Page 1

Control system

Rinnai

For the heating specialist

Operating and installation instructions

Room control unit RS100

Page 2

Contents

General safety instructions...........................................................3

Safety measures for electric - compliant installation .................3

Installation of the room control unit.............................................5

Mounting location .................................................................................................5

Mounting instructions ...........................................................................................5

Electrical connection ............................................................................................6

Electrical connection at boiler...............................................................................6

Accessories ....................................................................................7

Outdoor sensor ....................................................................................................7

Resistance values of outside sensor.....................................................................7

Co m m i s s io nin g o f t h e r oom c o n t r o l u n it.........................................8

Language .............................................................................................................8

Code input............................................................................................................8

Site information..........................................................................10

Parameter synoptic......................................................................11

Overview of installer parameters and adjustment options .................................12

2

Page 3

General safety instructions

All electrical connections and safety

measures have to be carried out by a

specialist in due consideration of valid

standards as well as the local regulations.

The electrical connection has to be done

according to the specications of the

respective boiler manufacturer.

WARNING

Indicates an imminently

hazardous situation

which, if not avoided,

could result in death or

serious injury.

WARNING

Disconnect power before opening. Making

connections under voltage may damage the

control or cause dangerous electrical shocks.

120 volts is supplied to the control.

Safety measures for electricalcompliant installation

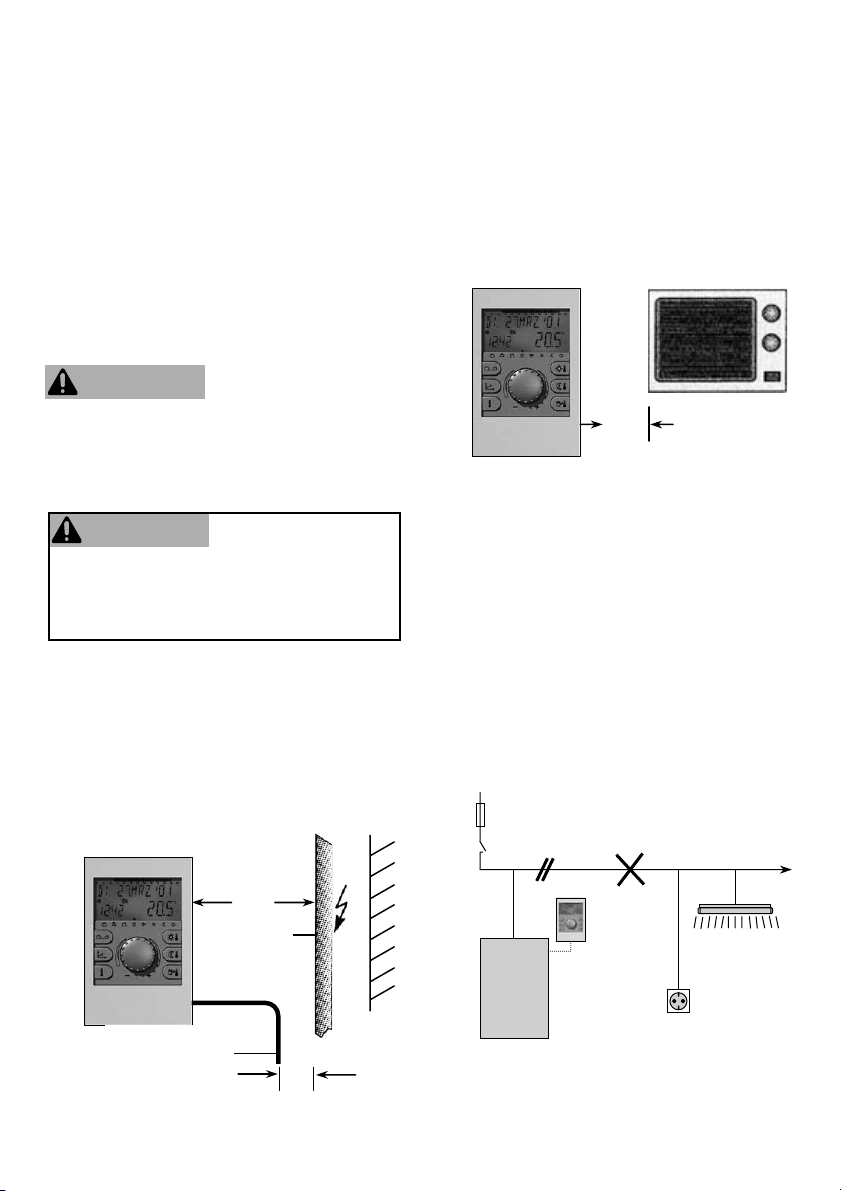

1. Cables with 120 V voltage must be

generally routed separately from

sensor lines and data bus cables.

