 Adjusting the Reregister Unit 3--20...................................................

3.3.4 Machine Start--Up 3--23............................................................

3.3.5 Start-Up for Run 3--35.............................................................

3.4 Handwheel and Tab Set-Up 3-37..........................................................

3.4.1 Hand Wheel and Tab Set-Up Definitions 3-38.........................................

HANDWHEEL SET-UPS FOR 5” SHEET WITH 3/16” MARGINS 3-40...............................

HANDWHEEL SET-UPS FOR 6” SHEET WITH 3/16” MARGINS 3-41...............................

HANDWHEEL SET-UPS FOR 7-1/4” SHEET WITH 3/16” MARGINS 3-42...........................

HANDWHEEL SET-UPS FOR 7-1/4” SHEET WITH 1/4” MARGINS 3-43.............................

HANDWHEEL SET-UPS FOR 7-3/4” SHEET WITH 3/16” MARGINS 3-44...........................

HANDWHEEL SET-UPS FOR 7-3/4” SHEET WITH 1/4” MARGINS 3-45.............................

HANDWHEEL SET-UPS FOR 8” SHEET WITH 3/16” MARGINS 3-46...............................

HANDWHEEL SET-UPS FOR 8-1/2” SHEET WITH 3/16” MARGINS 3-47...........................

HANDWHEEL SET-UPS FOR 8-1/2” SHEET WITH 1/4” MARGINS 3-48.............................

HANDWHEEL SET-UPS FOR 8-1/2” SHEET WITH 1/2” MARGINS 3-49.............................

HANDWHEEL SET-UPS FOR 9” SHEET WITH 3/16” MARGINS 3-50...............................

HANDWHEEL SET-UPS FOR 9-1/2” SHEET WITH 3/16” MARGINS 3-51...........................

HANDWHEEL SET-UPS FOR 9-1/2” SHEET WITH 1/4” MARGINS 3-52.............................

HANDWHEEL SET-UPS FOR 9-1/2” SHEET WITH 1/2” MARGINS 3-53.............................

HANDWHEEL SET-UPS FOR 11” SHEET WITH 1/8” MARGINS 3-54...............................

HANDWHEEL SET-UPS FOR 11” SHEET WITH 3/16” MARGINS 3-55..............................

HANDWHEEL SET-UPS FOR 11” SHEET WITH 1/4” MARGINS 3-56...............................

HANDWHEEL SET-UPS FOR 11” SHEET WITH 1/2” MARGINS 3-57...............................

HANDWHEEL SET-UPS FOR 12” SHEET WITH 3/16” MARGINS 3-58..............................

HANDWHEEL SET-UPS FOR 12” SHEET WITH 1/4” MARGINS 3-59...............................

HANDWHEEL SET-UPS FOR 12” SHEET WITH 1/2” MARGINS 3-60...............................

HANDWHEEL SET-UPS FOR 14” SHEET WITH 3/16” MARGINS 3-61..............................

HANDWHEEL SET-UPS FOR 14” SHEET WITH 1/4” MARGINS 3-62...............................

HANDWHEEL SET-UPS FOR 14” SHEET WITH 1/2” MARGINS 3-63...............................

METRIC HANDWHEEL SET-UPS FOR A4 (297mm x 210mm) TAB SIDE: 297 MM MARGIN: 0 MM 3-64

METRIC HANDWHEEL SET-UPS FOR A4 (297mm x 210mm) TAB SIDE: 210 MM MARGIN: 0 MM 3-65

METRIC HANDWHEEL SET-UPS FOR A4 (297mm x 210mm) TAB SIDE: 297 MM MARGIN: 1 MM 3-66

METRIC HANDWHEEL SET-UPS FOR A4 (297mm x 210mm) TAB SIDE: 210 MM MARGIN: 1 MM 3-67

4 MAINTENANCE 4--1......................................................................

4.1 Maintenance 4--3....................................................................

4.1.1 Machine Lubrication 4--3..........................................................

4.1.2 Chain Lubrication 4--4............................................................

Table of Contents

V

C9999--2 Issue 1

4.1.3 Vacuum Pump Maintenance 4--8...................................................

4.2 Machine Timing 4--10.................................................................

4.2.1 Maintenance Mode 4--11...........................................................

4.2.2 Preparation for Timing Procedures 4--12..............................................

4.2.3 ChainA&BRemoval 4--14.........................................................

4.2.4 Feeder Timing 4--15...............................................................

4.2.5 Plastic Feed & Cut Operating Arm 4--16..............................................

4.2.6 Tab Cutter Timing 4--17............................................................

4.2.7 Machine Cycle Cam Timing 4--18....................................................

4.2.8 Position of Kick Back Cam 4--19.....................................................

4.2.9 Reregister Section 4--20............................................................

4.2.10 Rubber Kick Back Roller 4--21......................................................

4.2.11 Tab Cutting 4--22..................................................................

4.2.12 Reinstall Chains 4--23..............................................................

4.2.13 Calibration 4--24..................................................................

4.2.14 Handwheel Settings 4--25..........................................................

4.2.15 Handwheel Calibration Procedures 4--26.............................................

4.2.16 Plastic Size Handwheel 4--27.......................................................

4.2.17 Plastic Position Handwheel 4--29....................................................

4.2.18 Tab Position Handwheel 4--31.......................................................

4.2.19 Tab Position Calibration 4--33.......................................................

4.2.20 Slip Rings and Brushes 4--35.......................................................

4.2.21 Plastic Feed and Fold Mechanism 4--36..............................................

4.2.22 Chip Removal System 4--40........................................................

4.2.23 Tip Die Assembly 4--41............................................................

4.2.24 Reinstalling the Tip Die Assembly 4--44..............................................

4.2.25 Hold Down Strap on Delivery Conveyor 4--45.........................................

4.2.26 Setting Tab Cutter Knives 4--46......................................................

4.2.27 Paper Stocks 4--50................................................................

4.2.28 Hot Roller 4--52...................................................................

4.2.29 Plastic Reel Holder Adjustment Procedure 4--54.......................................

4.2.30 Fiber Optics 4--55.................................................................

4.2.31 Machine Cleaning 4--58............................................................

4.2.32 Feed, Drive, Hold Down & Tension Rollers 4--58.......................................

5 SCOTT 10,000 PARTS 5-1................................................................

5.1 ASSEMBLY LOCATOR 5-4...............................................................

5.2 PILE FEED - REGISTER BOARD ADJUSTMENT 5-6........................................

5.3 PILE FEED DRIVE 5-8...................................................................

5.4 PILE FEED DRIVE & TENSIONER 5-10.....................................................

5.5 PILE FEED - VACUUM BAR DRIVE 5-12....................................................

5.6 PILE FEED - VACUUM BAR 5-14..........................................................

5.7 PILE FEED - PAPER GUIDE 5-16..........................................................

5.8 PILE FEED - OPTIC MOUNTING 5-18

......................................................

5.9 PILE HEIGHT ASSEMBL Y 5-20............................................................

5.10 PILE LIFT DRIVE 5-22...................................................................

5.11 PILE LIFT FRAME 5-24..................................................................

5.12 PILE LIFT HANDWHEEL 5-26............................................................

5.13 PILE FEED - SHEET SEPARATOR 5-28...................................................

5.14 PILE FEED -- STACK GUIDE 5-30.........................................................

Table of Contents

VI

C9999--2 Issue 1

5.15 PILE FEED - PNEUMATIC FITTINGS 5-32.................................................

5.16 PILE FEED - GUARDS, COVERS 5-34....................................................

5.17 PILE FEED - OPTIC MOUNTING 5-36.....................................................

5.18 PILE FEED - PNEUMATIC CONTROLS “A” 5-38............................................

5.19 PILE FEED - PNEUMATIC CONTROLS “B” 5-40............................................

5.20 PILE FEED - BELT & CHAIN LAYOUT 5-42.................................................

5.21 MAIN MOTOR & VACUUM PUMP 5-44....................................................

5.22 BASE & DRIVE 5-46....................................................................

5.23 BASE & DRIVE 5-48....................................................................

5.24 BASE & DRIVE 5-50....................................................................

5.25 MACHINE GUARDS 5-52................................................................

5.26 CHAIN ASSEMBLY & PG. 8 REF. 5-54.....................................................

5.27 REGISTER BOARD - HOLD DOWN PLATE 5-56............................................

5.28 REGISTER BOARD - CONVEYOR 5-58...................................................

5.29 PLASTIC CUT - BASE 5-60..............................................................

5.30 PLASTIC CUT ASSEMBLY 5-62..........................................................

5.31 TIP DIE UNIT 5-64......................................................................

5.32 PLASTIC FEED UNIT ASSEMBLY (A) 5-66.................................................

5.33 PLASTIC FEED UNIT ASSEMBLY (B) 5-68.................................................

5.34 PLASTIC FEED ASSEMBL Y (C) 5-70......................................................

5.35 PLASTIC FEED UNIT - ROLLERS 5-72....................................................

5.36 PLASTIC FEED - SLIDE 5-74.............................................................

5.37 PLASTIC FEED - DRIVE 5-76............................................................

5.38 PLASTIC FEED UNIT - COVERS & GUARDS 5-78..........................................

5.39 PLASTIC REEL HOLDER 5-80...........................................................

5.40 CONTROL PANEL 5-82..................................................................

5.41 HEAT ROLLER SHAFTS 5-84............................................................

5.42 HEAT ROLLER -- BEARING BLOCKS 5-86.................................................

5.43 PAPER SUPPORT PLATE -- TAB WIPER 5-88..............................................

5.44 HEAT ROLLER -- GEARS & SPROCKETS 5-90.............................................

5.45 Slip Ring Assembly 5-92.................................................................

5.46 Heat Roller -- Slip Rings & Brush Blocks 5-94...............................................

5.47 TAB WIPER UNIT 5-96..................................................................

5.48 TAB WIPER -- HOLD DOWN ROLLER 5-98................................................

5.49 HEAT ROLLER -- GUARDS 5-100..........................................................

5.50 REREGISTER UNIT -- REAR FRAME 5-102.................................................

5.51 REREGISTER UNIT -- LINKAGE 5-104.....................................................

5.52 TABCUTTER GUARD 5-106...............................................................

5.53 HOLDDOWN UNIT 5-108.................................................................

5.54 REREGISTER DRIVE 5-110...............................................................

5.55 KICK BACK UNIT 5-112..................................................................

5.56 KICK BACK UNIT 5-114

..................................................................

