Page 1

Refrigeration Line Set Installation

Details of Quick Connect Coupling Assembly

Quick connect coupling assembly can be as simple as tightening a nut. But if

not done properly, an expensive, not-covered-by-warranty refrigerant leak

will occur. This booklet lists correct assembly steps, shows results of partial

assembly and describes how a leak proof joint is made.

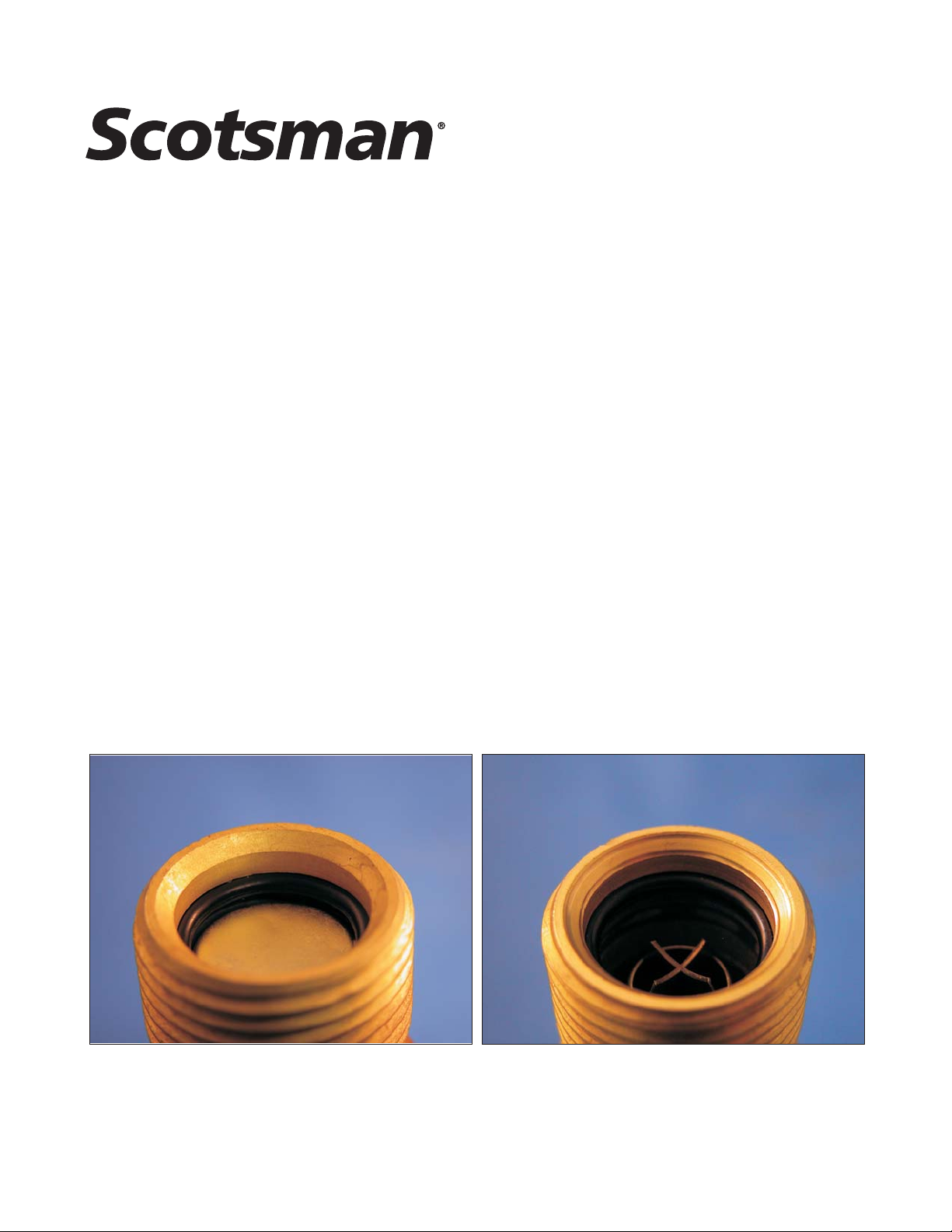

Male Fitting Before Connecting

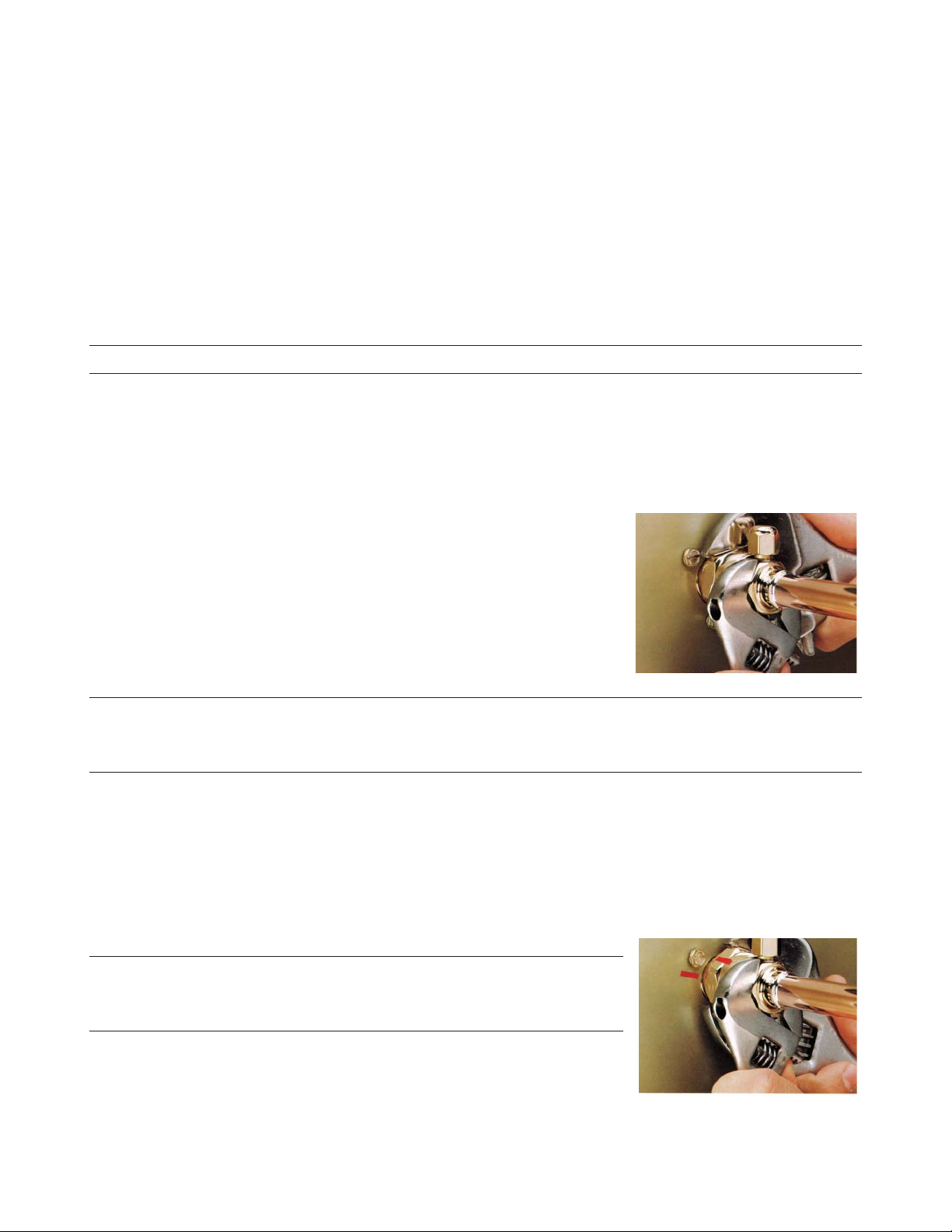

Male Fitting After Connecting

Page 2

Coupling Assembly Details

Coupling Connection Instructions

1. Remove the protector caps and plugs. Wipe the seats and threaded surfaces with a

clean cloth to remove any possible foreign matter.