A minimum distance of 0.8 in (2 cm) between

the lines is mandatory. Crossing of lines is

permitted.

Data bus line 12 V~

Fig. 1: Minim um dist anc es for e lectr ic al conn ec ti on

5.9 in

15 cm

Mains 120 V~

0.8 in

2 cm

3

2. When installing the room control unit a

minimum distance of 15.75 in (40 cm)

must be maintained to other electrical

utilities with electromagnetic emissions,

such as power contactors, motors,

transformers, dimmer switches,

microwave ovens and televisions,

loudspeakers, computers, mobile

phones etc.

Fig. 2: Minimum distance to other electric

instruments

The main connection for the heating

3.

15.75 in

40 cm

system (i.e. boiler - control unit) must be

designed as an independent electrical

circuit. Do not connect uorescent lamps

or other electrically powered devices which

could be a source of electrical interference.

Even the possibility of such

connections/interference should be ruled

out.

Control unit 16 A

Heating room emergency

switch

Only connect heating

room lighting and

sockets on separate

power circuit!

Room control

unit

Boiler

Fig. 3: Electric routing in heating room

Page 4

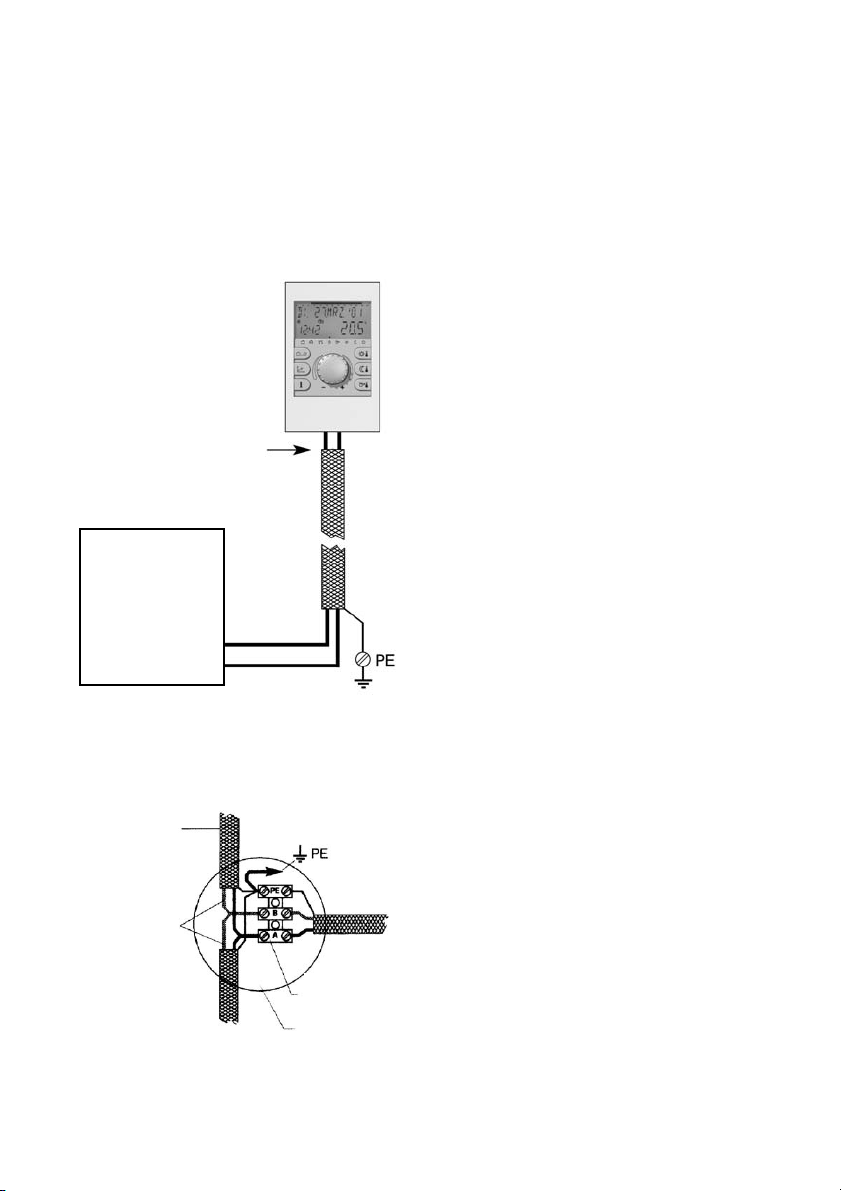

4. It is suggested to use a shielded cable

for all installations.

5. The shielding of the cable has to be

connected with earth potential, i.e.

boiler covering, connecting terminals for earth potential etc. Multiple

grounding is not permitted (humming

loop).

Do not ground here!

Boiler control in

boiler control unit

Connection,

depending on version,

directly or via suitable

interface

Fig. 4: Screen gr oun de d in centr e

In star shaped networks it is not

permitted to ground cables on both

sides. They should be grounded in the

center.

Screen

2-wire

data bus line

Distribution

terminal

Distribution box

Fig. 5: Grounding in star shaped networks

6. The outside sensor may not be

installed close to transmitting or

receiving equipment (on garage walls

close to receivers for radio-controlled

garage door openers, amateur radio