5.57 GEARBOX & REREGISTER SLIDE ASS’Y 5-116.............................................

5.58 CONVEYOR UNIT 5-118..................................................................

5.59 CONVEYOR UNIT 5-120..................................................................

5.60 PULL BACK UNIT 5-122..................................................................

5.61 PULL BACK UNIT 5-124..................................................................

5.62 PULL BACK UNIT 5-126..................................................................

5.63 REREGISTER DRIVE 5-128...............................................................

5.64 REREGISTER DRIVE 5-130...............................................................

5.65 REREGISTER UNIT -- VIEW -- A (PREV. PG’S.) 5-132........................................

Table of Contents

VII

C9999--2 Issue 1

5.66 REREGISTER UNIT -- VIEW -- B (PREV. PG’S.) 5-134........................................

5.67 INFEED UNIT 5-136......................................................................

5.68 TAPE SUPPORT PLATES 5-138...........................................................

5.69 TAB CUTTER - KNIFE CARRIER (L.H.) 5-140...............................................

5.70 TAB CUTTER - KNIFE CARRIER (R.H.) 5-142...............................................

5.71 TAB CUTTER 5-144......................................................................

5.72 TAB CUTTER 5-146......................................................................

5.73 TAB CUTTER DRIVE LINKAGE 5-148......................................................

5.74 HANDWHEEL UNIT -- REREGISTER/ TAB CUTTER 5-150....................................

5.75 HANDWHEEL UNIT -- PLASTIC POSITION 5-152............................................

5.76 HANDWHEEL UNIT -- PLASTIC SIZE 5-154.................................................

5.77 HANDWHEEL LOCAT OR 5-156............................................................

6 ELECTRICAL PAG E 6-1

1 Introduction & Safety

1--1

C9999--2 Issue 1

1 INTRODUCTION & SAFETY

C9999--2 Issue 1

1 Introduction & Safety

1--2

C9999--2 Issue 1

1 Introduction & Safety

1--3

C9999--2 Issue 1

1.1 Introduction

The Scott 10,000t uses a vacuum feeder for accuracy with many stocks, heated bonding rollers, tab

cutting knives and cross conveyor for hands--off operation.

Tab sizes range from 1/2 inch to 5 inches (12.7 mm to 127 mm) by simply rotating the Tab Size handwheel.

The extra long tool steel knives quickly and easily cut a one inch (25.4 mm) tab in the first position on a 14

inch (355.6 mm) long sheet.

CROSS

CONVEYOR

OPERATORS

PAN EL

PILE

FEEDER

TIP DIE

ELECTRICAL

BOX

PLASTIC SIZE

HANDWHEEL

PAPER LIFT

HANDWHEEL

PLASTIC

POSITION

HANDWHEEL

TAB

CUTTER

PULL BACK

ASSEMBLY

Fig. 1-1. Machine Front View

1 Introduction & Safety

1--4

C9999--2 Issue 1

TAB CUTTER

ASSEMBLY

TAB

SIZE

HANDWHEEL

TAB POSITION

HANDWHEEL

CROSS

CONVEYOR

REREGISTER UNIT

(UNDER CROSS

CONVEYOR)

Fig. 1-2. Reregister / Cross Conveyor

FILM

GUIDES

VACUUM

UNIT

MAIN POWER

INLET

REEL HOLDER

DRIVE

MOTOR

AREA

PLASTIC CHIP

VACUUM

PLUG

TRANSFORMER

Fig. 1-3. Machine Back View

1 Introduction & Safety

1--5

C9999--2 Issue 1

1.1.1 Scott 10,000 Machine Specifications and Utility Requirements

Model Scott 10,000t

Speed

Up to 10,000 plastic index tabs per hour

Sheet Size

355.6 mm x 342.9 mm (14” x 13--1/2”) maximum

127 mm x 111.1 mm (5” x 4--3/8”) minimum

Plastic Size

139.7 mm (5--1/2”) maximum

25.4 mm (1”) minimum

Tab Cut Siz e

127 mm (5”) maximum

12.7 mm (1/2”) minimum

Paper Load

Approximately 2000 sheets

Counter

1 -- 999,999

Motor

2 Horsepower

Electrical Requirements

40 Amps, 220VAC single phase, 50 or 60 Hz

Decibel Rating

94db

Dimensions

L-- 3200 mm, (126”) includes conveyor

W-- 1219 mm (48”)

W-- 1955 mm (77”) with conveyor

H--1752 mm (69”)

Shipping Weight

Approximately 1509.55 kg (3,325 lbs)

Warranty

One year against defects in parts and workmanship. Labor Not Included.

1 Introduction & Safety

1--6

C9999--2 Issue 1

1.2 General Safety Guidelines

Providing a safe working environment for operating your machine is the responsibility of the user. The

suggested precautions, material safety data and other suggestions that follow do not have preference over

the user’s own plant practices, regulations or safety committee recommendations.

Personal injury and equipment damage can be avoided by the continued adherence to the safety features

provided with this machine and in keeping with the necessary governmental requirements. The guarding

and interlocking safety switches have been installed on the machine for the operator’s safety. These items

should be maintained in good working order by the user.

It is assumed that the user’s safety department has established a safety program that is in keeping with a

complete analysis of industrial hazards. Before installing and operating or performing maintenance and

clean--up procedures on the machine, it is suggested that the safety program be reviewed to ensure that it

covers the possible hazards that might occur with the operation of this machine.

Due consideration must be given to those hazards which arise from the presence of electrical power, high

temperature, and cleaning materials used in the operational areas of the machine. Proper installation and

care of protective devices and over--pressure protective equipment should be considered an essential part of

any safety program.

Special lock--out features are to prevent the possibility of applying power to the equipment at any time when

maintenance work is in progress.

In general, personnel should be guided by all basic rules of safety associated with the equipment and the

process. It should be further understood that information contained in this manual does not relieve operating

and maintenance personnel of the responsibility of exercising normal good judgment in operating and care of

the machine and its attendant equipment.

1 Introduction & Safety

1--7

C9999--2 Issue 1

1.3 Safety Features

EMERGENCY

STOP

RUN/SAFE/MAINT

KEYSWITCH

STOP

PUSHBUTTON

Fig. 1-4. Safety Feature Locations

E--STOP

Fig. 1-5. Know Where Emergency Stop Button

is Located

These safety features are to be used in conjunction

with the installation, operation and maintenance

instructions contained in this manual.

1.3.1 Emergency Stop

Stops machine drive immediately. This pushbutton

must be manually pulled out to reset.

STOP

RUN

SAFE

MAINT

Fig. 1-6. Know How to Stop Machine & Set Key

Switch to SAFE

1.3.2 Stop and Safe

The machine operator, clean--up and maintenance

personnel MUST be shown how to stop the

machine and place the KEY SWITCH on the

operator’s CONTROL PANEL in the SAFE mode

whenever machine is accessed or clean--up

operations are performed.

1 Introduction & Safety

1--8

C9999--2 Issue 1

Fig. 1-7. Turn Machine Off Before Making

Adjustments

1.3.3 Main Power Switch

If machine is to be shut down for adjustments or

repairs, turn the power supply to the machine off.

Fig. 1-8. Blade Hazard Warning

1.3.4 Guards and Covers

All safety guards, protective screens and covers

MUST be in place and securely fastened before

operating the machine.

Observe Danger warnings. Use extra care around

moving cutting blades.

SAFETY

SWITCH

Fig. 1-9. Safety Devices

1.3.5 Safety Switches

The covers of the machine are connected to

interlock safety devices for your protection.

Machine will stop operating if a safety cover or

guard is opened while the machine is running. The

rollers will continue to maintain unless the rear

machine roller guard is removed.

1 Introduction & Safety

1--9

C9999--2 Issue 1

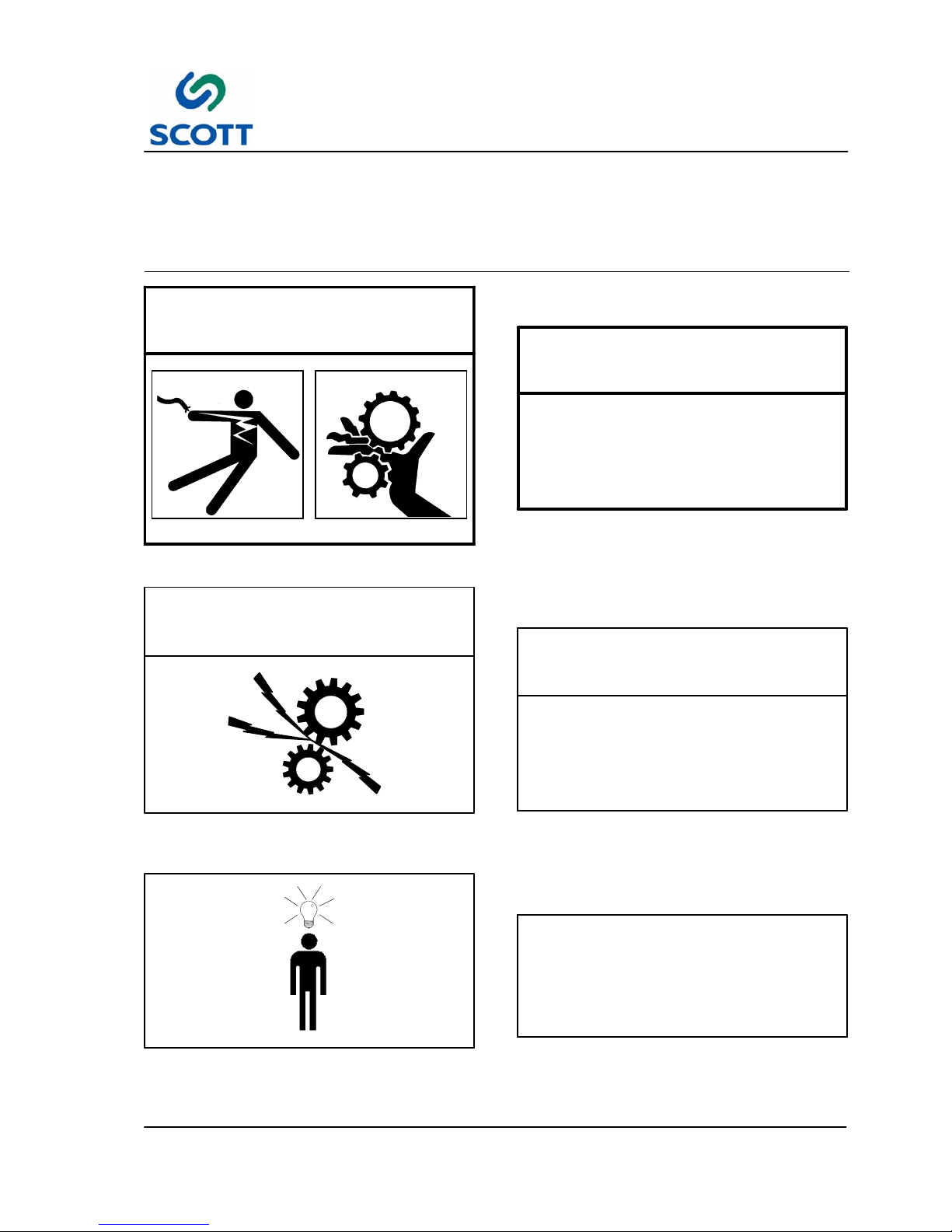

1.4 Warnings, Cautions & Notes

In order to emphasize certain areas in the interest of personal safety and a properly operated and maintained

machine, you will encounter the words WARNING, CAUTION, and NOTE throughout this manual.

