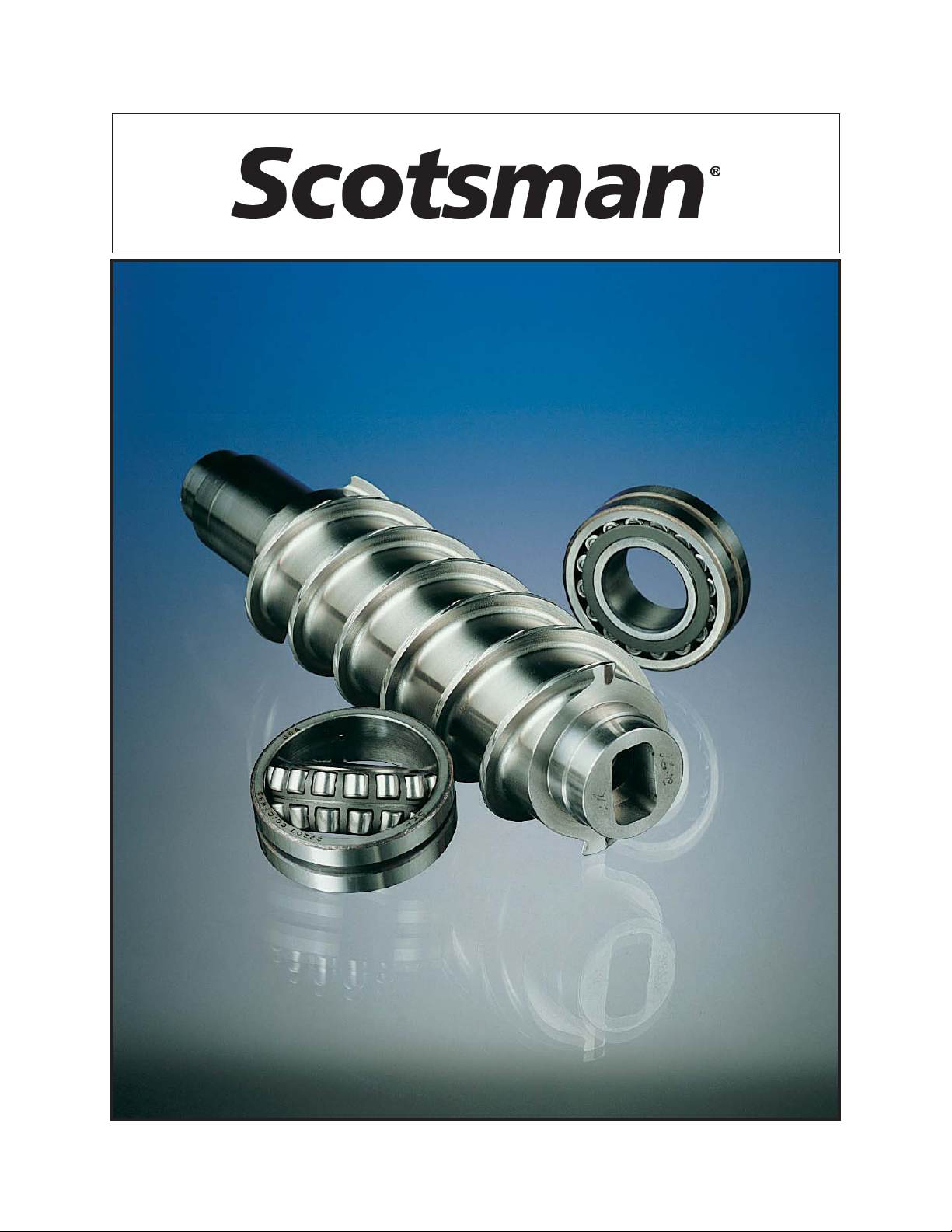

Scotsman Ice Machine AFE325 Service Manual

Flaked and Nugget

Ice Machines

Technical

Service Information

Table of Contents

Introduction .................................. Page 2

Definitions ................................... Page 3

Suggested Tools ................................ Page 4

Tubular Discharge Spout ........................... Page 5

Auger Removal - AFE325 ........................... Page 6

Center Point Breaker ............................. Page 7

MDT3 and MDT4 Variation .......................... Page 8

Auger Removal - AFE400, or MDT3, MDT4 ..................Page 9

Auger Removal - MFE400 ........................... Page 10

Bearing and Evaporator Service - all 2 inch brass & 1/10 HP .........Page 11

Water Seal and Bottom Bearing Installation - covers all 2 inch brass types . . Page 12

