Scotsman Ice Machine C1448R Installation Manual

Installation and

User's Manual

Models C1448R, C1848R, C2148R

Introduction

C1448, C1848, C2148

Remote Condenser Models - User Manual

The design of this modular remote cuber is the

result of years of experience with remote ice

machine refrigeration systems. Standard features

This installation and user manual is divided into

three sections: Installation, Use and Operation and

Maintenance.

of this product include front accessible on-off

switches, always-visible indicator lights,

mechanical assist ice harvest for extra efficiency,

automatically adjusting water purge and a control

system that optimizes system operation.

The Installation section provides the trade person

with the information needed to properly install and

start up this ice system. The Use and Operation

section provides the user with the information

needed to use the machine. The Maintenance

section contains the instructions and schedules for

the sanitation and cleaning of the machine.

Table of Contents

Installation: Product Specifications ....................................Page 2

Model Number Description ........................................Page 3

Product Description and Electrical Requirements ............................Page 4

Condenser and Ice Machine Layouts ..................................Page 5

Water ...................................................Page 6

Panel Removal ..............................................Page 7

Remote Condenser Location .......................................Page 8

For The Installer: Remote Condenser ..................................Page 9

Precharged Line Routing .........................................Page 10

Coupling Instructions ...........................................Page 11

Plumbing Requirements .........................................Page 12

Drains ...................................................Page 13

Electrical .................................................Page 14

Final Check List: .............................................Page 15

Initial Start Up ..............................................Page 16

Adjustments ...............................................Page 17

Use and Operation ............................................Page 18

Switches .................................................Page 19

Options and Other Information ......................................Page 20

Cleaning, Sanitation and Maintenance ..................................Page 21

Remote condenser ............................................Page 23

What to do before calling for service ...................................Page 24

Note the Caution and Warning symbols when they

appear on the product or in this manual. They

indicate potential hazards.

Keep this manual for future reference.

November 2006

Page 1

C1448, C1848, C2148

Remote Condenser Models - User Manual

Installation: Product Specifications

Location Limitations

This ice system is made up of three parts, the ice

making machine, or head; the remote condenser;

and the interconnecting tubing. The ice making

machine must be installed indoors, in a controlled

environment. Space must be provided near the

machine for service access. The remote condenser

may be installed above or below the ice machine,

per the limits stated later in this manual. The

remote condenser may be installed outdoors within

the temperature limits listed below. The

interconnecting tubing must be installed per the

directions stated in this manual, and the amount of

tubing exposed to uncontrolled temperatures must

be minimized.

Space Limitations

Although the machine will function with no

clearance to the top and sides, some space must

be allowed for service access. Building the

machine in with no access will cause higher service

cost, in many cases this extra cost may not be

covered by warranty.

