Scotsman Ice Machine C0322 Service Manual

Prodigy Series Modular Cuber

Technical Service Manual

Models C0322, C0522, C0722, C0330, C0530,

C0630, C0830, C1030, C1448, C1848 and

C2148

also includes CB0522, CB0330, CB0530,

CB0630, CB0830 and CB1030

Introduction

This technical manual covers the Prodigy line, excluding the Eclipse remote low side models.

All are shipped with an Installation and User's manual, which can be referred to separately.

General installation information is included in this manual.

Table of Contents

Model Number Description ......... page 2

Water ....................page 3

General Installation - Air or Water Cooled . page 4

Water purge setting ............ page 8

General Installation - Remote ....... page 9

Pre-Charged Tubing Coupling Connections page 17

General Installation - Remote ....... page 18

Adjustments ................ page 20

Prodigy Cuber System Information..... page 21

Controller Information ........... page 22

How It Works - Air Cooled ......... page 24

How It Works - Water Cooled ....... page 25

How It Works - Remote........... page 26

Electrical Sequence - Air or Water Cooled. page 27

Electrical Sequence - Remote Cooled . . . page 29

Diagnostics - Water Cooled ........ page 47

Low ice Making Capacity - Water Cooled . page 50

Makes Excessive Noise - Water Cooled . . page 51

Diagnostics - Remote Air Cooled ..... page 52

Low Ice Making Capacity - Remote .... page 55

Makes Excessive Noise - Remote ..... page 56

Test Procedures - Sensors......... page 57

Ice Thickness Sensor ........... page 58

Water Level Sensor ............ page 59

Temperature Sensors ........... page 60

Test Procedures - Loads .......... page 61

Compressor Electrical Chart ........ page 62

Refrigerant Charges ............ page 63

Test Procedures - Loads

Technical Information ........... page 72

.......... page 64

Remote Schematics ............ page 31

Electrical Component Details ....... page 32

Refrigeration ................page 35

Water System ............... page 36

Control Operation ............. page 37

Control Safeties .............. page 38

Restarts................... page 39

Control Button Use (from standby) ..... page 40

Control Button Use - continued ...... page 41

Diagnostics – Air Cooled .......... page 42

Low Ice Making Capacity - Air Cooled . . . page 45

Makes Excessive Noise - Air Cooled.... page 46

May 2011 Page 1

Heat Load & Condenser Water GPM . . . page 73

Controller Differences ........... page 74

Thermistor Values ............. page 75

Performance Data ............. page 76

Performance Data - Remotes ....... page 87

Wiring Diagrams .............. page 95

Wiring Diagram ............... page 103

Repair Procedures ............. page 108

Refrigeration Removal and Replacement Procedures

.......................page 116

Optional add-on control information .... page 121

Selected Prodigy Cuber Suction Graphs. . page 126

Wiring Diagram - 50 Hz .......... page 129

Model Number Description

Example:

C0530SA-1C

•

C= cuber. CB = Prodigy Advanced Sustainability Cuber

•

05= nominal ice capacity in 100s of pounds

•

30= nominal width of cabinet. Other sizes are 22 and 48.

•

S= Cube size. S=small or half dice cube. M=medium or full dice cube

•

A=Condenser type. A=air cooled. W=water cooled. R = Remote

•

-1=Electrical code. -1=115 volts. -32=208-230 single phase. -3=208-230 three phase.

•

-6=230 50 Hz

C=Series revision code. C=third series

•

Note: In some areas of this manual model numbers may include only the first five characters of

the model number, meaning that the cube size, condenser type and voltage differences are not

critical to the information listed there.

Scotsman reserves the right to make design changes and/or improvements at any time.

Specifications and design are subject to change without notice.

September 2011 Page 2

Water

The quality of the water supplied to the ice machine will have an impact on the time between

cleanings and ultimately on the life of the product. There are two ways water can contain

impurities: in suspension or in solution. Suspended solids can be filtered out. In solution or

dissolved solids cannot be filtered, they must be diluted or treated. Water filters are

recommended to remove suspended solids. Some filters have treatment in them for

suspended solids. Check with a water treatment service for a recommendation.

RO water. This machine can be supplied with Reverse Osmosis water, but the water

conductivity must be no less than 10 microSiemens/cm.

Potential for Airborne Contamination

Installing an ice machine near a source of yeast or similar material can result in the need for

more frequent sanitation cleanings due to the tendency of these materials to contaminate the

machine. Most water filters remove chlorine from the water supply to the machine which

contributes to this situation. Testing has shown that using a filter that does not remove

chlorine, such as the Scotsman Aqua Patrol, will greatly improve this situation, while the ice

making process itself will remove the chlorine from the ice, resulting in no taste or odor impact.

Additionally, devices intended to enhance ice machine sanitation, such as the Scotsman Aqua

Bullet, can be placed in the machine to keep it cleaner between manual cleanings.

Water Purge

Cube ice machines use more water than what ends up in the bin as ice. While most water is

used during ice making, a portion is designed to be drained out every cycle to reduce the

amount of hard water scale in the machine. That’s known as water purge, and an effective

purge can increase the time between needed water system cleaning.

In addition, this product has the capability to automatically vary the amount of water purgeed

based on the purity of the water supplied to it. The water purge rate can also be set manually.

Adjustments of purge due to local water conditions are not covered by warranty.

October 2012 Page 3

General Installation - Air or Water Cooled

Location Limitations:

The product is designed to be installed indoors, in a controlled environment. Air cooled models

discharge very warm air into the room out the back. Space must be allowed at the left side and

back for air intake and discharge. Water cooled models discharge warm water into the

building’s drain. Space needs to be provided on both sides and above for service access.

Space Limitations

Note: Although the machine will function, ice capacity of air cooled machines will be significantly reduced

with minimal clearance at the sides, back and top. Some space is recommended for service and

maintenance purposes on all models.

6" of space at the sides and back are required for adequate operation. To get the most

capacity, locate the machine away from heat producing appliances and heating ducts.

22 and 30 inch wide models: Airflow is in the left side, out the back (as viewed from the front).

48 inch wide models: Air flow is in the front and left side and out the back.

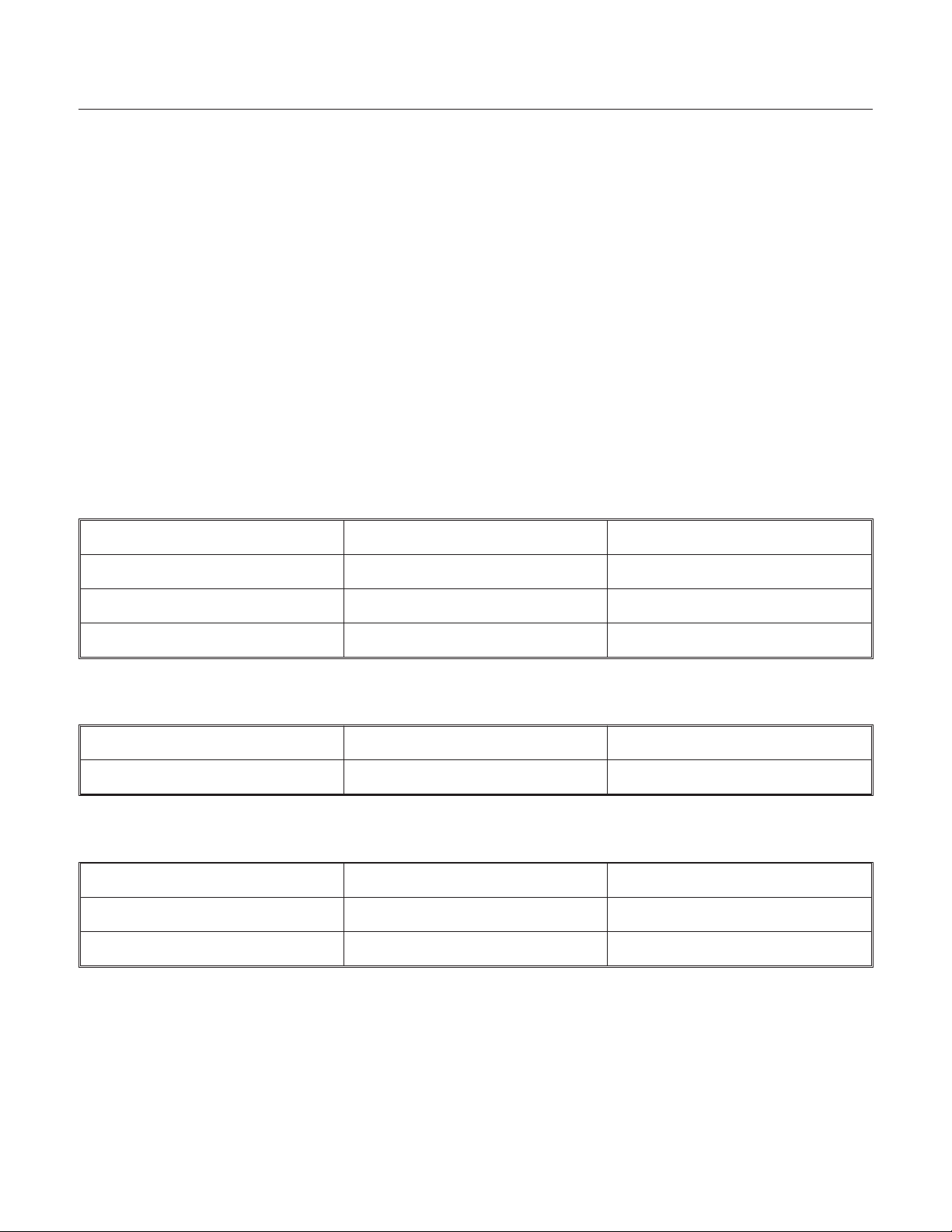

Environmental Limitations

Minimum Maximum

Air temperature 50

Water temperature 40

o

F. 100oF.

o

F. 100oF.

Water pressure 20 psi 80 psi

Power supply – acceptable voltage ranges

Minimum Maximum

115 volt model 104 volts 126 volts

208-230 volt model 198 volts 253 volts

Warranty Information

The warranty statement for this product is provided separately from this manual. Refer to it for

applicable coverage. In general warranty covers defects in material or workmanship. It does

not cover maintenance, corrections to installations, or situations when the machine is operated

in circumstances that exceed the limitations printed above.