Extruded Ice Type - Nugget or Flaked Ice ...................Page 13

Auger Removal ................................ Page 14

Auger Inspection ................................ Page 15

Evaporator Inspection ............................. Page 16

Bearing Service ................................ Page 17

Water Seal Installation ............................ Page 18

Addendum - New Bearing Design May 2010 .................Page 19

Introduction

Scotsman has been manufacturing flaked ice machines since the early 1950s and

nugget ice machines since the early 1980s. Although there have been significant

changes in drive systems, bearings, materials and refrigeration, the basic flaker remains

a vertical refrigerated cylinder containing water and a slowly rotating auger. As the

auger rotates it pushes soft, water laden crystalline ice to the outlet, where it is either

extruded or compressed into nugget or flaked ice.

This booklet contains the technical information to service all current and recent flaked or

nugget ice machines. Older, long obsolete models are not included.

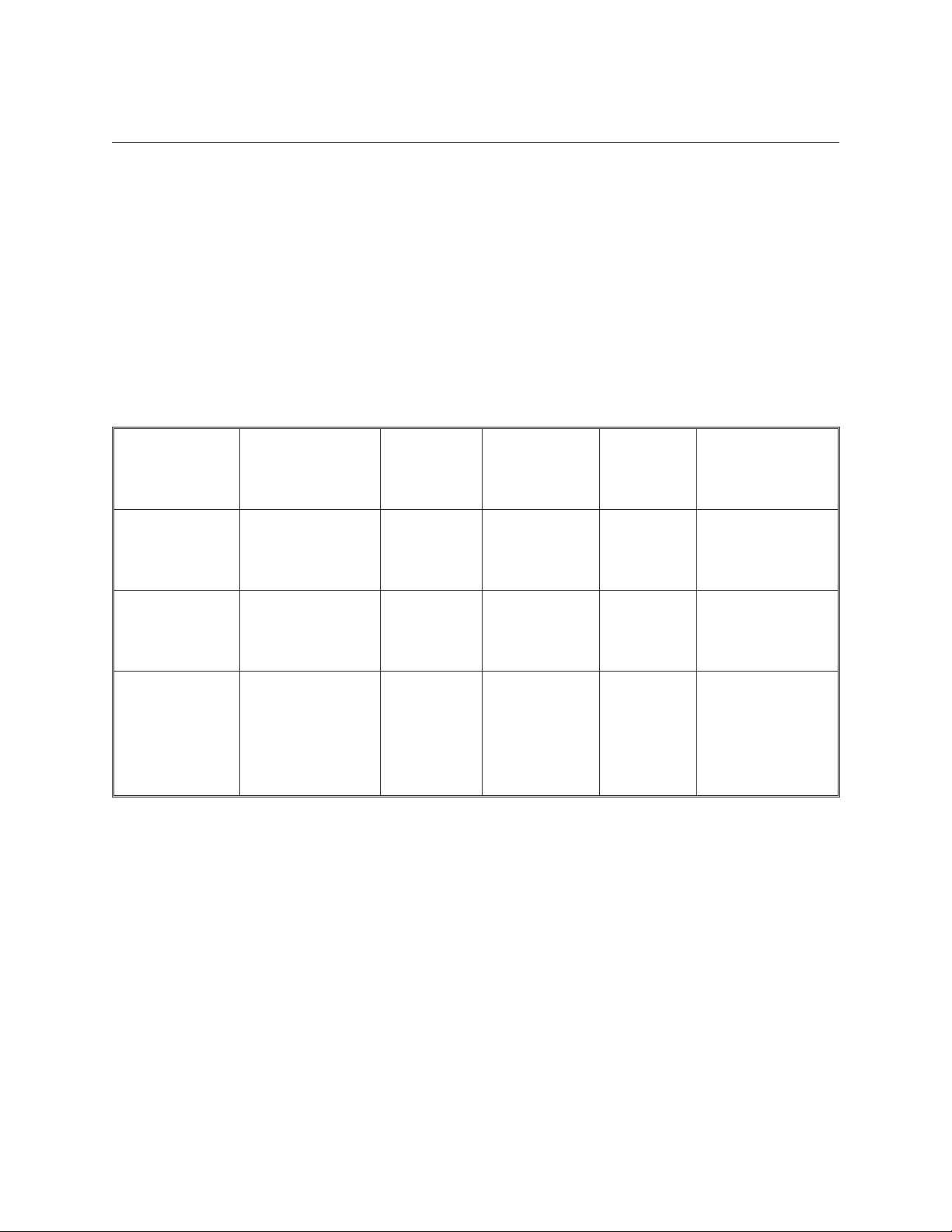

Current Flaker System Designs

Model Type

AFE325 Brass 2 inch 1/10 Cap tube

AFE400 or

AFE424

Prodigy

Flaker or

Nugget Ice

Machine,

NME or FME

The booklet's procedures are divided by platform type:

• AFE325 and prior

• MFE400, MDT3, MDT4, AFE400, AFE424 and prior. AFE424 new in 2010. MDT3

and MDT4 received updated bearings in May 2010.