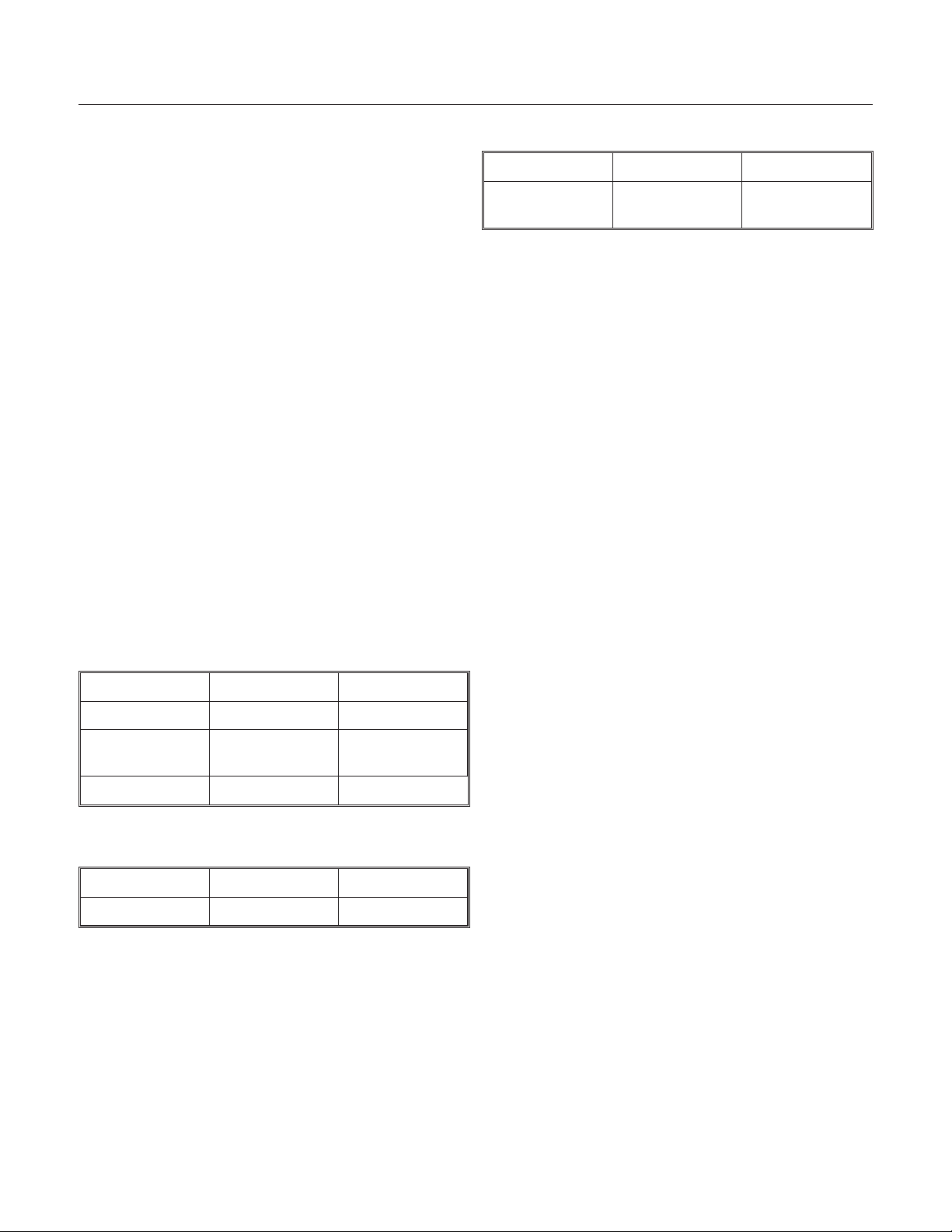

Environmental Limitations, ice machine:

Minimum Maximum

o

Air temperature 50

Water

temperature

Water pressure 20 psi 80 psi

F. 100oF.

o

40

F. 100oF.

Power Supply

Minimum Maximum

208-230 volt

model

198 volts 253 volts

Warranty Information

The warranty statement for this product is provided

separately from this manual. Refer to it for

applicable coverage. In general warranty covers

defects in material and workmanship. It does not

cover maintenance, corrections to installations, or

situations when the ice machine is operated in

circumstances that exceed the limitations printed

above.

Product Information

The machine is a specialized version of a modular

cuber. A modular cuber does not include any ice

storage, it is designed to be placed onto an ice

storage bin. Many installations only require the

matching bin, but some may need an adapter to be

placed between the ice machine and the bin.

Additionally, the machine must be connected to the

correct remote condenser and use the correct

pre-charged tubing. The machine is supplied with a

full refrigerant charge, field charging is not

required.

This product cannot be stacked. See the chart for

application information.

Remote condenser

Minimum Maximum

Air temperature -20

o

F. 120oF.

November 2006

Page 2

Model Number Description

C1448, C1848, C2148

Remote Condenser Models - User Manual

Example

C1448SR-32A

•

C=cuber

•

14=nominal capacity in 100s of pounds

•

48=nominal width of cabinet in inches

•

S=cube size, S=small or half dice,

•

M=medium or full dice

R=condenser type. R=Remote

•

-32=Electrical code. -32=208-230/60/1, -3=

•

208-230/60/3

A=series revision code. A=first series.