antennas, radio controlled alert

systems or close to large scale radio

transmission equipment).

Recommended cable cross-sections

and maximum permitted cable lengths:

A – Sensor lines

For all low voltage cables such as

sensors, external selectors, bus and

analogue in- and outputs, heat requiring

by means of external contact, modem

connection cables, etc.: 0.0008 in (0.5 mm )

2

(18 AWG)

Maximum permitted cable length: 164 ft

(50 m).

Longer connecting cables should be

avoided in order to reduce the risk of

electrical interference.

B – Data bus lines

Recommended cable:

J-Y(St)Y 2 x 0.0009 in (0.6 mm )

2

2

(18 AWG)

Maximum permitted cable length: 164 ft

(50m)

Longer connecting cables should be

avoided in order to reduce the risk of

electrical interference.

4

2

Page 5

Installation of the room control

unit

Mounting location

a – for applications without room sensor

If the internal room sensor is not to be

activated the unit may be mounted at

any location indoors.

b – for applications with room sensor

The activated room sensor should be

xed at a height of approx. 4-5 ft (1.2-1.5 m)

at a place most representative of all

rooms. It is recommended to choose a

partition wall in the coolest day room. In

order to ensure sucient air circulation

at the room station, it must be mounted

to the wall with a gap in between.

The unit must not be mounted:

– at locations subjected to direct solar

radiation (consider the position of the

sun during winter).

– close to heat-generating appliances,

such as televisions, refrigerators, wall

lamps, radiators etc.

– on walls with heating or domestic hot

water pipes or chimneys behind.

– on non-insulated outside walls

– in corners or wall recesses, shelves or

behind curtains (insucient ventilation)

– close to doors of unheated rooms

(inuence of low temperatures)

– on unsealed ush-type boxes

(inuence of external low temperatures

due to the chimney eect of installation

tubes)

– in rooms with radiators controlled by

thermostatic valves (mutual inuence).