• Prodigy Flakers, Prodigy Nugget Ice Machines, NME, FME, NSE, MDT5, MDT6

and prior

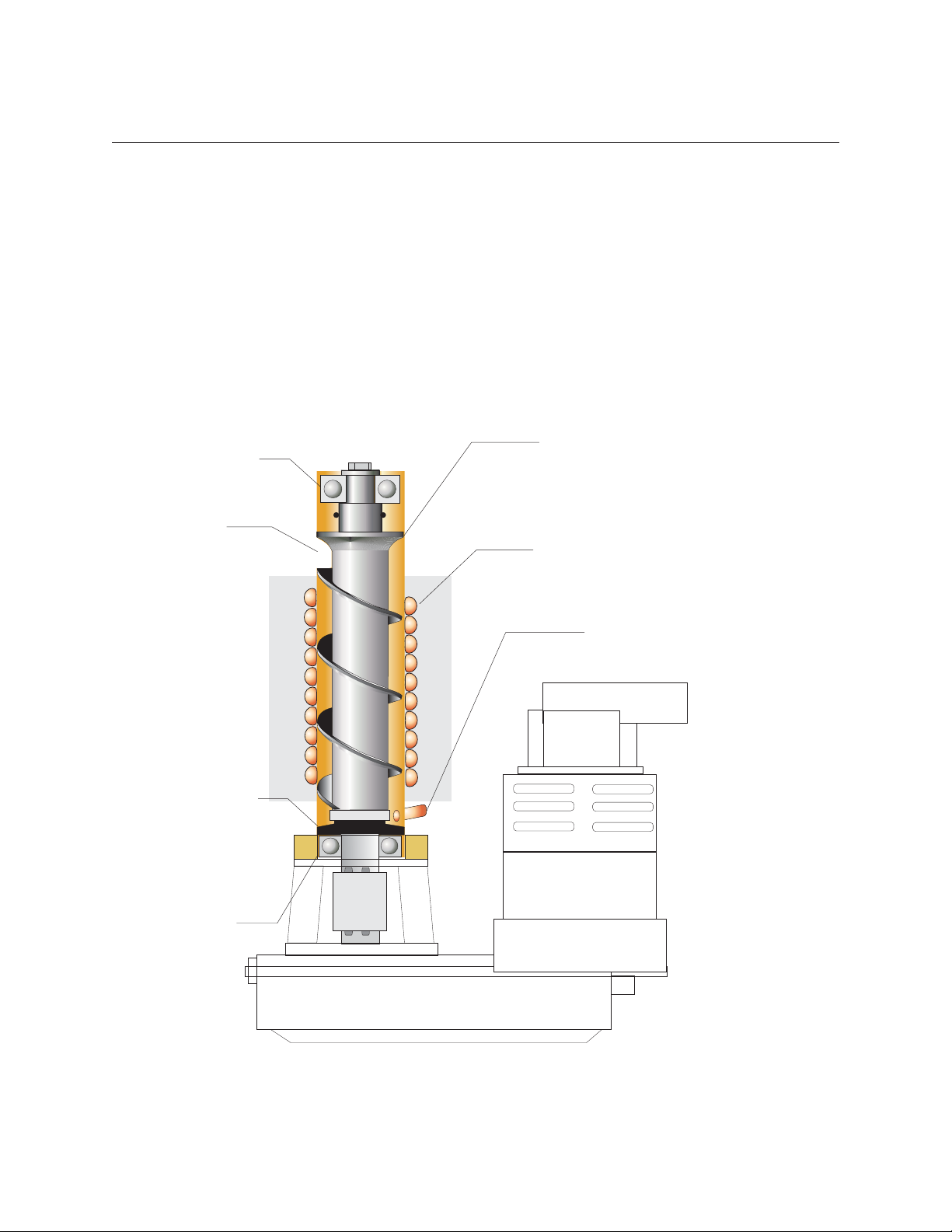

Evaporator Wall

Material

Brass 2 inch 1/10 TXV

Stainless steel 3 inch 1/4 TXV

Evaporator

Nominal

Diameter

Auger MotorHPMetering

device

Breaker

Flat bearing

retainer, ice

discharge tube

Center point

breaker/bearing

retainer

Extrusion - 16

holes or 6 slots

Page 2

Definitions

Breaker: The top bearing retainer that causes the soft ice to be compressed.

Auger: Stainless steel shaft with one or two spiral flights on it. Forces the flaked ice up

the walls of the evaporator.

Double-Flight Auger: Has two spirals to lift ice, 180 degrees from each other.

Rifling: grooves machined into the inside walls of the evaporator. Helps to guide the ice

vertically.

Water seal: A two piece seal, one rotating one stationary. The rotating part moves with

the auger.

Evaporator: Refrigerated tube of either stainless steel or brass, surrounded by a

continuous copper tube that contains the refrigerant. Also known as worm tube or

freezer.

Direct drive: Refers to the gear reducer with the motor rotor directly engaging gears.

Bearing retainer: Contains the bearing used to support the auger.

General Flaked or Nugget Ice Machine Cleaning Instructions see specific model's manual for complete instructions

Mineral scale on the auger and evaporator walls will reduce ice making efficiency and

add extra load to the auger drive system. Regular cleaning with ice machine cleaner will

reduce that load and improve ice output.

1. Switch the ice machine off.

2. Shut off the water to the evaporator.

3. Drain the reservoir and evaporator.

4. Mix 8 ounces of ice machine cleaner with 3 quarts of potable water.

5. Pour the cleaning solution into the reservoir until it is full.

6. Soak the machine with cleaner solution for 15 minutes.

7. Switch the ice machine on and pour the remainder of the cleaning solution into the

reservoir until it is all used.