October 2012 Page 4

General Installation - Air or Water Cooled

Plumbing Requirements

All models require connection to cold, potable water. A hand actuated valve within site of the

machine is required. Air cooled models have a single 3/8” FPT inlet water connection.

Water cooled models have the same inlet fitting plus an additional 3/8” FPT condenser inlet

water connection.

Water Filters

If connecting to water filtration, filter only the water to the reservoir, not to the condenser.

Install a new cartridge if the filters were used with a prior machine.

All models require drain tubing to be attached to them. Air cooled models have a single ¾”

FPT drain fitting in the back of the cabinet. Water cooled models have the same fitting plus an

additional ½” FPT drain fitting in the back of the cabinet.

Install new tubing when replacing a prior ice machine, as the tubing will have been sized for

the old model and might not be correct for this one.

Note: This NSF listed model has a 1" anti-back flow air gap between the water inlet tube end and the

highest possible reservoir water level, no back flow device is required for the potable water inlet.

Drain Tubing:

Use rigid drain tubes and route them separately – do not Tee into the bin’s drain and, if water

cooled, do not Tee the condenser drain into the reservoir or bin drain.

Vent the reservoir drain. A vertical vent at the back of the drain, extended about 8 – 10” will

allow the gravity drain to empty and also keep any surges during draining from discharging

water out the vent..

Horizontal runs of drain tubing need a ¼” fall per foot of run for proper draining.

Follow all applicable codes.

August 2013 Page 5

General Installation - Air or Water Cooled

Electrical

See the spec sheet or User's Manual for Minimum Circuit Ampacity or Maximum Fuse Size

ratings.

The machine is not supplied with a power cord, one must either be field installed or the

machine hard-wired.

The dataplate on the back of the cabinet details the power requirements, including voltage,

phase, minimum circuit ampacity and maximum fuse size. HACR type circuit breakers may be

used in place of fuses. Extension cords are not permitted. Use of a licensed electrician is

recommended.

Electrical connections are made inside the junction box in the back panel of the ice machine.

Follow all applicable local, state and national codes.

October 2012 Page 6

General Installation - Air or Water Cooled

Note: Indentations may be deeper on C0322 and C0330

Adjustments

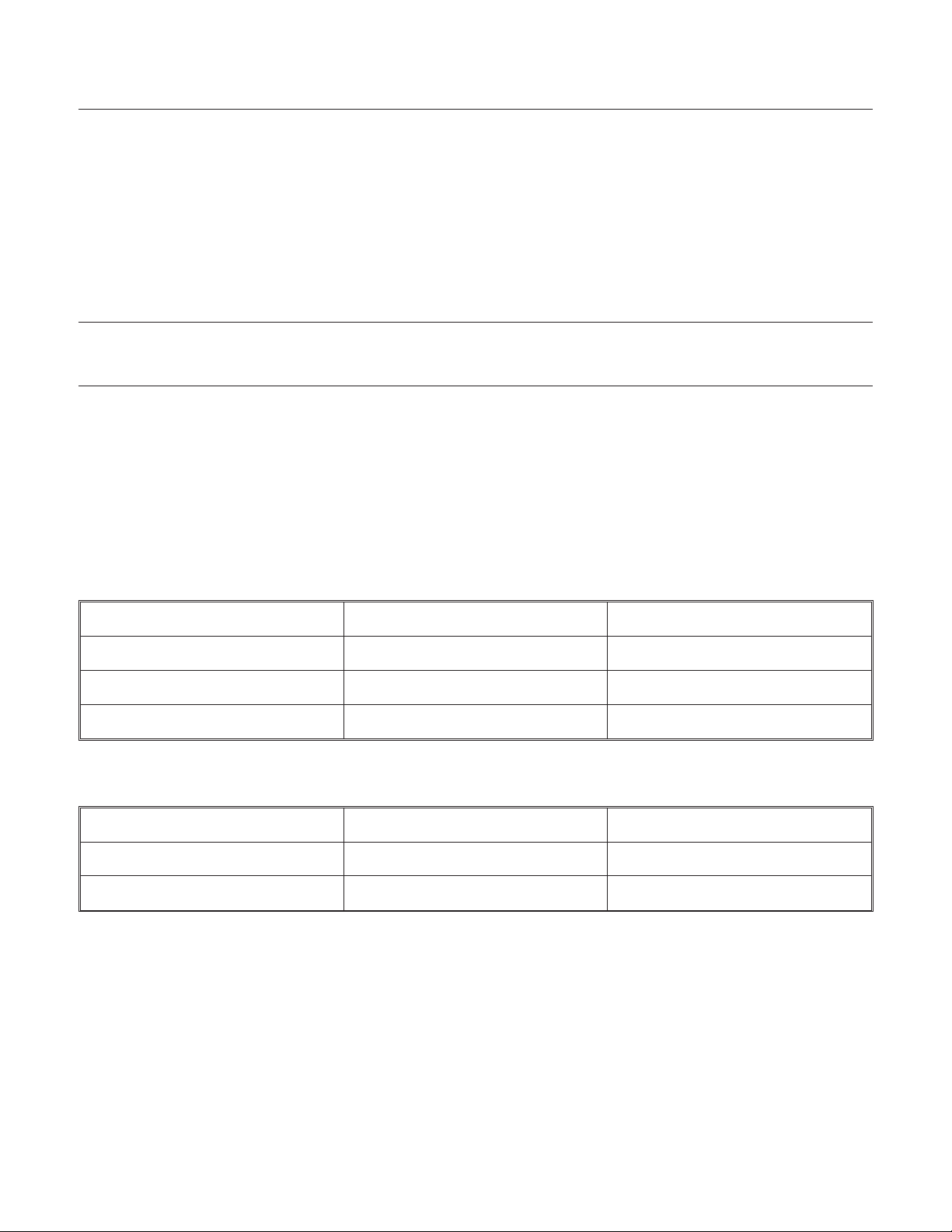

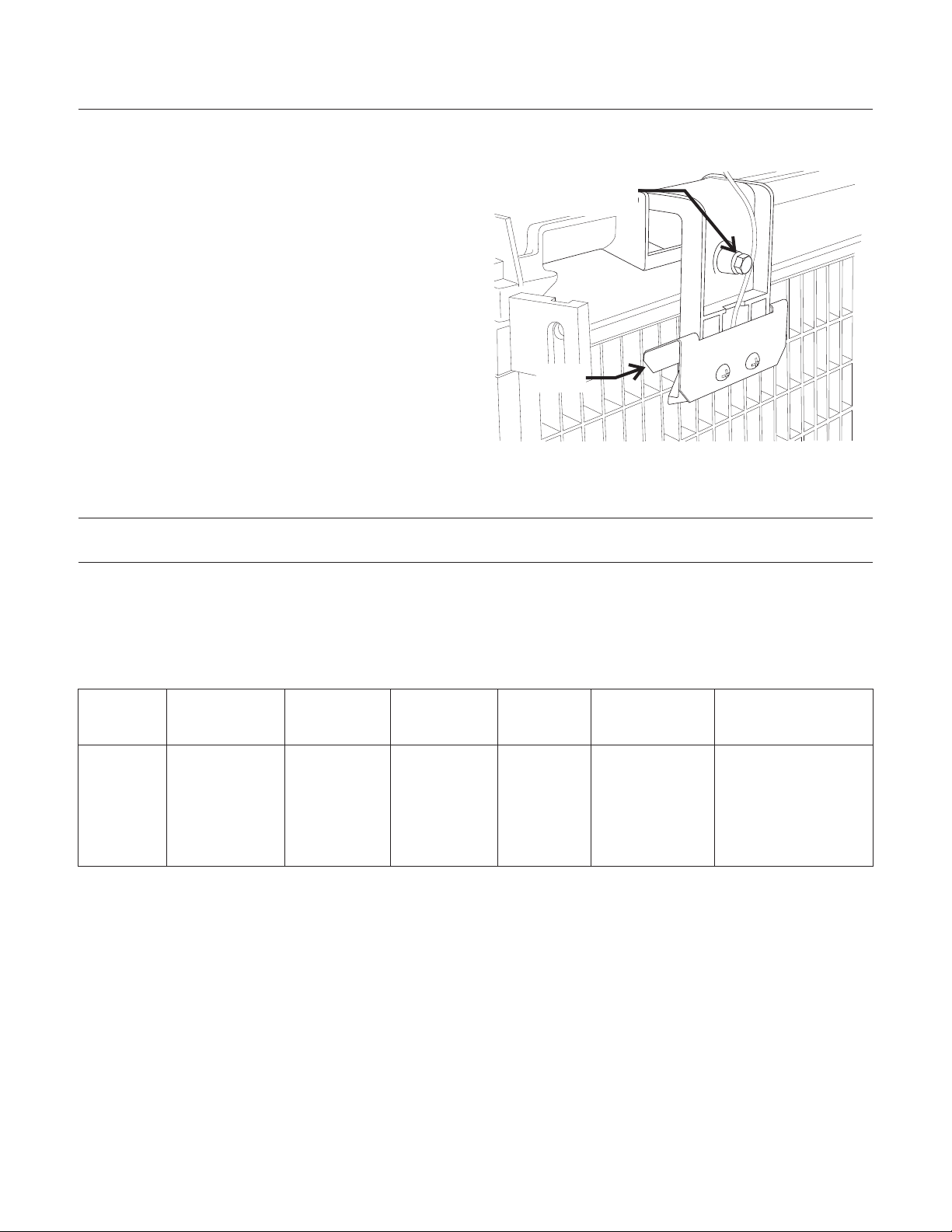

Ice Bridge Thickness

Caution: Do not make the bridge too thin or the

machine will not harvest properly. Bridge thickness

adjustments are not covered by warranty.

Shut machine off.

Access the ice thickness sensor.