2. Thoroughly lubricate the threads, o-rings, diaphragms and all internal coupling

surfaces with polyolester refrigerant oil. Failure to lubricate could cause a false

sense of tightness and a leak will result from the incomplete assembly.

Note: Scotsman line sets include lubricant packets.

3. Position the fittings on the correct connections on the condenser and ice machine.

4a. Begin to tighten the couplings together by hand. Continue to turn the swivel nuts

by hand until it is certain that the threads are properly engaged.

4b. Using two wrenches, one to rotate the swivel nut and

one to hold the tubing in place, tighten each coupling.

It is CRITICAL that ONLY the NUT on the pre-charged tube

be turned, or the diaphragms will be torn by the piercing

knives and become loose in the refrigeration system

causing severe operational problems.

Note: As the coupling is tightened, the diaphragms in the quick connect couplings will

begin to be pierced. As that happens, there will be increased resistance to tightening

the swivel nut.

4c. Continue tightening the swivel nut until it bottoms out or a very definite increase in

resistance is felt (no threads should be showing). Do NOT overtighten.

5. Use a marker or pen to mark a line on the coupling nut and unit panel. Then tighten

the coupling nut an additional one-quarter turn. The line will show the amount that the

nut turns.

Note: The final 1/4 turn forces two shoulders on the swivel

nut end into the beveled surface of the male end, resulting

in a sealed brass-to-brass connection.

6. After all connections have been made check the

couplings for leaks.

Page 2

Page 3

Coupling Assembly Details

Coupling Description

The following pages show the stages of coupling assembly as

the swivel nut and male fitting are drawn together.

The swivel nut end contains one diaphragm in the center post. The male fitting

contains the knife blades and its own diaphragm.

Note: 3/8 male ends have one knife blade.

No sealing takes place until the final stage, when the outer edge of the center post in

the swivel nut is forced against the bottom of the male fitting, creating a mechanical

seal.

Page 4 shows what appears to be a completed assembly with only two threads

•

showing, but the diaphragms have just begun to be pierced. Stopping here

causes severe operational issues as well as refrigerant leaks.

Page 5 shows an even more complete assembly, with only one thread showing.

•

However, this assembly is still not complete. If not tightened further there will be

refrigeration restrictions and leaks.

•

Page 6 shows the two parts almost together; the threads are flush. At this point

the main problem will be refrigerant leaks.

•

Page 7 shows the couplings properly assembled with the critical last 1/4 turn.

•

Page 8 shows details of the brass-to-brass sealing action, not visible when the

couplings are assembled.

Note that couplings that are screwed together but have threads

showing are not only leaking refrigerant, they are restricting the

flow of refrigerant through the small slits in the membranes or

diaphragms.

Page 3

Page 4

Coupling Assembly Details

Two Threads Showing

Barely Pierced

Knives Just Showing

Page 4

Page 5

Coupling Assembly Details

One Thread Showing

Page 5

Knives ExposedPartly Pierced

Page 6

Coupling Assembly Details

Threads Flush

Page 6

Knives VisiblePierced but will leak

Page 7

Coupling Assembly Details

Correctly Tightened

Page 7

Fully OpenFully Open

Page 8

Coupling Sealing Details

Coupling sealing occurs when the two sections seat together. At the final 1/4 turn,

the shoulders in the swivel nut end are compressed against the male end sealing

area, forming two grooves in it and sealing the coupling.

Sealing

Area

Sealing

Area

Shoulders

Male End Before Use

Formed Grooves

Create Seal

Male End After Connection

Swivel Nut End, Swivel Nut Removed

Seat

Seating Area, Swivel Nut Removed

Page 8

Scotsman Ice Systems

800-533-6006

item # 291-824

Loading...

Loading...