8. Open the water valve and let fresh water into the ice machine.

9. Discard any ice that was made during cleaning.

Page 3

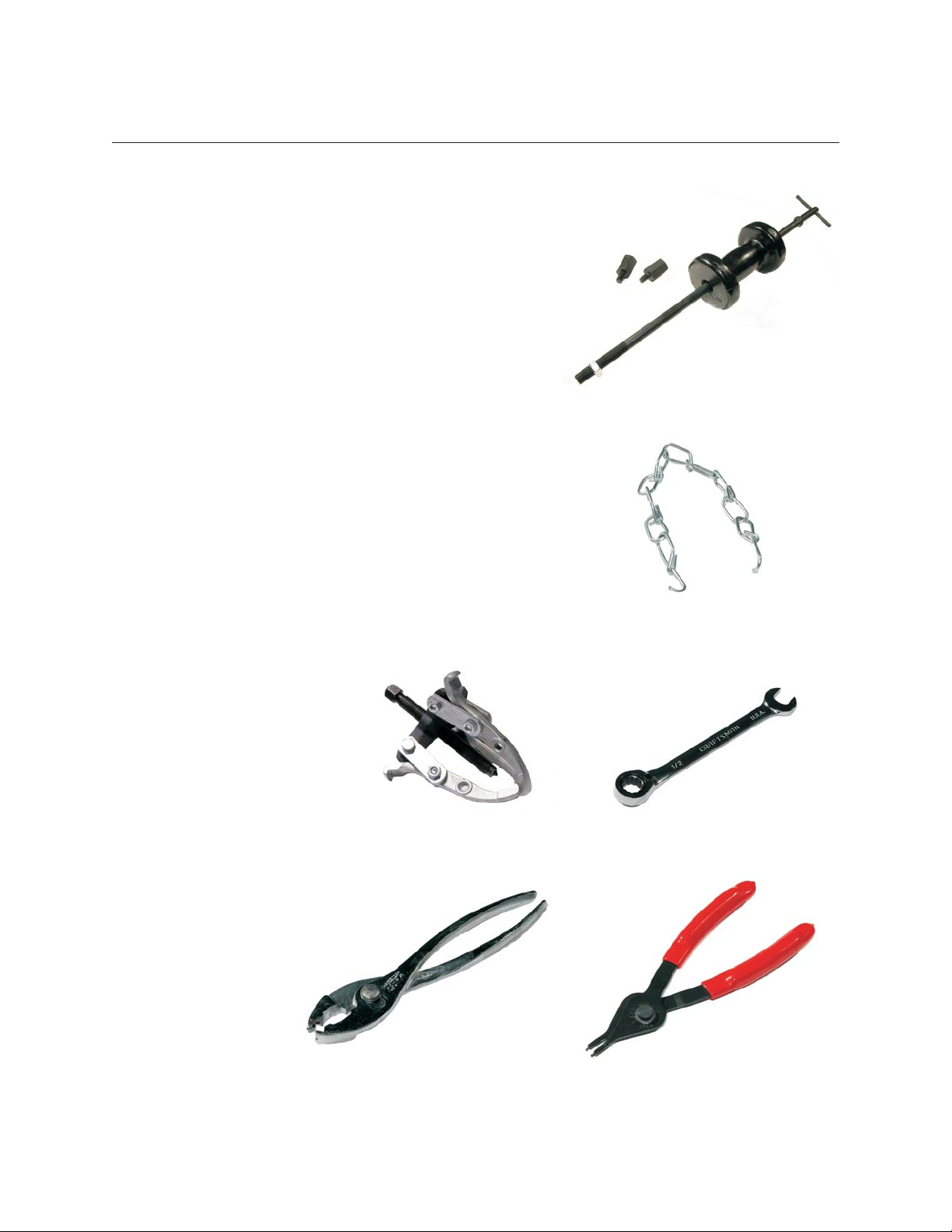

Suggested Tools

Pullers:

• 2 or 3 jaw puller – use for couplings & bearings

• Slide hammer puller – use to pull augers

Adapters to fit augers:

• Small brass flakers – 7/16 -14

• Large brass flakers –½-20

• Nugget - 5/8 – 18

• MDT2 - 7/16 -14

Breaker removal

• 1/8" wire chain cut to grab cap on small brass

flakers. Not applicable to AFE424 or updated

bearing units.

Slide Hammer with tips

Wrenches:

• ½” gear drive ratchet

for adapter & freezer

bolts

Misc:

• Snap ring pliers

• Corbin clamp pliers

Small Length of Chain

1/2" Gear Drive Wrench

3-jaw puller

Corbin Hose Clamp Pliers

Page 4

Snap Ring Pliers

Tubular Discharge Spout

Models Covered: AFE325

The main characteristic of the AF or prior MF system is the tubular discharge spout and

mushroom-topped auger. Ice is made in the normal way, but at the top of the

evaporator, the soft ice forced into a small area formed between the mushroom top and

the evaporator wall which compresses it into a dryer form. Then, as the auger turns, the

compressed ice is collected by the spout casting that is attached to the side of the

evaporator. The collected ice flows through a movable tube to the bin. A spout safety

switch is attached to the side of the tube, so if the tube becomes restricted with ice, the

tube is pushed away from the auger, tripping the switch and shutting the machine off.