Too Big

Check gap between metal tip and evaporator

grid. Small cube standard gap is 3/16 inch,

medium cube standard gap is 7/32 inch. To

set, place a 3/16" (small cube) or 7/32"

(medium cube) drill bit between sensor tip

and evaporator to check. Adjust gap using

adjustment screw.

Ice Bridge Thickness Measurement

Adjustment

Screw

1/8" indentation

1/8-3/16"

bridge

Just Right

Too Small

Restart unit and check ice bridge. Repeat as

needed.

Evaporator

Ice Thickness Sensor

Gap

Ice Thickness Sensor Adjustment

Gap

Side View of Evaporator and Ice Thickness

Sensor

October 2012 Page 7

Water purge setting

The water purge is factory set to the Automatic setting. The setting can be changed to one of 5

manual settings or placed on automatic. The purge setting shows in the Code Display.

purge

setting

Water

Type

To set:

Switch the machine OFF by holding the Off button in until a number or the letter A shows on

the display.

Press and release the On button repeatedly until the number on the display corresponds to the

desired setting.

Press and release the Off switch again to return to the normal control state.

1Minimum

RO water

or

equivalent,

TDS less

than 35

2Moderate3-Standard

Low TDS

non-RO

water

Setting

for typical

water

4Heavy

High

TDS

water

5Maximum

Very high

TDS water,

greater than

256

A - Automatic

Any with

conductivity

not less than

10

microSiemens/

cm

October 2012 Page 8

General Installation - Remote

Location Limitations

This ice system is made up of three parts, the ice making machine, or head; the remote

condenser; and the interconnecting tubing. The ice making machine must be installed indoors,

in a controlled environment. Space must be provided near the machine for service access. The

remote condenser may be installed above or below the ice machine, per the limits stated later

in this manual. The remote condenser may be installed outdoors within the temperature limits

listed below. The interconnecting tubing must be installed per the directions stated in this

manual, and the amount of tubing exposed to uncontrolled temperatures must be minimized.

Space Limitations

Although the machine will function with no clearance to the top and sides, some space must be

allowed for service access. Building the machine in with no access will cause higher service

cost, in many cases this extra cost may not be covered by warranty.

Environmental Limitations, ice machine:

Minimum Maximum

Air temperature 50

Water temperature 40

o

F. 100oF.

o

F. 100oF.

Water Pressure 20 psi 80 psi

Environmental Limitations, remote condenser

Minimum Maximum

Air temperature -20

o

F. 120oF.

Power Supply

Minimum Maximum

115 volt model 104 volts 126 volts

208-230 volt model 198 volts 253 volts

Warranty Information

The warranty statement for this product is provided separately from this manual. Refer to it for

applicable coverage. In general warranty covers defects in material and workmanship. It does

not cover maintenance, corrections to installations, or situations when the ice machine is

operated in circumstances that exceed the limitations printed above.

October 2012 Page 9

General Installation - Remote

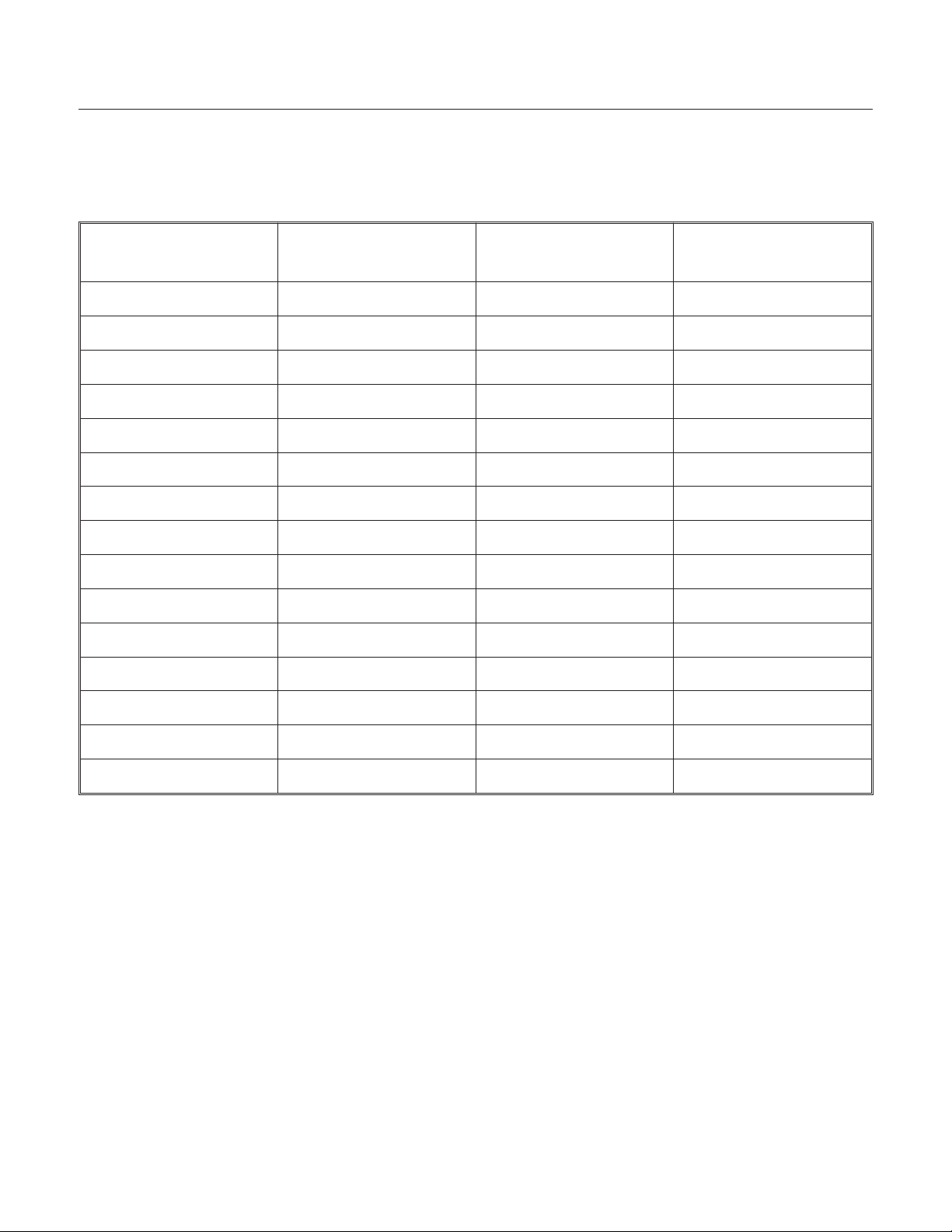

Product Description and Electrical Requirements

- See spec sheet or User's Manual for Minimum Circuit Ampacity or Maximum Fuse SIze

Dimensions

w”xd”xh”

22 x 24 x 23 C0522SR-1 115/60/1 ERC111-1

same same same ERC211-1**

30 x 24 x 23 C0530SR-1 115/60/1 ERC111-1

same same same ERC211-1**

same C0630SR-32 208-230/60/1 ERC311-32

30 x 24 x 29 C0830SR-32 208-230/60/1 ERC311-32

same C0830SR-3 208-230/60/3 ERC311-32

same C1030SR-32 208-230/60/1 ERC311-32

same C1030SR-3 208-230/60/3 ERC311-32

48 x 24 x 29 C1448SR-32 208-230/60/1 ERC311-32

same C1448SR-3 208-230/60/3 ERC311-32

same C1848SR-32 208-230/60/1 ERC611-32

Model Electrical Use condenser

same C1848SR-3 208-230/60/3 ERC611-32

same C2148SR-32 208-230/60/1 ERC611-32

same C2148SR-3 208-230/60/3 ERC611-32

** ERC211 has two circuits, when two C0522s or C0530s are connected to it, fan motor relay

kit KCMR120 must be used to control the fan motor.

Ratings include the remote condenser motor, as it is designed to be powered by the ice

machine. If connecting remote condenser independently of the ice machine, use the

information on the condenser's dataplate for fuse and wire sizes.

Table notes: Medium cube models have the same electrical characteristics as Small. Series

revision code omitted. All the listed condensers include a headmaster valve.

October 2012 Page 10

General Installation - Remote

Central Condenser Coils

The ice machine may be connected to a central condenser coil. The requirements are:

Coil – not previously used with mineral oil system. Virgin coil preferred.

•

Correct size (internal volume) and capacity (BTUH).

•

Includes a headmaster valve for discharge pressure control. Headmaster kit available for

•

certain MAC condensers, kit number is

Fan motor on all the time or controlled to be on whenever the ice machine is operating.

•

Non-Scotsman condensers must have prior Scotsman Engineering approval for warranty

•

coverage to be in effect.

Precharged tubing kits:

The ice making head’s and the remote condenser’s refrigeration circuits must be connected.

They are designed to be connected using precharged refrigerant tubing, supplied in kits of

liquid and discharge tubes. Several lengths are available, order the one that just exceeds the

length needed for the site.

RCKCME6GX.

10” 25’ 40’ 75’

RTE10 RTE25 RTE40 RTE75

No additional refrigerant is required. Note: Refrigerant charge is supplied with the ice machine.

January 2009 Page 11

General Installation - Remote

Water

The quality of the water supplied to the ice machine will have an impact on the time between

cleanings and ultimately on the life of the product. There are two ways water can contain

impurities: in suspension or in solution. Suspended solids can be filtered out. In solution or

dissolved solids cannot be filtered, they must be diluted or treated. Water filters are

recommended to remove suspended solids. Some filters have treatment in them for

suspended solids. Check with a water treatment service for a recommendation.

RO water. This machine can be supplied with Reverse Osmosis water, but the

conductivity must be no less than 10 microSiemens/cm.

Potential for Airborne Contamination

Installing an ice machine near a source of yeast or similar material can result in the need for

more frequent sanitation cleanings due to the tendency of these materials to contaminate the

machine. Most water filters remove chlorine from the water supply to the machine which

contributes to this situation. Testing has shown that using a filter that does not remove

chlorine, such as the Scotsman Aqua Patrol, will greatly improve this situation, while the ice

making process itself will remove the chlorine from the ice, resulting in no taste or odor impact.

Additionally, devices intended to enhance ice machine sanitation, such as the Scotsman Aqua

Bullet, can be placed in the machine to keep it cleaner between manual cleanings.