WARNING!

Fig. 1-10. Warnings Indicate Personal Danger

1.4.1 Warnings

AN OPERATING PROCEDURE,

PRACTICE, ETC. WHICH IF NOT

CORRECTLY FOLLOWED, COULD

RESULT IN PERSONAL INJURY OR

LOSS OF LIFE.

WARNING!

CAUTION!

Fig. 1-11. Cautions Indicate Potential Damage

to Equipment

1.4.2 Cautions

AN OPERATING PROCEDURE,

PRACTICE, ETC. WHICH, IF NOT

STRICTLY OBSERVED, COULD RESULT

IN DAMAGE TO OR DESTRUCTION OF

EQUIPMENT.

CAUTION!

Note !

Fig. 1-12. Notes Indicate Essential Information

1.4.3 Notes

An Operating Procedure, Condition,

etc. Which is Essential To Highlight.

Note !

1 Introduction & Safety

1--10

C9999--2 Issue 1

1.5 On Machine Warnings

Fig. 1-13. Heat Hazard

1.5.1 Heat Hazards

Forexample,thereisHOTSURFACEsignontop

of the Tab Wiper assembly. Look for warning signs

throughout the machine. They are there to alert

you to hazards.

Fig. 1-14. Electrical Shock Hazard

1.5.2 Electrical Shock Hazards

Look for warning signs on electrical cabinets and

circuit breaker boxes. They are there to alert you

to hazards of electrical shock.

1 Introduction & Safety

1--11

C9999--2 Issue 1

1.6 Safety Procedures

SAFETY SWITCH

Fig. 1-15. Do Not Disable Safety Devices

1.6.1 Safety Devices

Tampering with safety mechanisms in order to

disable them should not be tolerated.

IT IS EXTREMELY DANGEROUS TO ACCESS

MACHINE WHEN IT IS OPERATING OR

CAPABLE OF OPERATING.

Warning!

Fig. 1-16. Wear Proper Clothing

1.6.2 Appropriate Dress

Personnel working in the machine operation area

must remove jewelry and neckties. Personnel

must wear clothing appropriate for the work area.

Fig. 1-17. Keep Work Area Clean and Neat

1.6.3 Keep Area Clean

Loose materials, tools and equipment, not

essential to the operation of the machine, must be

removed from the machine work area.

Fig. 1-18. Clean Up Oil and Grease Spills

1.6.4 Grease and Oil

Clean up all oil and grease spills around the

machine work area.

Fig. 1-19. Read Manuals First

1.6.5 Manual Usage

Read and understand the instructions in the

manual before operating, adjusting or servicing

machine.

2 Installation

2--1

C9999--2 Issue 1

2 INSTALLATION

C9999--2 Issue 1

2 Installation

2--2

C9999--2 Issue 1

2 Installation

2--3

C9999--2 Issue 1

2.1 Installation Requirements

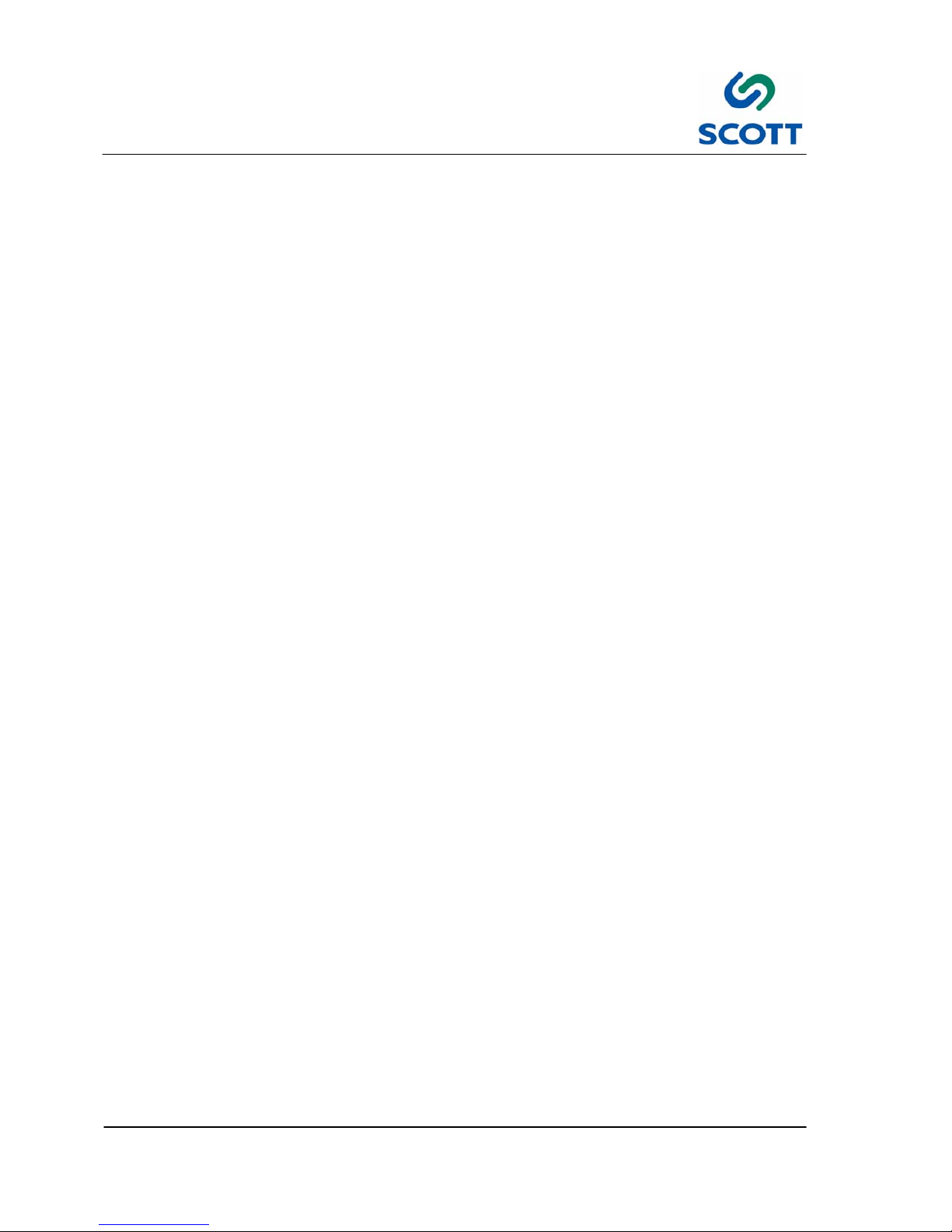

Fig. 2-1. Scott 10,000

All procedures in this section provide advance planning and site preparation data for installation of the Scott

10,000. Environmental requirements, unpacking instructions, electrical and physical specifications are

included. This information should be used as a reference during the development of site preparation plans

before you install your machine.

If any questions arise while performing any of the following procedures, contact:

Training is available from Scott Office Systems at / eight hour day, plus all travel expenses.

Note ! A forklift is required to lift the machine off the shipping skid and place it on the f loor.

2 Installation

2--4

C9999--2 Issue 1

2.2 Pre-Installation Requirements

The environmental requirements of the Scott 10,000 must be considered well in advance of the actual

installation. Providing a well suited operating environment will help ensure a trouble free installation process.

Consideration should be given to the following items:

● Power, location and rating of power connections.

● Floor strength

● Level floor

● Adequate space must be provided around all four sides of the machine to permit normal operation and

maintenance procedures. The figure shows the minimum space required.

ROLLERS

CROSS CONVEYOR

TAB CUTTER

FEEDER

15’ 9”

(4,800mm)

2’ 4”

(711mm)

3’ 2”

(965mm)

OPERAT OR

8’ 5”

(2565mm)

2’ 1”

(635mm)

6’6”

(1955mm)

Fig. 2-2. Scott 10,000 Space Requirements

● Space should be allocated near the feeder for a small table that can be used for jogging stock, small jobs,

samples, etc.

● Provide plenty of space In front of the machine so large jobs can be easily moved in and out with skids or

carts.

2 Installation

2--5

C9999--2 Issue 1

2.3 Uncrating & Placement

The machine will arrive in two crates. Inspect the external condition of the crates for visible signs of damage

before opening. If damage is noticeable, notify the carrier or Scott before proceeding with the installation.

To assist in the ease of installation, the machine is disassembled prior to shipping and requires some minor

assembly before the machine is operational.