•

Note: In some areas of this manual model numbers

may include only the first five characters of the

model number, meaning that cube size, condenser

type and voltage differences are not critical to the

information listed there.

Options:

There are several options available for field

installation. They include:

Scotsman ice systems are designed and

manufactured with the highest regard for safety

and performance. They meet or exceed the

standards of UL and NSF.

Scotsman assumes no liability of responsibility of

any kind for products manufactured by Scotsman

that have been altered in any way, including the

use of any part and/or other components not

specifically approved by Scotsman.

Scotsman reserves the right to make design

changes and/or improvements at any time.

Specifications and design are subject to change

without notice.

•

Vari-Smartä Adjustable ice level system

•

SmartBoardä Advanced feature control

Some installations require bin or dispenser

adapters. See the table below.

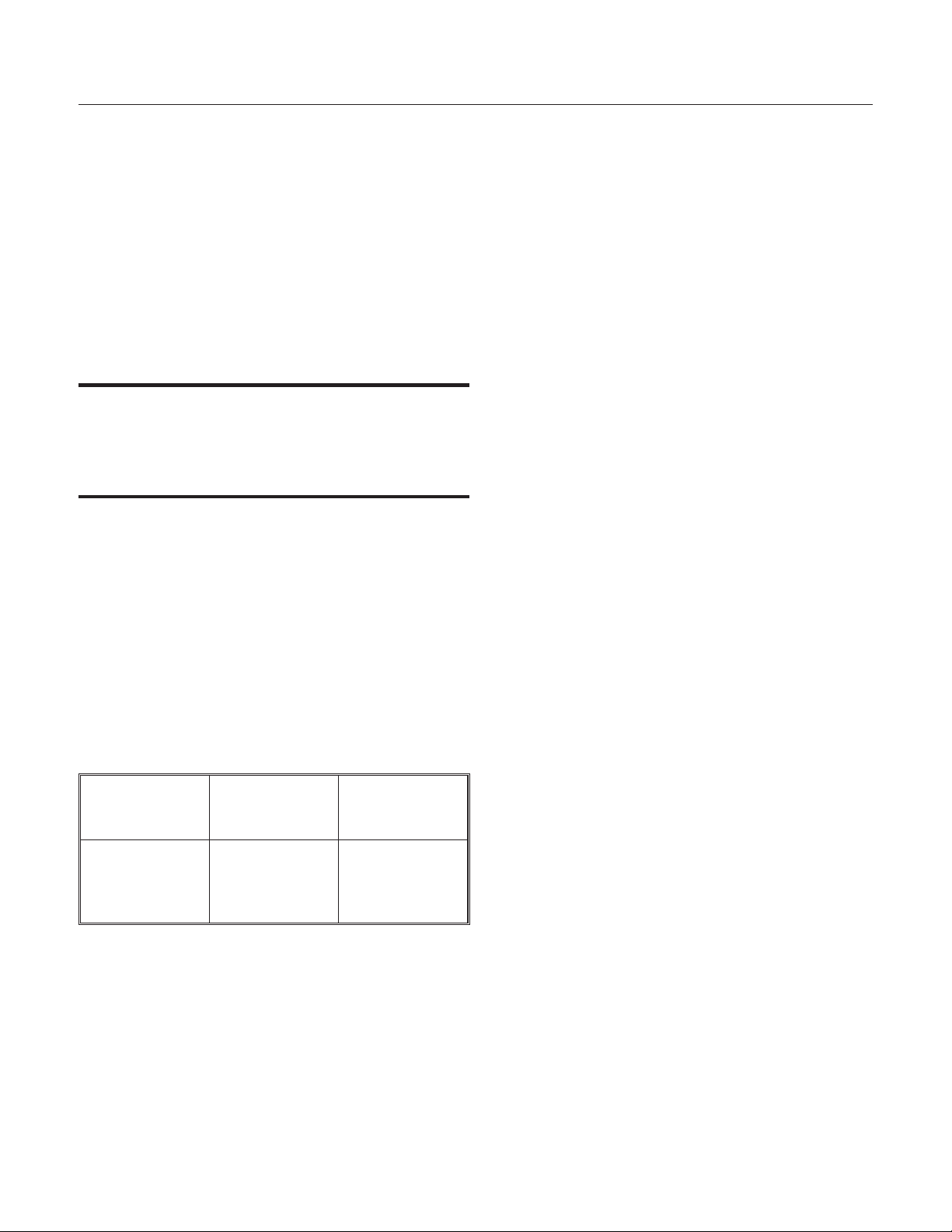

Standard bin applications – Adapter information

BH1100,

Model BH900* or B948

C1448, C1848

or C2148

* If stainless steel Kbaffle3 has been installed,

remove it and replace with the original plastic

baffle.

Other bins and applications:

Direct fit, no

adapter needed

BH1300 or

BH1600

Adapter panels

included with

bin, no adapter

needed

Note the drop zone and optional ultrasonic sensor

locations in the illustrations.