Water purge

Cube ice machines use more water than what ends up in the bin as ice. While most water is

used during ice making, a portion is designed to be drained out every cycle to reduce the

amount of hard water scale in the machine. That’s known as water purge, and an effective

purge can increase the time between needed water system cleaning.

water

In addition, this product is designed to automatically vary the amount of water purged based on

the purity of the water supplied to it. The water purge rate can also be set manually.

Adjustments of purge due to local water conditions are not covered by warranty.

October 2012 Page 12

General Installation - Remote

Remote Condenser Location

Use the following for planning the placement of the condenser relative to the ice machine - see

illustration on the following page.

Location Limits - condenser location must not exceed ANY of the following limits:

Maximum rise from the ice machine to the condenser is 35 physical feet

•

Maximum drop from the ice machine to the condenser is 15 physical feet

•

Physical line set maximum length is 100 feet.

•

Calculated line set length maximum is 150.

•

Calculation Formula:

Drop = dd x 6.6 (dd = distance in feet)

•

• Rise = rd x 1.7 (rd = distance in feet)

• Horizontal Run = hd x 1 (hd = distance in feet)

• Calculation: Drop(s) + Rise(s) + Horizontal Run = dd+rd+hd = Calculated Line Length

Configurations that do NOT meet these requirements must receive prior written

authorization from Scotsman.

Do NOT:

• Route a line set that rises, then falls, then rises.

•

Route a line set that falls, then rises, then falls.

Calculation Example 1:

The condenser is to be located 5 feet below the ice machine and then 20 feet away

horizontally.

5 feet x 6.6 = 33. 33 + 20 = 53. This location would be acceptable

Calculation Example 2:

The condenser is to be located 35 feet above and then 100 feet away horizontally. 35 x 1.7 =

59.5. 59.5 +100 = 159.5. 159.5 is greater than the 150 maximum and is NOT acceptable.

Operating a machine with an unacceptable configuration is misuse and will void the

warranty.

October 2012 Page 13

General Installation - Remote

22.87"

17.15"

40.35"

For The Installer: Remote Condenser

Locate the condenser as near as possible to the interior location of the ice machine.

Note: The location of the condenser is relative to the ice machine is LIMITED by the specification on the

prior page.

Meet all applicable building codes.

Roof Attachment

Install and attach the remote condenser to the roof of the building, using the methods and

practices of construction that conform to the local building codes, including having a roofing

contractor secure the condenser to the roof.

rd

dd

Max

35'

Max

15'

Remote

Condenser

Locate ABOVE

Remote

Condenser

Locate BELOW

hd

Condenser

Distance &

Location

October 2012 Page 14

General Installation - Remote

Precharged Line Routing

Do not connect the precharged tubing until all routing and forming of the tubing is complete.

See the Coupling Instructions for final connections.

1. Each set of pre-charged tubing lines contains a 3/8” diameter liquid line, and a 1/2” diameter

discharge line. Both ends of each line have quick connect couplings, the end without access

valves goes to the ice maker.

Note: The openings in the building ceiling or wall, listed in the next step, are the minimum sizes

recommended for passing the refrigerant lines through.

2. Have the roofing contractor cut a minimum hole for the refrigerant lines of 1 3/4”. Check

local codes, a separate hole may be required for the electrical power supply to the condenser.

Caution: Do NOT kink the refrigerant tubing while routing it.

3. Route the refrigerant tubes thru the roof opening. Follow straight line routing whenever

possible. Excess tubing may EITHER be coiled up INSIDE the building OR cut out prior to

connection to the ice maker and condenser.

If the excess tubing is cut out, after re-brazing the tubing must be evacuated prior to

connection to the ice maker or condenser.

Note brazing requires a nitrogen purge.

If the excess tubing is to be coiled, spiral it horizontally to avoid excess trapping in the lines.

5. Have the roofing contractor seal the holes in the roof per local codes

October 2012 Page 15

General Installation - Remote

Coupling Instructions

The couplings on the ends of the pre-charged line sets are self-sealing when installed properly.

Follow these instructions carefully.

These steps must be performed by an EPA Certified Type II or higher technician.

Initial Connections

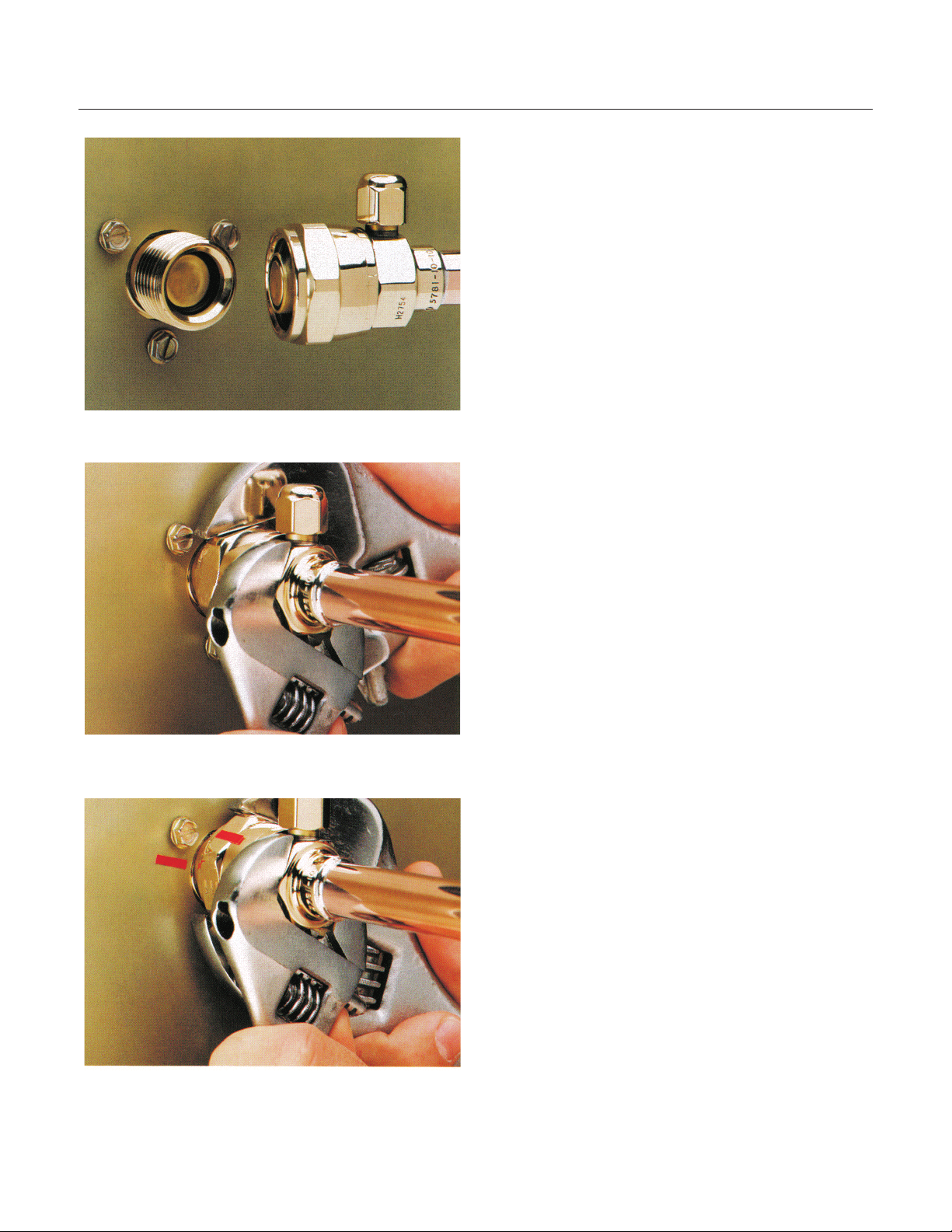

1. Remove the protector caps and plugs. Wipe the seats and threaded surfaces with a clean

cloth to remove any possible foreign matter.

2. Lubricate the inside of the couplings, especially the O-rings, with refrigerant oil.

3. Position the fittings on the correct connections on the condenser and ice machine.

• The 1/2" discharge line (schrader valve end) goes to the remote condenser fitting marked

“discharge line”.

• The 3/8" liquid line (schrader valve end) goes to the remote condenser fitting marked

“liquid line”.

• The 1/2" discharge line goes to the ice maker fitting marked “discharge line”.

• The 3/8" liquid line goes to the ice maker fitting marked “liquid line”.

Final Connections:

