Scotsman Ice Machine AFE400 Installation Manual

INTRODUCTION

AFE400

To the owner or user: This service manual is

intended to provide you, and the maintenance or

service technician, with the information needed to

install, start up, clean, maintain and repair this

product.

The AFE400 is an ice machine that produces

flaked ice and stores it in a insulated bin. It

automatically maintains the level of ice by turning

on when the ice level falls and switches off when it

is full.

This unit in serviceable in place; the ice storage

bin and hood may be removed from the chassis to

allow service access without removing the ice

machine from its installed location. The

refrigeration system uses R-134a as the

refrigerant.

Table of Contents

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 2

Limitations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 3

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 4

Plumbing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 5

Final Check List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 6

Cabinet Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 7

Component Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 8

Electrical Sequence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 9

Initial Start Up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 10

Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 11

Water Schematic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 15

Refrigeration Schematic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 16

Technical Charateristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 17

Service Diagnosis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 18

Removal and Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 20

Parts lists and wiring diagrams are located in

the center of this manual, printed on yellow

paper.

Keep this manual for reference.

This manual was printed on recycled paper.

May 1995

Page 1

AFE400

Specifications

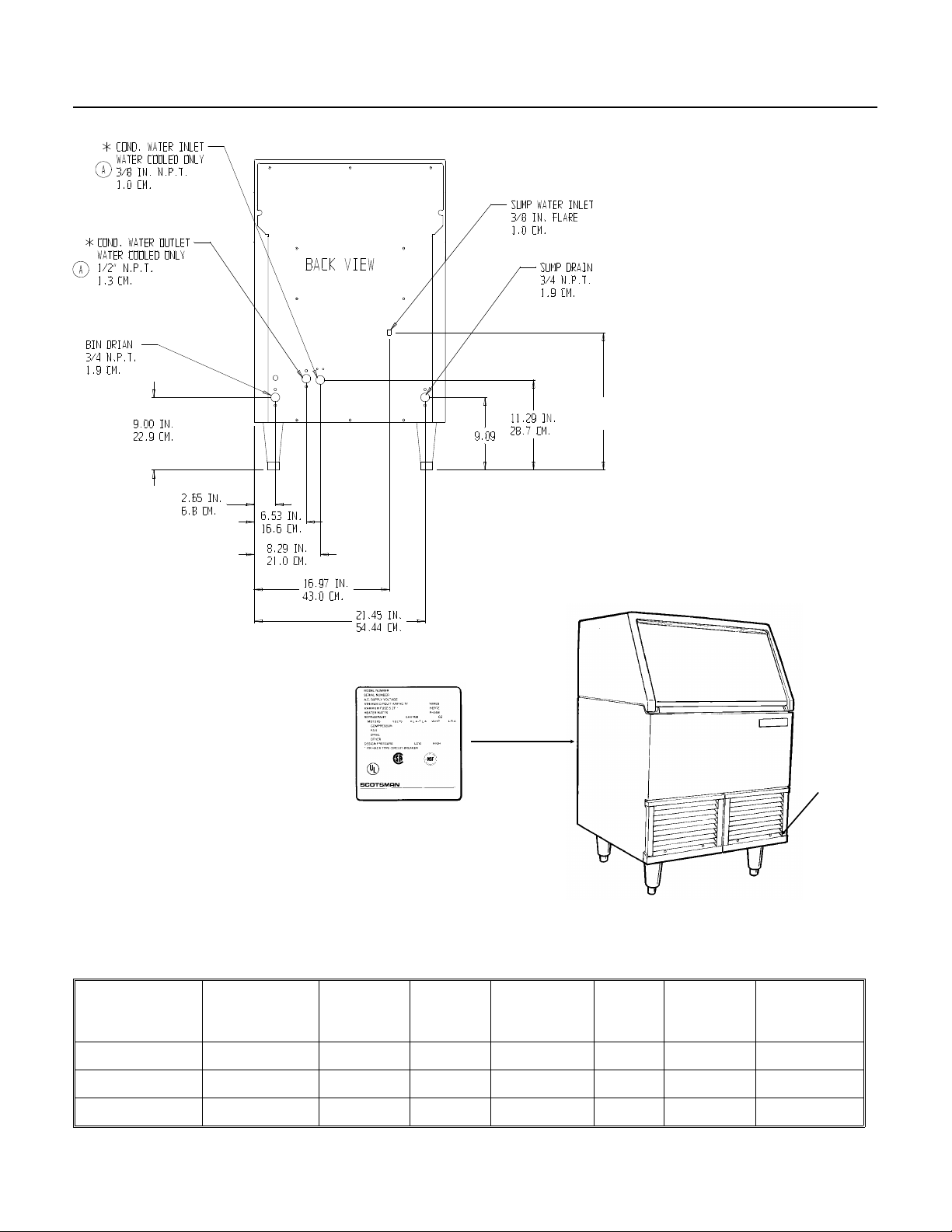

14.25 IN

The nameplate is located

on the back panel.