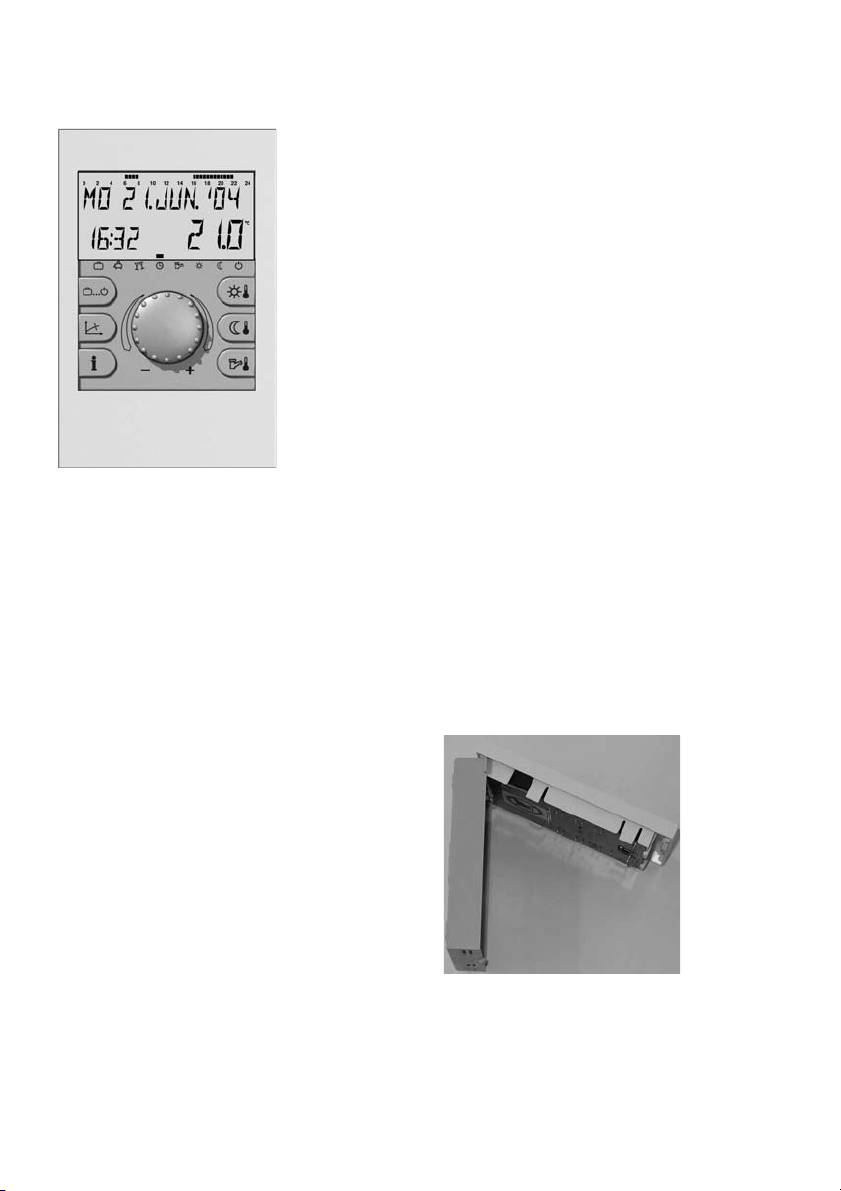

Mounting instructions

After removing the front panel by pressing

the locating lug the wall mounting base

can be taken o and mounted at the

desired location using the enclosed dowel

pins and screws. The data bus line must

thereby be routed through the bottom

cable gland.

Recommended connecting cable:

J-Y(ST)Y 2 x 0.0009 in (0.6 mm ) (18 AWG /

2 conductor twisted pair shielded cable)

(2 wires not in use).

Maximum cable length: 328 ft (100 m)

Note:

For new installations, a ush-mounting

switch box is recommended to ensure

perfect routing of the cable.

Locking lug

2

2

5

Page 6

Electrical connection

The 2-strand data bus cable is connected

to terminals A and B of the 2-pole terminal

strip on the bottom plate.

Socket (unit removed)

Important!

The connections are not interchangeable

and must be installed in the socket in

compliance with the identification A and B.

Once the electrical connection is

completed, the room control unit is hooked

in flush at the top of the wall mounting

base and folded down until the locking lug

audibly clicks into the wall mounting base.

A B

Electrical connection at

boiler

The electrical connection depends on the

type and version of the respective heating

generator and takes place directly at the

terminals A and B in the corresponding

boiler control or interface.

Further detailed information can be found

in the documentation for the

corresponding boiler.

6

Page 7

Accessories

Outdoor sensor

Outdoor sensor AF 120

Mounting Location

The outdoor sensor should be mounted on

the most exposed and coldest side of the

building (north or north-east) at a height of

min. 79 in (2 m) above ground.

Exception: If the preferred living area is

situated in a dierent

direction, the outside sensor

should be mounted on the

respective side of the building

accordingly.