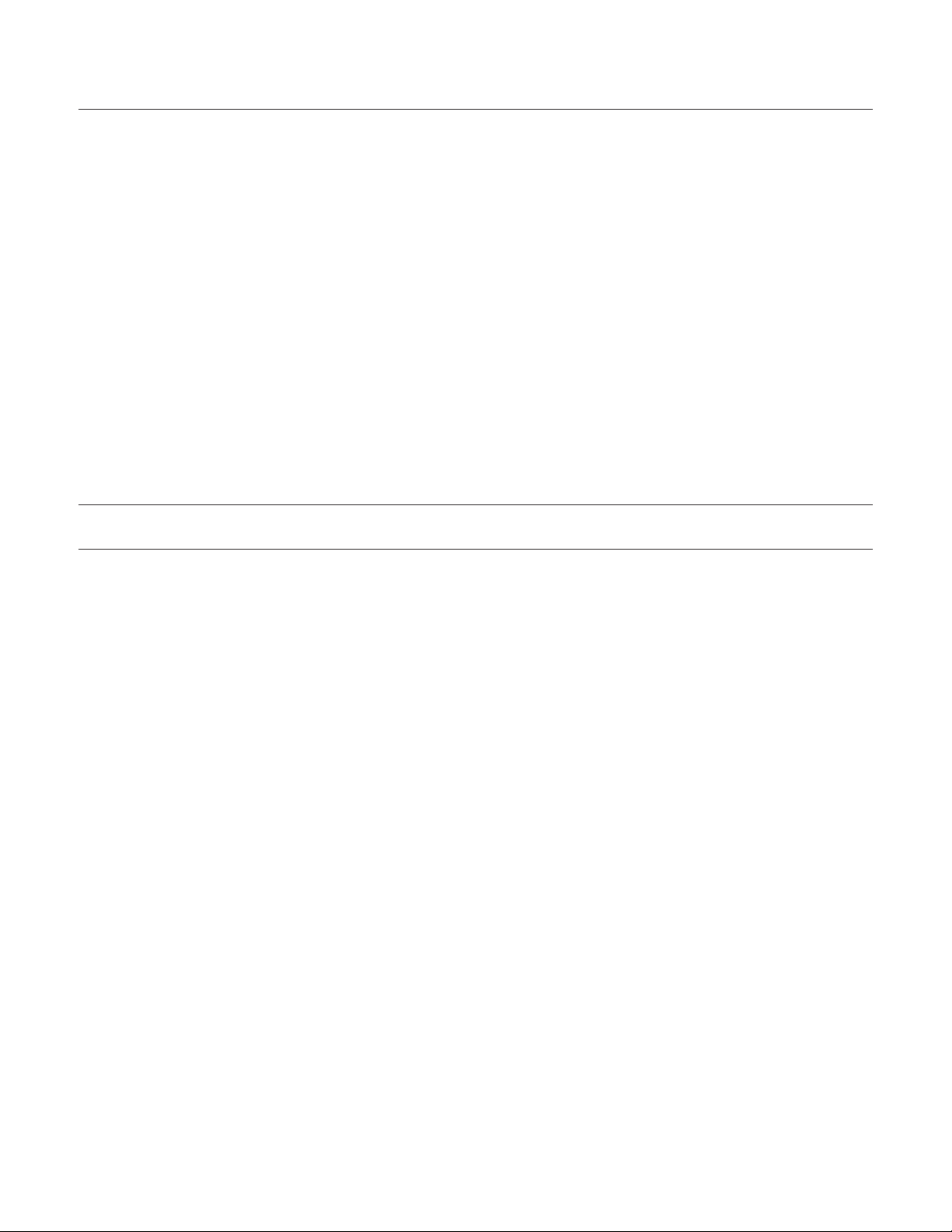

4a. Begin by tightening the couplings together by hand until it is certain that the threads are

properly engaged.

4b. Then using two wrenches tighten the coupling until it bottoms out or a definite increase in

resistance is felt.

It is important that ONLY the nut on the pre-charged tube be turned, or the diaphragms will be

torn out by the piercing knives and they will be loose in the refrigeration system. Note: As the

couplings are tightened, the diaphragms in the quick connect couplings will begin to be

pierced. As that happens, there will be some resistance to tightening the swivel nut.

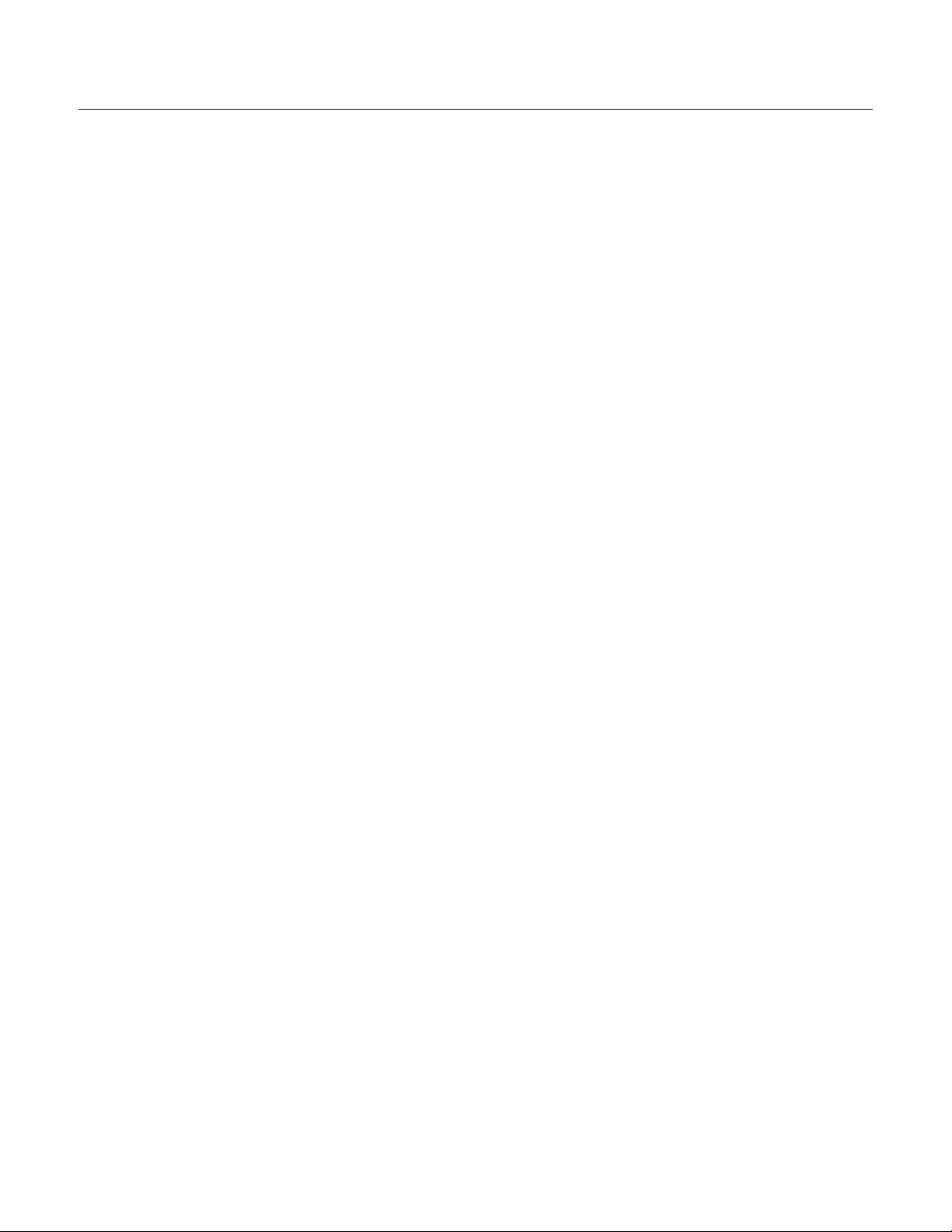

4c. Continue tightening the swivel nut until it bottoms out or a very definite increase in

resistance is felt (no threads should be showing).

5. Use a marker or pen to mark a line on the coupling nut and unit panel. Then tighten the

coupling nut an additional one-quarter turn. The line will show the amount that the nut turns.

Do NOT over tighten.

6. After all connections have been made, and after the receiver valve has been opened (open

at Initial Start Up), check the couplings for leaks.

October 2012 Page 16

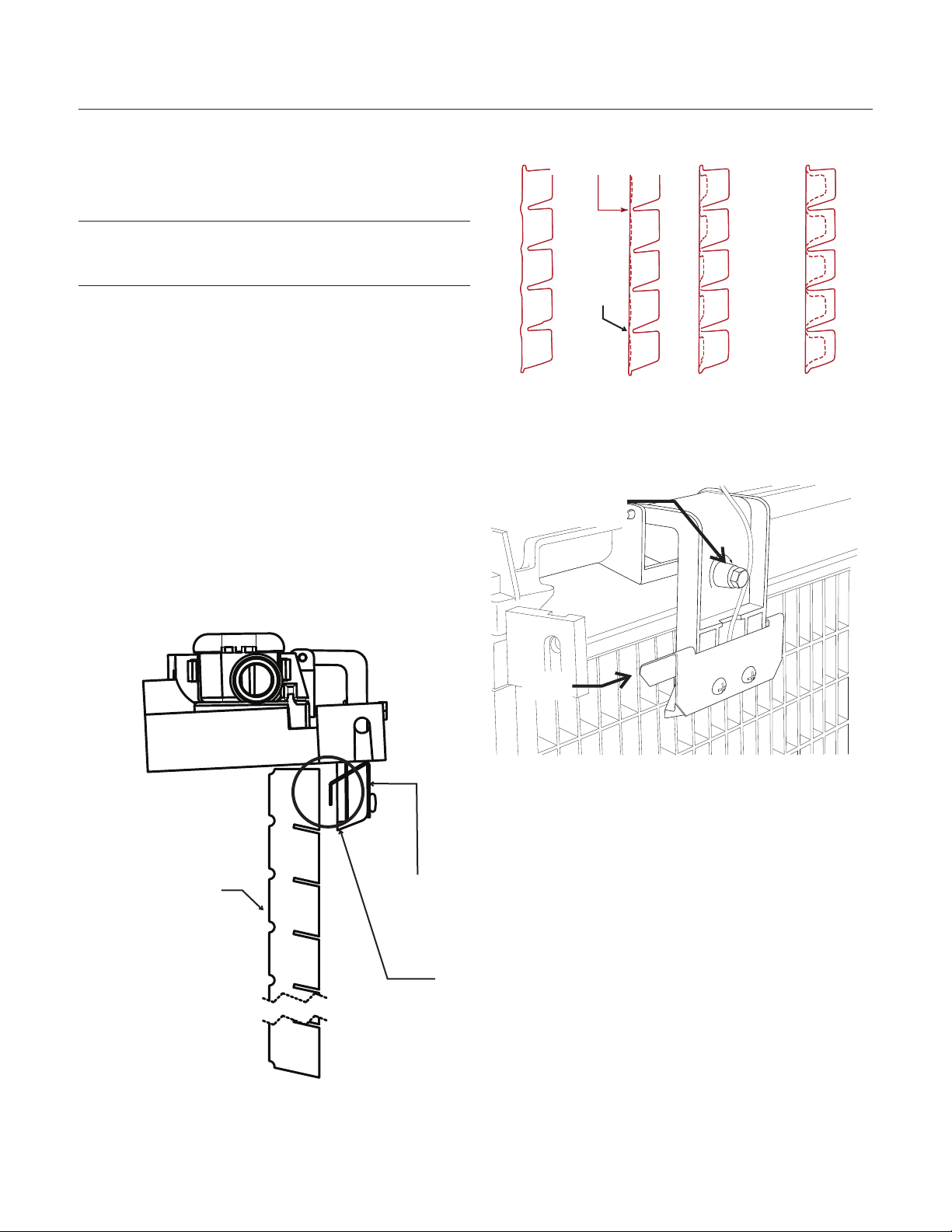

Pre-Charged Tubing Coupling Connections

Inspect couplings, wipe clean and lubricate

both parts with polyolester refrigerant oil.