November 2006

Page 3

C1448, C1848, C2148

Remote Condenser Models - User Manual

Product Description and Electrical Requirements

Dimensions

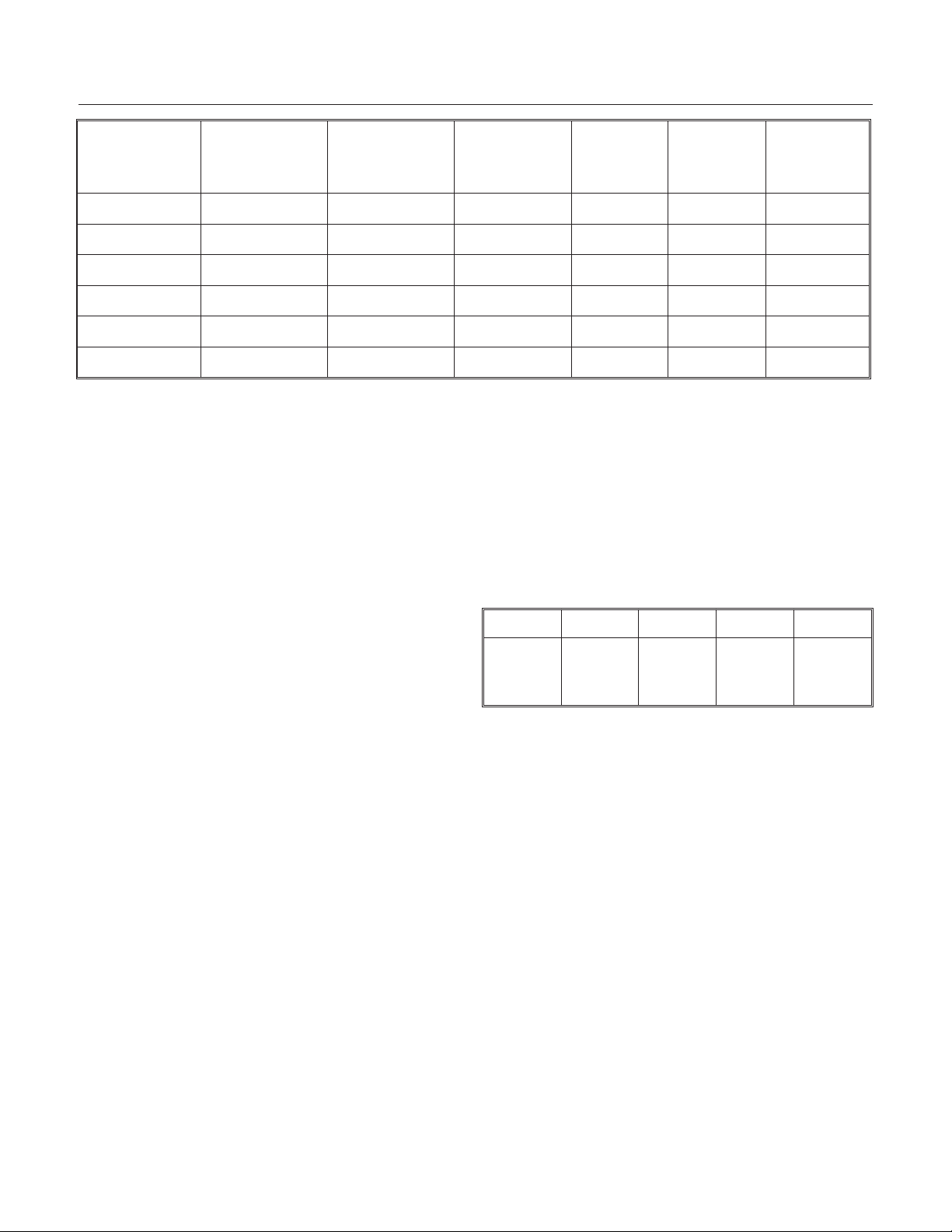

w”xd”xh”

48 x 24 x 29 C1448SR-32 208-230/60/1 ERC311-32 17.0 30 20

same C1448SR-3 208-230/60/3 ERC311-32 12.9 30 15

same C1848SR-32 208-230/60/1 ERC611-32 24.8 30 30

same C1848SR-3 208-230/60/3 ERC611-32 15.8 30 20

same C2148SR-32 208-230/60/1 ERC611-32 33.9 50 40

same C2148SR-3 208-230/60/3 ERC611-32 21.5 30 30

*Or HACR circuit breakers.

Table notes: Medium cube models have the same

electrical characteristics as Small. Series revision

code omitted. All the listed condensers include a

headmaster valve.

Ratings include the remote condenser motor, as it

is designed to be powered by the ice machine. If

connecting remote condenser independently of the

ice machine, use the information on the

condenser's dataplate for fuse and wire sizes.

Central Condenser (Rack) Coils

Model Electrical

Use

condenser

Precharged tubing kits:

The ice making head’s and the remote condenser’s

refrigeration circuits must be connected. They are

designed to be connected using precharged

refrigerant tubing, supplied in kits of liquid and

discharge tubes. Several lengths are available,

order the one that just exceeds the length needed

for the site.

C1448,

C1848,

C2148

Minimum

Circuit

Ampacity

10’ 20’ 40’ 75’

RTE10 RTE25 RTE40 RTE75

Maximum

Fuse*

Size

Suggested

Fuse* Size

The ice machine may be connected to a central

condenser coil. The requirements are:

•

Coil – not previously used with mineral oil

system. Virgin coil preferred.

•

Correct size (internal volume) and capacity

(BTUH).

•

Includes a headmaster valve for discharge

pressure control. Headmaster kit available

for certain MAC condensers, kit number is

RCKCME6GX.

•

Fan motor on all the time or controlled to be

on whenever the ice machine is operating.

•

U.L. listed for the ice machine

•

Non-Scotsman condensers must have prior

Scotsman Engineering approval for warranty

coverage to be in effect.

No additional refrigerant is required.