A serial number plate is

located behind the right

grill, in front of the control

box, on the base.

Model Number Dimensions

(w/o) legs

Basic

Electrical

H x W x D

AFE400AE-1A

AFE400WE-1A

AFE400AE-6A

33 x 24

33 x 24

33 x 24

1

⁄4 x 24

1

⁄4 x 24

1

⁄4 x 24

115/60/1 Flake Air 9 15 15 oz

115/60/1 Flake Water 9 15 10 oz

230/50/1 Flake Air 9 15 15 oz

A scoop and legs (6") are included.

The unit is equipped with an electrical power cord,

but should only be plugged into a circuit dedicated

to the ice machine.

Ice Type Condenser

Type

Typical

Amps

Maximum

Fuse

SERIAL

NUMBER

PLATE

Refrigerant

Charge,

R-134a.

June 1995

Page 2

For The Installer: Environmental Limitations

The ice machine must be installed indoors in a

controlled environment.

Minimum Maximum

Air Temp 50

Water Temp 40

Water Pressure 20 PSI 80 PSI

Voltage (60 Hz) 103.5 126.5

Voltage (50 Hz) 207 253

0

F. 1000F.

0

F. 1000F.

AFE400

AIR OUT

Operating the ice machine outside of the above

limitations, or outdoors, is potentially damaging to

the machine, and it is misuse of the machine. This

may void the war r a nt y.

Scotsman Ice Systems are designed and

manufactured with the highest regard for safety

and performance. They meet or exceed the

standards of UL, NSF , and CUL.

Scotsman assumes no liability or responsibility of

any kind for products manufactured by Scotsman

that have been altered in any way, including the

use of any part and/or other components not

specifically approved by Scotsman.

Scotsman reserves the right to make design

changes and/or improvements at any time.

Specifications and design are subject to change

without notice.

AIR IN

Airflow on air cooled models:

••Intake through the right grill.

••Exhaust from the left grill.

Do not install wher this air flow is blocked.