When mounting the sensor consider external

heat sources (heated chimneys, warm hot

air from air shafts, installation on black

surfaces, thermal bridges in the wall, etc.)

which could falsify the measuring value.

The cable outlet must always be directed

downwards in order to avoid the

penetration of moisture.

Installation and electrical connection

1– Route the sensor cable to the chosen

mounting location.

2– Loosen lid screws from sensor case

and remove top.

3– Mount sensor base with enclosed

central fastening screw. Use sealing

ring! The cable outlet must be directed

downwards!

4– Insert the sensor cable so that the

cable jacket is fully enclosed by the

sealing lip.

5– Establish the electrical connection. To

this end, preferably use a 2-strand

cable with a minimum cross-section of

2

(18 AWG). The connection is made

1 mm

at the 2 screw terminals inside the

sensor case and may be interchanged.

6– Attach the lid again and screw it

rmly onto the base. Ensure correct t

of sealing ring.

Resistance values of outside sensor

For outside sensor AF 120:

T (°F)

- 4

T (°C) R (k

- 20

- 5

14

23

- 15

- 10

- 5

32

41

± 0

5

50

10

59

15

68

20

77

25

86

30

Note:

If other outside sensors are in use, the

respective resistance values, depending

on the temperature, can be found in the

technical documentation of the boiler

manufacturer.

The electrical connection of the respective

sensor in the boiler is described

in the respective installation instructions of

the boiler.

)

98.93

76.02

58.88

45.95

36.13

28.60

22.88

18.30

14.77

12.00

9.804

7

Page 8

Commissioning of the room

control unit

Language

During the rst activation or with each

return of voltage after a power failure all

segments available in the display will

appear:

0 2 4 6 8 10 12 14 16 18 20 22 24

The desired language can be selected.

Ff Language

This is followed by the equipment version

and the current version number of the

software.

If there is no alarm present, the standard

display with date, time and current

boiler temperature will appear thereafter.

0 2 4 6 8 10 12 14 16 18 20 22 24

An active summer switch-o is identied

by a sunshade symbol (

0 2 4 6 8 10 12 14 16 18 20 22 24

An active frost protection function is

represented by a ice crystal symbol (

0 2 4 6 8 10 12 14 16 18 20 22 24

°C

KWh

Min

%

40 5

40 5

D

V3 .0

40 .5

Segment test

°C

KWh

Min

%

Unit version

Interface version and

version number

Standard display

Wed. Aug. 25, 2004

°C

16:32 hrs Temp. 40.5°

).

Summer shutdown

°C

active

Frost protection

°C

°C

active

C

).

Code input

Installer code

After entering the installer code all

parameters determined for the heating

specialist are released and can be edited

in accordance with the system version.

In order to enter the installer code, the

keys

simultaneously for approx. three seconds,

until the code input appears in the display.

CODE

Each ashing digit is set by using the

rotary pushbutton in accordance with the

code number and is conrmed by pressing

the button. All other digits are edited in the

same way.

After the code has been entered correctly,

the acknowledgement INSTALLER OK will

appear upon conrmation of the last digit,

after a wrong entry, the message CODE

ERROR will appear.

INSTALLER

The factory set installer code is :

Note: If the code is not accepted

Attention: Enabled parameters will be

and must be pressed

+

0

000

CODE ERROR

OK

1 2 3 4

you should consult the

manufacturer!

blocked again if no further

action takes place over a

period of ten minutes. In this

case the installer code must

be entered again.

8

Page 9

Alarm messages

In order to be able to perform an exact

diagnose in case of a problem the control

system is equipped with a comprehensive

fault alarm system. Depending on the

nature of the fault a corresponding alarm

message will appear in the display of the

room control unit.

The display and processing of logic alarms

is deactivated in the factory and can be

activated in the SYSTEM level by enabling

Parameter 13 (= Logic alarm). The entry

into the level selection and the entry into

the levels is shown in the Parameter

synoptic (see page 11).

Further processing of errors:

– Errors appear in the standard display of the

control

– System errors appear in the info-level at the

corresponding info-value

– Errors may be taken over into the error

message register (see description

opposite).

Detailed information about errors of the

boiler can be found in the

documentation of the boiler.