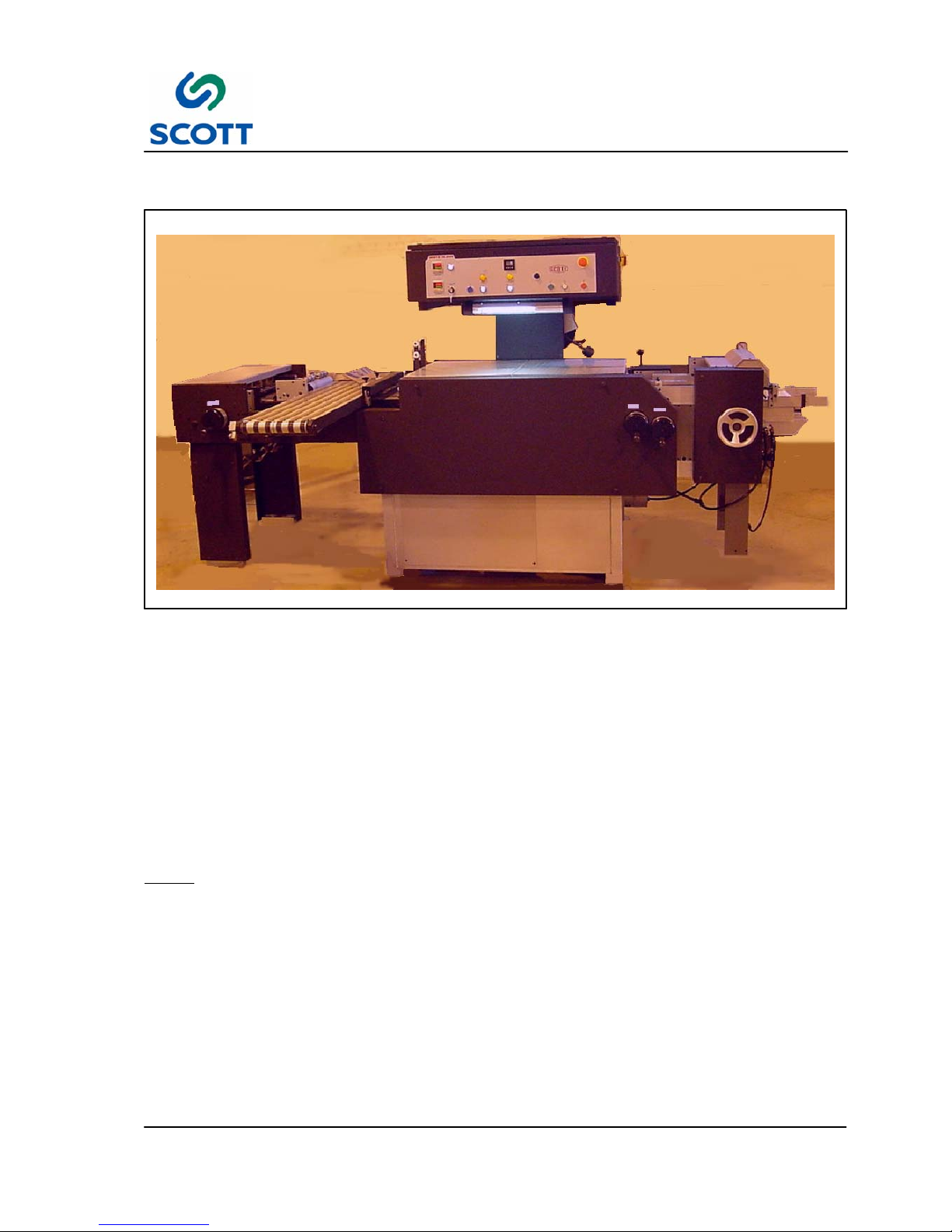

CONTROL

PAN EL

BRACE

Fig. 2-3. Scott Ten Thousand -- Crate 1

2.3.1 Crate 1 -- Main Machine

Step: 1. Remove metal banding straps from

cardboard surrounding shipping crates.

EXTREME CAUTION MUST BE

EXERCISED WHEN MOVING MACHINE

TO INSTALLATION LOCATION TO

PREVENT DAMAGE.

CAUTION!

Step: 2. Use a fork lift to place the main machine

shipping skid near the designated floor

area of operation.

LAG SCREW

LEVELING SCREWS

Fig. 2-4. Remove Lag Screws from Shipping

Skid

Step: 3. Remove four lag screws holding machine

to shipping skid.

Step: 4. Raise main machine with fork lift, remove

shipping skid assembly from under

machine.

Step: 5. Lower main machine to floor.

Step: 6. Remove all protective wrapping from

machine.

Step: 7. Remove front and rear covers and place

them aside so they won’t be damaged.

2 Installation

2--6

C9999--2 Issue 1

2.3.2 Crate 2 -- Additional Assemblies

Crate 2 contains all remaining equipment that was removed for shipping.

● Chip Removal Vacuum

● Tab Cutter Assembly

● Cross Conveyor Assembly

● Instruction Manual

● Miscellaneous Parts

TAB CUTTER UNIT

CROSS CONVEYOR UNIT

CHIP REMOVAL VACUUM

Fig. 2-5. Scott 10,000 on Shipping Skid (Crate 2)

Step: 1. Remove Cross Conveyor assembly from shipping skid. Place it to the side for later installation.

Step: 2. Remove vacuum unit from skid.

REREGISTER EXTENSION

MOUNTING SHAFT

Fig. 2-6. Remove Support Shaft

2.3.3 Install Tab Cutter Unit

Step: 1. Loosen hardware and slide reregister

extension frame mounting support shaft

out of tab cutter frame housing.

2 Installation

2--7

C9999--2 Issue 1

Fig. 2-7. Align Tab Cutter Assembly with Main

Machine

Step: 2. Remove Tab Cutter assembly from skid

and position it to left of the main machine

(as viewed from the front).

Step: 3. Align support shaft holes in Tab Cutter

assembly with holes in the main machine

housing.

THIS PROCEDURE REQUIRES 2--3

PERSONS.

CAUTION!

SHAFT

MAIN MACHINE FRAME

TAB CUTTER

Fig. 2-8. Reinstall Tab Cutter Shaft

Step: 4. Reinstall reregister extension frame

mounting shaft through the Tab Cutter

assembly and the gusset in the main

machine frame.

Fig. 2-9. Secure Tab Cutter Shaft

Step: 5. Secure the tab cutter shaft with socket

head screw.

2 Installation

2--8

C9999--2 Issue 1

2.3.4 Leveling the Machine

ROLLERS

CROSS CONVEYOR

TAB CUTTER

FEEDER

BACK

FRONT

RIGHT

LEFT

OPERATOR

Fig. 2-10. Locator

The machine should be on a level surface. However, if the machine is to be placed on an abnormally

uneven floor, the machine must be leveled in the following manner:

Note ! Tab Cutter/ Reregister / Conveyor section must be level with the main machine. Level the

knife section with the main machine to prevent excess wear of knives. It is important that

the knife section has the same pitch front to back as the main machine. Place a level in the

main machine across the roller keeper blocks and compare it to the knife packages. Adjust

knife package to the same bubble location on the level.

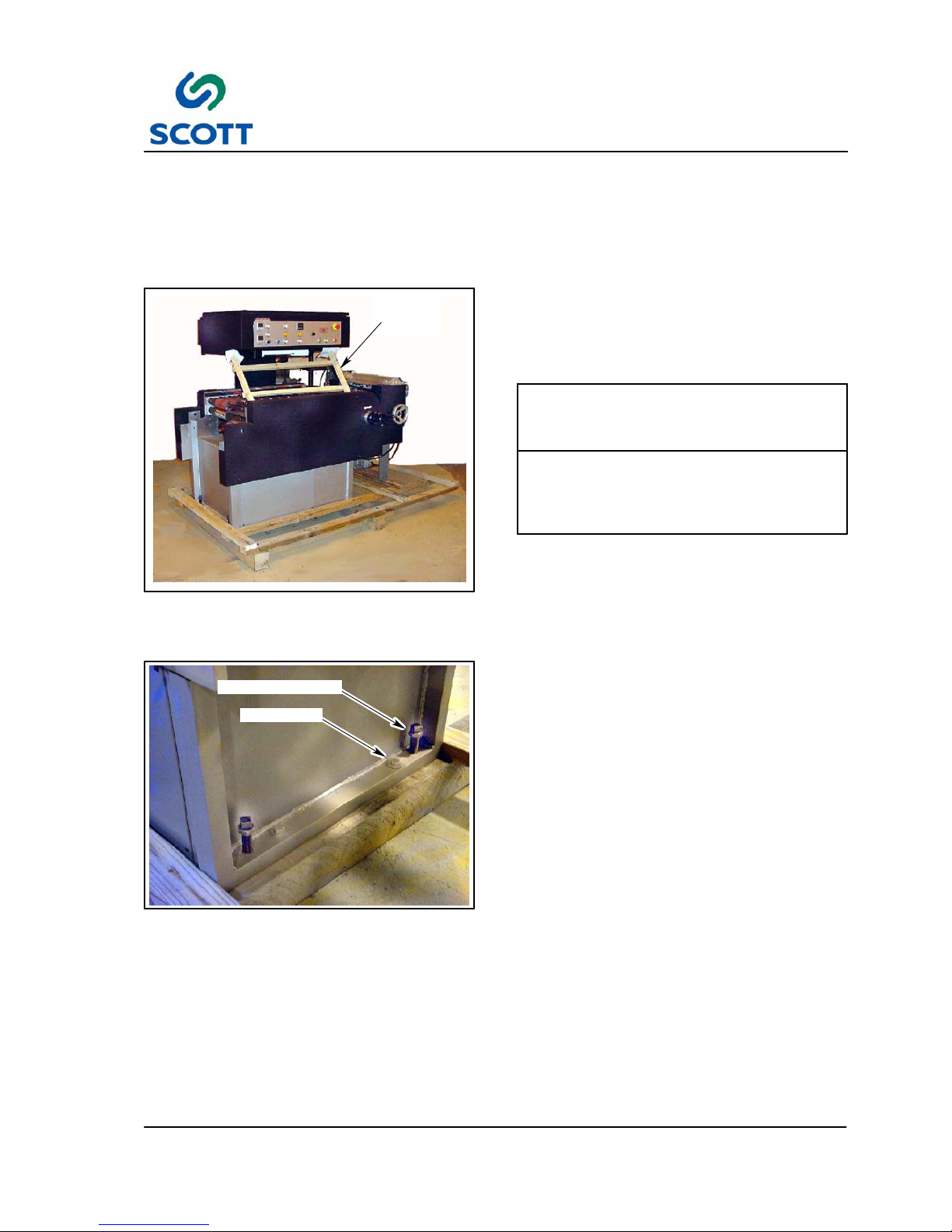

THREADED LEVELING

HOLES

(2 FRONT)

Fig. 2-11. Leveling Rod Installation (Front)

Step: 1. Install the 3/4” #10 leveling bolts through

four threaded holes in the machine

weldment.