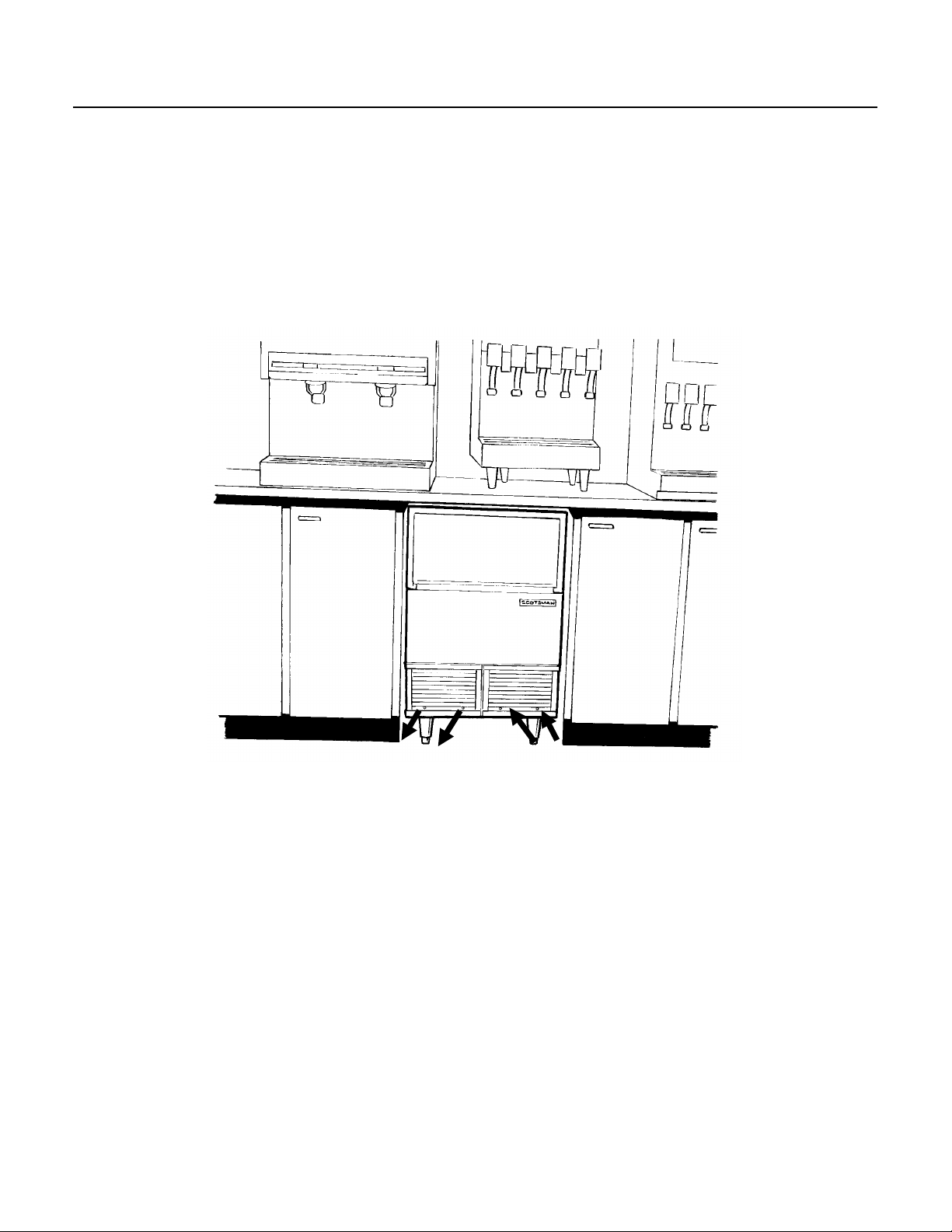

The AFE400 has a removable cabinet. When

installed, the machine should have some extra

clearance (1/8") on the left and right sides so that

the cabinet may be easily removed when the

machine is in place.

June 1995

Page 3

AFE400

Installation:

Water

The water supply for this ice machine has been in

contact with many materials since it fell from the

sky as rain. All rain is slightly acidic, and tends to

dissolve the materials it comes in contact with.

During water’s journey to the ice machine, it has

flowed over and through the ground, been picked

up by a municipal or private pump, forced through

a series of pipes of differing construction and may

have been treated by the municipality providing

the water.

The water supplied to this ice machine will then

contain a variety of substances that will likely show

up as solids during the ice making process. These

solids are similar to those found when water is

boiled out of a saucepan. Only the water boils

away, and the minerals that were in the water

solidify in the pan. During ice making the water is

frozen into ice, and many of the minerals stay

behind in the ice machine water system. After time

the minerals will have to be dissolved by ice

machine cleaner, then flushed away during the

cleaning process.

An ice machine is a food manufacturing plant; it

takes a raw material, in this case water, and

transforms it into a food product, ice. The purity of

the water is very important in obtaining pure ice

and in maximizing product life.

The water to the ice machine should be filtered.

Water filters vary greatly in ability and function.

Install one that filters out suspended solids to a

dimension of 5 microns or less. The finer the filter

the better, but finer filters may plug-up sooner than

course ones. It may be necessary to add a course

filter ahead of the fine filter to prolong filter life.

This ice machine may be installed in the open or

under a counter. No clearance is required at the

sides or top beyond what’s needed to place the

cabinet into position. Air cooled models blow air in

and out through the grills at the front. Space is

required for utility connections at the back.

The ice machine is not designed for outdoor

use. It must be installed indoors, in a

controlled environment. The air and water

temperatures must not exceed rated limits.

Electrical power is supplied through a cord

connected to the unit. All local codes must be

followed.

Pre-installation:

1. Inspect the place where the ice machine is to be

installed. Check for:

••space for the cabinet

••water supply,

••drain availability

••and electrical power supply.

No extension cords are allowed. The building drain

inlet must be lower than the drain outlet(s) at the

back of the ice machine. The water supply must

have a hand shut off valve accessible when the

unit is installed.

2. Determine the method of installation, is the

machine to be installed under the counter? Is the

drain in the floor under the machine? Is the water

inlet accessible from the top?