January 2009

Page 4

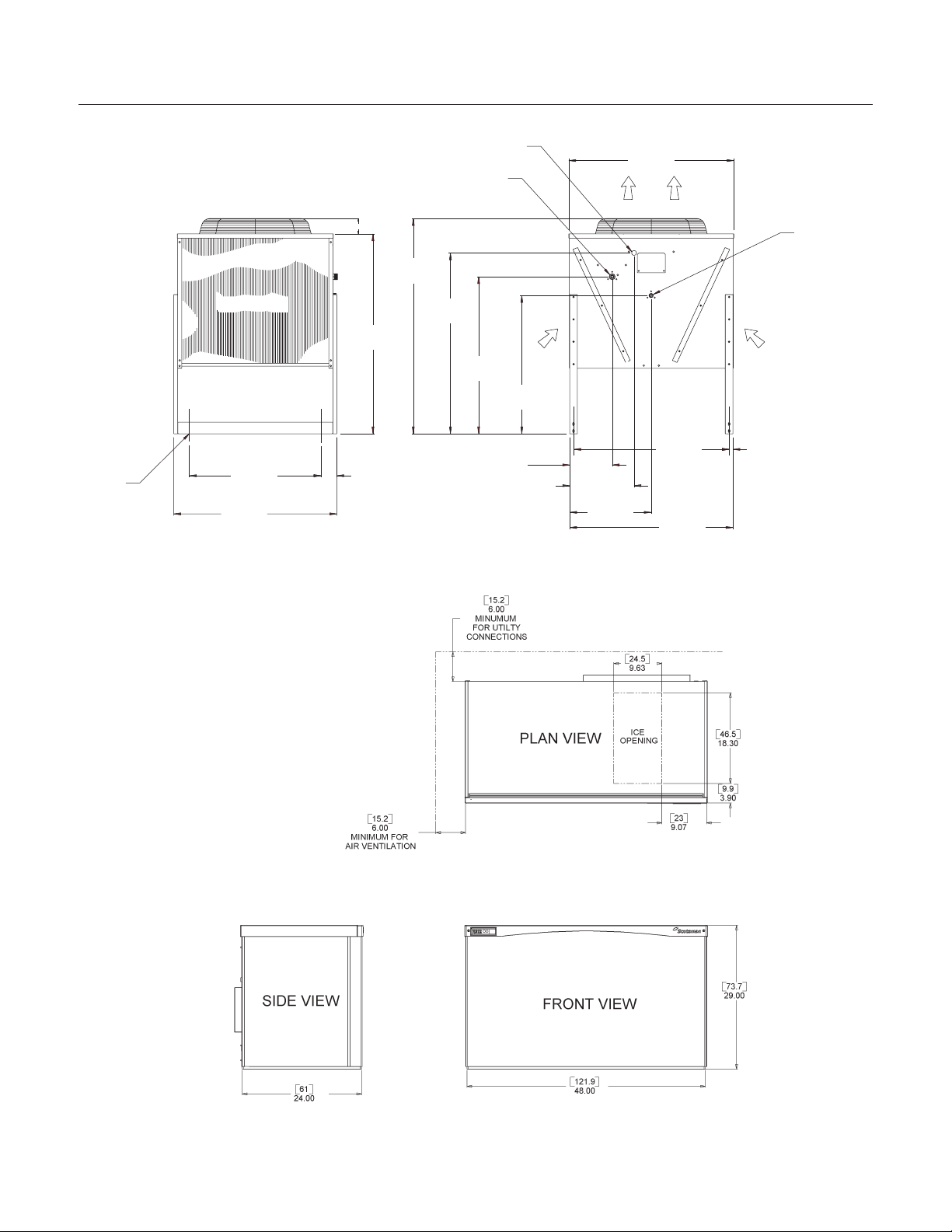

Condenser and Ice Machine Layouts

C1448, C1848, C2148

Remote Condenser Models - User Manual

.562 DIA.

MOUNTING

HOLES (4)

Cond. Fins

15-0782-01CANCAUSEINJURYOR DEATH:DISCONNECTALLREMOTEELECTRICPOWERSUPPLIESBEFORESERVICING.RISKOFELECTRICSHOCK^MWARNING

23.54 in

59.7 cm

29.15 in

74.0 cm

2.75

35.72 in

90.7 cm

2.84 in

7.2 cm

.88 DIA. ELECTRICAL

INLET

DISCHARGE LINE

1/2" MALE CPLG.