Step: 2. The leveling bolts can be then used to

level the machine. Tighten jam nuts to

maintain level position when attained.

2 Installation

2--9

C9999--2 Issue 1

THREADED LEVELING

HOLES

(2 BACK)

Fig. 2-12. Leveling Rod Installation (Back)

Fig. 2-13. Place Level on Main Machine Frame

Step: 3. Place a level on the machined surface of

the main machine frame.

Step: 4. Adjust threaded rods in machine base to

obtain level machine side to side.

ROLLER KEEPER

BLOCKS

Fig. 2-14. Place Level Across Machine as

Shown

Step: 5. Place a level across the roller keeper

blocks.

Step: 6. Adjust threaded rods in machine base to

obtain level machine front to rear.

2 Installation

2--10

C9999--2 Issue 1

KNIFE PACKAGE

Fig. 2-15. Level Tab Cutter Assembly Side to

Side

Step: 7. Place a level on machine frame to level

Tab Cutter assembly from Side to Side.

Fig. 2-16. Level Tab Cutter Assembly Front to

Back

Step: 8. Place a level on machine frame to level

Tab Cutter assembly from Front to Back.

Fig. 2-17. Remove Packing on Hold--Down

Roller Assembly

2.3.5 Continue Assembling Machine

Step: 1. Remove packing wrap from the

Hold--Down Roller assembly.

2 Installation

2--11

C9999--2 Issue 1

HOLD--DOWN

ASSEMBLY

THUMBSCREW

SUPPORT

SHAFT

Fig. 2-18. Attach Hold--Down Assembly

Step: 2. Loosen hardware and remove register

hold--down support shaft from mounting

blocks.

Step: 3. Rotate the longer Hold--Down Roller

assembly up and reinstall support shaft

through assembly and mounting blocks.

Step: 4. Tighten mounting hardware.

2 Installation

2--12

C9999--2 Issue 1

MACHINE CYCLE CAM

TAB CUTTER DRIVE SHAFT

PILE FEED & CUT

KICK BACK CAM

Fig. 2-19. Make Sure TIming Marks Are Aligned

Note ! Before installing the Tab Cutter drive chain, it is critical that all of the timing marks shown in

Fig. 2-19. are aligned and that the heat rollers are set in the positions shown in Fig. 2-20.

Step: 5. Make sure the timing marks on Pile Feed and Cut Linkage, the Machine Cycle Cam, Tab Cutter

Drive and Kick Back Cam are aligned.

2 Installation

2--13

C9999--2 Issue 1

REGISTER

DRIVE

CHAIN

HEATER ROLLERS

REGISTER DRIVE CHAIN TENSIONER

REPRESENTS

SPROCKETS

Fig. 2-20. Heat Roller Positions (Front)

Step: 6. Make sure all heaters are aligned as shown above.

Step: 7. Install register drive chain.

1” DEFLECTION

Fig. 2-21. Tighten Chain Tension

Step: 8. Adjust register drive chain tensioner so

that there is approximately one inch (1/2”

either side of centerline) of deflection in

chain.

2 Installation

2--14

C9999--2 Issue 1

REMOVE PROTECTIVE WRAP

KNIFE

BLADES

Fig. 2-22. Remove Shipping Wrap from Knife

Blades

Step: 9. Remove shipping protective wrap from

tab cutting knives.

Fig. 2-23. Attach Tab Cutter Drive Linkage

Step: 10.Attach tab cutter drive linkage.

Fig. 2-24. Safety Wiring Harness

Step: 11.Removetiewrapfromsafetywiring

harness.

2 Installation

2--15

C9999--2 Issue 1

Fig. 2-25. Connect Safety Wiring Harness

Step: 12.Connect safety wiring harness to tab

cutter guard safety switch.

Fig. 2-26. Install Cross Conveyor Assembly

2.3.6 Install Cross Conveyor

Step: 1. Install the Cross Conveyor assembly.

ASSEMBLING THE CROSS CONVEYOR

IS A TWO PERSON TASK.

CAUTION!

CROSS CONVEYOR SHAFT

BEARING BLOCK

Fig. 2-27. Insert Cross Conveyor Shaft Into

Bearing Block

Step: 2. Insert cross conveyor drive shaft into

bearing block on the main machine.

2 Installation

2--16

C9999--2 Issue 1

MOUNTING BLOCK

Fig. 2-28. Tighten Mounting Block Screws

Step: 3. Lightly tap mounting block with a rubber

mallet to align.

Step: 4. Tighten socket head screws in cross

conveyor mounting block.

CROSS CONVEYOR LINKAGE

Fig. 2-29. Attach Cross Conveyor Linkage

Step: 5. Attach the cross conveyor linkage.

PILE FEED

HOLD--DOWN

BAR

REGISTER BOARD

HOLD DOWN PLATE

Fig. 2-30. Install Ball Bearings

2.3.7 Install Steel Balls

Step: 1. Install steel balls in the register board

hold--down plate and the pile feed

hold--down bar.

2 Installation

2--17

C9999--2 Issue 1

Fig. 2-31. Install Vacuum Canister

2.3.8 Connect Vacuum Canister

Step: 1. Once the machine is in place, assemble

the vacuum blower and canister.

CHIP REMOVAL

VACUUM OUTLET

VACUUM HOSE

HOSE CONNECTION

Fig. 2-32. Connect Vacuum Hose

Step: 2. Route the vacuum hose under the tab

cutter end of the machine and connect to

the opening under the Tip Die assembly.

Step: 3. Plug power cord for vacuum blower into

auxiliary outlet located on the back of the

machine.

VACUUM

VALV E

Fig. 2-33. Install Vacuum Valve

2.3.9 Install Vacuum Valve

Step: 1. Install vacuum adjustment valve.

2 Installation

2--18

C9999--2 Issue 1

Fig. 2-34. Pile Feed Area

2.3.10 Install Paper Supports on Pile

Feeder

For shipping purposes, the paper support

assembly is removed from the machine.

SET SCREWS

Fig. 2-35. Loosen Set Screws in Block

Step: 1. Loosen set screws in stack support bar

mounting block.

ROD

SUPPORT

Fig. 2-36. Slide Rods to Mount Paper Support

Step: 2. Slide rods toward front of machine to

create clearance for end paper support.

Step: 3. Install paper support.

2 Installation

2--19

C9999--2 Issue 1

1/4”

ROD

PAPER SUPPORT

STACK SUPPORT BAR

MOUNTING BLOCK

Fig. 2-37. Rods Should Extend 1/4” Beyond

Supports

Step: 4. The ends of the stack support bars

should extend 1/4 inch beyond paper

support.

Step: 5. Tighten the set screws in the stack

support bar mounting block.

PAP ER S U PPO RT

Fig. 2-38. Install Remaining Support Blocks

Step: 6. Install remaining paper supports on stack

support rods.

Fig. 2-39. Install RH Side Paper Stack Guide

Step: 7. Install RH paper stack guide.

Step: 8. Tighten set screws.

2 Installation

2--20

C9999--2 Issue 1

Fig. 2-40. Install LH Side Paper Stack Guide

Step: 9. Install LH paper stack guide.

Step: 10.Tighten set screws.

RH STACK GUIDE

SIDE RACK GUIDE

Fig. 2-41. Slide the RH Stack Guide Flush with

Side Rack Guide

Step: 11.Slide the RH stack guide so that it is flush

with the edge of the side rack guide.

Step: 12.Tighten set screws.

Fig. 2-42. Pile Feed With All Supports and

Guides Installed

2 Installation

2--21

C9999--2 Issue 1

Fig. 2-43. Remove Wire Ties From Air Hoses

Step: 13.Carefully remove the wire ties holding the

air hoses.

Fig. 2-44. Insert Air Hoses into Connectors

Step: 14.Insert air hoses into connectors.

2 Installation

2--22

C9999--2 Issue 1

DANGER: ELECTRICAL CONNECTIONS

MUST BE MADE BY A QUALIFIED

ELECTRICIAN FAMILIAR WITH

APPLICABLE ELECTRICAL CODES

AND REGULATIONS. ELECTRICAL

CONNECTIONS MUST THEN BE MADE

ONLY AFTER REVIEWING AND

UNDERSTANDING THE ELECTRICAL

SCHEMATICS SUPPLIED WITH

MACHINE AND SAFETY SECTION OF

THIS MANUAL, FAILURE TO EXERCISE

NECESSARY SAFETY PRECAUTIONS

CAN RESULT IN SERIOUS BODILY

INJURY OR DEATH.

WARNING!

2.4 Utility Connections

2.4.1 Electrical Connections

The machine requires No. 8, 3 wire cable including

ground for 220 volt, single phase electrical power.

Note ! Electrical cables going to machine

should be routed overhead and be of

sufficient height to allow personnel to

travel around entire machine without

interference. The figure below shows

recommended installation

configuration.

GROUND

TERMINAL

1L1

TERMINAL

5L3

TERMINAL

Fig. 2-45. Installation Wiring Route

1. Route main power electrical cable through the conduit opening in the back of the control cabinet.

2. Connect two “hot” leads onto terminals 1L1 and 5L3 on main power relay. Connect neutral lead to

ground terminal.

3 Operation

3--1

C9999--2 Issue 1

3 OPERATION

C9999--2 Issue 1

3 Operation

3--2

C9999--2 Issue 1

3 Operation

3--3

C9999--2 Issue 1

3.1 GENERAL INFORMATION

3.1.1 Before Operating the Machine

AVOID SERIOUS INJURY OR EQUIPMENT

DAMAGE. RESTRICT OPERATION OF THIS

MACHINE TO TRAINED, QUALIFIED

PERSONNEL ONLY.

WARNING!

EACH OPERATOR SHOULD KNOW THE

LOCATION AND FUNCTION OF ALL

MACHINE STOPPING CONTROLS.

REVIEW MANUAL FOR EMERGENCY

STOP BUTTON LOCATION.

WARNING!