Have the water tested. Either acidic water or

alkaline water will cause corrosion. Dissolved

solids cannot be filtered out. Check with a water

treatment specialist regarding testing, treatment

and filters.

May 1995

Page 4

Installation:

AFE400

For The Plumber

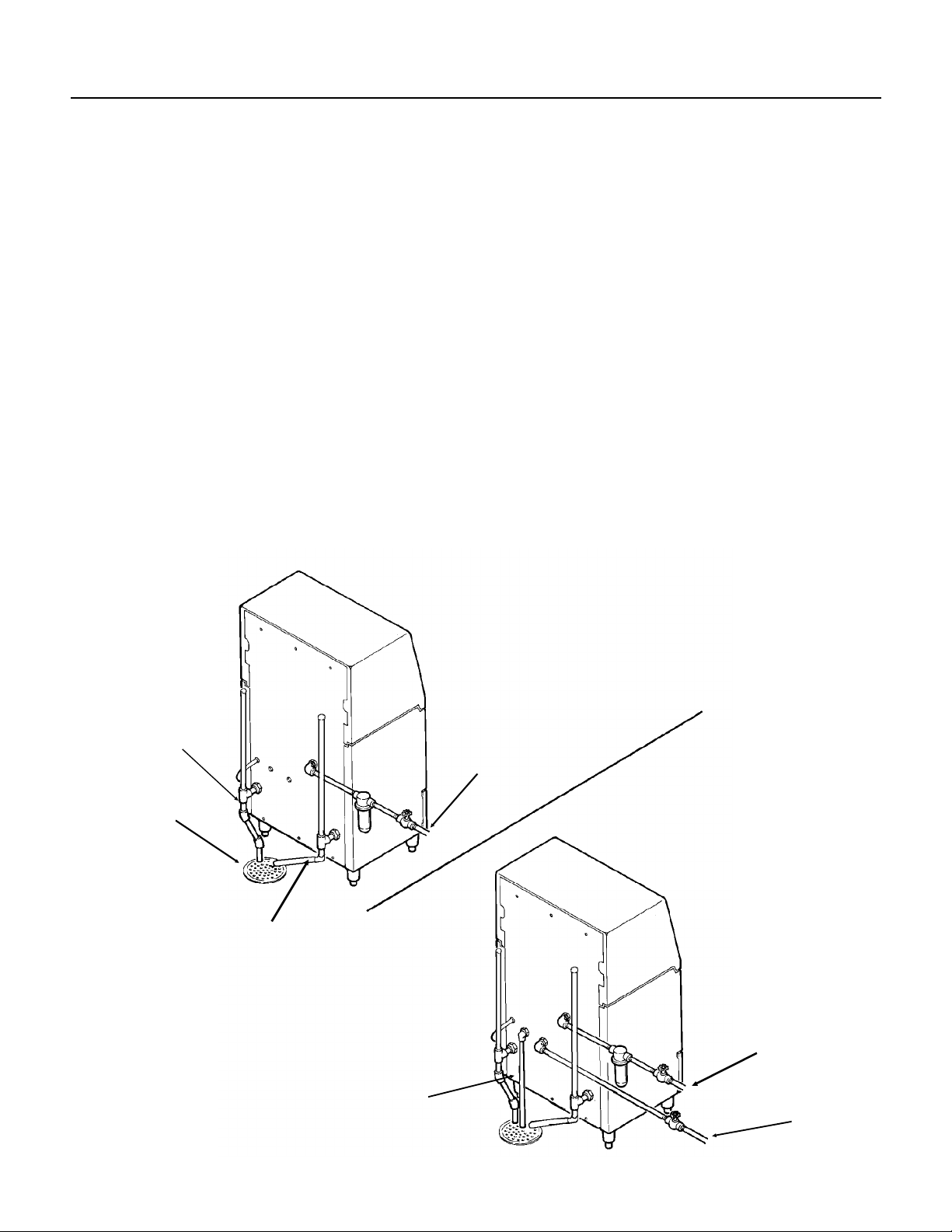

1. Connect cold potable water to the 3/8" male

flare at the top back of the cabinet. A water filter is

recommended. Flush the water line prior to

connecting to the ice machine.