Mushroom

Top Bearing

Ice Outlet

Area

Auger

Refrigeration

Tubing

Water Seal

Bottom

Bearing

Water Inlet

Tube

AFE325 Evaporator Schematic

Page 5

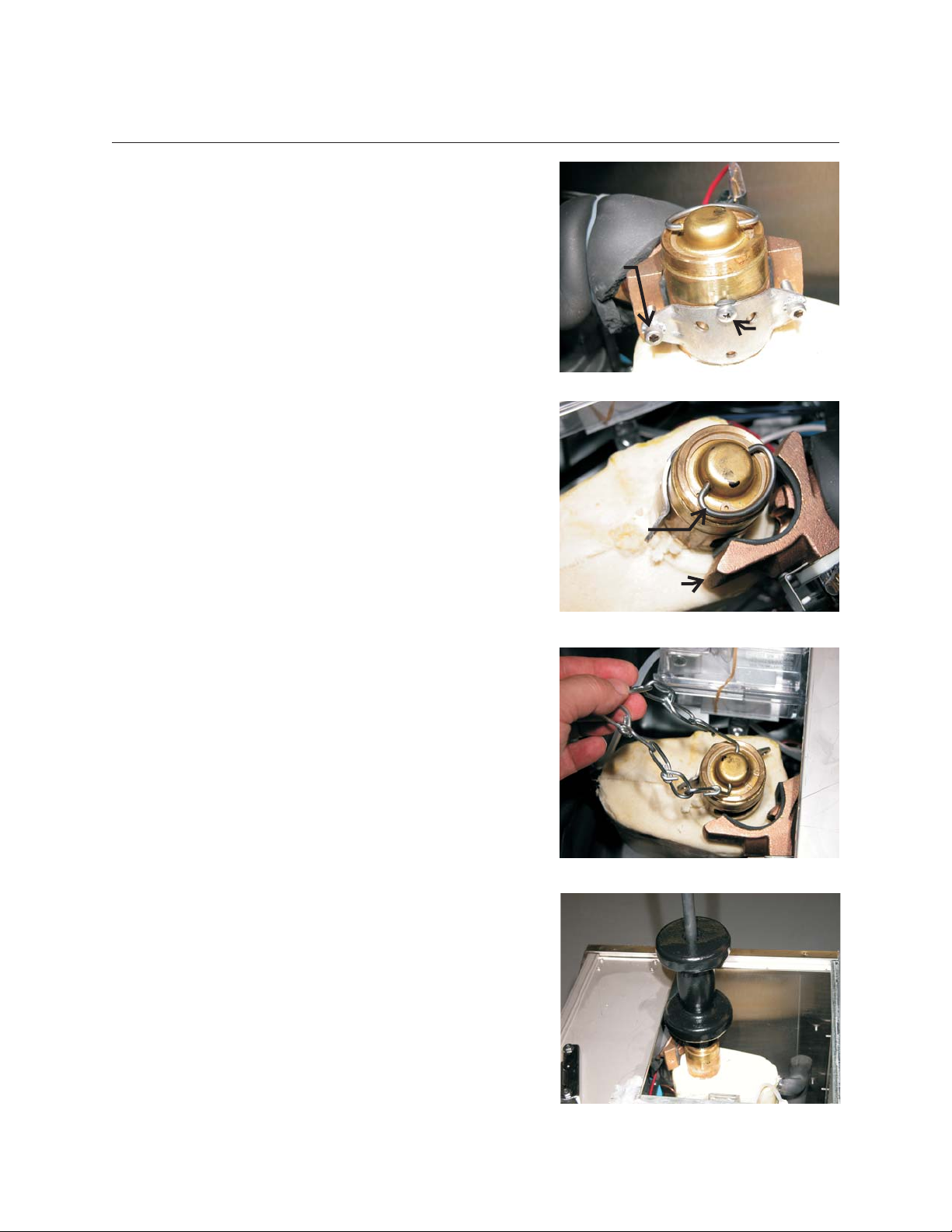

Auger Removal - AFE325

1. Disconnect electrical power.

2. Shut off water supply and drain reservoir and

evaporator.

3. Pull up on black rubber cap and remove it.

4. Remove two allen head screws holding spout

assembly to evaporator and disconnect spout from

evaporator.

5. Remove one screw holding top bearing retainer to

evaporator. It is holding the spout mounting plate to

the evaporator.

6. Pull up on cap hook to remove auger. If more

force is required, use a 12 inch length of 1/8" chain,

with each end cut into a hook. Remove the cap hook

and insert the chain into the holes. Insert a wrench

or hammer through the chain and pull up to pull out

the auger.

Allen

Head

Screw

Retaining

Screw

Spout Removal

Cap Hook

Spout

Top View, Spout Removal

Another method is to use a slide hammer puller. To

use, use a snap ring pliers to remove the cap hook

and the cap.

Remove the bolt at the top of the auger.

Thread the slide hammer into the auger, and use the

slide to remove the auger.

Using Chain

Using Slide Hammer

Page 6

Loading...

Loading...