Do not attempt to operate the machine before reading and understanding the manual. Pay close attention to

all WARNINGS, CAUTIONS and NOTES. Failure to do so may cause serious injury and extensive machine

damage.

Read through the inspection and pre--start procedures before starting the machine. Make these checks part

of your routine to insure efficiency and quality during the production run.

3 Operation

3--4

C9999--2 Issue 1

3.2 Operating Controls and Indicators Descriptions

3.2.1 Operator’s Control Panel Layout

STOP

PAP ER

FEED

RUN/SAFE/MAINT

RESET

ROLLER

HEAT

EMERGENCY

STOP

COUNTER

ON/OFF

COUNTER

DRIVE

SPEED

LOWER

HEAT

COUNT

REACHED

PLASTIC

FEED

START

OUT OF

PLASTIC

UPPER

HEAT

Fig. 3-1. Control Panel

E--STOP

Fig. 3-2. Emergency Stop Pushbutton

3.2.2 Machine Stopping Device

3.2.2.1 EMERGENCY STOP -- Red Pushbutton

Stops the machine drive immediately. The

Emergency Stop Button is on the front of the

machine. After a stop, the button must be

manually pulled out and the Reset button pushed

before cycling can resume.

3 Operation

3--5

C9999--2 Issue 1

3.2.3 Main Operator’s Panel Control Descriptions

The following is a list of each control on the operator’s panel and a description of the functions performed at

each setting.

HEATER

Fig. 3-3. Heaters Illuminated Pushbutton

3.2.3.1 ROLLER HEAT ON / OFF --

ON -- When pushed, the button illuminates,

indicating upper and lower heaters are turned ON.

OFF -- When pushed again, the heaters are turned

OFF.

Approximate warm up time for heaters is between

25--30 minutes.

RUN

SAFE

MAINT

Fig. 3-4. Run/Safe/Pendant Key Switch

3.2.3.2 SAFE / RUN / MAINT -- Key Switch

RUN -- The machine drive cycles continuously.

This is the normal switch position for production.

If conditions are safe, pushing RESET will allow

the machine to operate.

SAFE -- No machine cycle is possible.

MAINT (Maintenance) -- When the keyswitch is in

this position, the machine can only be indexed at a

slower speed. The safety doors and guards

(except for the tabcutter guard) can be removed to

perform maintenance and adjustments. If the rear

machine guard is removed, the rollers will not heat.

Always press the RESET button after changing the

switch from RUN to MAINT or visa versa.

RESET

Fig. 3-5. Reset Pushbutton

3.2.3.3 RESET -- Blue Pushbutton

Resets machine, and verifies it is safe to run after

an emergency stop.

Press this button when changing the

RUN/SAFE/MAINT switch from SAFE position to

RUN.

3 Operation

3--6

C9999--2 Issue 1

OUT OF

PLASTIC

Fig. 3-6. Out of Plastic Lamp

3.2.3.4 OUT OF PLASTIC -- LAMP

Lamp will illuminate when upon pushing the Plastic

Feed button, the proximity switch on the plastic

feed does not sense plastic at the feeder

discharge. The plastic chip removal vacuum and

the paper feed vacuum pump will also be disabled

until the plastic spool is refilled.

PLASTIC

FEED

Fig. 3-7. Plastic Feed Pushbutton

3.2.3.5 PLASTIC FEED -- White Illuminated

Pushbutton

Turns on the chip removal vacuum and allows

plastic to enter the Tip Die, if the reel is threaded

onto the machine. The plastic chip removal

vacuum operates only when Plastic Feed is on and

the machine is in Run with machine running.

COUNT

REACHED

Fig. 3-8. Count Reached Lamp

3.2.3.6 COUNTER REACHED -Amber Indicator Lamp

This lamp will illuminate when the machine has

produced the amount predetermined by the

counter. Once the count has been reached, the

paper feed vacuum pump will shut off so that paper

feed will stop. Also, if plastic is being applied to the

paper stock, the plastic chip removal vacuum will

shut off. Both units will resume operation once the

counter has been reset.

COUNTER

Fig. 3-9. Counter On/Off -- Illuminated

Pushbutton

3.2.3.7 COUNTER ON / OFF -White Illuminated Pushbutton

When the counter button is pushed, the button

illuminates indicating that the counter is on.

This will allow the operator to turn off the counter to

run make product without losing the current count.

3 Operation

3--7

C9999--2 Issue 1

START

Fig. 3-10. Start Pushbutton

3.2.3.8 START -- Green Pushbutton

Turns on main drive motor to begin machine

cycling.

This means:

● The safety switches indicate all the guards are

in place.

● The EMERGENCY STOP buttons are reset.

● The RESET button is pushed.

● The pushbutton turns on the main drive motor

for continuous machine cycling w ith the KEY

switch in RUN position only.

PAPER

FEED

Fig. 3-11. Paper Feed Pushbutton

3.2.3.9 PAPER FEED -- White Illuminated

Pushbutton

Starts the vacuum pump for the pile feeder vacuum

nozzles while the machine is cycling.

STOP

Fig. 3-12. Stop Drive Pushbutton

3.2.3.10 STOP -- Red Pushbutton

The pushbutton stops the machine drive. This is a

“soft” stop and is intended for planned stops, not

emergencies.

PLASTIC

ADVANCE

Fig. 3-13. Plastic Advance Pushbutton

3.2.3.11 PLASTIC ADVANCE -- Black

Pushbutton (Side of Machine)

It brings plastic into the Tip Die when the machine

is in Run position and cycling. It is used when

loading a new reel of film and must be held in to

move plastic to Tip Die area.

3 Operation

3--8

C9999--2 Issue 1

DRIVE SPEED

Fig. 3-14. Main Drive Feed

3.2.3.12 SPEED -- Adjustment Control

Adjusts main drive motor speed. The dial is turned

clockwise to increase, and counterclockwise to

decrease the machine drive speed.

COUNT SET

NUMBER

OF

SHEETS

RAN

COUNT SET

COUNT RESET

Fig. 3-15. Counter

3.2.3.13 COUNTER

Activating the Counter, allows operator to specify

an exact number of sheets to be run. The feeder

shuts off after the requirement has been met.

Note ! Additional sheets may be fed

depending on machine speed.

The counter only counts when the machine is in

RUN mode and the Counter button is ON. The

digital counter counts forwards to the number

specified, then shuts feeder and vacuum OFF

when that number is reached.

● Do not change setting while counter is running.

Fig. 3-16. Production Sheet Counter

3.2.3.14 PRODUCTION SHEET COUNTER

This counter will record total number of sheets.

The counter is located in the control cabinet

(CTR2).

Note ! Counter can not be reset.

3 Operation

3--9

C9999--2 Issue 1

PROCESS VALUE

SCROLL KEY

RETURN KEY

SET

VAL UE

CON:

Control

Output

ALM:

Alarm

Output

Fig. 3-17. Heater Temperature Control

3.2.3.15 Heater Temperature Control

Controls wheel heat temperature by cycling power

to the heaters. The setpoint temperature is

adjusted by using the buttons below the indicator

display.

The controller maintains process parameters when

power is off.

Touch Keys Description Function

Scroll Key Advances the index display to the desired position.

Indexes advanced continuously and cyclically by

pressing this keypad.

Up Key Increases the parameter (Set Point or Other)

Down Key Decreases the parameter (Set Point or Other)

Return Key Resets the controller to its normal status. Also stops

auto--tuning, output percentage monitoring and

manual mode operation.

Press for 6 seconds

Long Scroll Allows more parameters to be inspected or

changed.

Press for 6 seconds

Long Return 1. Executes auto--tuning function.

2. Calibrates control when in calibration level.

Press and

Output Percentage

Monitoring

Allows the set point display to indicate the control

output value in percent.

Press and

for 6 seconds

Manual Mode Execution Allows the controller to enter the manual mode.

This can be used if the sensor fails.

3 Operation

3--10

C9999--2 Issue 1

3.2.4 Telemecanique PLC Control

The Scott 10,000 incorporates two Telemecanique TSX07 Programmable Logic Controllers. Each controller

has a series of LEDs indicating the on/off status of its inputs and outputs. Separate LEDs also verify

communication between controllers. Check Electrical Sheets for a listing of the devices that are attached to

the controller and to which location (input/output), the device is attached.

When a device is active, the green LED is lit. The yellow com LED should always be lit. The second smaller

PLC will have a blinking red LED in the error position which is normal. The larger primary PLC error lamp

should not be lit.

Both PLC’s run LEDs should be solid green.

3 Operation

3--11

C9999--2 Issue 1

3.3 Preliminary Inspection and Start-Up Procedure

Fig. 3-18. Correctly Set Space Between Upper &

Lower Rollers

3.3.1 Preliminary Set-Up

3.3.1.1 Adjustment of the Space Between

Upper & Lower Bonding Rollers

It is important that the space between the upper

and lower bonding rollers is set correctly so that

the rollers grip the sheets properly but do not

actually contact each other. The rollers must not

bounce against each other as the sheets pass

through them.

If the rollers ride against each other, this will cause

the finish on the rollers to be damaged. Excessive

bouncing of the rollers will cause wear on the drive

gears and the chain drive. Bouncing will also

cause poor quality work since the rollers may not

maintain good contact with the tab just behind the

leading tab.

Step: 1. The machine must be in the Pendant

Mode when you adjust the space

between the rollers.

Fig. 3-19. Tighten Nuts to Raise Rollers

Step: 2. Raise the rollers by tightening the nuts on

the bearing blocks so as to lift the upper

rollers.

3 Operation

3--12

C9999--2 Issue 1

LOWER ROLLERS

UPPER ROLLERS

Fig. 3-20. Raise the Rollers By Tightening the

Nuts on the Bearing Blocks.

Step: 3. Insert a sheet of paper between the

rollers.

Step: 4. Lower the rollers until the paper is lightly

gripped.

Step: 5. Work back and forth between the two

rollers supported by each bearing block

until both rollers grip the paper lightly.

Step: 6. Check the rollers near the ends and

adjust between the inner and outer

bearing blocks until both ends of the

rollers grip the sheet uniformly.

Note ! The last step is important because if

the rollers and shaft are not parallel,

then many problems may occur. First,

if the gear set at the ends of the shaft

are either too tight or too loose, this

may cause the gears to wear

excessively. Second, if the rollers do

not grip the sheet all the way across,

this may cause the sheets to twist

causing quality problems.