38.47 in

97.7 cm

32.32 in

82.1 cm

28.07 in

71.2 cm

24.71 in

62.7 cm

7.60 in

19.3 cm

11. 50 in

29.2 cm

14.56 in

36.9 cm

29.50 in

74.9 cm

27.56 in

70.0 cm

29.19 in

74.1 cm

.65 in

1.7 cm

LIQUID LINE

3/8" MALE CPLG.

AIR FLOW

November 2006

Page 5

C1448, C1848, C2148

Remote Condenser Models - User Manual

Water

The quality of the water supplied to the ice machine

will have an impact on the time between cleanings

and ultimately on the life of the product. There are

two ways water can contain impurities: in

suspension or in solution. Suspended solids can be

filtered out. In solution or dissolved solids cannot

be filtered, they must be diluted or treated.

Scotsman filters:

A triple head filter is recommended. Either the

Scotsman SSM3 taste and odor filter system, or

the ADS-AP3 AquaPatrol system.

Water filters are recommended to remove

suspended solids. Some filters have treatment in

them for suspended solids. Check with a water

treatment service for a recommendation.

RO water. This machine can be supplied with

Reverse Osmosis water, but the water conductivity

must be no less than 10 microSiemens/cm.

Water Purge

Cube ice machines use more water than what ends

up in the bin as ice. While most water is used

during ice making, a portion is designed to be

drained out every cycle to reduce the amount of

hard water scale in the machine. That’s known as

water purge, and an effective purge can increase

the time between needed water system cleaning.

In addition, this product is designed to

automatically vary the amount of water purged

based on the purity of the water supplied to it. The

water purge rate can also be set manually.

Adjustments of purge due to local water conditions

are not covered by warranty.

Potential for Airborne Contamination

Installing an ice machine near a source of yeast or

similar material can result in the need for more

frequent sanitation cleanings due to the tendency

of these materials to contaminate the machine.

Most water filters remove chlorine from the water

supply to the machine which contributes to this

situation. Testing has shown that using a filter that

does not remove chlorine, such as the Scotsman

Aqua Patrol, will greatly improve this situation,

while the ice making process itself will remove the

chlorine from the ice, resulting in no taste or odor

impact. Additionally, devices intended to enhance

ice machine sanitation, such as the Scotsman

Aqua Bullet, can be placed in the machine to keep

it cleaner between manual cleanings.