Hand tighten to be sure threads are properly

engaged.

Use two wrenches and continue tightening the

couplings. As the diaphragms being to pierce,

the couplings will be harder to turn. Be sure

only the swivel nut is rotated.

Continue tightening until the swivel nut feels

like it is tight, then go to the next step. No

threads will be seen when the couplings are

tight.

After the swivel nut feels like it is tight, mark

the nut and the panel. Then tighten one

quarter turn more. That ensures that there is

a brass-to-brass joint inside the coupling.

October 2012 Page 17

General Installation - Remote

Plumbing Requirements

All models require connection to cold, potable water. A hand actuated valve within site of the

machine is required.

Water Filters

Install a new cartridge if the filters were used with a prior machine.

All models require drain tubing to be attached to them. There is a single ¾” FPT drain fitting in

the back of the cabinet.

Install new tubing when replacing a prior ice machine, as the tubing will have been sized for

the old model and might not be correct for this one.

Connect water supply to water inlet fitting.

Note: This NSF listed model has a 1" anti-back flow air gap between the potable water inlet tube end and

the highest possible reservoir water level, no back flow device is required.

Connect drain tubing to drain fitting.

Route the drain tubing to building drain. Follow local codes for drain air gap.

Use rigid drain tubes and route them separately – do not Tee into the bin’s drain.

Vent the reservoir drain. A vertical vent at the back of the drain, extended about 8 – 10” will

allow the gravity drain to empty and also keep any surges during draining from discharging

water.

Horizontal runs of drain tubing need a ¼” per fall per foot of run for proper draining.

Follow all applicable codes.

August 2013 Page 18

General Installation - Remote

Electrical

The machine is not supplied with a power cord, one must either be field installed or the

machine hard-wired.

The dataplate on the back of the cabinet details the power requirements, including voltage,

phase, minimum circuit ampacity and maximum fuse size. HACR type circuit breakers may be

used in place of fuses. Extension cords are not permitted. Use of a licensed electrician is

recommended.

The ice maker is designed to operate on its own electrical circuit and must be individually

fused. Voltage variation must not exceed the limits listed earlier.

The remote condenser is designed to be powered from the ice machine. A separate knockout

hole has been provided in the ice maker electrical junction box.

Electrical connections are made inside the junction box in the back panel of the ice machine.

Remove the junction box cover and route the power cord through the access hole and properly

attach the power supply wires to the leads in the junction box.

Attach the remote condenser fan motor wires to the wires in the junction box tagged “fan motor

leads”.

Install field supplied strain reliefs per code. Attach a ground wire to the ground connection in

the junction box.

Check voltage when complete.

Return the junction box cover to its original position and secure with the original screws.

Follow all applicable local, state and national codes.

October 2012 Page 19

Adjustments

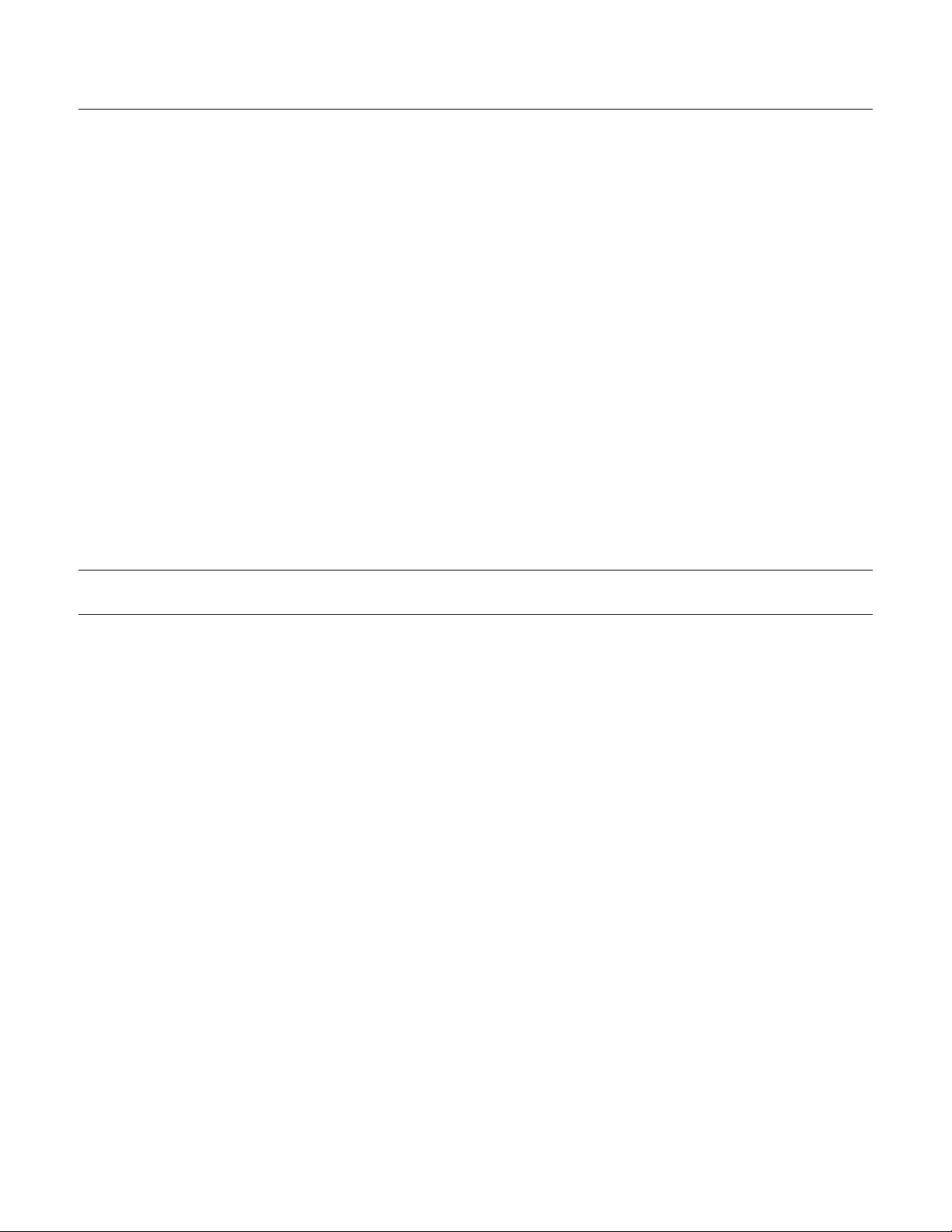

Bridge Thickness - For the Service Tech

Only

Adjustment

Push and hold Off till the machine stops.

Access ice thickness sensor.

Check gap between metal tip and evaporator

grid. Small cube standard gap is 3/16 inch,

medium cube standard gap is 7/32 inch. To

set, place a 3/16" (small cube) or 7/32"

(medium cube) drill bit between sensor tip

and evaporator to check. Adjust gap using

adjustment screw.

Restart unit and check ice bridge. Repeat as

needed

Caution: Do not make the bridge too thin or the machine will not harvest properly. Bridge thickness

adjustments are not covered by warranty.

Screw

Gap

Water purge setting

The water purge is factory set to Automatic. The setting can be changed to one of 5 manual

settings or left on automatic.

purge

setting

Water

Type

To set:

Switch the machine OFF by holding the Off button in until a number or the letter A shows on

the display.

Press and release the On button repeatedly until the number on the display corresponds to the

desired setting.

1Minimum

RO water

or

equivalent,

TDS less

than 35

2Moderate3-Standard

Low TDS

non-RO

water

Setting

for typical

water

4Heavy

High

TDS

water

5Maximum

Very hHigh

TDS water,

greater

than 256

A - Automatic

Any with

conductivity

not less than 10

microSiemens/

cm

Press and release the Off switch again to return to the normal control state.

October 2012 Page 20

Prodigy Cuber System Information

Overall System Type:

Refrigeration: Mechanical, either air cooled, water cooled or remote cooled.

•

Water System: Inlet water solenoid valve fills reservoir once per cycle. Purge solenoid

•

valve opens to discharge some reservoir water once per cycle.

Control System: Electronic

•

Harvest cycle sensor: Conductivity probe

•

Water full/empty sensor: Conductivity probe

•

Bin Control: Curtain Switch

•

Ice type: Unified

•

Harvest system: Hot gas defrost with mechanical assist

•

Electrical Components:

Compressor

•

Contactor

•

• Water Pump

• Inlet Water Solenoid Valve

• Purge or purge Valve

• Fan Motor(s)

• Fan motor pressure control

• High pressure cut out – certain AC models only

• Harvest Assist Solenoid(s)

• Hot Gas Valve(s)

• Controller

•

Transformer – 12v AC for the controller only

•

Water Level Sensor

•

Ice Thickness Sensor

•

Curtain Switch(es)