Fig. 3-21. Reregister Roller Assembly

3.3.1.2 Adjust Reregister Roller Assembly

These units provide the grip on the sheet to drive it

in tightly against the tab cutter back stop and hold

it there while the sheet is being registered and

tabcut. Each of these units is provided with an

extension spring which is adjustable in tension by

turning the brass knob. When running the normal

range of paper stocks, this spring tension should

not require adjustment. However, when running

either lighter or heavier stocks, it may be

necessary to adjust the tension. Lighter stocks

have a tendency to buckle if the roller pressure is

too great and heavier stocks tend to bounce and

not cut uniformly.

3 Operation

3--13

C9999--2 Issue 1

Fig. 3-22. Pile Feeder Assembly

3.3.2 Pile Feeder

The paper feeder is specially designed to feed

index stocks at high speeds. It is very important

for the operator to keep the feeder in good working

condition and to learn how to adjust and correct for

various operating conditions. The importance of

this is magnified by two conditions. First, the

machine is handling papers which have already

been through two or three other machines and,

because of this, may not be in pristine condition.

Second, the stocks being fed may vary, and will

vary greatly in feeding ability. Knowing how to

make fine adjustments to compensate for various

paper conditions will greatly increase the

productivity of this machine.

VACUUM NOZZLES

Fig. 3-23. Vacuum Nozzles

The most critical area in any paper feeder is at the

point where the vacuum nozzles contact the top

sheet to lift it from the stack. If papers and

operating conditions were uniform all of the time,

this would not present a problem. However, the

papers handled by this machine tend to have

various curls, warpage, ripples, etc., which greatly

hamper feeding. The sheets may tend to curl up or

down or the entire stack may be tilted due to

moisture from printing. The following “hints” will

help the operator to keep the Scott 10,000

operating at maximum production speeds.

MOUNTING

BLOCK

SHEET

SEPARATOR

FINGER

Fig. 3-24. Adjustment to Feeder Nozzle

3.3.2.1 Sheet Separator Fingers

The position and condition of the sheet separator

fingers should be carefully maintained. Each sheet

separator finger should be centered both top and

bottom and right to left of the mounting block

opening. Care should be taken to make certain

that the fingers are free and extend into the sheet

about 1/8--inch (6.3mm). Whenever the position of

nozzles is changed, the stack guide should be

moved until the finger is slightly to the left of the

nozzle.

The separator fInger should be 1/2” (12.7mm)

above the paper stack.

3 Operation

3--14

C9999--2 Issue 1

VACUUM NOZZLE

MOUNTING

BRACKET

RETAINING RING

VACUUM

NOZZLE

MOUNTING

BRACKET

Fig. 3-25. Vacuum Nozzles Height Adjustment

3.3.2.2 Vacuum Nozzles

The machine is equipped with a floating nozzle cup

which does two things. First, it allows for slight

variations in the height of the stack and, second, it

allows the cup of the nozzle to conform to the curl

of the paper. The advantage of the floating nozzle

cup is that it will compensate for a much wider

range of operating conditions. It is important to

make certain that there is no binding condition in

the floating “cup” of the nozzle which prevents it

from dropping down on the paper each time.

The height of the vacuum nozzle is correctly set

when the retaining ring is even with the top of the

horseshoe shaped mounting bracket for the sheet

separater finger.

THUMB SCREW

MOUNTING BLOCK

VACUUM NOZZLE

PLUG

JAM NUT

Fig. 3-26. Nozzle Set Up Side to Side

Vacuum Nozzle Adjustments

Depending on size of the stock used, the vacuum

nozzles may have to be moved from one mounting

block to another.

To remove the vaccum nozzles and rubber plugs:

Step: 1. Loosen jam nuts and thumb screws.

Step: 2. Loosen the thumb screws and remove

nozzles and rubber plugs.

To Install Nozzles and Rubber Plugs:

Step: 1. Push nozzles all the way into the

mounting block and gently tighten thumb

screws and jam nuts.

3 Operation

3--15

C9999--2 Issue 1

MOUNTING SCREW

IN FEED ROLLER

FEED WINDOW

Fig. 3-27. Plastic Feed Window

3.3.2.3 Plastic Feed Window Adjustment

The plastic feed window holds the mylar in its

proper open position.

Step: 1. Loosen the in--feed roller shaft mounting

screw.

Step: 2. Rotate in--feed roller out of the way.

THUMB SCREW

Fig. 3-28. Window Assembly

Step: 3. Loosen the jam nut on the plastic thumb

screw.

Step: 4. Turn the plastic thumb screw

counter--clockwise until the window

assembly is touching the tip die and the

plastic feed tunnel.

Step: 5. Lift up the window assembly and place a

piece of the index stock (that will be used

during the production run) over the tip die

area.

Fig. 3-29. Feed Index Stock Under Window

Assembly

Step: 6. Set the window assembly down on the

index stock and slowly turn the thumb

screw clockwise until the piece of index

stock can be slide back and forth easily

without any drag or resistance.

Step: 7. Gently tighten the jam nut.

3 Operation

3--16

C9999--2 Issue 1

MOUNTING SCREW

IN FEED ROLLER

FEED WINDOW

Fig. 3-30. Adjust Feed Roller Tension

3.3.2.4 In--Feed Roller Tension Adjustment

The In--Feed Rollers are used to assist sheets into

the Heat Rollers.

To Adjust the In--Feed Rollers

Step: 1. Loosen the In--Feed roller shaft mounting

screw.

Step: 2. Use your fingers to apply downward

pressure to the spring plates and tighten

the mounting screws.

PAP ER S TOC K

STATIONARY

PAPER

GUIDES

ADJUSTABLE

PAPER

GUIDES

MIDDLE

FRONT

GUIDE

Fig. 3-31. Paper Side and Back Guides

3.3.2.5 Paper Side and Back Guides

The right hand guide remains in the same position

for all sheet sizes. The left hand guide must be

adjusted for sheet size. Allow approximately 1/16”

(1.5mm) freedom in the stack. The back guides

should be adjusted close to the stack.

3.3.2.6 Compensating for a Tilted Stack of Paper

Uneven paper stacks can be compensated for by inserting strips of binder’s board every so often on the low

side of the stack. It is recommended to use a piece of binder’s board the same size as the sheet as a

platform for the stack. Make sure it is heavy enough not to be picked up by the nozzles.

3.3.2.7 Curled Stock

The nozzles will compensate for quite a bit of curl in the paper. However, if the curl is too bad, it may be

necessary to roll the stock by hand before loading it into the pile feeder.

3 Operation

3--17

C9999--2 Issue 1

PILE HEIGHT

ADJUSTMENT

KNOB

Fig. 3-32. Pile Height Adjustment Knob

3.3.2.8 Pile Height Adjustment

During the operation of the machine, the paper

stack automatically rises until the top sheet

reaches a predetermined height. The stack height

is controlled by a checking bar above the stack.

As the stack approaches the feeding height, the

checking bar begins to strike the top of the stack.

The higher the stack, the less the bar moves and

the less the stack rises until it finally stops rising at

all. As sheets are fed into the machine, this has the

effect of lowering the top of the stack and the stack

begins to rise.

The height that the stack will rise to is controlled by

a hand knob on the outside of the R.H. feeder

cover. Lifting this hand knob will cause the stack to

rise to a higher point. Lowering the hand knob will

cause the stack to stop rising at a lower point.

During operation, the operator should lower the

hand knob to it’s bottom point; then with the

machine running and the vacuum on, gradually lift

the knob until the feeder begins to feed. The knob

should be kept at it’s lowest position possible

allowing stock to feed.

ADJUSTMENT NUT

Fig. 3-33. Vacuum System Adjustment

3.3.2.9 Vacuum System for Feeding Paper

The machine is equipped with a vacuum pump

which provides both vacuum for pick--up and blown

air for separating the sheets. The degree of

vacuum can be adjusted by adjusting the nut on

the vacuum relief valve located on the vacuum

gage.

The degree to which the vacuum is adjusted

depends on the weight and porosity of the paper

being fed. Generally speaking, the lighter and

thinner the paper, the lower the vacuum required.

The normal range of vacuum required will vary

from about 5 to 10 inches (.18 to .34 BAR) of

mercury as shown on the gage. The best practice

is to run as low as possible with continuous feeding

and with as least vacuum as possible.

3 Operation

3--18

C9999--2 Issue 1

AIR BLOW NOZZLES

Fig. 3-34. Blow --Air System

3.3.2.10 Blow-Air System

The blow-air system performs several functions.

First, it separates the sheets so the effect of the

vacuum bleeding through the paper is less critical.

Also, with the second sheet separated from the

first sheet, it allows air to get in between the sheets

when the top sheet is removed from the stack. This

prevents the first sheet from sucking up the second

sheet. Another function of the blow--air is to lift the

top few sheets until the top sheet is up against the

sheet separator finger. This establishes a uniform

height for the top sheet so that it will be in the

proper position when the nozzles come down for

the pick--up.

The feeder is equipped with four blow nozzles.

Two of these blow in from the edges of the stack

and two blow in from the front of the stack.

Fig. 3-35. Side Air Blow Nozzles

Blow air nozzle height is pre--set at the factory and

should not need to be adjusted. If they need

adjusting, the side nozzles are adjusted in height

by screwing them either up or down. The front

nozzles can be adjusted in height by first tilting

them toward the stack and then screwing them

either up or down.

To adjust direction of air nozzle, rotate nozzle to

desired location.

EXHAUST VALVE

Fig. 3-36. Adjust the Air Blow At the Exhaust

Val ve

The amount of blow--air from the nozzles can be

adjusted by use of the exhaust valve located on

the feeder guards.

The right exhaust valve controls the RH side air

blow nozzle and RH top air blow nozzle. The left

exhaust valve controls the LH side and top air

nozzles.

DO NOT RESTRICT THE BLOW AIR TO

THE POINT WHERE IT OVERLOADS

THE VACUUM PUMP. THIS CAN CAUSE

THE MOTOR TO BE DAMAGED.

CAUTION!