A loop of copper tubing may be used between the

ice machine and the water supply. This will allow

the ice machine to be pulled out from its installed

location without disconnecting the water line. No

back-flow preventer is required in the inlet potable

water line because provision for that is

incorporated in this N.S.F. listed product (the float

seat is above the reservoir water level and cannot

siphon).

2. Connect a drain tube the drain fitting. If water

cooled, the drain tubes must be run separately.

The bin drain fitting is 3/4" F.P.T. brass.

AIR COOLED

PLUMBING

••Drain tube material must be rigid and meet local

code.

••Traps in the bin drain line without vents ahead

of them will cause poor draining.

••The bin drain must be vented if there is a long

horizontal run (5’ or more). All drains are

gravity, and must have a minimum fall of 1/4"

per foot of horizontal run.

••Maintain the air gap required by local code

between the end of the drain tubes and the

building drain receptacle.

••Drain tubing should be insulated to prevent

condensation from forming on the tubing.

3.The unit is set up for drain connections on the

outside of the cabinet. To connect the drains inside

would require the removal of the drain fittings

attached to the back panel, and field fabricated

drain tubes routed inside the base of the unit.

BIN DRAIN

FLOOR

DRAIN

RESERVOIR

OVERFLOW

DRAIN

CONDENSER

DRAIN

POTABLE

WATER

INLET

May 1995

Page 5

WATER COOLED

PLUMBING

POTABLE

WATER INLET

CONDENSER

INLET

AFE400

Installation

For The Electrician

This is a cord-connected unit, and must be on a

separate single pha se power supply. Check the

nameplate for the correct voltage. The maximum

fuse size for this circuit should be 15 amps, per the

nameplate use fuses, or HACR circuit breakers.

Follow All Local Codes - THIS UNIT MUST BE

GROUNDED. Do not use extension cords and do

not disable or by-pass ground plug on electrical

plug.

After Utility Connections:

1. Level the cabinet, use the leg levelers on the

end of the legs to adjust the cabinet height. (Legs

should have been installed when the unit was

unpacked).

2. Wash the bin and hood. If desired, the interior of

the bin could be sanitized.

3. Locate the scoop, wash it and have it available

for use when needed.

Final Check List

1. Is the ice maker cabinet in a room where

ambient temperatures are within the minimum and

maximum temperatures specified?

2. Has the water supply been connected?

3. Is the water pressure adequate?

4. Have the water connections been checked for

water leaks?

5. Have the drain connections been made?

6. Have the drain connections been checked for

leaks?

7. Is the cabinet level?

8. Is the ice machine plugged into an electrical

power supply of the correct voltage and is the ice

machine the only load on that circuit?

9. Has all of the shipping material been removed

from the inside of the cabinet?

12. Has the owner/user been given the name and

telephone number of the authorized Scotsman

Service Agency serving that location?

10. Has the bin and cabinet been wiped clean and

sanitized?

1 1. Has the Customer Evaluation & Warranty

Registration form been filled out? Check for correct

model and serial numbers from the nameplate,

then mail the completed form to Scotsman.