October 2012 Page 21

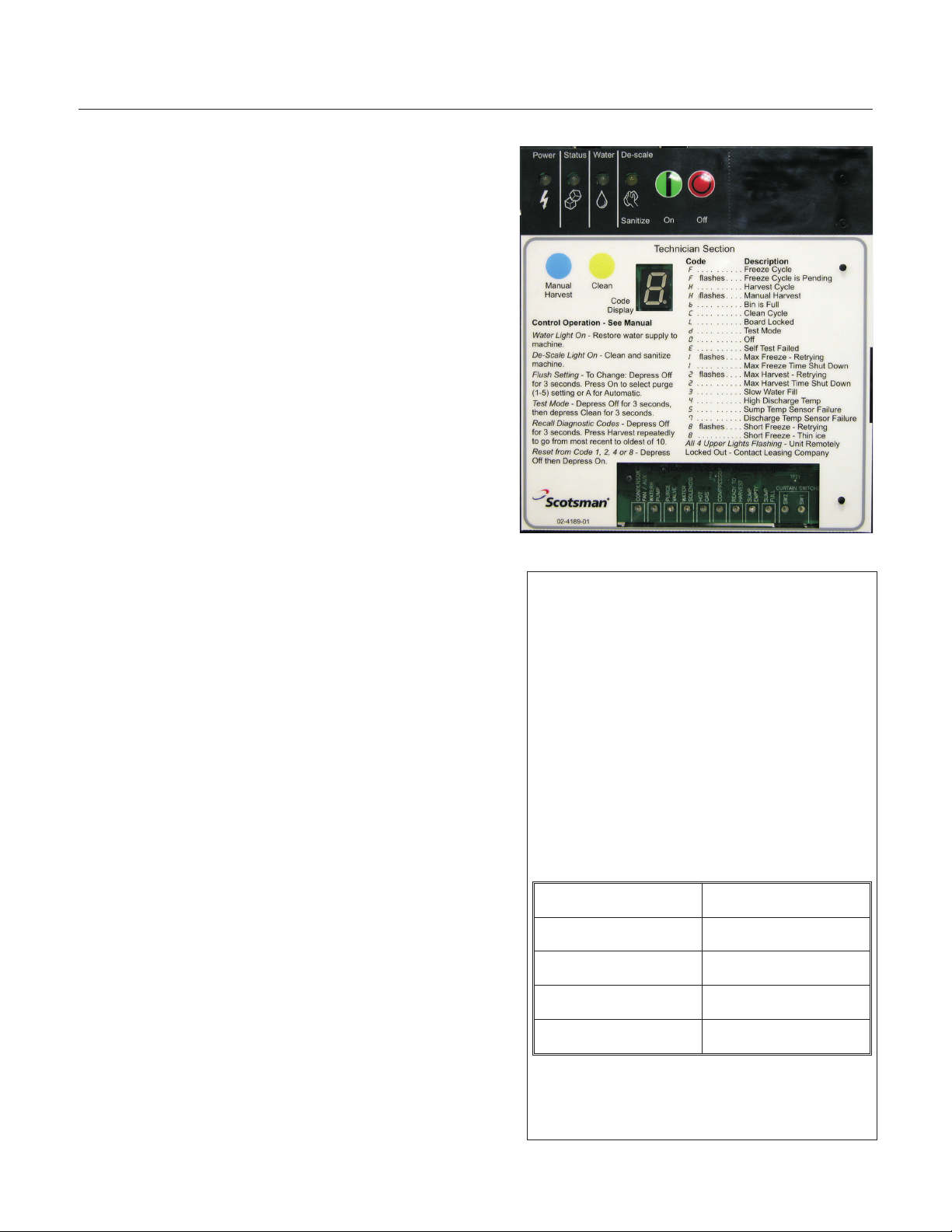

Controller Information

Machine Indicator Lights

Power

•

Status

•

Water

•

Clean

•

Code Display

Main codes - automatically displayed

F .......Freeze Cycle

F flashes . . Freeze Cycle is Pending

H .......Harvest Cycle

H flashes . . Manual Harvest

b .......BinisFull

C .......Clean Cycle

L .......Board Locked

d .......Test Mode

O .......Off

E .......Self Test Failed

1 flashes . . Max Freeze - Retrying

1 .......MaxFreeze Time Shut Down

2 flashes . . Max Harvest - Retrying

2 .......MaxHarvest Time Shut Down

3 .......Slow Water Fill

4 .......High Discharge Temp

5 .......Sump Temp Sensor Failure

7 .......Discharge Temp Sensor Failure

8 flashes . . Short Freeze - Retrying

8 .......Short Freeze - Thin ice

Change De-Scale Notification Interval This feature is accessible only from

standby (Status Light Off).

1. Press and hold harvest button for 3

seconds.

This starts the Time to Clean

Adjustment Mode and displays the

current time to clean setting.

Setting Codes - requires push button sequence

Water Purge Settings

A, 1, 2, 3, 4, 5

De-Scale notification

- see table to the right

November 2008 Page 22

2. Press the clean button repeatedly to

cycle through the 4 settings:

Prior Effective 11/6/08

3 months 1 year

4 months 0 or disabled

5 months 4 months

6 months (default) 6 months (default)

3. Push Off to confirm the selection.

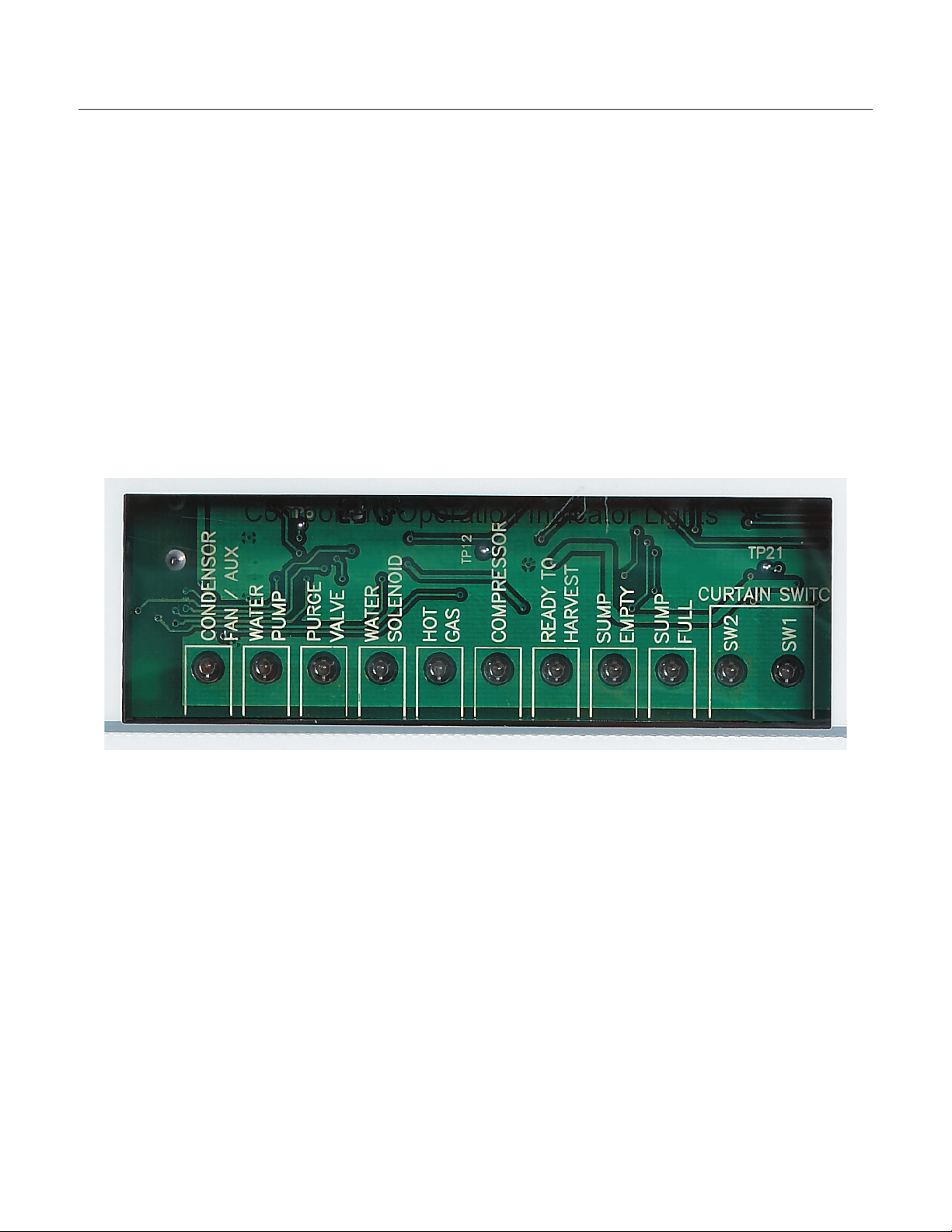

Controller Information

Component Indicator Lights

Condenser Fan / Aux (Aux = liquid line solenoid when a remote condenser model)

•

Water Pump

•

Purge Valve

•

Water Solenoid

•

Hot Gas

•

Compressor

•

Ready to Harvest

•

Sump Empty

•

Sump Full

•

Curtain SW1

•

Curtain SW2

•

Component Indicator Lights

October 2012 Page 23

How It Works - Air Cooled

Freeze Cycle. At start up the controller drains and refills the reservoir. The reservoir refills

when the mid length water level sensor probe is uncovered and continues to fill until the top

probe is in contact with water. When the reservoir has filled, the compressor and water pump

start. After the discharge pressure has increased past the cut in point of the fan pressure

control, the fan motor(s) will begin to operate and warm air will be discharged out the back of

the cabinet. The fan motor will switch on and off as the discharge pressure rises and falls.

Water flows over the evaporator as the refrigeration system begins to remove heat. When the

water temperature falls to a preset point, as measured by the water temperature sensor, the

controller shuts off the water pump for 30 seconds. The freeze cycle resumes when the pump

restarts and ice begins to form on the evaporator. As it forms, the water flowing over the ice

moves closer and closer to the metal tip of the ice thickness sensor. When it comes into

contact with the sensor for a few continuous seconds, that signals the controller that the freeze

cycle is complete.

The controller may shut the air cooled fan motor off for a variable period of time to build up

heat for harvest. This is dependant upon the temperature of the discharge line sensor.

Harvest Cycle. When the harvest cycle begins, the controller shuts off the fan motor, switches

on the hot gas valve, and through a parallel circuit, the harvest assist solenoid. After a few

seconds the purge valve opens and water is drained from the reservoir. Based on either the

automatic purge or manual purge setting, the pump and purge valve will be switched off at a

time determined to have drained enough water for that setting. The inlet water valve will open

to fill the reservoir anytime the mid length probe is uncovered, which occurs during the

reservoir drain cycle. Harvest continues as the hot discharge gas flows into the evaporator

serpentine, heating up the evaporator. At the same time the harvest assist solenoid is pushing

against the back of the ice slab. When the ice releases from the evaporator, it harvests as a

unit, and the harvest assist probe provides some additional force to push it off. When the ice

falls off it will force the curtain(s) open. An open curtain during the harvest cycle signals the

controller that the evaporator has released its ice. If this is a single evaporator machine the

controller will terminate harvest. If it is a two evaporator machine, the controller will continue

harvest until both curtains have opened. If one curtain remains open, the controller will shut the

machine down on bin full. Anytime harvest is complete the hot gas valve and harvest assist

solenoid are shut off. The harvest assist solenoid pin returns to its normal position by spring

pressure.