3 Operation

3--19

C9999--2 Issue 1

HAND

KNOB

HOLD--

DOWN

ROLLERS

Fig. 3-37. Pull-In / Hold--Down Rollers

3.3.2.11 Moving the Pull-In / Hold--Down

Rollers

The rollers can be positioned in any one of four

positions. To change, pull the hand knob up to

disengage and slide the assembly along the shaft

to the position desired.

3 Operation

3--20

C9999--2 Issue 1

3.3.3 Adjusting the Reregister Unit

Once the reregister section is adjusted for paper size, no operating adjustment should be necessary except

for dial positioning.

When the basic size of the sheet is changed, then it is necessary to adjust the unit.

Fig. 3-38. Sheet Length

3.3.3.1 Sheet Length

This is the length of the sheet from the binding side

to the edge of the tab.

The position of the delivery conveyor and the

pull--back unit should be adjusted so that the

spring gates are located approximately 1/2” in back

of the back edge (binding edge) of the sheet when

the front edge of the sheet is resting against the

tab cutter back stop in the position where it will be

tabcut. The sheet drive /holddown roller should be

tensioned as necessary using as many as

necessary to control the sheet. Adjust the sheet

catcher on the delivery conveyor so that it will

catch the sheets properly.

SHEET DRIVE /

HOLD--DOWN

ROLLER

REREGISTER

HOLDDOWN

ROLLER

Fig. 3-39. Sheet Width

3.3.3.2 Sheet Width

When the width of the sheet is changed, it may be

necessary to change one or more of the following

items:

1. Sheet Drive / Hold--Down Rollers: These

should be adjusted so that they hold the sheets

down near the outer edge. They must ride on

the feed tapes.

3 Operation

3--21

C9999--2 Issue 1

Fig. 3-40. Adjust Sheet Drive / Hold--Down

Rollers

Loosen knob and slide hold--down roller

assemblies where necessary.

MAKE CERTAIN THAT THE REAR TIP

OF THE HOLD--DOWN SHOE IS

NEITHER DOWN TOO TIGHT ON THE

LOWER TABCUTTER KNIFE SO AS TO

CAUSE THE SHEETS TO BIND OR SO

HIGH THAT THE INCOMING SHEETS

TEND TO STRIKE THE UPPER

TABCUTTER KNIVES.

CAUTION!

PAPER

HOLD--DOWN

ROLLERS

PAPER HOLD--DOWN BAR

REREGISTER BELTS

Fig. 3-41. Rollers

2. Paper Hold--Down Rollers underneath the

delivery conveyor: These rollers should be

aligned so that they on top of the register belts.

The paper hold--down bars should be between

the belts when the cross conveyor is in the

operating position (down).

HOLD--DOWN BAR ALLEN SCREW

COLLER

HOLD-- DOWN ROLLER

Fig. 3-42. Adjust Hold--Down Rollers and Bars

To adjust the hold--down roller position: Loosen the

Allen screws in the retaining collars and slide

rollers into correct position. Tighten Allen screw on

collers when roller assembly is in correct position.

To adjust the hold--down Bars: Loosen the Allen

screws in the bars and slide into position. Tighten .

3 Operation

3--22

C9999--2 Issue 1

PULLBACK HOLD--DOWN ROLLERS

Fig. 3-43. Pullback Hold--Down Rollers

3. Pullback Hold--Down Rollers: Adjust so that the

two outside units hold down near the outer

edges of the paper.

Fig. 3-44. Adjust Pullback Hold--Down Rollers

Loosen the Allen screw to move the guide

assembly. Always make sure the lower roller is on

the crown of the small pullback roller.

PULLBACK

ROLLERS

Fig. 3-45. Kick Back Rollers

4. Pull--Back Rollers: Normally no adjustment is

necessary.

3 Operation

3--23

C9999--2 Issue 1

MAIN

POWER

SWITCH

Fig. 3-46. Circuit Breaker Switch (ON)

3.3.4 Machine Start--Up

Step: 1. Main Power Switch ON.

HEATER

Fig. 3-47. Warm Up Heater

To laminate plastic to paper:

Step: 2. Press HEATER pushbutton.

Step: 3. Set temperature controllers to

220--230_F as a starting point.

Note ! Starting Heaters now will allow

heaters to reach operating

temperature while the rest of the

machine is being set up.

ADJUSTMENT KNOB

Fig. 3-48. Loosen Folding Roller Guide

Adjustment Knob

Reel Holder

Step: 1. Loosen adjustment knob on the bottom

folding roller guide.

3 Operation

3--24

C9999--2 Issue 1

3 FILM THICKNESS

3 FILM THICKNESS

DRIVE ROLLER

FOLDING ROLLER GUIDES

Fig. 3-49. Set Gap Between Plastic Feed Roller

Guides to 3 Film Thickness

Step: 2. Set the gap between the plastic folding

roller guides to three film thickness by

moving the lower roller guide.

Step: 3. Tighten the adjustment knob.

FILM

REEL

FILM

SPOOL

FILM

GUIDES

Fig. 3-50. Loading the Film

Step: 4. Load film reel on the reel holder.

Note ! Film from the factory is wound on the

spool with the glue side facing out.

Step: 5. Thread film through the film guides as

shown.

3 Operation

3--25

C9999--2 Issue 1

PLASTIC FEEDER

GUIDE ROLLER

Fig. 3-51. Hand Feed Film into Machine

Step: 6. Hand feed film into the plastic feed

mechanism.

Note ! The glue side of the film should be

against the guide roller.

RUN

SAFE

MAINT

Fig. 3-52. Key Switch

Step: 7. Turn key switch to RUN.

RESET

Fig. 3-53. Reset Pushbutton

Step: 8. Press RESET pushbutton.

DRIVE SPEED

Fig. 3-54. Adjust Drive Speed to 7

Step: 9. Adjust Drive Speed to 7.

3 Operation

3--26

C9999--2 Issue 1

START

Fig. 3-55. Start Pushbutton

Step: 10.Press START pushbutton.

PLASTIC

ADVANCE

Fig. 3-56. Plastic Advance Pushbutton

Step: 11.Press and hold PLASTIC ADVANCE

pushbutton till plastic (Mylar) enters the

Tip Die.

Note ! The Plastic Advance button is located

on the right side of the electrical

cabinet directly over the Tip Die

assembly.

STOP

Fig. 3-57. Stop Drive Pushbutton

Step: 12.Press STOP pushbutton.

3 Operation

3--27

C9999--2 Issue 1

FILM TIP DIE

FILM STOP

ADJUSTMENT

SCREW

1/32”

Fig. 3-58. Remove Film Scrap from Tip Die Area

Step: 13.Lift the window assembly to expose the

Tip Die.

Step: 14.Loosen the film stop adjustment screw.

Step: 15.Set film stop to 1/32” from edge of film

after plastic size handwheel has been

set.

Step: 16.Retighten the film stop adjustment screw.

Step: 17.Remove film from Tip Die.

Step: 18.Lower the window assembly.

DRIVE ROLLERS

FOLDING

ROLLERS

GUIDES

Fig. 3-59. Inspect Plastic Feed Area

Step: 19.Inspect the folded plastic (Mylar) film that

has been fed through the folding roller

guides and into the drive roller assembly.

3 Operation

3--28

C9999--2 Issue 1

DRAG

ROLLER

KNOB

MYLAR

FOLD

UNEVEN

EDGE

MYLAR FILM

TOP VIEW

ROLLER

FOLDING

GUIDE

ROLLER

Fig. 3-60. Move Drag Roller Left If Mylar is

Tracking Unevenly

Step: 20.If the plastic (Mylar) fold is uneven, move

roller to the left as shown in Fig. 3-60.

3 Operation

3--29

C9999--2 Issue 1

DRAG ROLLER KNOB

MYLAR FILM

TOP VIEW

ROLLER GUIDE

ROLLER

FRONT VIEW

ROLLER

MYLAR

FOLDING ROLLER GUIDE

MYLAR

Fig. 3-61. Inspect Plastic Feed Tracking

Step: 21.If Mylar is tracking behind the fold and drive rollers, move roller to the right as shown in Fig. 3-61.

3 Operation

3--30

C9999--2 Issue 1

PAP ER L I FT

HAND-

WHEEL

PAP ER

SUPPORTS

Fig. 3-62. Set Paper Lift

Loader Set--Up.

Step: 1. Pull out the paper lift handwheel and

lower the paper lift.

Step: 2. Set paper supports to fit paper.

Note ! Make sure left support is not

underneath left guide rail.

3 Operation

3--31

C9999--2 Issue 1

PAP ER L I FT

HANDWHEEL

PAP ER

STOCK

PAPER

GUIDES

MIDDLE

FRONT

GUIDE

Fig. 3-63. Load Stock

Step: 3. Load paper stock.

Step: 4. Push handwheel in and raise the paper

lift till the paper is level with top screw of

the middle front guide.

Note ! Make sure paper lift handwheel is fully

engaged. If not, the stack may fall

without warning.

Step: 5. Adjust paper guides (length & width).

PILE HEIGHT

ADJUSTMENT

KNOB

Fig. 3-64. Adjustment Knob

Step: 6. Depending on the curl and weight of the

stock, adjust the pile height with the

adjustment knob.

● Up for heavier or downward curl stock.

● Middle for normal and straight stock.

● Down for lighter or upward curl stock.

SPRING

HEX

NUT

VACUUM

GAGE

PLUNGER

Fig. 3-65. Vacuum Setting

Step: 7. Adjust Vacuum.

Note ! The vacuum starting point is 10 inch

pounds (0.34 kPa) for standard index

stock. The vacuum can be adjusted

by turning the hex nut to tighten or

loosen the spring, while keeping the

plunger stationary.

3 Operation

3--32

C9999--2 Issue 1

PAPER

FEED

RESET

Fig. 3-66. Start Up Air Valves

Set Sheet Separators And Separator Air Valves

Adjust valves according to the size and weight of

the paper. The following steps will start the Blower,

so that the system can be adjusted.

Step: 1. Push RESET button.

Step: 2. Push PAPER FEED button.

Step: 3. If the vacuum nozzles are not in an

upward position, index machine to place

them there.

LH SIDE

BLOW

AIR NOZZLE

LH TOP

BLOW

AIR NOZZLE

SEPARATOR

FINGERS

RIGHT EXHAUST VALVE

LEFT EXHAUST VALVE

EXHAUST VALVE

Fig. 3-67. Set Up Air Valves