June 1995

Page 6

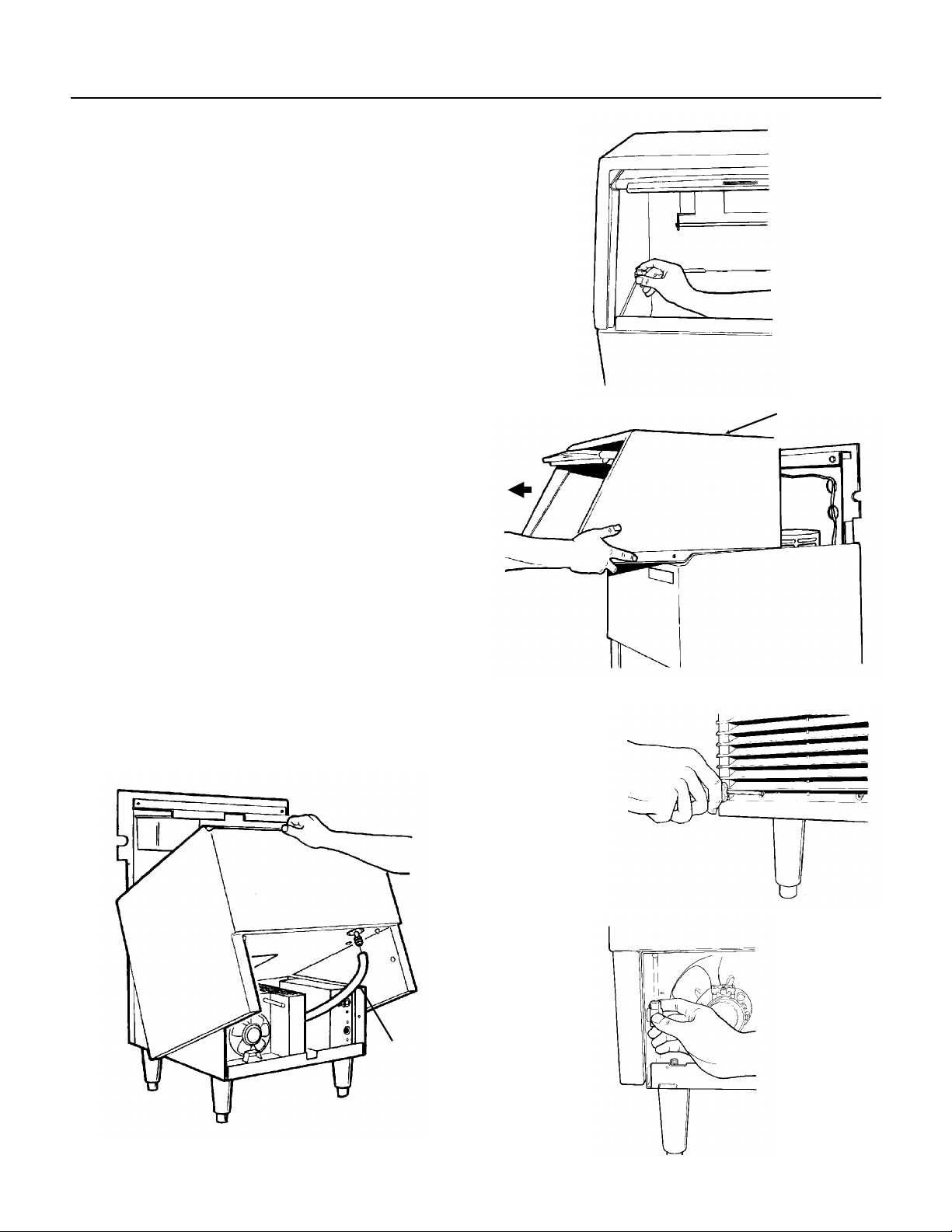

Removal of the Cabinet

One of the most useful features of this ice machine

is the ability to remove the cabinet from the ice

machine without removing the ice machine from its

installed position.

To Remove:

1. Switch the master switch to OFF. Be certain the

ice machine has been switched off.

2. Open the bin door and turn the knobs to

unscrew the mounting bolts at the left and right

inside of the ice storage bin. Remove the mounting

bolts.

3. Pull the hood and door assembly straight out

until it can be lifted up. Caution: the door may be

free to come out the back of the hood when

removed from the cabinet base.

4. To remove the cabinet base the hood must be

removed first.

5. Remove 4 screws and the two grills at the front

of the base.

STEP 2

STEP 3

AFE400

HOOD

6. In the area exposed when the grills are removed

are two knobs similar to those removed in step 2.

Unscrew and remove the two knobs.

7. Locate bin drain. Loosen hose clamp holding

drain tube to fitting and pull the drain tube off of the

fitting.

8. Lift up the front of the base and rotate the base

up and off of the ice machine.

The machine is now exposed for service.