Alarm message register

The room control unit is provided with an

alarm message register, which is able to

hold maximum 20 alarms. The alarms are

displayed with date, time, and nature of

fault (error number), the errors are polled

in the sequence of their occurrence in the

level ALARM.

The latest (= up-to-date) alarm is

prioritized at first position, alarms that

have arrived before appear in the order of

their occurrence. Upon arrival of a new

alarm the last (20.) alarm will be deleted.

Alarm messages from condensing boiler

controls represent a special feature. If

enabled (SYSTEM parameters 27 and

28), these will be written into an own alarm

message memory.

Alarm messages from boiler control

If boiler controls are used in the respective

boiler, the alarm messages are

divided into:

A - permanent faults (permanent locking)

with error code E-XX

B - temporary faults (self-eliminating

locking) with error code B-XX

Fault category A Locking E-XX

Fault category B Blockage B-XX

9

Page 10

Site information

After accessing the information level using the

information key

system temperatures can be requested one

by one by turning the rotary pushbutton

clockwise or counter-clockwise. Entry occurs

at the respective outside temperature.

INFORMATION DISPLAY VALUE DISPLAY CONDITIONS

, all available site- and

A - Site and system temperatures

If set value is displayed in the following

table in the category "display value", it will

appear when the rotary pushbutton is

pushed.

The following displays only appear under

the specied display conditions.

Outside temperature

Outside temperature

Boiler

temperature

Boiler

return ow

temperature

Flue gas temperature Actual value If ue gas sensor is present

Hydraulic pressure Actual value If pressure sensor is present

Hot water generator

Room temperature

Direct circuit

B - Operat ing st at es

After entering the information level by means of

the information key

states and usage data such as

INFORMATION DISPLAY VALUE COMMENTS

Status

Direct circuit

Status

domestic hot

water circuit

Status

Boiler

Starts

Boiler

Operating hours

Boiler

Thermostat function

Direct circuit

Actual value/

Set value = mean value

Minimum/maximum

value (0.00 to 24.00 h)

Actual value/ set value

Actual value If return ow sensor is present

Actual value/ set value

Actual value/ set value

all available operating

AUTO P2 DAY

HC ON

AUTO DAY

DHW OFF

HEAT GENER.

ON

STARTS

1483

OPER. HOURS

485

THERMOSTAT

HC OFF

If outside sensor is connected

If outside sensor is connected

If hot water generator os present

If room sensor is enabled

counter readings, specied performance data

etc. can be requested after each other by turning

the rotary push-button counter-clockwise.

Operating mode /

status of heating pump

Operating mode /

status of heating pump

switching condition of boiler(ON/OFF)

Sum of boiler starts

Sum of boiler operating hours

Room thermostat function is active

Room temperature limitation currently ON/OFF

-program/ heating mode

-program/ heating mode

10

Page 11

Parameter synoptic

Entry into the level selection: Hold rotary push-button pressed for approx. 3 seconds - automatic call of time programs

Programming Configuration Control circuits Service

DATE

TIME-

Param. No.

TIME

1

(h/min)

YEAR

2

DAY-

3

MONTH

CHANGE

4

Su-Wi AUTO

5

6

7

8

9

10

11

12

13

14

15

16

17 ERR-17 ERR-17

18

19

20 ERR-20 ERR-20

21

22

23

24

25 HC name Out-lock

26 .

27

28 Alarms 2

Parameters without background color: User Parameter, accessible without code

Parameters with light grey background: Installer Parameter, only accessible with installer code

Parameters with dark grey background: Only accessible with installer code and certain settings

GRAMS

TIMEPRO-

See

instructions

Select required level via rotary push-button and conrm, enter code if necessary

Output

SOL-P

Output

HC

HYDRAULIC

SYSTEM

LANGUAGE

TIME PROGRAM

CONTROL

MODE

SUMMER

(switch-o)

System frost

protection

DHW ma x. limi t

Climate zone

Building

Time for

automatic exit

Logical error

message

Release

Cycle temperature

Frost protect.mode

Constant/cycli c

operation

Anti-blocking

protection

Fahrenheit range

Alarm messages

boiler control

RESET to factory

values

DHW

DHW-NIGHT

temperature

LEGION. PROT.