November 2006

Page 6

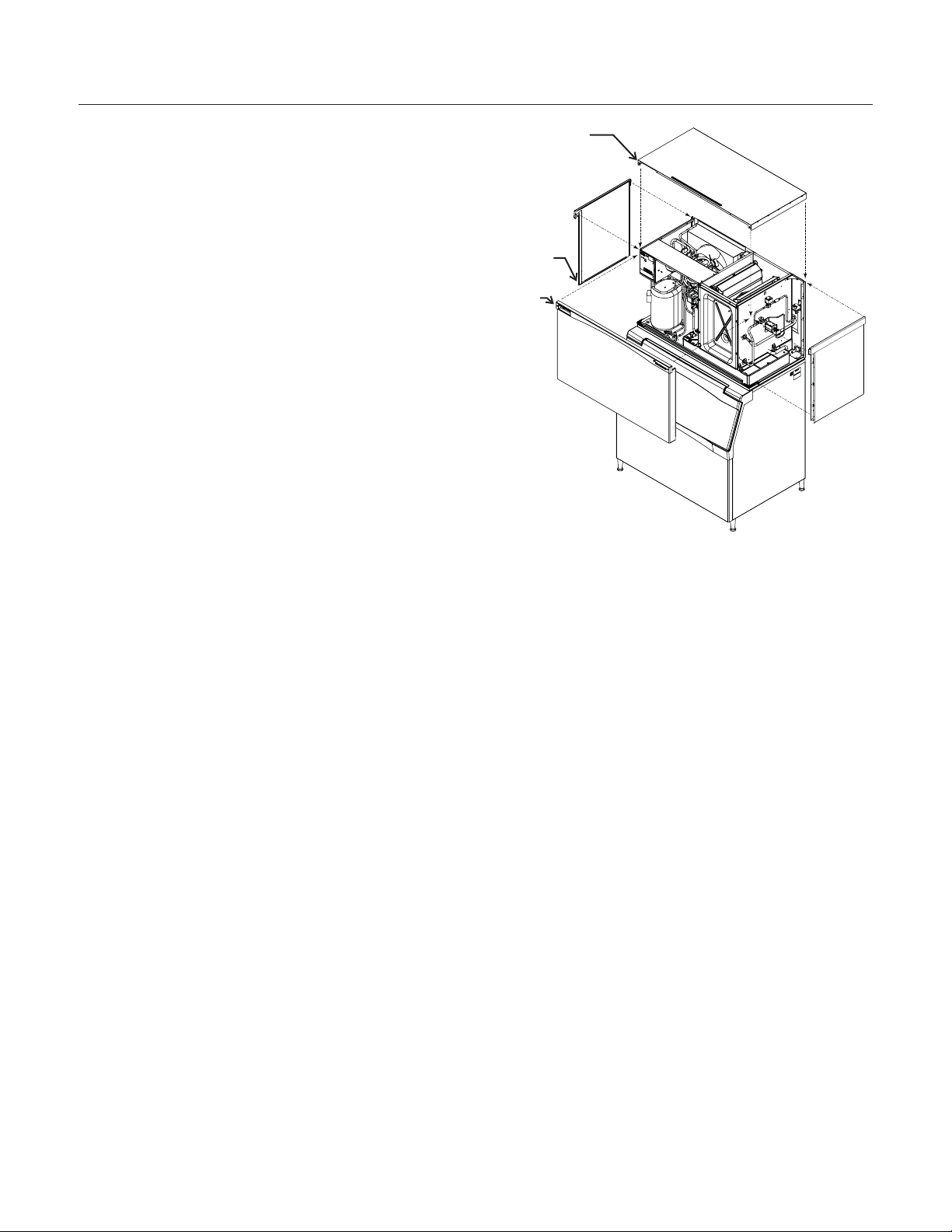

Panel Removal

C1448, C1848, C2148

Remote Condenser Models - User Manual

1. Locate and loosen the two screws at the front

edge of the top panel.

2. Pull the front panel out at the top until it

clears the top panel.

3. Lift the front panel up and off the machine.

4. Remove two screws from the front edge of

the top panel.

5. Lift up the front of the top panel, push it back

an inch, then lift to remove.

6. Locate and loosen the screw holding each

side panel to the base.

7. Pull the side panel forward to release it from

the back panel.

This manual covers several models of remote

cubers. The model number on the ice machine can

be found either on the dataplate, which is on the

back panel, or the serial number tag, which is

behind the front panel. See the illustration for the

locations of the dataplate and the serial number

tag.

The remote condenser has a separate model and

serial number. Its model and serial number is on

the dataplate on the condenser near the quick

connect fittings.

Write the model and serial number of the ice

machine here:

Write the model and serial number of the remote

condenser here:

Write the model and serial number of the ice

storage bin here:

Write the day of initial start up here: That day

starts the warranty period.

5

6

1

Panel Removal

Uncrate and Set Up

Begin with the ice storage bin. Remove the carton,

and, using part of the carton as a cushion, tip the

bin on its back to remove the skid. Attach the

supplied legs or optional casters. Return the bin to

a normal, upright position.

Check the bin top gasket for tears or gaps. If

recycling an older bin, replace the gasket or repair

with food grade sealant prior to placing the ice

machine on the bin.

Install the bin top adapter or ice dispenser adapter,

if one is required for the application.

If the ice machine has not been unpacked, do so

now. Remove the carton from the skid. Cut away

any shipping strapping. Lift the ice machine off the

skid directly onto the bin.

Note: The machine is heavy. Use a mechanical lift

if necessary.

Secure the ice machine to the bin with the

hardware provided (two metal straps and four

bolts).

November 2006

Page 7

Loading...

Loading...