STEP 8

STEP 5

STEP 6

BIN

DRAIN

May 1995

Page 7

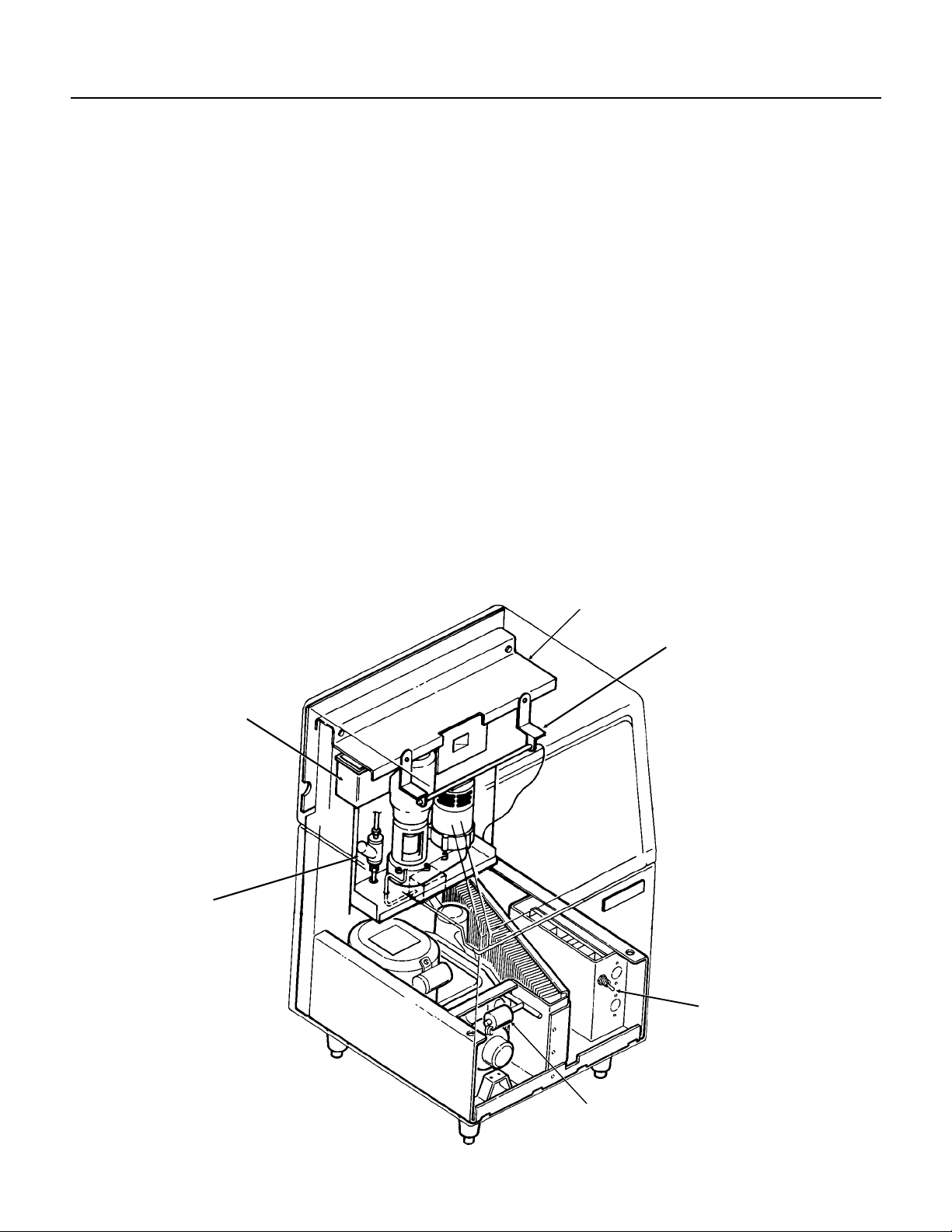

AFE400

Component Location

The ice machine is designed for front service.

Many components are serviceable from the front

without removing the cabinet. With the cabinet

removed, nearly all components are serviceable.

In the bin area can be found

•• Float

•• Reservoir

•• Evaporator

•• Bin Thermostat sensing tube

Behind the right front grill on the front edge of the

control box:

•• Bin thermostat

•• Master switch

Inside the control box are the auger delay control,

low pressure cut out, and the contactor.

Auger Delay Pressure Control: This pressure

switch, connected to the low side of the

refrigeration system, controls the auger drive

motor.

High Pressure Cut Out (water cooled only): The

pressure switch is designed to open and shut off

the machine should the high side refrigeration

pressure become too high, usually as a result of

not enough water through the water cooled

condenser.

It is a manual reset.

On-Off switch: This toggle switch shuts off the

machine. It is not a complete disconnect.

Bin Thermostat: This thermostat turns the

machine on and off in response to changes in

temperature of the capillary tube. At the minimum

setting, it opens at 350 F. and closes at 450 F. At

the maximum setting, it opens at 51oF. and closes

at 61oF. See "Initial Start Up" for adjustment

information.

CUTAWAY VIEW

Air Cooled Shown

RESERVOIR

STRAINER

COVER PLATE

BIN THERMOSTAT

BRACKET

CONTROL BOX

May 1995

Page 8

HI PRESSURE CUT OUT

(Water Cooled Only)

Loading...

Loading...