DAY (week-day)

Legionella

protection (time)

Legionella

protection

(temperature)

ERR-10 ERR-10

ERR-18 ERR-18

ERR-19 ERR-19

CIRC

UNMIXED

RED.

HEATING

HEAT.SYSTEM

Room sensor

Room eect

factor

Adaptation

heating curve

Inrush

Optimization

Heating limit

Room frost

protection

temperature

Room thermostat

function

Constant

control unit

Min-limit

heating circuit

Max-limit

heating circuit

Excess

boiler

Screed

function

Room control

P-range

Room control

Adaptation time

11

HEAT

ERR-1 ERR- 1

ERR-2 ERR-2

ERR-3 ERR-3

ERR-4 ERR-4

Boiler set

back

ERR-6 ERR-6

ERR-7 ERR-7

ERR-8 ERR-8

ERR-9 ERR-9

ERR-11 ERR-11

ERR-12 ERR-12

ERR-13 ERR-13

ERR-15 ERR-15

ERR-16 ERR-16

RESET

Oper.data

ALARM

GENER.

ERR-5 ERR-5

ERR-14 ERR-14

ALARM 2

Room sensor

Unmixed circ.

SENSOR

Outdoor

sensor

ADJ.

Page 12

Overview of installer parameters and adjustment options

HYDRAULIC Level

The parameters of this level refer to the general hydraulic system of the b o i l er as

well as to the functionality and conguration of the programmable inputs and outputs for

the corresponding boiler components.

Parameter Designation Setting range / Setting values

02

05

Function assignment of output

for DHW-loading pump

Function assignment of output

for unmixed circuit pump

OFF No function

1 DHW-loading pump

OFF No function

2 Unmixed circuit pump

6 Constant control unit

Fact.

setting

1

2

SYSTEM Level

The parameters in this level refer to the general limiting parameters and setting values in

the heating system to be used.

Parameter

LANGUAGE

TIME

PROGRAM

CONTROL

MODE

SUMMER

05

09

10

11

13

18

19

23

Designation Setting range / Setting values

DE German CZ Czech

GB English PL Polish

Font language

selection

Number of enabled time

programs

Enabling of separate control

mode setting

Limit temperature for summer

switch o

System frost protection

Climate zone -4°F..32°F (-20..0.0°C)

Type of building

Time for automatic exit

Logical error message OFF, ON OFF

Release cycle temperature OFF, ON ON

Frost protection mode

Anti-blocking protection OFF (0000), 0001...9999 OFF

FR French RO Romanian

IT Italian RU Russian

NL Dutch TR Turkish

ES Spanish S Swedish

PT Portuguese N Norwegian

HU Hungarian

P1 Only one time program enabled

(unmarked)

P1-P3 Three time programs enabled,

(marked)

1 Common adjustment for all

Heating circuits

2 Separate adjustment for every

individual heating circuit

OFF no function

System frost protection…86°F (30 °C)

OFF no function

-4°F (-20°C)...Summer switch-o

1 light construction

2 medium construction

3 heavy construction

OFF No automatic return

0,5...5 after adaptation time, autom.

(min) return to standard display

OFF Permafrost protection according to Adj.

Param. 5

0,5...60 min cy clic ope rati on

Fact.

setting

D

P1

1

68 °F

20 °C

37 °F

3 °C

10 °F

-12 °C

2

2 min

OFF

setting

Individual

setting

Individual

12

Page 13

24

27*

28

RESET

Fahrenheit range OFF, ON OFF

1 Shown on display screen only

2 Message from system interlocks

Alarm messages system

handling

Automatic boiler control

Alarm message memory 2 OFF, ON

Reset to factory values

3 Messages from interlocks and

blockages into the system

4 Message from interlocks,

blockages and warnings into the

system

in dependence on access code only to

released parameters

OFF

OFF

–

* Function dependent upon support from boiler control system

DHW level

This level contains all parameters which are necessary to program the DHW circuit with

the exception of the DHW time programs.

PARAMETER

DHW NIGHT DH W ec o no m y t em p e ra t u re

LEGION.PROT.

DAY

03

04

06

1)

Setting ranges and maximum temperatures, depending on the version, are set by the boiler control

Designation Setting range / Setting values

DHW legionella protection - day

(to enable, select weekday)

DHW legionella protection - time

(only appears if Parameter

LEGION.PROT. DAY is

enabled)

DHW-legionella protection-temp.