If the curtain(s) re-close after harvest, the freeze cycle will restart.

October 2012 Page 24

How It Works - Water Cooled

Freeze Cycle. At start up the controller drains and refills the reservoir. The reservoir refills

when the mid length water level sensor probe is uncovered and continues to fill until the top

probe is in contact with water. When the reservoir has filled, the compressor and water pump

start. After the discharge pressure has increased past the set point of the water regulating

valve, the water regulating valve will open and warm water will be discharged out the

condenser drain. The water regulating valve will modulate to maintain a relatively constant

discharge pressure. Water flows over the evaporator as the refrigeration system begins to

remove heat. When the water temperature falls to a preset point, as measured by the water

temperature sensor, the controller shuts off the water pump for 30 seconds. The freeze cycle

resumes when the pump restarts and ice begins to form on the evaporator. As it forms, the

water flowing over the ice moves closer and closer to the metal tip of the ice thickness sensor.

When it comes into contact with the sensor for a few continuous seconds, that signals the

controller that the freeze cycle is complete.

Harvest Cycle. When the harvest cycle begins, the controller switches on the hot gas valve,

and through a parallel circuit, the harvest assist solenoid. After a few seconds the purge valve

opens and water is drained from the reservoir. Based on either the automatic purge or manual

purge setting, the pump and purge valve will be switched off at a time determined to have

drained enough water for that setting. The inlet water valve will open to fill the reservoir

anytime the mid length probe is uncovered, which occurs during the reservoir drain cycle.

Harvest continues as the hot discharge gas flows into the evaporator serpentine, heating up

the evaporator. At the same time the harvest assist solenoid is pushing against the back of the

ice slab. When the ice releases from the evaporator, it harvests as a unit, and the harvest

assist probe provides some additional force to push it off. When the ice falls off it will force the

curtain(s) open. An open curtain during the harvest cycle signals the controller that the

evaporator has released its ice. If this is a single evaporator machine the controller will

terminate harvest. If it is a two evaporator machine, the controller will continue harvest until

both curtains have opened. If a curtain remains open, the controller will shut the machine down

on bin full. Anytime harvest is complete the hot gas valve and harvest assist solenoid are shut

off. The harvest assist solenoid pin returns to its normal position by spring pressure.

If the curtain(s) re-close after harvest, the freeze cycle will restart.

January 2010 Page 25

How It Works - Remote

Freeze Cycle. At start up the controller drains and refills the reservoir. The reservoir refills

when the mid length water level sensor probe is uncovered and continues to fill until the top

probe is in contact with water. When the reservoir has filled, the liquid line valve, compressor

and water pump are switched on. After the discharge pressure has increased past the set point

of the headmaster in the condenser, the headmaster will direct refrigerant gas into the

condenser and warm air will be discharged out of the condenser. The headmaster will

modulate to maintain a minimum discharge pressure. Water flows over the evaporator as the

refrigeration system begins to remove heat. When the water temperature falls to a preset point,

as measured by the water temperature sensor, the controller shuts off the water pump for 30

seconds. The freeze cycle resumes when the pump restarts and ice begins to form on the

evaporator. As it forms, the water flowing over the ice moves closer and closer to the metal tip

of the ice thickness sensor. When it comes into contact with the sensor for a few continuous

seconds, that signals the controller that the freeze cycle is complete.

Harvest Cycle. When the harvest cycle begins, the controller switches on the hot gas valve,

and through a parallel circuit, the harvest assist solenoid. After a few seconds the purge valve

opens and water is drained from the reservoir. Based on either the automatic purge or manual

purge setting, the pump and purge valve will be switched off at a time determined to have

drained enough water for that setting. The inlet water valve will open to fill the reservoir

anytime the mid length probe is uncovered, which occurs during the reservoir drain cycle.

Harvest continues as the hot discharge gas flows into the evaporator serpentine, heating up

the evaporator. At the same time the harvest assist solenoid is pushing against the back of the

ice slab. When the ice releases from the evaporator, it harvests as a unit, and the harvest

assist probe provides some additional force to push it off. When the ice falls off it will force the

curtain(s) open. An open curtain during the harvest cycle signals the controller that the

evaporator has released its ice. If this is a single evaporator machine the controller will

terminate harvest. If it is a two evaporator machine, the controller will continue harvest until

both curtains have opened. If a curtain remains open, the controller will shut the machine

down. Anytime harvest is complete the hot gas valve and harvest assist solenoid are shut off.

The harvest assist solenoid pin returns to its normal position by spring pressure.

If the curtain(s) re-close after harvest, the freeze cycle will restart.

Shut down occurs when a curtain remains open after a harvest cycle. The controller will switch

off the liquid line solenoid valve and operate the compressor for 30 seconds, then shut it off.

November 2006 Page 26

Electrical Sequence - Air or Water Cooled

Power connected, unit previously switched Off.

Control board does a self check. If the self check fails, the unit displays an E and no further

action will occur.

If the self check passes, the controller will display a 0, the curtain light(s) will be ON and the

Power and Sump Empty lights will be ON.

Pushing and releasing the On button will start the ice making process.

The display will begin to blink F. The component indicator lights will switch on and off to match the

following process:

The purge valve opens and the water pump starts to empty the reservoir. This is done to

discharge any excess water from ice melting into the reservoir.

The hot gas valve and the harvest assist solenoid are energized.

The inlet water valve will open to fill the reservoir. The water valve can open any time the water

level is low.

After a few seconds the purge valve closes and the pump shuts off.

When the reservoir is full the inlet water valve stops and the compressor switches on. Five

seconds after the compressor starts the hot gas valve and the harvest assist solenoid are

de-energized.

Light Information: The display shows a non-blinking F. The Power and Status Lights will be Green. The

compressor, fan motor, water pump, sump full and one or two curtain switch lights will be ON.

The air cooled model's fan motor will start to turn when the discharge pressure has built up to

the fan pressure control's cut in point. This is about 15 seconds after the compressor starts.

The Freeze cycle continues. The compressor, water pump, fan motor and curtain indicator

lights will be ON. When the reservoir water temperature falls to a certain preset point, the

water pump will shut off for 30 seconds. This is the anti-slush period. At this time the controller

checks the conductivity of the water in the reservoir for the auto-purge feature. After the water

pump restarts the Sump Full light will go out and neither sump lights will be on for the rest of

the freeze cycle.

When the ice has built up enough so that the water flowing over the evaporator comes into

continuous contact with the ice level sensor, the Ready to Harvest light will begin to blink on

and off. When it has been On continuously for 5 seconds, the controller will switch the machine

into a Harvest cycle.

October 2012 Page 27

Electrical Sequence - Air or Water Cooled

Indicator Information: The display shows a non-blinking H. The Power and Status Lights will be Green.

The compressor, hot gas valve and one or two curtain switch lights will be ON. After a few seconds the

water pump, purge valve and inlet water valve lights will come on.

The fan motor(s) shut off and remain off throughout the harvest cycle.

The harvest assist solenoid is connected in parallel with the hot gas valve. Although it is

energized throughout the harvest cycle, its piston does not move until the ice has become

partially loosened from the evaporator plate by the action of the hot refrigerant gas passing

through the evaporator serpentine.

The water pump and purge valve will shut off when the purge level setting time has been

reached, either the manual time or the automatic time. The inlet water valve will remain on until

it fills the reservoir. The Ready to Harvest light will switch Off when the ice falls from the

evaporator.

Harvest continues until the ice slab is ejected from the evaporator and falls, opening the

curtain. When the curtain opens, the magnetic reed curtain switch opens, breaking the circuit

to the controller. If the curtain re-closes within 30 seconds, the controller switches the machine

back into another freeze cycle. If the curtain switch remains open, the controller shuts the

machine down and puts it into a standby position.

October 2012 Page 28

Electrical Sequence - Remote Cooled

Power connected, unit previously switched Off.

Control board does a self check. If the self check fails, the unit displays an E and no further

action will occur.

If the self check passes, the controller will display a 0, the curtain light(s) will be ON and the

Power and Sump Empty lights will be ON.

Pushing and releasing the On button will start the ice making process.

The display will begin to blink F. The component indicator lights will switch on and off to match the

following process:

The purge valve opens and the water pump starts to empty the reservoir. This is done to

discharge any excess water from ice melting into the reservoir.

The hot gas valve and the harvest assist solenoid are energized.

The inlet water valve will open to fill the reservoir. The water valve can open any time the water

level is low.

After a few seconds the purge valve closes and the pump shuts off.

When the reservoir is full the inlet water valve stops, the liquid line valve is opened and the

compressor switches on. Five seconds after the compressor starts the hot gas valve and the

harvest assist solenoid are de-energized.

Light Information: The display shows a non-blinking F. The Power and Status Lights will be Green. The

compressor, fan motor, water pump, sump full and one or two curtain switch lights will be ON.

The Freeze cycle continues. When the reservoir water temperature falls to a certain preset

point, the water pump will shut off for 30 seconds. This is the anti-slush period. At this time the

controller checks the conductivity of the water in the reservoir for the auto-purge feature. After

the water pump restarts the Sump Full light will go out and neither sump lights will be on for the

rest of the freeze cycle.

When the ice has built up enough so that the water flowing over the evaporator comes into

continuous contact with the ice level sensor, the Ready to Harvest light will begin to blink on

and off. When it has been On continuously for 3 seconds, the controller will switch the machine

into a Harvest cycle.

Indicator Information: The display shows a non-blinking H. The Power and Status Lights will be Green.

The compressor, hot gas valve and one or two curtain switch lights will be ON. After a few seconds the

water pump, purge valve and inlet water valve lights will come on.

October 2012 Page 29

Loading...

Loading...