(only appears if Parameter

LEGION.PROT. DAY is

enabled)

DHW- maximum temperature

limit

41°F (5 °C) ... DHW maximum temperature

OT OFF ... DHW Day

OFF No legionella protection

Mo...Su Legionella protection on the

specied weekday

ALL Legionella protection every weekday

00:00...23:00 o'clock

50°F (10°C)

68°F (20°C)

temperature

1)

... DHW maximum temperature

1)

... Boiler maximum

1)

Fact.

setting

104 °F

40 °C

OFF

02:00

149 °F

1)

65°C

149 °F

65°C

1)

1)

Level UNMIXED CIRCUIT

This level contains all necessary parameters for the programming of the unmixed

heating circuit with the exception of the time programs.

PARAMETER Designation Setting range / Setting values

RED.

HEATING

HEAT.SYSTEM Heating system (exponent) 1.00 … 10.00

03

04 Room eect factor OFF, 10 ... 500 %, RC (only room control)

Type of reduced operation

Room intrusion (in

connection with room

sensor)

ECO - switch-o operation

RED - set-back operation

OFF - without room sensor

1 - room sensor enabled

3 - room sensor only for room-temp display

Fact.

ECO

1,3

OFF

OFF

setting

setting

Individual

setting

Individual

13

Page 14

05 Adaptation heating curve OFF, ON (not during HC = constant control)

06 Inrush optimization

07 Heating limit

08

09 Room thermostat function OFF, 0.5 ... 5 K

11 Constant control unit 10 ... 95°C (only if Par. 05 – Hydraulic =6)

12 Minimum temperature limit

13 Maximum temperature limit

14

16 Screed function OFF, 1, 2, 3 (only if funct. SPL = OFF)

23*

24*

HC-name

* only if remote unit is room controller (PARAMETER 04 = RC)

Room frost protection

temperat ure

Temperature excess boiler

heating circuits

Room control

P-range (K-factor)

Room control

Adaptation time Tn

Heating circuit name 00000 … ZZZZZ empty

OFF, 1 ... 16 h

OFF, 0,5...40,0 K (not during HC= constant

contr.)

5 ... 30 °C

10 °C ... setting

Maximum temperature limit (Parameter 13)

Minimum temperature limit (Parameter 12) ...

95 °C

-5 ... 20 K

1 ... 100 (only if Parameter 4 = RC)

5 ... 240 (only if Parameter 4 = RC)

OFF

OFF

OFF

10 °C

OFF

20 °C

20 °C

75 °C

0 K

OFF

8

35

Level HEAT GENER.

This level contains all parameters which are necessary to program the heating generator.

PARAMETER Designation Setting range / Setting values

05

25 Outside temperature limit OFF, -20 ... +30

31 Reset operation data SET

Limiting mode

WE-minimum temperature

1 = Minimum limitation depending on demand

2 = Limited minimum limitation

3 = Unlimited minimum limitation

Fact.

1

OFF

--

setting

Level ALARM MESSAGE

In this level up to 20 alarm messages can be stored, these are permanently updated.

Parameter

01 Alarm message #1

02 Alarm message #2 Next to last alarm message

…

20

Designation Setting range / Setting values

Last alarm message

… …

Alarm message #20 First alarm message

Fact.

setting

14

setting

Individual

setting

Individual

Page 15

ALARM 2 Level (..C..)*

In this level up to 20 alarm messages can be stored, these are permanently updated.

Parameter

01 Alarm message #1

02 Alarm message #2 Next to last alarm message

…

20

* only in connection with a H-GEM interface and SYSTEM-parameter 28=ON

Designation Setting range / Setting values

Last alarm message

… …

Alarm message #20 First alarm message

preset

Factory

setting

Individual

Level SENSOR CALIBRATION

In this level all sensors connected to the central control unit can be corrected by ± 5 K with

respect to the factory settings.

PARAMETER Designation Setting range / Setting values

01 Room sensor adaptation

02

Outside temperature

adaptation

- 5 K ... + 5 K

- 5 K ... + 5 K

Fact.

setting

setting

Individual

15

Page 16

Notes

100000157 9/2009

16

Loading...

Loading...